Page 1

Universal Temperature/Process

Controllers 1⁄8 and 1⁄4 DIN Sizes

P

a

n

e

l

p

u

n

c

h

e

a

v

a

o

m

p

a

n

n

i

e

l

b

a

l

i

a

Av

o

s

Al

1

N

I

D

6

1

⁄

a

P

e

e

S

D

r

o

f

All models shown smaller

than actual size.

!

ze

i

S

e

g

t

e

3

4

-

P

.

s

l

i

a

i

l

a

b

e

g

a

e

l

p

u

s

l

e

,

v

i

s

i

t

.

c

o

m

/

n

c

h

e

s

CN8541TC-R1, $314.

CN8500 Series

Starts at

$

314

NEMA 4X (IP65)

Front Panel Standard

Universal Power Supply

User-Selectable

Ramp to Setpoint

Smooth Auto/Manual

Operation

Optional RS232 or

RS485 Communications

Autotuning Heat or Cool

Thermocouple, RTD,

Voltage, or Current Input

Plug-In Outputs Modules

(Field Installable)

Dual Outputs and Alarms

Optional Heater Break

Alarm, Remote Setpoint,

Transducer Power Supply,

and Recorder Output

The CN8500 Series temperature

controller is versatile and

user-friendly. The operator needs to

review only those parameters

relevant to the particular application.

A dual digital display offers optimal

process information at a glance.

The dedicated upper display shows

the process temperature, while the

lower display displays setpoint and

setup parameters. Individual LEDs

CN8561TC-R1, $404.

CN8551TC-R1, $317.

identify the status outputs, alarms,

digital communications, and special

options. The CN8500 Series

features a NEMA 4X front panel and

a universal power supply that

accepts 103 to 253 Vac and

103 to 330 Vdc.

Control algorithms available are P,

PI, PD, PID, and on/off. The

autotune feature automatically sets

proportional band, rate, and reset

before the process reaches

setpoint. These parameters provide

quick stabilization of both the

heating and cooling process without

overshoot, hunting, or cycling. The

standard dual control outputs can

be configured in a variety of control

and alarm applications such as

heat, heat/cool, heat/alarm, cool, or

cool/alarm. The ramp-to-setpoint

feature allows the user to define the

rate of rise to reach the setpoint,

thus minimizing thermal shock to

the load during start-up.

P-57

Page 2

Specifications

erformance

P

Accuracy: ±0.2% FS, ±1 digit

Setpoint Resolution:

1 count/0.1 count

Repeatability: ±1.0 count

emperature Stability: 5 µV/°C max;

T

3 µV/°C typical

Thermocouple Cold-Junction

Tracking: 0.05°C/°C ambient

Common Mode Rejection: >100 dBA

Series Mode Rejection: >70 dBA

rocess Sampling: 10 Hz (100 ms)

P

Inputs

Thermocouple Lead Resistance:

100 Ω max for rated accuracy

Response Time: 0.1, 1.0 or 10 s

Decimal Position: Selectable

Outputs

Output #1: Reverse acting (heating)

Output #2: Direct acting (cooling)

Mechanical Relay:

Rated 5 A @ 120 Vac,

3 A @ 240 Vac

Current: 4 to 20 mA, 500 Ω max

Voltage: 20 Vdc pulse, 1 kΩ min load

Triac: Solid state relay, 120/240 Vac,

zero voltage switched rated 1 A

continuous, 10 A surge @ 25°C (77°F)

Alarms: Optically isolated triac rated

1 A, 120/240 Vac @ 25°C (77°F)

Control Characteristics

etpoint Limits: Limited to configured

S

range for thermocouple and RTD;

limited to scaled range

Alarms: Adjustable for high/low,

process or deviation

Rate: 0 to 900 s

Reset: 0 to 3600 s

Cycle Time: 0.2 to 120 s

Gain: 0 to 400

Gain Ratio:

0 to 2.0 (in 0.1 increments)

On/Off Deadband: 1 to 100 counts

Spread (Output 2):

0 to 100 counts (above setpoint)

Damping: Adjustable (low, normal

or high)

Ramp to Setpoint: 1 to 100 minutes

Autotune: Operator-initiated from

front panel

Manual Control: Operator-initiated

from front panel

General

Power: 115 to 230 Vac ±10%,

50/60 Hz; 115 to 300 Vdc ±10%

(auto-polarity)

Display: Dual LED, 4-digit process

display, green menu/parameter display;

9.2 mm (0.37") high for

1

⁄8 DIN models; 14 mm (0.55") process

display for

Power Consumption: Less than

6 VA (instrument) @ 120 Vac

1

⁄4 DIN units

Input Types and Ranges

Input

Code Type Range Resolution

-18 to 760°C 1°C

Iron-constantan 0 to 1400°F 1°F

-18 to 1349°C 1°C

0 to 2460°F 1°F

CHROMEGA®-ALOMEGA

®

-129 to 316°C 1°C

TC Copper-constantan -200 to 600°F 1°F

-18 to 1299°C 1°C

0 to 2370°F 1°F

OMEGALLOY

®

-18 to 1299°C 1°C

Pt/13% Rh-Pt 0 to 3200°F 1°F

-18 to 1299°C 1°C

Pt/10% Rh-Pt 0 to 3200°F 1°F

-200 to 850°C 1°C

RTD 3-wire, 100 Ω Pt -328 to 1562°F 1°F

-128.8 to 232.2°C 0.1°C

3-wire, 100 Ω Pt -199.0 to 450.0°F 0.1°F

V5 1 to 5 V Scalable (-1999 to 9999) Selectable

0 to 5 V Scalable (-1999 to 9999) Selectable

V10 2 to 10 V Scalable (-1999 to 9999) Selectable

0 to 10 V Scalable (-1999 to 9999) Selectable

MV 10 to 50 mV Scalable (-1999 to 9999) Selectable

0 to 50 mV Scalable (-1999 to 9999) Selectable

MA 4 to 29 mA Scalable (-1999 to 9999) Selectable

0 to 20 mA Scalable (-1999 to 9999) Selectable

For CN8200,

CN8240 and

CN8260 Series

Controllers

Software Can Support

Up to 254 CN8200,

CN8240 or CN8260

Controllers

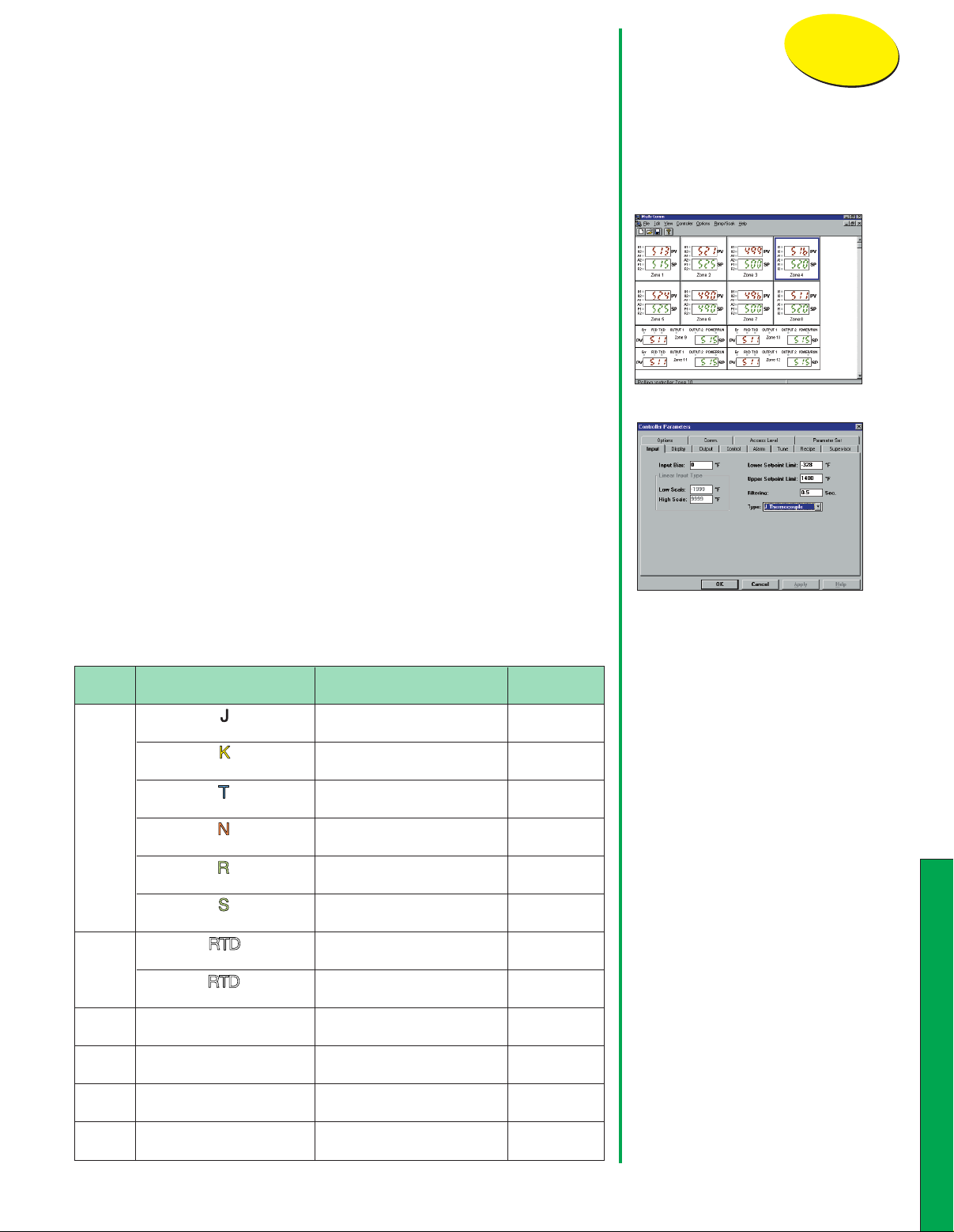

Sample of screen displaying status

of multiple controllers.

Sample of screen displaying

controller parameters.

The CN8-SW software is designed

to interface with the CN8200,

CN8240 and CN8260 Series

controllers with optional

communication hardware.

Designed for use on laptops or

PC’s, this development provides

the user with:

• Time saving benefit and

convenience of remotely

configuring and adjusting units.

• Saving and retrieving settings to

and from files.

• Cloning settings to other instruments.

• Highly flexible logging and

“real time” charting capability

for providing hard copy QA

records for ISO-9000 and other

management purposes.

The CN8-SW software is a powerful

process development tool for the

OEM customer or process engineer.

With compatible modems and PC

computers, remote site supervisory

control and data acquisition can

take place to facilitate periodic or

continuous monitoring and

troubleshooting.

Data is stored to file in a tamper

resistant format to ensure the

integrity of reports for quality

monitoring requirements.

Sof

t

w

ar

FREE

e

P

P-58

Page 3

CN8551RTD-R1, $317.

Extended Warranty

Program

SM

CN8541RTD-R1,

$314.

All models

shown smaller

than actual size.

MOST POPULAR MODELS HIGHLIGHTED!

To Order (Specify Model Number)

odel No. Price Cutout Description

M

CN8541(*)-(**) $3141⁄8 DIN vertical Single output

CN8542(*)-(**)-(**) 3441⁄8 DIN vertical Dual output

CN8551(*)-(**) 3171⁄8 DIN horizontal Single output

CN8552(*)-(**)-(**) 3471⁄8 DIN horizontal Dual output

N8561(*)-(**) 404

C

CN8562(*)-(**)-(**) 4341⁄4 DIN Dual output

Comes complete with operator’s manual.

Specify input code: “-TC” (thermocouple), “-RTD”, “-MV” (voltage to 50 mV) or

*

“-MA” (current to 20 mA). See Input Table on page P-58 for details.

Specify output code(s) from Output Types table below. Single output units can be ordered

**

for either heat (reverse) or cool (direct) action.

Output Types (No Additional Cost)

1st Output–Heat Only 2nd Output–Cool Only

Output Type (Reverse) Order Suffix (Direct)* Order Suffix

5 A Relay -R1 -R2

1 A SSR -T1 -T2

4 to 20 mA -F1 -F2

20 Vdc Pulse -DC1 -DC2

Single output controllers can be ordered for either heat (reverse) or cool (direct) acting.

*

Ordering Examples: CN8561TC-R2,1⁄4 DIN controller, thermocouple input, 5 A relay,

2nd output configured for cooling operation, $404.

CN8561TC-DC1-AL1-C2-PV4, single-output controller for thermocouple input, 1st output DC pluse

with 1 alarm output, RS232C communications and recorder output, $404 + 25 + 95 + 75 = $599.

OCW-2, 2-year warranty extension $599 + 108 = $707.

1

IN Single output

⁄4 D

CN8561RTD-R1, $404.

Weight (1⁄8 DIN): 0.34 kg (12 oz)

1

Weight (

Panel Cutout (

⁄4 DIN): 0.425 kg (15 oz)

1

⁄8 DIN): 45 x 92 mm

(1.772 x 3.622")

Panel Cutout (

1

⁄4 DIN):

92 mm (3.622") square

Dimensions (

1

⁄8 DIN Horizontal):

53 x 100 mm (2.1 x 3.95");

18.3 mm (0.72") depth

Dimensions (

1

⁄4 DIN):

100 W x 100 H x 18.3 min bezel

(3.95 x 3.95 x 0.72")

Panel Depth: 100 mm (3.937")

Front-Panel Rating:

NEMA 4X (IP65)

Operating Ambient Range:

0 to 55°C (32 to 131°F) @ 90% RH

max, non-condensing

Memory Protection: Solid state

non-volatile memory

Connections: Rear barrier strip with

locking terminals

Contacts: Twin bifurcated

Options*

Ordering Suffix Add’l Price Description

-AL1 $25 Single alarm

-AL2 50 Dual alarms

-C2 95 RS232 communications

-C4 95 RS485 communications

†

†

-XP1 75 Transducer power supply, 15 Vdc

1 alarm option, 1 communications option and the XP1 option can be installed in a unit.

*

† Free CN8-SW software download available at

omega.com/cn8500

Other Options (Only 1 Option Available Per Unit)

Ordering Suffix Add’l Price Description

-PV3 $75 Recorder output, 4 to 20 mA

-PV4 75 Recorder output, 0 to 5 Vdc

-HB1 75 Heater break alarm, 0 to 20 A

-HB2 75 Heater break alarm, 0 to 60 A

-RSP4 75 Remoter setpoint, 0 to 5 Vdc

-RSP5 75 Remote setpoint, 1 to 5 Vdc

-RSP6 75 Remote setpoint, 0 to 20 mA

-RSP7 75 Remote setpoint, 4 to 20 mA

Accessories

Model No. Price Description

CNQUENCHARC $8 Noise suppression RC

snubber (2 leads),

110 to 230 Vac

CN8500-ALI 20 Alarm relay module

CN8500-DC 35 DC pulse output module

CN8500-F 35 4 to 20 mA output module

CN8500-R 35 Relay output module

CN8500-T 35 1 A SSR output module

OMEGACARESMextended

warranty program is

available for models

shown on this page. Ask

your sales representative

for full details when

placing an order.

OMEGACARESMcovers

parts, labor and

equivalent loaners.

P-59

Page 4

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...