www.omega.com

e-mail: info@omega.com

User ’s Guide

CN9600 SERIES

Autotune Temperature Controllers

omega.com

®

®

Shop online at

SM

®

OMEGA

CARE

Extended Warranty

Program

Where Do I Find Everything I Need for Process Measurement

and Control? OM EGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes,

Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Load Cells & Pressure Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow

Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL MONITORING

AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

M3736/0601

33065/02/0901/000M19

omega.com

®

®

OMEGAnet®On-Line Service Internet e-mail

www.omega.com info@omega.com

Benelux:

Postbus 8034, 1180 LAAmstelveen

The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic:

Rude´arma´dy 1868, 733 01 Karvina´ 8

Tel: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France:

9, rue Denis Papin, 78190 Trappes

Tel: +33 (0)130 621 400 FAX: +33 (0)130 699 120

Toll Free in France: 0800-4-06342

e-mail: sales@omega.fr

Servicing Europe:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934

CABLE: OMEGA

USA: ISO 9001 Cer

tified

One Omega Drive, Box 4047

Stamford CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Servicing North America:

For immediate technical or application assistance:

Mexico:

En Espan~ol: (001) 203-359-7803

FAX: (001) 203-359-7807

e-mail: espanol@omega.com

info@omega.com.mx

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.dl

United Kingdom: ISO 9002 Cer

tified

One Omega Drive

River Bend Technology Centre

Northbank, Irlam

Manchester M44 5BD United Kingdom

T el: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

Canada:

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

The CN9 Series Controllers

CN9400 Series

CN9-SW Software

CN9600 Series

CN9500 Series

CN9300 Series

INDEX INSTRUMENT PANEL FEATURES

INSTRUMENT PANEL FEATURES 2

FUNCTIONS MENU 3

GETTING STARTED 4

Initial Set-up 4

AUTOTUNE 4

Tune or tune at setpoint program 5

PROPORTIONAL CYCLE-TIME 5

Cycle-time recommendations 5

SECOND AND THIRD SETPOINTS (SP2 and SP3) 5

Error messages 6

LINEAR INPUT 6

Set-up procedure 6

FUNCTION LIST 7

Level 1 7

Level 2 7

Level 3 8

Output Options Table 8

Re-transmission 8

Level 4 9

Level A 10

PROGRAMMER 11

Function overview 11

Getting started (Programmer) 12

Program run mode 12

Display functions 12

Example program 13

Function map 14

Function list 16

Memory allocation table 17

Memory full indicator 17

Programming example 18

Program edit example 18

MECHANICAL INSTALLATION 19

DIN panel cut-out 19

Mounting 19

Cleaning 19

ELECTRICAL INSTALLATION 19

Typical application 20

SAFETY AND WARRANTY 20

Input options (diagrams) 21

Output options (diagrams) 21

INPUT SENSOR SELECTION 22

Temperature sensors 22

Linear input 22

SPECIFICATION 22

APPENDIX 1 23

NOTES 24

WARRANTY / DISCLAIMER 25

2

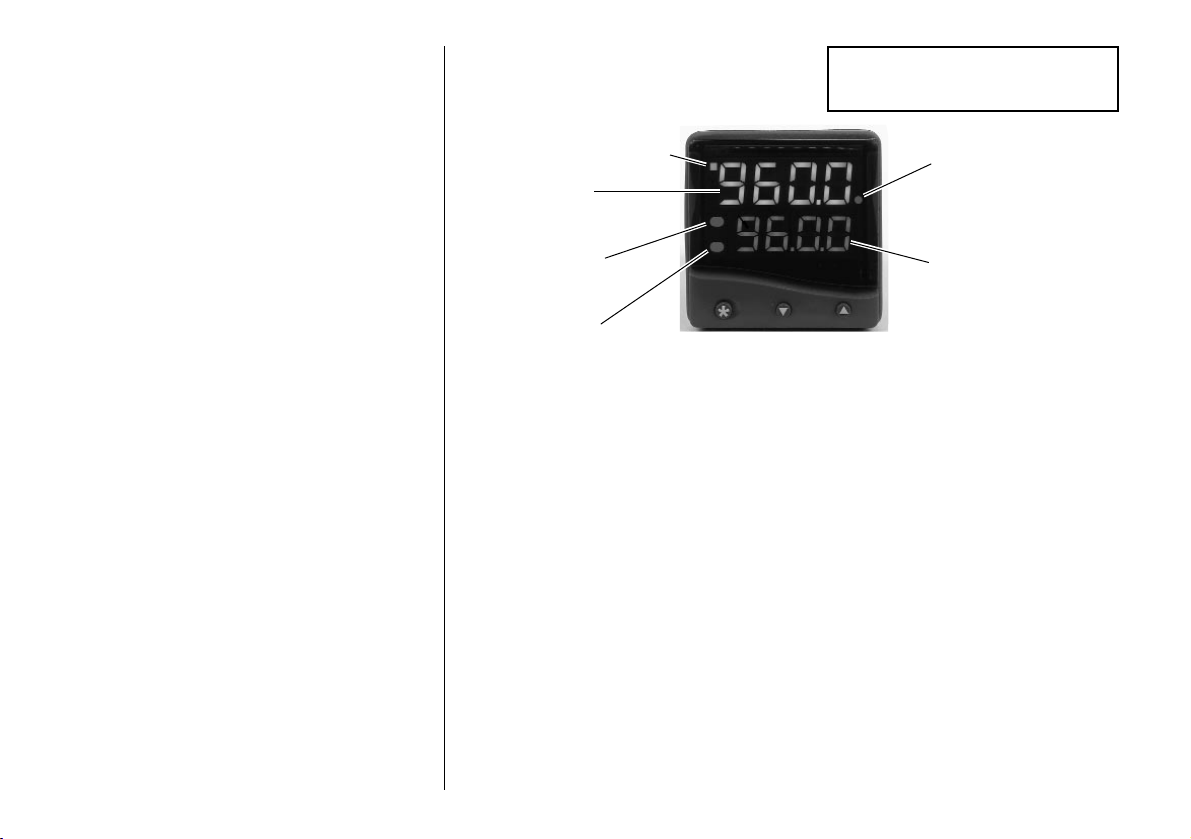

Right Red LED:

Program Holdback

indicator

Orange Display:

Setpoint value or

program selection

Green LED:

Setpoint 1 output indicator

Upper Red LED:

Setpoint 2 output

indicator

Lower Red LED:

Setpoint 3 output

indicator

Green Display:

Process variable or

Function/Option

ADJUSTMENTS

To enter or exit program mode: Press ▲ ▼ together for 3 seconds

To scroll through functions: Press ▲ or ▼

To change levels or options: Press ✱ ▲ together or ✱ ▼ together

To view setpoint units: Press ✱

To increase setpoint: Press ✱ ▲ together

To decrease setpoint: Press ✱ ▼ together

To reset latched alarm or tune fail: Press ▲ ▼ together briefly

To run or Hold a program: Press ✱ ▼ together for 3 seconds

Notes: If in difficulty by becoming “lost” in program mode, press ▲ and ▼ together for 3

seconds to return to display mode, check the INSTRUMENT ADJUSTMENTS above and

try again.

When in program mode, after 60 seconds of key inactivity the display will revert to

either

inPt : nonE

or, if the initial configuration has been completed, the measured

value. Any settings already completed will be retained. During Program Configuration it

is recommended that this feature is inhibited. Select

ProG StAY

in Level 4.

This page can be photocopied and

used as a visual aid and bookmark when

working in other parts of the manual.

!

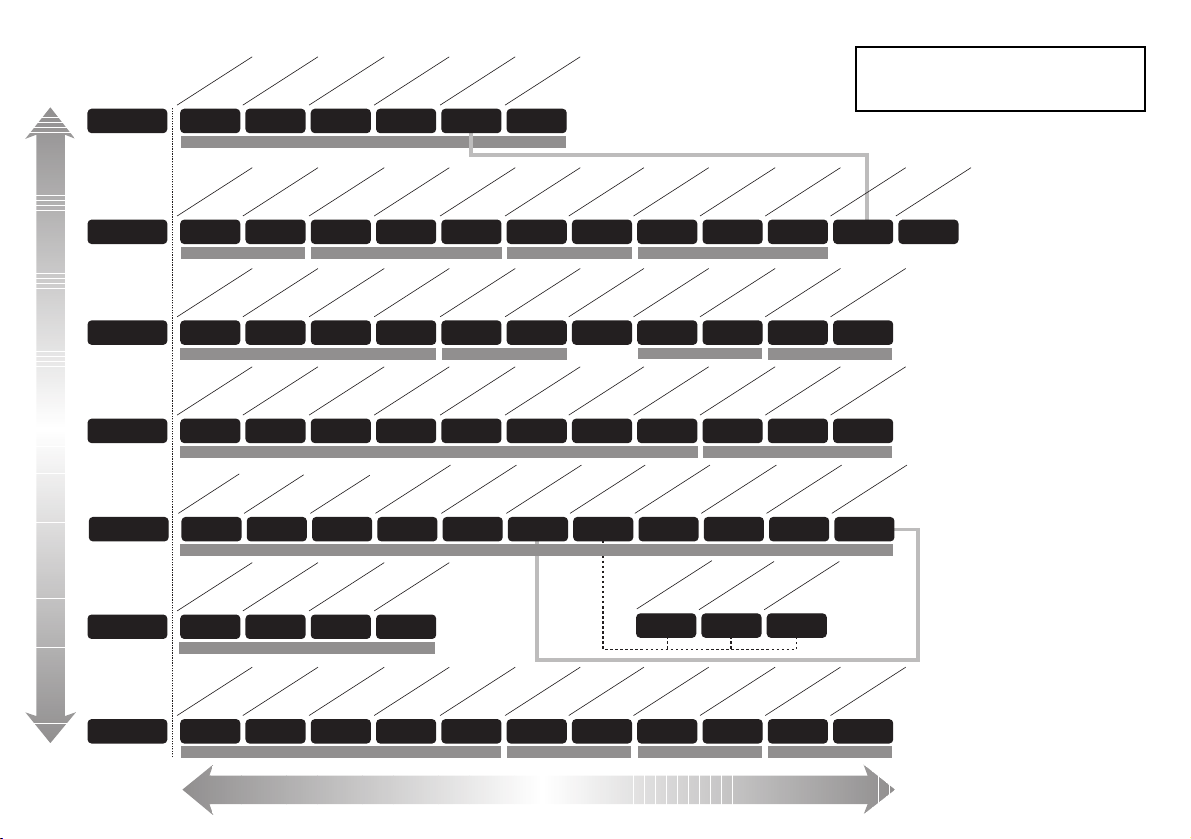

SINT PCYC SUB.P

Call sub-program number

nonE; 1 to number

of programs

Soak time interval

Cont; 0.1 to 1400

(10) min

Program re-cycle count

Cont; 1 to 999

DER.S DI.SS NO.AL PROG LOCK SET.L

Derivative sensitivity

0.1 to 1.0 x dEr.t (0.5)

Display averaging

dir; 1 to 32 ( )

Disable -AL- alarm

display

; on

Disable program auto-exit

Auto; StAY

Security lock

nonE; LEV 3; LEV 2; ALL

Change program entry point

Off; on

USER-PROTECTED SETTINGS

LEVL 4

SP2 output device

none; SSd; rly; (read only)

Sensor burn-out

uP.SC; dn.SC; 1u.2d; 1d.2u

Zero adjustment

0.0 to 25% sensor

full scale

Set Monitor

Off; on

Read Monitor

VAr; hi; lo deg

Read Tune Data

CtA; Ctb; Ct1; Ct2; Ct3; Ct4;

oS1; uS; oS2

Software version

Consult unit

RESET

nonE; ALL

SP1.D SP2.D BURN REU.D REU.L SPAN ZERO CHEK READ TECH UER RSET

SP1 output device

none; rly; SSd; AnLG

Reverse outputs

1r.2d; 1d.2d; 1r.2r; 1d.2r

Reverse O/P LEDs

1n.2n; 1i.2n; 1n.2i; 1i.2i

Span adjustment

0.0 to 25% sensor

full scale

LEVL 3

CONFIGURE OUTPUT SAFETY SETTINGS CALIBRATION PERFORMANCE DATA

Read SP1 output %

0 to 100% read only

SP1 manual output %

0 to100% proportional

mode only

Limit SP1 output %

100 to 0%

Limit SP2 output %

100 to 0%

Main SP2 mode

nonE; dV.hi; dV.Lo; bAnd;

FS.hi; FS.Lo; Cool; EoP

Second SP2 mode

nonE; LtCH; hold; Lt.ho;

nLin

Display resolution

1 or 0.1 degree

Set scale maximum

0.0 Sensor max to sensor

full scale

Set scale minimum

0.0 Sensor min to sensor

full scale

Select input sensor

nonE

Select display units

nonE;°C; °F; bAr;

PSi; Ph; rH; SEt

\\

SP1.P HAND PL.1 PL.2 SP2.A SP2.B DISP HI.SC LO.SC INPT UNITLEVL 2

MANUAL ADJUSTMENTS SP2 MODES CONFIGURE INPUT

RANGING

TUNE BAND INT.T DER.T DAC CYC.T OFST SP.LK SET.2 BND.2 CYC.2LEVL 1

SP1 SETTINGS SP2 SETTINGS

Autotune or Park

Off; on; ParK; At.SP

SP1 Prop band (gain)/

hyst 0.1 deg to 100%

sensor f/s (10°C/18°F)

Integral time (reset)

Off; 0.1 to 60 min

(5 min)

Derivative time (rate)

Off; 1 to 200 sec

(25 sec)

Derivative approach

0.5 to 5.0 x bAnd

(1.5)

Cycle time or on/off

On.off; 0.1 to 81 sec

(20 sec)

Offset (manual reset)

0 to 50% x bAnd

(In.t = off)

Setpoint lock (SP1)

Off; on

Adjust SP2 setpoint

+/– sensor full scale or

full scale

SP2 prop band/Gain/

Hyst 0.1 deg to 100%

sensor f/s (2°C/3.6°F)

SP2 Cycle on/off

On.off; 0.1 to 81 sec

Program number

1 to 31

Run program

oFF; on; hoLd; dEL

inS; CoPY; PStE

Power failure

recovery mode

rSEt; Cont; hoLd

Program start value

PV; SP

Setpoint ramp time units

hour; 60s

Holdback value

oFF; 0.1 to 150

(0-240 in Lin)

Event output (SP2A or SP3A)

nonE; 2d; 2E; 3d; 3E; 2d.3d;

2E.3d; 2d.3E; 2E.3E

PROG RUN FAIL ST.U SPRU SEG TYPE SPRR T.SP HB.V EO.PLEVL P

PROGRAMMER SETTINGS

S

egment number

1 to 126 max.

Define segment type

SPr; SoAK; StEP; LooP;

Call; EoP; dEL; inS

Setpoint ramp rate

1 to 9990 (100)

units/time

Adjust target setpoint

+/– sensor full scale or

full scale

Instrument address

0 to 255

Baud rate

1200; 2400; 4800

9600; 19k2

Data format

18n1; 18E1; 1801

TxRx activity

Off; on

ADDR BAUD DATA DBUCLEVL C

COMMS SETTINGS

High scale 1000

-1999 to 9999

Low scale 0

-1999 to 9999

Input high 50.0

0.1 to 50.0

Input low 10.0

0.0 to 49.9

Decimal 0000

000.0 or 00.00

Burnout SP3 - uPSC

dhSC

R

everse O/P3 3D

3r

AN.HI ANLO HI.IN LO.IN DECP SP3.A SP3.B SET.3 HYS.3 BRN.3 REV.3LEVL A

SP3 SAFETY SETTINGS

Main mode nonE

dv.hi; dVLo; bAnd; Fshi;

FSLo; EoP

Second mode nonE

LtCh; hoLd; Lt.ho

Set SP3 0

0 to 2500

Hysteresis SP3 20

1–100% sensor

full scale

SP3 ADJUSTMENTSSP3 MODESLINEAR SCALING AND INPUT SETTINGS

➔

INITIAL

SET-UP

ENTRY

➔

PROGRAM ENTRY (DEFAULT)

Level C only visible

when COMMS

Option fitted

KEY ✱ ▼ OR ✱ ▲ TOGETHER TO CHANGE LEVELS OR OPTIONS

KEY ▼ OR ▲ TO VIEW FUNCTIONS

3

FUNCTIONS MENU

Range of Adjustment shown

under description.

If applicable, factory settings

shown in bold.

For a full description of menu

functions refer to pages 7 to

10, and 16/17 in Programmer

section.

Note: The letter K appears in

the instrument display as the

character K

This page can be photocopied and

used as a visual aid and bookmark when

working in other parts of the manual.

!

Press and hold ✱ and use the ▲ or ▼ buttons to select from the choices

Rly,SSd

or

AnLG

depending on the model supplied. SP2 and SP3 outputs will be automatically

allocated. (See output options table on page 8).

4 To enter initial configuration into controller memory

Press and hold both ▲ and ▼ buttons for 3 seconds. The display will now read

PArK

and measured variable (e.g. ambient temperature 23°).

PArK

is displayed because a

setpoint has not yet been entered.

To display setpoint units

Press and hold ✱ The displays will now read

unit

(eg. °C) and

0

To enter setpoint

Press and hold ✱ and use ▲ button to increase or ▼ button to decrease the reading and

scroll to required setpoint value. (The digit roll-over rate increases with time).

THE CONTROLLER IS NOW OPERATIONAL

WITH THE FOLLOWING FACTORY SETTINGS

Proportional band/Gain 10ºC/18ºF/100 units

Integral time/Reset 5 mins

Derivative time/Rate 25 secs

Proportional cycle-time 20 secs

(Typical setting for relay output)

DAC Derivative approach control 1.5

(Average setting for minimum overshoot)

Note: For more precise control or for non temperature applications where a Linear input

transducer is being used, the controller may need to be tuned to the process.

Please refer to the following section on AUTOTUNE.

AUTOTUNE

This is a single shot procedure to match the controller to the process. Select either Tune or

Tune at Setpoint from the criteria given below.

The Tune program should be used for applications other than those listed under Tune at

Setpoint below. The procedure will apply disturbances when the temperature or process

reaches 75% of the setpoint value, causing overshoot which is monitored in order to adjust

the DAC overshoot inhibit feature. Care should be taken to ensure that any overshoot is safe

for the process.

The Tune at Setpoint program is recommended when:

●

The process is already at setpoint and control is poor

●

The setpoint is less than 100°C in a temperature application

●

Re-tuning after a large setpoint change

●

Tuning multi-zone and/or heat-cool applications.

Notes: DAC is not re-adjusted by Tune at setpoint. Proportional Cycle Time can be pre-

selected before running the Autotune program. (see page 5).

GETTING STARTED

After power-up the controller requires programming with the following information:

Type of Sensor (See list of sensors p.22)

Operating unit

°C °F bAr PSi Ph rh SEt

Allocation of Output Device to SP1/SP2 (Relay / SSd) or analog. SP3 is always relay.

Setpoint

When the above information has been programmed into the controller it will be

operational with factory PID settings.

INITIAL SET-UP

On power-up the controller will display the self test sequence followed by the initial

display

inPt : nonE

1 Select input sensor.

Press and hold ✱ and use the ▲ or ▼ buttons to scroll through the sensor selection

list until the correct sensor is displayed. Release the buttons. The display will now read

selected sensor type e.g.

inPt : tCS

(type S thermocouple).

Press ▲ once The display will now read

unit : nonE

LINEAR INPUT

When Linear Input is selected, the display resolution of the setpoint and many other

functions will be changed from the setting previously made at

di.SP

in Level 2, to that set

at

dECP

in Level A.

It is therefore recommended that on completion of the Initial Set-up the Linear Input

settings in Level A be completed before moving on to configure Levels 1, 2 and 3. (see

Set-up Procedure page 6).

2 Select operating unit.

Press and hold ✱ and use the ▲ or ▼ buttons to scroll through the unit selection list

until the correct unit is displayed. Release the buttons. The display will read selected

unit e.g.

unit : °C

Press ▲ once The display will now read

SP1.d : nonE

3 Select SP1 (Main setpoint output device)

Analog output

For optimum control use a proportional cycle time setting of one second. Where the

analog output is allocated to SP2, the default setting on/off must be manually

changed in Level 1 to a time proportioning setting to enable the analog output to

operate in proportional control mode.

4

AUTOTUNE (continued)

TUNE OR TUNE AT SETPOINT PROGRAM

Enter program (▲▼) and from the display

tunE : oFF

press and hold ✱ and press ▲ to

display

tunE : on

or

tunE : At.SP

Exit program mode (▲▼).

The TUNE program will now start. The display will show

tunE

as the process variable

climbs to setpoint.

Note: Avoid tuning while running a program as SP1 may be different from the target

setpoint..

When the TUNE or TUNE AT SETPOINT program is complete the PID values are entered

automatically. The process will rise to setpoint and control should be stable. If not, this may

be because optimum cycle time is not automatically implemented. To set the cycle time

see PROPORTIONAL CYCLE-TIME.

PROPORTIONAL CYCLE-TIME

The choice of cycle-time is influenced by the external switching device or load. eg.

contactor, SSR, valve. A setting that is too long for the process will cause oscillation and a

setting that is too short will cause unnecessary wear to an electro-mechanical switching

device.

Factory set

To use the 20 sec factory set cycle-time no action is needed whether autotune is used or

not.

To Manually Select AUTOTUNE Calculated CYCLE-TIME

When AUTOTUNE is completed, enter program (▲▼) and select

CYC.t

in Level 1. The

display will read

CYC.t : 20

(the factory setting).

To view the new calculated optimum value, press and hold both ✱ and ▼ buttons until

indexing stops. The calculated value will be displayed eg.

A16

. If acceptable, exit program

(▲▼) to implement this setting.

To Pre-select Automatic Acceptance of AUTOTUNE Calculated CYCLE-TIME

Before AUTOTUNE is initiated select

CYC.t

in Level1, press and hold both ✱ and ▼ buttons

until indexing stops at

A

– – . Exit program (▲▼) to accept calculated value automatically.

To Manually Pre-select Preferred CYCLE-TIME

Before AUTOTUNE is initiated select

CYC.t

in Level 1, press and hold both ✱ and ▲ or ▼

buttons until indexing stops at preferred value then exit program (▲▼) to accept.

CYCLE-TIME RECOMMENDATIONS

SECOND AND THIRD SETPOINTS (SP2 and SP3)

PRIMARY ALARM MODES

Configure SP2 output to operate as an alarm from

SP2.A

in Level 2 and set the alarm

setting in

SEt.2

Level 1.

Configure SP3 alarm mode

SP3.A

and setting

SEt.3

in Level A. The alarms will be

individually triggered when the process value changes according to the options listed

below.

dV.hi

Rises above the main setpoint by the value inserted at

SEt.2/3.

dV.Lo

Falls below the main setpoint by the value inserted at

SEt.2/3.

BAnd

Rises above or falls below the main setpoint by the value inserted at

SEt.2/3.

FS.hi

Rises above the full scale setting of

SEt.2

or

SEt.3.

FS.Lo

Falls below the full scale setting of

SEt.2

or

SEt.3.

EoP

Event Output (See Programmer section pages 11 to 18)

SUBSIDIARY SP2 / SP3 MODES

The following additional Subsidiary alarm functions can be added to any Primary alarm

configurations using the settings found at

SP2.b

in Level 2 and

SP3.b

in Level A.

LtCh

Once activated, the alarms will latch and can be manually reset when the alarm

condition has been removed.

Hold

This feature inhibits alarm operations on power-up and is automatically disabled

once the process reaches the alarm setting.

Lt.ho

Combines the effects of both

LtCh

and

hoLd

and can be applied to any Primary

alarm configuration.

SECOND SETPOINT (SP2) Proportional control output

Configure in Level 1 using

CyC.2

to select proportional cycle time and

bnd.2

to adjust

proportioning band. For Heat/Cool operation see Operating Manual.

In on–off mode,

bnd.2

adjusts SP2 hysterisis.

5

Output Device

Factory Setting

Recommended Minimum

Internal relays

20 seconds

20 seconds

10 seconds

Solid state drives

0.1 seconds

Hereafter in the Manual the symbol (▲▼) signifies both buttons are held pressed

for 3 seconds to ENTER or EXIT Program mode.

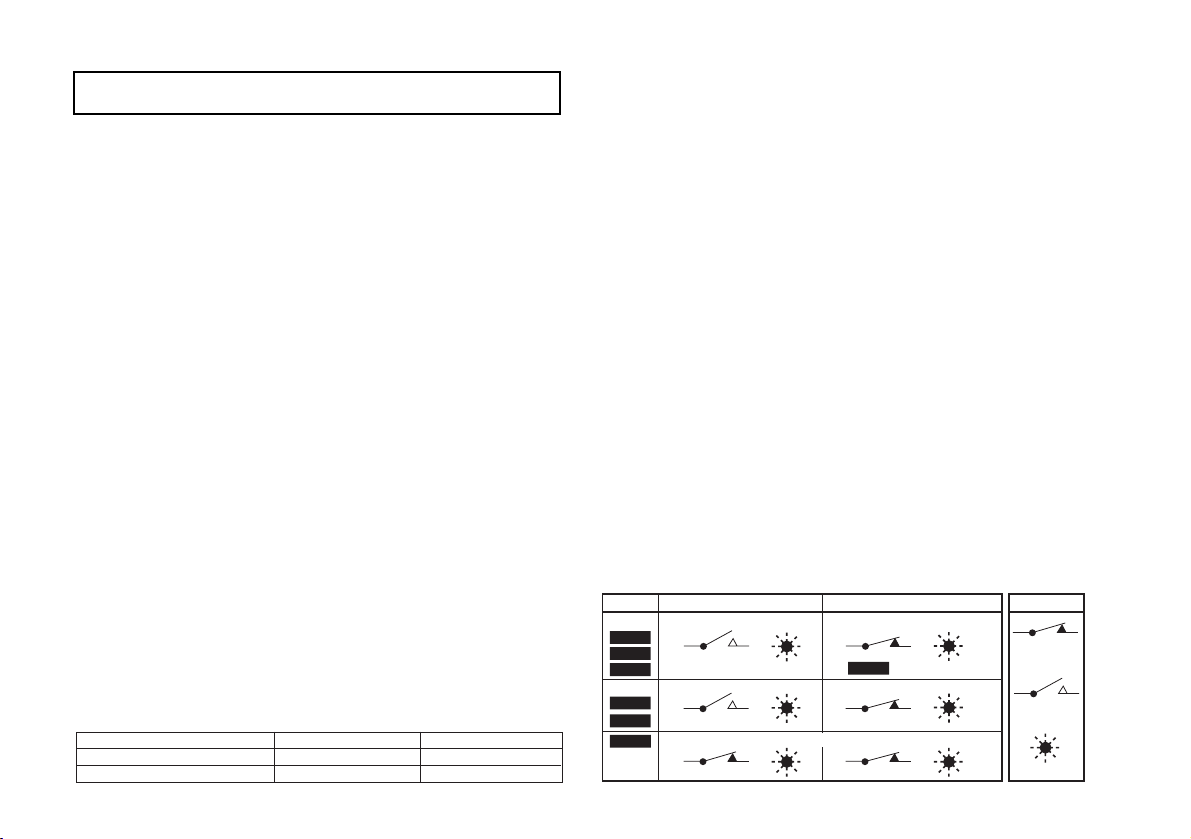

Alarm type On-Off operating mode SP2 and SP3 Proportional operating mode SP2 only

FS.HI

COOL

FS.LO

BAND

DV.LO

DV.HI

Deviation

Full scale

Strategy

Output state LED state Output state LED state

BAND

: on-off mode only

Output ON

(Relay or SSd

energised)

Output OFF

(Relay or SSd

de-energised)

LED ON

Temperature above setpoint

Legend

SP2 / SP3 OUTPUT AND LED STATUS IN ALARM CONDITION

SP2 / SP3 ALARM ANNUNCIATOR

If a Primary Alarm mode has been configured, when an alarm condition occurs the alarm

annunciator

-AL-

will be displayed alternating with the process variable. The alarm

together with the display, will be automatically reset as soon as the alarm condition has

been cleared.

The annunciator may be disabled by selecting

no.AL: on

, in Level 4.

ERROR MESSAGES

SENSOR FAULT

Display flashes:

inPt: FAiL

Indicates: sensor open or short circuit or linear input over-range.

Action: Check sensor/wiring/connectors

NON-VOLATILE MEMORY ERROR

Display flashes:

dAtA:FAiL

Action: De-power briefly. Replace unit if problem persists

MANUAL POWER ERROR

Display flashes:

hAnd :FAiL

SP1 set to on–off in

CYC.t

Action: Select proportional mode

IMMEDIATE FAIL ON AUTOTUNE START

Display flashes:

tunE :FAiL

Setpoint display 0

1. No setpoint entered.

Action: Enter setpoint

2. SP1 set to ON/OFF in

CyC.t

Action: Select proportional mode

Note: To reset and clear error press ▲▼ together briefly to cancel message.

FAIL LATER DURING AUTOTUNE CYCLE

The thermal characteristics of the load exceed the Autotune algorithm limits. The failure

point indicated by any display 0.0 in

tech

e.g.

Ctb

= 0.0

Action: 1. Change the conditions. eg. raise setpoint

2. Try

tunE : At.SP

3. If the error message persists, call Omega for advice.

6

LINEAR INPUT

Set-up Procedure

The 4–20mA input model converts current into voltage using an internal resistor which

spreads the signal across the input range 10 to 50 mV. using multiplier of 2.5. When using a

transducer with an output less than 4–20mA, the input maximum and minimum mV values

can be calculated using the same multiplier.

Models with 0 to 5V input use an internal resistor to spread the signal across the input

range 0 to 50 mV using a divider of 100. Where a transducer provides a smaller output, the

input maximum and minimum values can be similarly calculated.

Decide what scale minimum and maximum will be required, and whether the scale needs

inverting. (See Level A; Linear Input Scaling for list of settings and limits, page 10).

The example below shows how a 4–20mA linear Input should be configured.

# e.g. 4–20mA = 60 to 260 units where 4mA = 60 units

Follow INITIAL SET-UP procedure (also see page 4).

1. Select input sensor Select

inPt:Lin

2. Select unit Select required unit, if not available Select

unit:SEt

3. Select SP1 output Select from:

Rly,SSd

or

AnLG

Enter initial configuration into controller memory

DO NOT ENTER SETPOINT until Linear Input has been configured in Level A

See functions menu page 3

and functions list page 10.

Configure Linear Input Enter level A

(Then using example given # above)

4. Enter scale maximum Select

An.hi:260

5. Enter scale minimum Select

An.Lo:60

6. Enter input maximum Select

hi.in:50.0

7. Enter input minimum Select

Lo.in:10.0

8. Enter display resolution Select

dECP:0000

(WARNING – otherwise settings

marked may be altered)

Enter Linear Input configuration into controller memory and enter setpoint.

Now configure Levels 1, 2 and 3 and if required proceed with AUTOTUNE.

Note: Any apparent calibration errors can be removed using the

ZEro

and

SPAn

adjustments in Level 3.

✢

Will be affected by dECP settings in Level A

✢