Omega Products PX541-003GI Installation Manual

PX541 SERIES

Pressure Transducers

INSTRUCTION

SHEET

M1145/0402

GENERAL DESCRIPTION

The OMEGA

®

PX541 pressure transmitter consists of a pressure connection section with built-in piezoresistive

pressure sensor, and a case for housing the electronic equipment and the electrical connection. The pressure sensor is

immersed in silicone oil, which is separated from the medium being measured with a thin stainless steel diaphragm.

Characteristics of the PX541 include:

• 4-20 mA Current Output, which is Ideal for Long Distance Signal Transmitting and Industrial Environments

• High Accuracy and Repeatability

• Corrosion Resistant

• Rugged NEMA-12 Dust-tight/Drip-tight Enclosure

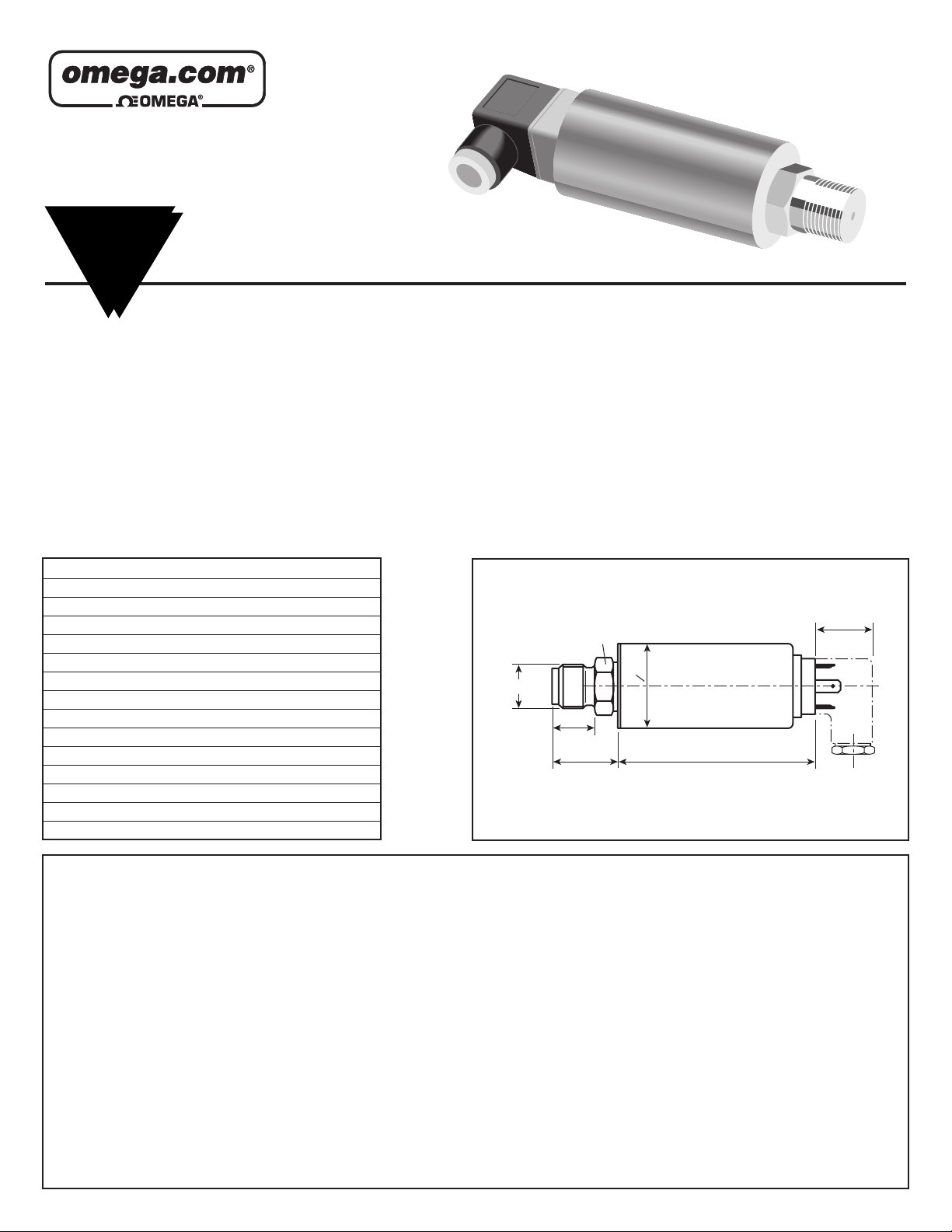

AVAILABLE MODELS DIMENSIONS

WARNING!

READ BEFORE INSTALLATION

Fluid hammer and surges can destroy any pressure transducer and must always be avoided. Apressure

snubber should be installed to eliminate the damaging hammer effects.

Fluid hammer occurs when a liquid flow is suddenly stopped, as with quick closing solenoid valves. Surges

occur when flow is suddenly begun, as when a pump is turned on at full power or a valve is quickly opened.

Liquid surges are particularly damaging to pressure transducers if the pipe is originally empty. To avoid

damaging surges, fluid lines should remain full (if possible), pumps should be brought up to power slowly,

and valves opened slowly. To avoid damage from both fluid hammer and surges, a surge chamber should be

installed, and a pressure snubber should be installed on every transducer.

Symptoms of fluid hammer and surge’s damaging effects:

a) Pressure transducer exhibits an output at zero pressure (large zero offset). If zero offset is less than 10% FS,

user can usually re-zero meter, install proper snubber and continue monitoring pressures.

b) Pressure transducer output remains constant regardless of pressure.

c) In severe cases, there will be no output.

RANGE (PSI) MODEL

-15- to 15 PX541-15V15GI

15 to 30 PX541-15V30GI

-15 to 0 PX541-030VACI

0 to 1.5 PX541-1.5GI

0 to 3 PX541-003GI

0 to 7.5 PX541-7.5GI

0 to 15 PX541-015GI

0 to 30 PX541-030GI

0 to 75 PX541-075GI

0 to 150 PX541-150GI

0 to 300 PX541-300GI

0 to 750 PX541-750GI

0 to 1500 PX541-1.5KGI

0 to 3000 PX541-3KGI

SW 24

mm (inch)

1/2 NPT

20

.79

o

40

(1.57)

17.02

(.67)

30.5

(1.20)

109.98 (4.33) ≤ 150 PSI

85.85 (3.38) ≥ 300 PSI

WIRING

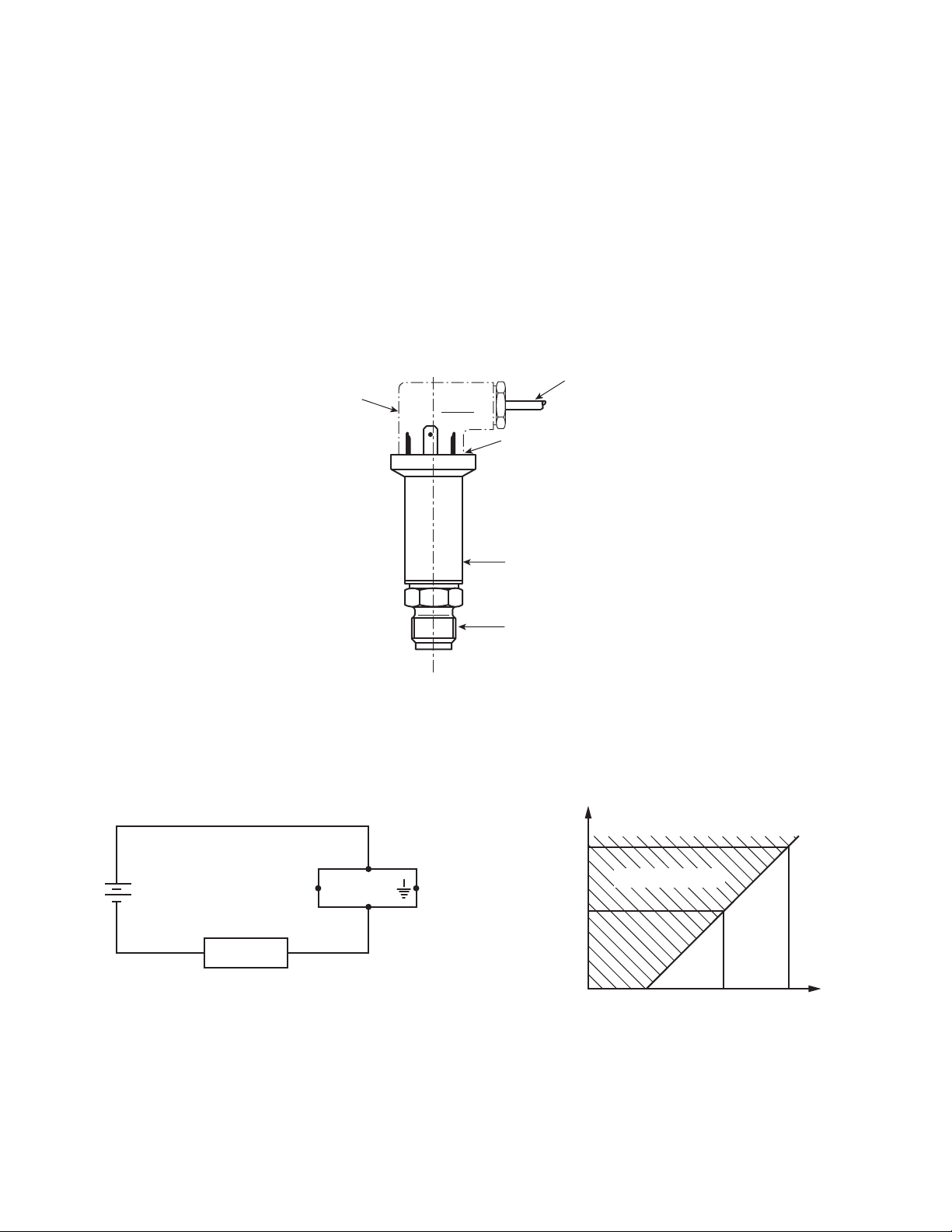

To access the screw terminals and wire the transducer, refer to Figure 1, and the following procedure:

1. Locate the screw at the top of the transducer and unscrew.

2. Separate connector from the rest of the transducer body. Remove the screw and rubber gasket from

the connector and set aside.

3. Using a small blade screwdriver, insert it in the corner slot and pry off square cover (and terminals).

4. Insert cable into hole (not screw hole) past grommet and feed through into square part of assembly.

Wire terminals in terminal block using wiring diagram (refer to Figure 2).

5. Replace terminal block and snap in place.

6. Put rubber gasket on unit.

7. Connect larger part of transducer to wired unit, observing positions of blades.

8. Insert screw in screw hole and tighten two parts to each other.

Figure 1. Pressure Transducer

Figure 2. Wiring Diagram Figure 3. Operating Range of Transducer

USER-PROVIDED

WIRE

RUBBER GASKET

CONNECTOR

TRANSDUCER

SCREW THREADS

+ SUPPLY

+

+

–

–

CASE

GROUND

– SUPPLY

POWER

SUPPLY

1

2

3

0

0

700

1000

LOOP RESISTANCE

(OHMS)

prohibiting zone

10 24 30

VDC EXCITATION

Loading...

Loading...