Page 1

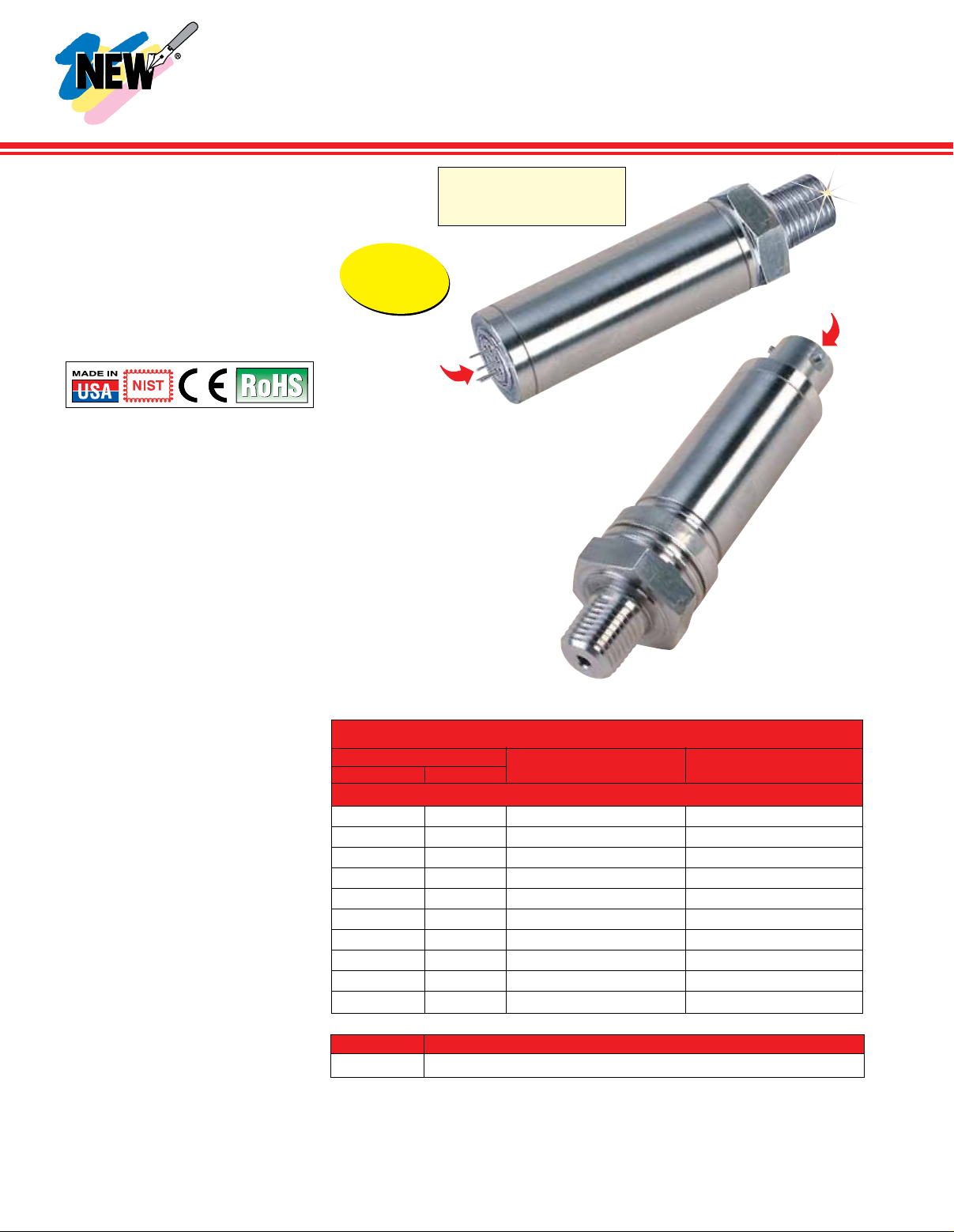

HERMETICALLY SEALED GAGE

TRANSDUCERS

DESIGNED FOR THE HARSHEST ENVIRONMENTS

100 mV Output

0-100 to 0-5000 psi Sealed Gage

6.9 to 345 bar

PX409 Series

Sealed Gage

Standard

The hermetically sealed gage

version of the PX409 Series

features all welded Stainless Steel

construction, 316L wetted parts and

glass to metal seals (GMS) at the

electrical outlets with either twist

lock connector (PX429) or solder

pins (PX449) terminations. This

ensures that the unit is hermetically

sealed from external environments

and the media. Designed for

use on automotive and aircraft

test platforms and anywhere

environmental concerns demand

the most durable characteristics.

The sealed gage models have the

PX409 Series micro machined

silicon core that provides high

accuracy, low drift and excellent

long term stability in the harshest

environments.

mV/V Specifications

Output: mV/V, 100 mV @ 10 Vdc

(ratiometric 5 to 10 Vdc)

Supply Voltage: 10 Vdc

Input/Output Resistance: 5000 Ω

±20% typical

Accuracy (Combined Linearity,

Hysteresis and Repeatability):

±0.08% BSL max

Zero Balance: ±0.5% FS typical

1% max (1% typical, 2% max

for 1 psi and below)

Span Setting: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below);

calibrated in vertical direction with

fitting down

Shock: 50 g, 11 mS half sine, vertical

and horizontal axis

Vibration: 5-2000-5 Hz, 30 minute cycle,

Curve L, Mil-Spec 810 figure 514-2-2,

vertical and horizontal axis

Metric thread

adaptors available,

visit omega.com/mta_brlk

Stock Delivery

for Most Ranges!

Visit omega.com/

px409_series

Glass-to-metal seal

solder pins style.

PX449-250SGV

shown actual size.

Operating Temperature Range:

-45 to 121°C (-49 to 250°F)

Compensated Temperature:

Ranges >5 psi: -29 to 85°C

(-20 to 185°F)

Ranges ≤ 5 psi: -17 to 85°C

(0 to 185°F)

Thermal Effects Zero

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

Thermal Effects Span

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

To Order

psi bar

10 mV/V OUTPUT, SEALED GAGE PRESSURE RANGES

100 6.9 PX429-100SGV PX449-100SGV

150 10.3 PX429-150SGV PX449-150SGV

250 17.2 PX429-250SGV PX449-250SGV

500 34.5 PX429-500SGV PX449-500SGV

750 51.7 PX429-750SGV PX449-750SGV

1000 69 PX429-1.0KSGV PX449-1.0KSGV

1500 103 PX429-1.5KSGV PX449-1.5KSGV

2500 172 PX429-2.5KSGV PX449-2.5KSGV

3500 241 PX429-3.5KSGV PX449-3.5KSGV

5000 345 PX429-5.0KSGV PX449-5.0KSGV

ACCESSORY

MODEL NO. DESCRIPTION

PT06F10-6S Mating connector for PX429 series transducers

Comes complete with 5-point NIST traceable calibration. Visit omega.com for compatible meters.

Ordering Examples: PX449-250SGV, 10 mV/V output, 250 psi sealed gage pressure range,

glass to metal sealed pin termination.

PX429-1.0KSGV, 10 mV/V output, 1000 psi sealed gage pressure range, hermetically sealed

twist-lock termination, PT06F10-6S, mating twist-lock connector (sold separately) and

DP25B-S, 4-digit meter.

Visit omega.com/px429-sgv for Pricing and Details

RANGE

TWIST-LOCK GLASS TO METAL

TERMINATION SEAL PINS

PX429-3.5KSGV

shown actual size.

Twist-lock

style.

B-57

Page 2

HERMETICALLY SEALED

GAGE TRANSDUCERS

DESIGNED FOR THE HARSHEST ENVIRONMENTS

0 to 5 Vdc Output

0-100 to 0-5000 psi Sealed Gage

6.9 to 0-345 bar

PX409 Series

Sealed Gage

Standard

U Micro-Machined Silicon

The hermetically sealed gage

version of the PX409 Series

features all welded Stainless Steel

construction, 316L wetted parts and

glass to metal seals (GMS) at the

electrical outlets with either twist

lock connector (PX429) or solder

pins (PX449) terminations. This

ensures that the unit is hermetically

sealed from external environments

and the media. Designed for

use on automotive and aircraft

test platforms and anywhere

environmental concerns demand

the most durable characteristics.

The sealed gage models have the

PX409 Series micro machined

silicon core that provides high

accuracy, low drift and excellent

long term stability in the harshest

environments.

Amplified Voltage Output

Specifications

Output/Supply

0 to 5 Vdc: 10 to 30 Vdc@10 mA

0 to 10 Vdc: 15 to 30 Vdc@10 mA

Accuracy (Combined Linearity,

Hysteresis and Repeatability):

±0.08% BSL max

Zero Balance: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below)

Span Setting: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below);

calibrated in vertical direction with

fitting down

Shock: 50 g, 11 mS half sine, vertical

and horizontal axis

Vibration: 5-2000-5 Hz, 30 minute cycle,

Curve L, Mil-Spec 810 figure 514-2-2,

vertical and horizontal axis

Operating Temperature Range:

-45 to 115°C (-49 to 240°F)

Stock Delivery

for Most Ranges!

Visit omega.com/

px409_series

Glass-to-metalseal solder pins.

Compensated Temperature:

Ranges >5 psi: -29 to 85°C

(-20 to 185°F)

Ranges ≤5 psi: -17 to 85°C

(0 to 185°F)

Thermal Effects Zero

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

Thermal Effects Span

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi:

±1.0% span

To Order

psi bar

10 mV/V OUTPUT, SEALED GAGE PRESSURE RANGES

100 6.9 PX429-100SG5V PX449-100SG5V

150 10.3 PX429-150SG5V PX449-150SG5V

250 17.2 PX429-250SG5V PX449-250SG5V

500 34.5 PX429-500SG5V PX449-500SG5V

750 51.7 PX429-750SG5V PX449-750SG5V

1000 69 PX429-1.0KSG5V PX449-1.0KSG5V

1500 103 PX429-1.5KSG5V PX449-1.5KSG5V

2500 172 PX429-2.5KSG5V PX449-2.5KSG5V

3500 241 PX429-3.5KSG5V PX449-3.5KSG5V

5000 345 PX429-5.0KSG5V PX449-5.0KSG5V

ACCESSORY

MODEL NO. DESCRIPTION

PT06F10-6S Mating connector for PX429 (sold separately)

Comes complete with 5-point NIST traceable calibration. Visit omega.com for compatible meters.

Note: To order 0 to 10 Vdc output, change “5V” in model number to “10V”, no extra charge.

Ordering Examples: PX449-250SG5V, 0 to 5 Vdc output, 250 psi sealed gage pressure range,

glass to metal sealed pin termination.

PX429-1.0KSG10V, 0 to 10 Vdc output, 1000 psi sealed gage pressure range, hermetically

sealed twist-lock termination, PT06F10-6S, mating twist-lock connector (sold separately) and

DP25B-S, 4-digit meter.

Visit omega.com/px429-sg5v for Pricing and Details

RANGE

TWIST-LOCK GLASS TO METAL

TERMINATION SEAL PINS

PX449-250SG5V

shown actual size.

Twist-lock

style.

B

PX429-3.5KSG5V

shown actual size.

Metric thread

adaptors available,

visit omega.com/mta_brlk

B-58

Page 3

HERMETICALLY SEALED

GAGE RANGES

DESIGNED FOR THE HARSHEST ENVIRONMENTS

4 to 20 mA Output

0-100 to 0-5000 psi Sealed Gage

6.9 to 0-345 bar

PX409 Series

Sealed Gage

Standard

The hermetically sealed gage

version of the PX409 Series

features all welded Stainless Steel

construction, 316L wetted parts and

glass to metal seals (GMS) at the

electrical outlets with either twist

lock connector (PX429) or solder

pins (PX449) terminations. This

ensures that the unit is hermetically

sealed from external environments

and the media. Designed for use

on automotive and aircraft

test platforms and anywhere

environmental concerns demand

the most durable characteristics.

The sealed gage models have the

PX409 Series micro machined

silicon core that provides high

accuracy, low drift and excellent

long term stability in the harshest

environments.

4 to 20 mA

Specifications

Output: 4 to 20 mA

Supply Voltage: 9 to 30 Vdc

max loop res Ω = (Vs-9)x50

[9 to 20 Vdc above 105°C (229°F)]

Accuracy (Combined Linearity,

Hysteresis and Repeatability):

±0.08% BSL max

Zero Balance: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below)

Span Setting: ±0.5% FS typical 1% max

(1% typical, 2% max for 1 psi and below).

Calibrated in vertical direction with

fitting down

Shock: 50 g, 11 mS half sine, vertical

and horizontal axis

Vibration: 5-2000-5 Hz, 30 minute cycle,

Curve L, Mil-Spec 810 figure 514-2-2,

vertical and horizontal axis

Operating Temperature Range:

-45 to 115°C (-49 to 240°F)

Stock Delivery

for Most Ranges!

Visit omega.com/

px409_series

Sealed

twist-lock

Glass-to-metal

seal solder pins.

PX449-250SGI

shown actual size.

Compensated Temperature:

Ranges >5 psi: -29 to 85°C

(-20 to 185°F)

Ranges ≤ 5 psi: -17 to 85°C

(0 to 185°F)

Thermal Effects Zero

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

Thermal Effects Span

(Over Compensated Range):

Ranges >5 psi: ±0.5% span

Ranges ≤5 psi: ±1.0% span

To Order

psi bar

10 mV/V OUTPUT, SEALED GAGE PRESSURE RANGES

100 6.9 PX429-100SGI PX449-100SGI

150 10.3 PX429-150SGI PX449-150SGI

250 17.2 PX429-250SGI PX449-250SGI

500 34.5 PX429-500SGI PX449-500SGI

750 51.7 PX429-750SGI PX449-750SGI

1000 69 PX429-1.0KSGI PX449-1.0KSGI

1500 103 PX429-1.5KSGI PX449-1.5KSGI

2500 172 PX429-2.5KSGI PX449-2.5KSGI

3500 241 PX429-3.5KSGI PX449-3.5KSGI

5000 345 PX429-5.0KSGI PX449-5.0KSGI

ACCESSORY

MODEL NO. DESCRIPTION

PT06F10-6S Mating connector for PX429 (sold separately)

Comes complete with 5-point NIST traceable calibration. Visit omega.com for compatible meters.

Ordering Examples: PX449-250SGI, 4 to 20 mA output, 250 psi sealed gage pressure range,

glass to metal sealed pin termination.

PX429-1.0KSGI, 4 to 20 mA output, 1000 psi sealed gage pressure range, hermetically sealed

twist-lock termination, PT06F10-6S, mating twist-lock connector (sold separately) and DP25B-S,

4-digit meter.

Visit omega.com/px429-sgi for Pricing and Details

RANGE

TWIST-LOCK GLASS TO METAL

TERMINATION SEAL PINS

adaptors available,

visit omega.com/mta_brlk

PX429-3.5KSGI

shown actual size.

Metric thread

style.

B-59

Loading...

Loading...