Page 1

TABLE OF CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CN4321

Model Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

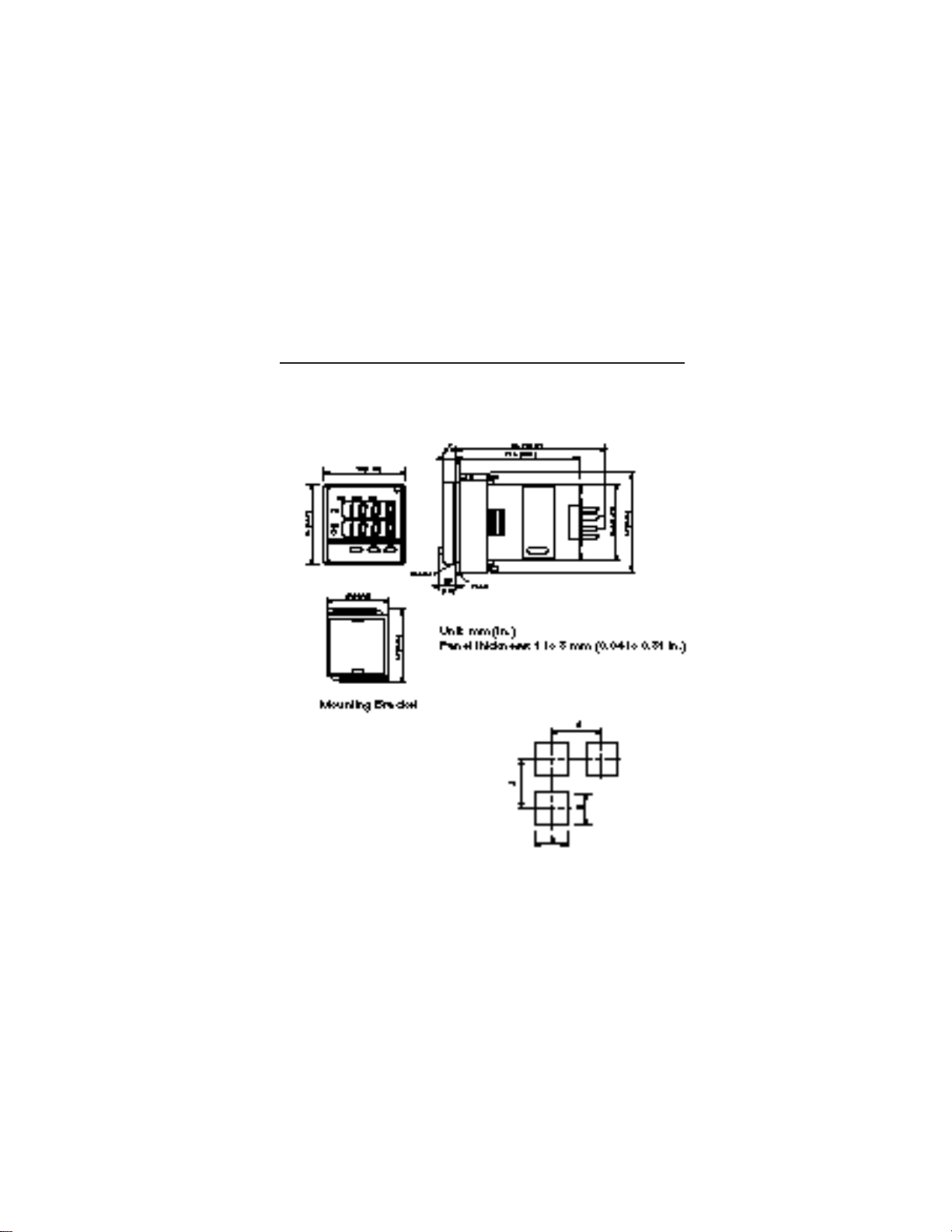

Outer Dimensions and Panel Cutout Size . . . . . . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Instructions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CN4431

Model Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Outer Dimensions and Panel Cutout Size . . . . . . . . . . . . . . . . . . . . . 25

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wiring Instructions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

System Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Front Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Autotuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programming

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Factory Preset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix A: Autotuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix B: Manual Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendix C: Heat/Cool Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Quick Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Page 2

2

INTRODUCTION

The OMEGA®CN4321 and CN4431 controllers are economical

process controllers that accept temperature or process inputs, and

have sophisticated control capabilities, providing on/off control, PID, or

autotune PID, with Fuzzy Logic. They feature an 8-segment ramp/soak

function.

The CN4431 is a 1/16 DIN controller that has dual digital display for

simultaneous indication of process value and setpoint. It is available

with a single output that includes mechanical relay, 24V DC SSR driver,

or 4-20 mA output. Options available include alarms (configurable as

high/low, deviation, or zone alarm).

The CN4321 is a 1/32 DIN controller that has a single digital display.

It is available with either single or dual outputs; dual output models can

be used for heat/cool, heat/heat or cool/cool control. Output options

include mechanical relay and 5V DC SSR driver. It also has an optional

programmable alarm output.

The first section of this manual details the specifications and general description for the CN4321 controller. The second section will cover

the CN4431 controller, followed by a detailed description of the programming parameters, which are common to both the controllers. Several appendices describe some of the controlling techniques. Finally, a

Quick Reference guide gives a listing of all the parameters and their

default values.

Page 3

3

FEATURES

• Fuzzy Logic Control

• PID Autotune with manual override - heating or cooling

• Programmable control action reverse or direct

• Programmable cycle time

• Programmable inputs - Thermocouple/RTD, or Current/ Voltage

• Sensor burn-out protection

• Zero/span calibration

• Outputs: Relay, Solid-state relay

drive, or 4-20mA DC (4-20mA

not available on CN4321)

• Secondary output for

cooling (optional)

• High/low alarm

outputs (optional)

• Menu-driven format

• Setting – touch keys on front

panel

• Programmable 8-segment

ramp/soak function

• Digital filtering (to suppress

factory noise)

• Adjustable setpoint range

• Selectable °F/°C

• Offset adjustments

• Programmable decimal point

• Programmable lock-up feature

• Advanced security options to

prevent unauthorized parameter changes

• 4-digit, LED indication

• Output status indication

• Fault indication

• Non-volatile memory

• 1/32 or 1/16 DIN panel mount

package with plastic bracket

• NEMA 4X faceplate

• ABS plastic housing

• Termination– terminal block

(CN4321) or socket with screwdown terminals (CN4431)

• 85 to 264V AC free voltage

power supply

• 24V AC/DC optional power

supply (on CN4431 only)

• UL and C-UL recognized

• CE approved

Page 4

4

SAFETY PRECAUTIONS

Before using this product, the user is requested to read the following

precautions carefully to ensure safety. The safety requirements are

classified as either “warning” or “caution” according to the following

explanations:

Warning

Wiring

1. If there is danger of serious accident resulting from a failure or

defect in this unit, provide the unit with an appropriate external protective circuit to prevent an accident.

2. The unit is normally supplied without a power switch or a fuse. Use

power switch and fuse as required (Rating of the fuse: 250V, 1A)

Power supply

1. Be sure to use the rated power supply voltage to protect the unit

against damage and to prevent failure.

2. Keep the power off until all of the wiring is completed so that electric

shock and trouble with the unit can be prevented.

General

1. Never attempt to disassemble, modify, or repair this unit. Tampering

with the unit may result in malfunction, electric shock, or fire.

2. Do not use the unit in combustible or explosive gaseous atmos-

pheres.

Page 5

5

Caution

Installation

1. Avoid installing the unit in places where:

• the ambient temperature may reach beyond the range of -10 to 50°C

(14 to 122°F) while in operation

• the ambient humidity may reach higher than 90% RH while in

operation

• a change in the ambient temperature is so rapid as to cause

condensation

• corrosive gases (sulfide and ammonia gas, in particular) or

combustible gases are emitted

• the unit is subject to vibration or shock

• the unit is likely to come in contact with water, oil, chemicals, steam,

or vapor

• the unit is exposed to dust, salt, or air containing iron particles

• the unit is subject to interference with static electricity, magnetism,

or noise

• the unit is exposed to direct sunlight

• heat may be accumulated due to the radiation of heat

Maintenance

1. Do not use organic solvents such as alcohol or benzene to wipe this

unit. Use a neutral detergent.

Page 6

UNPACKING

Remove the Packing List and verify that you have received all equipment,

including the following (quantities in parenthesis):

• Process controller (1)

• Mounting bracket (1)

• Socket with CN4431 (1)

• Operator’s manual (1)

• Waterproof gasket (1)

• 250Ω precision resistor (when required) (1)

• Current transformer (when required) (1)

If you have any questions about the shipment, please call the OMEGA

®

Cus-

tomer Service Department.

When you receive the shipment, inspect the container and equipment for signs

of damage. Note any evidence of rough handling in transit. Immediately report

any damage to the shipping agent.

Note:

The carrier will not honor damage claims unless all shipping materials are

saved for inspection. After examining and removing contents, save packing

material and carton in the event reshipment is necessary.

6

Page 7

7

CN4321 MODEL CONFIGURATION

MODEL DESCRIPTION

Single Output Models

_________________________________________________________________

CN4321(*)-R1 1/32 DIN controller, relay output

CN4321(*)-D1 1/32 DIN controller, DC SSR driver output

_________________________________________________________________

Dual Output Models

_________________________________________________________________

CN4322(*)-R1-R2 1/32 DIN controller, dual relay output

CN4322(*)-D1-R2 1/32 DIN controller, DCSSR driver and relay output

_________________________________________________________________

* Specify TR for Thermocouple/RTD input or CV for current/voltage input

ALARM OPTION (Not Available with CN4322)

_________________________________________________________________

-A 1A, SPST relay

_________________________________________________________________

Page 8

8

CN4321 SPECIFICATIONS

INPUT RANGE TABLE:

_________________________________________________________

Input Signal Input Range Input Range Remarks

(°C) (°F)

_________________________________________________________

Thermocouple*

J 0 ~ 800 32 ~ 1472 Cold Junction

K 0 ~ 1200 32 ~ 2192 compensating

R 0 ~ 1600 32 ~ 2912 function built-in

B 0 ~ 1800 32 ~ 3272

S 0 ~ 1600 32 ~ 2912

T -199 ~ 200 -328 ~ 392

T -150 ~ 400 -238 ~ 752

E -199 ~ 800 -328 ~ 1472

N 0 ~ 1300 32 ~ 2372

PL2 0 ~ 1300 32 ~ 2372

_________________________________________________________

RTD*

Pt100 -150 ~ 850 -238 ~ 1562 Allowable wiring

α= .00385 resistance 10 ohms

max (per wire).

_________________________________________________________

DC Voltage/

Current**

1-5V Scaling Range: -1999 to 9999 For current input, use

0-5V Engineering the 250Ω resistor to

4-20mA units obtain 1-5V DC or

0-20mA 0-5V DC input.

_________________________________________________________

* For TR models

** For CV models

See also the description for parameter P-n2 in the programming section, on

how to program for a particular input.

Page 9

9

CONTROL FUNCTION

(SINGLE OUTPUT)

_________________________________________________________

Control action PID control with auto-tuning

Fuzzy control with auto-tuning

_________________________________________________________

Proportional band (P) 0-999.9% of full scale (FS), setting in 0.1% steps

_________________________________________________________

Integral time (I) 0-3200 sec, setting in 1 sec steps

_________________________________________________________

Differential time (D) 0-999.9 sec, setting in 0.1 sec steps

_________________________________________________________

P,I,D = 0: On/Off action

I,D = 0: Proportional action

_________________________________________________________

Proportional cycle 1-150 sec, setting in 1 sec steps, for relay contact

output and DC SSR driver output only

_________________________________________________________

Hysteresis width 0-50% FS, setting in 1 E.U. (Engineering Unit) steps

On/Off action only

_________________________________________________________

Anti-reset wind up 0-100% FS, setting in 1 E.U. steps, auto-setting

with auto-tuning

_________________________________________________________

Input sampling cycle 0.5 sec

_________________________________________________________

CONTROL FUNCTION

(DUAL OUTPUT) (Heat/Cool Type)

_________________________________________________________

Heating Proportional band P x 1/2 (P= 0-999.9%)

_________________________________________________________

Cooling Proportional band Heating proportional band x Cooling proportional

band coefficient

Cooling proportional band coefficient= 0-100

0: On/Off action

_________________________________________________________

Integral time 0-3200 sec for heating and cooling

_________________________________________________________

Differential time 0-999.9 sec for heating and cooling

_________________________________________________________

Page 10

10

_________________________________________________________

P,I,D= 0: On/Off action (without dead band) for heating and cooling

I,D= 0: Proportional action

_________________________________________________________

Proportional cycle 1-150 sec, for relay contact output and DC SSR

driver output only

_________________________________________________________

Hysteresis width On/Off action for heating and cooling:

0.5% FS

On/Off action for cooling: 0.5% FS

_________________________________________________________

Anti-reset wind-up 0-100% FS, setting in 1 E.U. steps, auto setting

with auto-tuning

_________________________________________________________

Overlap/dead band ±50% of heating proportional band

_________________________________________________________

Input sampling cycle 0.5 sec

_________________________________________________________

OUTPUT

_________________________________________________________

Relay contact output: 220V AC/30V DC 2A (resistive load)

Mechanical life: 10

7

times (under no load)

Electrical life: 10

5

times (under the rated load)

_________________________________________________________

SSR driver output: On-5V DC typ. (5.5V ±1V), 20mA max.

Off-0.5V or less

_________________________________________________________

Alarm output/ 1 point, 220V AC/ 30V DC 2A (resistive load)

2nd control output:

_________________________________________________________

Alarm: Configurable from the front panel keys as

Absolute, Deviation, Zone, or Combination alarms

with or without the hold feature.

_________________________________________________________

SETTING AND INDICATION

_________________________________________________________

Accuracy: ±0.5% of FS ±1 digit

R T/C: 0-400°C: ±1% FS ±1 digit

B T/C: 0-500°C: ±5% FS ±1 digit

_________________________________________________________

Indication: 4 digit, 7-segment LED (green)

_________________________________________________________

Page 11

11

ADDITIONAL FUNCTIONS

_________________________________________________________

8-segment ramp-soak: 4 ramp/4 soak with 16 different modes

Setpoint setting: 0-100% FS

Ramp/soak period: 0-99 hrs 59 mins

_________________________________________________________

Parameter mask: Parameters can be masked from being displayed

_________________________________________________________

Self-diagnosis: Watchdog timer monitors program error

_________________________________________________________

PROTECTION FROM POWER FAILURE

_________________________________________________________

Memory protection: Non-volatile memory. Parameter values

remain unchanged with disruption of power.

Ramp/soak function has to be re-initiated.

_________________________________________________________

OPERATING AND STORAGE CONDITIONS

_________________________________________________________

Operating temperature: -10 to 50°C (14 to 122°F)

_________________________________________________________

Operating humidity: Less than 90% RH (non-condensing)

_________________________________________________________

Storage temperature: -20 to 60°C (-4 to 140°F)

_________________________________________________________

GENERAL SPECIFICATIONS

_________________________________________________________

Rated voltage: 85-264V AC, 50/60 Hz, or

24V AC/DC ±10% (optional)

_________________________________________________________

Power consumption: 5VA or less (100V AC)

8VA or less (240V AC)

_________________________________________________________

Insulation resistance: 20MΩ or more (500V DC)

_________________________________________________________

Withstand voltage: Power source-Earth: 1500V AC, 1 min

Power source-input terminal: 1500V AC, 1 min

Earth-relay output: 1500V AC, 1 min

Earth-Alarm output: 1500V AC, 1 min

Between other terminals: 500V AC, 1 min

_________________________________________________________

Input impedance: Thermocouple: 1MΩor more

Voltage: 450KΩor more

Current: 250Ω (external resistor)

_________________________________________________________

Page 12

_________________________________________________________

Allowable signal Thermocouple: 100Ω or less

source resistance: Voltage: 1KΩ or less

_________________________________________________________

Allowable wiring RTD: 10Ω or less per wire

resistance:

_________________________________________________________

Reference junction ±1 °C (at 23°C)

compensation accuracy:

_________________________________________________________

Process variable offset: ±10% FS

_________________________________________________________

Setpoint variable offset: ±50% FS

_________________________________________________________

Input filter: 0-900.0 sec, setting in 0.1 sec steps

(primary lagging filter)

_________________________________________________________

Noise rejection ratio: Normal mode noise (50/60Hz): 50dB or more

Common mode noise (50/60Hz): 140dB or more

_________________________________________________________

STRUCTURE

_________________________________________________________

Mounting method: Panel mounting

_________________________________________________________

Enclosure: Plastic housing

_________________________________________________________

External terminal: Terminal block with screw connection

_________________________________________________________

External dimensions: 48 (W) x 24.5 (H) x 99 (D) mm

1.89 x 0.96 x 3.90 in.

_________________________________________________________

Weight: Approx. 100 g

_________________________________________________________

Finish color: Black (front panel)

_________________________________________________________

Protection: Front panel: NEMA 4X (equivalent to IEC IP66)

Protection against corrosion, windblown dust

and rain, and hose-directed water.

Rear case: IEC IP20. Protection against solid

objects up to 12mm.

_________________________________________________________

Installation category: II

_________________________________________________________

Pollution degree: 2

_________________________________________________________

12

Page 13

13

OUTER DIMENSIONS & PANEL CUTOUT SIZE

Outer Dimensions

Panel Cutout Size

When installing “n” number of units

+0.5(0.02)

-0

A: 57 (2.24) or more

B: 34 (1.34) or more

+0.3(0.01)

-0

D: 22.2 (0.87)

Page 14

14

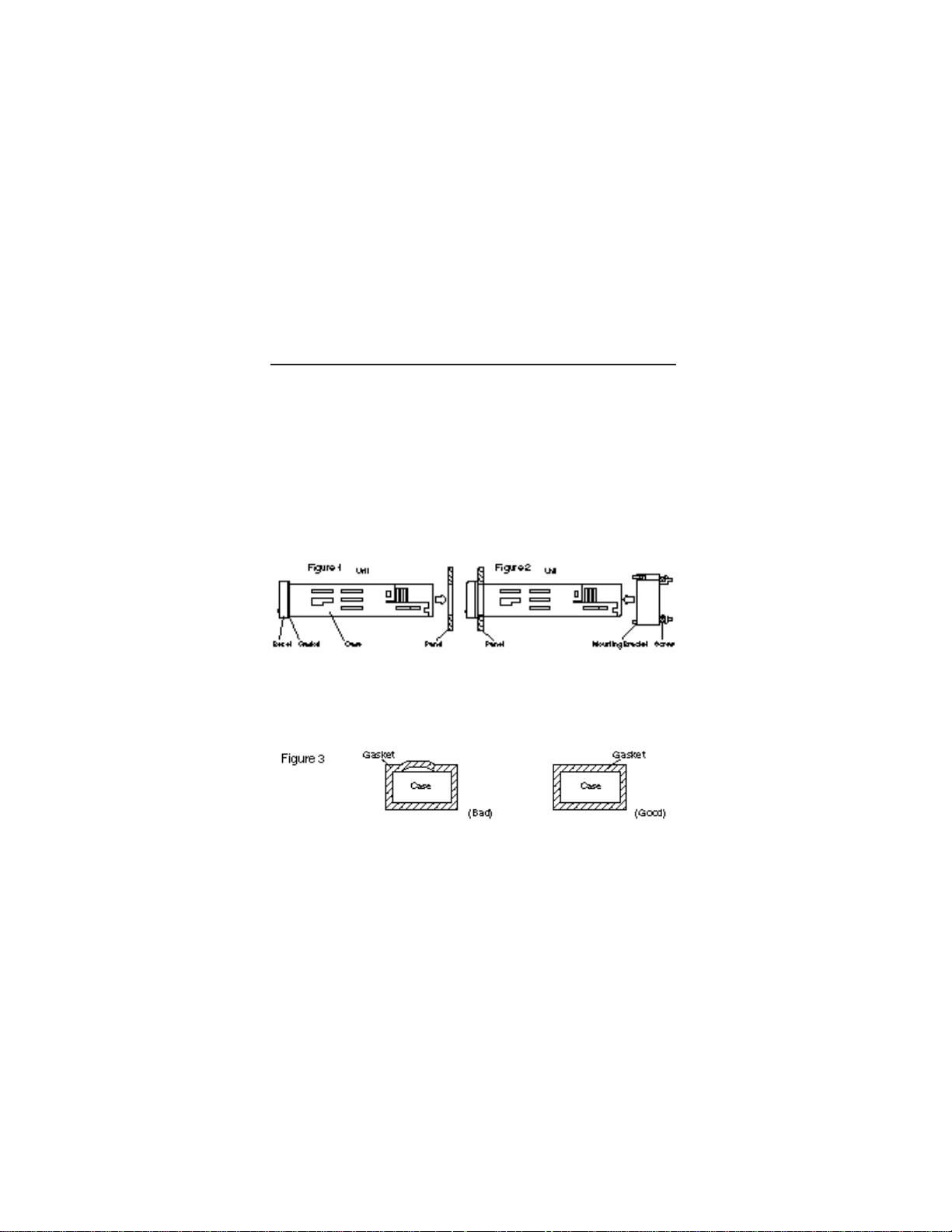

INSTALLATION

NEMA 4X Integrity

The front side of this instrument conforms to NEMA 4X. To ensure the

waterproofness between the instrument and the panel, use the gasket

that is provided with the unit according to the installation procedure

described below.

1. Install the gasket over the enclosure and insert the unit into the

panel as shown in Figure 1.

2. Slide the mounting bracket and tighten the screws as shown in

Figure 2.

Caution: After the mounting bracket is installed, check the gasket for

displacement and detachment as shown in Figure 3.

Page 15

15

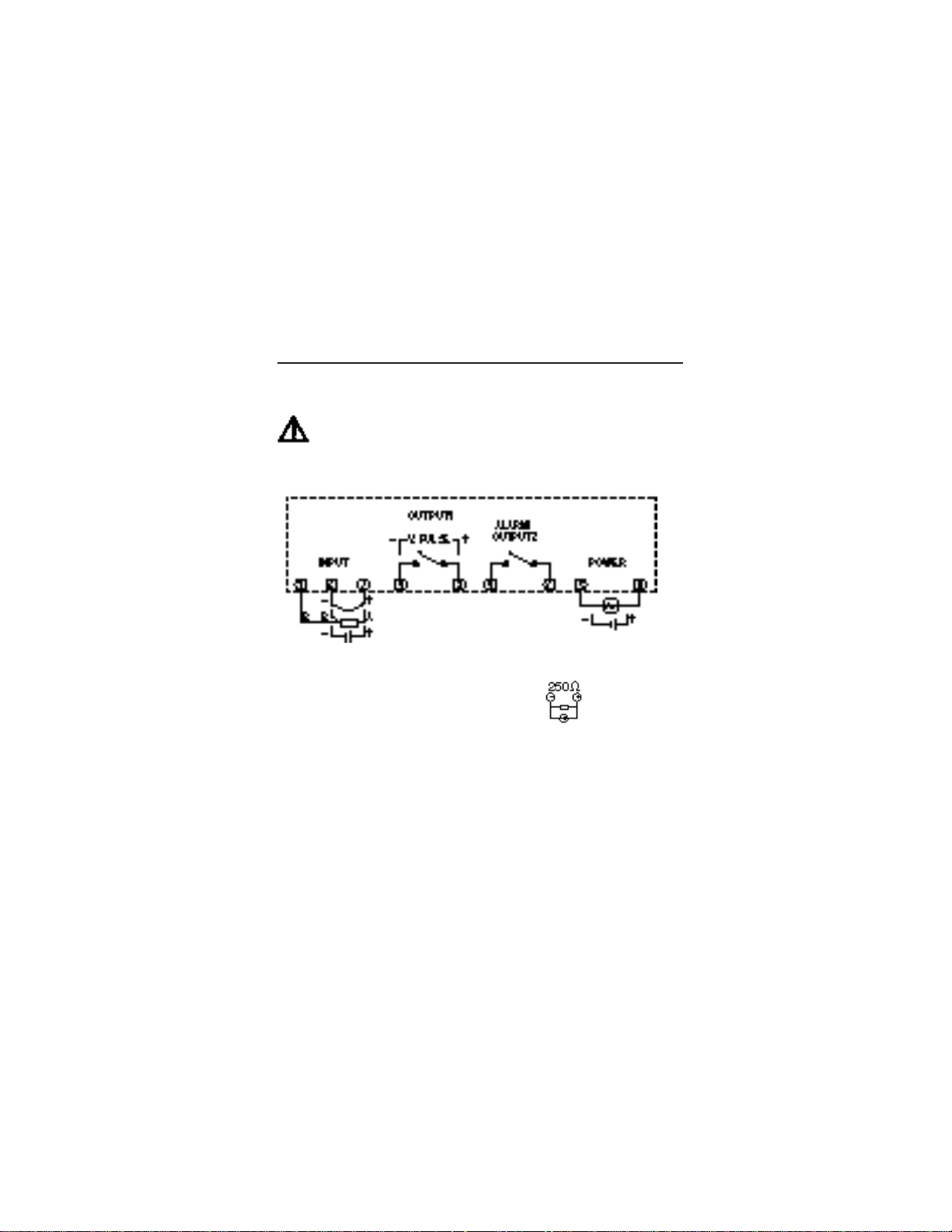

WIRING INSTRUCTIONS

Terminal connection

Wiring material

1. For terminals 1, 2, 3, use 18 ~ 26 gauge wire.

2. For terminals 4 to 9, use 14 ~ 24 gauge wire.

Please refer to Page 28 for further instructions on wiring power,

input and output to the controller.

Warning

Be sure to use the rated power supply voltage and polarity.

* For current input, install the 250Ω precision

resistor (accessory) before using the unit.

Page 16

16

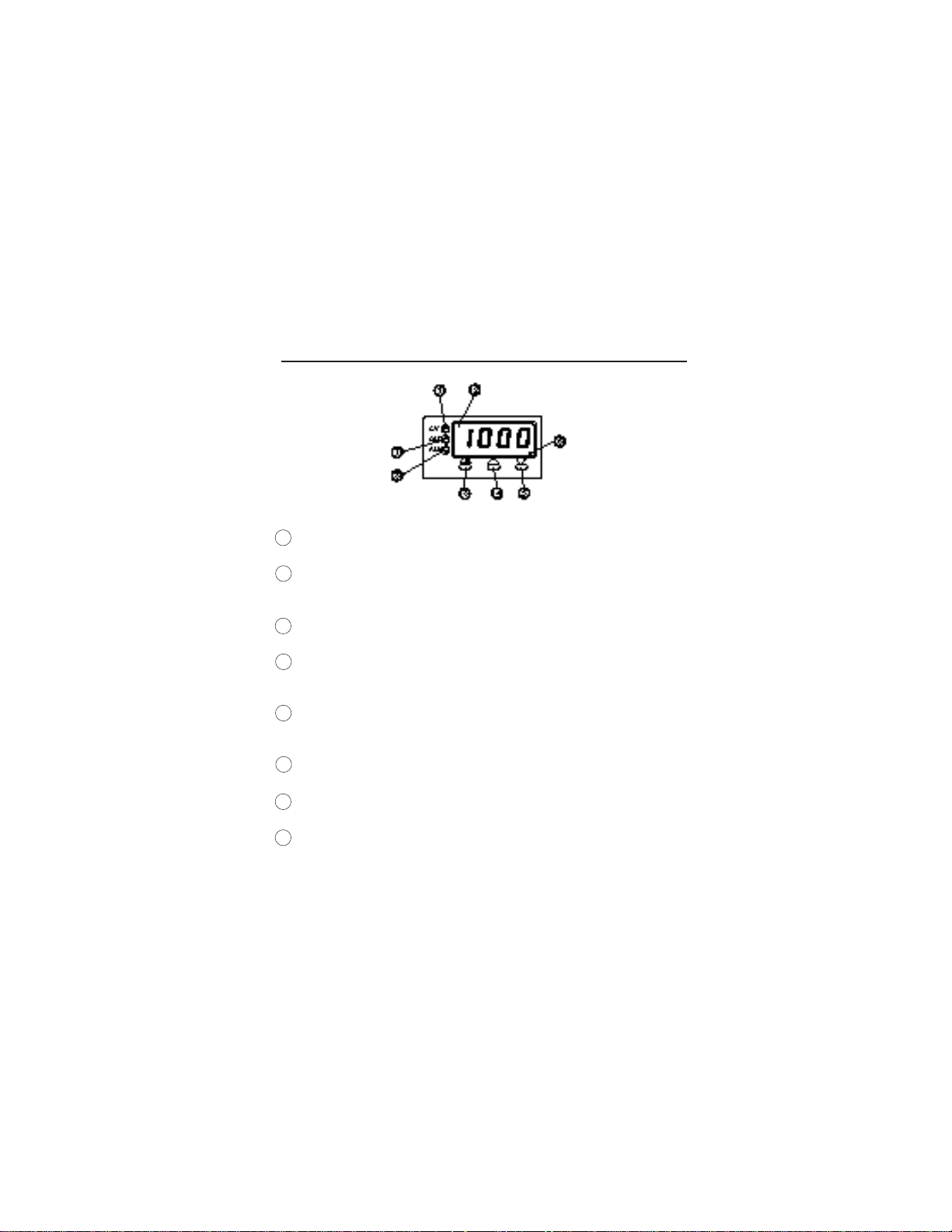

FRONT PANEL DESCRIPTION

NAME FUNCTION

1 Set value (SV) Comes on when the set value (SV)

indication lamp is displayed

2 Measured value (PV)/ Measured value (PV), Setpoint value (SV),

Set value (SV)/ or parameter symbols and codes are

parameter display displayed.

3 Select key To be used when the first, second, or

third block parameters are selected

4 UP key Pressing the key once will increase the

value by one. By pressing and holding it,

the value is continuously incremented.

5 DOWN key Pressing the key once will decrease the

value by one. By pressing and holding it,

the value is continuously decremented.

6 Autotuning indication Blinks while PID autotuning is being

lamp performed

7 Control output Comes on when the control output is ON

indication lamp

8 Alarm indication lamp Comes on when the alarm/second output

is activated. Blinks while the alarm is

being set.

Page 17

17

FRONT PANEL OPERATION

The programming menu consists of three blocks— SETUP MENU,

SYSTEM MENU, and FACTORY PRESET MENU. At power up the controller

will be in the operational mode– process variable (PV) will be displayed.

This is the variable that is being controlled, and it is not programmable.

When setting the parameters, turn off the power to the load (operating

equipment) to ensure safety. Allow 30 minutes for the unit to stabilize in

terms of temperature, and to achieve the rated accuracy. Option-related

features are displayed only when the options are provided.

Viewing and Setting Parameters

• The data is automatically registered in 3 seconds after the setting.

It can also be registered by pressing the SEL key.

How to set Setpoint value (SV)

Operation Display

1. Power on – Process value (PV)

2. Press SEL key – SV value; SV lamp is lit

3. Press UP or DOWN key – SVvalue changes accordingly

4. Press SEL key to go back to – Process value (PV); SV lamp off

the operational mode

SETUP MENU

Operation Display

1. Operational mode – Process value (PV)

2. Press SEL key for 3 seconds – roFF

3. Press UP key to select – rrUn/rHLd

rrUn/rHLd, if necessary

4. Press SEL key once – ALM LEDblinks; AH data (for

units with alarm option)

Page 18

18

5. Press SEL key to access the – AT 0, ......

next parameter

6. Press SEL key for 3 secs. – Operational mode

SYSTEM MENU

Operation Display

1. Operational mode – Process value

2. Press and hold SEL key – 3 seconds later, “roFF”

7 seconds later, “P”

3. Release and press SEL key again – “P” data

4. Press UP or DOWN key – “P” data changes accordingly

5. Press SEL key once – “P”

6. Press DOWN key to scroll down – “i”, “d”, ..... “Mod”

the menu

7. Press SEL key for 3 secs. – Operational mode

FACTORY PRESET MENU

Operation Display

1. Operational mode – Process value

2. Press and hold SEL key – 3 seconds later, “roFF”

7 seconds later, “P”

9 seconds later, “P-n1”

3. Release and press SEL key again – “P-n1” data

4. Press UP or DOWN key – “P-n1” data changed

5. Press SEL key once – “P-n1”

6. Press DOWN key to scroll down – “P-dF”, ........ “dSP7”

the menu

7. Press SEL key for 3 secs. – Operational mode

Please refer to Quick Reference guide for a listing of all the parameters.

Page 19

19

CN4431 MODEL CONFIGURATION

MODEL DESCRIPTION

_________________________________________________________________

CN4431(*)-R1 1/16 DIN controller, relay output

CN4431(*)-D1 1/16 DIN controller, DC SSR driver output

CN4431(*)-F1 1/16 DIN controller, 4-20 mA DC output

_________________________________________________________________

* Specify TR for Thermocouple/RTD input or CV for current/voltage input

ALARM OPTION

_________________________________________________________________

-A 2A, SPST relay

_________________________________________________________________

LOW VOLTAGE POWER SUPPLY OPTION

_________________________________________________________________

-24V 24V AC/DC, 50/60 Hz

_________________________________________________________________

Page 20

20

CN4431 SPECIFICATIONS

INPUT RANGE TABLE:

_________________________________________________________

Input Signal Input Range Input Range Remarks

(°C) (°F)

_________________________________________________________

Thermocouple*

J 0 ~ 800 32 ~ 1472 Cold Junction

K 0 ~ 1200 32 ~ 2192 compensating

R 0 ~ 1600 32 ~ 2912 function built-in

B 0 ~ 1800 32 ~ 3272

S 0 ~ 1600 32 ~ 2912

T -199 ~ 200 -328 ~ 392

T -150 ~ 400 -238 ~ 752

E -199 ~ 800 -328 ~ 1472

N 0 ~ 1300 32 ~ 2372

PL2 0 ~ 1300 32 ~ 2372

_________________________________________________________

RTD*

Pt100 -150 ~ 850 -238 ~ 1562 Allowable wiring

α= .00385 resistance 10 ohms

max (per wire).

_________________________________________________________

DC Voltage/

Current**

1-5V Scaling Range: -1999 to 9999 For current input, use

0-5V Engineering the 250Ω resistor to

4-20mA units obtain 1-5V DC or

0-20mA 0-5V DC input.

_________________________________________________________

* For TR models

** For CV models

See also the description for parameter P-n2 in the programming section, on

how to program for `a particular input.

Page 21

21

CONTROL FUNCTION

(SINGLE OUTPUT)

_________________________________________________________

Control action PID control with auto-tuning

Fuzzy control with auto-tuning

_________________________________________________________

Proportional band (P) 0-999.9%, of full scale (FS), setting in 0.1% steps

_________________________________________________________

Integral time (I) 0-3200 sec, setting in 1 sec steps

_________________________________________________________

Differential time (D) 0-999.9 sec, setting in 0.1 sec steps

_________________________________________________________

P,I,D = 0: On/Off action

I,D = 0: Proportional action

_________________________________________________________

Proportional cycle 1-150 sec, setting in 1 sec steps, for relay contact

output and DC SSR driver output only

_________________________________________________________

Hysteresis width 0-50% FS, setting in 1 E.U. (Engineering Unit) steps

On/Off action only

_________________________________________________________

Anti-reset wind up 0-100% FS, setting in 1 E.U. steps, auto-setting

with auto-tuning

_________________________________________________________

Input sampling cycle 0.5 sec

_________________________________________________________

OUTPUT

(Single Output)

_________________________________________________________

Control output One of the following three types is selected:

(1) Relay contact (SPDT)

220V AC/30V DC, 3A (resistive load)

Mechanical life: 10

7

times (under no load)

Electrical life: 10

5

times (under the rated load)

(2) DC SSR driver (voltage pulse):

15-30V DC at ON/0.5V DC or less at OFF.

Current– 60mA or less.

(3) 4-20mA DC:

Allowable load resistance– 600Ω or less.

_________________________________________________________

Page 22

22

ALARM

_________________________________________________________

Alarm output 1-point relay contact (SPST),

220V AC/30V DC, 1A (resistive load)

_________________________________________________________

SETTING AND INDICATION

_________________________________________________________

Parameter setting method Digital setting with three keys

_________________________________________________________

PV/SV display method Dual display for PV/SV

4 digits each, PV=red, SV=green

_________________________________________________________

Status display Control output, alarm output

_________________________________________________________

Indication accuracy Thermocouple: ±0.5% FS ±1 digit ±1°C

(at 23°C) R thermocouple: 0-400°C; ±1% FS ±1 digit ±1°C

B thermocouple: 0-500°C; ±5% FS ±1 digit ±1°C

RTD, voltage, current: ±0.5% FS ±1 digit

_________________________________________________________

ADDITIONAL FUNCTIONS

_________________________________________________________

8-segment ramp-soak: 4 ramp/4 soak with 16 different modes

Setpoint setting: 0-100% FS

Ramp/soak period: 0-99 hrs 59 mins

_________________________________________________________

Parameter mask: Parameters can be masked from being displayed

_________________________________________________________

Self-diagnosis: Watchdog timer monitors program error

_________________________________________________________

GENERAL SPECIFICATIONS

_________________________________________________________

Rated voltage 85-264V AC, 50/60 Hz, or

24V AC/DC ±10% (optional)

_________________________________________________________

Power consumption 10VA or less (100V AC)

15VA or less (240V AC)

_________________________________________________________

Insulation resistance 50MΩ or more (500V DC)

_________________________________________________________

Page 23

23

_______________________________________________________

Withstand voltage Power source-Earth: 1500V AC, 1 min

Power source-input terminal: 1500V AC, 1 min

Earth-relay output: 1500V AC, 1 min

Earth-Alarm output: 1500V AC, 1 min

Between other terminals: 500V AC, 1 min

_______________________________________________________

Input impedance Thermocouple: 1MΩ or more

Voltage: 450KΩor more

Current: 250Ω (external resistor)

_______________________________________________________

Allowable signal Thermocouple: 100Ω or less

source resistance Voltage: 1KΩ or less

_______________________________________________________

Allowable wiring RTD: 10Ω or less per wire

resistance

_______________________________________________________

Reference junction ±1°C (at 23°C)

compensation accuracy

_______________________________________________________

Process variable offset ±10% FS

_______________________________________________________

Setpoint variable offset ±50% FS

_______________________________________________________

Input filter 0-900.0 sec, setting in 0.1 sec steps

(primary lagging filter)

_______________________________________________________

Noise rejection ratio Normal mode noise (50/60Hz): 50dB or more

Common mode noise (50/60Hz): 140dB or more

_______________________________________________________

POWER FAILURE PROTECTION

_______________________________________________________

Memory protection: Non-volatile memory. Parameter values

remain unchanged with disruption of power.

Ramp/soak function has to be re-initiated.

_______________________________________________________

Page 24

24

OPERATING AND STORAGE CONDITIONS

_______________________________________________________

Operating temperature -10 to 50°C (14 to 122°F)

_______________________________________________________

Operating humidity Less than 90% RH (non-condensing)

_______________________________________________________

Storage temperature -20 to 60°C (-4 to 140°F)

_________________________________________________________

STRUCTURE

_______________________________________________________

Mounting method Panel mounting or surface mounting

_______________________________________________________

External terminal 8-pin or 11-pin socket

_______________________________________________________

Enclosure Black ABS plastic

_______________________________________________________

Dimensions 48 x 48 x 85.7mm (1/16 DIN)

1.89 x 1.89 x 3.37 in. (W x H x D)

_______________________________________________________

Weight Approx. 150g

_______________________________________________________

Protective structure Front panel: NEMA 4X (equivalent to IEC IP66)

Protection against corrosion, windblown dust

and rain, and hose-directed water.

Rear case: IEC IP20. Protection against solid

objects up to 12mm.

_______________________________________________________

Installation category: II

_______________________________________________________

Pollution degree: 2

_______________________________________________________

Page 25

25

OUTER DIMENSIONS & PANEL CUTOUT SIZE

CN4431

Panel cutout size: when installing

“n” numbers of units.

+0.5(0.02)

-0

B: 45 (1.77)

A: 63 (2.48) or more

Page 26

26

INSTALLATION

NEMA 4X Integrity

The front side of this instrument conforms to NEMA 4X. To ensure the

waterproofness between the instrument and the panel, use the gasket

that is provided with the unit according to the installation procedure

described below.

How to install the unit

Install the unit in the panel as shown below, and tighten the screws on

the mounting bracket until the unit is secure. Make sure there is no

space between the front side of the unit and the gasket, and between

the gasket and the panel.

Caution: After the mounting bracket is installed, check the gasket for

any displacement as shown in Figure 3.

Page 27

27

* For current input, install the 250Ω precision

resistor (accessory) before using the unit.

WIRING INSTRUCTIONS

Warning

Be sure to use the rated power supply voltage and polarity.

Page 28

28

Wiring Power to the Controllers

• Be sure to use the rated power supply voltage and polarity to avoid

failure or damage to the unit.

• Keep the power off until all of the wiring is completed to prevent

electric shock and abnormal operation.

• Keep the power supply wires separated from the input and output

wires.

• Power connections should be made with 18-gauge or larger insulated

wire. Stranded wire improves noise immunity. Noise filters and isolation transformers are recommended in case of noisy power lines.

Wiring Inputs

There are two input categories available: Thermocouple/RTD or

current/voltage. Make sure you have the right type before wiring the

inputs. Refer to Table of Input Type Codes and set the parameter

“P-n2” accordingly.

Note: In order to minimize the risk of high frequency noise induced by

coils and windings in relays, solenoids, and transformers, use leads

which have braided sheath and ground one end of the sheath. Keep

your input leads separate from power and output leads. If you have to

bring the input signal from a long distance, a signal transmitter might be

needed to maintain an accurate reading; in this case, a unit that

accepts current/voltage input would be necessary.

Thermocouple

• Connect thermocouples directly to the input terminals whenever

possible.

Page 29

29

• If using extension wires, make sure they are of the same thermocouple material and grade; any dissimilar metal junctions will lead to

erroneous readings.

• Ungrounded thermocouples are recommended for optimal performance and to prevent ground loops.

• Make sure the polarity is correct.

RTD Pt100

• Use a 3-wire Pt100Ω RTD whenever possible. All three wires must

have low lead resistance (less than 10Ω) and no resistance differentials among them.

• If using a 2-wire RTD, jumper the two B-legs with a wire of equal

resistance.

• Make sure A and B leads are connected to the right terminals.

Current/Voltage

• The controller accepts 1-5V, 0-5V, 4-20mA, and 0-20mA DC signals. If

wiring for a voltage input, feed the signal directly to the input terminals. For current inputs, first connect the 250Ω precision resistor that

comes with the unit.

• Make sure the polarity is correct.

Wiring Outputs

Before wiring the outputs, make sure the unit has the right kind of

control output, and that all the load handling devices conform to the

controller specifications. Note that it takes 5 seconds for the outputs to

activate after the power is turned on.

Refer to parameter “P-n1” and to the Table of Output Type Codes to

choose the preferred type of control action– reverse-acting or directacting.

Page 30

30

If using two outputs in a heat/cool type control, please refer to

Appendix C for more details.

Relay

• Connecting a load to full capacity of the relay will shorten the relay

life, especially if it is operated at a rapid rate. To protect the output

relay, an external relay or a contactor should be used. If a higher

current rating is required, a solid-state relay driver type output is

recommended.

• Connect the load between the normally opened contacts of the relay.

This way, if power to the controller is disrupted, the output circuit

would open, preventing the load from running out of control.

• Set the proportional time cycle parameter, “TC” to 15 secs. or more.

(30 secs typical).

• Use of MOV circuit is recommended to protect the relay against

switching surges and to ensure the product’s long life. Connect it

between the contacts of the relay as shown in the example below.

Part No.: MOV-100 (power supply voltage: 100V)

MOV-200 (power supply voltage: 200V)

CN4431

(8-pin)

CN4321

Z-Trap

Page 31

31

DC SSR Driver (voltage pulse)

• The non-isolated DC output is used to drive an external load-handling

device such as Solid-State Relay(SSR) or Solid-State Contactor(SSC).

• The total current drawn should be within the allowed value.

• Make sure the polarity is correct.

• Set the proportional time cycle parameter, “TC” to 1 sec. or more.

4 to 20mA DC

• The output is a non-isolated analog signal used to drive a variety of

output devices such as SCRs and valve actuators.

• The load resistance must be less than 600Ω.

• Make sure the polarity is correct.

• The proportional time cycle parameter, “TC” is set to 0, and is not

displayed on the programming menu.

• Not available on CN4321.

Wiring Alarms

• Make sure the load does not exceed the rated capacity of the relay.

• Several types of alarm configurations can be programmed and does

not require a change in the wiring. Refer to parameters AL, AH, P-AH,

P-AL, P-An.

Page 32

32

SYSTEM WIRING DIAGRAMS

Example 1:

Example 2:

Page 33

33

FRONT PANEL DESCRIPTION

Name Function

1 Process Value (PV) display Displays the measured value.

2 Set value (SV) indication lamp Comes on while the set value is displayed.

3 Set value (SV) and Set value (SV), or parameter symbols and

parameter display codes are displayed.

4 SELECT key Key for switching between the parameter blocks

and for scrolling through the parameters.

5 UP key For incrementing the numerical value or scrolling

up the menu. Numerical value is incremented

continuously when held pressed.

6 DOWN key For decrementing the numerical value or scrolling

down the menu. Numerical value is decremented

continuously when held pressed.

7 Auto-tuning indicator Point LED blinks while PID auto-tuning is being

performed.

8 Control Output indication lamp Stays on while control output is ON.

9 Upper limit alarm Comes on when the upper limit alarm is activated.

indication lamp Blinks while the alarm value is being set.

10 Lower limit alarm Comes on when the lower limit alarm is activated.

indication lamp Blinks while the alarm value is being set.

Page 34

34

FRONT PANEL OPERATION

The CN4431 programming menu consists of three blocks— SETUP

MENU, SYSTEM MENU, and FACTORY PRESET MENU. At power up the

controller will be in the operational mode, and process variable (PV)

and setpoint variable (SV) will be displayed. PV is the variable that is

being controlled, and it is not programmable. When setting the parameters, turn off the power to the load (operating equipment) to ensure

safety. Allow 30 minutes for the unit to stabilize in terms of temperature,

and to achieve the rated accuracy. Option-related features are

displayed only when the options are used.

Viewing and Setting Parameters

• The data is automatically registered in 3 seconds after the setting.

It can also be registered by pressing the SEL key.

How to set Setpoint value (SV)

Operation Display

1. Power on – Operational mode

2. Press UP or DOWN key – SVvalue changes accordingly

SETUP MENU

Operation Display

1. Operational mode – PV, SV

2. Press SEL key for 3 seconds – roFF

3. Press UP key to select – rrUn/rHLd

rrUn/rHLd, if necessary

4. Press SEL key once – ‘H’ LED blinks; AH data (for

units with alarm option)

Page 35

35

5. Press SEL key to access the – ‘L’ LEDblinks, ....

next parameter

6. Press SEL key for 3 secs. – Operational mode

SYSTEM MENU

Operation Display

1. Operational mode – PV, SV

2. Press and hold SEL key – 3 seconds later, “roFF”

7 seconds later, “P”

3. Release and press SEL key again – “P” data

4. Press UP or DOWN key – “P” data changes accordingly

5. Press SEL key once – “P”

6. Press DOWN key to scroll down – “i”, “d”, ..... “Mod”

the menu

7. Press SEL key for 3 secs. – Operational mode

FACTORY PRESET MENU

Operation Display

1. Operational mode – PV, SV

2. Press and hold SEL key – 3 seconds later, “roFF”

7 seconds later, “P”

9 seconds later, “P-n1”

3. Release and press SEL key again – “P-n1” data

4. Press UP or DOWN key – “P-n1” data changed

5. Press SEL key once – “P-n1”

6. Press DOWN key to scroll down – “P-dF”, ........ “dSP7”

the menu

7. Press SEL key for 3 secs. – Operational mode

Please refer to Quick Reference guide for a listing of all the parameters.

Page 36

36

AUTOTUNING

Before initiating the autotune function, first decide if you would like

to autotune at setpoint or 10% of full scale below setpoint. Set the setpoint (SV), alarms (AL, AH) and the cycle time (TC). Bring your process

near setpoint before starting the autotune procedure. Autotuning works

best for heating processes in which the setpoint is 100°F (60°C) above

ambient temperature.

Set the parameter AT to either “1” (to auto-tune at setpoint) or “2” (to

auto-tune at 10% of full scale below setpoint) and press SEL key to start

auto-tuning. The point indicator at lower right will then start blinking.

When the auto-tuning is completed, the point indicator stops blinking

and the parameter AT will automatically be set to “0.”

Duration of the autotune process varies with every application. The

auto-tuning process may take between 1 and 30 minutes to complete.

If it fails to complete, an abnormality may be suspected. In this case,

recheck the wiring, control action, and input type code. Refer to

page 38 and Appendix A for additional details.

The PID parameters calculated by autotuning will be retained even if

the power is lost. However, if the power is turned off during the autotuning process, you must restart Autotuning. To abort the autotune

procedure, set AT to “0.” Auto-tuning has to be repeated if there is a

significant change in SV, P-SL or P-SU, or in the controlled process.

Autotuning can also be performed while fuzzy control is selected.

Page 37

37

SETUP MENU

See Quick Reference (p.74) for a listing of the menu.

PARAMETER DESCRIPTION

roFF - rhLd Ramp/Soak Command: The Ramp/Soak program auto-

matically changes the setpoint value with time

according to a preset pattern.

Setting: roFF : Normal operation is performed

rrUn : Ramp/Soak operation is performed

rhLd : Ramp/Soak operation is suspended

rEnd indicates that the operation is terminated.

AH High Alarm Setpoint: The High Alarm Setpoint is that

point of the process above which, the high alarm output

relay is energized. If the alarm type, programmed in the

setup menu, includes an absolute value for the High

Alarm Setpoint, enter the actual value you want the

alarm to be activated at regardless of what the main setpoint is set for. If the alarm type includes a deviation

value for the High Alarm Setpoint, enter the number of

units above main setpoint in which you want the alarm to

be activated at; the deviation alarm tracks main setpoint.

Set within the Input Range.

Not indicated without the alarm option.

AL Low Alarm Setpoint: The Low Alarm Setpoint is that

point of the process below which, the low alarm output

relay is energized. Absolute and deviation alarm configurations are programmable from within the secondary

menu.

Blinking

‘H’ LED

Blinking

‘L’ LED

Page 38

Set within the Input Range.

Not indicated without the alarm option, or in CN4321.

AT Autotuning: Autotuning is the automatic calculation and

entering of the control parameters (P, Iand D) into memory. Autotuning will also automatically set anti-reset windup (Ar).There are two types of Autotuning that can be

performed by the controller, Autotuning at main setpoint

or Autotuning at 10% of full scale below main setpoint.

The latter may yield slightly different values, not as precise, but the process overshoot encountered during the

autotuning procedure would not be as much. Enter the

value for the type of autotuning you would like to run on

your particular application based on overshoot tolerances

and the precision of the PID parameters needed. For

more information on principles of Autotuning, refer to

Appendix A. See also page 36.

Setting:

0 - Autotuning off

1 - Autotuning performed at setpoint

2 - Autotuning performed at 10% of F.S. below setpoint

38

Standard type (AT=1)

Low PV type (AT=2)

Page 39

LoC Parameter lock: This function enables or disables

changing the settings of parameters.

Code:

0 - All parameter settings are changeable

1 - All parameter settings are locked; cannot be changed

2 - Only the main setpoint can be changed; all other

parameter settings are locked and cannot be changed.

39

Page 40

40

SYSTEM MENU

P Proportional Band: The proportional band is that area

around main setpoint where the control output is neither

fully on nor fully off.

Setting range: 0.0 to 999.9% of full scale

For On/Off control, set to “0”

I Integral Time (reset): The Integral Time is the speed at

which a corrective increase or decrease in output is

made to compensate for offset which usually accompanies proportional only processes. The more Integral Time

entered, the slower the action. The less Integral Time

entered, the faster the action. Enter a value that would

eliminate offset without overcompensation, that could

result in process oscillations.

Setting Range: 0 to 3200 secs

Integral action is turned off when set to “0”

d Derivative Time (Rate): The Derivative Time is that time

used in calculating rate of change and thermal lag in

helping to eliminate overshoot that results in response to

process upsets. This overshoot usually accompanies

proportional-only and proportional-integral processes.

The derivative action dampens proportional and integral

action as it anticipates where the process should be.

The more Derivative Time entered, the more the damping

action. The less Derivative Time entered, the less the

damping action. Enter as much Derivative Time as necessary to eliminate overshoot without over-damping the

process, that could result in process oscillations.

Setting Range: 0.0 to 999.9 secs

Derivative action is disabled when set to “0”

Page 41

41

TC Cycle Time (Output #1): The Cycle Time for output #1 is

that time where the output is on for a percentage of that

time and off for a percentage of that time, creating a

proportioning effect. The Cycle Time is only used when

P, PI, PD, or PID control action is used, and when the

output is time proportional as with the relay or SSR driver outputs. The shorter the Cycle Time, the higher the

proportioning resolution is, and better is the control, but

there will be an increased strain on the output device.

Enter a value that is based on the limitations of your

controller’s output type.

Setting range: 1 to 150 secs.

For relay output: Set to 15 secs. or more (30 secs typ.).

For DC SSR driver output: Set to 1 sec or more.

For current output: Set to 0 (normally not indicated)

Page 42

42

HYS Hysteresis: Hysteresis is that area around the main set-

point where the output does not change condition. That

area or deadband is intended to eliminate relay chatter

at setpoint for On/Off control applications. The wider the

Hysteresis, the longer it takes for the controller to

change output condition. The narrower the Hysteresis,

the less time it takes for the controller to change output

condition. When the Hysteresis is narrow, the On/Off

control is more accurate but the wear on the output relay

is increased. Enter a value which is small enough to meet

the control tolerance of the application but large enough

to eliminate relay chatter.

Setting range: 0 to 50% of FS, set in E.U., for output #1.

Hysteresis for On/Off action for dual outputs (heating and

cooling) is fixed at 0.5% of full scale.

Page 43

43

TC2 Cycle Time (Output #2) The Cycle Time for output #2 is

similar in function to Cycle Time for output #1. Output #2

is the cooling side of heat/cool controller CN4321. Enter

a value that is based on the limitations of your controller’s output type.

Setting Range: 1 to 150 secs.

Not indicated without the control output #2 option

Not indicated with current output.

Cool Proportional Band Coefficient for Cooling: The Propor-

tional

Band

Coefficient for

Cooling

is a multiplier for

the pro-

portional

band on the cooling side of a heat/cool controller. It

varies the width of the proportional band on the cooling

side. A large value would establish a larger proportional

band for more powerful cooling loads. A small value

would establish a smaller proportional band for less

Page 44

44

Deadband/Overlap

Page 45

45

powerful cooling loads. Enter a value based on the

power of your cooling load.

Setting Range: 0.0 to 100.0

Not indicated without control output #2 option.

Set to “0” for On/Off control.

db Deadband/Overlap: The Deadband/Overlap is that per-

centage of the heating side of the proportional band

where the heating (output #1) and the cooling (output #2)

outputs are separated by a deadband or where they

overlap on a heat/cool controller. A value greater than

zero establishes a Deadband area where neither the

heating nor cooling outputs are energized, for more powerful heating and cooling loads. A value less than zero

establishes an Overlap area where both the heating and

cooling outputs are energized at the same time, for less

powerful heating and cooling loads. Enter a value based

on the power of your heating and cooling loads as well

as the application’s efficiency in maintaining tight

Page 46

46

heat/cool control.

Setting range: -50.0 to 50.0% of the heating proportional

band.

Not indicated without control output #2 option

bAL Balance: Balance is used to pre-position the proportional

band with respect to setpoint. With Balance (MV Offset)

set at 50% the proportional band will be centered around

setpoint. To move the band left or right, decrease or

increase the balance setting respectively.

Setting range: 0-100%

Ar Anti-Reset Wind-up: Anti-Reset is used to limit the range

where integration occurs. This helps in stabilizing a system. With Anti-Reset at 100%, integration will occur

throughout the proportional band. With Anti-Reset set to

90%, integration will occur at 90% of the band above the

setpoint and 90% of the band below the setpoint. Autotuning automatically sets Ar.

Setting range: 0-100% of full scale, set in E.U.

P-n2 Input type: The Input Type is the type of sensor to be

used with the controller in sensing the process variable.

The Input Type must be correctly programmed into the

controller in order for the controller to perform with the

selected sensor type. Depending on the type of sensor to

be used, the controller comes in two models. One model

accepts J, K, R, B, S, T, E, N thermocouples and RTDs

(Pt100), and the other model accepts 1-5/0-5V DC and 420/0-20mA DC signals.

The current/voltage model comes with a 250Ω precision

resistor. Wired directly to the controller, it converts a

current signal into a voltage signal. There is no need to

Page 47

47

Table of Input Type Codes

Page 48

48

use the resistor if a voltage signal is applied directly.

After the appropriate physical changes have been

made, the controller will still need the correct code for

the input type to be used. Enter the appropriate code

from the Table of Input Type Codes.

P-SL Lower Limit of Input Range: The Lower Limit of Input

Range is that value which establishes the desired low

limit for the type of input used. The value must be

greater than or equal to the input type’s lowest limit.

Setpoint settings are restricted to values greater than

the low limit. Parameters which are calculated as a percentage of full scale are affected by this setting. An

underscale error message is indicated on the process

variable display when the process variable goes below

the Lower Limit of Input Range setting by 5% of full

scale. The primary purpose of the Lower Limit of Input

Range when used with a thermocouple or RTD sensor

input is to limit setpoint settings. Making the input range

smaller does not increase the accuracy. The primary

purpose of the Lower Limit of Input range when used

with 1-5/0-5V DC or 4-20/0-20mA DC signal input is to

scale the range so that 1/0V DC on a 1-5/0-5V DC signal

and 4/0mA DC on a 4-20/0-20mA DC signal equals the

low limit of the engineering unit range used. The engineering unit range could be %, PSI, GPM, PH, or any

range which can be scaled between -1999 and 9999

units.

Enter a value to set Lower Limit of Input range based on

the type of input used.

P-SU Upper Limit of Input Range: The Upper Limit of Input

Range is that value which establishes the desired high

Page 49

49

Page 50

50

limit for the type of input used. The value must be less

than or equal to the input type’s highest limit. Setpoint

settings are restricted to values less than the high limit.

Parameters which are calculated as a percentage of full

scale are affected by this setting. An overscale error

message is indicated on the process variable display

when the process variable goes above the Upper Limit

of Input Range setting by 5% of full scale. The primary

purpose of the upper limit when used with a thermocouple or RTD input is to limit setpoint settings. Making the

input range smaller does not increase the accuracy. The

primary purpose of the Upper Limit of Input range when

used with 1-5/0-5V DC or 4-20/0-20mA DC signal input is

to scale the range so that 5V DC on a 1-5/0-5VDC signal

and 20mA DC on a 4-20/0-20mA DC signal equals the

high limit of the engineering unit range used. The engineering unit range could be %, PSI, PH, or any range

which can be scaled between -1999 and 9999 units.

Enter a value to set Upper Limit of Input range based on

the type of input used.

P-dP Decimal Point Position (Resolution): The Decimal Point

Position is the resolution at which the controller displays

the process variable and other parameter values. The

display can indicate integers, tenths or hundredths of a

unit. The Decimal Point Position does not increase the

accuracy of the controller, it only increases the resolution.

For a thermocouple, integers are usually sufficient due to

the accuracy rating and the programmed input range. For

a RTD (Pt100), integers or tenths of a degree may be

entered, because of the increased accuracy of these

sensors, depending on the programmed input range. For a

Page 51

51

1-5/0-5V DC or 4-20/0-20mA DC signal, integers, tenths or

hundredths of a unit may be entered depending on the

programmed input range.

Setting:

0 -None

1- Tenths of a unit

2 - Hundredths of a unit

P-AH Alarm Type 1:

P-AL Alarm Type 2: These functions set the control action

for the optional alarm output relays. They can be programmed for absolute, deviation, combination, or zone

alarm configuration. The high and low alarm setpoints

are set with primary menu parameters AH and AL (AL is

not applicable in the case of CN4321). The absolute

alarm configurations are independent of main setpoint.

The alarm output relays are energized when the

process variable exceeds the alarm setpoint, an

absolute value. The deviation alarm configuration is

main setpoint tracking. The alarm output relays are

energized when the process variable exceeds the main

setpoint by a deviation value set by AL or AH. The combination alarm

configurations are a mixture of both the deviation and

absolute value settings for the high and low alarms.

With zone alarm configurations the alarm output is

energized between the range set by AL and AH.

One of the alarm types is Alarm with Hold. In this case

the alarm is not turned on the first time the measured

value is in the alarm band. Instead it turns on only when

the measured value goes out of the band and enters it

again. This type is useful when using deviation alarm

with step type input.

Page 52

52

Table of Alarm Action Type Codes—CN4321

Page 53

53

Table of Alarm Action Type Codes—CN4431

Page 54

54

Enter the code for P-AH and P-AL from the Table of Alarm

Action Type Codes. See pages 57 &58.

P-AL is not applicable in the case of CN4321.

Note 1: A change of alarm action type can cause the alarm

set value to change, but this is not a malfunction.

Note 2: After the alarm type is changed, turn off the power

to the unit once.

PVOF Process Variable Offset: The Process variable Offset is

the amount by which the indicated process variable is

shifted in a positive or negative direction. Both the indicated as well as the measured process variable will be

changed. This parameter can be used to correct for differences in sensors, sensor placement, and standardization problems. Enter a value which is the difference

between the measured process value and the actual

process value of the system.

Setting range: -10 – 10% of full scale

SVOF Setpoint Variable Offset: The Setpoint Variable Offset

is that amount of offset which shifts the measured setpoint variable in a positive or negative direction. The

measured setpoint variable is changed but the

indicated

setpoint variable remains unchanged. Be careful when

using this variable because what you see as the setpoint variable may be very different from the actual setpoint variable.

Setting range: -50 – 50% of full scale

Indicated Setpoint Variable is Unchanged

Measured Setpoint Variable is Changed

P-F C/F Selection: The C/F Selection allows choosing either

the Celsius or the Fahrenheit scale. If using the con-

Page 55

55

troller to control a process other than temperature using

the current/voltage input model, the C/F Selection is not

important because the scaling is done using the lower

limit of the input range and upper limit of input range

parameters, and the indication is in engineering units.

Setting: °C or °F

STAT Ramp/Soak Status: The Ramp/Soak program automati-

cally changes the setpoint value with time in accordance

with a preset pattern, as shown in the figure. This device

allows a maximum of four ramp and four soak segments.

Ramp: Region in which the setpoint changes toward the target value.

Soak: Region in which the setpoint stays unchanged at the target value.

Note 1: SV cannot be changed while the operation is running or suspended.

Note 2: The use of fuzzy control is inhibited while Ramp-Soak operation is being performed.

Ramp is the region in which SV changes toward the target

value. Soak is the region in which the target value is maintained. STAT displays the current ramp/soak status. No setting can be made.

Page 56

56

1. Power on Start: Program starts from the current PV value.

2. Output on END: Output condition at the end of the program (rEnd)

3. Output on OFF: Output condition when program is terminated (roFF)

4. Repeat function: Ramp-soak program operates repeatedly.

If the repeat function is off, the SV value on the last

step is maintained.

Stand-by mode: Output -3%, Alarm off.

Going on Control: When program ends (rEnd), control is at the SV value

on the last step. When program is terminated (roFF), control

is at the main SV value.

MOD Power on start Output on END Output on OFF Repeat function

0 No Continue controlling Continue controlling No

1 No Continue controlling Continue controlling Yes

2 No Continue controlling Stand-by mode No

3 No Continue controlling Stand-by mode Yes

4 No Stand-by mode Continue controlling No

5 No Stand-by mode Continue controlling Yes

6 No Stand-by mode Stand-by mode No

7 No Stand-by mode Stand-by mode Yes

8 Yes Continue controlling Continue controlling No

9 Yes Continue controlling Continue controlling Yes

10 Yes Continue controlling Stand-by mode No

11 Yes Continue controlling Stand-by mode Yes

12 Yes Stand-by mode Continue controlling No

13 Yes Stand-by mode Continue controlling Yes

14 Yes Stand-by mode Stand-by mode No

15 Yes Stand-by mode Stand-by mode Yes

Table of Ramp/Soak Modes

Page 57

57

oFF: Not in operation

1-rP – 4-rP: Executing 1st – 4th ramp

1-St – 4-St: Executing 1st – 4th soak

End: End of program

SV-1 Ramp Target Value: Sets the target value for each ramp

to to segment.

SV-4 Setting range: 0-100% of full scale

TM1r Ramp Segment Time: Sets the duration of each ramp

to to segment.

TM4r Setting range: 00.00 to 99hrs 59mins.

TM1S Soak Segment Time: Sets the duration of each soak

to to segment.

TM4S Setting range: 00.00 to 99hrs 59mins.

Mod Ramp/Soak Mode: Up to 16 different modes of ramp/soak

operations are possible. Choose the appropriate code

from the Table of Ramp/Soak Modes

Setting: 0-15

FACTORY PRESET MENU

P-n1 Control Action & Sensor Burn-out Protection: The

Control Action is the direction of the output relative to

the process variable. The controller can be programmed

as either a reverse-acting or a direct-acting controller.

In a reverse-acting controller, the controller’s output

decreases as the process variable increases. A heating

Page 58

58

Table of Output Type Codes

Page 59

59

application would require reverse acting control. In a

direct-acting controller, the output increases as the

process variable increases. A cooling application would

require direct-acting control. Enter the code from the

Table of Output Type Codes which establishes the controller as either a reverse or direct-acting controller.

The Sensor Burn-out Protection is the intended direction of the output in the event of a thermocouple or RTD

sensor break, or a break in the analog input. The controller can be programmed with either upscale or downscale burn-out direction. With upscale burnout, 100%

output will be delivered in the event of sensor burnout.

With downscale burnout, 0% output will be delivered in

the event of sensor burnout. Enter the appropriate code

from the Table of Output Type Codes.

Refer to Error Messages on page 62 for more details.

P-dF Input Filter Constant: The Input Filter is used to filter out

the quick changes that occur to the process variable in

a dynamic or quick responding application that might

cause erratic control. By slowing down the response

Page 60

time, the controller averages out the peaks and valleys of

a dynamic system which, in turn, stabilizes the control.

The digital filter also aids in controlling processes where

the electrical noise is affecting the input signal. The larger the value entered, the more filter added and the slower the controller reacts to process variable changes. The

smaller the value entered, the less filter added and the

quicker the controller reacts to process variable

changes. Enter as small a value as possible that pro-

vides accurate and stable control.

Setting range: 0.0-900.0 secs

P-An Alarm Hysteresis: The Alarm Hysteresis is that area on

one side of the alarm setpoint where the output does not

change condition. That area or deadband is intended to

eliminate relay chatter at alarm setpoint with less wear

on the relay. With a wide Alarm Hysteresis, the controller

takes a longer time to change output condition. With a

narrow Alarm Hysteresis, the controller takes a shorter

time to change output condition. Enter a value which is

just large enough to eliminate relay chatter.

Setting Range: 0 to 50% of full scale, set in E.U.

60

Page 61

61

FUZY Fuzzy Logic Control: Employing Fuzzy Logic Control in

addition to PID control eliminates system overshoot and

effectively suppresses fluctuation of the process variable due to external disturbances. This function may be

enabled even during auto-tuning. Note that fuzzy control

is not effective in units with dual outputs, due to the

complexity of the process. Fuzzy control is also inhibited

while the Ramp/Soak function is in operation.

ADJ0 Zero/span Calibration: This function is used for zero/

ADJ span calibration of the input. Calibration is effected by

first applying the appropriate signal for zero and span

Page 62

ERROR MESSAGES

Error

Indication Cause Control Output

1. Thermocouple burnt out. When the burn-out

2. RTD (A) leg burnt out. control output is set for

3. PV value exceeds P-SU lower limit (standard):

by 5% FS. OFF,or 4mA or less.

1. When RTD (B or C) is When the burn-out

burnt out. control output is set for

2. When RTD (between upper limit: ON, or 20mA

A and B, or between or less.

A and C) is shorted.

3. When PV value is below

P-SL by 5% FS.

4. When analog input wiring

is open or short.

When PV value goes below Control is continued until

-1999. the value reaches -5% FS

or less, after which burnout condition will occur.

HB lamp ON Heater burnout condition Normal control output for

heating is continued.

When the setting of OFF, or, 4mA or less.

P-SL/P-SU is improper

Fault in the unit Undefined. Stop use

immediately.

62

Page 63

63

APPENDIX A

Autotuning

By autotuning, the controller selects what it calculates to be the optimal

PID control parameters for a particular process and then stores them in

EEPROM memory for future use. The PID parameters are stored so that

when the controller is powered up after being shut down, the controller

does not need to be autotuned again. The controller uses the same autotuned PID parameters until the Autotune function is again initiated. The

Autotune parameters are only good for the process the Autotune function was used on. If the setpoint is significantly changed, the input sensor is changed, the load or output device is changed or relocated, or any

other disturbances occur which might change the dynamics of the system, the Autotune function should be performed again. The autotuned

control parameters are not always perfect for every application but

almost always give the operator a good starting point from which further

refinement of the control parameters can be performed manually.

The autotuning algorithm used here is particularly suited for temperature

control applications and may not always autotune effectively for other

processes. Here are cases where the Autotune function does not perform well or does not perform at all:

1. The system is affected by process disturbances external to the control

loop. Adjacent heater zones, changing material levels, exothermic

reactions are examples of process disturbances which are external

to the control loop. The controller would never be able to autotune

such an unstable process.

2. The system is very dynamic. The process variable changes very quick-

ly. Certain pressure and flow applications would be characterized as

Page 64

64

very dynamic. Because of how the Autotune function is performed, a

very dynamic system would create very large overshoots which

could damage the process.

3. The system is very insulated and cannot cool down in a timely manner. With such heating systems the autotuning function would take a

long time to complete, with questionable results.

During autotuning test signals are sent to the process. The test signals

are 100% output and 0% output at the Autotune point. The Autotune

point can either be at setpoint or 10% of full scale below setpoint.

The controller performs as an On/Off controller. See diagram below.

The

Page 65

65

controller then reads the reaction of these test signals on the process.

Keep in mind that every process is different and therefore every reaction to the test signals is different. This is why PID parameters are not

the same for all processes. The amplitude (L) or lag time which is the

overshoot and undershoot of the system when autotuning, and the time

constant (T) which is the time the process takes to go through one

On/Off cycle are measured. See diagram below.

The measurements are then used with the Autotune algorithm for calculation of the proper PID parameters for the system, as shown below,

where K is the proportionality constant and S is the Laplace operator.

K

e

-LS

(1+TS)

Page 66

66

APPENDIX B

Manual Tuning

Tune the controller if any of the following occurs:

• The controller is installed in a new system

• The controller is used as a replacement in an existing system

• The input sensor is relocated or changed

• The output device is relocated or changed

• The setpoint is significantly changed

• Any other condition that will alter the dynamics of the system

Proportional Band

The proportional band is a band around the setpoint of the CN4431

where the output is between 0% and 100%. The percentage of output is

proportional to the amount of error between the setpoint variable (SV)

and the process variable (PV). Outside of the proportional band the output is either 0% or 100%

The proportional band on CN4321/CN4431 is equidistant from the main

setpoint as illustrated below.

Page 67

67

An example of proportioning would be a vehicle approaching a stop sign

at an intersection. If the driver were traveling at 50mph and only applied

his brakes once at the intersection, his car would skid through the intersection before coming to a full stop. This illustrates how On/Off control

acts. If, however, the driver started slowing down some distance before

the stop sign and continued slowing down at some rate, he could conceivably come to a full stop at the stop sign. This illustrates how proportional control acts. The distance where the speed of the car goes from 50

to 0 MPH illustrates the proportional band. As you can see, as the car

travels closer to the stop sign, the speed is reduced accordingly. In other

words, as the error or distance between the car and the stop sign

becomes smaller, the output or speed of the car is proportionally diminished. Figuring out when the vehicle should start slowing down depends

on many variables such as speed, weight, tire tread, and braking power

of the car, road conditions, and weather much like figuring out the proportional band of a control process with its many variables.

The width of the proportional band depends on the dynamics of the system. The first question to ask is, how strong must my output be to eliminate the error between the setpoint variable and process variable? The

larger the proportional band (low gain), the less reactive the process. A

proportional band too large, however, can lead to process wandering or

sluggishness. The smaller the proportional band (high gain), the more

Page 68

68

reactive the output becomes. A proportional band too small, however,

can lead to over-responsiveness leading to process oscillation.

A proportional band which is correct in width approaches main setpoint

as fast as possible while minimizing overshoot. If a faster approach to

setpoint is desired and process overshoot is not a problem, a smaller or

narrower proportional band may be used. This would establish an overdamped system or one where the output would change greatly, proportional to the error. If process overshoot cannot be tolerated and the

approach to setpoint does not have to be quick, a larger or wider proportional band may be used. This would establish an under-damped

system or one where the output would change little, proportional to the

error.

To Calculate Proportional Band:

Proportional Band Proportional Band

(as a percentage) =

____________________

X 100%

Input Range

Example:

30°C

3% =

__________

X 100%

100°C

Proportional Band

(as a percentage)

Proportional Band Range =

____________________

X 1000°C

100%

Example:

3%

30°C =

__________

X 1000°C