Page 1

Page 2

1

Page 3

CONTENTS

MODEL CONFIGURATION……………………………………………….………………………...……………………………. 3

SPECIFICATIONS……………….………………………………………………………..………………………………………...7

PARAMETER AND SETTING…………………………………………………………………….………………………………11

FIELD PARAMETER TABLE …………………………………………………………….……………………………………… 13

SYSTEM PARAMETER TABLE…………………………………………………………………………………………………. 15

SYMBOL DESCRIPTIONS………………………………………………………………………………………………………33

INSTRUMENT INSTALLATION AND WIRING…………………………………………………………………..……………34

DISPLAYS AND OPERATIONS………………………………………………………….………………………………………36

OPERATION DESCRIPTION………………………………………………………………………………………………….…38

PARAMETER SETTING FLOW CHART…..…………………………………………………………………………….………46

PROGRAMMING AND OPERATION……………………………….....……………..…………………………………………47

2

Page 4

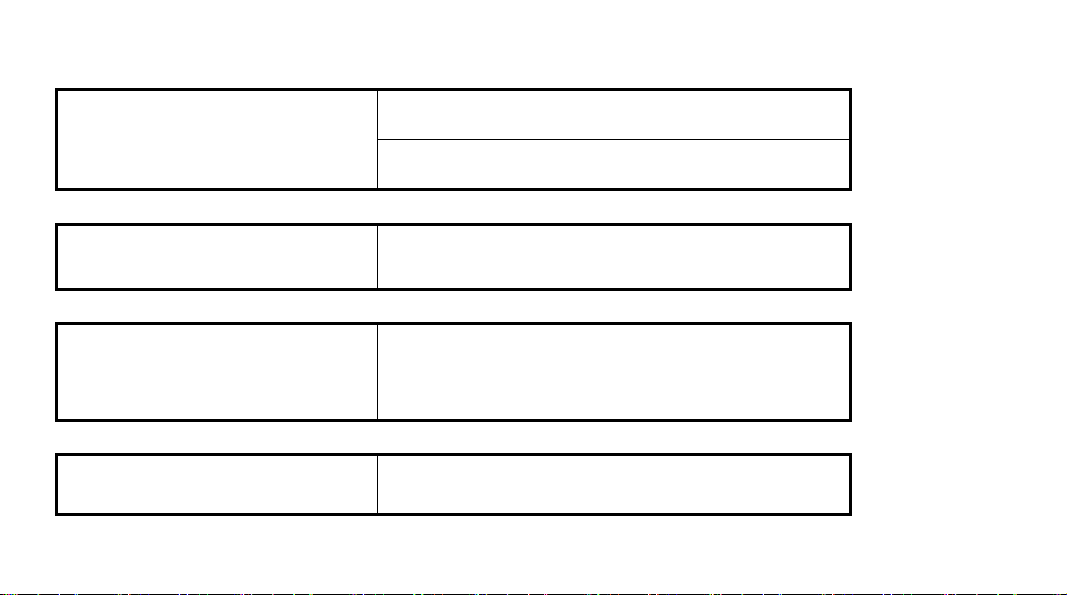

MODEL CONFIGURATION

Model

CN4316(*)-(**)-(***)

CN434(*)-(**)-(***)

CN438V(*)-(**)-(***)

CN438H(*)-(**)-(***)

Description

1/16 DIN controller, Support 0~5/1~5V Voltage Input

1/4 DIN controller, Support 0~5/1~5V Voltage Input

1/8 DIN Vertical controller, Support 0~5/1~5V Voltage Input

1/8 DIN Horizontal controller, Support 0~5/1~5V Voltage Input

3

Page 5

Programmable Controller

CN4416(*)-(**)-(***)

CN444(*)-(**)-(***)

CN448V(*)-(**)-(***)

CN448H(*)-(**)-(***)

1/16 DIN controller, 30 Segment, Support 0~5/1~5V Voltage Input

1/4 DIN controller, 30 Segment, Support 0~5/1~5V Voltage Input

1/8 DIN Vertical controller, 30 Segment, Support 0~5/1~5V Voltage Input

1/8 DIN Horizontal controller, 30 Segment, Support 0~5/1~5V Voltage Input

* Specify controlling output code from Output Options table below

** Specify alarm output code from Alarm Options table below

*** Low voltage power supply option (-LV)

4

Page 6

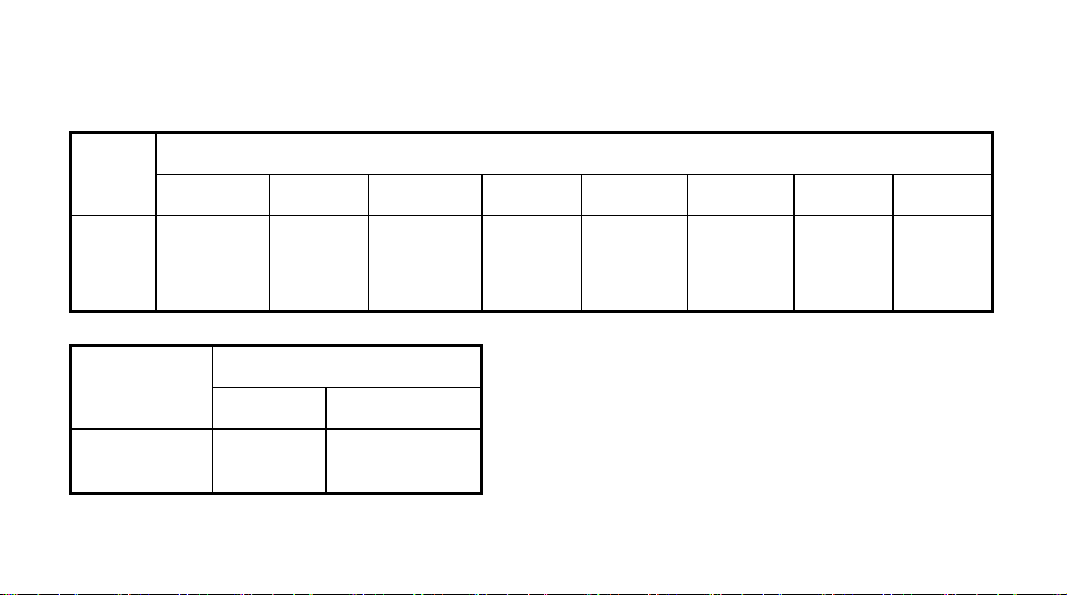

Control output options

Option Type Controlling output code

Relay -R1

DC SSR driver -DC1

4~20 mA Linear Current -F1

5

Page 7

Alarm output options

Option Type

Relay -R2

DC SSR driver -DC2

Alarm output code

Low voltage power supply option

-LV 24V AC/DC, 50/60 Hz

6

Page 8

SPECIFICATIONS

Input

Type

Range

℃/ ℉

Input Type

Range ℃/ ℉

Thermocouple

K S R E J T B N

-50 to1300 ℃

-58 to 2372 ℉

-50 to1700℃

-58 to 3092 ℉

-50 to1700℃

-58 to 3092 ℉

0 to 800℃

32 to 1472 ℉

0 to1000℃

32 to 1832 ℉

-200 to 350℃

-328 to 662 ℉

200 to1800℃

392 to 3272 ℉

0 to 1300℃

32 to 2372 ℉

RTD

Cu50 PT100

-50 to 150℃

-58 to 302 ℉

-200 to 800℃

-328 to 1472 ℉

7

Page 9

Input Type

Accuracy

Display Resolution

Linear Voltage

0 to 5V, 1 to 5V, 0 to 1V,

0 to 20mV, 0 to 100mV

Linear Current

(external resistor needed)

0 to 10mA, 0 to 20mA, 4 to 20mA

0.3%FS ± 0.1℃/ 0.18

℉

0.1℃/0.1℉

8

Page 10

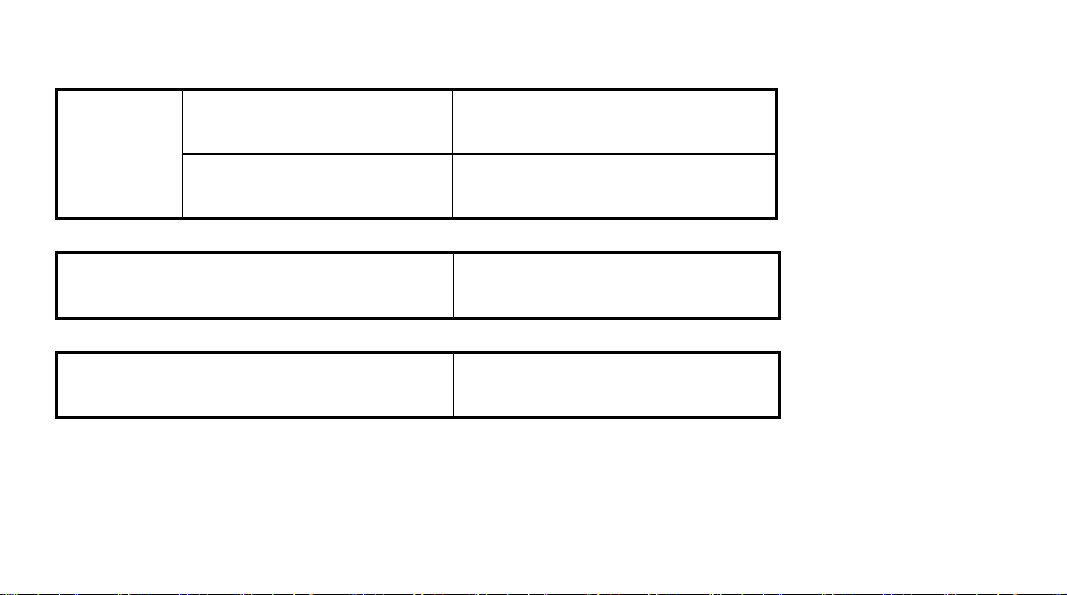

ON / OFF Control

Control Method

Output Type

Alarm

AI PID Control with Auto Tuning (AT)

Standard PID with Auto Tuning (AT)

Relay Output (1A/250VAC)

Voltage Output for SSR (15V/30mA)

Linear Current (4 to 20 mA)

Limit High / Limit Low

High deviation / Low deviation

9

Page 11

Supply Voltage

100~240VAC (-15%, +10%), or 24VDC

50~60Hz

Power Consumption

Operating Environments

Electromagnetic compatibility

≦ 3W

Temperature: -10~+60℃ / 14~140℉

Humidity: 0~90RH%

IEC61000-4-4: ± 4KV/5KHz, IEC61000-4-5: 4KV

10

Page 12

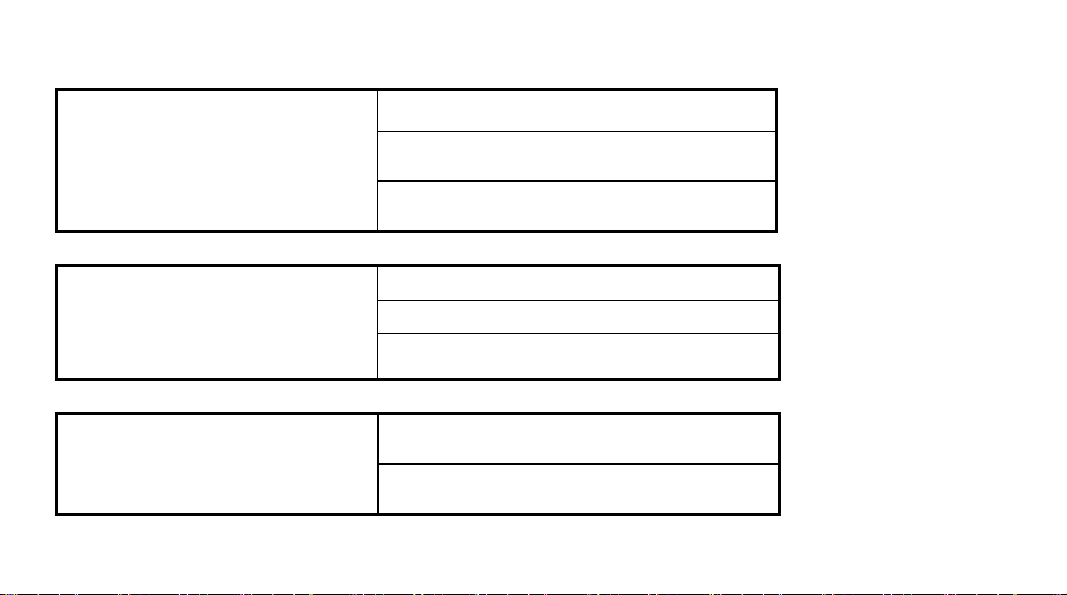

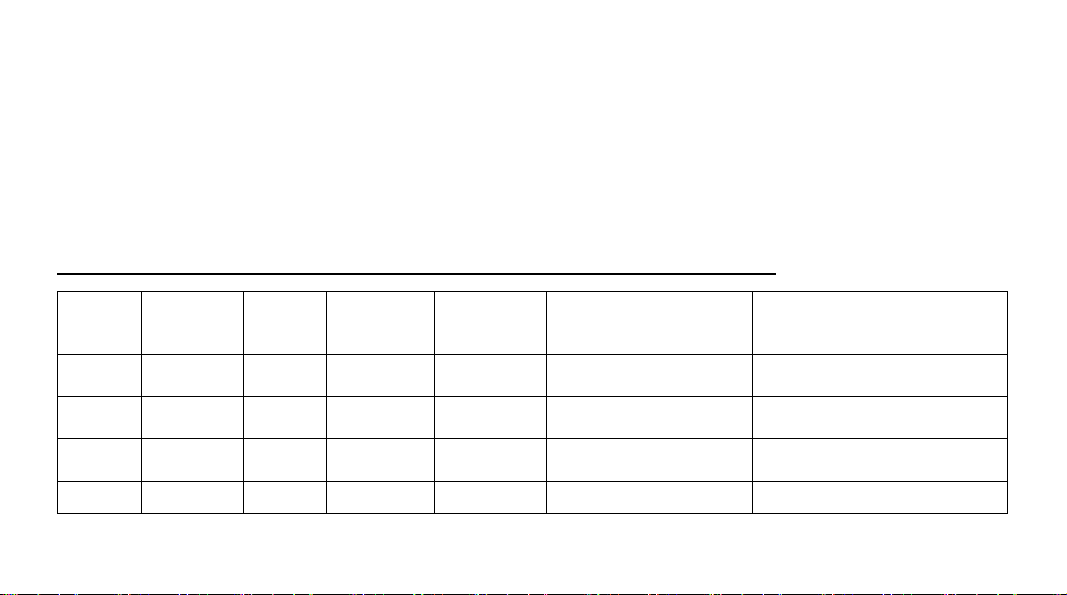

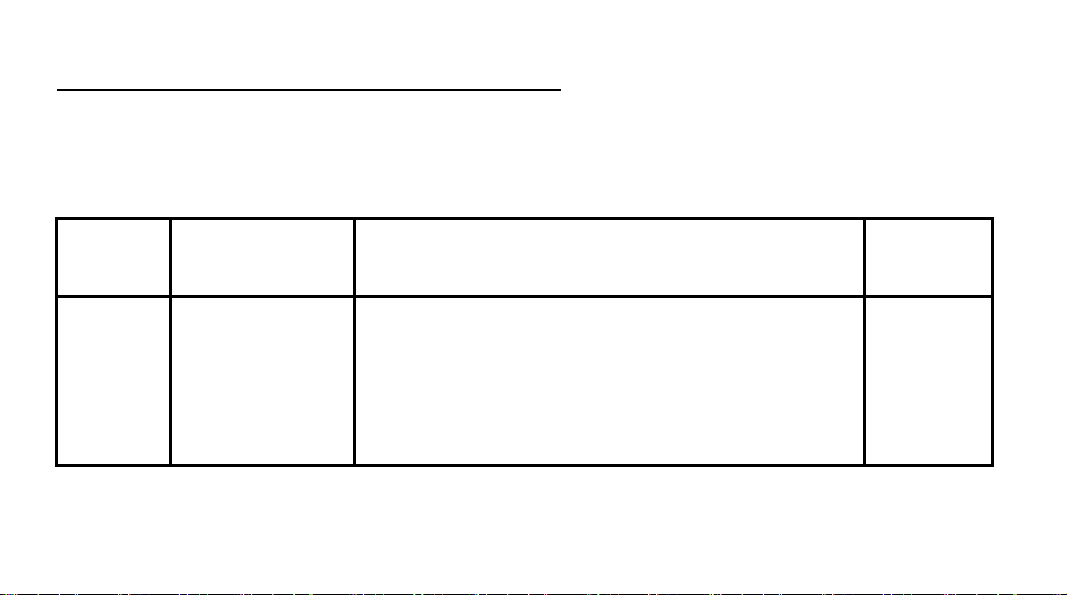

PARAMETER AND SETTING

Parameter is protected by LOC (Parameter LOCK) to prevent setting error. The function was shown as

below:

√ : allow to modify data or execute

X : not allow to modify data or execute

Run, Stop, Hold. and Program Time & Temp. function just for CN 44 only

Loc SV AT

0 √ √ √ X √ √

1 √ X √ X X √

2 X X √ X √ X

3 X X √ X X X

Primary

Parameter

Secondary

Parameter

Status changing to

Run, Stop or Hold

11

Program Step Time & Temp.

Page 13

4~255 X X X X X X

808 √ √ √ √ √ √

Loc 808 is the master password, can be changed by parameter PASd.

Please set PASd cautiously, if the password lost, you can’t access the parameter table again.

1 to 8 field parameters can be defined by parameters EP1 to EP8. If the number of the field parameters

is less than 8, the first idle EP parameter should be set to “nonE”. The initial values of EPs and Loc are

EP1=HIAL, EP2=LoAL, EP3=HdAL, EP4=LdAL, EP5=nonE, EP6=nonE, EP7=nonE, EP8=nonE and

Loc=0.

You can redefine field parameters and Loc to change operation style. For example, you can execute

auto tuning from field parameter instead of by pressing

in basic display status, and only take HIAL

and HdAL as field parameter.

The EP paramters and Loc should be set as below:

EP1=HIAL, EP2=HdAL, EP3=At, EP4=nonE, Loc=1

12 13

Page 14

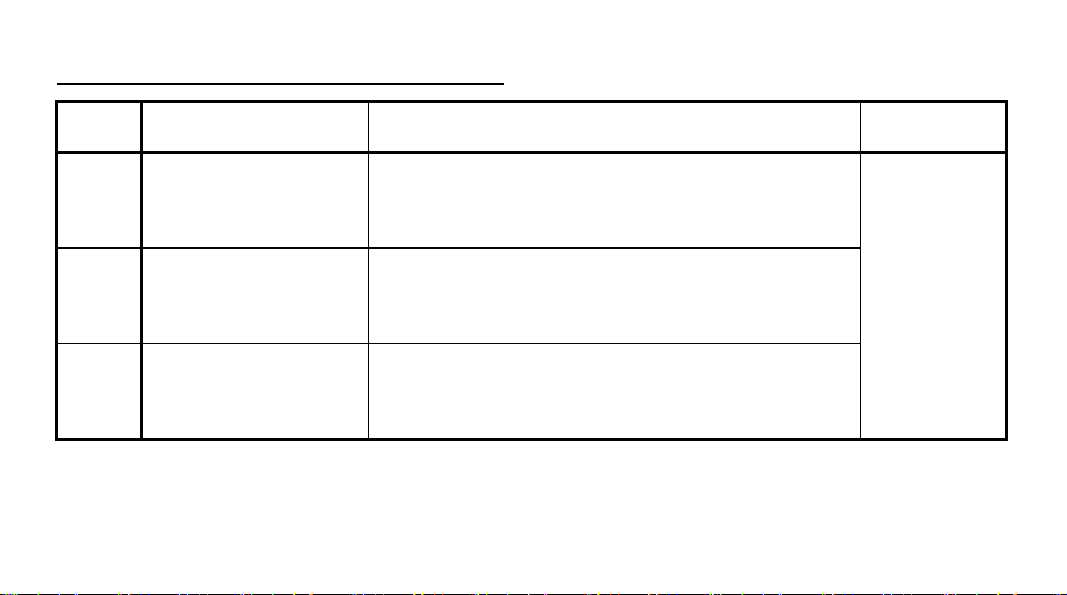

Field parameter table (Primary parameters)

Code Description Remarks

Alarm on when PV>HIAL

HIAL

High limit alarm

LoAL Low limit alarm

HdAL Deviation high alarm

Alarm off when PV<HIAL-AHYS,

When the value set to Max. will disable this function

Alarm on when PV<LoAL;

Alarm off when PV>LoAL+AHYS,

When the value set to Min. will disable this function

Alarm on when PV-SV>HdAL;

Alarm off when PV-SV<HdAL-AHYS,

When the value set to Max. will disable this function

Setting

Range

-9990~30000

Page 15

LdAL Deviation low alarm

Alarm on when PV-SV<LdAL;

Alarm off when PV-SV>LdAL+AHYS,

When the value set to Min. will disable this function

14

Page 16

System parameter table (Secondary parameters)

Set the parameter ‘Loc’=808 to enter:

***: Those Parameters just for CN 44 (Programmable Controller) Only

AHYS Alarm hysteresis

AdIS

Alarm display

Avoid frequent alarm on-off action because of the

fluctuation of PV

oFF : Will not display alarm message in the lower

display window when alarming;

on : Alternately display alarm message in the lower

display window when alarming.

15

0~2000

oFF / on

Page 17

Output to

Alarm

LdAL

(x 1000)

HdAL

(x100)

LoAL

(x10)

HIAL

(x1)

AOP

Alarm output

assignment

None

AL1

AU1

0 0 0 0

1 1 1 1

3 3 3 3

eg: AOP=1101 means LdAL, HdAL and HIAL have

alarm action from AL1; LoAL, no alarm action.

For 1/4 DIN and 1/8 DIN controller, the alarm contact

will trigger form AL1. (Terminal No.5 and No.7)

For 1/16 DIN controller, the alarm contact will trigger

form AU1. (Terminal No.3 and No.5, need set

parameter bAud=0)

16

0~4444

Page 18

CtrL

Srun

Control mode

Running status

onoF : On-off control

APId : AI PID control, high precision (Recommend)

nPId: Standard PID algorithm with

Anti-integral-saturation function (no integral when

PV-SV > proportional band);

PoP: Transmit PV. The instrument works as a

temperature retransmitter.

SoP: No function

run: Control was running, “RUN” led light on

StoP: Control was stopped. Lower display keep

flashing “StoP” and “RUN” led light off.

HoLd: Keeping Temperature. If the parameter

Pno=0(Non timing limitation mode), controller keep

running and cannot change the running status from

17

OnoF /

APId, nPID

/ PoP,

SoP

run / StoP /

HoLd

Page 19

Act

Acting method

panel, if Pno>0 (in program mode), and Srun was shown

HoLd, means

the timer stops and the temperature

remains; user can resume the time by pressing the

“Hold” from panel.

rE: Reverse acting. Increase in measured variable

causes decrease in the output, such as heating control.

dr: Direct acting. Increase in measured variable causes

an increase in the output, Such as refrigerating control.

rEbA: Reverse acting with low limit alarm and deviation

low alarm blocking when the beginning of power on.

drbA: Direct acting with high limit alarm and deviation

high alarm blocking when the beginning of power on.

rE /dr/

rEbA/drbA

At

Auto tuning

oFF: Auto tuning function was off.

on: Active auto turning function to calculate the values

18

oFF / On /

FoFF

Page 20

FoFF : Auto tuning function was off, cannot activate

again by pressing key from panel .

P Proportion band Proportion band in PID with unit ℃ or ℉ 1~32000

I Time of Integral No integral effect when I=0, with unit 1 Sec.

d

Time of

derivative

No derivative effect when d=0, with unit 0.1 Sec.

1~9999

Sec

0~3200

Sec

Small value can improve control accuracy. For SSR

output, generally 0.5 to 3 seconds.

Large value can increase using life of relay. For Relay

CtI Control period

output, generally 15 to 40 seconds.

When parameter Opt =rELY, Ctl will limited more than 3

seconds.

value considering both control precision and mechanical

switch longevity.

Auto tuning will automatically set CtI to suitable

19

0.2~300.0

Sec

Page 21

When the parameter CtrL = onoF, CtI will used as timer to

make delay time to avoid the power restart in short period. It

suit for compressor protection.

P2 N/A

I2 N/A

d2 N/A

CtI2 N/A

CHYS

Control

hysteresis

No any function on this model.

No any function on this model.

No any function on this model.

No any function on this model.

CHYS is used for ON-OFF Control. To avoid too

frequent action on relay.

In reverse acting (heating) PV > SV, output turns off,

when PV<SV-CHYS, output turns on.

In direct acting (cooling), PV<SV, output off, when

PV>SV+CHYS, output on.

20

1~32000

1~9999

0~3200

0.2~300.0

0~2000

Page 22

InP

Input

specification

InP Input spec. InP Input spec.

0 K 1 S

2 R 3 T

4 E 5 J

6 B 7 N

8-16 Spare 17 K (0~300℃)

18 J(0~300℃) 20 Cu50

0~37

21 Pt100 22

Pt100

(-80~300℃)

25 0~75mV 26 0~80ohms

27 0~400ohms 28 0~20mV

21

Page 23

29 0~100mV 30 0~60mV

31 0~500mV 32 100~500mV

33 1~5V 34 0~5V

35 0~10V 36 2~10V

37 0~20V

Four display resolution can selected by setting:

dPt

Display

resolution

0 / 0.0 / 0.00 / 0.000. For linear voltage input,

recommend set to =0.000

22

Page 24

SCL

Signal scale low

limit

Define scale low limit of input. It is also the low limit of

retransmission output (CtrL=POP)

-9990~

32000

SCH

Signal scale high

Scb Input shift

limit

Define scale high limit of input. It is also the high limit of

retransmission output.(CtrL=POP)

Parameter Scb is used to make input shift to

compensate the error produced by sensor or input

signal itself.

PV-after-compensation= PV-before-compensation +

Scb.

23

-1999~

+4000

Default

value=0

Page 25

FILt PV input filter

The value of FILt will determine the ability of filtering

noise.

When a large value is set, the measurement input was

stabilized but the response speed will decreased.

Generally, if great interference exists, then you can

increase parameter “FILt” gradually to make

momentary fluctuation of measured value less than 2 to

5.

When the meter of the instrument is being examined at

laboratory, “FILt” should be set to 0 or 1 to short the

response time. Unit of FILT= 0.5Sec.

24

0~40

Page 26

50C: 50Hz,display .℃ , 50F: 50Hz, display ℉

60C: 60Hz,display . ℃ , 60F: 60Hz, display ℉.

Input has max. anti-interference ability to 50Hz or 60Hz

frequency when parameter set;

50C, 50F

60C, 60F

Fru

Selection of

power frequency

and temperature

scale

SSr: Output SSr drive voltage. The output power can

be adjusted by the on-off time proportion. The period

Opt

Main output

type

(CtI) is generally 0.5~4 seconds.

rELy: For relay contact output or for execution system

with mechanical contact switch.

To protect the mechanical switch, the output period

(CtI) is limited to 3~120 seconds, generally is 1/5 to

1/10 of derivative time.

SSr

rELy

0-20

4-20

PHA

0-20: 0~20mA linear current output.

4-20: 4~20mA linear current output.

25

Page 27

PHA : No Function.

Aut

OPL

OPH

OEF

NA

Output low

limit

Output upper

limit

Work range of

OPH

No any function on this model.

0~100%: OPL is for set minimum output of OUTP in

single directional control system.

OPL limits the maximum of OUTP (main output) when

PV<OEF. OPH should be greater than OPL.

When PV<OEF, the upper limit of OUTP is OPH;

When PV>OEF, the upper limit of OUTP is 100%.

This function is for avoid the temperature raises too

fast. For example: the heater only can working 30%

power when the temperature under 150 degree.

We can set : OEF =150.0 (℃), OPH=30(%)

26

SSr / rELy

0-20 / 4-20

0~100%

0~110%

-1999 ~

3000.0

Page 28

Addr

bAud

Et

AF

N/A

N/A

N/A

Advanced

function

No any function on this model. 0~100

No any function on this model. 0

none/ ruSt

No any function on this model.

AF is used to select advanced function. The value of

AF is calculated as below:

AF=Ax1 + Bx2 + Cx4 + Dx8 + Ex16 + Fx32 + Gx64

A=0

B=0, alarm and control hysteresis work as unilateral

hysteresis; B=1, as bilateral hysteresis

C=0,

D=0, when set Loc=808 can access the whole

27

/SP1.2/

PId2

0~255

Page 29

parameter table;

D=1, when set Loc=PASd can access the parameter

table.

E=0

F=0, Fine control mode, internal control resolution was

demonstration’s 10 times. When on linear input mode,

biggest display value is 3200 units

F=1,Wide range display mode, when the value is bigger

than 3200 ,chooses this option

G=0, When the thermocouple or RTD input is burnt out,

PV value will increase and trigger the high limit alarm.

G=1, When the thermocouple or RTD input is burnt out,

PV value will increase and NOT trigger the high limit

alarm. After it was sets, High Limit alarm will have 30

28

Page 30

PASd

Custom

password

sec. delay for trigger in normal usage.

Note: AF=0 is recommended.

When PASd=0~255 or AF.D=0, set Loc=808 can enter

the whole parameter table.

When PASd=256~9999 and AF.D=1, only setting

Loc=PASd can access the whole parameter table.

Please set PASd cautiously, if the password is lost, you

can’t access the parameter table again.

0~9999

SPL

SPH

SP1

SP2

Low limit of SV

Upper limit of SV

Set point 1

N/A

Minimum value that SV is allowed to be

Maximum value that SV is allowed to be

When Pno=0 or 1, SV=SP1

No any function on this model.

29

-9990~

30000

SPL~SPH

Page 31

Once SPr was set, if PV<SV when program start, the

SPr

Ramp slope limit

***

Pno

***

No. of program

step

first step of ramp slope will limited by SPr value, under

this limitation, the RUN lamp will keep flashing.

For Ramp mode. SPr had effect on first step only.

For Soak mode, SPr had effect on each step.

To define the number of program in use.

Pno= 0, disable the program running mode, can set the

parameter “SPr” to limit the ramp time.

Pno=1~30, CN44 working as normal programmable

controller

30

0~3200℃

/Min

0~30

Page 32

PonP

***

Program run

mode after power

restart

Cont : Continue to run the program from the original

break point. If STOP STATUS was activated before

power cut, then it (the program) will keep stop status

after power restart.

StoP : Stop the program after power restart

run1 : Start to run the program from step 1 unless the

instrument was in “stop” state before power cut.

dASt : If these have deviation alarm after power

resume, then stop the program, otherwise, continue run

the program from the original break point.

HoLd : Go into HOLD state after power on. If it is in

StoP state before power cut, then keep in StoP State

after power on.

31

Cont / StoP

/ run1 /

dASt / HoLd

Page 33

PAF

***

Program

Running mode

PAF = Ax1 + Bx2 + Cx4 + Dx8

When

A=0, Enable ready (rdy) function

A=1, Disenable ready (rdy) function

B=0, Ramp mode.

B=1, Soak mode

C=0, Time unit in Minute, the range is 0.1~3200.

C=1, Time unit in Hour, the range is 0.1~3200

D=0, Disable PV start up function.

D=1, Enable PV start up function.

EP1~

EP8

Field

parameter

definition

Define 0~8 of the parameters as field parameters.

32

Page 34

SYMBOL DESCRIPTIONS

Symbol Description

Input specification setting is incorrect

Or

orAL

HIAL High limit alarm

LoAL Low limit alarm

HdAL Deviation high alarm

LdAL Deviation low alarm

EErr IC Software error

8888 IC Software error

Input wiring is disconnected/ thermocouple problem

Or

Short circuited

33

Page 35

INSTRUMENT INSTALLATION AND WIRING

A

A

Wiring graph for instruments with dimension 1/4 DIN; 1/8 DIN Vertical and Horizontal

Note 1: The compensation wires for

different kinds of thermocouple are

different, and should be directly connect to

the terminals. Connecting the common wire

between the compensation wire and the

terminals will cause measurement error.

Note 2: For linear voltage input, if the

range is below 500mV, connect to

terminals 19 and 18. 0~5V or 1~5V signal

can be inputted from terminals 17 and 18.

100-240VAC~

34

1

2

3

4

5

6

7

8

9

10

L1

N/O

+

N/C

+

COM

LM

COM

N/C

N/O

+

OUTP

11

12

13

14

15

16

17

+

18

19

+

20

Note: The graph suits for

upright instruments with

1/4DIN or 1/16DIN

Vert ical

For instruments with

horizontal, just clockwise

rotate the graph 90 degree.

Page 36

A

A

Wiring graph for 1/16 DIN dimensi

Note 1: 1/16 DIN di ’t support 0~5V or 1

~5V linear voltage input. However, 0~5V or 1~5V signal can

be converted to 0~500mV or 100~500mV by connecting

external precise resistors, 4~20mA can be converted to10

500mV by connecting a 25ohm resistor, then be inputted from

terminals 8 and 9

Note 2: When AU

“bAud” should set to = 0, it will be used for AU1 for alarm output.

mension instruments don

X need work as alaming function, parameter

on instruments

0~

35

:

100-240VAC~

1

2

3

4

5

N/O

+

N/C

+

COM

UX

+

U1

COM

N/O

OUTP

9

10

6

7

8

+

Page 37

DISPLAYS AND OPERA TIONS

① Upper display window, displays PV, parameter code, etc.

② Lower display window, displays SV, parameter value, or alarm

message

③ Setup key, for accessing parameter table and conforming

parameter modification.

④ Data shift key, and auto tuning

⑤ Data decrease key, and also run/pause switch

⑥ Data increase key, and also stop key

⑦ LED indicator. MAN, MIO, Al2, AU2 and COMM indicators is non-applicable.

OP1, AL1 and AU1 LED indicate I/O operation of the corresponding module. RUN LED, which only works for CN44,

means that the program control is running.

36

Page 38

Basic display status:

When power on, the upper display window of the instrument shows the process value (PV), and the lower window

shows the set-point (SV). This status is called basic display status.

When the input signal is out of the measurable range ( e.g., the thermocouple or RTD circuit is break, or input

specification sets wrong), the upper display window will alternately display “oral”, and the instrument will automatically

stop output.

If the lower display window alternately display “HIAL”, “LoAL”, “HdAL” or “LdAL”, it means high limit alarm, low limit

alarm, deviation high alarm, and deviation low alarm happening.

For programmable controller (CN44): The lower display may alternately display between SV and “StoP”, ”HoLd”

or ”rdy” which means the program is stop, pause and ready.

If don’t want to display the alarm message, can disable by set ADIS=oFF

37

Page 39

OPERATION DESCRIPTION

● Parameter Setting:

In basal display status, press and hold for about 2 seconds can access Field Parameter Table.

Press

Press

Press and hold

Press

table. The instrument will escape auomatically from the parameter table if no key is pressed within 25

seconds.

Set Loc=808 and then press can access System Parameter Table.

can go to the next parameter;

、 or can modify a parameter.

can return to the preceding parameter.

(don't release) and then press key simultaneously can escape from the parameter

38

Page 40

● Set Value Setting:

In basal display status, if the parameter lock “Loc” isn't locked, we can set setpoint (SV) by pressing

first、then can , or to adjust value.

Press

key to decrease the value, key to increase the value, and key to move to the

digit expected to modify.

Keep pressing

or , the speed of decreasing or inscreasing value get quick. The range of

setpoint is between the parameter SPL and SPH. The default range is 0 to 400.

● Control Run and Stop

Start controlling run: Press and hold 2 seconds, and let RUN led on. For CN 44, it will start the

program run again

Stop Controlling: Press

and hold 2 seconds, and let STOP led on. For CN 44, it will stop the program

and Step value will reset to StEP=1.

39

Page 41

● AI control and auto tuning

When AI control method is chosen (CtrL=APId / nPId), the PID parameters can be obtained by running

auto-tuning.

In basal display status, press

for 2 seconds, the “At” parameter will appear. Press to

change the value of “At” from “oFF” to “on”, then press

to active the auto-tuning process.

During auto tuning, the instrument executes on-off control. After 2-3 times of on-off action, the

instrument will obtain the optimal control parameter value.

If you want to escape from auto tuning status, press and hold the

"At" parameter appear again. Change “At” from “on” to “oFF”, press

key for about 2 seconds until the

to confirm, then the auto

tuning process will be cancelled. (P.S. If parameter “SPr” activate and the heating was running, then will

stop the “At” until completed the heat up process. )

Note 1: If the setpoint is different, the parameters obtained from auto-tuning are possible different. So

you’d better set setpoint to an often-used value or middle value first, and then start auto-tuning.

40 41

Page 42

For the ovens with good heat preservation, the setpoint can be set at the highest applicable

temperature. Depending on the system, the auto-tuning time can be from several seconds to

several hours.

Note 2: Parameter CHYS (on-off differential, control hysteresis) has influence on the accuracy of

auto-tuning. Generally, the smaller the value of CHYS, the higher the precision of auto tuning.

But CHYS parameter value should be large enough to prevent the instrument from error action

around setpoint due to the oscillation of input. CHYS is recommended to be 2.0.

Note 3: AI series instrument has the function of self-learning. It is able to learn the process while

working. The control effect at the first run after auto tuning is probably not perfect, but excellent

control result will be obtained after a period of time because of self-learning.

Page 43

●

Program setting (Only For CN44)

Press the key once and release in the display status, the instrument will be in the setup program

status. The set point of the current program StEP will be displayed.

Pressing

、 or can modify the value.

Pressing

can go to next parameter. The program parameters will be displayed in the sequence

of setpoint1, time1, setpoint2, time2.

Pressing and holding

for about 2 seconds will return to the previous parameter. Program step can

modify anytime even the program still in running.

Run / Hold

In basic display status, if the program is in stoP status (“StoP” is alternately displayed on the lower

window), press and hold the

key for about 2 seconds until the lower display window displays the

"Run" symbol, the instrument then will start the program.

At running status, press and hold the

key for about 2 seconds until the lower display window displays

42

Page 44

the "HoLd" symbol, the instrument changes to hold status.

At Hold status, the program is still executing, and the process value is controlled same as setpoint, but

the timer stop working, and the running time and setpoint remains. At Hold status, press and hold the

key for about 2 seconds until the lower display window displays the "Run" symbol, the instrument

will back to run program

Stop

Press and hold the

key for about 2 seconds in the basic display status, until the lower display

window displays the "stoP" symbol, the stoP operation is executed now, when program stopped, timer

will be reset and stop. This operation forces the instrument to stop running, meanwhile, the StEP

number will reset to 1, and control output is also stopped

Power cut/resume event handling:

There are 5 events handling method selectable for power resume after power cut. Please refer to

parameter PonP.

43 44

Page 45

PV startup and PV preparation function (rdy function) :

At the beginning of starting a program, resuming a program after power cut or continuing to run a

program after it is just modified, the PV (process value) are often quite different from the set point. PV

startup function and PV preparation function can make PV and set point consistent, and avoid

unexpected result. When PV startup function enabled, the instrument will adjust the running time

automatically to make the expected set point is the same as the current PV.

For example, the program is set that the temperature will be raised form 25 ℃ to 625 ℃ in 600 minutes.

But the current PV is 100℃, then the instrument will automatically to run this program start from 75

minutes, that mean changed the temperature raised from 100 ℃ to 625 ℃ in 525 minutes (600-75) min.

At the above situation(PV=100, SV=25, first step SV), when PV preparation function is enable, the

alarm function will be blocked at that time, and PV will be adjusted to approach SV until the deviation

alarm condition is released (PV is between SV-LdAL and SV+HdAL). After deviation alarm was off, the

controller start the program again. Preparation function (rdy Function) is helpful to keep the integrity of

Page 46

the program, but it will prolong the program time because the start of the program is postponed.

PV startup function is prior to PV preparation function. If both function are enabled, the system apply PV

startup first, if PV startup function works, PV preparation function will not be activated.

Curve fitting:

Curve fitting is adopted as a kind of control technology for CN44 series instrument. As controlled process often has

lag time in system response, by the way of curve fitting the instrument will smooth the turning point of the linear

heating-up, cooling-down and constant temperature curves automatically. The degree of the smooth is relevant

with the system’s lag time t (t=d+CtI) ; the longer of the lag time, the curve will more smooth. On the opposite the

smooth function will be weaker. Generally the shorter of the process lag time (such as temperature inertia), the

better of the program control on effect. By the way of the curve fitting to deal with the program curves, will avoid

overshoot. Note: The characteristic of the curve fitting will force the program control to generate fixed negative

deviation during the linear heating-up and fixed positive deviation during the linear cooling-down, the deviation is

direct proportional to the lag time and the speed of heating-up (cooling-down). This phenomenon is normal.

45

Page 47

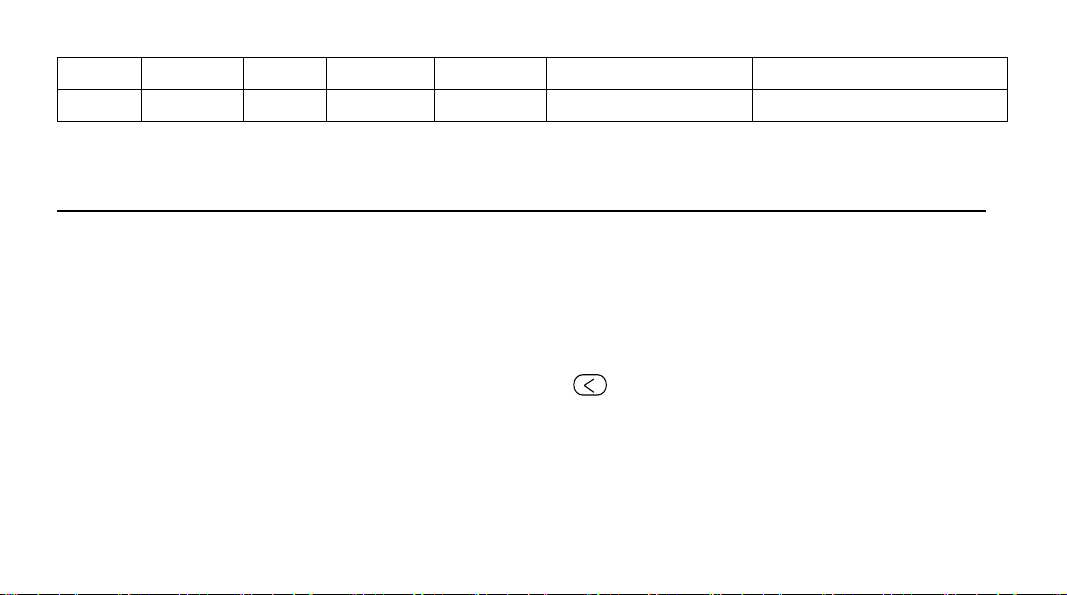

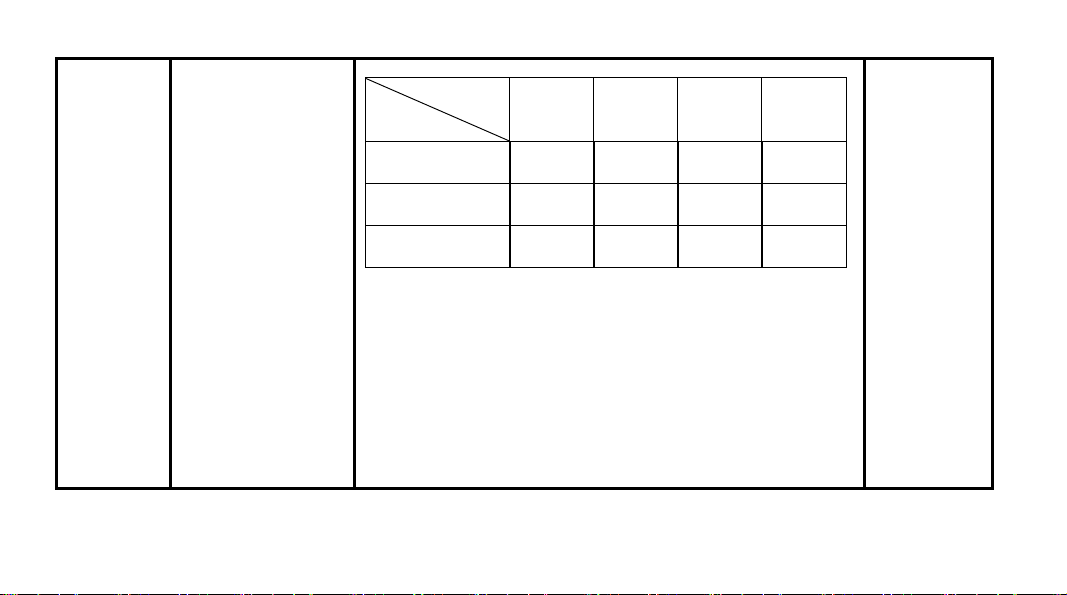

PARAMETER SETTING FLOW CHART

Note: Only CN 44 will display status 3 , 4 and 5

46

Page 48

PROGRAMMING AND OPERATION (For CN44 only)

Ramp Mode(PAF : B=0)

Programming of instrument has uniform format of temperature-time-temperature, which means

temperature “A”(SP 1), passed Time “A”(t01), then reached Temperature “B”(SP 2). The unit of

temperature set is ℃ and the unit of time set is minute. The following example includes 5 steps, which

is linear temperature heating up, constant temperature, linear temperature cooling down, jump cycling,

ready, Hold..

StEP1: SP 1=100.0, t 1=30.0 Start linear temperature heating up from 100℃, and the time needed 30

minutes to reach SP 2(400 degree).

StEP2: SP 2=400.0, t 2=60.0 Temperature raised to 400℃, slope of raising curve is 10℃/minute, The

program take 60 minutes to raise temperature to SP3 (400 degree). It means keep the same

temperature in 60 minutes.

StEP3: SP 3=400.0, t 3=120.0 This is the step for temperature cooling down, slope of cooling curve is

47

Page 49

2℃/minute, and the time needed is 120 minutes to reach SP4 (160degree).

StEP4: SP 4=160.0, t 4=0.0 When temperature reached 160 degree, the program get in Hold state. If

need go to next step, it needed operator to executed the “run” for next step.

StEP5: SP 5=160.0, t05=-1.0 Jump to StEP1 to start from beginning.

In this example, it is assumed that the deviation high alarm is set to 5℃. Because the

temperature of StEP 5 is 160℃, and the temperature of StEP1 is 100℃, when program jumps from

StEP 5 to StEP 1, the program will change to preparation state at first(if preparation mode “rdy” was

enabled), i.e., Control the temperature until the deviation between setpoint and PV is less than

deviation high alarm value. After temperature is controlled to 105℃, the program will be started from

StEP 1, and run the above steps again. The temperature control drawing was shown below.

48

Page 50

Soak mode(PAF : B=1)

Suitable for the process which does not need to establish the temperature slope, can simplify the

programming and more effective. Each step also can set parameter “SPr” to define temperature raise

49 50

Page 51

slope, if “SPr=0” raising speed will set to maximum. Because cannot know the actual time which spend

on temperature raising, user can enable “rdy” function to ensure the correct soak time.

Time setting

Set “t-xx” = 0.1~3200 (min)

Set the time of xx StEP. (Time units can be change to Hour by parameter “PAF”.)

Set “t-xx” = 0.0

The program hold on StEP xx, program will hold running and hold counting time.

Set “t-xx” = -121.0

The program stops, and switches to stop status.

Set “t-xx” = -0.1~-122.0

Negative value of this range represents a jump operation which will jump to step xx and event output.

Range -1~-120 is for step jumping application. The step jumping cannot greater than “Pno”(No. of

Program step).

Page 52

Decimal point use for control the event output from AL1 and AL2. (Modular), Note, if parameter AOP

was assigned alarm action will trigger from AL1 and AL2, the event output also will cause alarm from

AL1 and AL2.

When set

-XXX.1, AL1 activate, AL2 release

-XXX.2, AL1 release, AL2 activate

-XXX.3, AL1 and AL2 activate

-XXX.4, AL1 and AL2 release

Example:

Example 1 : t -5 = -1.1 ; means when the program arrived step 5, AL1 activate, AL2 release and

will jump to step 1 continues running

Example 2 : t-6 = -0.3 ; means when the program arrived step 6, AL1 and AL2 activate and

continuous next step.

Note: The program will be held if it jump from a control segment to another control segment (an Hold

51

Page 53

action will be inserted between two control sections), external run/Hold operation is needed to release

the Hold status. It is not allowed that the jump section jump to itself (for example: t 06= -6), otherwise,

the Hold status cannot be released.

Program arrangement of multi-curve operation

CN 44 has the advanced function of flexible program arrangement. Normally, when the program

stops, the StEP will be automatically set to1. Thus if StEP is not change to other value, a program will

start from step1. If multiple curves are defined, the control can jump to different curve by setting step 1

as jump segment.

For example: There are three curves with the length of 3 steps represent three groups of process

parameter, they are separately arranged on StEP2-StEP4, StEP5-StEP7, StEP8-StEP10. Settings are

as follows:

t -1=-2.0 Execute the program of curve 1 (StEP2-StEP4)

t -1=-5.0 Execute the program of curve 2 (StEP5-StEP7)

52

Page 54

t -1=-8.0 Execute the program of curve 3 (StEP8-StEP10)

Note: Can choose the curves by setting the value of StEP “t-1“ set to -2, -5 or -8 before the program

startup.

53

Page 55

54

Page 56

M-4546/0208

55