Omega Products CN606RTD Installation Manual

Table of Contents

SECTION

SECTION 1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . .

1 .1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 .2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 .3 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 RS-232 COMMUNICATIONS . . . . . . . . . . . . .

2 .1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 RS-232 Cable Connections . . . . . . . . . . . . . . . . . . .

2 .3 RS-232 PC Screens . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Operating Protocol . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . .

3 .1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 .2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 .3 Outline Dimensions . . . . . . . . . . . . . . . . . . . . . . . .

3 .4 Wiring the Power Ciruit . . . . . . . . . . . . . . . . . . . . .

3.5 Changing Line Voltage Setting . . . . . . . . . . . . . . . .

3 .6 Sensor Placement . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 PARTS OF THE SCANNER . . . . . . . . . . . . . . .

4 .1 Front of the Scanner . . . . . . . . . . . . . . . . . . . . . . . .

4 .2 Button Functions . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 .3 Back of the Scanner . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Temperature/Setpoint Display . . . . . . . . . . . . . . . .

SECTION 5 SETUP AND OPERATION . . . . . . . . . . . . . . .

5 .1 "RUN" Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 .2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 .3 Functions Description . . . . . . . . . . . . . . . . . . . . . . .

5 .4 "FUNCTION SELECT" Mode . . . . . . . . . . . . . . . . .

5 .5 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Entering the Password . . . . . . . . . . . . . . . . . . . . . .

5 .7 Wiring RTD Models . . . . . . . . . . . . . . . . . . . . . . . .

5 .8 Wiring OC Models . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Thermocouple Ranges . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . .

PAGE

1

1

1

2

2

2

3

3

6

9

. 9

. 9

10

10

11

12

12

12

13

14

15

15

15

16

17

22

22

23

25

25

26

27

SECTION 1

INTRODUCTION

1.1 Description

The CN600 Series is a second generation of industrial scanners based

on the field proven CN100 six zone temperature monitor/alarm system.

Several models and options are available.

The CN600 Series is a microprocessor based scanner which accepts

signals from thermocouples or RTD's. In the basic unit, six zones are

sequentially scanned with a selectable display rate of 1 to 40 seconds

each. A single output relay is provided to indicate an alarm condition on

any zone. The faceplate has been arranged to call attention to an alarm

condition by flashing the main temperature display and indicating the

zone in alarm with a flashing zone number display. To prevent alarm on

startup, Lo alarm is not activated until enabled zones cross Lo alarm

setpoint.The CN600 Series implements a security password to protect

certain functions.

1.2 Features

• Six Zones or 12 Zones

• Adjustable Display Time

• Field Proven Zone Switching

• Temperature and Setpoint Monitoring

• Four Digit Display of Temperature

• 2 Digit Display of Zones

• 5 Amp Latching or Non-Latching Relay

• Standard Thermocouples [T,E,J,K,S,R,B,C]

• Extended Ranges

• Six RTD Inputs (2 or 3 wire)

• Six Optional Independent Outputs

• Programmable Selection of HI, LO or HI/LO Alarms

• Password Protection

• Optional Inputs Other Than Thermometer

• 1/4 DIN Aluminum Box

• Splash Proof Face

• Plug-In I/O Terminals

• RS-232 Communication

NOTE: Consult RS-232 Software for use of RS-232 Communications.

1

1.3 Models

The following Models are available:

- Standard Thermocouple

- Extended Range

- RTD Input

- 12 Zone Thermocouple

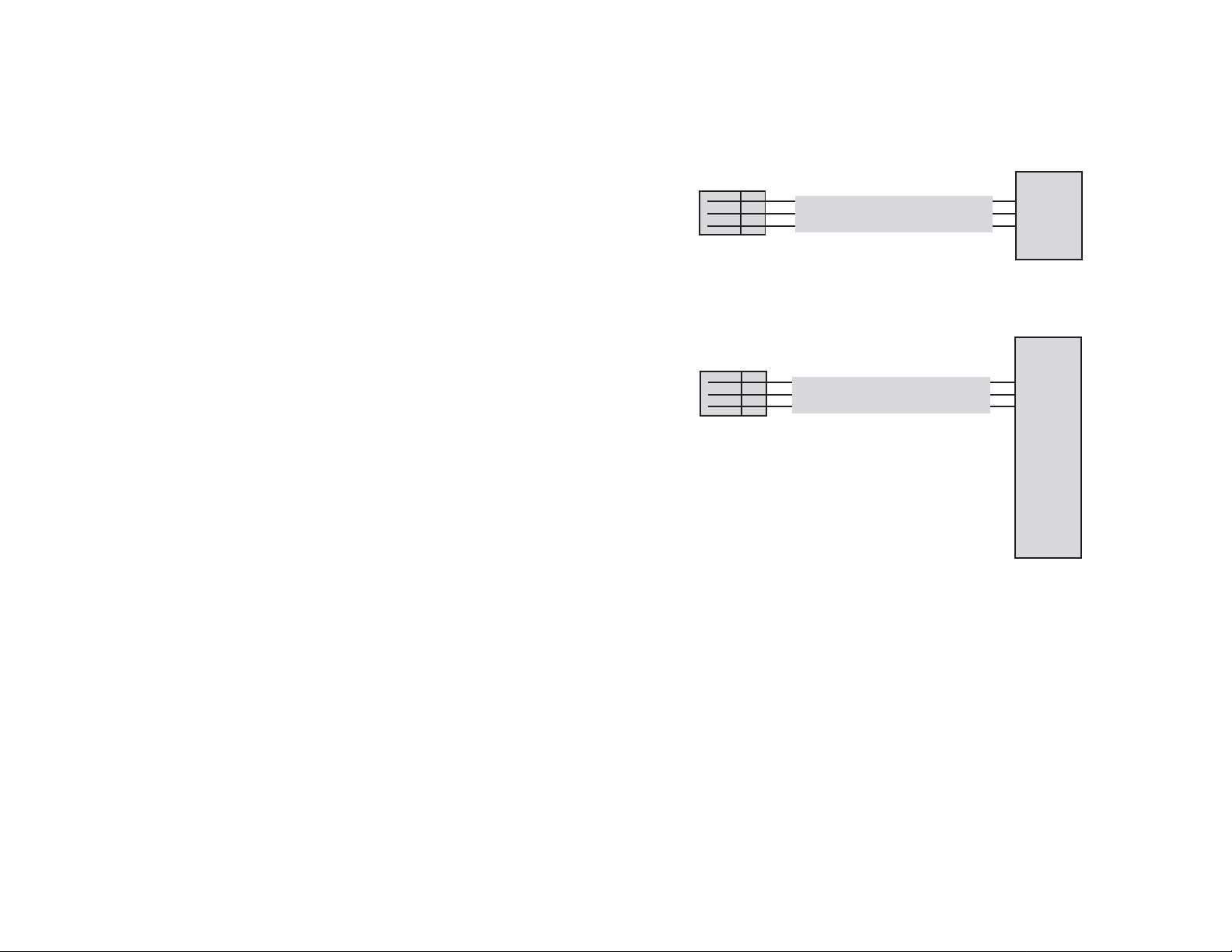

2.2 RS-232 Cable Connections

9 PIN

COMPORT

Model Number Description

CN606TC1 6 Zone T/C

CN606TC2 6 Zone T/C w/Extended Range

CN606RTD 6 Zone RTD (2 Wire)

CN606RTD-C 6 Zone RTD (2 Wire) Copper

CN612RTD 12 Zone RTD (2 Wire)

CN612RTD-C 12 Zone RTD (2 Wire) Copper

CN606RTD-3 6 Zone RTD (3 Wire)

CN606RTD-3C 6 Zone RTD (3 Wire) Copper

CN612TC1 12 Zone T/C

CN612TC2 12 Zone T/C w/Extended Range

(Open Collector Option)

CN606TC1-OC 6 Zone T/C

CN606TC2-OC 6 Zone T/C w/Extended Range

CN606RTD-OC 6 Zone RTD (2 Wire)

CN 6 06 RT D -O C- C 6 Zone RTD (2 Wire) Copper

SECTION 2

RS-232 COMMUNICATIONS

2.1 Description

NOTE: Minimum requirements to run RS-232 software is a PC

computer with Windows 95.

C

IN

OUT

SCANNER

PLUG

C

IN

OUT

SCANNER

PLUG

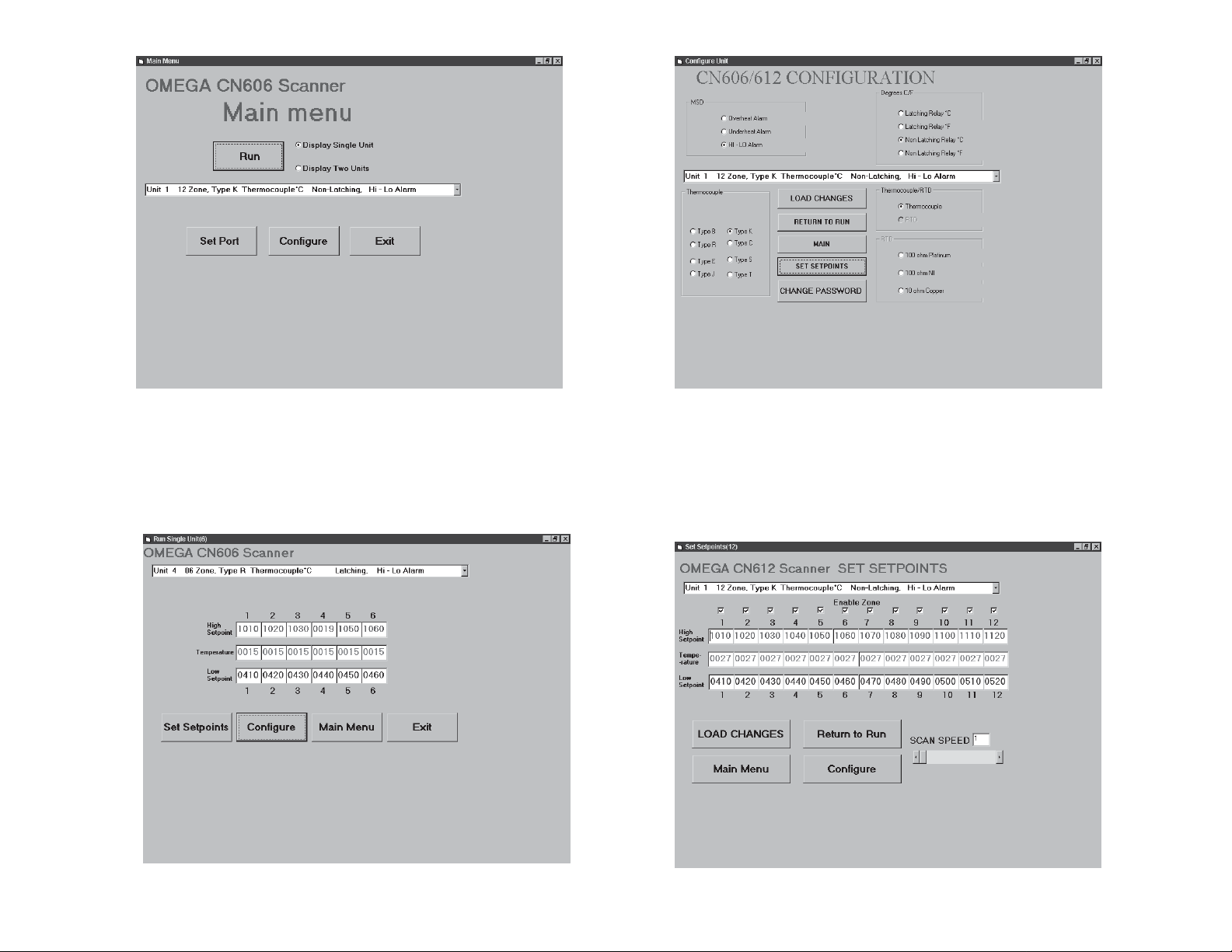

2.3 RS-232 PC Screens

3 WIRE CABLE

3 WIRE CABLE

5

3

2

25 PIN

COMPORT

7

2

3

Up to ten scanners can be connected in parallel to a single RS-232

communications port on a PC. Each scanner is assigned a serial number

from 0 to 9. The computer uses these numbers to determine which

scanner unit to address at a given time.

A simple set of menus is provided in the software which allows the

operator to change the settings of each connected scanner unit and

display individual operating parameters.

For users with advanced software capabilities, see Section 2.4 for an

operating protocol.

2

The following screen menus are provided:

1. SELECT PORT- Scans all available PC ports and indicates

which port is connected to scanners.

3

2. MAIN MENU- Allows the following operations:

• CONFIGURE UNIT allows individual unit type selection, including:

T/C Type, Temperature Scale, Latching or Nonlatching Alarm, and Hi,

Lo or Hi/Lo Alarm.

• RUN one unit display or two units simultaneously.

4

• SET SETPOINTS allows changes to individual unit Hi and Low

setpoints, scan time settings and allows zones to be enabled/disabled.

5

2.4 Operating Protocol for RS-232 Communications

The CN606 Scanner is designed with standard RS-232 three wire serial

communication capabilities. Up to ten scanners can be parallel connected

to a single PC. The transmission line is held in tristate to avoid cross-talk

between scanners except when the computer addresses a specific

scanner for communication.

Configuration

BAUD rate = 4800

Data bits = 8

Parity = N

Stop = 1 ( or 2 on some computers)

Communication software for the PC is written in Visual Basic. This

software package has been created to operate on PC Windows 95

platform meeting the minimum requirements.

Customers can communicate with CN606 scanners through a PC by

using the following protocol:

• Scanners will not initiate communication. The RS-232

Command Module (computer or similar device) must initiate.

• All communication is in ASCII format except Check Sum.

Check Sum is generated by hexadecimal addition with

carry of data string (one byte).

• To start communication, the Command Module must send

alert code ASCII [L] hex 4C. This commands the scanners to cease

RS232 communication and listen for an ID Code. The Command

Module then sends the Identification Number for the scanner that it

needs to address, ASCII [0 to 9] hex 30 to 39. The identified scanner

will then expect a command code. All the other scanners on-line will wait

for the next alert code.

• Command codes are divided into two groups:

ASCII Zones/ Alarms/ Scan time 15 bytes

1 byte [binary] zones 1 to 6 [0011 1 111] = (3F h)

1 byte [binary] zones 7 to 12 [0 011 1111] = (3F h)

1 byte [binary] zones 1 to 6 Hi alarm [0011 1111] = (3F h)

1 byte [binary] zones 7 to 12 Hi alarm [0011 1111] = (3F h)

1 byte [binary] zones 1 to 6 Lo alarm [0011 1111] = (3F h)

1 byte [binary] zones 7 to 12 Lo alarm [0011 1111] = (3F h)

2 digit scan time

+ check sum

ASCII Model/ Password/ ID#/ # of zones 13 bytes

4 digit model code 4 bytes

4 digit password 4 bytes

2 digit ID# 2 bytes

2 digit number of zones 2 bytes

+ check sum 1 byte

ASCII Coded Setpoints 97 bytes

12 zones, 4 digits each zone [Lo setpoint] 48 bytes

12 zones, 4 digits each zone [Hi setpoint] 48 bytes

+ check sum 1 byte

ASCII Coded Temperature 49 bytes

12 zones, 4 digits each zone 48 bytes

+ check sum 1 byte

Group 2. Commands preparing scanner to receive data:

ASCII [m] hex 6D = Model/ Password/ ID#

ASCII [e] hex 65 = Zone enable/ Scan time

ASCII [s} hex 73 = Setpoints

ASCII Model/ Password/ ID# 10 bytes

4 digit model code 4 bytes

4 digit password 4 bytes

1 byte ID 1 byte

+ check sum 1 byte

Group 1. Commands requesting data from the scanner:

ASCII [A] hex 41 = Zones/ Alarms/ Scan time

ASCII [M] hex 4D = Model/ Password/ ID#/ # of zones

ASCII [S] hex 53 = Setpoints

ASCII [T] hex 54 = Temperature

6

ASCII Zone enable/ Scan time 7 bytes

1 byte [binary] zones 1 to 6 [0011 1111] 2 bytes

1 byte [binary] zones 7 to 12 [0011 1111] 2 bytes

2 digit scan time 2 bytes

+ check sum 1 byte

7

ASCII Coded setpoints 97 bytes

12 zones, 4 digits each zone [Lo setpoint] 48 bytes

12 zones, 4 digits each zone [Hi setpoint] 48 bytes

+ check sum 1 byte

• The four digit code for model selection is as follows:

SECTION 3

INSTALLATION

3.1 Unpacking

Upon receipt of shipment, inspect the container and equipment

for any signs of damage. Take particular note of any evidence

of rough handling in transit. Immediately report any damage to

the shipping agent.

Digit 1. (msd)

0 = Overheat Alarm

1 = Underheat Alarm

2 = Hi/ Lo Alarm

Digit 2.

0 = Latching Relay °C

1 = Latching Relay °F

2 = Nonlatching Relay °C

3 = Nonlatching Relay °F

Digit 3. (preset at the factory)

0 = Thermocouple

1 = RTD

Digit 4. (Thermocouple units only)

0 = Type B

1 = Type C

2 = Type E

3 = Type J

4 = Type K

5 = Type R

6 = Type S

7 = Type T

Digit 4. (RTD units only)

0 = 100 ohm Platinum

1 = 100 ohm Nickel

2 = 10 ohm Copper

Remove the packing list and verify that all equipment has been

received. Each package should contain:

• Scanner (CN606 or CN612)

• Operator's Manual

• RS-232 Software

• Two mounting slides with screws

• Power plug (9 pin)

• RS-232 plug (3 pin)

• Two T/C plugs (6 pin)

• (CN612 only) Two Additional T/C plugs (6 pin)

If there are any questions about the shipment, please call the

Customer Service Department.

NOTE: The carrier will not honor any claims unless all shipping

material is saved for their examination. After examining and

removing contents, save packing material and carton in the event

reshipment is necessary.

3.2 Mounting

Select a location for the monitor that is free from excessive

shock, vibration, dirt, moisture and oil. Mount the monitor into a

3 5/8" (92mm) square cutout. The monitor as shipped is 1/4 DIN

(92mm square), so it does not have to be removed from it's

housing to be mounted.

Remove the two screws that secure the mounting slides. Remove

the slides and insert the case into the cutout from the front side

of the panel. Reinstall the two slides and two screws. The length

of the slides must be reduced if the monitor is to be mounted in

an extra thick panel.

8

9

Loading...

Loading...