Omega Products CNi8C-EN Installation Manual

User’s Guide

Shop on line at

www.omega.com

e-mail: info@omega.com

iSeries info:

www.omega.com/specs/iseries

Temperature & Process

Controller/Monitor Manual

CNi8C-EN

TABLE OF CONTENTS

Part 1: Introduction .....................................................................................1

1.1 Description ...................................................................................1

1.2 Safety Considerations ....................................................................2

1.3 Before You Begin ...........................................................................3

Part 2: Setup ................................................................................................4

2.1 Front Panel ...................................................................................4

2.2 Disassembly ...................................................................................5

2.3 Electrical Installation ......................................................................6

2.3.1 Power Connections ............................................................6

2.3.2 Rear Panel Connections ....................................................8

2.3.3 Thermocouple - Input Connection ....................................10

2.3.4 Two / Three / Four Wire RTD-Hookups ...........................11

2.3.5 Process Current - Wiring Hookup ....................................12

2.3.6 Process Voltage - Wiring Hookup ....................................12

2.3.7 Wiring Outputs - Wiring Hookup .......................................13

Part 3: Operation: Configuration Mode ...................................................16

3.1 Introduction .................................................................................16

Turning your Instrument On for the First Time .................16

Buttons Functions in Configuration Mode ........................17

Appendix A: ...............................................................................................18

i

LIST OF FIGURES:

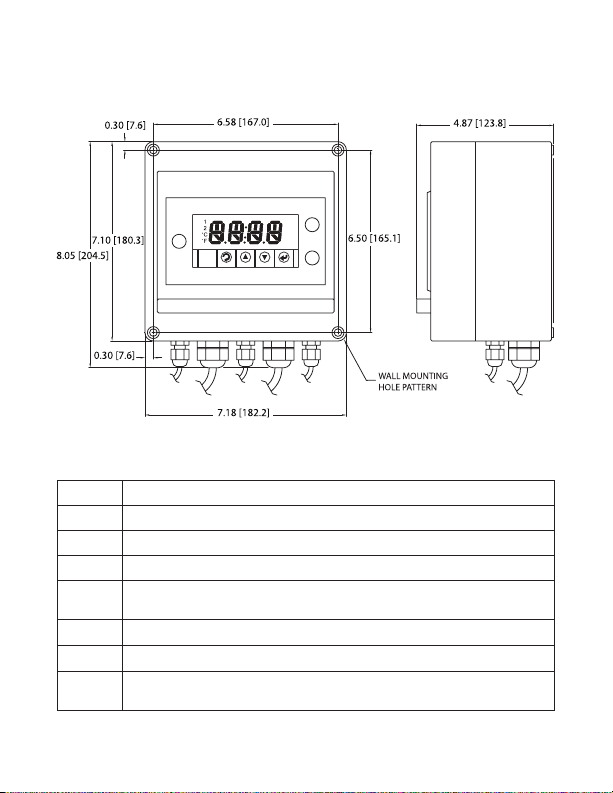

Figure 2.1 Front Panel Display ........................................................................4

Figure 2.2 Disassembly ...................................................................................5

Figure 2.3 Main Power Connections ...............................................................6

Figure 2.4 Rear View - For Models with Outputs: 22, 23, 33 ..........................7

Figure 2.5 Rear View - For Models with Outputs: 52, 53 ................................7

Figure 2.6 Rear View - For Models with Outputs: 00 ......................................8

Figure 2.7 Rear Panel Power and Output Connector Labels ..........................8

Figure 2.8 Rear Panel Input Connector Labels ...............................................9

Figure 2.9 Thermocouple Wiring Hookup .....................................................10

Figure 2.10 Two/Three/Four-wire RTD

a) RTD-1000 ohm and 500 ohm Wiring Hookup ..............................11

b) RTD-100 ohm Wiring Hookup ......................................................11

Figure 2.11 Process Current Wiring Hookup

(Internal and External Excitation) .................................................12

Figure 2.12 Process Voltage Wiring Hookup

a) Without Sensor Excitation ............................................................12

b) With Sensor Excitation .................................................................12

Figure 2.13 Output Connections:

a) Mechanical Relay and SSR Outputs – Wiring Hook up ...............13

b) Pulse and Analog Outputs – Wiring Hook up ...............................13

Figure 2.14 Typical Application .......................................................................14

Figure 2.15 Communication Output:

a) RS-232 Output – Wiring Hook up ................................................14

b) RS-485 Output – Wiring Hook up ................................................14

Figure 2.16 Excitation Output ..........................................................................15

Figure 2.17 Snubber Circuits Wiring Hookup ..................................................15

Figure A-1 Plug-Kit ........................................................................................18

LIST OF TABLES:

Table 2.1 Front Panel Annunciators ..............................................................4

Table 2.2 Fuse Requirement .........................................................................6

Table 2.3 Rear Panel Connector ...................................................................9

Table 2.4 TC Wire Color Chart ....................................................................10

Table 3.1 Button Function in Configuration Mode ........................................17

ii

NOTES, WARNINGS and CAUTIONS

Information that is especially important to note is identified by the following labels:

• NOTE

• WARNING or CAUTION

• IMPORTANT

• TIP

NOTE: Provide you with information that is important to successfully

setup and use the Programmable Digital System.

CAUTION or WARNING: Tells you about the risk of

electrical shock.

CAUTION, WARNING or IMPORTANT: Tells you of circumstances or

practices that can affect the instrument’s functionality and must refer to

accompanying documents.

TIP: Provides you helpful hints.

PART 1

INTRODUCTION

1.1 Description

This Device is a compact, wall-mountable controller or monitor that can be used

for applications that need a fixed location, when a control panel is not required.

The controller supports a variety of temperature and process inputs. The flip-top

enclosure makes programming and wire access easy to use.

For more complete specifications of the controller/monitor refer to the main

operator manual.

1

1.2 Safety Considerations

This device is marked with the international caution symbol. It is

important to read this manual before installing or commissioning this

device as it contains important information relating to Safety and

EMC (Electromagnetic Compatibility).

This instrument is a panel mount device protected in accordance with

EN 61010-1:2001, electrical safety requirements for electrical equipment

for measurement, control and laboratory. Installation of this instrument

should be done by qualified personnel. In order to ensure safe

operation, the following instructions should be followed.

This instrument has no power-on switch. An external switch or circuitbreaker shall be included in the building installation as a disconnecting

device. It shall be marked to indicate this function, and it shall be in

close proximity to the equipment within easy reach of the operator. The

switch or circuit-breaker shall meet the relevant requirements of IEC

947–1 and IEC 947-3 (International Electrotechnical Commission). The

switch shall not be incorporated in the main supply cord.

Furthermore, to provide protection against excessive energy being

drawn from the main supply in case of a fault in the equipment, an

overcurrent protection device shall be installed.

• Do not exceed voltage rating on the label located on the top of

the instrument housing.

• Always disconnect power before changing signal and power

connections.

• Do not use this instrument on a work bench without its case for

safety reasons.

• Do not operate this instrument in flammable or explosive

atmospheres.

• Unit mounting should allow for adequate ventilation to ensure

instrument does not exceed operating temperature rating.

• Use electrical wires with adequate size to handle mechanical

strain and power requirements. Install without exposing bare wire

outside the connector to minimize electrical shock hazards.

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wires close to the instrument if

EMC problems persist.

Failure to follow all instructions and warnings may result in injury!

2

1.3 Before you Begin

Inspecting Your Shipment:

Remove the packing slip and verify that you have received everything

listed. Inspect the container and equipment for signs of damage as

soon as you receive the shipment. Note any evidence of rough handling

in transit. Immediately report any damage to the shipping agent. The

carrier will not honor damage claims unless all shipping material is

saved for inspection. After examining and removing the contents, save

the packing material and carton in the event reshipment is necessary.

Customer Service:

If you need assistance, please call the nearest Customer Service

Department, listed in this manual.

Manuals, Software:

The latest Operation and Communication Manual as well as free

configuration software are available from the website listed in this

manual.

For first-time users: Refer to the QuickStart Manual for basic operation

and set-up instructions.

If you have the Serial Communications you can easily configure the

controller on your computer or on-line.

To Disable Outputs:

To ensure that menu changes are properly stored, Standby Mode

should be used during setup of the instrument. During Standby Mode,

the instrument remains in a ready condition, but all outputs are disabled.

Standby Mode is useful when maintenance of the system is necessary.

When the instrument is in “RUN” Mode, push d twice to disable all

outputs and alarms. It is now in “STANDBY” Mode. Push d once more

to resume “RUN” Mode.

PUSH d TWICE to disable the system during an EMERGENCY.

To Reset the Meter:

When the controller is in the “MENU” Mode, push c once to direct

controller one step backward of the top menu item.

Push c twice to reset controller, prior to resuming “Run” Mode except

after “Alarms”, that will go to the “Run” Mode without resetting the

controller.

3

PART 2

SETUP

2.1 Front Panel

Figure 2.1 Front Panel Display

Table 2.1 Front Annunciators

1 Output 1/Setpoint 1/ Alarm 1 indicator

2 Output 2/Setpoint 2/ Alarm 2 indicator

ºC °C unit indicator

ºF °F unit indicator

Changes display to Configuration Mode

a

and advances through menu items*

Used in Program Mode and Peak Recall*

b

Used in Program Mode and Valley Recall*

c

Accesses submenus in Configuration Mode

d

* See Part 3 Operation: Configuration Mode

and stores selected values*

4

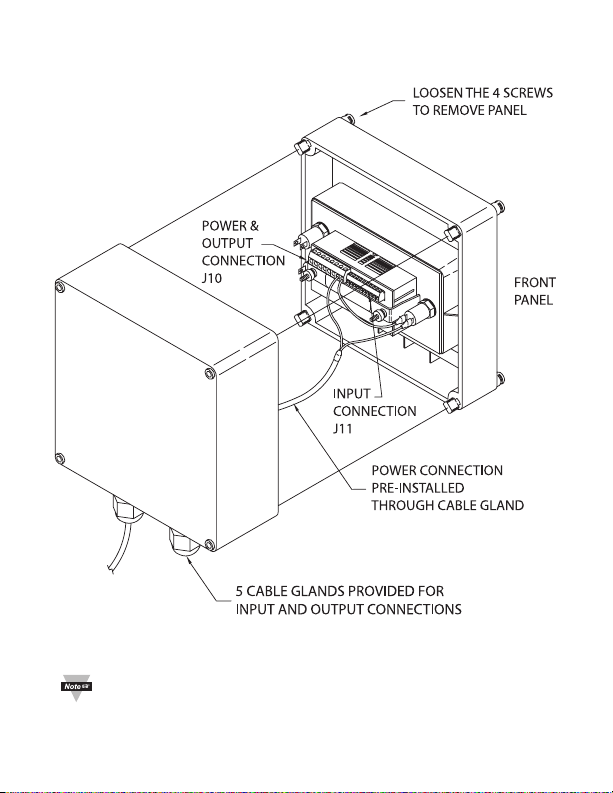

2.2 Disassembly

Figure 2.2 Disassembly

Not all cable glands may be in use. Please use the provided

“Plug-Kit” to keep the NEMA 4 rating on the unused glands.

See Appendix A for detailed diagram.

5

Loading...

Loading...