User’s Guide

www.omega.com

e-mail: info@omega.com

CN8590 Series

1/32 DIN Te m p e r a t u re / P ro c e s s

C o n t ro l l e r s

OMEGAnet®On-Line Service Internet e-mail

w w w. o m e g a . c o m i n f o @ o m e g a . c o m

USA: ISO 9001 Certified

Servicing North America:

One Omega Drive, P.O. Box 4047

Stamford CT 06907-0047

TEL: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada:

976 Bergar

Laval (Quebec) H7L5A1

TEL: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USAand Canada:

Sales Service: 1-800-826-6342/ 1-800-TC-OMEGA

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering Service: 1-800-872-9436/ 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

®

Mexico:

TEL: (001) 800-826-6342

FAX: (001) 203-359-7807

®

En Espan~ol: (001) 203-359-7803

e-mail: espanol@omega.com

info@omega.com.mx

Se r vi c i n g Europe:

Benelux:

Postbus 8034, 1180 LAAmstelveen

The Netherlands

TEL: +31 (0)20 6418405 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic:

Rude´arma´dy 1868, 733 01 Karvina´ 8

TEL: +420 (0)69 6311 8 9 9 FAX: +420 (0)69 631111 4

Toll Free in Czech Republic: 0800-1-66342

e-mail: czech@omega.com

France:

9, rue Denis Papin, 78190 Trappes

TEL: +33 (0)130 621 400 FAX: +33 (0)130 699 120

Toll Free in France: 0800-4-06342 e-mail: france@omega.com

It is the policy of OMEGAto comply with all worldwide safety and EMC/EMI regulations that apply.OMEGAis constantly pursuing certification of its

products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The inf orma t ion cont a ined in this do c ument is beli eved to be correct,but OM EGAEngine ering,In c. a ccepts no liab ility for any errors it cont a ins,and

re s erves the ri ght to alter specifi ca t ions without not i ce.

WARNING: These products are not de si gned for use in,and should not be used for, p a t i ent - c onnected app li ca t ions.

i

2

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

TEL: +49 (0)7056 3017 FAX: +49 (0)7056 8540

Toll Free in Germany: 0800 TC-OMEGA

e-mail: germany@omega.com

United Kingdom: ISO 9002 Cert i f i e d

One Omega Drive

River Bend Technology Centre

Northbank, Irlam

Manchester M44 5EX United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800488488

e-mail: sales@omega.co.uk

SM

Fe at u re s

S a fety Wa rn i n g

Field-Selectable Thermocouple, RTD, or Voltage Input

C u rrent Input (with External 2.5 Ohm Resistor)

On/Off Through Full PID Operation

Autotuning - Heat or Cool

Adjustable On/Off Output Hysteresis

Dual Outputs

Field-Configurable Process or Deviation Alarms

Output % or Process Value Display

Bumpless, Auto-Manual Transfer

NEMA 4X Front Bezel

4-Digit (0.40") Alphanumeric Display

Approvals: UL, cUL, CE-compliant

In addition to presenting a potential fire hazard, high voltage

and high temperature can damage equipment and cause

severe injury or death. When installing or using this instrument, follow all instructions carefully and use approved

safety controls. Electrical connections and wiring should

be performed only by suitably trained personnel.

Do not locate this instrument where it is subject to excessive

shock, vibration, dirt, moisture, oil, or other liquids. The safe

operating temperature range for this unit is 32°F to 140°F

(0°C to 60°C).

3

Table of

C o n t e n t s

Installation 5

Dimensions and Mounting 6

Wiring 7

Output Types 10

Operation 12

Front Panel Controls 12

Power On 13

Security Levels 14

Menu System 15

Initial Setup Sequence 20

Menus and Parameters 21

Operating Modes 29

Alarms 31

Available Control Methods 32

Autotuning 33

Manual Tuning 34

Error Codes 36

Technical Specifications 37

Ordering Code 40

Recalibration Procedures 41

Quick–Helps 42

Quick Setup Instructions 46

Warranty/Repairs 51

I n s t a l l at i o n

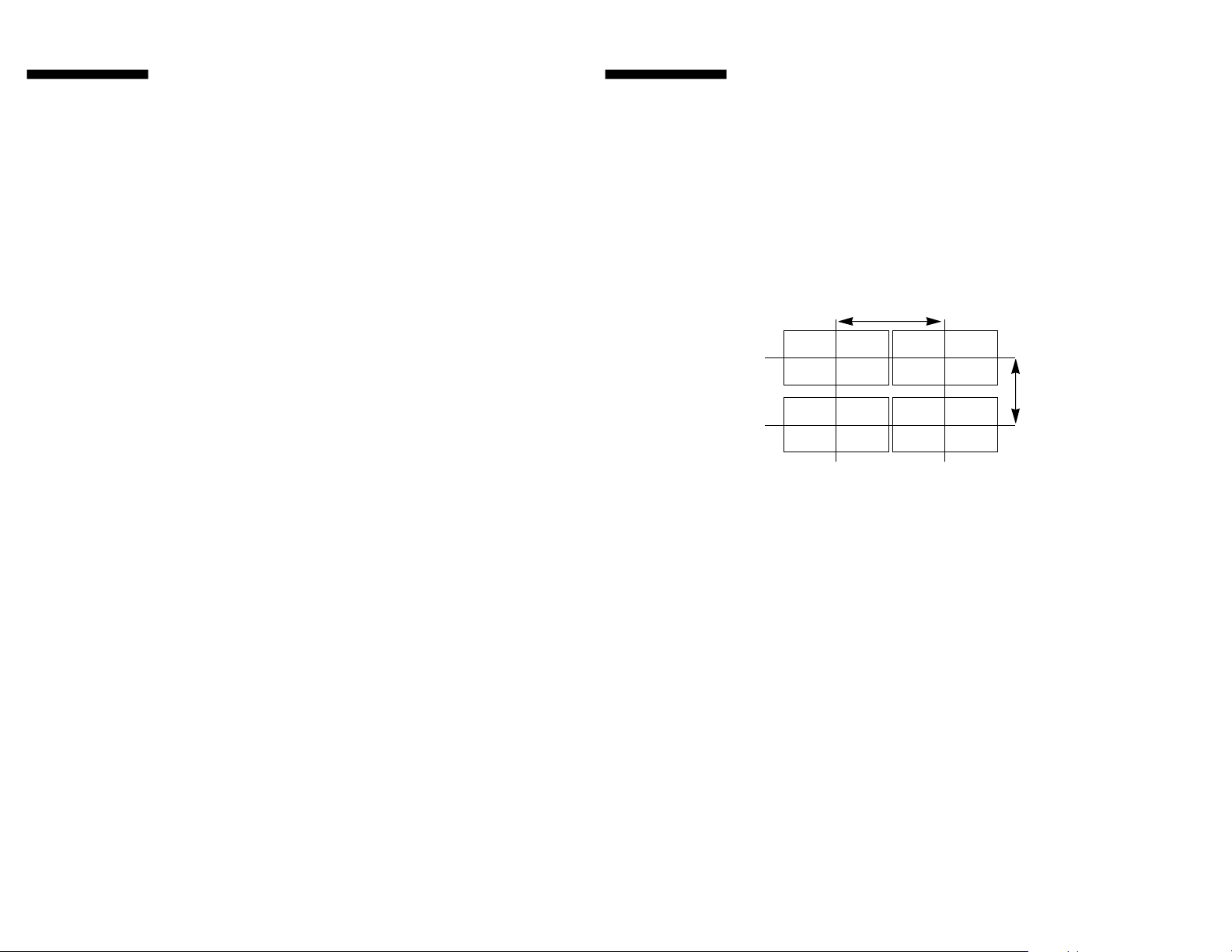

Measurements between

centerlines of panel

cutouts are minimum

recommended.

Unpacking and Inspection

1. Inspect shipping carton for obvious signs of mishandling.

2. After removing the controller from the shipping carton,

inspect it carefully for damage. Never attempt to install

and use a damaged unit.

3. Verify that the ordering code number indicated on the side

of the controller matches what was ordered.

Figure 1.

Recommended Panel Layout for Multiple Controllers

C

L

2.10"

(53.34 mm)

C

L

C

L

1.50"

(38.10 mm)

C

L

54

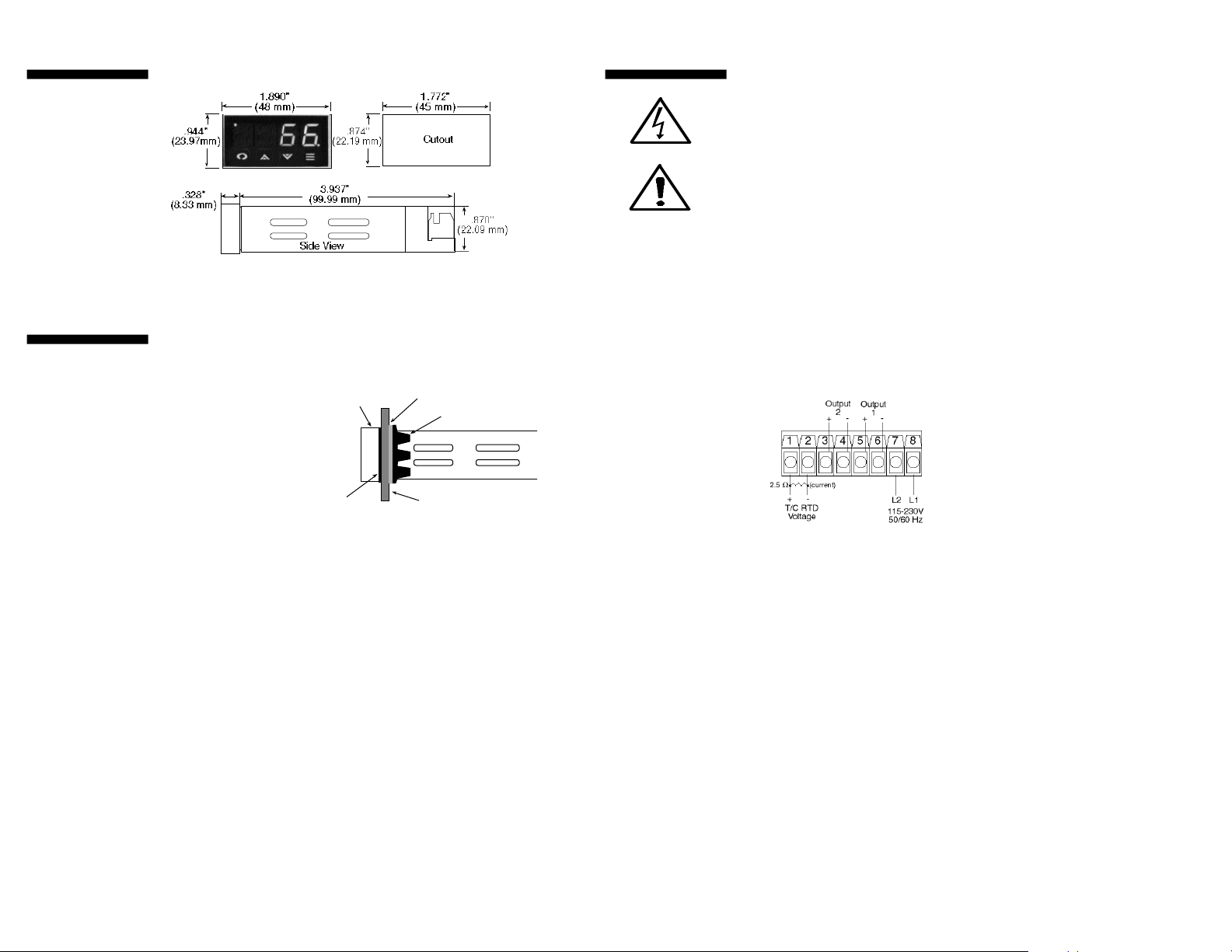

D i m e n s i o n s

Bezel

Customer Panel

Mounting Collar

Black Gasket

(Bevel faces user)

Gray Gasket

M o u n t i n g

Figure 2. Case Dimensions

Prior to mounting the CN8590 in your panel, make sure that

the cutout opening is of the right size, 0.874" x 1.772" (22.19

mm x 45.0 mm), and deburred to enable a smooth fit. A minimum of 4.5" (113 mm) of depth behind the panel is required.

Figure 3. Mounting Diagram

Insert the CN8590 through the front panel cutout and slide

the mounting collar

back onto the unit

from behind the panel.

Push the mounting

collar up tight to the

back of the mounting

Side View

panel.

Wi ri n g

IMPORTANT: All electrical wiring connections should be made

only by trained personnel, and in strict accordance with the

National Electrical Code and local regulations.

The CN8590 controller has built-in circuitry to reduce

the effects of electrical noise (RFI) from various sources.

However, power and signal wires should always be kept

separate. We recommend separating connecting wires into

bundles: power; signal; alarms; and outputs. These bundles

should then be routed through individual conduits. Shielded

sensor cables should always be terminated at one end only.

If additional RFI attenuation is required, noise suppression

devices such as an R.C. snubber at the external noise source

may be used. If you wish, you may order this suppressor

directly from Omega, part number 1821-101.

Figure 4. Contact Identification

76

Wi ri n g

Thermocouple circuit

resistance should not

exceed 100 ohms for

rated accuracy; errors

will occur at higher

resistance values.

If shielded thermocouple wire is used,

terminate the shield

only at one end.

When using an RTD

sensor, an approximate

error of 6 °F (3.3 °C)

will result for each

ohm of resistance

encountered in the

lead wires. If shielded

RTD wire is used,

terminate the shield

only at one end.

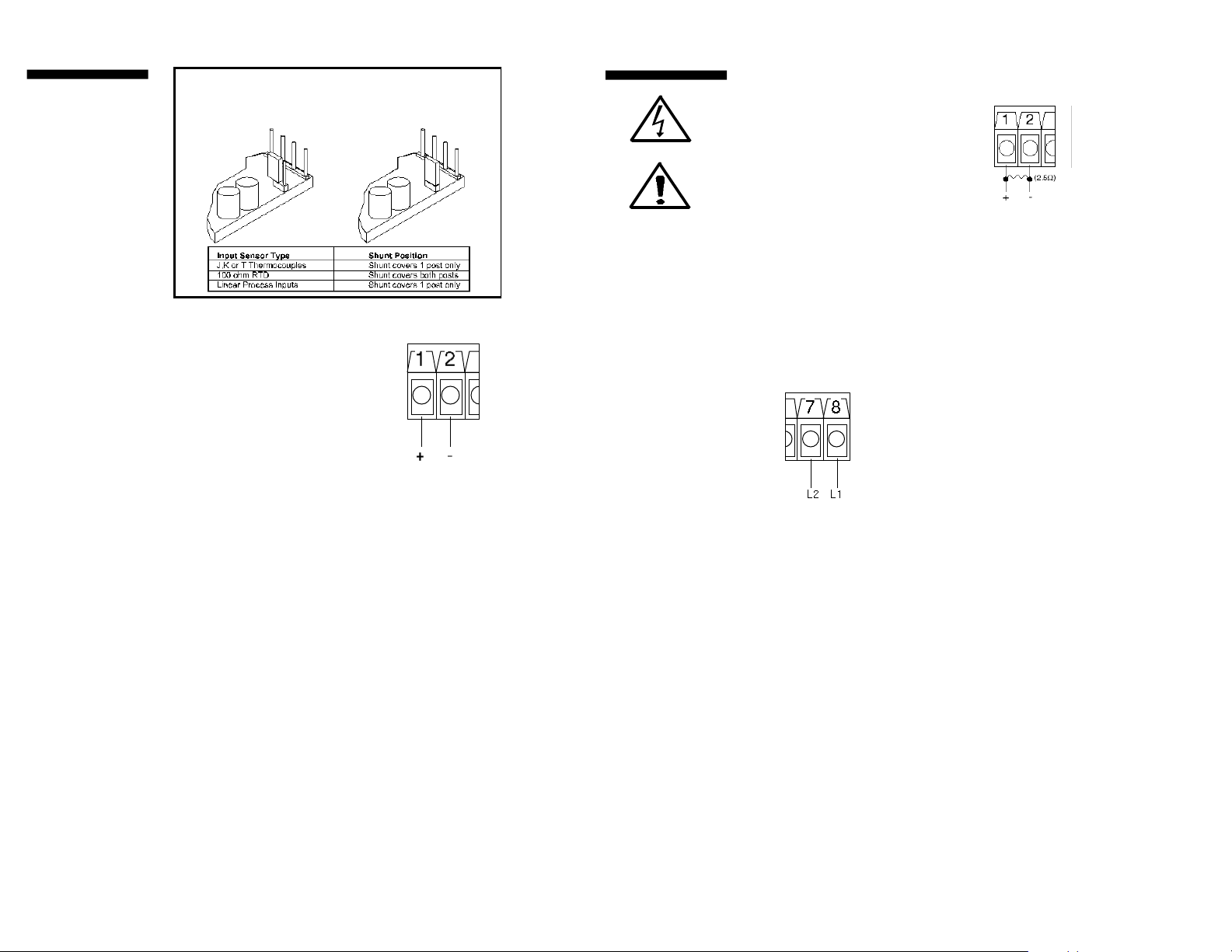

The CN8590 accepts Type J, K, or T thermocouples, 100 ohm RTDs and linear inputs

(suppressed or unsuppressed).It is shipped from the factory set for thermocouple or

linear input;however, a shunt jumper is located on the PC board near the rear of the

unit.This jumper (JMP01) is accessible by removing the back portion of the case.It is

not necessary to remove the PC board from the case.See table below.

Thermocouple Input Wiring

Using the appropriate thermocouple

and extension wire, connect the negative lead (generally colored red in

ISA-type thermocouples) to contact 2;

connect the positive lead to contact 1.

Extension wires must be the same

polarity as the thermocouple.

RTD Wiring

Connect 2-wire, 100 ohm platinum

RTD to contacts 1 and 2. Keep leads

short and use copper extension wire.

Figure 5. Thermocouple,

RTD, and Voltage

Connections

Wi ri n g

Process and Linear Input Wiring

Voltage Inputs: Connect the positive voltage input to contact

1 and the negative to contact 2 (Figure 5).

Current Inputs: (Figure 6) Connect the positive current input to contact 1 and the

negative current input to contact 2.

Connect an external 2.5 ohm shunt

resistor across the contacts.

Figure 6. Current Input Wiring

The CN8590 accepts both 85 to 265 Vac and 120 to 375 Vdc

line power without any switch settings or polarity considerations. All connections should be made in accordance with the

National Electrical Code and local regulations, using only NEC

Class 1 wiring for all power terminals.

Both of the incoming power lines should be fused with 2AG,

0.5 amp maximum rated fuses. Be sure that only instrument

power input is fused — not power to the load.

Figure 7. Power Wiring Connection

98

Output Ty p e s

The Type “R” output

is a mechanical device

and subject to wear.

To extend the life of

the relay, set the Cycle

Time for the relay

output to the longest

duration that still

affords good control.

When you ordered your CN8590 controller, a specific output

device combination was specified. See page 40 for the ordering code, and compare it to the part number on the controller

label. Your controller was also configured at the factory with

either one or two output actions. Generally, output 1 is used

as a reverse-acting (heat) function and output 2 is a direct-

acting (cool) function. However, the CN8590 provides the

option of having either or both outputs configured as reverse

or direct acting. For best results, follow the recommendations

given below for setting cycle times. A brief description of output devices follows on the next page.

For Control Output Type — Select Cycle Time

(in seconds)

R (Output 1 Only) 15

DC 0

T 15

Output Ty p e s

Output 1

O None

R Electromechanical relay, 5A @ 120/240

Vac, normally open, used for switching

resistive loads.

DC DC logic output @ 5 Vdc pulsed

T Solid-state relay, zero voltage-switched

and optically isolated from drive signal.

Resistive loads to 1 A @ 120/240 Vac may

be controlled directly. Larger loads may be

controlled using an external contactor.

Output 2

O None

DC DC logic output @ 5 Vdc pulsed

T Solid-state relay, zero voltage-switched

and optically isolated from drive signal.

Resistive loads to 1 A @ 120/240 Vac may

be controlled directly. Larger loads may be

controlled using an external contactor.

1110

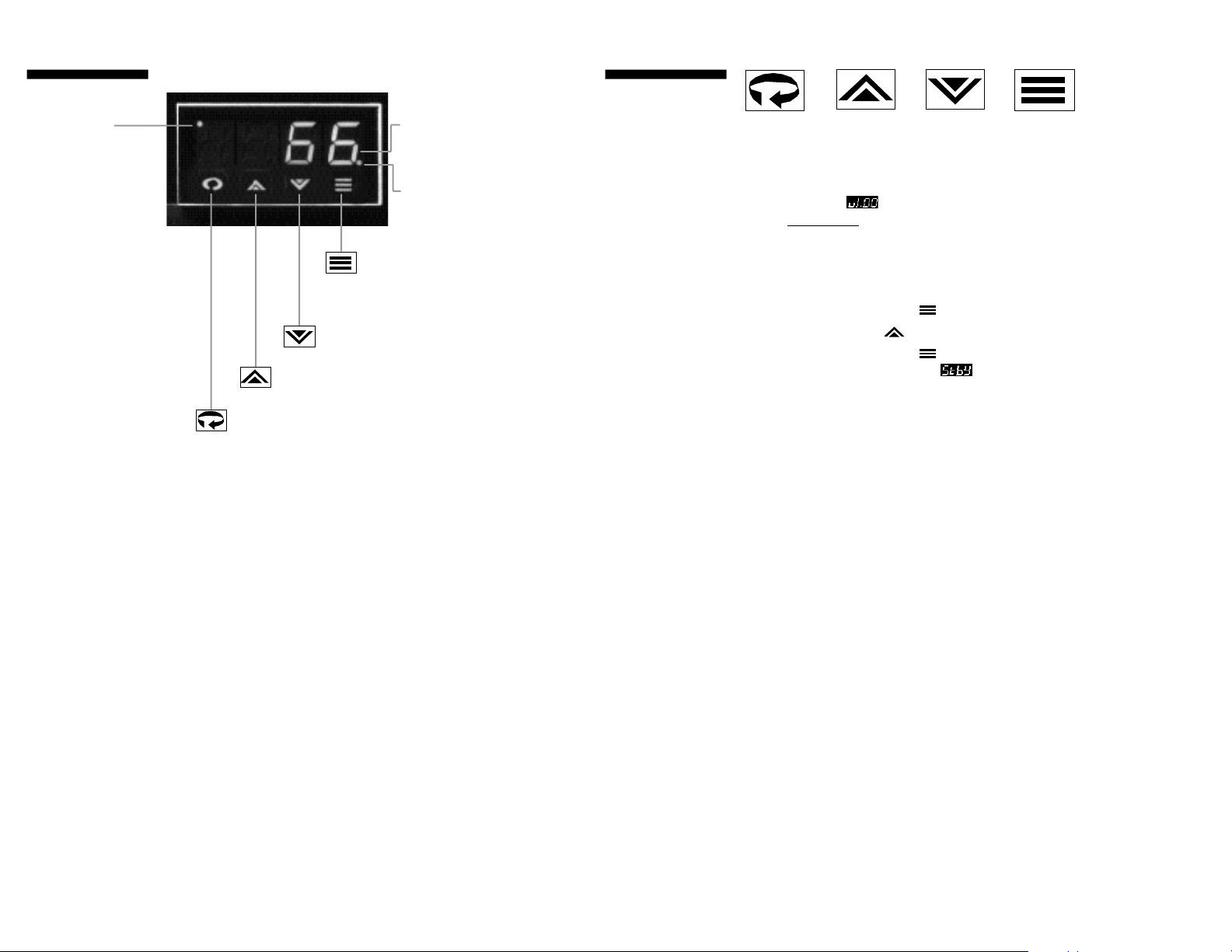

O p e rat i o n

Output Indicator

Used to indicate

activation of Output 1.

Figure 8. Front Panel Controls and Indicators

Four-Digit LED Display

Displays measured

process value, setpoint,

or parameter labels and

settings.

Output Indicator

Used to indicate

activation of Output 2.

Mode/Enter Key

Used to enter Parameter selections, access operating modes,

silence latched alarms, and index

through menu items.

Lower Key

Used to decrease values.

(Hold for fast-step progression)

Raise Key

Used to increase values.

(Hold for fast-step progression)

Menu Access Key

Used to enter or exit the menu system, index to the next

menu, and enter the Security Level menu.

Power On

The CN8590 con-

troller's functional

hierarchy is organized

into three distinct

user-programmable

groupings: Security

Level, Menu System,

and Operating Mode.

Please provide the

software version

number, along with

the controller’s full

model number, when

contacting us regarding

your controller.

When power is first applied to the CN8590, all segments of

the LED display will be momentarily illuminated while the

instrument goes through a series of diagnostic checks to

verify proper operation. A software version number will then

be displayed, e.g., , followed by the measured process

value. IMPORTANT: On initial startup, there is a possibility

that outputs may be activated. We recommend placing the

unit in Standby mode until you have configured the controller

according to your application requirements. To place the

controller in Standby, follow this procedure:

1) Press Mode/Enter key once.

2) Press Raise key once.

3) Press Mode/Enter key again. (The display

will alternate between and process value.

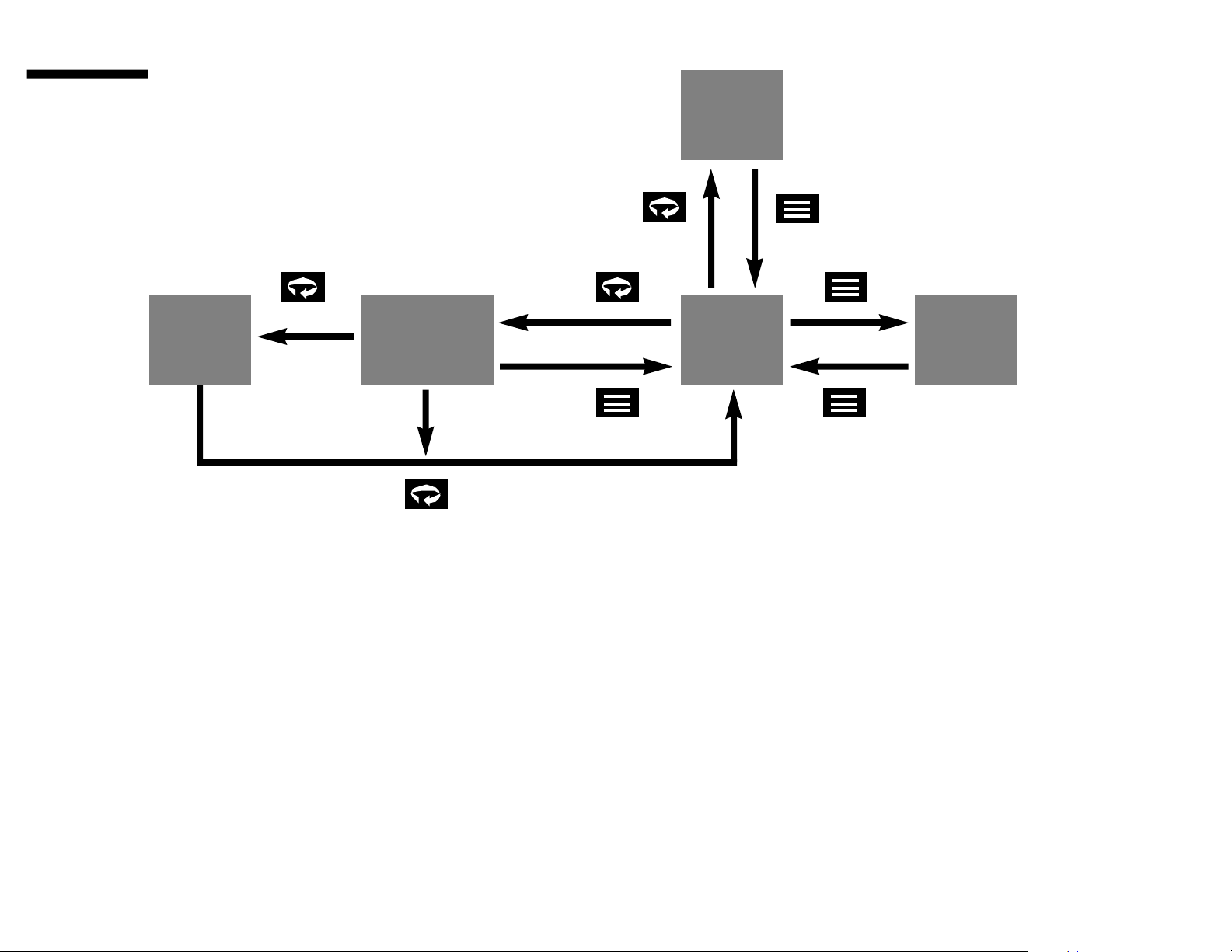

Operations Overview

The user interface of the CN8590 allows you to use menus to

set up the instrument, set the desired security level, change

the setpoint, and conveniently change operating modes.

Figure 9 on page 16 provides a functional representation of

the user interface and the key presses necessary to perform

the basic functions.

1312

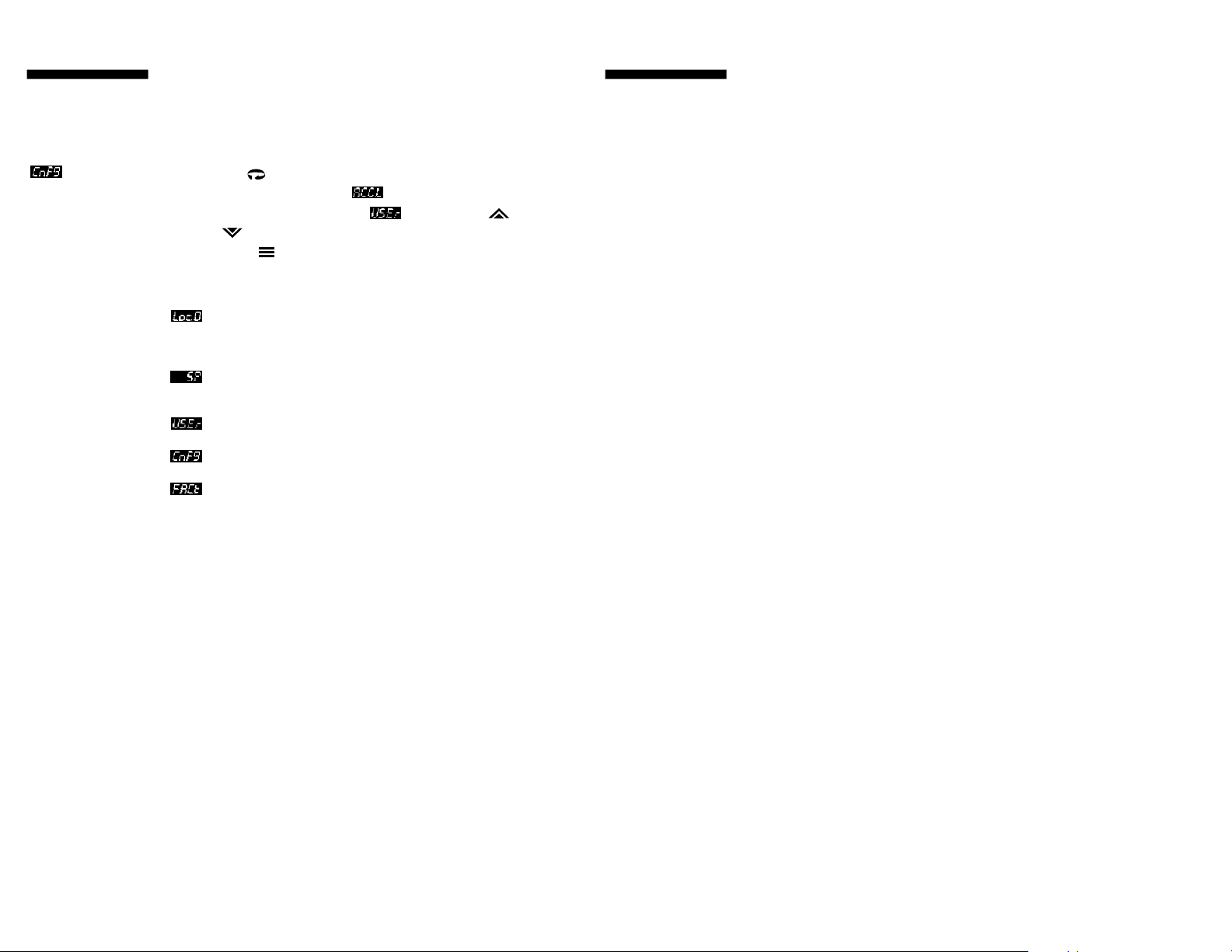

S e c u rity Leve l s

The controller’s initial

security level, set at the

factory, is Configuration

. When you have

completed configuring

the instrument, we recommend the security

level be set to the most

restrictive level suitable

for your application.

The security level feature allows you to limit access to the

menus, setpoint, and operating mode selection according to

the needs of your application. The five security levels provided are Key Lockout, Setpoint, User, Configuration, and

Factory. To view or change security level, press and hold the

Menu Access key for approximately ten seconds. The

controller will alternately display (Access Level) and

the current security level label, e.g., . Use the Raise

or Lower keys to index through the security levels. Press

the Mode/Enter key to select the new security level

desired and return to the Process Value display.

Security Levels and Access Restrictions

Key Lockout Highest security level. No access to any

controller functions. To escape, follow

instructions above for changing security

levels.

Setpoint No access to menus. Only allows setpoint

value, output percentage (manual mode),

or operating mode to be changed.

User All “Setpoint” level privileges as well as

access to Autotune and Control menus.

Configuration All “User” level privileges as well as Input,

Output, Display, and Supervisor menus.

Factory All “Configuration” level privileges as well

as access to Calibration menu.

M e nu System

If a key press is not

sensed within five minutes, the controller

automatically exits the

Menu System and

reverts to the Process

Value display.

The Menu System is organized into seven menus: Control,

Autotune, Input, Output, Display , Supervisor, and

Calibration . Pressing the Menu Access key indexes from

menu to menu. Pressing the Mode/Enter key indexes through

the parameters in a particular menu. The Raise and Lower

keys are used to modify the visible menu parameter.

Each menu contains a logical group of parameters related to

one another. Furthermore, the sequence of the menus has

been carefully chosen to put the most frequently used menus

first. For example, provided access is permitted, the first

menu presented upon entering the Menu System is the

Setpoint Menu.

1514

M e nu System

Figure 9. CN8590 Functional Diagram

Security

Levels

for 10 seconds

for 3 seconds

Menu

System

Setpoint

Modification

for 3 seconds

Process

Mode

Variable

Selection

Display

1716

Loading...

Loading...