Page 1

Installation and Maintenance

omega.comomega.com

TM

®

Instructions for OMEGA

®

PX5200 Differrential Pressure

Transmitter M-5109/0112

User’s Guide

Shop online at

omega.com

omegamanual.info

LOOK FOR THIS

AGENCY MARK ON

OUR PRODUCTS

e-mail: info@omega.com

For latest product manuals:

Version 6.03 5/11

PX5200

M5109/0212

Page 2

OMEGAnet®Online Service Internet e-mail

omega.comomega.com

T

M

®

omega.com info@omega.com

Servicing North America:

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Canada: 976 Bergar

Stamford, CT 06907-0047

Toll-Free: 1-800-826-6342 Tel: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Laval (Quebec), Canada H7L 5A1

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

Mexico: En Español: 001 (203) 359-7803 FAX: (001) 203-359-7807

Customer Service: 1-800-622-2378/1-800-622-BEST

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

info@omega.com.mx e-mail: espanol@omega.com

®

®

®

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Czech Republic: Frystatska 184

France: Managed by the United Kingdom Office

Germany/Austria: Daimlerstrasse 26

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omega.nl

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

D-75392 Deckenpfronn, Germany

Toll-Free: 0 800 6397678 TEL: +49 (0) 7059 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD England

Toll-Free: 0800-488-488 TEL: +44 (0)161 777-6611

FAX: +44 (0)161 777-6622 e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European

New Approach Directives. OMEGA will add the CE mark to every appropriate device upon

certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

2

Page 3

CONTENTS

CAUTION................................................................................................ 4-5

1. PREFACE.............................................................................................. 5

2. OVERVIEW .......................................................................................... 5

3. FEATURES............................................................................................ 5

4. SPECIFICATIONS .................................................................................. 6

5. MOUNTING .......................................................................................... 8

5.1 Mounting Location........................................................................ 8

5.2 Mounting Options ........................................................................ 8

5.3 Pressure Connection.................................................................... 8

6. PIPING ................................................................................................ 9

7. WIRING................................................................................................ 10

7.1 Cable / Wiring Specifications........................................................ 10

7.2 Wiring Instructions........................................................................ 10

8. DISPLAY FUNCTIONS ............................................................................ 13

9. MODE CHANGES .................................................................................. 14

10. POWER-ON MESSAGE .......................................................................... 14

11. MEASUREMENT MODE .......................................................................... 15

11.1 Filter (Damping) .......................................................................... 15

11.2 Pressure Display Mode (Re-scaling in “inH

O” units).................. 15

2

11.3 Linear Display Mode

(Re-scaling in arbitrary user defined units) .................................. 16

11.4 Flow Measurement/Square Root Extraction Mode...................... 19

11.5 Min/Max Display .......................................................................... 26

12. ZERO ADJUSTMENT MODE .................................................................... 27

13. KEY LOCK ............................................................................................ 28

14. SETTING MODE .................................................................................... 20

14.1 Setting Items for Pressure Display Mode

(Re-scaling in “inH

O” units) ........................................................ 28

2

14.2 Setting Items for Linear Display Mode

(Re-scaling in arbitrary user defined units) .................................. 29

14.3 Setting Items for Square Root Extraction (Flow Measurement) .. 31

14.4 Setting Procedure ........................................................................ 32

14.5 Loop Check .................................................................................. 34

15. DIMENSIONAL DRAWINGS .................................................................... 35

16. MAINTENANCE...................................................................................... 36

3

Page 4

WARNING! READ BEFORE INSTALLATION

GENERAL:

A failure resulting in injury or damage may be caused by excessive

overpressure, excessive vibration or pressure pulsation, excessive instrument temperature, corrosion of the pressure containing parts, or

other misuse.

OVERPRESSURE:

Pressure spikes in excess of the rated overpressure capability of the transmitter may cause irreversible electrical and/or mechanical damage to the

pressure measuring and containing elements.

Fluid hammer and surges can destroy any pressure transmitter and must always be avoided. A pressure snubber should be installed to eliminate the

damaging hammer effects. Fluid hammer occurs when a liquid flow is suddenly stopped, as with quick closing solenoid valves. Surges occur when flow

is suddenly begun, as when a pump is turned on at full power or a valve is

quickly opened.

Liquid surges are particularly damaging to pressure transmitters if the pipe is

originally empty. To avoid damaging surges, fluid lines should remain full (if

possible), pumps should be brought up to power slowly, and valves opened

slowly. To avoid damage from both fluid hammer and surges, a surge chamber

should be installed.

Symptoms of fluid hammer and surge’s damaging effects:

• Pressure transmitter exhibits an output at zero pressure (large zero offset).

• Pressure transmitter output remains constant regardless of pressure

• In severe cases, there will be no output.

FREEZING:

Prohibit freezing of media in pressure port. Unit should be drained to prevent

possible overpressure damage from frozen media.

STATIC ELECTRICAL CHARGES:

Any electrical device may be susceptible to damage when exposed to static

electrical charges. To avoid damage to the transmitter observe the following:

• Ground the body of the transmitter BEFORE making any electrical

connections.

• When disconnecting, remove the ground LAST!

4

Page 5

Note: The shield and drain wire in the cable (if supplied) is not connected to the

transmitter body, and is not a suitable ground.

1. PREFACE

Thank you for purchasing the PX5200 Rangeable Differential Pressure

Transmitter. Refer to the Omega PX5200 Data Sheet for product specifications and applicable operating conditions.

2. OVERVIEW

The PX5200 is a 4-20mA loop powered (two-wire) differential pressure

transmitter with integral display incorporating Ashcroft’s proven SiGlas silicon

based variable capacitance sensor with stainless steel media isolation diaphragms and silicone pressure transmission fluid. The device was designed

to offer the user small size and user adjustable ranging for applications such

as tank level measurements and gas / liquid flow measurements.

3. FEATURES

(1) Media Compatibility: Wetted materials consist of 316 stainless steel,

alumina ceramic and viton to handle a wide range of media with the

ability to offer ranges as low as 4˝ W.C. F.S. (URL).

(2) Linear Scaling Function:The linear (scaling) function allows the user

to adjust zero and span values providing a corresponding

4-20mA output signal.

(3) Flow Measurement/Square Root Extraction Function: Momentary

flow rate and integrated volume can be displayed and analog signal

can be output.

(4) Digital Filter Function: User adjustable damping of the output signal

by means of internally calculated moving average to provide a stable

output signal in applications where the user wants to reduce the pulsating of the display and / or output signal.

(5) LED Back Light: To supplement the LCD display when conditions re-

quire (dark area, night etc.).

(

6) Loop Check Function: Allows the user to output an analog signal cor-

responding to differential pressure without applying pressure, simplifying system maintenance and troubleshooting.

5

Page 6

(7) Zero and Span Adjustment: The adjustment of the Zero (4mA) and

Span (20mA) reading via internal push buttons.

(8) Key Lock Function: Prevents inadvertent overwriting of setting values.

Can not be reset by restoring power when activated.

(9) IP65 / NEMA 4X Environmental Rating: Enclosure environmental rat-

ing suitable for indoor and outdoor installation, depending upon operating temperature range.*

(10) CE Compliance: EN613261 1997, A1/1998, A2/2001 (Heavy Industrial).

*Display not to be mounted in direct sunlight.

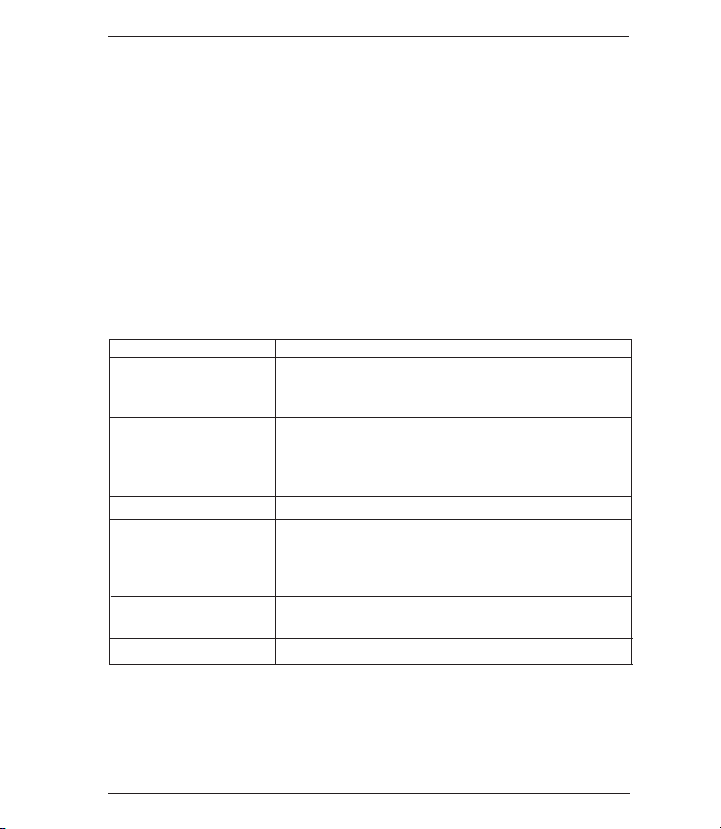

4. SPECIFICATIONS

ITEM DESCRIPTION

1. Media/Wetted Parts

Gas or liquid compatible with 316SS, viton and alumina

ceramic (isolation fluid is silicone oil). Media temperature range: –10 to +70°C

2. Overpressure

(Proof)

Static (Line) Pressure: 300psi all ranges

Singe Side (Differential) Limits:

• Pressure Ranges <8˝W.C., ±4˝W.C.; 30psid

• Pressure Ranges >20˝W.C., ±8˝W.C.; 100psid

3. Supply Voltage

4. Output

12-32Vdc

4-20mAdc (two wires, Output range: 3.2 to 20.8mAdc)

Response Time: 100ms (with “0” filter setting)

Resolution: 0.1%F.S.,

Load resistance: 500Ω max.

5. Accuracy

±0.5% F.S. (URL) at 73°F (23°C); includes the effects of

non-linearity, hysteresis and non-repeatability)

6. Display Accuracy

±0.50% F.S. (URL) + 1 digit at 23°C

6

Page 7

7. Rangeability /

Adjustment

8. Display

9. Units

10. Setting Adjustments

11. Enclosure

12. Pressure Connection

13. Electrical

Termination

14. Memory Protection

15. EMC Directive

16. Operating

Temperature

17. Storage

Temperature

18. Vibration

19. Shock

20. Insulation

Resistance

21. Weight

Zero: –10 to +110% FS

Span: –10 to + 110% FS

Character height: 10mm, with LCD display with LED

backlight

Pressure / linear display: (4) LCD digits max.

Display update: 500 ms

Pressure Units: inH2O (2), (1) arbitrary

Internal key switches (Mode, T, S)

Scaling function: Linear output, linear and momentary

flow rate display/output.

Filter function: User adjustable output damping select

from 0, 2, 4, 8 and 16 (None, 2, 4, 8, and 16 (s)).

Loop check function: User adjustable output for loop/

system check and troubleshooting, 4-20mA.

Material: Aluminum die cast

Environmental Rating: IP65 / NEMA 4X

1

⁄4 NPT female pressure ports w/equalizing valve

Cable Gland (Optional): Cable diameter 0.35 to 0.47˝

(9-12mm)

1

⁄2 NPT Female Conduit Adapter (Optional)

Terminal Block: 14-22 AWG (stranded or solid wire)

Permanently stored by EEPROM (nonvolatile memory)

CE Compliance: EN61326/1997, A1/1998, A2/2001

–10 to 60°C (14 to 140°F)

–20 to 70°C (–4 to 158°F)

5g’s, 150Hz

10g’s, 16ms

50Vdc, 100MΩ or more

Approx. 670g (1.5lbs)

7

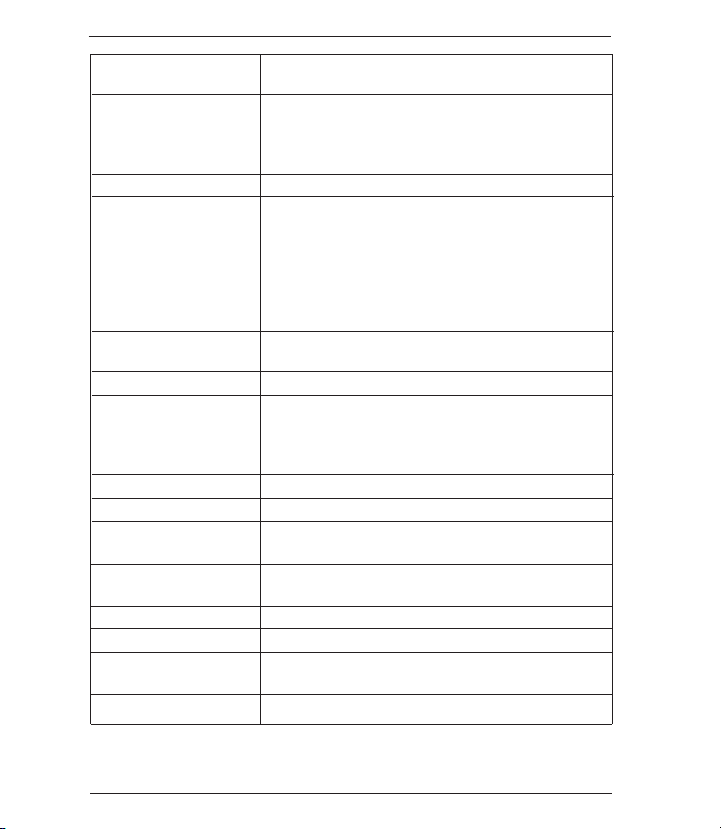

Page 8

5. MOUNTING

5.1 General

The GC52 was designed to be mounted using the bracket supplied.

Pressure connections via the (2)

1

⁄4 NPT female pressure ports. Al-

though the display can be rotated in 90 degree increments by removing the display cover it is preferable to orientate the electrical

termination downward, particularly in applications where protection

from the environment is required.

5.2 Mounting Orientation

It is preferable to orientate the unit with the pressure ports either

downward or upward. If mounting with pressure ports to the side an

“orientation effect” will be seen at zero pressure as the pressure generated by the silicone oil fill will appear as a zero offset. If mounting in

this manner this effect may be taken out by re-setting zero in final

mounting orientation.

5.3 Installing Pressure Port Manifold

(1) Mounting 25.4mm Manifold (

1

⁄4˝ NPT female ports)

Manifold is secured using the (4) socket head bolts (M4x40) and

appropriate allen wrench which is supplied. Check for dust and

dirt on the O-ring and seal area, clean if necessary, before installing to ensure proper connection. The direction of the manifold

is not important, determine best position by ability to operate the

equalizing valve.The equalizing valve is used to open both ports

to the line pressure at time of installation. Once installed and the

system has been pressurized the valve needs to be closed to isolate the low and high pressure sides of the device.

Tighten the equalizing valve with a torque of 0.75 ft-lbs±15%.

When loosening the valve do not back off by more than three

turns from the closed position.

(2) Panel Mounting

Similar to (1) above except that the PX5200 is put between the

manifold and the bracket and then the (4) socket head bolts

(M4x40) are installed.

8

Page 9

(2) 1/4˝ NPTF

1.4 (35)

.55 (14)

.83 (21)

1.8 (45.4)

1.0 (25.4)

Hex .83 (21)

.33 (8.5)

Equalizing

valve

Low pressure

inlet (L)

Panel mounting

bracket

High pressure

inlet (H)

Equalizing

valve

M4 x 40

O-rings

Lower connection diagram

Connection: Lower side.

• 1.0 in. (25.4mm) mounting manifold

6. PIPING

Note: High (H) and Low (L) pressure

sides of the device are marked on the

yellow label affixed to the housing of

the unit.

Install the high pressure side of the applied differential pressure in the pressure inlet of the high pressure side (H)

and the low pressure side in the pressure inlet of the low pressure side (L).

(Refer to the outline drawing of section 14.)

After the piping is completed check for leaks.

(1) Piping of 1.0 in (25.4mm) Manifold (

Use caution when installing to keep metal chips and other debris from

entering pressure transmitter. In addition, when sealing tape is used,

do not apply to last two threads at the end of the fitting

1

⁄4˝ npt female ports)

9

Page 10

Note:

• When transporting and / or mounting do not apply excessive shock

or use device as a step.

• The piping should be of proper length so as not to apply load to the

connection point on the transmitter.

• At the time of mounting or when bleeding air from the device be sure

to open the equalizing valve with a flathead screwdriver so that excessive pressure (more than the allowable maximum differential pressure) is not applied to the differential pressure sensor. Maximum torque

to apply to equalizer valve is 0.75 ft-lbs ±5%.

7. WIRING

7.1 Cable/Wire Specifications

Use appropriate cable described below which is suitable for power

supply requirements and ground to housing.

Terminal Strip

Cable

Requirements

SMKDSP1.5/2-5.08 Phoenix Contact

• Two core shielded cable

• Cable outer diameter: 0.35˝ to 0.47˝ 9-12mm

(Required for correct installation with Cable

Gland option)

• Wire Gauge: 14-22 AWG (multi-strand or solid)

7.2. Wiring Instructions

• To reduce potential for noise do not run pressure transmitter cable /

wires alongside (same conduit as) high voltage (line power) lines.

For optimum results use dedicated conduit for PX5200 cable / wires.

• If using the Cable Gland termination option must use cable within

previously noted diameters to maintain environmental ratings.

• When connecting shield / drain wire, only connect one end which

should be at the receiver ground.

• Wiring stripping instructions, remove cable jacket 2-3˝ and strip wires

±0.25˝. Shield / drain wire should not be exposed at the pressure

transmitter termination.

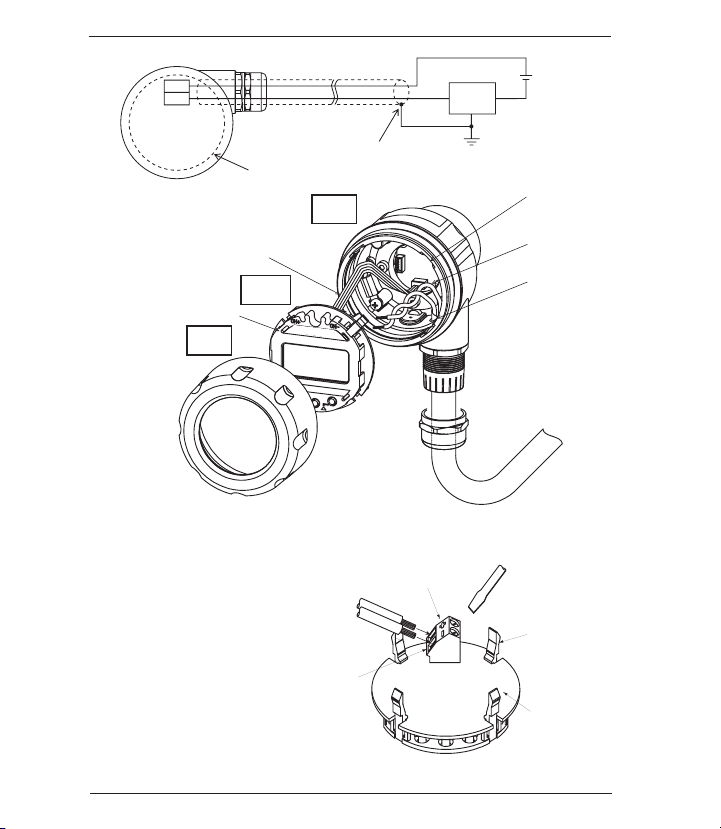

• Remove cover and carefully remove the display to access the terminal strip, take care not to mishandle the display and associated electronics.

10

Page 11

+

−

Terminal box

Display (board)

Shield

Power source

+ −

Receiver

Transmission cable

CASE

DISPLAY

CAP

Inside sensor Line

LCD holder

Notch

Transmission cable

(Twist)

Sheath

Display

Wire terminals

Wire

Turn with a screwdriver

LCD clips (4)

Display board

Power supply

terminal block

P

X

5

2

0

0

• Turn display over to

expose terminal strip,

make positive and

negative connections,

insert wire depth is

equal to recommended

strip length (0.25˝).

11

Page 12

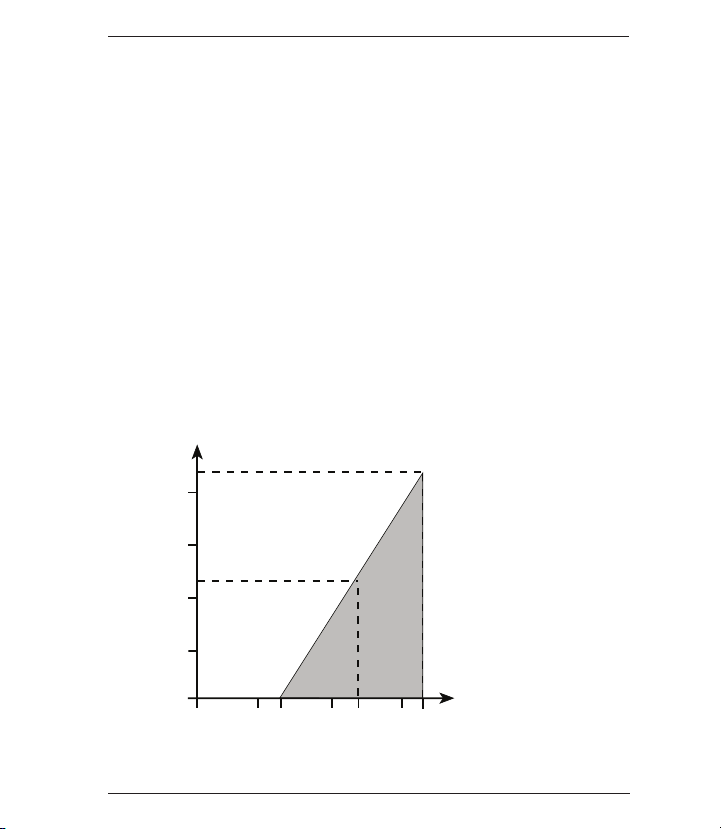

• After completing connections locate retaining clips in the appropri-

1000

750

500

250

0

0 322010

1020

30

Load Limitations 4-20mA Output Only

12 24

545

OPERATING

REGION

Loop Resistance (V)

ate notches and carefully place into the housing. Be sure that internal sensor transmission wire does not cross the power supply lines

just installed.

• If using the Cable Gland be sure to properly tighten sealing grommet

before applying any tension on the cable, the cable gland provides

strain relief and environmental sealing.

• Tighten GC52 cover to maintain environmental rating.

• Connect to power source and receiver and power on to confirm correct wiring (see Section 10 for more detail).

• Power Supply Requirements: Although the 4-20mA signal can travel

over long distances one of the most common problems is inadequate

power at the pressure transmitter due to the voltage drop across the

loop. Be sure to review table below to determine that 12-32V is getting to the pressure transmitter.

12

Page 13

In H2O

Test Terminals

8.8.8.8.8.8.

2

Differential Pressure

Unit Monitor

7

Linear Scaling Mode

5 DOWN key

6 UP key

8 No Function

3 Scaling-Arbitary

Unit Monitor

1 Measured Data

Display

L Total Flow Volume

Display (X1000)

K Total Flow Volume

Display (X100)

4 MODE key

9

Total Flow Volume

Display (X1)

J

Total Flow Volume

Display (X1)

M

CH+

CH–

PX5200-200WUDI

8. DISPLAY FUNCTIONS

DESIGNATION FUNCTION

Measured data

display

Differential

pressure unit

monitor

Scaling;

arbitrary unit

monitor

MODE key

(M)

DOWN key

S

UP key

T

Differential pressure, linear scaling

value are displayed.

When this unit monitor is ON, the

differential pressure (in H

cated on the measured data display.

When this unit monitor is ON, the

scaling value of an arbitrary unit

(linear scaling), is indicated on the

measured data display.

This key is used to switch the setting

mode and the measurement mode

and to change the setting item.

This key is used to change (decrease)and select the set value .

This key is used to change (increase) and select the set value

and to shift from the measurement mode to the zero adjustment mode.

O) is indi-

2

13

DESIGNATION FUNCTION

Linear

scaling

mode

Used to adjust zero/

span values

to 4-20mA

output signal.

No None

function

to

Total flow

volume

display

Page 14

9. MODE CHANGES

8.8.8.8.8.8.

80.0

g[52

• Measurement Mode (Section 11 for further detail) will be entered upon

power-on. Setting Mode (Section 14 for further detail) is entered by

pressing and holding the MODE button for more than 3 seconds. If there

is no button operation for 10 minutes in the setting mode, it will shift back

to the Measurement Mode automatically.

• To go from the Measurement Mode to the Zero Adjustment Mode (Sec-

tion 12 for further detail) press and hold the UP T button for more than

3 seconds.

Power ON

Power on message

(M) key for more than 3 seconds (

Setting mode

(M) key for more than 3 seconds or if there

is no operation for 10 minutes

10. POWER-ON MESSAGE

After the power is turned on, the power-on message is displayed for 6

seconds as shown below and then the display is shifted to the measurement mode (section 11). In addition, the analog output during power-on

message is at the zero point (4mA).

Measurement mode

All lights

two seconds

Differential

pressure range

two seconds

Product

14

▲

) key for more than 3 seconds

Zero adjustment mode

Finish

Page 15

11. MEASUREMENT MODE

The measurement mode includes differential pressure display mode, and

linear (scaling) display mode. For the setting items to

27 , please refer to

the Setting Mode (section14).

11.1 Filter

Set the filter before setting pressure display mode or linear (scaling)

display mode.

The filter is based on the moving average of the pressure data to decrease display “bounce” and to smooth the analog output due to system pressure fluctuations at the user’s discretion.

Five selections: (0, 2, 4, 8, and 16 seconds).

If “0” is selected the filter is not applied.

See Section 14.4 for full menu.

Filter Setting ==> item

11.2 Differential Pressure Display Mode (Re-scaling in “inH

0” units)

2

This mode is used for display and analog output of the actual differential pressure.

(1) Analog output

The analog output can be adjusted as follows; the zero point

(4mA) and the span point (20mA) can each be adjusted from –10

to 110%F.S. (URL)*.

(2) Pressure display

The pressure display has a display span between the zero point

and the span point as determined by the adjustment of zero and

span (see previous paragraph) and can display the range of –5

to 105%F.S.(URL). In addition, the decimal point position of the

pressure display is fixed for each pressure range.

Pressure Unit: in.H

See Section 14.4 for full menu.

O

2

Output zero point and span point setting ==> Setting item ,

*This means that although the zero point is typically set at 0%F.S. (in the case of bi-directional

ranges 0%Span) and the span point is set as 100%F.S., the zero point can be adjusted to the

point where zero (4mA) is 110%F.S. and the span point (20mA) can be adjusted to -10%F.S thus

reversing the output. In addition, through this adjustment zero and span can be adjusted accordingly for elevated tank levels.

15

Page 16

8.00

Setting example 1 : Differential pressure display mode

The setting to use the differential pressure range 0 to 20in.H

and to display the zero point and span point of the analog output as –2

in.H2O and 18 in.H2O respectively is as follows:

In the example the filter (moving average time) is set at 2 seconds, the

differential pressure display and the analog output are based on the

moving average equivalent to the differential pressure data per 100ms

for the past 2 seconds (20 times).

Select the filter of “2 seconds” ==> Setting item

Select the “Differential pressure display mode” ==> Setting item

Set output zero point as “–10.0%F.S.” ==> Setting item

Set output span point as “90.0%F.S.” ==>Setting item

䡵 Display and analog output

Ex. Differential pressure of 8 inH

• Differential pressure display: 8.00(H

• Analog output: 12(mA) in.H

O

2

O)

2

O

2

Differential

O (“W.C.)

2

Pressure Analog

Display Output

O) (mA)

(inH

2

Output span point 18.00 ==> 20

兰兰

8.00 ==> 12

Output zero points –2.000 ==> 4

11.3 Linear Display Mode (Re-scaling in arbitrary user defined units)

This mode is used for display / analog output of the scaling value

where the differential pressure is linearly converted to an arbitrary

physical quantity.

(1) Linear display

By setting the OFFSET to the minimum differential pressure P

and the FULL SCALE to the maximum differential pressure P2,

the linear display indicates the value on the line between the two

points (the maximum display span). The actual linear display

span depends on the setting of the zero point and span point of

the analog output as shown in (2) of the next page. It can display

the range of –5 to 105%F.S. of the linear display span.

1

16

Page 17

Display

Display

Full Scale

Full Scale

(20mA)

(4mA)

Offset

(4mA)

Offset

(20mA)

Differential

Pressure

Differential

Pressure

P

1

(Min.)

P

2

(Max.)

P

1

(Min.)

P

2

(Max.)

• The setting range for the minimum differential pressure P

the maximum differential pressure P2is 0 to 100%F.S. of the differential pressure range, and the maximum differential pressure P

is set from the value which is more than 25%F.S. of the differential

and

1

2

pressure range above the minimum differential pressure P1.

• The setting range for the OFFSET and FULL SCALE values

is –1999 to 1999, and the decimal point can be set arbitrarily. At

this time, the arbitrary unit monitor turns on

See Section 14.4 for full menu.

Min. differential pressure P1and

max. differential pressure P2setting ==> Setting item ,

OFFSET & FULL SCALE setting ==>Setting item , ,

(2) Analog output

The zero point (4mA) and span point (20mA) of analog output can be

set in the range of –10 to 110%F.S. of the maximum display span (between OFFSET and FULL SCALE). The span between the zero point

and the span point in this analog output is the linear display span.

Analog output zero point

and span point setting Setting item ,

As shown in the previous diagram, usually, the OFFSET is set as Output zero point (4mA) and the FULL SCALE is set as Output span point

(20mA), but the OFFSET can be reversed to Output span point

(20mA) and the FULL SCALE can be reversed to Output zero point (4mA).

䡵 Setting example 2 : Linear display mode

17

A level gauge using a differential pressure range of 0 to 200 in.H

the linear display setting to display the OFFSET for minimum 20

in.H2O as 0.0, the FULL SCALE for maximum differential pressure 120

in.H2O as 50.0, the unit as arbitrary unit (m), the zero point (4mA) analog output as 0.0, and the span point (20mA) as 50.0 is as follows:

O,

2

Page 18

8.00

See Section 14.4 for full menu.

For display mode, select “Linear display mode” ==> Setting item

Set min. differential pressure P1 as “20 in.H

Set max. differential pressure P2 as “120 in.H

O” ==>Setting item

2

O” ==> Setting item

2

Set decimal point position of linear display

as “one digit” ==> Setting item

Set OFFSET of linear display as “0.0m” ==> Setting item

Set FULL SCALE of linear display as “50.0m” ==> Setting item

Set output zero point as “0.0%F.S.”

(0.0m) of max. display span* ==> Setting item

Set output span point as “100.0%F.S.”

(50.0m) of max. display span* ==> Setting item

*Maximum display span: OFFSET to FULL SCALE

䡵 Linear display and analog output

Ex. Differential pressure 70 in.H

O

2

• Linear display: 25.0(m)

• Analog output: 12(mA)

(1)

m

Differential Linear Analog

Pressure Display Output

O) (m) (mA)

(in.H

2

120 ==> 50.0 ==> 20 Span Point

兰兰 兰

70 ==> 25.0 ==> 12

20 ==> 0.0 ==> 4 Zero Point

(1) Put the arbitrary unit sticker.

18

Page 19

11.4 Flow Measurement/Square Root Extraction Mode

Square Root Display Mode

Combining the sensing elements (orifice and pitot tube) with this product, the mode is used for the display of the momentary flow rate, integrated volume and for analog output corresponding to the momentary

flow rate.

(1) Momentary flow rate

Maximum display span from zero to the maximum momentary flow

rate. The Momentary flow rate display span depends on the set-

ting of the zero point and span point of the analog output as shown

in (2) analog output. It can display 0 to 105%F.S. of the momentary

flow rate display span. The scaling method can be performed only

by setting the maximum momentary flow rate and then generate

differential pressure using the following square root formula.

Momentary flow rate Dx is expressed by the square root formula

(a), and can be calculated only by measuring the generated differential pressure Px (percent value over the differential pressure

range).

(%)

P

(a)

In addition, the coefficient k is determined by substituting the

maximum momentary flow rate Dm, which is measured from the

formula (a), and the then generated differential pressure Pm into

the formula (b).

(a)

• The differential pressure generated during the maximum momen-

tary flow rate can be set in the range of 25 to 100%F.S. of the differential pressure range.

• The setting range for values of the maximum momentary flow rate

is 0 to 1999. Note: The decimal point can be set arbitrarily.

Setting of max. momentary flow rate and then

generated differential pressure ==> Setting item , ,

Dx= k x

k =

D

P

公

100

m

m

公

00

x

100(%)

19

Page 20

• When the display resolution lowers and the wobbling of momentary

999999

0

0

overflows

clr

flow rate increases in the low flow domain of the differential pressure

flow meter, the domain (below the set value) will be forcedly indicated as zero by means of the low-cut for momentary flow rate.

Moreover, the analog output has a fixed value of 4mA at the zero

point. For setting of low-cut, input the percent value over the maximum

display span. Its range is 0 to 30%F.S. and the decimal point position

can be set up to one digit after decimal point as fixed point.

Setting of low-cut ==> Setting item

(2) Analog output

The zero point (4mA) and span point (20mA) of analog output can

be set in the range of 0 to 110%F.S. of the maximum display span

(0 to maximum momentary flow rate). The span between the zero

point and the span point in this analog output is the momentary

flow rate display span.

(3) Integrated volume

• The units of integrated volume include two standards: Time

factor and flow rate volume factor.

Setting of integrated volume unit ==> Setting item

• The number of digits of integrated volume display is a

maximum of 6 figures (999999); the display will return to 0 once

the maximum reading has been met.

• The zero reset of an integrated volume is executed by pressing S key

for more than 3 seconds and displaying "cLr" (clear) for 2 seconds.

20 , 21

• As backup in case of POWER OFF, the integrated volume value

is stored in the nonvolatile memory for every hour. After power returns, integration starts from the integrated volume value stored in

the memory.

20

Page 21

• Integration is halted during the "FFF" display at the time of

differential pressure range OVER (Refer to paragraph 11.5 (1) ).

• The indicated value which is blinking is integrated during the

"blink" display at the time of momentary flow rate display span

OVER (Refer to paragraph 11.5 (2) ).

(4) Display switching method of momentary flow rate and

integrated volume

Display switching methods of momentary flow rate and integrated

volume include the automatic switching display method to display them by turns at intervals of fixed time (1 to 10 seconds) and

the manual switching display method to change the display by

pressing (M) key.

Selection of display switching method

(automatic or manual) ==> Setting item

22

Setting of display switching time

for automatic ==> Setting item

23

䡵 Setting example 3: Standard unit for square root display mode

In the differential flow meter whose differential pressure generated at

maximum momentary flow rate of 120 is 32IW (80%F.S.) and which

uses a differential pressure range of 0 to 40IW, the scaling setting of

the momentary flow rate of standard unit and the setting of integrated

volume of the standard unit are as follows:

In this case, the low-cut is set as 15%F.S., the display switching

method is set as automatic, and the switching time is set as 5 seconds.

Select the “Square root display mode ==> Setting item

Set the differential pressure at max. momen-

tary flow rate as 32.0IW (80%F.S.) ==> Setting item

Select “1-digit” as decimal point position

of momentary flow rate ==> Setting item

Set the max. momentary flow

rate as “120.0.” ==> Setting item

Set the low-cut as “15.0%F.S.” of

max. display span* ==> Setting item

Set the output zero point as “0.0%F.S.”

(0.0 arbitrary unit of measure) of

max. display span* ==> Setting item

21

Page 22

Set the output span point as “100.0%F.S.”

84.9

270225

(120.0 arbitrary unit of measure) of

max. display span* ==> Setting item

Set time factor selection

(seconds, minutes, hours) ==> Setting item

Select standard “I” as flow rate volume factor ==> Setting item

Select “ti” (automatic) as display

switching method ==> Setting item

Set automatic display switching time

as “5 seconds” ==> Setting item

*Maximum display span: 0 to Maximum momentary flow rate

䡵 Arbitrary unit of square root display and analog

Momentary flow rate display (standard)

Outbreak differential pressure: 16IW Integrated volume display (arbitrary unit)

• Second flow quantity: 84.9 Integrated volume 270225

(Next page reference)

• Analog output: 15.3 mA

Differential Pressure Momentary Flow Rate Unit Analog Output

IW) (mA)

(

32 120 20

|||

16 84.9 15.3

|||

004

It It is alternation

indication for every

five seconds

(Automatically)

Span Point

Zero Point

21

22

23

22

Page 23

120

(Dx)

(Max.)

84.9

0

20

40

60

80 100

Differential Pressure

(%F.S.)

Momentary Flow Rate

(16IW)

(32IW)

䡵 Square Root

The momentary flow rate Dx at a generated differential pressure of 16IW

(40%F.S.) is calculated by the following formula:

The coefficient k is determined by substituting the maximum momentary flow

rate Dm=120 and the then differential pressure Pm=80%F.S.(32IW) into the

formula (b) of the preceding paragraph 11.4 (1).

00

D

k =

Therefore, the momentary flow rate Dx is determined by the formula (a) of

the preceding paragraph 11.4(1).

Dx= kx

P

m

公

100

公

m

P

x

100

120

=

80

公

100

= 134.2

=

134.2

40

公

100

= 84.9

䡵 Setting example 4: Arbitrary unit of square root display mode

Setting of momentary flow rate

In order to set a momentary flow rate to an “arbitrary unit,” the

momentary flow rate unit must be set as the arbitrary unit, and the

maximum momentary flow rate of the arbitrary unit and the then

generated differential pressure must be set.

23

Page 24

Setting of integrated volume

When a momentary flow rate unit is set as an arbitrary unit, the

integrated volume is also an arbitrary unit and the factor of the

two following points must be set:

• Setting of time factor (second, minute, hour)

• Setting of flow factor weight (1, 10, 100, 1000)

In the differential flow meter whose differential pressure generated

at maximum momentary flow rate of 1.000L/s is 16IW (80%F.S.)

and which uses a differential pressure range of 0 to 2.0 IW, the

setting of momentary flow rate of arbitrary unit and the setting of

integrated volume of the arbitrary unit (in order to display 1 per

count) are as follows: In this case, the low-cut is set as 10%F.S.

and the display switching method is set as manual.

Select the “Square root display mode” ==> Setting item

Set the differential pressure at max. momen-

tary flow rate as 16IW (80%F.S.) ==> Setting item

Select “3-digit” as decimal point position

of momentary flow rate ==> Setting item

Set the max. momentary flow rate as “1.000.” ==> Setting item

Set the low-cut as “10.0%F.S.” of max.

display span* ==> Setting item

Set the output zero point as “0.0%F.S.”

0 of max. display span* ==> Setting item

Set the output span point as “100.0%F.S.”

1 of max. display span* ==> Setting item

Select “SEC” (second) as time factor of

integrated volume ==> Setting item

Select “1” as weight of flow factor of

integrated volume ==> Setting item

Select “bt” (manual) as display

switching method ==> Setting item

*Maximum display span: 0 to Maximum momentary flow rate

21

22

24

Page 25

䡵 Square root display and analog

0.868

570616

Momentary flow rate display (arbitrary unit)

Differential pressure: 12IW Integrated volume display (arbitrary unit)

• Momentary flow rate 0.868 Integrated volume: 570616

• Analog output: 17.9 mA

Display alternation

whenever the

(M) key is pushed

(Manual)

Differential Momentary Flow

Pressure Rate Unit Analog Output

(IW) (mA)

16 1.000 20

|||

12 0.868 17.9

|||

004

Span Point

Zero Point

25

Page 26

11.5 Out of Range Display

(1) Range Over display

In the Measurement Mode, if the pressure is below –15% F.S.

(URL) “–FFF” will be displayed, and if it is more than 115%F.S.,

“FFF” will be displayed.

(2) Span Over display

When the user has adjusted the span of the device this case will

apply. The display range in each display mode is –5 to 105%F.S.

of the display span. When this range is exceeded, the value

of –5%F.S. or 105%F.S. will be held (depending upon whether

unit is below or above the span values) in a blinking state.

(3) Analog output

The analog output is linked with the display and is at 3.2mA when

the display span is at or exceeded –5%F.S. and at 20.8mA when

the display span is at or greater than 105%F.S.

䡵 Out of Range Display

Differential pressure mode (Differential pressure range 0 to 20in.H

Pressure display span 20in.H2O)

Span point: 20.0

Zero point: 0.0

• Overage display

O)

2

26

Page 27

• Overage display

-0.050

-fff

fff

1.050

–15%F.S. (–3.0 inH2O) more/less

– 5%F.S. (–1.0 inH

2

O) more/less

115%F.S. (23.0 inH

2

O) more/less

105%F.S. (21.0 inH

2

O) more/less

Adj

e-0

– Normal Message –

– Error Message –

• Span over display

12. ZERO ADJUSTMENT MODE

In the measurement mode, the pressure connection (H, L) is open to the

atmosphere and T key is pressed for more than 3 seconds in order to

shift to zero adjustment mode (refer to section 11) for zero point adjustment of the differential pressure sensor.

• If the zero point adjustment is correctly performed, the message "AdJ"

will be displayed for 2 seconds, and the display will return to the measurement mode.

• If zero point correction is performed when the applied pressure is over

±10%F.S., the error message “E-0” will be displayed for 2 seconds, and

the display will return to the measurement mode without completing the

zero point adjustment.

CAUTION: Only perform the zero point correction when both the

H and L ports are open to the atmosphere. If done incorrectly the

accuracy of the device may be effected.

27

Page 28

13. KEY LOCK

Function Key Manual Indicator

Setting of key lock MODE+$one second LoC

Release of key lock MODE+$one second UnL

Operation during keylock

Function Key Manual Indicator

Zero adjust. mode

Hold value reset

key greater than 3 sec. LoC (Key invalidity)

$

key greater than 3 sec. LoC (Key invalidity)

#

14. SETTING MODE

The setting modes include differential pressure display mode setting, linear

display mode setting, and flow measurement/square root mode setting. In

addition, loop check (refer to section 14.5) can be performed in each

mode setting.

For the setting procedure of each display mode, refer to paragraphs 14.3

and 14.4.

14.1 List of Setting Items for Differential Pressure Display Mode

(Re-scaling in “inH

O” units). Set the filter before setting the differential

2

pressure setting mode. See page 24 for full menu.

No. Setting Item LCD Display Setting Description Setting Range Default*

Filter Selection of 0,2,4,8,16,sec 4

f00002

moving average

time of differential

pressure: 2 (sec)

*The factory default.

28

Page 29

The setting of the following table is the Setting example

1: pressure display mode of Section 11-2. This applies when

re-scaling in “inH

No. Setting Item LCD Display Setting Description Setting Range Default

Display mode

Output zero

(1)

point

Output span

(1)

point

Loop check

(1) For setting of zero point and span point in the analog output, input the percent value over the differential

pressure range.

(2) Regardless of generated differential pressure, the loop check can be changed by arbitrarily linking the pres-

sure display with the analog output using ▲, ▼ key. (Refer to Section 14.3). This example of LCD display

shows the zero point display at the time of loop check start.

14.2 Setting Items for Linear Display Mode (Re-scaling in arbitrary user

(2)

defined units) Set the filter before setting the linear display mode

(Refer to the preceding Section 11.1). The setting of the following table

is the Setting example 2: Linear display mode of Section 11.3.

(Arbitrary unit: m). This applies when re-scalingin arbitrary user

defined units. See Section 14.4 for full menu.

0” units. See Section 14.4 for full menu.

2

Selection of differ-

-

n00non

a0-10.0

a0-90.0

[0-10.0

-

ential pressure display mode: non

Differential pressure of analog

output zero point

4mA: –10.0(%F.S.)

Differential

pressure of analog

output span point

(20mA):

90.0(%F.S.)

Arbitrary change of

differential pressure display and

analog output:

–10.00 (psi).)

non: Differential

pressure display

mode

Lin: Linear display

mode

Differential pressure range:

–10 to 110%F.S.

Differential

pressure range:

–10 to 110%F.S.

Display: Differential

pressure display

span; Analog

output: 4 to 20mA

non

0.0

100.0

0.0

(4.00

mA)

29

Page 30

No Setting Item LCD Display Setting Description Setting Range Default

Display mode

Min. differential pressure

Max. differential pressure

Decimal point

position

OFFSET

-

n00l0n

(1)

p0 -20

(1)

p0-120

d0-001

d0-00.0

FULL SCALE

d0-50.0

Output zero

(2)

point

Output span

point

Loop check

(2)

a0-50.0

a0100.0

(3)

[0-50.0

(1) The decimal point position is fixed for each differential pressure range. (Refer to section 10, Power-on Message).

The max. differential pressure can be set from the value which is 25%F.S above the minimum differential pressure.

The values under 25%F.S. cannot be increased or decreased by T, S key.

(2) For setting zero point and span point of the analog output, input the percent value over the maximum display span

(between OFFSET and FULL SCALE). Its decimal point position can be set up to one digit after the decimal point

(xx.x).

(3) Regardless of whether pressure is applied or not, the loop check can be activated which links the display and the

output allowing the operator to arbitrarily adjust the output to check the system, troubleshoot etc (using the T, S

keys), ref section 14.4. This example shows the display set to the span point.

Selection of linear

display mode: Lin

-

Min. differential

pressure corresponding to OFF-

:20.0(inH

SET

Max. differential

pressure corresponding to FULL

:120inH

SCALE

Display after decimal point Number

of digits:1(digit)

OFFSET corresponding min. differential

pressure

FULL SCALE corresponding to max.

differential pres-

:50.0 (m)

sure

Analog output zero

point : (4mA): 0.0

(%F.S.)

Analog output span

point : (20mA):

100.0 (%F.S.)

Arbitrary change of

linear display and

analog output:

50.0 (m), 20mA

30

2

O)

2

: 0.0 (m)

non: Differential

pressure display

mode; Lin: Linear

display mode

Differential pressure range:

0 to 75%F.S.

O)

Differential

pressure range:

25 to 100%F.S.

0,1,2,3 digit

–1999 to 1999

–1999 to 1999

Max. display span:

–10 to 110%F.S.

Max. display span:

–10 to 110%F.S.

Display: Linear display span; Analog

output: 4 to 20mA

non

0.0

100.0

0

0

1000

0.0

100.0

0

(4.0mA)

Page 31

14.3 Flow Measurement/Square Root Extraction Mode

No. Setting Item LCD Display Setting Description Setting Range Default

Display mode

Maximum

differential

selection

Flow rate deci-

mal pt. position

Max. momen-

tary flow

Low cut

Output zero

point

Output span

point

Time factor

Flow rate vol-

21

ume factor

Display

switch set-

22

ting

Switch time

interval

23

Loop check

24

(1) In the setting of a differential pressure the decimal point position is fixed for each differential pressure range. (Refer

to paragraph 12, Power-on Message). The max. differential pressure can be set from the value which is 25%F.S of

the differential pressure range above the minimum differential pressure.The values under 25%F.S. cannot be increased or decreased by T, S key.

(2) For setting zero point and span point of the analog output, input the percent value over the maximum display span

(between OFFSET and FULL SCALE). Its decimal point position can be set up to one digit after the decimal point (xx.x).

(3) Regardless of generated differential pressure or low-cut, the loop check can be changed arbitrarily linking the mo-

mentary flow rate display with the analog output using the T, S keys. (Refer to 14.5.) This example of LCD display

shows the display set to span point.

n~ roT

p. 400

1

D 0

D 1000

l 0.0

2

A 0.0

2

A100.0

U SE[

U 1

s bT

T 5

3

c 0.0

Selection for flow measurement/ square root extraction

mode

Maximum differential pressure relating to the flow rate

Displays of value after decimal point, # of digits

Max. momentary of flow

using arbitrary units

Forces display and output to

zero

Momentary flow rate of analog output zero point (4mA):

100.0% F.S.

Momentary flow rate of ana-

log output zero point

(20mA): 100.0% F.S.

Measurement of max. momentary flow rate over time

selected

Flow rate x time selected 1,10,100,1000

Selection of display switching

method of momentary flow

rate and integrated volume

Selection for ti: automatic

Displays switching time interval in seconds

Output check using arbitrary

value – displays pressure

correlating to the 4 to 20mA

signal

non: Differential pressure

display mode Lin: Linear

display mode Rot: Square

root display mode

25 to 100% F.S. of sensor

range

0,1,2,3 digit

0 to 1999

0.0 to 30.0% F.S. of max.

display span

–10 to 100% F.S. of max.

display span

–10 to 100% F.S. of max.

display span

Seconds, minutes or hours

ti = automatic

bt = manual

1 to 10 seconds (10 stage)

Display: momentary flow

rate display span

Analog output: 4 to 20mA

0.0 to 100.0%

non

100.0%

of sensor

range

0

1000

0.0

0.0

100.0

Sec

1

bt

5

0

(4.0mA)

31

Page 32

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

a

b

e

c

d

f

g

h

i

j

k

l

u 6.00

f 2

n non

n l n

a 10.0

a 90.0

[ 1.00[ 1.00

p 20.0

p 120.0

d 1

d 0.0

d 50.0

a 0.0

a 100.0

[ 50.0

-

`

-

-

Linear display

mode setting

Differential pressure

display mode setting

Differential

pressure

display mode

Output span

point pressure

Output zero

point pressure

Loop check

(zero point)

V

ersion display

Filter

Linear display

mode

Min. pressure

(Re-scaling in

“inH

2

O” units)

(Re-scaling in arbitrary

user defined units)

Max. pressure

Decimal point

position

OFFSET

Full scale

Output zero

point

Output span

point

Loop check

(span point)

B

asic key operation

The setting item is changed by

u

M key.

The set value is changed or selected by

▲ key or ▼ key. When changing the value,

it is increased or decreased by pressing

▲ key or ▼ key, respectively.

(Refer to next page)

key for more

t

han 3 seconds

Setting Mode

Measurement Mode

m

Flow

Measurement

Mode

See

Page 6

14.4 Setting Procedure (Setting Examples from 14.1, 14.2)

32

See

Section

14.4

Page 33

u

M

u

M

u

M

u

M

u

M

N ROT

d 0 d i d Z d 3

a 100.0

L 0.0

P. 4.00

a 0.0

U SE1

U SE( U houU n~In

U 10 U 100 U 1000

Flow Measurement Mode

(Square Root Extraction Settings)

Refer to

P

age 5

b Flow Measurement / Square Root

Extraction Mode

n Maximum Differential

Selection (Exam ft:4in)

o Flow Rate

Decimal Point

Position

5 Bt

u22 Display Switch

Setting

u

23 Switch Time

Interval

u

24 Loop Check

Returns to

Setting Mode

See Page 5

q Low Cut

s Output Span Point

t Time Factor

u

M

u

M

u

M

u

M

u

M

u

M

u

M

u

M

p Maximum Momentry

Flow

C

D

C

D

C

D

C

D

C

D

t 5

c 0.0

u21 Flow Rate

Volume Factor

C

D

C

D

C

D

C

D

u

M

r Output Zero Point

u22

5 t;

D 1000

33

Page 34

Check

Terminals

14.5 Loop Check

In each display mode, regardless of applied pressure, the loop check can

be changed by arbitrarily linking the display with the analog output using

the key operation. The display will show representative pressure readings

correlating to the 4-20mA signal.

䡲 Loop check method

(1) Remove the lid of this product.

(2) Shift to either the differential pressure, linear display or flow

measurement modes. (See Section 14). Use (M) button to scroll to

Loop Check function as indicated within Section 14.1, 14.2 or 14.3 respectively. The display and output (4mA) are at the zero point when

loop check starts.

(3) If the T is pressed, the display will increase along with the

output. By pressing S key, decrease will occur. Release the

key at the desired indication. For example, if the key is released at

25.0m, the display will stop and be held at analog output 12mA corresponding to the indication, ref. example from section 14.2

䡲 Analog Output Check Terminals

When the front cover is removed, the analog output check terminals

(pad: CH+, CH–) are visible at the upper part of the display substrate.

The analog output can be checked during measurement mode or loop

check by applying a probe, such as a tester for current measurement,

onto the check terminal of the substrate, as shown in the following figure.

In addition, receivers are not affected by the tester's probes.

Loop check / linear display

PX5100

34

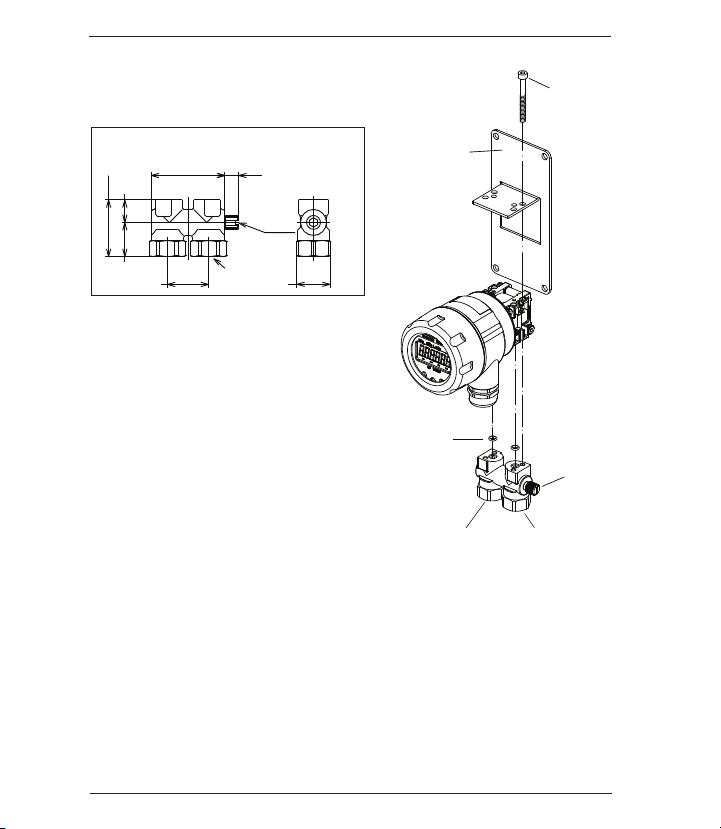

Page 35

Dimension Drawings

Dimensions in inches

1.0

4.49

3.62

2.91

2.28

4.72

5.12

1.97

2.36

.69

2 x Ø .06

Drain

4 x Ø .22

P

anel Mounting Holes

Bracket t = .08

Ø 2.56

.42

2.07

Drain Outlet

Equalizing Valve

High Pressure Port

1/4 NPT female

.82

1.42

Electrical Connection PG 13.5

threaded housing, factory installed

options include cable gland or

1/2 FNPT conduit connection

inH2O

G

C52

15. DIMENSION DRAWINGS

PX5100

35

Page 36

16. MAINTENANCE AND WARRANTY

䡲 Periodic inspection

Depending upon the type of use periodic inspection is recommeded

at least once a year. Please refer to the following items for periodic

inspection.

(1) Appearance

(2) Display/output check via appropriate pressure standard

(3) Display/output check via Loop Check

(2)

䡲 CAUTION

• Avoid electrostatic charging. When cleaning this product, please use

a soft, damp, cloth.

• Do not use thinner, etc. which may cause deterioration and failure.

䡲 Product warranty

Except as otherwise provided, the product warranty of this product is

as follows:

Period: 12 months after delivery

Warrantable defects: Defects resulting from the design and manufac-

ture of our company, the quality of the material, etc.

Implementation of warranty: This warranty will be completed by substi-

tution or repair of the product concerned.

We will not take responsibility for consequential damages caused by

product defects.

• If you have any questions about this document, please contact the

sales office or distributor nearest you.

• This document is subject to change without notice due to upgrade etc.

(1) If zero correction is required refer to section 12.

(2) Loop check, see section 14.5.

(1)

36

Page 37

373839

Page 38

Page 39

OMEG A ENGI NEERING, INC. warra nts this unit to be f ree of defects in mate ria ls and

WARRANTY/DISCLAIMER

workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds an

additional one (1) month grace period to the normal one (1) year product warranty to cover

h

andling and shipping time. This ensures that OMEGA’s customers receive maximum coverage

on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any actio n of the purchaser, includ ing but not limited to misha ndling, impr ope r

interfacing, operation outside of design limits, improper repair, or unauthorized modification.

This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows

evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture

or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only

that the par ts manufactured by the company wil l be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liabil ity or otherwise, shal l not exceed the

purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1)

as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or

activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or

with any nuclear installation or activity, medical application, used on humans, or misused in

any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from

any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFOR E R ETURNING ANY PRO DUCT (S) TO OMEGA, PU RCHASER MU ST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked

on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to mak e running changes, not model changes, wheneve r an improvem ent is possi ble.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2009 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, re-

produced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

RETURN REQUESTS/INQUIRIES

RETURNS, please have

FOR NON-WARRANTY REPAIRS,

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of theproduct, and

3. Repair instructions and/or specific problems

relative to the product.

consult

Page 40

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

40

SM

M5109/0212

Loading...

Loading...