Omega Products CN4420 Installation Manual

TABLE OF CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Model Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Outer Dimensions and Panel Cutout Size . . . . . . . . . . . . . . . . . . . . . . . 15

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Instructions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Front Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Autotuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Programming

1. Set Up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2. System Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix A: Autotuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix B: Manual Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Appendix C: Heater Burnout Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix D: Heat/Cool Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Quick Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2

INTRODUCTION

The OMEGA CN4420, CN4520, CN4620, and CN4720 Series controllers

are economical process controllers that accept temperature or process

inputs, and have sophisticated control capabilities, providing on/off

control, PID, or autotune PID, with Fuzzy Logic. The controllers have

common features, but differ in panel-size requirements. They are available with mechanical relay, 24 VDC SSR driver, or 4-20 mA output. They

also come with an 8-segment ramp/soak function.

The CN4420 units have single digital display for indication of process/

setpoint values. These are available with a single control output and

optional process alarm. They are used in conjunction with a socket.

The CN4520, CN4620, and CN4720 units have dual digital displays for

simultaneous indication of process value and setpoint. These units are

available with either single or dual outputs; dual output models can be

used for heat/cool, heat/heat or cool/cool control. Options available

include dual alarms (user-selectable between high/low and deviation

action), as well as an inoperative-heater alarm. The heater alarm is a

1A mechanical relay that is triggered when the heater current transformer senses that the heater is not getting power.

3

FEATURES

• Fuzzy Logic Control

• PID Autotune with manual over-

ride - heating or cooling

• Programmable control action -

reverse or direct

• Programmable cycle time

• Programmable inputs - Thermo-

couple/RTD or

DC Current/Voltage

• Sensor burn-out protection

• Zero/span calibration

• Outputs: Relay, Solid-state relay

drive, and 4-20mA DC

• Secondary output for

cooling (optional)

• High/low alarm

outputs (optional)

• Heater burnout alarm (optional)

(only on CN4520, CN4620,

CN4720)

• Menu driven format

• Setting – touch keys on front

panel

• Programmable 8-segment

ramp/soak function

• Digital filtering (to suppress

factory noise)

• Adjustable setpoint range

• Selectable °F/°C

• Offset adjustments

• Programmable decimal point

• Programmable lock feature

• Advanced security options to

prevent unauthorized parameter changes

• 4-digit, LED indication

• Output status indication

• Fault indication

• Non-volatile memory

• 1/16, 1/8, 1/4 DIN and 72mm

panel mount package

• NEMA 4X faceplate

• ABS plastic housing

• Termination– screw-down type

(CN4520, CN4620, CN4720) or

socket with screw-down

terminals (CN4420)

• Metal mounting bracket; plastic

bracket for CN4420

• 85 to 264V AC free voltage

power supply

• 24V AC/DC power supply

(optional)

• UL, C-UL recognized

• CE approved

4

SAFETY PRECAUTIONS

Before using this product, the user is requested to read the following

precautions carefully to ensure safety. The safety requirements are

classified as either “warning” or “caution” according to the following

explanations:

Warning

Wiring

1. If there is danger of serious accident resulting from a failure or

defect in this unit, provide the unit with an appropriate external

protective circuit to prevent an accident.

2. The unit is normally supplied without a power switch or a fuse. Use

power switch and fuse as required (Rating of the fuse: 250V, 1A)

Power supply

1. Be sure to use the rated power supply voltage to protect the unit

against damage and to prevent failure.

2. Keep the power off until all of the wiring is completed so that electric

shock and trouble with the unit can be prevented.

General

1. Never attempt to disassemble, modify, or repair this unit. Tampering

with the unit may result in malfunction, electric shock, or fire.

2. Do not use the unit in combustible or explosive gaseous atmospheres.

Warning

Caution

suggesting that the user's mishandling can

result in personal death or serious injury.

suggesting that the user's mishandling can result

in personal injury or damage to the property.

5

Caution

Installation

1. Avoid installing the unit in places where:

• the ambient temperature may reach beyond the range of -10 to 50°C

(14 to 122°F) while in operation

• the humidity may reach higher than 90% RH while in operation

• a change in the ambient temperature is so rapid as to cause

condensation

• corrosive gases (sulfide and ammonia gas, in particular) or

combustible gases are emitted

• the unit is subject to vibration or shock

• the unit is likely to come in contact with water, oil, chemicals, steam,

or vapor

• the unit is exposed to dust, salt, or air containing iron particles

• the unit is subject to interference with static electricity, magnetism,

or noise

• the unit is exposed to direct sunlight

• heat may be accumulated due to radiation

Maintenance

1. Do not use organic solvents such as alcohol or benzene to wipe this

unit. Use a neutral detergent.

6

UNPACKING

Remove the packing list and verify that you have received all equipment,

including the following (quantities in parenthesis):

• Process controller (1)

• Mounting bracket (1)

• Socket with CN4420 (1)

• Operator’s manual (1)

• Waterproof gasket (1)

• 250Ω precision resistor (when required) (1)

• Current transformer (when required) (1)

If you have any questions about the shipment please call the OMEGA

Customer Service Department.

When you receive the shipment, inspect the container and equipment for signs

of damage. Note any evidence of rough handling in transit. Immediately report

any damage to the shipping agent.

Note:

The carrier will not honor damage claims unless all shipping materials are

saved for inspection. After examining and removing contents, save packing

material and carton in the event reshipment is necessary.

7

MODEL DESCRIPTION

Single Output Models

_________________________________________________________________

CN4421(*)-(**) 1/16 DIN controller

CN4521(*)-(**) 1/8 DIN controller

CN4621(*)-(**) 1/4 DIN controller

CN4721(*)-(**) 72 mm sq. controller

_________________________________________________________________

Dual Output Models

_________________________________________________________________

CN4522(*)-(**)-(***) 1/8 DIN controller

CN4622(*)-(**)-(***) 1/4 DIN controller

CN4722(*)-(**)-(***) 72 mm sq. controller

_________________________________________________________________

* Specify TR for Thermocouple/RTD input or CV for current/voltage input

** Specify first output code from Output Options table below

*** Specify second output code from Output Options table below

OUTPUT OPTIONS

_________________________________________________________________

Option Type First Output Second Output*

_________________________________________________________________

Relay -R1 -R2

DC SSR driver -D1 -D2

4-20 mA -F1 -F2

_________________________________________________________________

* Available on CN4522, 4622, and 4722 models only

ALARM OPTION FOR CN4421

_________________________________________________________________

-A Single alarm

ALARM OPTIONS FOR CN4520, 4620, AND 4720 SERIES

_________________________________________________________________

-A2 Dual alarms

-H30* Heater burnout alarm, includes 0 to 30A current transformer

-H50* Heater burnout alarm, includes 20 to 50A current transformer

_________________________________________________________________

* Not available with options F1 or F2

All alarm relays share the same common

Both process and heater burnout alarm can be selected at the same time

LOW VOLTAGE POWER SUPPLY OPTION

_________________________________________________________________

-24V 24V AC/DC, 50/60 Hz

MODEL CONFIGURATION

SPECIFICATIONS

INPUT RANGE TABLE:

_________________________________________________________

Input Signal Input Range Input Range Remarks

(°C) (°F)

_________________________________________________________

Thermocouple*

J 0 ~ 800 32 ~ 1472 Cold Junction

K 0 ~ 1200 32 ~ 2192 compensating

R 0 ~ 1600 32 ~ 2912 function built-in

B 0 ~ 1800 32 ~ 3272

S 0 ~ 1600 32 ~ 2912

T -199 ~ 200 -328 ~ 392

T -150 ~ 400 -238 ~ 752

E -199 ~ 800 -328 ~ 1472

N 0 ~ 1300 32 ~ 2372

PL2 0 ~ 1300 32 ~ 2372

_________________________________________________________

RTD*

Pt100 -150 ~ 850 -238 ~ 1562 Allowable wiring

α= .00385 resistance 10 ohms

max (per wire).

_________________________________________________________

DC Voltage/

Current**

1-5V Scaling Range: -1999 to 9999 For current input, use

0-5V Engineering the 250Ω resistor to

4-20mA units obtain 1-5V DC or

0-20mA 0-5V DC input.

_________________________________________________________

* For TR models

** For CV models

See also the description for parameter P-n2 in the programming section, on

how to program for a particular input.

8

9

CONTROL FUNCTION

(SINGLE OUTPUT)

_________________________________________________________

Control action PID control with auto-tuning

Fuzzy control with auto-tuning

_________________________________________________________

Proportional band (P) 0-999.9% of full scale (FS), setting in 0.1% steps

_________________________________________________________

Integral time (I) 0-3200 sec, setting in 1 sec steps

_________________________________________________________

Differential time (D) 0-999.9 sec, setting in 0.1 sec steps

_________________________________________________________

P,I,D = 0: On/off action

I,D = 0: Proportional action

_________________________________________________________

Proportional cycle 1-150 sec, setting in 1 sec steps, for relay contact

output and DC SSR driver output only

_________________________________________________________

Hysteresis width 0-50% FS, setting in 1 E.U.(Engineering Units) steps

On/Off action only

_________________________________________________________

Anti-reset wind up 0-100% FS, setting in 1 E.U. steps, auto-setting

with auto-tuning

_________________________________________________________

Input sampling cycle 0.5 sec

_________________________________________________________

CONTROL FUNCTION

(DUAL OUTPUT) (Heat/Cool Type) CN4522, CN4622, CN4722 only

_________________________________________________________

Heating Proportional band P x 1/2 (P= 0-999.9%)

_________________________________________________________

Cooling Proportional band Heating proportional band x Cooling proportional

band coefficient

Cooling proportional band coefficient= 0-100

0: On/Off action

_________________________________________________________

Integral time 0-3200 sec for heating and cooling

_________________________________________________________

Differential time 0-999.9 sec for heating and cooling

_________________________________________________________

10

_________________________________________________________

P,I,D= 0: On/Off action (without dead band) for heating and cooling

I,D= 0: Proportional action

_________________________________________________________

Proportional cycle 1-150 sec, for relay contact output and DC SSR

driver output only

_________________________________________________________

Hysteresis width On/Off action for heating and cooling: 0.5% FS

On/Off action for cooling: 0.5% FS

_________________________________________________________

Anti-reset wind-up 0-100% FS, setting in 1 E.U. steps, auto-setting

with auto-tuning

_________________________________________________________

Overlap/dead band ±50% of heating proportional band

_________________________________________________________

Input sampling cycle 0.5 sec

_________________________________________________________

OUTPUT

(Single Output)

_________________________________________________________

Control output One of the following three types is selected:

(1) Relay contact (SPDT)

220V AC/30V DC, 3A (resistive load)

Mechanical life: 10

7

times (under no load)

Electrical life: 10

5

times (under the rated load)

(2) DC SSR driver (voltage pulse):

15-30V DC at ON/0.5V DC or less at OFF.

Current: 60mA or less.

(3) 4-20mA DC:

Allowable load resistance– 600Ω or less.

_________________________________________________________

11

OUTPUT

(Dual Output) CN4522, CN4622, CN4722 only

_________________________________________________________

Control output For dual output type, one of the following three

types is selected on both heating and cooling types:

(Not available on CN4420)

(1) Relay contact (SPDT):

220V AC/30V DC, 3A (resistive load)

(2) DC SSR driver (voltage pulse):

15-30V DC at ON/0.5V DC or less at OFF.

Current: 60mA or less

(3) 4-20mA DC:

Allowable load resistance – 600Ω or less

(Note: When DC SSR driver output for heating/

cooling side is selected, the total current should

be less than 60mA)

_________________________________________________________

ALARM

_______________________________________________________

Alarm output Relay contact (SPST),

220V AC/30V DC, 1A (resistive load)

CN4420: 1 point, Other types: 2 points

_______________________________________________________

Heater burnout Relay contact (SPST),

alarm output 220V AC/30V DC, 1A (resistive load)

Not available on CN4420

_______________________________________________________

SETTING AND INDICATION

_________________________________________________________

Parameter setting method Digital setting with eight keys

_________________________________________________________

PV/SV display method CN4420: PV/SV red display, 4 digits

CN4520, CN4720, CN4620: Dual display for PV/SV

4 digits each, PV= red, SV= green

_________________________________________________________

12

_______________________________________________________

Status display Control output, alarm output, heater burnout

alarm output (on CN4520, 4620 and 4720 only).

_______________________________________________________

Indication accuracy Thermocouple: ±0.5% FS ±1 digit ±1°C

(at 23°C) R thermocouple: 0-400°C; ±1% FS ±1 digit ±1°C

B thermocouple: 0-500°C; ±5% FS ±1 digit ±1°C

RTD, voltage, current: ±0.5% FS ±1 digit

_______________________________________________________

GENERAL SPECIFICATIONS

_______________________________________________________

Rated voltage 85-264V AC, 50/60 Hz, or 24V AC/DC ±10%

_______________________________________________________

Power consumption 10VA or less (100V AC)

15VA or less (240V AC)

_______________________________________________________

Insulation resistance 50MΩor more (500V DC)

_______________________________________________________

Withstand voltage Power source-Earth: 1500V AC, 1 min

Power source-input terminal: 1500V AC, 1 min

Earth-relay output: 1500V AC, 1 min

Earth-Alarm output: 1500V AC, 1 min

Between other terminals: 500V AC, 1 min

_______________________________________________________

Input impedance Thermocouple: 1MΩ or more

Voltage: 450KΩor more

Current: 250Ω (external resistor)

_______________________________________________________

Allowable signal Thermocouple: 100Ω or less

source resistance Voltage: 1KΩ or less

_______________________________________________________

Allowable wiring RTD: 10Ω or less per wire

resistance

_______________________________________________________

Reference junction ±1°C (at 23°C)

compensation accuracy

_______________________________________________________

13

_______________________________________________________

Process variable offset ±10% FS

_______________________________________________________

Setpoint variable offset ±50% FS

_______________________________________________________

Input filter 0-900.0 sec, setting in 0.1 sec steps

(primary lagging filter)

_______________________________________________________

Noise rejection ratio Normal mode noise (50/60Hz): 50dB or more

Common mode noise (50/60Hz): 140dB or more

_______________________________________________________

POWER FAILURE PROTECTION

_______________________________________________________

Memory protection: Non-volatile memory. Parameter values

remain unchanged with disruption of power.

Ramp/soak function has to be re-initiated.

_______________________________________________________

OPERATING AND STORAGE CONDITIONS

_______________________________________________________

Operating temperature -10 to 50°C (14 to 122°F)

_______________________________________________________

Operating humidity Less than 90% RH (non-condensing)

_______________________________________________________

Storage temperature -20 to 60°C (-4 to 140°F)

_______________________________________________________

ADDITIONAL FUNCTIONS

_______________________________________________________

8-segment ramp-soak: 4 ramp/4 soak with 16 different modes

Setpoint setting: 0-100% FS

Ramp/soak period: 0-99 hrs 59 mins

_______________________________________________________

Parameter mask: Parameters can be masked from being displayed

_______________________________________________________

Self-diagnosis: Watchdog timer monitors program error

_______________________________________________________

14

STRUCTURE

_______________________________________________________

Mounting method Panel mounting or surface mounting

Surface mounting: CN4420 only

_______________________________________________________

External terminal CN4420: 8-pin or 11-pin socket

Other types: screw terminal (M3.5 screw)

_______________________________________________________

Enclosure Black ABS plastic

_______________________________________________________

Dimensions CN4420 48 x 48 x 85.7mm (1/16 DIN)

1.89 x 1.89 x 3.37 in. (W x H x D)

CN4520 52.5 x 100.5 x 95.8mm (1/8 DIN)

2.07 x 3.96 x 3.77 in. (W x H x D)

CN4620 100.5 x 100.5 x 95.8mm (1/4 DIN)

3.96 x 3.96 x 3.77 in. (W x H x D)

CN4720 76.5 x 76.5 x 95.8mm (72 mm)

3.01 x 3.01 x 3.77 in. (W x H x D)

_______________________________________________________

Weight CN4420 approx. 150g (0.33 lb)

CN4520 approx. 300g (0.66 lb)

CN4620 approx. 400g (0.88 lb)

CN4720 approx. 300g (0.66 lb)

_______________________________________________________

Protective structure Front panel: NEMA 4X (equivalent to IEC IP66)

Protection against corrosion, windblown dust

and rain, and hose-directed water.

Rear case: IEC IP20; Protection against solid

objects up to 12mm.

_______________________________________________________

Installation category II

_______________________________________________________

Pollution degree 2

_______________________________________________________

15

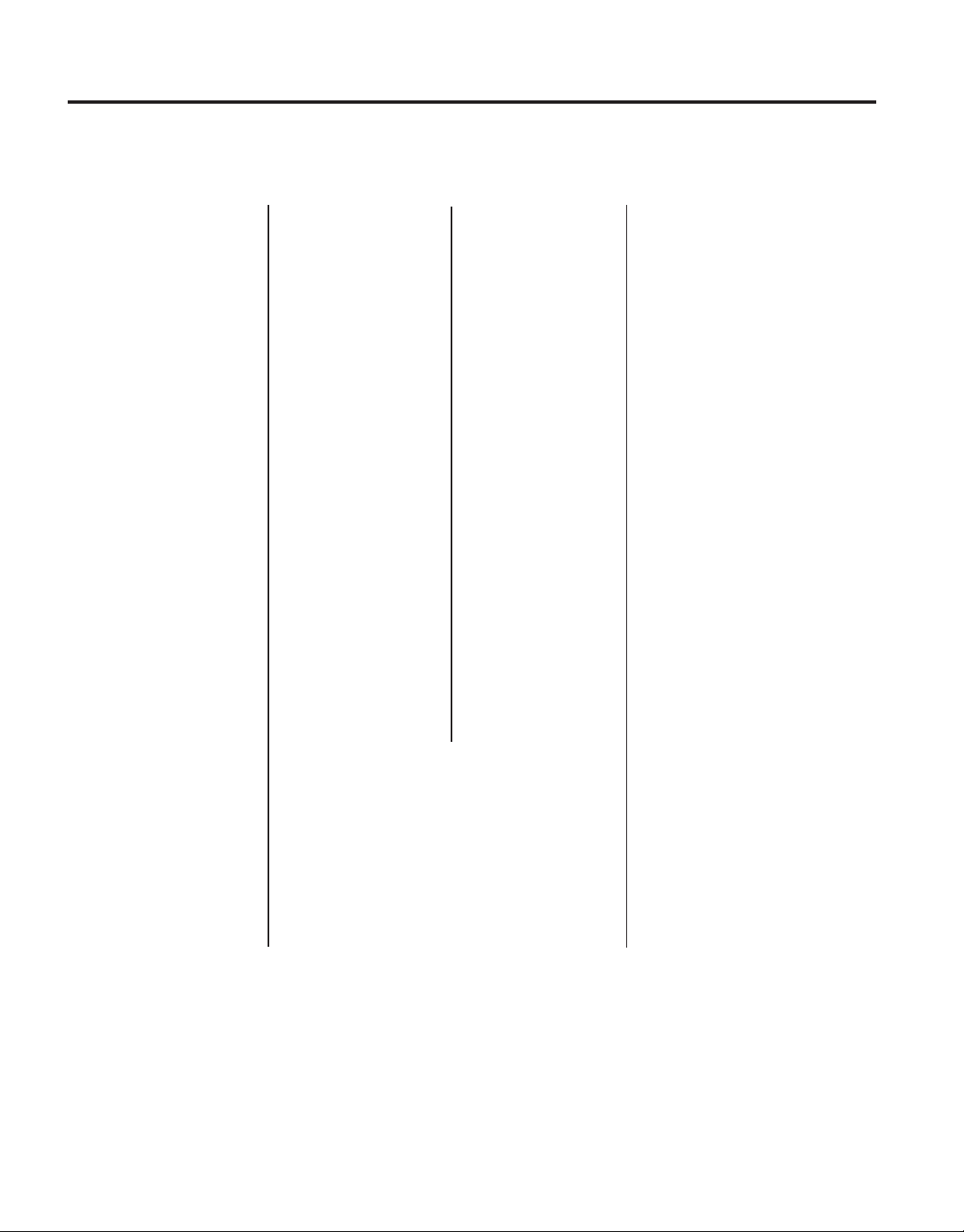

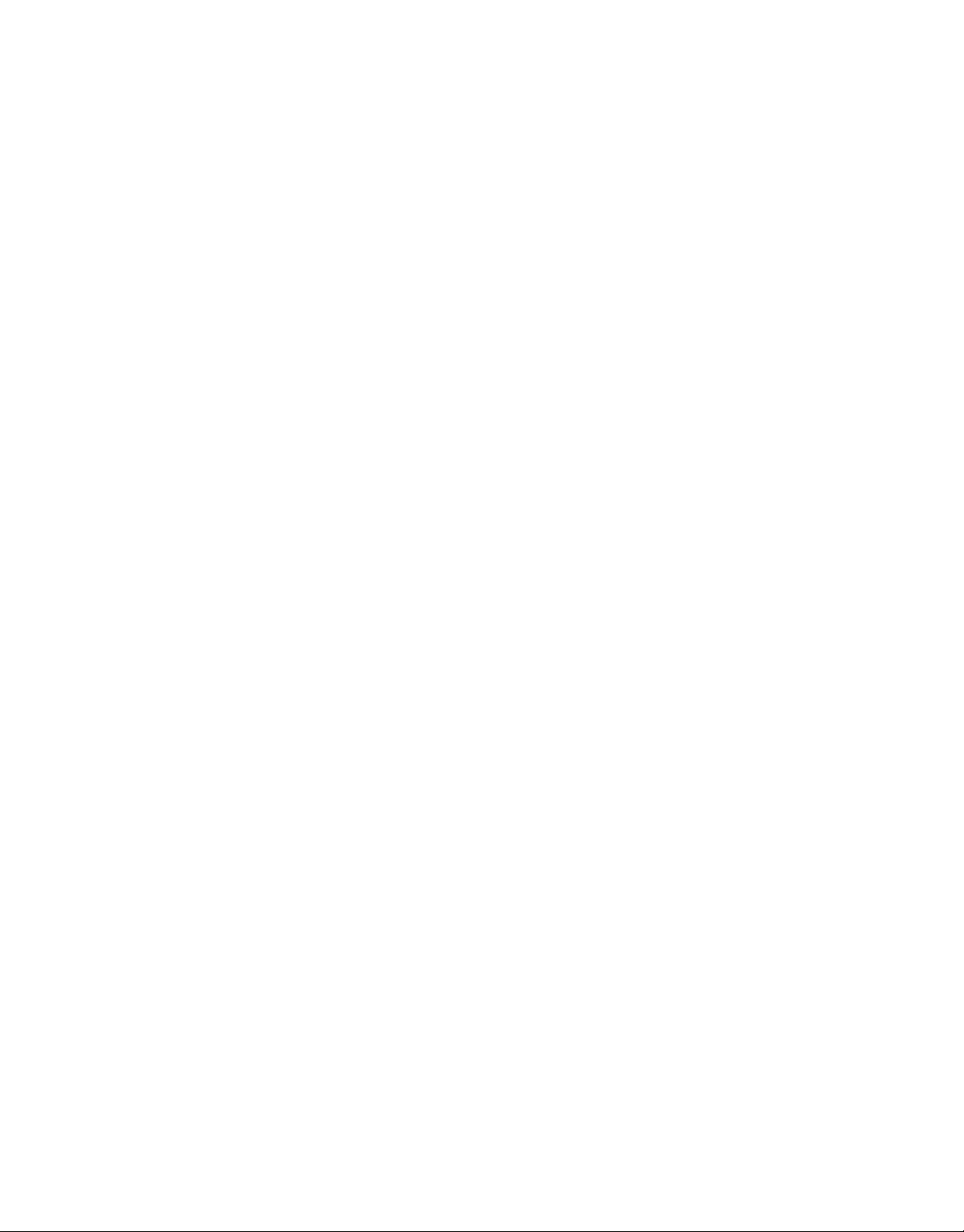

OUTER DIMENSIONS AND PANEL CUTOUT SIZE

CN4420

Mounting bracket

Panel cutout size: when installing

“n” numbers of units.

A

A

B

B

Unit: mm (in.)

Panel thickness: 1 to 8 mm (0.04 to 0.31)

+0.5(0.02)

-0

B: 45 (1.77)

A: 63 (2.48) or more

7

(0.28)

48 (1.89)

85.7 (3.37)

71.5 (2.81)

F

48 (1.89)

CPVH L

SV

SEL

48 (1.89)

DATA ENTPV/SV

Gasket

57 (2.24)

57 (2.24)

44.8 (1.76)

9.5

(0.37)

Panel

16

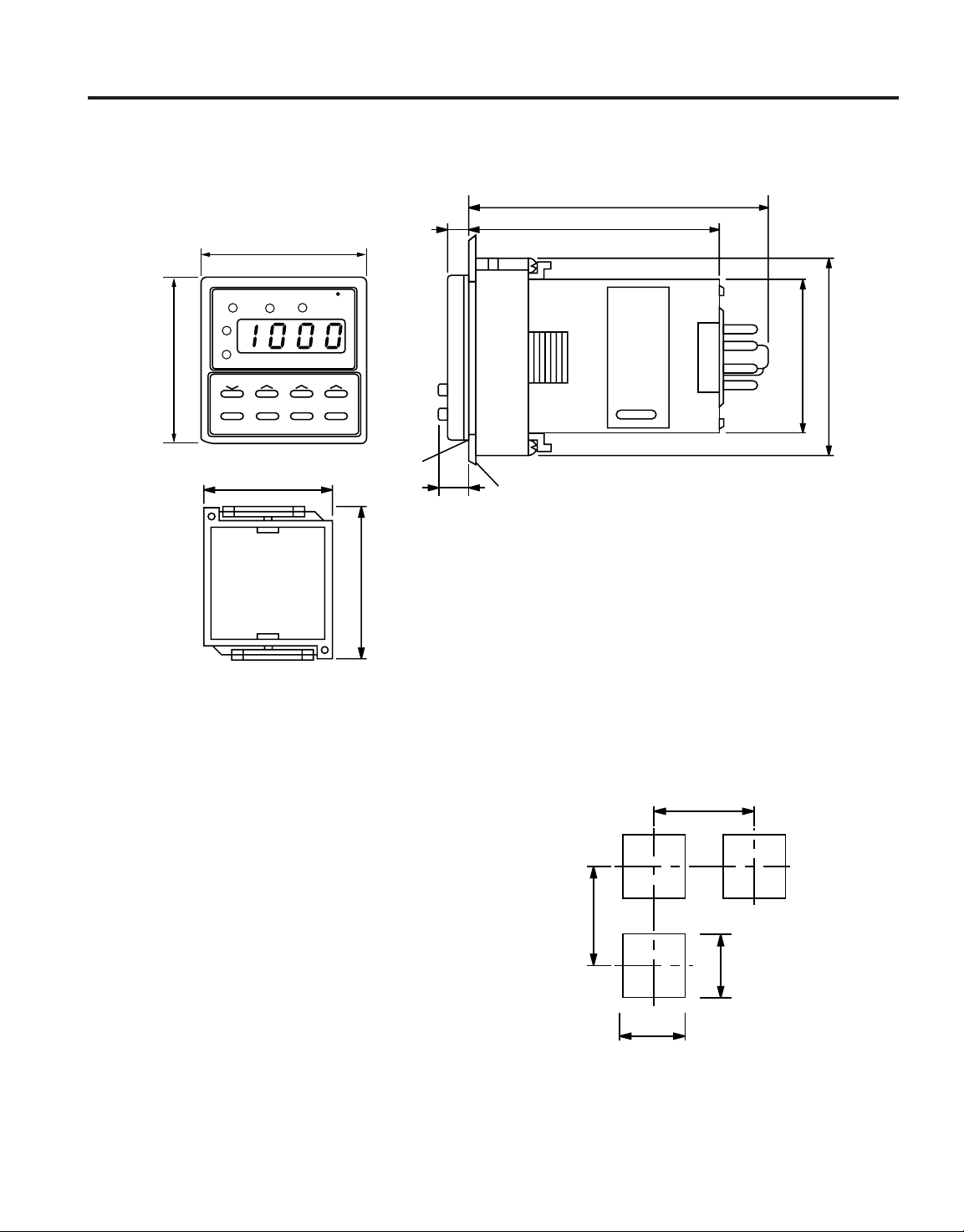

CN4520, CN4720, CN4620

F

C1

PV

SV

A

B

95.8

DC

C2 H HBL

SEL DATA ENTSV

16.2

18.7

Panel

Gasket

Model

CN4520

CN4720

CN4620

A

52.5

76.5

100.5

B

100.5

76.5

100.5

C

90.5

67

90.5

D

114.5

91

114.5

E

45

68

92

0.6

-0

0.7

-0

0.8

-0

F

92

68

92

0.8

-0

0.7

-0

0.8

-0

G

120Min.

96Min.

120Min.

H

92Min.

116 Min.

140 Min.

2.07 3.96

3.56 4.51 1.77

0.02

-0

3.62

0.03

-0

4.72Min.3.62Min.

3.01

3.01

2.64 3.58 2.68

0.03

-0

2.68

0.03

-0

3.78Min. 4.57 Min.

3.96

3.96

3.56 4.51 3.62

0.3

-0

3.62

0.03

-0

4.72Min. 5.51Min.

mm

in.

mm

in.

mm

in.

Units

Unit: mm (in.)

Panel thickness: 1 to 8 mm (0.04 to 0.31)

Panel cutout size: when installing

“n” numbers of units.

E

H

G

F

17

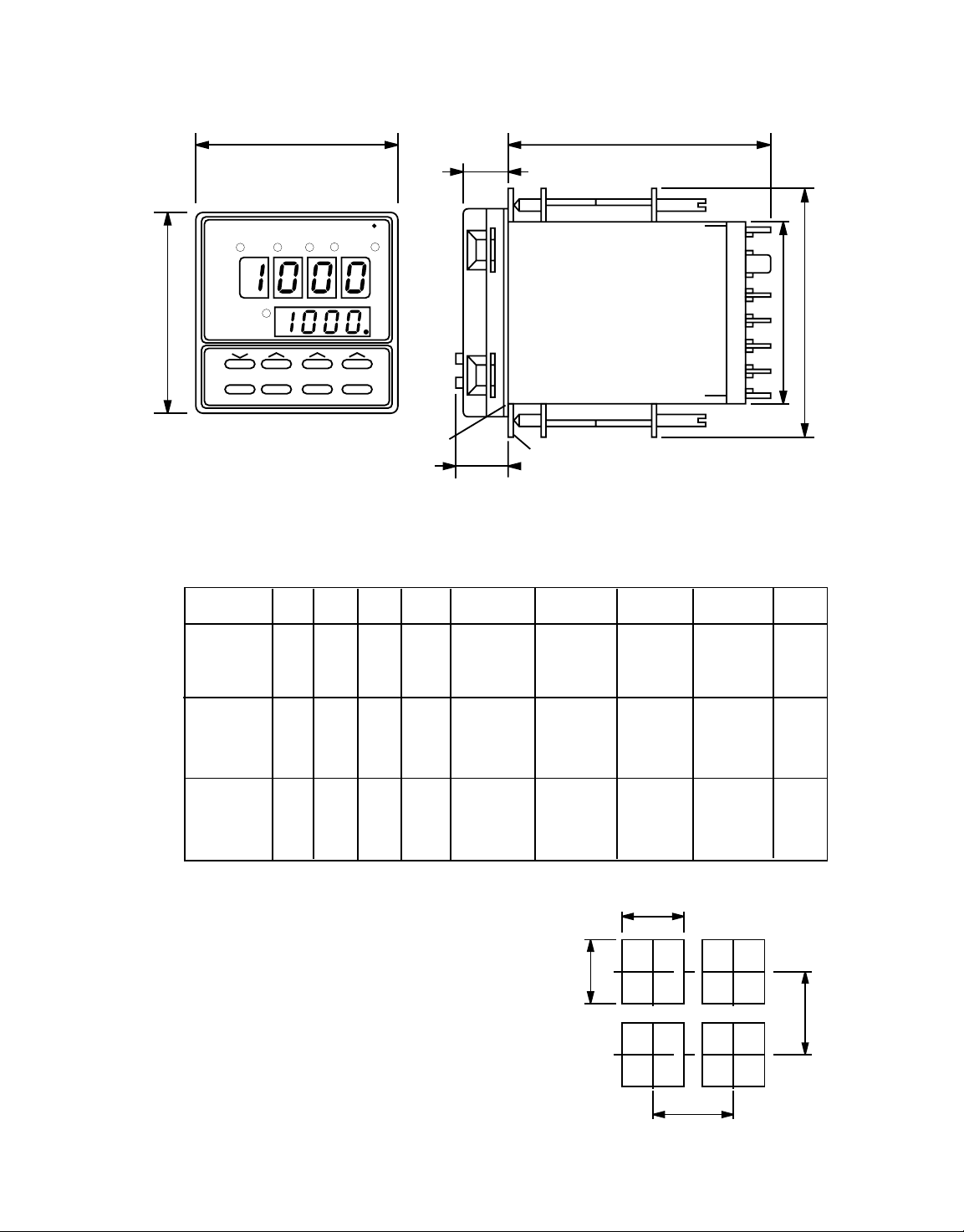

NEMA 4X Integrity

The front side of this instrument conforms to NEMA 4X. To ensure the

waterproofness between the instrument and the panel, use the gasket

that is provided with the unit according to the installation procedure

described below.

How to install the unit

For CN4520, CN4620, CN4720 Series install the two metal brackets, one

on the top and the other on the bottom, and tighten the screws to a

torque of about 14.7N-cm (1.5kg-cm). For CN4420 install the unit in the

panel as shown below, and tighten the screws on the mounting bracket

until the unit is secure. Make sure there is no space between the front

side of the unit and the gasket, and between the gasket and the panel.

Caution: After the mounting bracket is installed, check the gasket for

any displacement as shown in Figure 3.

INSTALLATION

Figure 1 Figure 2

Front Gasket Case

Unit

Unit

Panel Panel Mounting bracket Screw

Gasket Gasket

Case Case

Figure 3

(Bad) (Good)

WIRING INSTRUCTIONS

18

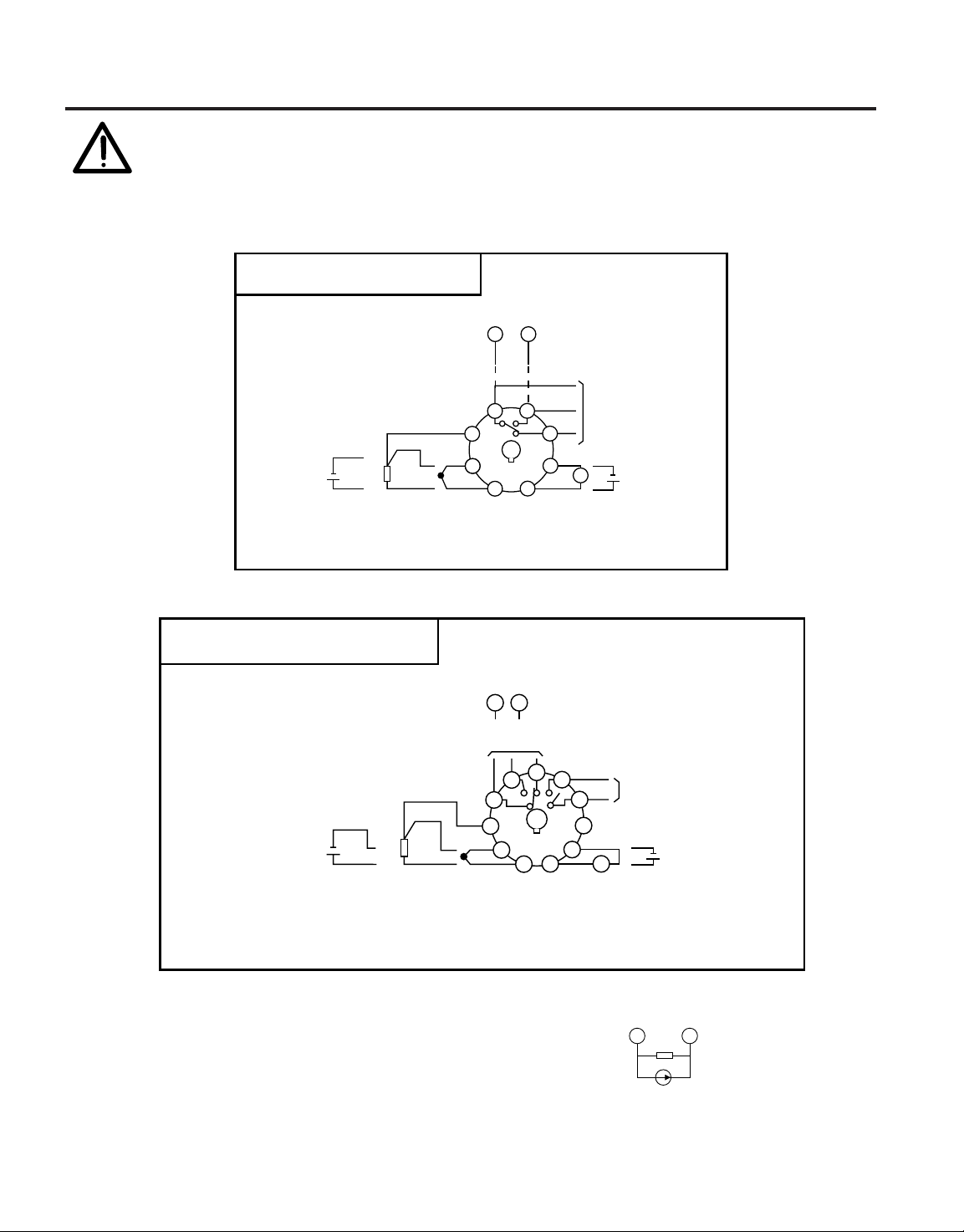

CN4421-A (with alarm)

1

2

3

4

5

6

7

8

9

10

11 ~

+

–

B

B

A

–

+

Current output, DC SSR driver output

Contact output

*Voltage/

current

Alarm output

Thermocouple

input

Power supply

(viewing from the

back of instrument)

–

+

RTD

* For current input, install the 250Ω precision

resistor (accessory) before using the unit.

Warning

Be sure to use the rated power supply voltage and polarity.

CN4421 (without alarm)

Current output, DC SSR driver output

RTD

*Voltage/current

B

–

B

A

+

–

+

Thermocouple

input

(viewing from the back

of instrument)

+

–

5

4

3

2

1

6

7

8

~

Contact output

–

Power supply

+

–

+

250Ω

–

+

19

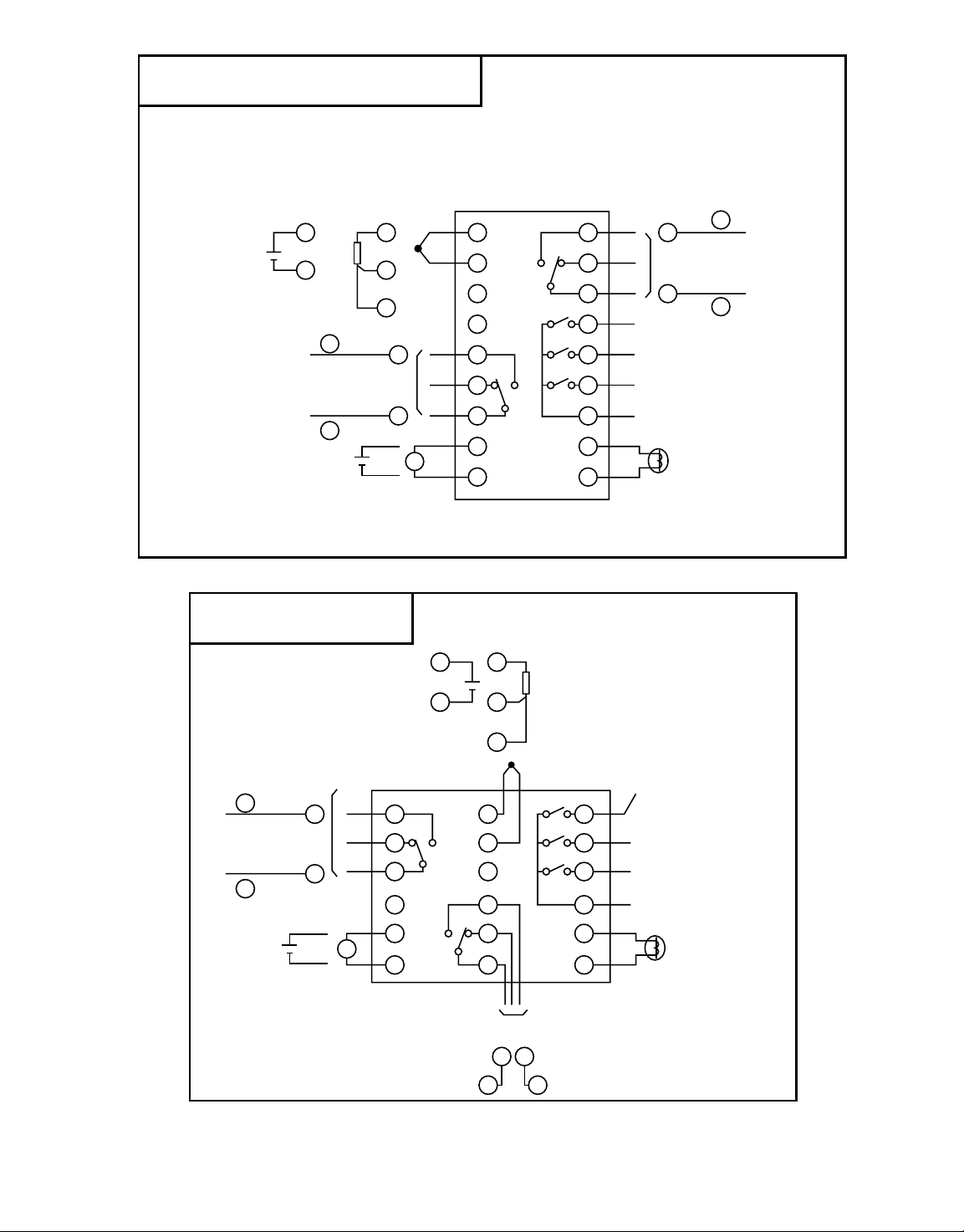

CN4520, CN4620 Series

*Voltage/

Current

Current output,

DC SSR driver

output

Control output 1

Power supply

CN4720 Series

Current output,

DC SSR driver output

+

Control output 1

–

Power supply

input

1

2

RTD

+

–

*Voltage/

Current

1

3

+

~

–

A

1

B

2

B

3

+

–

input

Current output, DC SSR

driver outputT.C.

+

1

–

2

3

4

5

7

5

6

7

8

10

11

12

13

14

15

16

17

10

Control output 2

(on the cooling side)

12

Alarm 1 (upper limit alarm)

Alarm 2 (lower limit alarm)

Heater burnout alarm

Common

+

–

~

9

18

CT input

RTD

A

7

8

7

B

8

B

9

–

+

T.C.

Alarm 1

(Upper limit alarm)

1

2

3

4

5

10

11

7

8

9

13

14

15

16

17

Alarm 2

(Lower limit alarm)

Heater burnout

alarm output

Common

CT input

6

12

18

Control output 2(on the cooling side)

1012

Current output, DC SSR

–

driver output

+

20

Wiring Power to the Controller

• Be sure to use the rated power supply voltage and polarity for the unit

to protect it against damage and failure.

• Keep the power off until all of the wiring is completed to prevent

electric shock and abnormal operation.

• Keep the power supply wires separated from the input and output

wires.

• Power connections should be made with 18-gauge or larger insulated

wire. Stranded wire improves noise immunity. Noise filters and isolation transformers are recommended in case of noisy power lines.

• When the Heater Burnout option is selected, use the same power line

for both the controller and the heater.

Wiring Inputs

There are two input categories available: Thermocouple/RTD or

current/voltage. Make sure you have the right type before wiring the

inputs. Refer to Table of Input Type Codes and set the parameter

“P-n2” accordingly.

Note: In order to minimize the risk of high frequency noise induced by

coils and windings in relays, solenoids, and transformers, use leads

which have braided shield and ground one end of the sheath. Keep

your input leads separate from power and output leads. If you have to

bring the input signal from a long distance, a signal transmitter might be

needed to maintain an accurate reading; in this case, a unit that

accepts current/voltage input would be necessary.

Thermocouple

• Connect thermocouples directly to the input terminals whenever

possible.

21

• If using extension wires, make sure they are of the same thermocouple material and grade; any dissimilar metal junctions will lead to

erroneous readings.

• Ungrounded thermocouples are recommended for optimal performance and to prevent ground loops.

• Make sure the polarity is correct.

RTD Pt100

• Use a 3-wire Pt100Ω RTD whenever possible. All three wires must

have low lead resistance (less than 10Ω) and no resistance differen-

tials among them.

• If using a 2-wire RTD, jumper the two B-legs with a wire of equal

resistance.

• Make sure A and B leads are connected to the right terminals.

Current/Voltage

• The controller accepts 1-5V, 0-5V, 4-20mA, and 0-20mA DC signals. If

wiring for a voltage input, feed the signal directly to the input termi-

nals. For current inputs, first connect the 250Ω precision resistor that

comes with the unit.

• Make sure the polarity is correct.

Wiring Outputs

Before wiring the outputs, make sure the unit has the right kind of

control output, and that all the load handling devices conform to the

controller specifications. Note that it takes 5 seconds for the outputs to

activate after the power is turned on.

Refer to parameter “P-n1” and to the Table of Output Type Codes to

choose the preferred type of control action– reverse-acting or directacting.

22

If using two outputs in a heat/cool type control, please refer to Appendix D for more details.

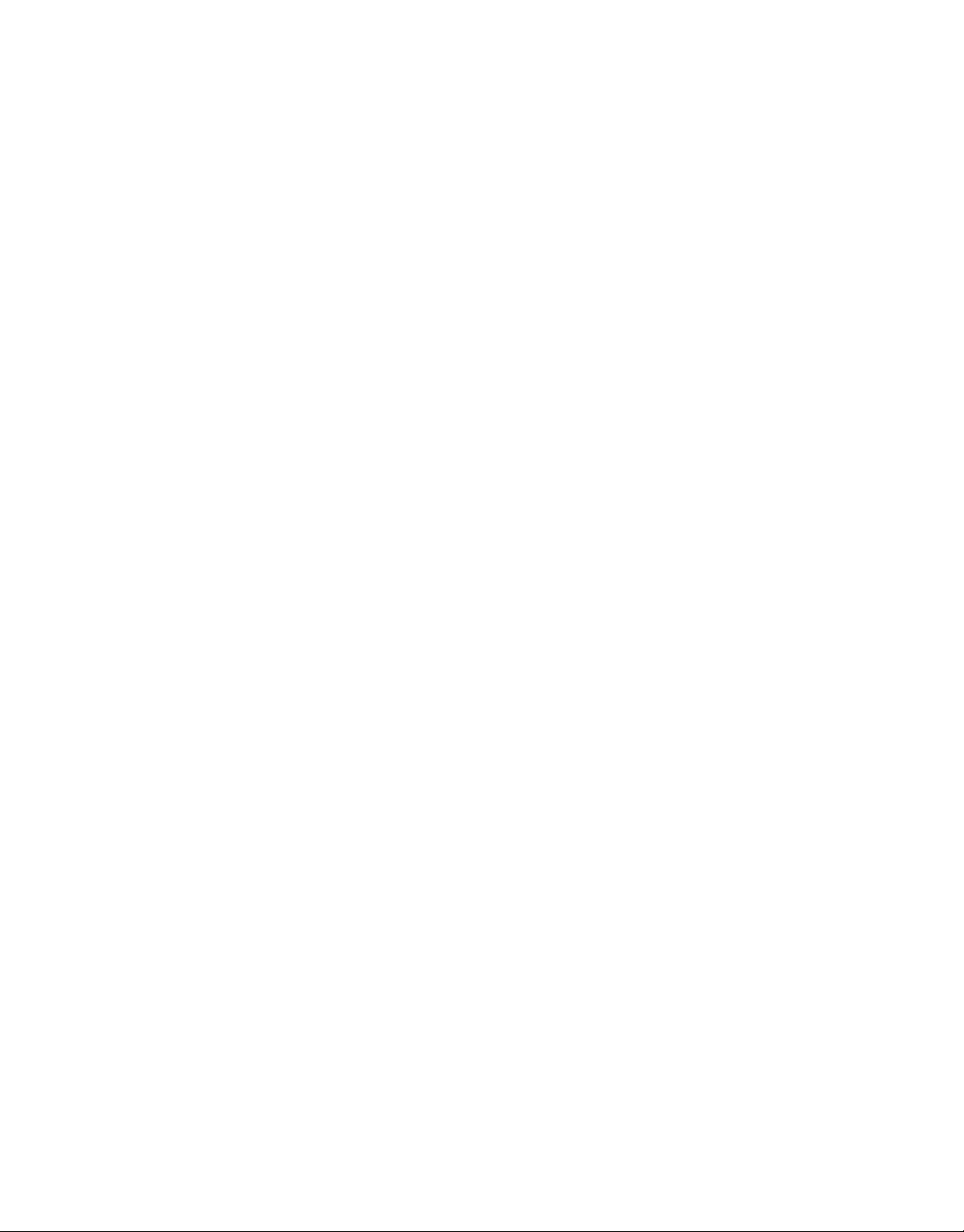

Relay

• Connecting a load to full capacity of the relay will shorten the relay

life, especially if it is operated at a rapid rate. To protect the output

relay, an external relay or a contactor should be used. If a higher

current rating is required, a solid-state relay driver type output is

recommended.

• Connect the load between the normally opened contacts of the relay.

This way, if power to the controller is disrupted, the output circuit

would open, preventing the load from running out of control.

• Set the proportional time cycle parameter, “TC” to 15 secs. or more

(30 secs. typical).

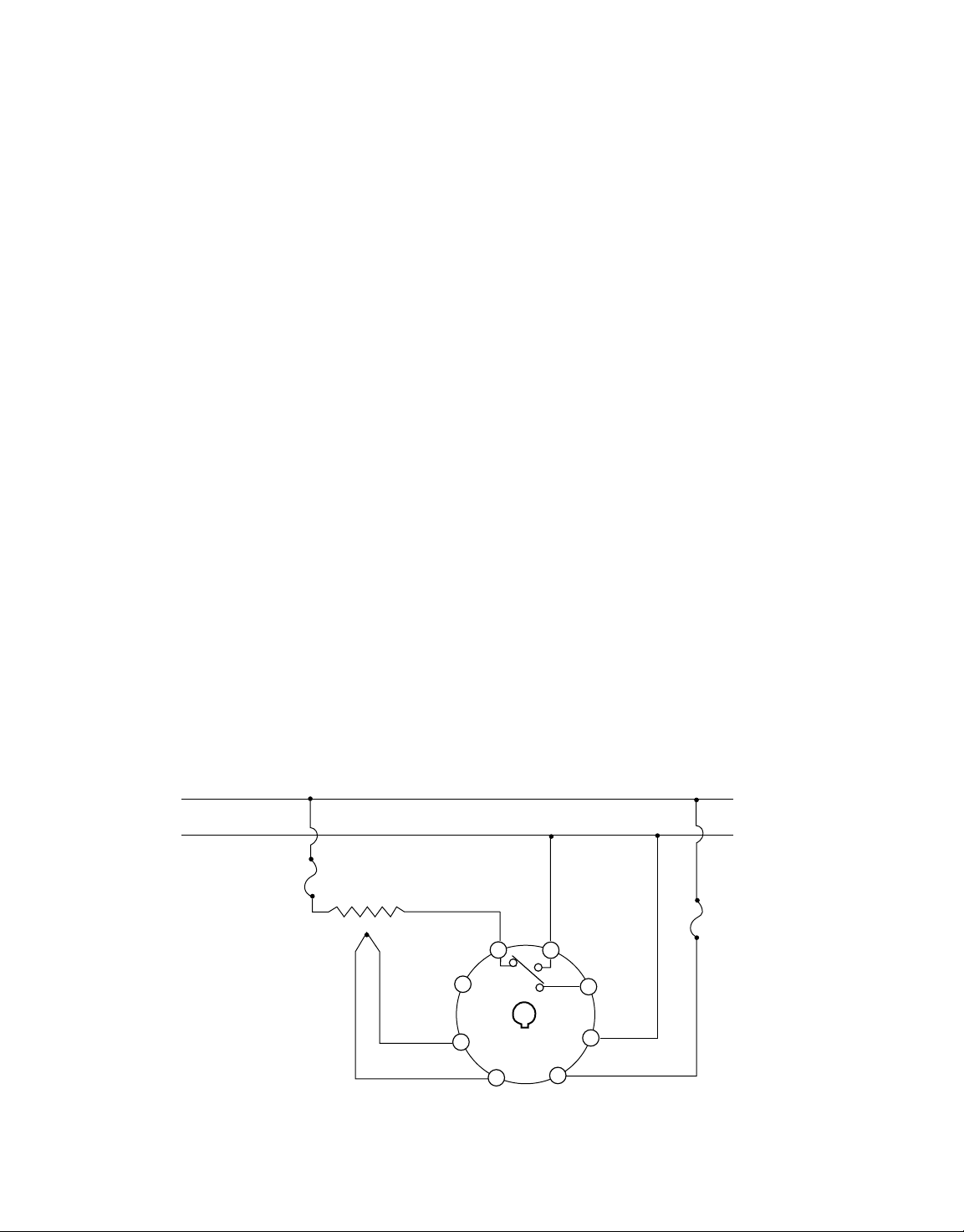

• Use of MOV circuit is recommended to

protect the relay against switching

surges and to ensure the product’s long

life. Connect it between the contacts of

the relay as shown in the example.

Part No.:

MOV-100

(power supply voltage: 100V)

MOV-200 (power supply voltage: 200V)

DC SSR Driver (voltage pulse)

• The non-isolated DC output is used to drive an external load-handling

device such as Solid-State Relay(SSR) or Solid-State Contactor(SSC).

• The total current drawn, for both single and dual outputs, should be

within the allowed value.

• Make sure the polarity is correct.

• Set the proportional time cycle parameter, “TC” to 1 sec. or more.

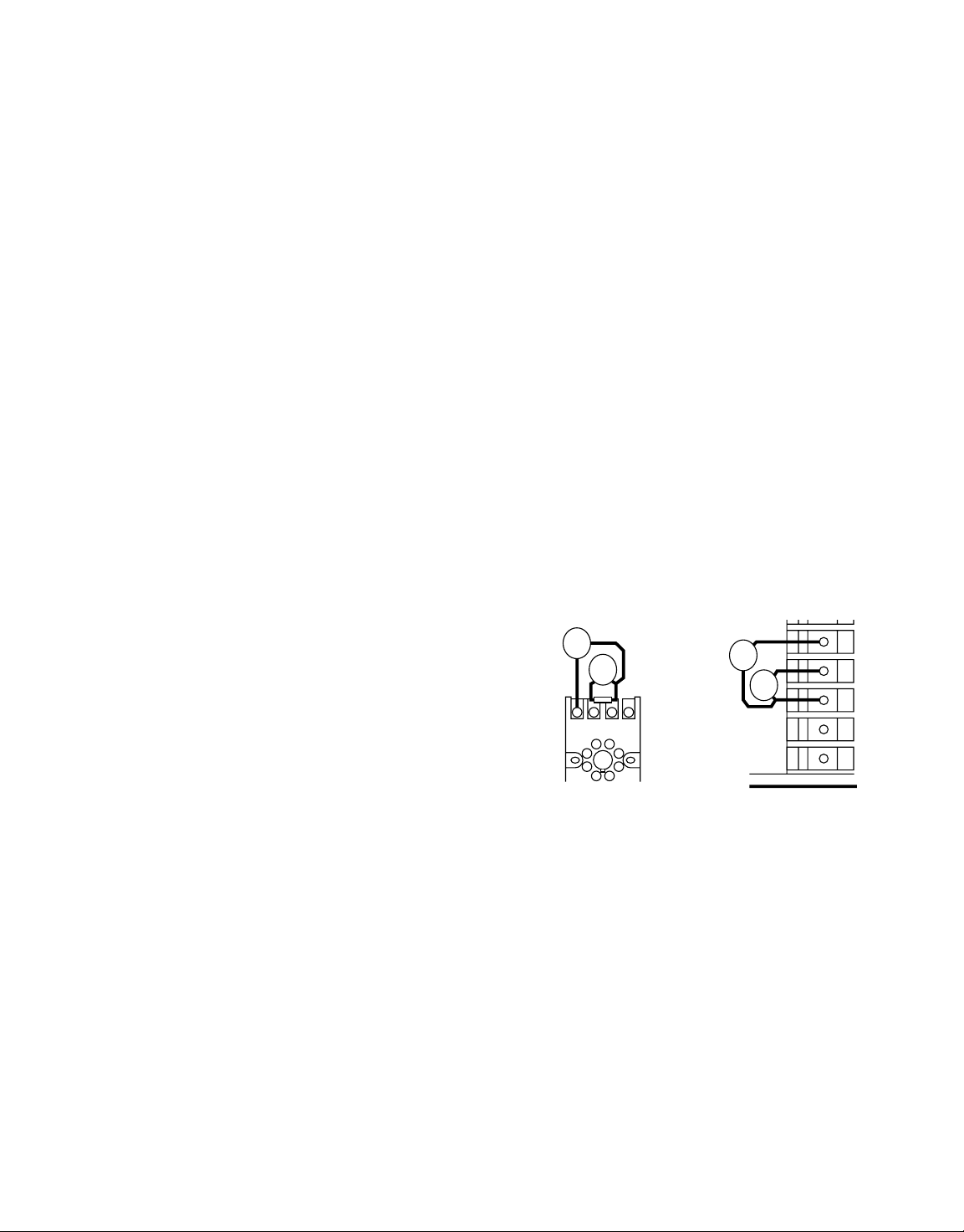

6543

5

6

7

8

9

CN4420

(8-pin)

CN4620

23

4 to 20mA DC

• The output is a non-isolated analog signal used to drive a variety of

output devices such as SCRs and valve actuators.

• The load resistance must be less than 600Ω.

• Make sure the polarity is correct.

• The proportional time cycle parameter, “TC” is set to 0, and is not displayed on the programming menu.

Wiring Alarms

• Make sure the load does not exceed the rated capacity of the relay.

• Several types of alarm configurations can be programmed and does

not require a change in the wiring. Refer to parameters AL, AH, P-AH,

P-AL, P-An.

• For details on Heater Burnout alarm, please refer to Appendix D and

the Heater Burnout Alarm Setpoint parameter “Hb” in the programming section.

System Wiring Diagram

Example:

L

120V AC

N

Fuse

(250V, 3A)

CN4421TR-R1

Heater (3A or less)

–

+

Thermocouple

Input

Relay Contact

Output

4

3

2

1

5

6

7

8

Fuse

(250V, 1A)

Power

85 to 264 VAC

50/60Hz

Loading...

Loading...