Page 1

®

PX540 Series

Pressure Transducers

Operator’s Manual: M1137/0698

General Description

The OMEGA

®

PX540 Pressure Transducer consists of a pressure connection section with welded stainless steel

diaphragm and a case for housing the electronic equipment and the electrical connection. The piezoresistive pressure sensor is installed behind the diaphragm, with the intervening space filled with silicone oil as pressure transmission liquid.

The pressure sensor’s signal is converted by an amplifier to a signal of 4 to 20 mA. The pressure connection DIN

3852 is used as a seal behind threads by means of the added NBR O-ring. (No flush-mounted seal).

Characteristics of this transducer include:

• 4 to 20 mA current output which is ideal for long distance signal transmitting and industrial environments.

• High accuracy and repeatability.

• Corrosion resistant, and

• Rugged NEMA=12 dust-tight/drip-tight enclosure.

How To Adjust Zero and Span

NOTE:

Unit has been factory calibrated. No adjustment is

required upon delivery from OMEGA Engineering.

Zero adjustment must be performed at no pressure

and the output reading must be 4 mA.

Span adjustment must be performed at full scale pressure and the output reading must be 20 mA.

If you do not get either of these readings at the

required no pressure or full scale pressure, go through

the following procedure to get to the screws.

Remove the connector from the body of the transmitter as described in steps 1 and 2 in the Wiring Section.

Adjust the zero screw so the output reading is 4 mA at

no pressure. At full scale pressure, the output must be

20 mA; if it is not, adjust the span screw.

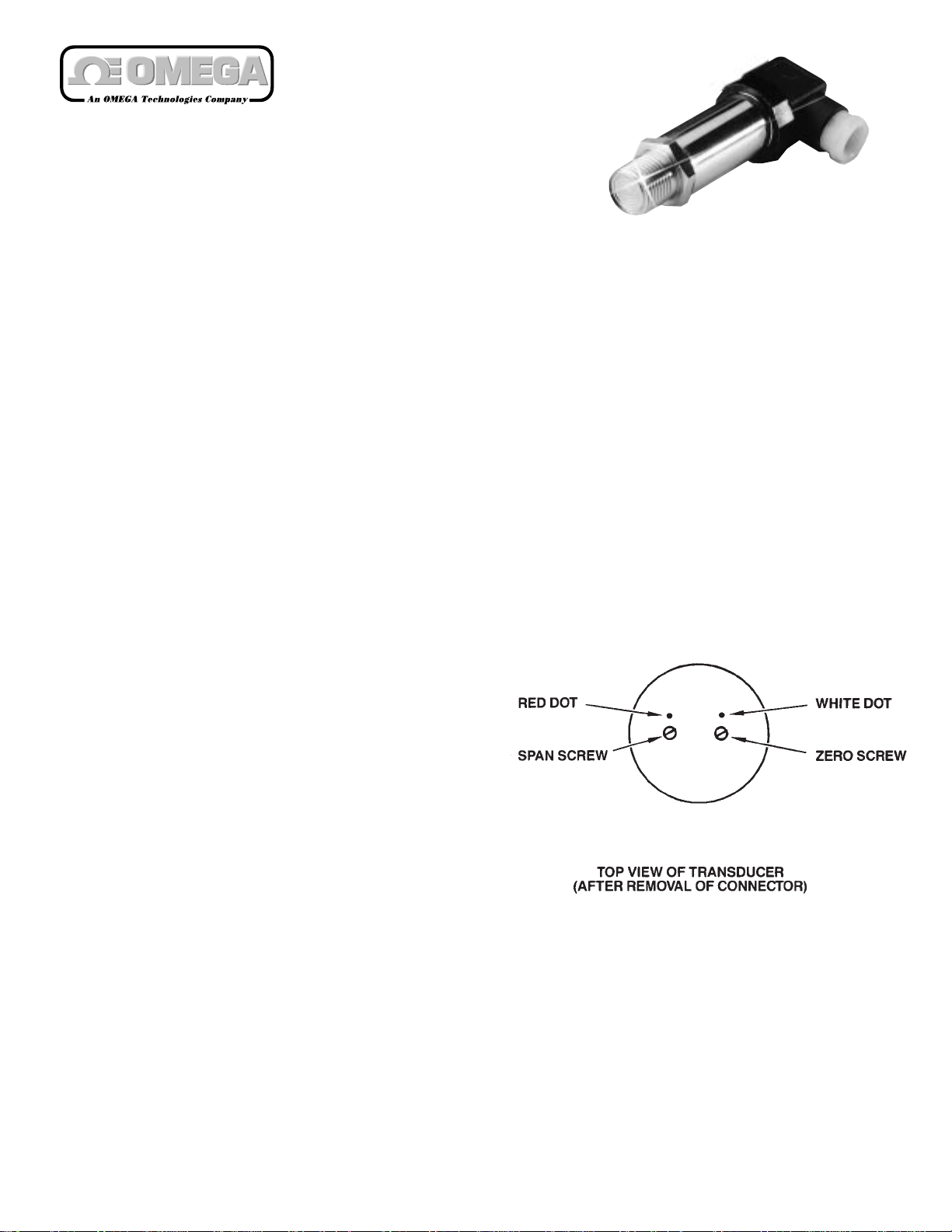

The Zero screw is marked with a white dot. The span

screw is marked with a red dot. Refer to Figure 1.

Figure 1.

Location of Adjustment

Screws

Page 2

Wiring

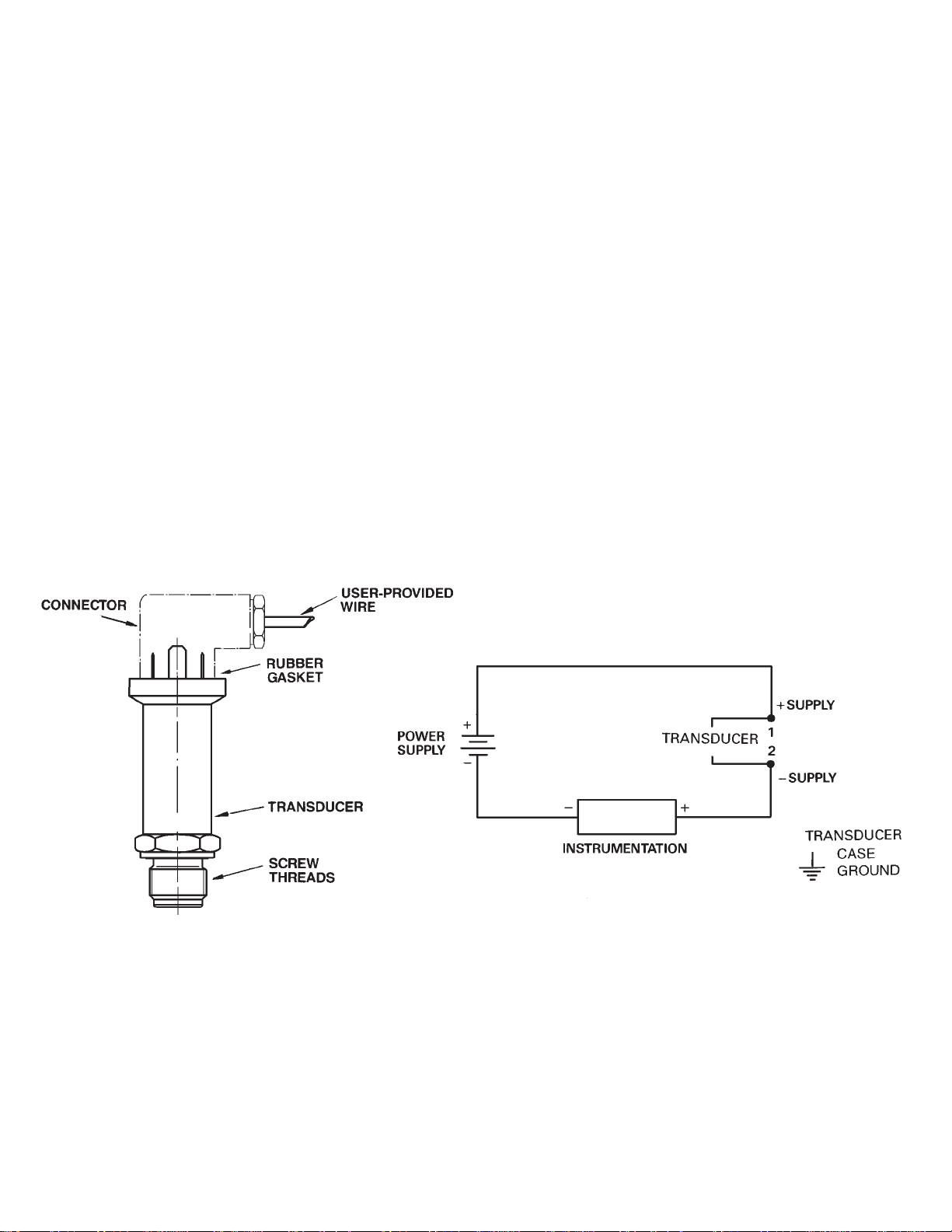

To access the screw terminals and wire the transducer, refer to Figure 2, and the following procedure.

1. Locate the screw at the top of the transducer and unscrew.

2. Separate connector from the rest of the transducer body. Remove the screw and rubber gasket from the connector and set aside.

3. Using a small blade screwdriver, insert it in the corner slot and pry off square cover (and terminals).

4. Insert cable into hole (not screw hole) and feed through into square part of assembly. Wire terminals in terminal

block using wiring diagram (refer to Figure 3).

5. Replace terminal block and snap in place.

6. Put rubber gasket on unit.

7. Connect larger part of transducer to wired unit observing positions of blades.

8. Insert screw in screw hole and tighten two parts to each other.

Figure 2.

Pressure Transducer

Figure 3.

Wiring Diagram

Page 3

Specifications

Excitation: 10 to 30 VDC

Output: 4 to 20 mA two wire

Insulation Resistance: 500 VAC

Maximum Loop Impedance: (Supply Voltage -10) x 50 (refer to Figure 4)

Performance

Accuracy: 0.3% F.S. Typ (0.5% max)

Hysteresis and Repeatability: 0.1% F.S.

Compensated Temperature Range: 32˚ to 122˚ F (0˚ to 50˚ C)

Operating Temperature Range: -4˚ to 175˚ F (-20˚ to 80˚ C)

Thermal Zero Effect: 0.03% F.S./˚ C

Thermal Sensitivity Effect: 0.03% F.S>/˚ C

Maximum Pressure: 150% Full Scale

Construction

Body Material: Stainless steel

Wetted Parts: ANSI 316L Stainless steel

Fill Fluid: Silicone oil

Process Connection: 1/2 NPT male

Electrical Connection: DIN connector with screw terminals

Response Time: 2 ms

Weight: 0.35 lb.

Dimensions: Refer to Figure 5.

WARNING!

Read Before Installation

Fluid hammer and surges can destroy any pressure transducer and must always be avoided. A pressure snubber should be installed to eliminate the damaging hammer effects.

Fluid hammer occurs when a liquid flow is suddenly stopped, as with quick closing solenoid valves. Surges

occur when flow is suddenly begun, as when a pump is turned on at full power or a valve is quickly opened.

Liquid surges are particularly damaging to pressure transducers if the pipe is originally empty. To avoid damaging surges, fluid lines should remain full (if possible), pumps should be brought up to power slowly, and

valves opened slowly. To avoid damage from both fluid hammer and surges, a surge chamber should be

installed, and a pressure snubber should be installed on every transducer.

Symptoms of fluid hammer and surge’s damaging effects:

a) Pressure transducer exhibits an output at zero pressure (large zero offset). If zero offset is less than 10% F.S.,

user can usually re-zero meter, install proper snubber and continue monitoring pressures.

b) Pressure transducer output remains constant regardless of pressure.

c) In severe cases, there will be no output.

Page 4

Benelux:

Postbus 8034, 1180 LA Amstelveen,

The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic:

ul. Rude armady 1868, 733 01 Karvina-Hranice,

Czech Republic

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

e-mail: czech@omega.com

France:

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Servicing Europe:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

SM

Customer Service: 1-800-622-2378 / 1-800-622-BEST

SM

Engineering Service: 1-800-872-9436 /

1-800-USA-WHEN

SM

TELEX: 996404

EASYLINK: 62968934 CABLE: OMEGA

USA: ISO 9001 Cer

tified

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Servicing North America:

For immediate technical or application assistance:

Mexico and Latin America:

Tel: (95) 800-TC-OMEGA

SM

FAX: (95) 203-359-7807

En Espan~ol: (203) 359-7803

e-mail: espanol@omega.com

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: ISO 9002 Cer

tified

•One Omega Drive, Riverbend Tech Centre,

Northbank, Irlam,

Manchester, M44 5BD, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

Canada:

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: canada@omega.com

®

OMEGAnetSMOn-Line Service Internet e-mail

http://www.omega.com info@omega.com

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN

ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the

outside of the return package and on any correspondence.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE contacting OMEGA:

1. P.O. number under which the product was

PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS OR CALIBRA-

TION,

consult OMEGA for current repair/calibration charges. Have the following information available BEFORE contacting OMEGA:

1. P.O. number to cover the COST of the

repair/calibration,

2. Model and serial number of product, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This

affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1995 OMEGA ENGINEERING, INC. All rights reserved. This documentation may not be copied, pho-

tocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or

in part, without prior written consent of OMEGA ENGINEERING, INC.

WARRANTY

OMEGA warrants this unit to be free of defects in materials and workmanship and to give satisfactory service for a period of 13 months from date of purchase. OMEGA Warranty adds an additional one

(1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product. If the

unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no

charge. However, this WARRANTY is VOID if the unit shows evidence of having been tampered with

or shows evidence of being damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside of

OMEGA’s control. Components which wear or which are damaged by misuse are not warranted. These

include contact points, fuses, and triacs.

OMEGA is glad to offer suggestions on the use of its various products. Nevertheless,

OMEGA only warrants that the parts manufactured by it will be as specified and free of

defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE AND ALL IMPLIED WARRANTIES

INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and the

total liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the purchase

price of the component upon which liability is based. In no event shall OMEGA be liable

for consequential, incidental or special damages.

Every precaution for accuracy has been taken in the preparation of this manual; however, OMEGA

ENGINEERING, INC. neither assumes responsibility for any omissions or errors that may appear nor

assumes liability for any damages that result from the use of the products in accordance with the information contained in the manual.

SPECIAL CONDITION: Should this equipment be used in or with any nuclear installation or activity,

purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the equipment in such a manner.

Figure 5. Dimensional Diagram

MADE

ININ

UUSASA

Page 5

Over 100,000 Products Available

Online at omega.com

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable, Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

www.omega.com

ONE OMEGA DRIVE, STAMFORD, CT 06907 USA

TEL: 1-888-TC-OMEGA

(1-888-826-6342)

Loading...

Loading...