Page 1

DPi Series

Starts at

$

150

TEMPERATURE, PROCESS

i/32

User Friendly,

Simple to Configure

High Quality

Extended 5-Year Warranty

Powerful Features

Free Software,

Active X Controls

Full Autotune PID Control

Totally Programmable

Color Displays, Standard

High Accuracy ±0.5°C

(0.9°F), 0.03% Reading

Temperature Stability

±0.04°C/°C RTD and

±0.05°C/°C TC @ 25°C (77°F)

Both RS232 and RS485

MODBUS®on One

Instrument Selectable

From Menu, Optional

Universal Inputs:

Thermocouple, RTD,

Process Voltage/Current,

Strain

Built-in Excitation, Standard

2 Control or Alarm

Outputs. Choice of dc

Pulse, Solid State Relays,

Mechanical Relays, Analog

Voltage and Current

Embedded Ethernet

Connectivity

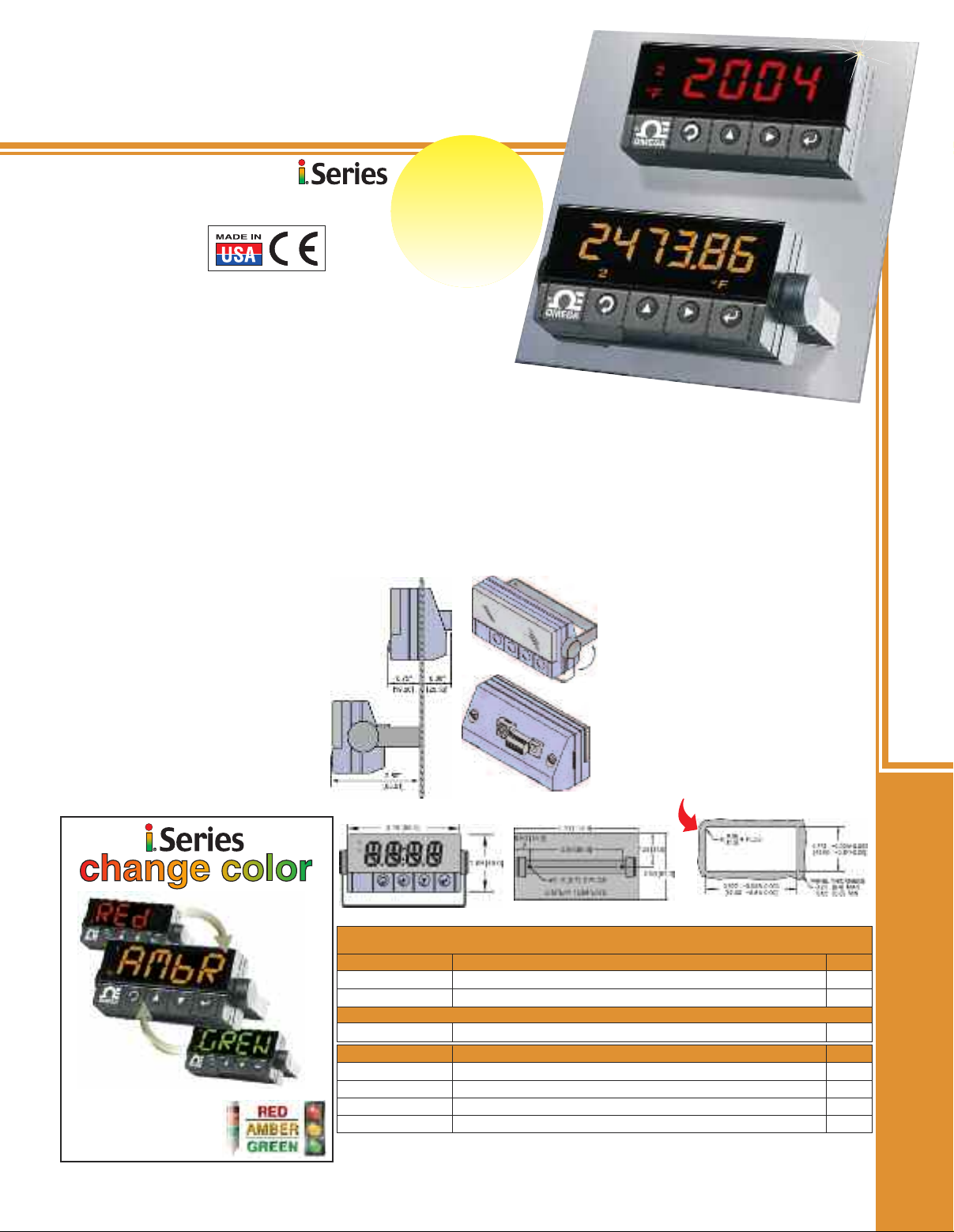

The innovative OMEGA®iSeries devices

feature state of the art technology,

uncompromising accuracy, and quality

backed by an extended 5-year warranty.

The iSeries family includes extremely

accurate digital panel meters and single

i/16

loop PID controllers that are simple to

configure and use, while providing

tremendous versatility and a wealth of

powerful features.

Embedded Internet and Serial

Communications

Featuring optional “Embedded Internet”

(specify -EI option) the iSeries are the

first instruments of their kind that

connect directly to an Ethernet network

and transmit data in standard TCP/IP

packets, or even serve Web pages over

a LAN or the Internet. The iSeries are

also available with serial

communications. With the -C24 option,

the user can select from the push-button

menu between RS232, RS422, and

RS485, with straightforward ASCII

commands or MODBUS.

iSeries FAMILY

The OMEGA®iSeries is a family of

microprocessor-based instruments

offered in three true DIN sizes with

NEMA-4 (IP65) rated front bezels. All of

the instruments share a similar set-up

and configuration menu and method of

operation, which is a tremendous time

saver for integration of a large system.

Programmable Color Display

The OMEGA iSeries are the first

complete series of

process control instruments with totally

programmable color displays. The

display can be programmed to change

color at any set point or alarm point. For

example, the instrument can be

programmed to display the process

value in GREEN during warm-up,

switching to AMBER to signal the

normal operating range, and in RED to

signal an alarm condition.

The changes in color are quickly seen

from a distance, and machine operators

can intuitively react to changing conditions.

The colors can be programmed to

change back when the value drops

1

⁄8, 1⁄16 and 1⁄32 DIN

D-7

i®Series is a trademark of Newport Electronics, Inc.

i/8

back below the alarm point or to “latch”

on until being reset by the operator.

The instrument can also be

programmed to display only one

unchanging color: GREEN, AMBER, or

RED. This is a useful way to let an

operator identify, at a glance, process

values in three separate locations, or

to display three different measurements

such as Temperature, Pressure,

and Flow.

QUALITY and TECHNOLOGY

Designed and manufactured in the USA,

the innovative OMEGA

meters & controllers features an

extended five (5) YEAR warranty at no

extra charge. The iSeries packs a wealth

of power and features into the smallest

of packages, utilizing COB (chip-onboard) and SMT (surface mount

technology) assembly techniques and

automation. Every iSeries instrument is

thoroughly calibrated and tested at

several stages throughout production.

The iSeries offers the highest accuracy

for industrial instrumentation at 0.03% of

reading. The analog-to-digital conversion

utilizes a proprietary 20-bit ASIC

(application specific integrated circuit)

patented algorithms and smart filtering.

Universal Inputs

The innovative iSeries offers the

broadest selection of signal inputs

available on one industrial instrument.

The choices are easily selected from the

menu with four front panel pushbuttons,

or by serial or Ethernet communications.

10 Thermocouple Types

The iSeries handles TEN (10)

thermocouple types: K, J, T, E, R, S, B,

C, N, and J DIN. The patented

thermocouple linearization algorithms

employed in the iSeries produce the

highest standard of accuracy.

®

iSeries of

Page 2

AND STRAIN METERS

92 (3.622)

45

(1.772)

45 (1.772)

22.2

(0.87)

45 (1.772)

45

(1.772) sq.

45 x 22.2

(1.772 x 0.87)

92 x 45

(3.622 x 1.772)

CNi Series

Starts at

AND PID CONTROLLERS

Most Accurate RTD

Measurements

The iSeries works with the widest

selection of RTD’s and produces the

most accurate RTD measurements.

Handles both Pt 0.00385 and 0.00392

curves, and 100 (ohm), 500 (ohm) and

1000 (ohm). A choice of 2-, 3- and 4wire RTD connections ensures the

absolute highest degree of accuracy.

The MIL Standard Nickel RTD with MILT-7990B curve is available as a Factory

Setup.

Process Voltage and Current

The OMEGA®iSeries measures process

voltage: 0 to 100 mVdc, 0 to 1 Vdc,

0 to 10 Vdc ranges, and process

current: 0 to 20 mA.

Strain Gauge

The STRAIN/PROCESS meters and

controllers measure inputs from Load

Cells, Pressure Transducers, and most

any strain gauge sensor. Input ranges

include 0 to 100 mVdc, -100 mVdc to

1 Vdc and 0 to 10 Vdc in addition to 0 to

20 mA. Excitation for transducers of

5 Volt and 10 Volt is standard.

Strain/Process meters and controllers

are available in all iSeries Models.

Analog Output

The optional analog

output can be

programmed within a

range of 0 to 10 Vdc or 0

to 20 mA. It is selectable

as either a control output

or as a calibrated

retransmission of the

process value—a unique

feature among

controllers.

Control Functions

The iSeries can control simple manual

operation to ON-OFF and full Autotune

PID control. (Selectable preset tune,

adaptive tune, PID, PI, PD control

modes). The dual control outputs can be

configured for a variety of independent

control and alarm applications such as

heat/heat, heat/cool, heat/alarm,

cool/cool, cool/alarm or alarm/alarm.

The ramp-to-setpoint feature allows the

user to define the rate of rise to setpoint,

minimizing thermal shock to the load

during start-up. Maximum ramp time:

99.59 (HH.MM), Soak: 00.00 to

99.59 (HH.MM), Damping: 1 to 8 in

unit steps.

For applications that do not require PID

control, just simplified programming,

$

195

Dimensions: mm (inches)

there are 2 options available: -AL Limit

Alarm and -SM Simplified Menu

ON-OFF Control.

Built-in Excitation Standard

The temperature/process (model “i”)

comes standard with built-in excitation

(24 Vdc @ 25 mA). Any excitation voltage

between 5 and 24 Vdc is available by

special order. This means the same

instrument can handle thermocouple,

standard RTD’s, or 4 to 20 mA transmitters,

with the meter’s built-in excitation. The

strain/process (model “iS”) comes standard

with built-in excitation (10 Vdc @ 60 mA),

5V excitation is user selectable. (Built-in

excitation is not available with optional

isolated RS232/RS485 serial

communications or DC power option).

INSTRUMENTATION

D

PATENTED

at any

setpoint

Totally Programmable

Color Displays

The OMEGA

first complete series of

process control instruments with totally

programmable color displays. The

display can be programmed to

change

color

at any

setpoint

or alarm

point.

®

i/8, i/16, and i/32 are the

1

⁄8, 1⁄16 and 1⁄32 DIN

D-8

Autoscaling: Automatically shifts the

decimal point right or left depending on the

process value of the meter. AutoScaling is

active only for temperature reading.

Page 3

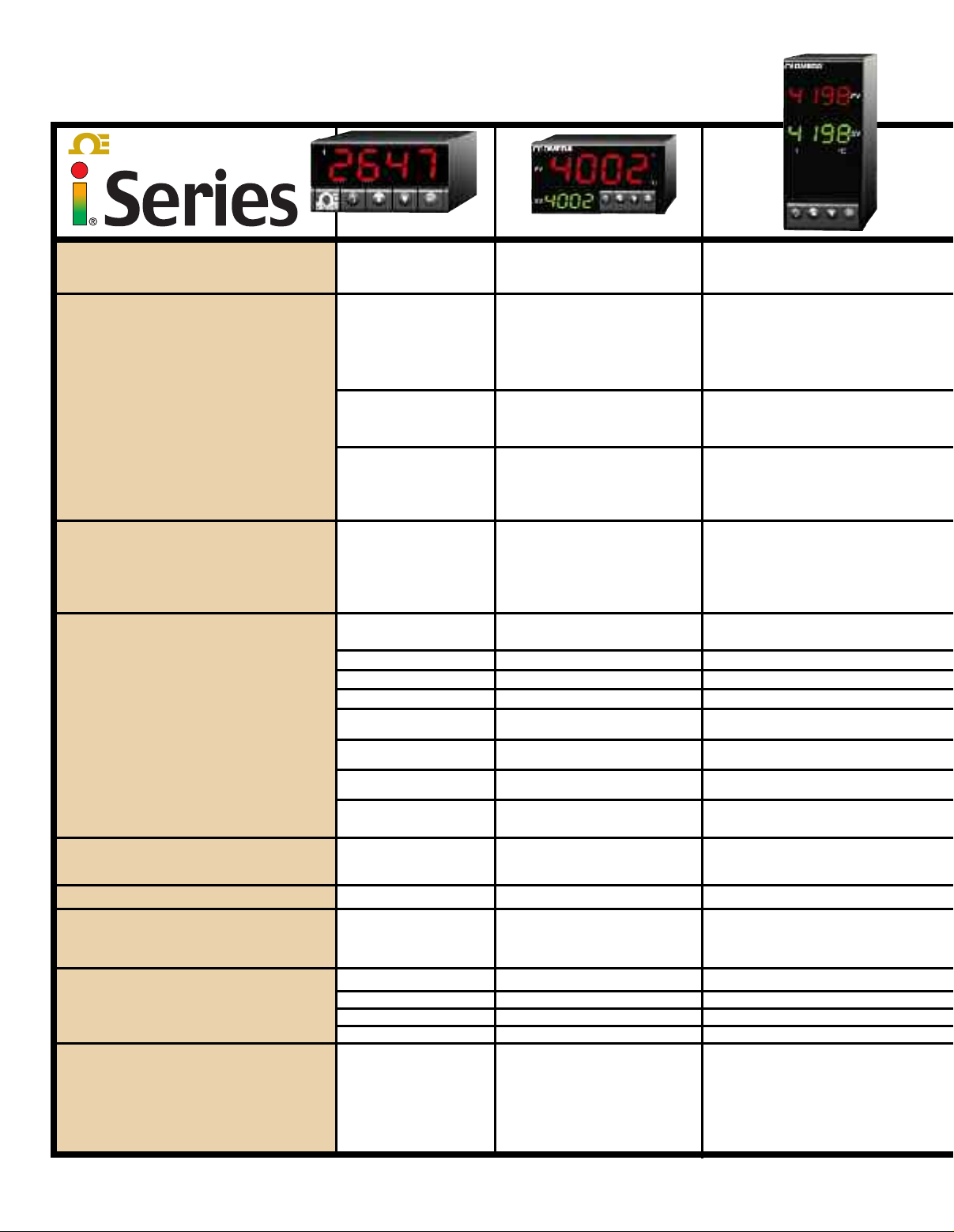

METER SELECTION GUIDE

MONOGRAM

®

®

1

⁄8 DIN Single Display

Description

Input

Process and Temperature (model “i”)

T/C: (J, K, T, E, R, S, B, N, C, J DIN)

RTD: Pt 100, 500, 1000 Ohms (385,392)

4 to 20 mA, 0 to 100 mV, 0 to 1V, 0 to 10V

Strain and Process (model “iS”)

4 to 20 mA, 0 to 100 mVdc, -100 mVdc to 1 Vdc, 0 to 10 Vdc

Ratiometric/Non-Ratiometric; 10 pt linearization

Humidity and Temperature (model “iTH”)

RH: 0 to 100% @ ±2% to ±3%

Temp: -40 to 124°C @ ±0.5° to ±1°C

(-40 to 254°F @ ±1° to ±2°F)

Display

Nine Segment LED Digits

Color Programmable: Red, Amber, Green

Height of Digits

Available Output Options

(Any combination of Two)

SSR’s: Solid State Relays 0.5A @120/240 Vac

Relays: Form “C” SPDT 3A @120/240 Vac

Pulse: 10 Vdc @ 20 mA (for use w/ external SSR)

Programmable Analog Voltage & Current Output

(non-isolated)

Other Output Options

Isolated Programmable Analog Voltage

& Current Output

Limit Alarm (-AL) or Simplified Menu (-SM)

Amber

Monitor/ Controller

Single Display Dual Display Dual Display

21 mm (0.83")

CNi8/DPi8

CNi8DH CNi8DV

1

⁄8 DIN Dual Display

Horizontal PID Controller

1

⁄8 DIN Dual Display

Vertical PID Controller

⻬⻬ ⻬

⻬⻬ ⻬

⻬⻬

Process Value: 21 mm (0.83") top display

Setpoint Value: 10.2 mm (0.40") bottom display

Two Outputs Standard

⻬⻬ ⻬

⻬⻬ ⻬

⻬⻬ ⻬

Process Value: 10.2 mm (0.40") top display

Setpoint Value: 10.2 mm (0.40") bottom display

Two Outputs Standard

⻬⻬ ⻬

⻬

⻬⻬ ⻬

Power (standard) 90-240 Vac, 50-400 Hz

110-375 Vdc, Equivalent voltage

Low Voltage Power Option 12-36 Vdc, 3 W

Mechanical

(size: H x W x D )

Weight

Network Options

1. RS232, RS422, RS485, MODBUS

2. Ethernet + RS485, MODBUS

3. Ethernet (-EI)

Base Unit Pricing

Most Popular Model

®

(-C24)

®

(-C4EI)

12 to 36 Vdc

48 x 96 x 127 mm

(1.89 x 3.78 x 5")

295 g (0.65 Ib)

DPi8 $240

CNi833-C24

1

with two mechanical relay

output + serial output

⻬⻬ ⻬

⻬⻬ ⻬

⻬⻬ ⻬

⻬⻬ ⻬

⁄8 DIN single display controller

D-9

20 to 36 Vdc

48 x 96 x 127 mm

(1.89 x 3.78 x 5")

295 g (0.65 Ib)

CNi8DH33 $340

CNi8DH33-C4EI

1

⁄8 DIN dual display horizontal controller

with two mechanical relay output + serial

and Ethernet output

20 to 36 Vdc

96 x 48 x 127 mm

(3.78 x 1.89 x 5")

295 g (0.65 Ib)

CNi8DV33 $340

CNi8DV43

1

⁄8 DIN dual display vertical controller

with pulse and relay output

Page 4

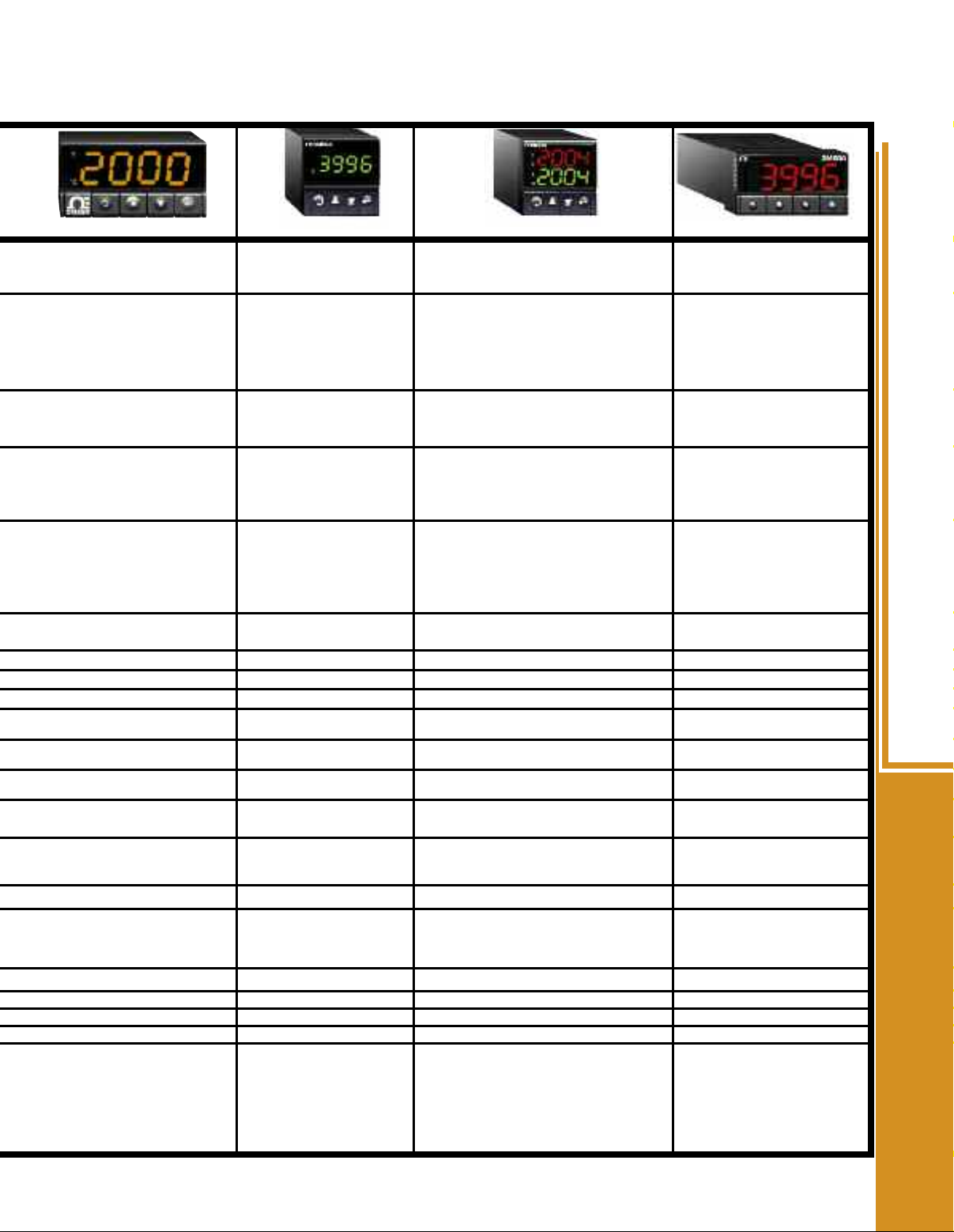

TEMPERATURE,PROCESS

,

AND STRAIN METERS AND PID CONTROLLERS

C

CNi/DPi8C

Ni/DPi16

CNi16D CNi/DPi32

1

⁄8 DIN Ultra Compact

Monitor/Controller

⻬⻬ ⻬

⻬⻬ ⻬

21 mm (0.83")

⻬⻬ ⻬

⻬⻬ ⻬

⻬⻬ ⻬

1

⁄16 DIN Single

Monitor/Controller

10.2 mm (0.40")

1

⁄16 DIN Dual Display

PID Controller

⻬⻬

Process Value: 10.2 mm (0.40") top display

Setpoint Value: 10.2 mm (0.40") bottom display

Two Outputs Standard

1

⁄32 DIN Single

Monitor/Controller

10.2 mm (0.40")

INSTRUMENTATION

⻬⻬ ⻬

⻬⻬ ⻬

⻬⻬ ⻬

12 to 36 Vdc

48 x 96 x 54.84 mm

(1.89 x 3.78 x 2.16")

255 g (0.55 Ib)

⻬⻬ ⻬

EIS-2B or EIS-W

DPi8C $285

CNi8C53

1

⁄8 DIN compact controller with

analog and relay output

12 to 36 Vdc

48 x 48 x 127 mm

(1.89 x 1.89 x 5")

159 g (0.35 Ib)

EIS-2B or EIS-W

DPi16 $180

CNi1633

1

⁄16 DIN single display controller

with two relay outputs

20 to 36 Vdc

48 x 48 x 127 mm

(1.89 x 1.89 x 5")

159 g (0.35 Ib)

⻬

⻬

CNi16D33 $245

CNi16D43-C24

1

⁄16 DIN dual display with pulse and

relay output + serial output

D-10

12 to 36 Vdc

25.4 x 48 x 127 mm

(1.0 x 1.89 x 5")

127 g (0.28 Ib)

EIS-2B or EIS-W

DPi32 $150

CNi3243-C24

1

⁄32 DIN controller with pulse and

relay output + serial output

D

Page 5

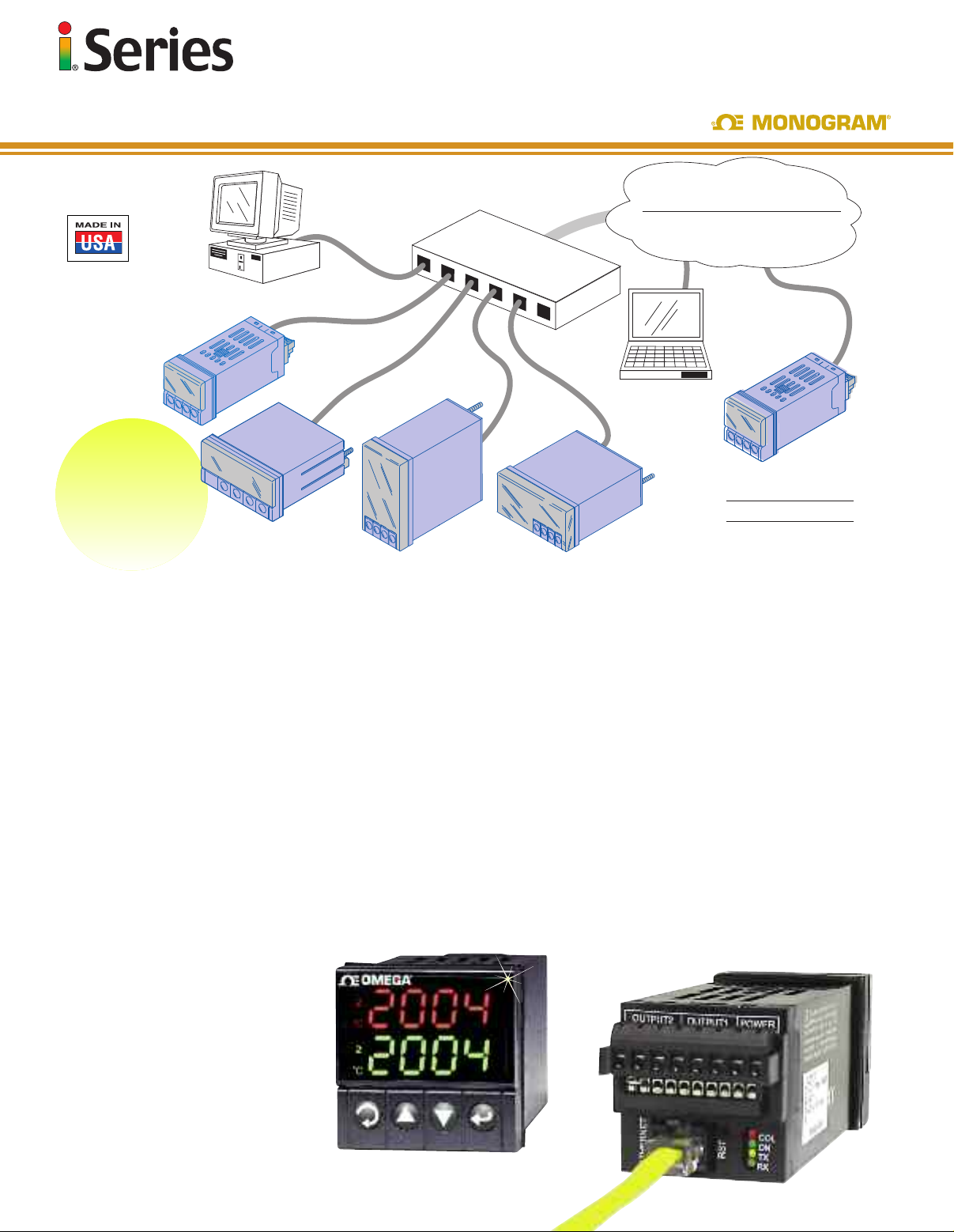

EMBEDDED INTERNET

10BASE-T

10BASE-T

1

0BASE-T

10BASE-T

10BASE-T

i8 Controller

with EI Option

Standard Ethernet

Hub or Switch

i8 Controller

with EI Option

i16 Controller

with EI Option

Internet IP Address

“Web Controller”

P

C on LAN

PC on Internet

Ethernet LAN

INTERNET

i8 Panel Meter

with EI Option

i16 Controller

with EI Option

iSeries METERS AND CONTROLLERS—DIRECT CONNECTION

TO ETHERNET (EACH DEVICE HAS ITS OWN IP ADDRESS)

CNi16D

Starts at

$

295

Embedded Internet

The OMEGA®iSeries devices can

connect directly to an Ethernet network

with a standard RJ45 connector and can

send and receive data in standard

TCP/IP packets. (Please specify -EI

or -C4EI option).

The iSeries devices can serve Web

pages over an Ethernet LAN or even

over the Internet making it possible to

monitor and control a process through a

web browser (such as Microsoft Internet

Explorer) from anywhere in the facility or

anywhere in the world.

Remote Control

For example, using an iSeries 1⁄16 DIN

temperature controller to control a

heater, an engineer can monitor the

temperature, change set points or alarm

points, turn the heater on and off, or

make other modifications from

anywhere on the local network, or

anywhere on the Internet. The web

pages are easily customized and secure

password protected access to the

devices is easily controlled. And it

requires absolutely no special software

on the engineer’s computer to view the

data and “supervise” the controller-nothing other than a Web Browser.

Email and Alarm

In fact, the iSeries controller can even

send an email to the engineer (or

anyone they choose) alerting them to an

alarm condition or updating the status.

Leveraging the technology of the

Internet, the engineer could receive a

message from the iSeries controller on

an Internet enabled pager or cell phone.

Most remarkable is that all this can be

accomplished without a computer. The

OMEGA

controller) connects directly to the

Ethernet Network—not to the serial port

of a computer functioning as a

“server” and “master” to “slave”

instruments connected through serial

communications. The iSeries devices

are also available with RS232, RS422,

RS485 and MODBUS

communications. (Specify the -C24

option). In fact, the iSeries are the first

instruments of this type which include all

these serial protocols on one device,

selectable from a menu.

®

iSeries device (meter or

®

serial

Internet Appliances

With the -EI option, these small 1⁄8 DIN

1

and

⁄16DIN instruments are stand-alone

Web Servers. The Ethernet and Web

Server capability is actually embedded

in the device. (The smallest

device must be connected to an

external iServer).

The OMEGA

an IP address on the network and can

also be assigned an easily remembered

name such as “Heater1”. In fact, the

device could be assigned an authorized

Internet IP address from an Internet

Service Provider and function as a

World Wide Web Server delivering

whatever specific information is called

for. (For an example, please see

www.omega.com/iserver)

The iSeries devices work well with

conventional industrial automation, data

acquisition and control programs as

well as Microsoft Visual Basic and

Excel. OMEGA

and demos which makes it fast and

easy to get up and running with

many applications.

1

⁄32 DIN size

®

iSeries device is assigned

®

provides free software

D-11

With option

“EI” Ethernet

Page 6

Standard Ethernet

Hub or Switch

i8 Controller

with C4EI Option

i8 Controller

with C24 Option

i8 Panel Meter

with C24 Option

i

16 Controller

w

ith C24 Option

i 32 Controller

with C24 Option

RS485

R

S485

RS485

RS485

10BASE-T

1

0BASE-T

S

tandard Ethernet

Hub or Switch

iServer

i8 Controller

w

ith C24 Option

i

8 Controller

with C24 Option

i8 Panel Meter

with C24 Option

i16 Controller

with C24 Option

i 32 Controller

with C24 Option

RS485

RS485

R

S485

RS485

10BASE-T

RS485

10BASE-T

Using iServer as HUB/Server

Standard Ethernet

Hub or Switch

i8 Controller

w

ith C24 Option

i

8 Controller

with C24 Option

i8 Panel Meter

w

ith C24 Option

i16 Controller

w

ith C24 Option

i 32 Controller

w

ith C24 Option

RS485

R

S485

R

S485

R

S485

1

0BASE-T

or Up to 32 Devices

f

1

®

Using OMEGA

⁄8 DIN iSeries

Controller with C4EI Option as HUB

for Up to 32 Devices

Conventional Serial Communication

Connections using PC with RS485

Serial Communication

Get Internet E-mail Notification

of Alarm Status on Your Web

$

195

The “iServer” is a DIN

rail device which can be

a hub connecting up to

32 instruments to the

Ethernet and Internet.

The “iServer” is both a

Web Server and an

Ethernet-Serial bridge.

To connect to the

iServer, iSeries devices

must feature the “-C24”

Serial Communications

option. The OMEGA

iServer is also compatible with the MICROMEGA

high performance digital panel meters and the OMEGA iDRX

family of Signal Conditioners. The iServer can also connect

almost any RS232 or RS485 Serial Device to Ethernet.

®

family of ultra

Enabled Phone or PDA.

EIS-2B

*

⻬ A Web Server and an

Ethernet Bridge

⻬ Serves Up to 32 Devices

The iServer is an alternate way to connect iSeries

devices to an Ethernet LAN or Internet. Instead of

Connecting each iSeries device directly to the Ethernet

network, with individual IP Addresses for each device,

the iServer can be a HUB/Server for up to 32 devices.

To Order (Specify Model Number)

Model No. Description Price

D-12

EIS-2B iServer industrial MicroServer™, $195

Option

iDRN-PS-1000 Power supply (switching), $150

Contact SALES for quantity and OEM pricing.

*

serves 32 devices

95 to 240 Vac input, 24 Vdc output

@ 1 A (powers 10 units)

INSTRUMENTATION

D

Page 7

1

⁄8 DIN TEMPERATURE,

PROCESS, STRAIN METERS

i/8

⻬ High Quality

⻬ 5-Year Warranty

⻬ High Accuracy ±0.5°C

(0.9°F), 0.03% Reading

⻬ User-Friendly, Simple to

Configure

⻬ Free Software

⻬ Full Autotune PID Control

⻬ Universal Inputs:

Thermocouple, RTD,

Process Voltage/Current,

Strain

⻬ Totally Programmable

Color Displays, Standard

⻬ Built-In Excitation,

Standard

⻬ 2 Control or Alarm

Outputs, Choice of

dc Pulse, Mechanical

Relays, Analog Voltage

and Current

⻬ Front Removable

The OMEGA®DPi8/CNi8 is a 1⁄8 DIN size

(96 x 48 mm) Digital Panel Meter

featuring the big iSeries color-changing

display. The digits are twice the size of

1

typical

meters feature the only LED displays

that can be programmed to change color

between GREEN, AMBER, and RED at

any set point or alarm point.

The “DPi8/CNi8” model is available as an

extremely accurate programmable digital

panel meter with no outputs or with dual

outputs for controlling or alarming

functions. Other options include isolated

programmable analog output, serial

communications, MODBUS

Ethernet. The user can easily program

the DPi8/CNi8 for any control or alarming

requirement from simple on-off to full

autotune PID with a choice of Form C

SPDT relays, Solid State Relays, DC

pulse, and Analog (voltage and

current) outputs.

Fully Isolated Analog Output for

retransmission of the process value is

available in addition to the control and

alarm relays (specify model CNi8A33).

The DPi8/CNi8 covers a broad selection

of transducer and transmitter inputs with

two input models:

The UNIVERSAL TEMPERATURE &

PROCESS instrument (model “i”)

handles ten common types of

thermocouples, multiple RTD’s, and

⁄8 DIN panel meters. The iSeries

®

and

AND PID CONTROLLERS

DPi8 Meter

Starts at

Controller

$

310

$

240

several Process (DC) Voltage and

Current ranges.

This model also features built-in

excitation, 24 Vdc @ 25 mA. With it's

wide choice of signal inputs, this model

is an excellent choice for measuring or

controlling temperature with a

thermocouple, RTD, or 4-20 mA

transmitter.

The STRAIN & PROCESS instrument

(model “iS”) measures inputs from Load

Cells, Pressure Transducers, and most

any strain gauge sensor as well as

Process Voltage and Current ranges.

Input Type Range Accuracy

Universal Temperature / Process

Iron-Constantan -210 to 760°C / -346 to 1400°F 0.4°C / 0.7°F

CHROMEGA

Copper-Constantan

CHROMEGA

30%Rh-Pt/6%Rh-Pt

5%Re-W/26%Re-W 0 to 2320°C / 32 to 4208°F 0.4°C / 0.7°F

L

Pt, 0.00385, 100, 500, 1000 Ω -200 to 900°C / -328 to 1652°F 0.4°C / 0.7°F

Pt, 0.00392, 100, 500, 1000 Ω -200 to 850°C / -328 to 1562°F 0.4°C / 0.7°F

RTD-1N Nickel MIL-T-7990B 0 to 200°C / 32 to 392°F 0.1°C / 0.2°F

RTD-2N Nickel MIL-T-7990B -40 to 300°C / -40 to 572°F 0.3°C / 0.5°F

®

-ALOMEGA

®

-Constantan

Pt/13%Rh-Pt

Pt/10%Rh-Pt

Nicrosil-Nisil

J DIN -200 to 900°C / -328 to 1652°F 0.4°C / 0.7°F

D-13

®

Nickel RTD Input (FS required)

The “iS” has built-in 5 or 10 Vdc

excitation for bridge transducers,

5 Vdc@ 40 mA or 10 Vdc @ 60 mA.

(Any excitation voltage between 5 and

24 Vdc is available by special order).

This “iS” model supports 4 and 6 wire

bridge configurations, ratiometric and

non-ratiometric measurements. The “iS”

features fast and easy “in process”

calibration/scaling of the signal inputs to

any engineering units. This model also

features 10 Point Linearization which

allows the user to linearize the signal

input from extremely nonlinear

transducers of all kinds.

-270 to -160°C / -160 to 1372°C 1.0°C / 0.4°C

-454 to -256°F / -256 to 2502°F 1.8°F / 0.7°F

-270 to -190°C / -190 to 400°C 1.0°C / 0.4°C

-454 to -310°F / -310 to 752°F 1.8°F / 0.7°F

-270 to -220°C / -220 to 1000°C 1.0°C / 0.4°C

-454 to -364°F / -364 to 1832°F 1.8°F / 0.7°F

-50 to 40°C / 40 to 1768°C 1.0°C / 0.5°C

-58 to 104°F / 104 to 3214°F 1.8°F / 0.9°F

-50 to 100°C / 100 to 1768°C 1.0°C / 0.5°C

-58 to 212°F / 212 to 3214°F 1.8°F / 0.9°F

100 to 640°C / 640 to 1820°C 1.0°C / 0.5°C

212 to 1184°F / 1184 to 3308°F 1.8°F / 0.9°F

-250 to -100°C / -100 to 1300°C 1.0°C / 0.4°C

-418 to -148°F / -148 to 2372°F 1.8°F / 0.7°F

CNi8

Starts at

Page 8

Dimensions: in (mm)

A

NALOPO

SALIDA

SALIDA

S

ALIDA

P

ULSO

P

1K

i/8

Please visit

omega.com/panelpunches

for standard DIN size

panel punches.

Front

Removable

at any

setpoint

PATENTED

Totally Programmable

Color Displays

The OMEGA

first complete series of

DIN process control instruments with

totally programmable color displays.

The display can be programmed to

change

color at

any

setpoint

or alarm

point.

®

i/8, i/16, and i/32 are the

1

⁄8, 1⁄16 and 1⁄32

RJ45 10BaseT

Connection

B

R

eset

utton

LED

Indicators

Communication

Connectors

AVAILABLE FOR FAST DELIVERY!

To Order (*Specify Model Number)

MODEL NO. DESCRIPTION

DPi8 Temperature/Process (Monitor only)

DPi8A Temperature/Process Monitor with Isolated Analog Output

DPiS8 Strain/Process (Monitor only)

1

DIN $240

⁄

8

1

DIN 275

⁄

8

1

CONTROL OUTPUTS #1 & 2 Direct (Cool) or Reverse (Heat) Acting

CNi8 (*)(*) Temperature/Process with 2 Control Outputs $310

CNi8A (*) (*) Temperature/Process with Isolated AnalogOutput and 2 Outputs*

CNiS8 (*) (*) Strain/Process with 2 Control Outputs 370

22Two solid state relays (SSR’s): 0.5 A @ 120/240 Vac continuous

23

24

SSR and relay: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

SSR and pulsed 10 Vdc @ 20 mA (for use with external SSR)

332 Relays: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

42

Pulsed 10 Vdc @ 20 mA (for use with external SSR) and SSR

43Pulsed 10 Vdc @ 20 mA (for use with external SSR) and relay:

Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

44Two pulsed 10 Vdc @ 20 mA (for use with external SSR)

52Analog Output selectable as either control or retransmission of

process value; 0 to 10 Vdc or 0-20 mA @ 500 ohm max. and SSR

53Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max. and Relay

54Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max. and Pulse 10 Vdc

-AL Limit Alarm Version (Alarm Menu, No PID Control)

*

-SM Simplified Menu Version (ON/OFF Control, No PID)

NETWORK OPTIONS (One Option Max.)

-EI Ethernet with Embedded Internet

-C24 Isolated RS232 and RS485 300 to 19.2 k baud

-C4EI Ethernet with Embedded Web Server + Isolated RS485/422

hub for up to 31 devices

1

*

2

*

POWER SUPPLY (Select One)

* Standard power input: 90 to 240 Vac/dc, 50-400 Hz (no entry required) N/C

-DC 12 to 36 Vdc (for CN/DPi8), 20 to 36 Vdc (for CN/DPi8A), 24 Vac

FACTORY SETUP (Requires Network Option)

-FS Factory Setup and Configuration

-FS(RTD-1N) Factory Scaled for MIL-T-7990B Nickel RTD input (0 to 200°C) N/C

-FS(RTD-2N) Factory Scaled for MIL-T-7990B Nickel RTD input (-40 to 300°C) N/C

SOFTWARE (Requires Network Option)

OPC-SERVER LICENSE OPC Server/Driver Software License

1 Analog Output (Option 5) and Ethernet Options are not available for the CN/DPi8A.

*

2 -DC, -C24, or -C4EI not available with excitation.

*

3 Analog Output (Option 5) is not available with -AL units.

*

4 For CNi8A0*-AL: One Analog Retransmission and One Alarm (Output 1 is not available).

*

5 Strain CN/DPiS8 and/or Isolated Analog Output CN/DPi8A are not available with -SM units.

*

O

rdering Examples: DPi8A

the process value $295; CNi833-AL-C24

communication $370.

CNiS833-C24-FS(RTD-1N)

is factory scaled for MIL Standard MIL-T-7990B Nickel RTD input $430.

1

DIN Meter with isolated scalable analog retransmission of

⁄

8

1

DIN Indicator and Dual Alarm only with serial

⁄

8

1

DIN Controller with 2 relay outputs, serial communication and

⁄

8

*

D-14

PRICE

DIN *1295

⁄

8

1

4

,

*

3

4

,

*

5

*

PRICE

2

PRICE

$

365

N/C

$

55

60

115

$

25

N/C

295

INSTRUMENTATION

D

Page 9

1

⁄8 DIN DUAL DISPLAY

TEMPERATURE,

i/8D

CNi8D

Dual Output

Controller

Starts at

$

340

⻬ High Quality

⻬ 5-Year Warranty

⻬ High Accuracy ±0.5°C

(0.9°F), 0.03% Reading

⻬ First 1⁄8 DIN Controller

with Embedded Ethernet

Connectivity (Optional)

⻬ Dual Display with Bright

Color Changing Feature

⻬ Programmable

Digital Filter

⻬ 2 Control or Alarm

Outputs. Choice of DC

Pulse, Solid State Relays,

Mechanical Relays,

Analog Voltage and

Current

⻬ Full Autotune PID

Control

⻬ Built-In Excitation

Standard

⻬ Front Removable

The OMEGA®CNi8DH and CNi8DV are

high quality, highly accurate single loop

Autotune PID Temperature and Process

Controllers for

horizontal or vertical panel cutouts. Both

devices feature the same state of the art

technology, uncompromising accuracy,

and quality backed by an extended 5year warranty. The CNi8DH and CNi8DV

are simple to configure and use, while

providing tremendous versatility and a

wealth of powerful features.

The CNi8DH and CNi8DV come standard

with your choice of two control or alarm

outputs in almost any combination: solid

1

⁄8 DIN (96 x 48 mm)

PROCESS AND

STRAIN PID

CONTROLLERS

state relays (SSR) rated at 0.5 A

@120/240 Vac; Form “C” SPDT (Single

Pole Double Throw) relays rated at

3 amps @120/240 Vac; pulsed 10 Vdc

output for use with an external SSR; or

Analog Output (0 to 10 Vdc or 0 to 20

mA) selectable for control or

retransmission of the process value.

The UNIVERSAL TEMPERATURE &

PROCESS instrument (model “i”) offers a

selection of 10 thermocouple types as

well as 2, 3 or 4 wire RTD’s, process

voltage and current. The CNi8DH and

CNi8DV are ideal controllers for use with

transmitters and amplified transducers.

Built in excitation is standard (24 Vdc @

25 mA). The devices handle 0 to 20 mA

Process Current and Process Voltage in

three scales: 0 to 100 mV, 0 to 1V, and

0 to 10V.

As with all iSeries devices, the Process

Value display can be programmed to

change color between GREEN, AMBER,

and RED at any set point or alarm point.

The LED's displaying the Process Value

on the i8DH (horizontal

largest digits of any

The STRAIN/PROCESS instrument

(model “iS”) meters and controllers

measure inputs from Load Cells,

Pressure Transducers, and most any

strain gauge sensor. Input ranges include

0 to 100 mVdc, -100 mVdc to 1 Vdc,

0 to 10 Vdc in addition to 0 to 20 mA.

Excitation for transducers of 5 Volt and

10 Volt is standard.

1

⁄8 DIN) are the

1

⁄8 DIN controller.

The highly recommended Networking

and Communications options include

direct Ethernet LAN connectivity with an

Embedded Web Server, and serial

communications.

The -C24 serial communications option

includes both RS232 and RS485 which

can be selected from the menu as well

as both a straightforward ASCII protocol

or MODBUS

both Ethernet and RS485 ASCII/

MODBUS on one device.

The iSeries, with the network option, are

designed for easy integration with

popular industrial automation, data

acquisition and control programs as well

as Microsoft Visual Basic and Excel.

OMEGA provides free configuration

software which makes it fast and easy to

get up and running. Available on

CD-ROM and for download off the Web.

®

. The -C4EI option includes

at any

setpoint

Input Type Range Accuracy

Universal Temperature/Process

Process Voltage 0 to 100 mV, 0 to 1V, 0 to 10 Vdc 0.03% rdg

Process Current 0 to 20 mA (4 to 20 mA) 0.03% rdg

Excitation 24V @ 25 mA -

Universal Strain/Process

Process Voltage 0 to 100 mV, -100 mV to 1V, 0 to 10 Vdc 0.03% rdg

Process Current 0 to 20 mA (4 to 20 mA) 0.03% rdg

Excitation 5V @ 40 mA, 10V @ 60 mV -

D-15

Totally

Programmable

Color

Displays

PATENTED

Page 10

CNi8DV

i/8D

CNi8DH

omega.com/panelpunches for

Please visit

standard DIN size panel punches.

The i/8 Series controllers feature

plug/removable connectors and a sturdy

panel mounting sleeve with adjustable thumb

nuts for easy secure installation.

Dimensions:

in (mm)

To Order (*Specify Model Number)

MODEL NO. DESCRIPTION

CONTROL OUTPUTS #1 & 2 Direct (Cool) or Reverse (Heat) Acting

CNi8DH

CNi8DV

CNiS8DH

CNiS8DV

(*)(*) Temperature/Process

with 2 Control Outputs $340

(*)(*) Temperature/Process

with 2 Control Outputs 340

(*)(*) Strain/Process

with 2 Control Outputs 400

(*)(*) Strain/Process

with 2 Control Outputs 400

1

DIN Dual Display Horizontal

⁄

8

1

DIN Dual Display Vertical

⁄

8

1

DIN Dual Display Horizontal

⁄

8

1

DIN Dual Display Vertical

⁄

8

22Two solid state relays (SSR's): 0.5 A @ 120/240 Vac continuous

23

24

SSR and relay: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

SSR and pulsed 10 Vdc @ 20 mA (for use with external SSR)

332 Relays: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

42

Pulsed 10 Vdc @ 20 mA (for use with external SSR)an Solid State

43Pulsed 10 Vdc @ 20 mA (for use with external SSR) and relay:

Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

44Two pulsed 10 Vdc @ 20 mA (for use with external SSR)

52Analog Output selectable as either control or retransmission of

process value; 0 to 10 Vdc or 0-20 mA @ 500 ohm max and SSR

53Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Relay

54Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Pulse

10 Vdc

-AL Limit Alarm Version (Alarm Menu, No PID Control)*

-SM Simplified Menu Version (ON/OFF Control, No PID)*

NETWORK OPTIONS (One Option Max)

-EI Ethernet with Embedded Internet

-C24 Isolated RS232 and RS485 300 to 19.2 k baud

-C4EI Ethernet with Embedded Web Server + Isolated RS485/422

hub for up to 31 devices

1

*

1

*

POWER SUPPLY (Select One)

* Standard power input: 90 to 240 Vac/dc, 50-400 Hz (no entry required) N/C

-DC 20 to 36 Vdc, 24 Vac*

FACTORY SETUP (Requires Network Option)

-FS Factory Setup and Configuration

-FS(RTD-1N) Factory Scaled for MIL-T-7990B Nickel RTD input (0 to 200°C) N/C

-FS(RTD-2N) Factory Scaled for MIL-T-7990B Nickel RTD input (-40 to 300°C) N/C

SOFTWARE (Requires Network Option)

OPC-SERVER LICENSE OPC Server/Driver Software License

1 -DC, -C24, or -C4EI not available with excitation.

*

2 Analog Output (Option 5) is not available with -AL units.

*

3 Strain CNiS8DH or CNiS8DV is not available with -SM units.

*

Ordering Examples: CNi8DH43 horizontal

CNiS8DH43-C24-FS(RTD-1N) factory scaled for MIL Standard MIL-T-7990B Nickel RTD

input $460.

1

1

DIN Dual display with pulse and relay $340.

⁄

8

D-16

PRICE

N/C

2

3

PRICE

$

115

$

N/C

PRICE

$

295

INSTRUMENTATION

D

55

60

25

Page 11

1

⁄16 DIN TEMPERATURE,

PROCESS AND STRAIN METERS

DPi16 Meters

Starts at

AND PID CONTROLLERS

$

180

C

St

t

a

s

t

r

a

s

r

e

l

ol

r

ont

C

6

1

i

N

$

225

⻬ High Quality

⻬ 5-Year Warranty

⻬ High Accuracy ±0.5°C

(0.9°F), 0.03% Reading

1

⻬ First

with Totally

Programmable Color

Displays (Standard)

⻬ User-Friendly, Simple to

Configure

⻬ Free Software

⻬ Full Autotune PID Control

⻬ Universal Inputs:

Thermocouple, RTD,

Process Voltage/Current,

Strain

⻬ Embedded Ethernet

Connectivity

The OMEGA®DPi16/CNi16 is the popular

1

⁄16 DIN size (48 mm square) meter or

controller. The meter (model “DPi16”)

displays the process value and has no

control outputs.

The controller is available with a single

(model “CNi16”) or dual display (model

“CNi16D”) that displays a set point along

with the process value. The DPi16/CNi16

display can be programmed to change

color at any set point or alarm point.

The CNi16 is the first

with the option of both RS232 and RS485

in one instrument with both MODBUS

serial protocol and the straightforward

OMEGA

the CNi16 is the first

can connect directly to an ethernet

network and features an embedded web

server. OMEGA

configuration and data acquisition

software for the iSeries on CD-ROM and

for download off the Web.

The DPi16/CNi16 enclosure has a

NEMA 4 (IP65) rated front bezel. The

electronics are removable from the

front panel.

⁄16DIN Controller

1

⁄16 DIN controller

®

ASCII protocol. And of course

1

⁄16 DIN Controller that

®

provides free

®

1

⻬ First

Offering Both RS232 and

RS485 Serial

Communications in One

Instrument (Optional)

⻬ First

with Built-in Excitation,

24 Vdc, Standard

⻬ First

with Analog Output

Selectable as a Control

Output or as a Calibrated

Retransmission of

Process Variable

⁄16 DIN Controller

1

⁄16 DIN Controller

1

⁄16 DIN Instrument

⻬ NEMA-4 (IP65) Front Bezel

⻬ 2 Control or Alarm

Outputs (Optional) dc

Pulse, Solid State Relays

(SSR’s), Mechanical

Relays, Analog Voltage &

Current

⻬ Temperature Stability

±0.04°C/°C RTD and

±0.05°C/°C TC @ 25°C

(77°F)

⻬ Front Removable and

Plug Connectors

Access Vital information Anytime,

Anywhere, On the World Wide Web

1

16

/

DIN Controller With

Embedded Web Server, Dual

Control Outputs, Dual Display

D-17

i/16

Page 12

External Excitation

1 v/10 V

Return

100 mV

Jumper

RTD 1000/500

PANEL CUTOUT

1

omega.com/panelpunches for

standard DIN size panel punches

Please visit

⁄16 DIN

Dimensions: in (mm)

i/16

“EI” and “C4EI”

options

EAR VIEW

R

INGLE DISPLAY DUAL DISPLAY

S

To Order (*Specify Model Number)

Model No. Description

DPi16 Temperature/Process (Monitor only)

DPiS16 Strain/Process (Monitor only)

CONTROL OUTPUTS #1 & 2 Direct (Cool) or Reverse (Heat) Acting

CNi16 (*)(*) Temperature/Process with 2 Control Outputs $225

CNi16D (*)(*) Temperature/Process Dual Display with 2 Control Outputs *1245

CNiS16 (*)(*) Strain/Process with 2 Control Outputs 275

CNiS16D

NETWORK OPTIONS (One Option Max)

-EI Ethernet with Embedded Internet

-C24 Isolated RS232 and RS485 300 to 19.2 k baud

-C4EI Ethernet with Embedded Web Server + Isolated RS485/422

POWER SUPPLY (Select One)

-DC

FACTORY SETUP (Requires Network Option)

-FS Factory Setup and Configuration

-FS(RTD-1N) Factory Scaled for MIL-T-7990B Nickel RTD input (0 to 200°C) N/C

-FS(RTD-2N) Factory Scaled for MIL-T-7990B Nickel RTD input (-40 to 300°C) N/C

SOFTWARE (Requires Network Option)

OPC-SERVER LICENSE OPC Server/Driver Software License $295

1 Ethernet options are available for the CNi16D and CNiS16D Controller only.

*

2 -DC, -C24 or -C4EI not available with excitation.

*

3 Analog Output (Option 5) is not available with -AL units.

*

4 Strain DP/CNiS16 or CNiS16D is not available with -SM units.

*

Ordering Examples: CNi16D44

outputs $245.

CNiS16DH44-C24-FS(RTD-1N) factory scaled for MIL Standard MIL-T-7990B Nickel RTD

input $355.

(*)(*) Strain/Process Dual Display with 2 Control Outputs *

22

23

24

Two solid state relays (SSR’s): 0.5 A @ 120/240 Vac continuous

SSR and relay: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

SSR and pulsed 10 Vdc @ 20 mA (for use with external SSR)

332 Relays: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

42

Pulsed 10 Vdc @ 20 mA (for use with external SSR) and SSR

43Pulsed 10 Vdc @ 20 mA (for use with external SSR) and

relay: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

44Two pulsed 10 Vdc @ 20 mA (for use with external SSR)

52Analog Output selectable as either control or retransmission of

process value; 0 to 10 Vdc or 0-20 mA @ 500 ohm max and SSR

53Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Relay

54Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Pulse

10 Vdc

-AL Limit Alarm Version (Alarm Menu, No PID Control)*

-SM Simplified Menu Version (ON/OFF Control, No PID)*

hub for up to 31 devices

* Standard power input: 90 to 240 Vac/dc, 50-400 Hz (no entry required) N/C

12 to 36 Vdc (for CN/DPi16), 20 to 36 Vdc (for CNi16D), 24 Vac

D-18

FRONT VIEWS

AVAILABLE FOR FAST DELIVERY!

1

DIN $180

⁄

6

1

1

DIN 230

⁄

6

1

1

1

*

1

2

,

*

*

1

DIN dual display PID Controller with two pulse control

⁄

16

2

*

PRICE

295

N/C

3

4

PRICE

$50

60

110

2

*

$25

N/C

PRICE

INSTRUMENTATION

D

Page 13

7-segment display

9-segment display

DPi32 Meters

Starts at

$

150

1

⁄32 DIN TEMPERATURE,

i/32

PROCESS AND STRAIN

METERS AND PID CONTROLLERS

CNi32

Controllers

Starts at

$

195

⻬ High Quality

⻬ 5-Year Warranty

⻬ High Accuracy ±0.5°C

(0.9°F), 0.03% Reading

1

⻬ First

⁄32DIN Instrument

with Totally

Programmable Color

Displays (Standard)

⻬ User-friendly, Simple to

Configure

⻬ Free Software, Active X

Controls

⻬ Full Autotune PID Control

The OMEGA®DPi32/CNi32 is the

iSeries meter (DPi32) and controller

(CNi32) in the extremely compact and

increasingly popular

DPi32/CNi32 is the most sophisticated

and accurate instrument available in the

1

⁄32 DIN package, yet is still easy

small

to configure.

The DPi32/CNi32 handles more

thermocouple, RTD, process voltage

and current inputs than any other

1

⁄32 DIN controller.

The DPi32/CNi32 is the first 1⁄32 DIN

controller with built-in excitation for

transmitters or other devices, 24 Vdc

@ 25 mA.

The DPiS32/CNiS32 has built-in

excitation for bridge transducers, 5 Vdc

@ 40 mA or 10 Vdc @ 60 mA. When

communications options are installed,

external excitation may be used and

ratiometric operation maintained by

connecting the external excitation to the

sense leads. Both 4 or 6-wire bridge

configurations are supported for internal

or external excitation. Non-ratiometric

operation is supported for voltage and

current transducers and is also valuable

in measuring offset and millivolt output

1

⁄32 DIN size. The

⻬ Universal Inputs:

Thermocouple, RTD,

Process Voltage/Current,

Strain

⻬ First 1⁄32 DIN Instrument

Offering Both RS232 and

RS485 Serial

Communications in One

Instrument (Optional)

⻬ First 1⁄32 DIN Instrument

with Built-in Excitation,

24 Vdc, Standard

⻬ Temperature Stability

±0.04°C/°C RTD and

±0.05°C/°C TC @ 25°C (77°F)

of bridge devices during manufacturing

and calibration.

This model also features 10 Point

Linearization which allows the user to

linearize the signal input from extremely

nonlinear transducers of all kinds.

The DPi32/CNi32 and DPiS32/CNiS32

introduce a number of unique features

not yet found on any other

instrument. The DPi32/CNi32 and

DPiS32/CNiS32 are the first

controllers with a totally programmable

display that can change color at any set

point or alarm point. The unique

The iSeries displays feature unique 9-segment LED characters, which greatly

improves alphanumeric representations. The 7-segment LED characters found on

most instruments are adequate for presenting numbers, but not letters. Words are

9-segment LED

D-19

1

⁄32 DIN

1

⁄32 DIN

easier to read with the unique 9-segment LED

characters on the iSeries, which makes operating

and programming simpler and easier.

⻬ NEMA-4 (IP65) Front Bezel

⻬ First 1⁄32 DIN Instrument

with Analog Output

Selectable as a Control

Output or as

Retransmission of

Process Variable

⻬ 2 Control or Alarm

Outputs (Optional) dc

Pulse, Solid State Relays

(SSR’s), Mechanical

Relays, Analog Voltage &

Current

⻬ Front Removable and Plug

Connectors

9-segment LED characters greatly

improves alphanumeric representations.

The DPi32/CNi32 and DPiS32/CNiS32

are the first

2 SPDT (Single Pole Double Throw)

Form C relays, instead of the single

throw relays on typical

The DPi32/CNi32 and DPiS32/CNiS32

are the first to offer both RS232 and

RS422/485 serial communications in one

instrument (-C24 option). Both ASCII

protocol and modbus protocol are

selectable from the menu.

1

⁄32 DIN controllers offering

1

⁄32 DIN controllers.

Page 14

Process & Strain Meters & PID Controllers

Dimensions: inches (mm)

The “iServer” is a DIN

rail mounted device

which can be a hub

connecting up to 32

instruments to the

Ethernet and Internet.

The “iServer” is both

a Web Server and an

Ethernet-Serial bridge.

To connect to the

iServer, iSeries

devices must feature

the “C24” Serial

Communications

option.

ANEL CUTOUT

P

1

⁄32 DIN

$

195

See page

D-12

DPi32-B-COVER

supplied with

each unit,

standard.

omega.com/panelpunches for

standard DIN size panel punches.

i/32

Please visit

AVAILABLE FOR FAST DELIVERY!

To Order (*Specify Model Number)

MODEL NO. DESCRIPTION

DPi32 Temperature/Process (Monitor only)

DPiS32

Strain/Process (Monitor only)

1

DIN $150

⁄

32

1

DIN 195

⁄

32

CONTROL OUTPUTS #1 & 2 Direct (Cool) or Reverse (Heat) Acting

CNi32 (*)(*) Temperature/Process with 2 Control Outputs $195

CNiS32

(*)(*) Strain/Process with 2 Control Outputs 240

22

Two solid state relays (SSR’s): 0.5 A @ 120/240 Vac continuous

23

SSR and relay: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

24

SSR and pulsed 10 Vdc @ 20 mA (for use with external SSR)

332 Relays: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

42

Pulsed 10 Vdc @ 20 mA (for use with external SSR) and SSR

43Pulsed 10 Vdc @ 20 mA (for use with external SSR) and

relay: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

44Two pulsed 10 Vdc @ 20 mA (for use with external SSR)

52Analog Output selectable as either control or retransmission of

process value; 0 to 10 Vdc or 0-20 mA @ 500 ohm max and SSR

53Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Relay

54Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Pulse

10 Vdc

-AL Limit Alarm Version (Alarm Menu, No PID Control)

-SM Simplified Menu Version (ON/OFF Control, No PID)

NETWORK OPTIONS

-C24 Isolated RS232 and R485/422. 300 to 19.2k Baud

*

2

*

3

*

1

POWER SUPPLY (Select One)

*

Standard power input: 90 to 240 Vac/dc, 50-400 Hz (no entry required) N/C

-DC 12 to 36 Vdc, 24 Vac

1

*

FACTORY SETUP (Requires Network Option)

-FS

Factory Setup and Configuration

-FS(RTD-1N) Factory Scaled for MIL-T-7990B Nickel RTD input (0 to 200°C) N/C

-FS(RTD-2N) Factory Scaled for MIL-T-7990B Nickel RTD input (-40 to 300°C) N/C

MODEL NO. DESCRIPTION

EIS-2B iServer MicroServer, serves 32 devices, page D-12 $195

EIS-W iServer MicroServer for Serial to Ethernet applications 195

visit omega.com/eis-w for Complete Details

SOFTWARE (Requires Network Option)

OPC-SERVER LICENSE OPC Server/Driver Software License $295

1 -DC, -C24 not available with Excitation.

*

2 Analog Output (Option 5) is not available with -AL units.

*

3 Strain DP/CNiS32 is not available with -SM units.

*

Ordering Examples: CNi3222-C24

PID control and serial communications, both RS232 and RS485 $195 + 60 = $255.

CNiS3222-C24-FS(RTD-1N) factory scaled for MIL Standard MIL-T-7990B Nickel RTD

input $300.

1

DIN PID Controller with two solid state relays for

⁄

32

D-20

PRICE

N/C

PRICE

$60

$

N/C

PRICE

PRICE

INSTRUMENTATION

D

25

Page 15

1

⁄8 DIN ULTRA COMPACT

i/8C

CASE TEMPERATURE,

PROCESS AND STRAIN METERS

AND PID CONTROLLERS

Shown actual size.

⻬ Ultra Compact

and Controller

⻬ Built-In Excitation

⻬ NEMA 4 (IP65) Bezel

⻬ RS232, RS422/485 or MODBUS

Communication, Menu Selectable

The Ultra Compact DPi8C/CNi8C and

DPiS8C/CNiS8C Meters and Controllers are

similar to the full size i8 in an Ultra Compact

enclosure. Only 2 inches behind the panel.

1

⁄8 DIN Meter

Please visit

omega.com/panelpunches

for standard DIN size

panel punches.

PANEL CUTOUT

1

⁄8 DIN

CNi8C

Controllers

Starts at

Dimensions:

in (mm)

2.159" [54.84 mm]

$

355

4.100" [104.10 mm]

DPi8C Meters

Starts at

$

285

AVAILABLE FOR FAST DELIVERY!

To Order (*Specify Model Number)

Model No. Description Price

®

DPi8C Temperature/Process (Monitor only)

DPiS8C Strain/Process (Monitor only)

CONTROL OUTPUTS #1 & 2 Direct (Cool) or Reverse (Heat) Acting

CNi8C (*)(*) Temperature/Process with 2 Control Outputs Compact Case $355

CNiS8C (*)(*) Strain/Process with 2 Control Outputs Compact Case 415

22Two solid state relays (SSR’s): 0.5 A @ 120/240 Vac continuous

23

24

332 Relays: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

42

43Pulsed 10 Vdc @ 20 mA (for use with external SSR) and relay:

44Two pulsed 10 Vdc @ 20 mA (for use with external SSR)

52Analog Output selectable as either control or retransmission of

53Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Relay

54Analog Output 0 to 10 Vdc or 0-20 mA @ 500 ohm max and Pulse 10 Vdc

NETWORK OPTIONS

-C24 Isolated RS232 and R485/422. 300 to 19.2k Baud

POWER SUPPLY

Standard power input: 90 to 240 Vac/dc, 50-400 Hz (no entry required)

*

-DC 12 to 36 Vdc, 24 Vac

FACTORY SETUP

-FS

Factory Setup and Configuration (req. -C24 Serial Communication option)

Model No. Description

EIS-2B iServer MicroServer, serves 32 devices, page D-12

EIS-W iServer MicroServer for Serial to Ethernet applications 195

SOFTWARE (Requires Network Option)

OPC-SERVER LICENSE OPC Server/Driver Software License

1 -DC, -C24, not available with excitation.

*

2 Analog Output (Option 5) is not available with -AL units.

*

3 Strain CN/DPiS8C is not available with -SM units.

*

Ordering Examples: CNi8C33 is a

controller with 2 relay output $355.

DPiS8C,

1

⁄

8

SSR and relay: Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

SSR and pulsed 10 Vdc @ 20 mA (for use with external SSR)

Pulsed 10 Vdc @ 20 mA (for use with external SSR) and SSR

Form “C” SPDT 3 A @ 120 Vac, 3 A @ 240 Vac

process value; 0 to 10 Vdc or 0-20 mA @ 500 ohm max and SSR

-AL Limit Alarm Version (Alarm Menu, No PID Control)

-SM Simplified Menu Version (ON/OFF Control, No PID)

1

*

visit omega.com/eis-w for Complete Details

1

DIN Compact universal temperature process

⁄

8

DIN Strain/Process meter in compact case, $345.

1

DIN Compact Case $285

⁄

8

1

DIN Compact Case 345

⁄

8

2

*

*

1

*

CNi8C

CNi8

DP41

DP25

N/C

3

Price

$

60

N/C

$

25

N/C

Price

$

195

Price

$

295

D-21

Page 16

REMOTE DISPLAY/

PROGRAMMER

Compatible with all

Meters and Controllers

RD4/RD6

1

⻬

⁄8 DIN Panel Cutout or Surface Mount

⻬ Big LED’s–RD4 is 21 mm (0.83") and

RD6 is 17.3 mm (0.68")

⻬ Alarm Indicators, and Color change

⻬ Serial Input ASCII RS232, RS485

Menu Selectable

⻬ NEMA-4 (IP65)

⻬ 20 mm (0.80") Behind Panel

and Only 39 mm (1.6") Overall

REMOTE DISPLAY

The RD4/RD6 are 4 or 6 digit master/

slave displays providing remote readout

from instruments such as programmable

controllers, digital panel meters and other

instruments with serial output. Two

communication interfaces are supported

in remote Display: RS232 and RS485

and can be programmed through front

panel buttons. The RD4/RD6 remote

display can be mounted in a

cutout, or surface mounted with the

included bale. The RD4 and RD6

features big bright 21 mm (0.83") and

17.3 mm (0.68") 9-segment LED's that

can be programmed to change color

between GREEN, AMBER, and RED to

indicate alarms. Serial Connections can

be made to an RJ-11 jack or screw

terminals.

In the Slave mode, the RD4 and RD6

can be used for displaying

1

⁄8 DIN Bezel

1

⁄8 DIN panel

Alphanumerical characters from a

computer. Power is supplied from

10 to 36 Vdc power supply or optional

universal (100 to 240 Vac) power

adaptor.

(Compatible Host device must feature

serial RS232 or RS485 output)

(RD4 shown)

Starts at

$

150

Specifications

Serial: ASCII Interface RS232/RS485

Baud Rate:

300, 600, 1200, 2400, 4800, 9600, 19200

Data Formats: 7 data/odd parity/1 stop,

7 data/even parity/1 stop, 8 data/no parity

/1 stop.

Power Requirements: 10 to 36 Vdc, or

universal power adaptor, nominal output:

9 Vdc @ 0.5 mA; input: 100-240 Vac,

50/60Hz

Power Consumption: 2 W

Operating Temperature: 0 to 50°C

(32 to 122°F)

Relative Humidity: 0 to 85%

Storage Temperature:

-20 to +85°C (-4 to +185°F)

RD4 Display:

4-Digit, 9-segment LED 21 mm (0.83")

RD6 Display:

6-Digit, 9-segment LED 17.3 mm (0.68")

Protection: NEMA-4 (IP65)

Mechanical Dimensions:

96 x 48 x 39 mm (

Panel Cutout: 92 x 45 mm (3.622 x 1.772")

Dimensions: in (mm)

3.78 x 1.89 x 1.6")

Visit omega.com/panelpunches

for DIN size panel punches.

INSTRUMENTATION

D

PATENTED

Totally

Programmable

Color Displays

at any

setpoint

AVAILABLE FOR FAST DELIVERY!

To Order (*Specify Model Number)

Model No. Description Price

RD4 4-Digit Remote Display for iSeries Monitors and Controllers $150

RD6 6-Digit Remote Display for iSeries Monitors and Controllers 200

Options

UNIV-AC-100/240 Universal Power Adaptor $25

Model No. Description Price

iLD24-EI 2.25" 4-digit display with Ethernet, RS485/422 Input

iLD44-EI 4" 4-digit display with Ethernet, RS485/422 Input

iLD26-EI 2.25" 6-digit display with Ethernet, RS485/422 Input

iLD46-EI 4" 6-digit display with Ethernet, RS485/422 Input

Please see iLD Series on page D-43.

*

Ordering Example: RD4, 4-digit remote display for iSeries monitors and controllers, $150.

D-22

*

*

*

*

$795

1195

995

995

Page 17

COMMON SPECIFICATIONS (ALL i/8, i/16, i/32 DIN)

Universal Temperature and Process

Input (Model “i”)

Accuracy: ±0.5°C; 0.03% rdg

Resolution: 1°/0.1°; 10 µV process

Temperature Stability:

RTD: 0.04°C/°C

Thermocouple @ 25°C (77°F):

0.05°C/°C cold-junction compensation

Process: 50 ppm/°C

NMRR: 60 dB

CMRR: 120 dB

A/D Conversion: Dual slope

Reading Rate: 3 samples per second

Digital Filter: Programmable

Display: 4-digit, 9-segment LED;

10.2 mm (0.40"): i32, i16, i16D, i8DV;

21 mm (0.83"): i8; 10.2 mm (0.40") and

21 mm (0.83"): i8DH; red, green and

amber programmable colors for process

variable, setpoint and temperature units

Input Types: Thermocouple, RTD,

analog voltage, analog current

Thermocouple Lead Resistance:

100 Ω max

Thermocouple Type (ITS 90): J, K, T,

E, R, S, B, C, N, L

RTD Input (ITS 68): 100/500/1000 Ω

Pt sensor, 2-, 3- or 4-wire; 0.00385 or

0.00392 curve

Voltage Input: 0 to 100 mV, 0 to 1V,

0 to 10 Vdc

Input Impedance: 10 MΩ for 100 mV;

1 MΩ for 1 or 10 Vdc

Current Input: 0 to 20 mA (5 Ω load)

Configuration: Single-ended

Polarity: Unipolar

Step Response: 0.7 s for 99.9%

Decimal Selection: None, 0.1 for

temperature; none, 0.1, 0.01 or 0.001

for process

Setpoint Adjustment: -1999 to 9999

counts

Span Adjustment: 0.001 to 9999

counts

Offset Adjustment: -1999 to 9999

Universal Strain and Process Input

(Model “

Accuracy: 0.03% rdg

Resolution: 10/1 µV

Temperature Stability: 50 ppm/°C

NMRR: 60 dB

CMRR: 120 dB

A/D Conversion: Dual slope

Reading Rate: 3 samples per second

Digital Filter: Programmable

Input Types: Analog voltage, analog

current

Voltage Input: 0 to 100 mVdc,

-100 mVdc to 1 Vdc, 0 to 10 Vdc

Input Impedance: 10 MΩ for 100 mV;

1MΩ for 1V or 10 Vdc

Current Input: 0 to 20 mA (5 Ω load)

Linearization Points: Up to 10

Configuration: Single-ended

Polarity: Unipolar

Step Response: 0.7 s for 99.9%

Decimal Selection: None, 0.1, 0.01

or 0.001

Setpoint Adjustment:

-1999 to 9999 counts

Span Adjustment:

0.001 to 9999 counts

iS”)

Offset Adjustment: -1999 to ±9999

Excitation (Optional in Place of

Communication): 5 Vdc @ 40 mA;

10 Vdc @ 60 mA

Control

Action: Reverse (heat) or direct (cool)

Modes: Time and amplitude proportional

ontrol modes; manual or auto PID,

c

proportional, proportional with integral,

proportional with derivative with anti-reset

windup and ON/OFF

Rate: 0 to 399.9 s

Reset: 0 to 3999 s

Cycle Time: 1 to 199 s; set to

0 for ON/OFF operation

Gain: 0.5 to 100% of span; setpoints 1 or 2

Damping: 0000 to 0008

Soak: 00.00 to 99.59 (HH:MM), or OFF

Ramp to Setpoint:

00.00 to 99.59 (HH:MM), or OFF

Autotune: Selectable from front panel

Control Output 1 and 2

Relay: 250 Vac or 30 Vdc @ 3 A

(resistive load); configurable for ON/OFF,

PID, ramp and soak

Output 1: SPDT type; can be configured

as alarm 1 output

Output 2: SPDT type; can be configured

as alarm 2 output

SSR: 20 to 265 Vac @ 0.05 to 0.5 A

(resistive load); continuous

DC Pulse: Non-isolated; 10 Vdc @ 20 mA

Analog Output (Output 1 Only):

Non-isolated, proportional 0 to 10 Vdc or

0 to 20 mA; 500 Ω max

Network and Communications

Ethernet: In compliance with IEEE 802.3

10 Base-T

Supported Protocols:

TCP/IP, ARP, HTTPGET

RS232/RS422/RS485: Selectable from

menu; both ASCII and MODBUS

selectable from menu; p

300 to 19.2K baud; complete programmable

setup capability; program to transmit current

display, alarm status, min/max, actual

measured input value and status

RS485: Addressable from 0 to 199

Connection: Screw terminals

rogrammable

Alarm 1 and 2 (Programmable)

Type: Same as output 1 and 2

Operation: High/low, above/below, band,

latch/unlatch, normally open/normally

closed and process/deviation; front-panel

configurations

Analog Output (Programmable):

Non-isolated, retransmission 0 to 10 Vdc

or 0 to 20 mA, 500 Ω max (output 1 only).

Accuracy is ±1% FS when following

conditions are satisfied:

1) Input is not scaled below 1% of

input FS

2) Analog output is not scaled below

3% of output FS

Excitation

(Not Included with Communication):

24 Vdc @ 25 mA (not available for

low power option)

®

protocol

Insulation

Power to Input or Output: 2500 Vac per

1-minute test

For Low-Voltage Power Option:

1500 Vac per 1-minute test

(RS232/485, input or output)

ower to Relay/SSR Option:

P

2500 Vac per 1-minute test

elay/SSR to Relay/SSR Option:

R

500 Vac per 1-minute test

2

RS232/485 to Input/Options:

500 Vac per 1-minute test

Approvals: UL, C-UL, CE per EN50081-1,

EN50082-2, EN61010- 1

(RS232/485, input or output)

General

Power: 90 to 240 Vac ±10%,

50 to 400 Hz*, 110 to 375 Vdc,

equivalent voltage

Low Voltage Power Option: 24 Vac

±10%, 12 to 36 Vdc, from qualified safety

approved source

Environmental Conditions:

0 to 50°C (32 to 122°F), 90% RH

non-condensing—CNi8DV, CNi8DH,

CNi16D; 0 to 55°C (32 to 131°F) 90% RH

non-condensing—i/8, i/16, i/32

Installation Category:

II per EN61010-1

Equipment Class: II per EN61010-1

Pollution Degree: II per EN61010-1

Protection: NEMA 4 (IP65) front bezel

Dimensions

i/8 Series: 48 H x 96 W x 127 mm D

(1.89 x 3.78 x 5.00")

i/16 Series: 48 H x 48 W x 127 mm D

(1.89 x 1.89 x 5.00")

i/32 Series: 25.4 H x 48 W x 127 mm D

(1.0 x 1.89 x 5.00")

Panel Cutout

i/8 Series: 45 H x 92 mm W

(1.772" x 3.622"),

i/16 Series: 45 mm (1.772") square, 1⁄16 DIN

i/32 Series: 22.5 H x 45 mm W

(0.886" x 1.772"),

1

⁄8 DIN

1

⁄32 DIN

Weight

i/8 Series: 295 g (0.65 lb)

i/16 Series: 159 g (0.35 lb)

i/32 Series: 127 g (0.28 lb)

No CE compliance above 60 Hz

*

At Any

Setpoint

*

Totally

Programmable

Color Displays

D-47

Page 18

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...