Omega Products PX437 Installation Manual

PX437, PX438, PX439

Deep Depth Submersible Pressure Transmitter

INSTRUCTION

SHEET

M2075/1008

Shop online at: omega.com e-mail: info@omega.com

For latest product manuals: omegamanual.info

General Description

The OMEGA®PX437, PX438, PX439 Series Pressure

Transmitters can be used in cases where the transmitter is to be submerged. The 4 to 20 rnA output

signal can be transmitted up to 10,000 feet.

Theory of Operation

The transducers incorporate an isolated diaphragm

sensor which is specifically designed for use with

hostile fluids and gases. The sensors utilize a silicon

pressure cell that has been fitted into a stainless steel

package with integral, compliant stainless steel

barrier diaphragm. This sensor assembly is housed

in a rugged 316SS case which proVides for a variety

of pressure ranges. These devices feature internal

signal conditioning, and the output is 4 to 20 mA.

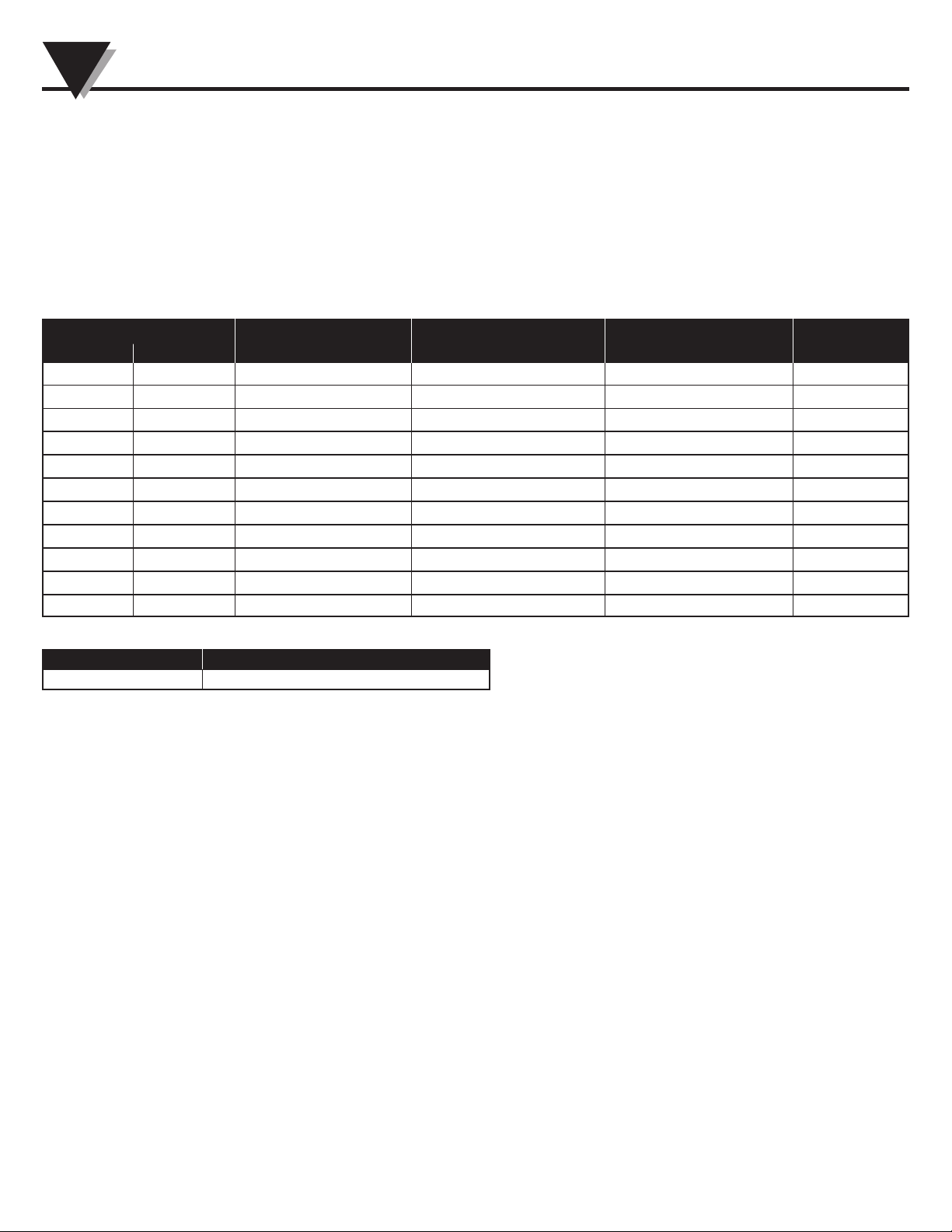

Typical Wiring 4-20mA Configuration

PX430-TRAP Option Attached to Vented Cable

Optional PX430-TRAP Vent Filter/Water Vapor

Trap

The PX430-TRAP is a replaceable vent tube

dehumidifier intended for use with PX430 series

submersible pressure transducers. This device

protects sensitive electronic components from

mildew, corrosion, rust and prevents the formation

of liquid column in the vent tube. Any such column

affects the calibrationThe PX430-TRAP can be

exposed to air, industrial gases, refrigerants, organic

liquids and solvents. It should not be used when

ammonia is present.

The PX430-TRAP connects to the existing vent tube

via a 10" flexible tube (locate the plastic tube near the

two wires on the transducer cable). The acrylic

drying tube is 6" long and the diameter is 3/4".

Inserted in each pull-off molded polypropylene

drying tube end cap is a 20 micron polypropylene

filter.

The drying tube is filled with 30 grams of indicat-ing

desiccant (drying agent). The maximum flow rate

through the drying tube is 300 cubic centime-ters per

minute, more than sufficient flow through to allow

the transducer to respond to barometric changes. As

air passes through the drying tube, moisture is

absorbed by the desiccant. The desi-cant changes

from blue to a rose red as its drying capacity

becomes diminished.

Desiccant can be rejuvenated after normal use by

spreading it in a single layer in a container and

heating for 1 hour at 205°C (400°F).

Drying Transducers

Transducers can be dryed on-site if water has entered

the vent tube. Place coiled cable and transducer in a

container and heat in an oven at 50°C (122°P) for 2

hours. Do not exceed the temperature, or else the

transducer and cable may be damaged.

Bending Cable

Minimum bending radius is 1 inch. Do not crimp the

vent tube inside the cable.

Cable Compression

Compression fittings can be used to secure the

jacketed cable. 15 ft/lb of force is allowable with-out

damaging the cable or crimping the vent tube.

Specifications

Excitation: 9-30 Vdc,

reverse polarity protected

Output: 4-20 mA dc, 2-wire

Input Current: 20 mA max

Insulation Resistance: 100 MΩ at 50 Vde

Proof Pressure: 150%

Burst Pressure: 200%

Wetted Parts: 316 Stainless Steel, and Viton

PX437, PX438, PX439 Series Submersible Pressure Thermometers

Accuracy: PX437: 0.1% FS BFSL

PX438: 0.25% FS BFSL

PX439: 0.5% FS BFSL

(includes linearity, hysteresis, and repeatability)

Response Time: 2 msec.

Zero Offset: ±0.12 mA max

Operating Temperature: 15°F to 140°F (-10°C to 60°C)

Compensated Temperature: 32°F to 120°F (0°C to 50°C)

Fill Fluid: Silicone oil

Combined Thermal Effect: ±0.05% FS/°C

(Zero and Span)

Mounting Provisions: Suspended by cable

Electronic Connections: Submersible cable terminating in

pigtail leads

Cable: Polyurathane jacketed shielded cable

with polyethylene vent tube and Kevlar

tension members. 200 lbs pull strength.

Weight: 7 oz. (198 g.) (cable not included)

Range 0.1% FS Accuracy 0.25% FS Accuracy 0.5% FS Accuracy Cable

PSIG FtH2O Model Model Model Length

0-2 5 PX437-002GI PX438-002GI PX-439-002GI 20 ft.

0-5 11.5 PX437-005GI PX438-005GI PX439-006GI 20 ft.

0-10 23.1 PX437-010GI PX438-010GI PX439-010GI 40 ft.

0-15 34.6 PX437-015GI PX438-015GI PX439-015GI 50 ft.

0-30 69.2 PX437-030GI PX438-030GI PX439-030GI 90 ft.

0-50 115 PX437-050GI PX438-050GI PX439-050GI 135 ft.

0-100 230 PX437-100GI PX438-100GI PX439-100GI 250 ft.

0-150 345 PX437-150GI PX438-150GI PX439-150GI 365 ft.

0-200 460 PX437-200GI PX438-200GI PX439-200GI 480 ft.

0-250 575 PX437-250GI PX438-250GI PX439-250GI 595 ft.

0-300 690 PX437-300GI PX438-300GI PX439-300GI 710 ft.

Available Models

Accessories

Model Description

PX430-TRAP Vent Filter/Water Vapor Trap

Loading...

Loading...