Page 1

The name "LEXT" is formed from the words "Laser" and "Next," and means "next-generation 3D confocal laser microscopes".

CONFOCAL LASER SCANNING

MICROSCOPE

OLS3100

TM

NEW

Page 2

Greater simplicity with higher precision:

The next step in the evolution of three dimensional

laser confocal metrology.

1

LEXT minimizes manual operation, improving ease of use for everyone.

Even a first-time user can operate the system like an expert, and obtain fast reliable measurement results.

The system features not only improved functionality, but also an even higher level of measurement performance.

Constantly evolving toward greater simplicity and higher precision,

LEXT meets a diverse range of needs in fine surface profile measurement.

Page 3

2

Welcome to the world of LEXT 3D

Page 4

Automatic operation achieves speedy, high-precision output.

Position and

magnification settings

New, Operation Navigator feature is an online wizard

that guides the user in the operation of the LEXT

The operation navigator provides

animations to guide the user through

each step of microscopic observation.

You can complete a series of steps by

simply operating the mouse in the same

way as shown in the animations

appearing on the screen.

The motorized, high-speed revolving nosepiece ensures

the safe and speedy microscopic inspections

Motorized switching between magnifications helps the user to

increase work efficiency and to keep the specimen safe; an

automatic retracting function prevents an objective lens from

coming contact with a specimen. It also

offers excellent parfocality of all

objective lenses and an automatic light

intensity adjusting function keeps

brightness levels unchanged after

magnification switching.

High-speed automatic focusing and one-push gain

enable the user to complete preparations for 3D image

capturing quickly and easily

The speed of the automatic focusing function has been made

three times faster so that the user can reach an image or a point

on an image in an instant. Additionally, one-push gain allows the

user to adjust brightness optimally and to complete preparations

for 3D image capturing with ease.

Click

3D image capturing with one click automatically

detecting upper and lower limits

With LEXT, 3D image capturing is performed by just one click of

the “3D capture button.” Upper- and lower-limit settings or other

cumbersome preparations are unnecessary. A beginner can

obtain a 3D image of the best quality easily. For experienced

users, this automated 3D image capturing feature lightens their

work load and contributes greatly to increasing their work

efficiency.

3

Page 5

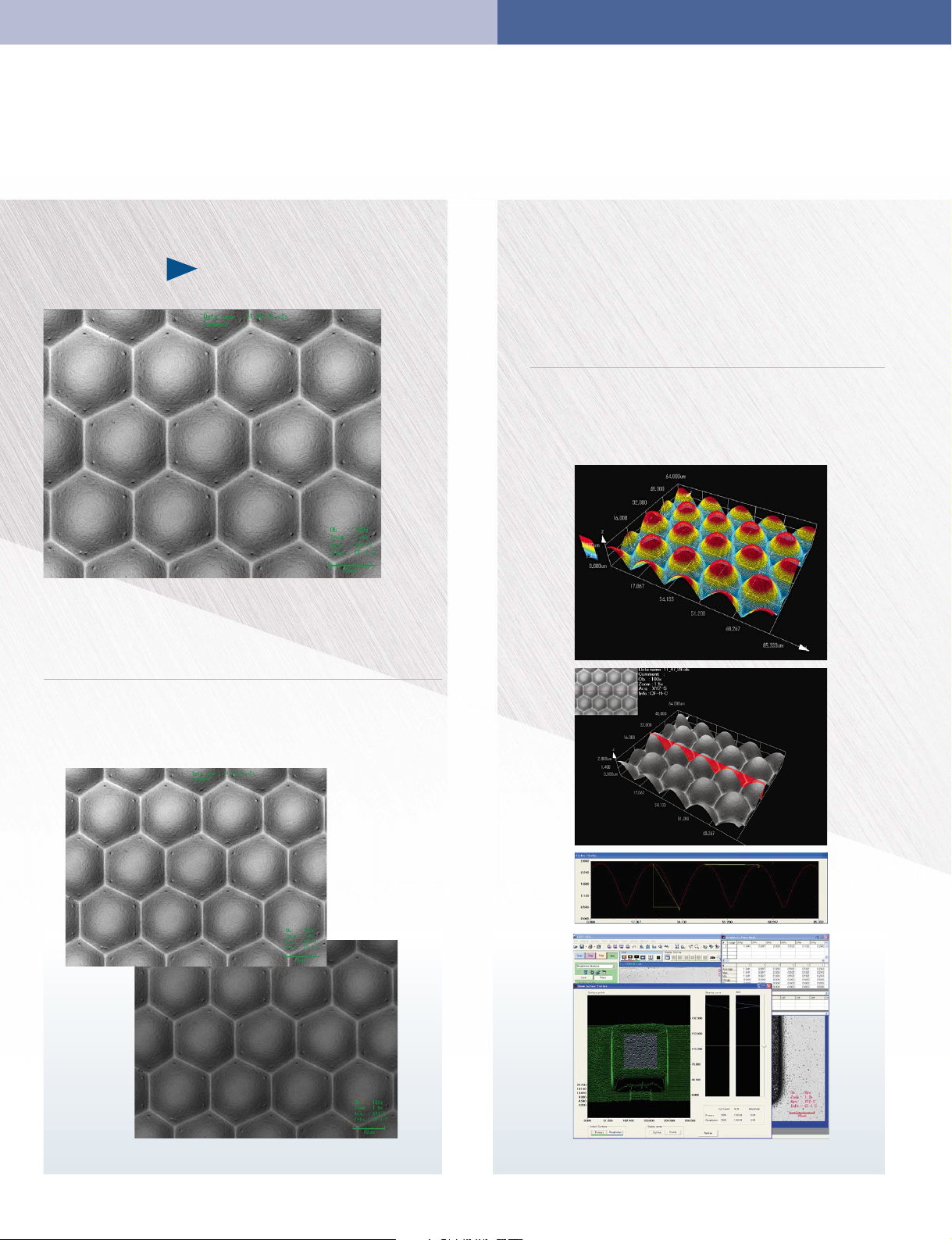

Auto Fine View does it all automatically

The brightness and contrast of a captured image are automatically adjusted. Image conditioning is typically a manual process

requiring an experienced operator. Using the auto fine view

function of LEXT, anybody can acquire ideal, high-quality 3D

images without special training.

Introducing the user to a new 3D world

by providing a variety of image presentation

patterns, high precision measurement and

advanced analytical techniques

A captured image is rendered to an ideal 3D image by

using LEXT’s display capabilities. High precise

measurement, high repeatability, and advanced analytical

techniques related to roughness and particle analyses

provide the user with a new dimension of microscopic

observation.

Welcome to the world of LEXT 3D

Display, measurement and

analysis

Image

capturing

Wired frame

Microlens

Image intensity

profile

Step height

measurement

Surface

roughness

analysis

After auto

processing

Before

processing

4

Wafer bump

Page 6

Powerful 3D display facilitates measurement and analysis.

● Adjustable 3D image

The angle of a 3D image can be now changed freely

with the mouse by grabbing the image. In addition,

the 3D image can be scaled up or down in 100 steps

using the mouse wheel. This is done using a unique

algorithm to prevent the quality of the enlarged image

from deteriorating. The background color can now

also be changed to improve the observation and

contrast of the specimen.

● 3D measurement

Step height, line width and the distance between two

points can now be measured on the 3D image.

Allowing measurement conditions to be recognized

intuitively.

Display

Measurement

Step height measurement

Line width measurement

Distance between two points measurement

5

Filamentation electrode

Page 7

● A variety of 3D image presentation patterns

A variety of 3D image presentation patterns are provided,

including surface texture, real color, wired frame, etc. A 3D image

can be rendered to make it more visually effective.

● Surface roughness analysis

Non-contact surface roughness measurement can be gathered

using the small laser spot. Further minute roughness analysis can

be made using the unique ROI function. Roughness can also be

made along a single line much like conventional roughness

gauges.

Welcome to the world of LEXT 3D

Analysis

Toner film

Surface

Surface 1

Corny layer cells

Reverse face of a Si wafer

Texture

Surface 2

Wired frame

Texture

Real color (brightfield observation)

Stud bump

Surface

Perspective

Balance perspective

Surface roughness

analysis

Light guide plate (for LCD)

6

Page 8

7

Versatile observation methods to handle a wide range of applic

● Brightfield observation

Color information can be obtained from brightfield (color)

observation. Therefore, brightfield observation can be used

effectively to observe a flaw on a color filter or to locate the

position of an area of corrosion on metal.

● DIC (Differential Interference Contrast) observation

In DIC observation, it is possible to observe a scratch or flaw as

small as a few nanometers in height that could not be observed in

a brightfield observation.

● Laser confocal

Observation with a much higher level of resolution impracticable

with conventional microscopes is now possible through a

combination of a 408 nm laser and confocal optics.

● Laser confocal DIC

Microscopic unevenness on a surface can be observed in three

dimensions in real time, which is impossible with conventional

laser microscopes. Observation of surface conditions with the

level of dimensional reality comparable to that of an SEM has

been made fully possible, opening up a new dimension in surface

profile observation.

Display

Laser printer toner

Reverse face of a wafer

Circuits patterns on wafer

Polymeric film

Non confocal image

Confocal image

Page 9

8

ations.

Welcome to the world of LEXT 3D

● Real-time distance measurement

A distance can be measured in real time by using image intensity

profile. A distance can be measured in live observation.

● Particle analysis

Particles can be automatically separated using the separator

function, threshold values can be set, and the range of detection

can be specified. Automatic measurement of all particles can be

made using various particle measurement parameters, and

measured data can be statistically processed to support

advanced particle analyses.

● Split screen display

An image observed in one observation mode and the same image

observed in another observation mode can be displayed

simultaneously during live observation. A target point can be

located easily by observing a microscopic image with color

information and a high-resolution LSM (Laser Scanning

Microscope) image simultaneously. By using this two-screen

display function, the quality of a specimen can be checked by

comparing it with a reference specimen in live observation, and

whether it is acceptable or not can be determined.

Measurement

Analysis

Stud bump

Test patterns (Chromium)

Corny layer cells

Page 10

9

World-class resolution and precision.

Objective lens

Circular confocal

pinhole

LED light

CCD

Photomultiplier

Laser

● World’s highest level of resolution

The optical system designed exclusively for use with 408-nm

laser light (violet opt system) prevents the occurrence of

aberrations associated with the use of a short-wavelength light

source, and brings the highest performance out of the 408-nm

light source. Such a high level of resolution has been made

possible by the confocal optical system having an optimized

circular pinhole and the highspeed XY scanner with the

MEMS technology of Olympus.

With the world's highest-level

planar resolution, a line or space

of 0.12 µm can be resolved.

Additionally, the 0.01 µm height

resolution supports the user in

undertaking measurements of

microscopic surface profiles.

Basic concept of a light path in the violet opt system

Basic concept of the two-dimensional scanner

Multiple points

at peak

intensity

Intensity

Height

MEMS scanner

Incident light

Scan pattern

0.12 µm line and space 14,400x

● Further advanced, the world’s highest level of

repeatability

Advanced optical techniques of Olympus accumulated over

years have made possible the planar measurement

repeatability of 3σ = 0.02 µm and the height measurement

repeatability of 3σ = 0.04 + 0.002L mm (L = measured length

in µm). A guide with high performance in terms of straightness

and a high-precision linear scale are used for Z-axis scanning.

These parts combined with the further advanced CFO search

function contribute to very high level of repeatability. The high

degree of reliability makes it possible for LEXT to meet the

highly demanding needs of diverse fields of research and

industry.

● Measurements that can be trusted

Highly reliable data can be provided based on the strict

traceability system that is linked with the JCSS (Japan

Calibration Service System).

JCSS Japan Calibration Service System

Block Gauge

OLYMPUS

Stabilized He-Ne Laser

Calibration standard

Calibration block

LEXT (OLS3100)

Traceability chart

Japan (NMIJ/AIST)

CFO search function

The original I-Z curve is

drawn based on the upper,

high-luminance points, and

maximum luminance values

are calculated with high

accuracy by using an

advanced formula. The high

repeatability of LEXT is

made possible through the

height data being obtained

in this process.

Page 11

10

● Objective lens designed exclusively for LEXT

Confocal Laser Scanning Microscope

An apochromatic objective lens exclusively for Confocal Laser

Scanning Microscope, which enables to improve the optical

performance with a 408-nm laser light, was developed. This

special objective lens developed with the world-class optical

technology of Olympus has made possible the highest level of

observational clarity and measurement accuracy at high

magnifications.

● ROI (Region of Interest) noise filter

Areas can be specified on the screen, and different filtering

operations can be performed for each area. An ideal 3D image

can be obtained.

● 5-step sensitivity switching function

LEXT allows sensitivity to be set at each Z position (note) and an

image to be captured by switching from one level of sensitivity to

another. In the case of a specimen with multi-structure patterns

and holes, varying reflectances pose a difficulty in measuring the

height. Using this sensitivity switching function, it is possible to

obtain information on optimal height and luminance for such

types of specimen.

Note: Sensitivity can be set for a maximum of five Z positions.

Welcome to the world of LEXT 3D

Enhanced mode ON

Enhanced mode OFF

PCB (Printed Circuit Board)

● Enhanced mode to capture clear images of

specimens with different reflectances

In the case of a conventional laser microscope, it is difficult to turn

specimens with different reflectances into an image, such as the

surface of a printed circuit board or copper wiring board, or an

inclined plane with weak reflection. LEXT equipped with the

enhanced mode allows such specimens to be turned into clear

images.

Sensitivity setting 5

Sensitivity setting 4

Sensitivity setting 3

Sensitivity setting 2

Sensitivity setting 1

Simulations

Before processing

After processing

Camel hair

Page 12

Full range of measurement/analysis functions to meet virtually

Laser confocal 3D image Laser confocal DIC image

Laser confocal 3D image Particle analysis

Spherocrystal of polyamide resin

Foam (fluoro rubber)

The image shown below is a three-dimensional image of a spherocrystal of an injection molded polyamide resin (PA66) product

observed using the N-ARC method. Such a spiral-shaped higher-order structure is observed in the spherocrystal growth process

after injection molding, although it is of rare occurrence. LEXT with the DIC capability can capture a minute level difference of

several nanometers as a clear 3D image, as shown in the image to the left.

Foam made by being injected with tiny air bubbles has outstanding properties—they are heat-insulating, flexible and shockabsorbing. Therefore, such foam is widely used as the material of wet suits, as packing and weather strips, and as the material to

make many other products. The size of air bubbles and how uniformly the air bubbles are distributed have a great influence on the

merchantability of a foam product. The image on the left is a 3D image of a cross section cut through a piece of fluoro rubber

foam in a cooled condition. By processing this image, data on the volume and area of this foam can be obtained. This type of data

can be provided so that the user can use the data to identify defects in foam products, to improve production conditions, and for

other purposes.

11

Page 13

any requirement.

Laser confocal 3D image Cross-section measurement

Data: Courtesy of NISSAN ARC, Ltd.

3D image in real color Line roughness analysis

Solder (after ion etching)

Paper applied with an adhesive (sticky note)

Welcome to the world of LEXT 3D

Because solder is very soft, years of experience and know-how are required to make specimen preparations before observing the

composition of solder under a microscope. Polished surface techniques using the ion etching method have made considerable

progress in recent years. The image shown below is the surface of solder processed with the ion etching method. This image

shows that the tin (Sn) layer (white part) is made smoother by using the ion etching method. An SEM requires vapor deposition,

whereas LEXT does not require pretreatment. Therefore, by using LEXT a specimen can be observed in its actual state.

Sticky notes are widely used for the convenient feature of applying, peeling and applying again. Minute spherical adhesives are

distributed where an adhesive is applied to a sticky note, as shown in the image below. The way they are distributed, the

thickness of an adhesive, etc., are thought to determine the ease of use (merchantability) of sticky notes. Using LEXT, such

adhesives and paper (fiber) can be observed and measured without pretreatment in a noncontact manner.

12

Page 14

Models to respond to individual needs.

● Stitching (Tiling) function to allow the user to make

measurements over a wider area

LEXT is equipped with the tiling function for integrating a multiple

of images into a single image. An observational area up to 12.8

mm x 12.8 mm can be viewed as one image. Measurement can

also be made by viewing a tiled image. Furthermore, work

efficiency can be increased considerably by specifying the image

capturing method as a recipe setting.

Measured image

Motorized stage/OLS30-CS150AS

● Consecutive measurement of multiple points

Registered positions on a specimen can be automatically and

consecutively captured under the same conditions. This makes it

possible to automate the taking of measurements.

Recipe setting screen

Consecutive setting screen

Stitched (Tiled)

image

Configuration with a motorized stage

Confocal laser scanning microscope for 300-mm

wafer observation/OLS3000-300

This product may not be available in your area.

Please consult your Olympus dealer.

13

Page 15

279

177

464

494

559

520 (–620)

680

700

700 520

580 800

(Unit: mm)

(Unit: mm)

349.5

350 170

353

417 176

406~456

190

415

■ Monitor *

LEXT unit dimensions LEXT configuration dimensions

■ Control unit

■ PC *

14

Welcome to the world of LEXT 3D

Specifications

Laser scan Universal

Observation method Laser Laser, Laser confocal DIC, Brightfield, DIC

Microscope stand Illumination Laser 408 nm LD laser, Class 2

White light — White LED illumination

Z stage Vertical movement/Maximum height of specimen 70 mm/100 mm

Z revolving nosepiece Stroke/Resolution/Repeatability 10 mm/0.01 µm/3 σ =0.04+0.002L µm

Objective lens 5x, 10x, 20x, 50x, 100x

Total magnification 120x–14400x

Field of view 2560x2560–21x21 µm

Optical zoom 1x–6x

Stage * Manual stage/Motorized stage 100x100 mm/150x100 mm

Frame memory Intensity/Height 1024x1024x12 bit/1024x1024x16 bit

AF Laser reflection type

Dimensions 464(W)x559(D)x620(H) mm

Weight 56.9 kg 57.5 kg

*300 mm x 300 mm stage is optional upon special order basis.

* PC & monitor have slightly different dimensions dependent on the area of region.

Page 16

Specifications are subject to change without any obligation on the part of the manufacturer.

•OLYMPUS CORPORATION has obtained ISO9001/ISO14001.

Printed in Japan M1619E-0107B

Loading...

Loading...