Page 1

INSTRUCTIONS

ENDOSCOPIC FLUSHING PUMP

OFP

CAUTION

Federal (USA) law restricts this device to sale

by or on the order of a physician.

0086

Page 2

IMPORTANT

Please read this manual carefully before attemptingtousetheOlympus OFP as it contains importantinformation on the proper care,

handling and use of the equipment. In addition, read the manuals of any other units (endoscope, light source, etc.) that form part

of the system.

The safety and performance of an endoscopic systemdepends not only on the endoscope but also on the ancillary equipment used

with it. Ensure any ancillary equipment is compatible with the endoscope and other equipment used. These instructions should be

retained for reference during the life of the product. If you have any questions concerning the material contained in this manual,

please contact your Olympus representative or nearest Olympus office.

INTENDED USE

The Olympus OFP is a peristaltic flushing pump intended for use in medical facilities under the direction of a trained physician. The

OFP has been designed to be used with Olympus EVIS EXERA gastrointestinal videoscopes hav ing an auxiliary water inlet as part

of an Olympus endoscopic imaging system to facilitate washing of gastric and colonic mucosa to remove blood, faeces and other

organic matter, enabling improved visualisation, diagnosis and therapy during endoscopic procedures.

Do not use the equipment for any purpose other than its intended application.

WARNING SYMBOLS USED ON DEVICE

Refer to instructions

SIGNAL WORDS

WARNING: D Indicates a potentially hazar dous situation which, if not avoided, could result in death or serious injury.

CAUTION: D Indicates a potentially hazar dous situation which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices or potential equipment damage.

NOTE: D Indicates additional, helpful information.

Page 3

CONTENTS

PAGE

1 ST ANDARD SET & FEATURES 1..........................................

2 OPERATING PRECAUTIONS 3............................................

3 INSTRUCTIONS FOR USE 4..............................................

4 STEAM STERILIZATION (AUTOCLAVING) 9..................................

5 CARE AND STORAGE 10................................................

6 MAINTENANCE AND REPAIR 10..........................................

7 SPARES & ACCESSORIES 12............................................

8 SPECIFICATIONS 12...................................................

9 TECHNICAL DESCRIPTION 13............................................

10 ENVIRONMENT AL PROTECTION 13.......................................

11 TROUBLESHOOTING 14................................................

Page 4

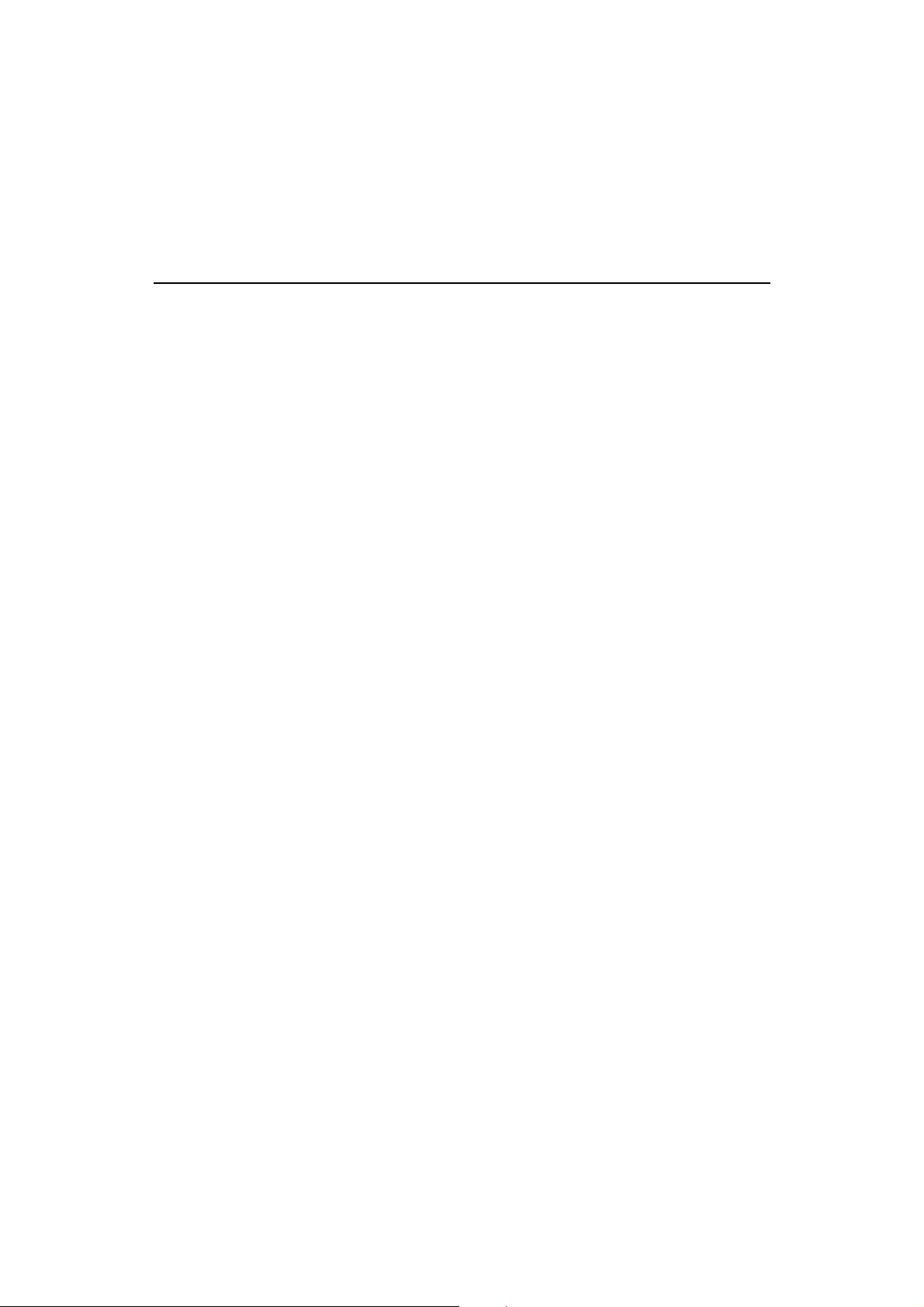

1 STANDARD SET & FEATURES

1.1 Standard set

Unpack the OFP and associated items from the packaging. Refer to Figure 1-1 below and confirm that all items in the

standard set are present. Contact your Olympus service centre or nearest Olympus office if any parts are damaged or

missing.

FIGURE 1-1

1

2

4

3

5

Contents Qty

OlympusFlushingPumpOFP .............................. 1

1

2 Fluidcontainer(suppliednon--sterile) ......................... 1

3 Irrigationtube(suppliednon--sterile) .......................... 2

4 Footswitch ............................................ 1

5 Filter(supplied non--sterile) ............................... 10

6 Powercable(notshown) .................................. 1

7 Instructions(notshown)................................... 1

1

FLUSHING PUMP OFP

Page 5

1.2 Features

ON/OFF

power switch

Flow control

Autoclavable

irrigation tube

Autoclavable 1 litre

fluid container

Fluid container

strap

Label 1

Label 2

Footswitch

connection port

Remote control

cable connection

IEC power receptacle

(with integral fuses)

Rear panel

Fluid container

holder

Peristaltic pump

FIGURE 1-2

Label 3

Potential equalisation terminal

1.3 Labels

Label 1 -- Refer to Instructions

Label 2 -- Footswitch connection port

Label 3 -- Rating plate

2010--06

Label 4 -- “USE BY” Indicates the last month during which the device is intended to be used.

FLUSHING PUMP OFP

eg: June 2010 becomes 2010--06

(label 4 is affixed to the irrigation tube).

2

Page 6

2 OPERATING PRECAUTIONS

2.1 Explosion hazard -- never install or use the OFP within the zone of risk of flammable gases.

2.2 The OFP should only be used in a medical facility under the direction of a trained physician.

2.3 The operator must assess the condition of the patient and use clinical judgement to set the flow rate from the pump to a

suitable level to avoid patient trauma. The flow control should always be set to MIN at the start of the procedure and be

increased progressively to a level commensurate with the clinical condition of the patient and degree of washing required.

Note that when the flow control is set to MAX, the flow rate through the washing channel of the endoscope will be in

excess of that which can be delivered when using a 50ml syringe.

2.4 Use only in conjunction with Olympus EVIS EXERA series endoscopes having an auxiliary water inlet.

2.5 Only use the Olympus auxiliary water tube (MAJ--855) and irrigation tube supplied to connect the OFP to the endoscope,

otherwise patient safety may be compromised or damage to the pump may occur.

2.6 Note that the luer lock connector on the MAJ--855 which attaches to the OFP filter includes a one--way valve to prevent

backflow -- do NOT use the MAJ--855 without this connector in place, or irrigation tube and filter, container contamination

and damage may result.

2.7 The irrigation tube and filter MUST be autoclaved before use.

2.8 The irrigation tube and filter MUST be replaced daily -- failure to do so may lead to patient infection and a reduction in

equipment performance.

2.9 Reprocess the MAJ--855 following each use according to the manufacturer’s instructions supplied with the product.

2.10 Check the “USE BY” date of the tubing as indicated on the packaging label. Do not use any tubes beyond the specified

“USE BY” date.

2.11 Never allow the fluid container to run dry, otherwise air will be supplied to the patient.

2.12 To prevent free--flow of fluid to the patient, do not open the pump cover when the OFP is connected to an endoscope which

is inserted into the patient and ensure the OFP is positioned below patient level.

2.13 If the filter becomes blocked or the irrigation tube from the pump to the fluid container is blocked or kinked, the flow rate will

be noticeably reduced. Check the tube for kinks or blockages and the filter for contamination, replace if necessary.

2.14 Should the OFP be operated with a blocked endoscope or filter,damage to the irrigation tube may occur. In this event, care

must be taken when disconnecting the fluid path as the system may be pressurised. To depressurise the system, the pump

head should be opened to allow fluid back into the bottle. This must only be carried out with the endoscope removed from

the patient. The filter and irrigation tube MUST be replaced before the unit is reused.

2.15 Always switch off the pump before fitting or replacing the irrigation tube.

2.16 When the irrigation tube has been correctly installed and the pump operated,do not disturb the position ofthe irrigation tube

eg: by opening the pump head, otherwise the irrigation tube must be replaced. Failure to do so may lead to a reduction in

equipment performance.

2.17 Periodically inspect the MAJ--855 for obvious signs of wear or damage and replace if necessary or as recommended in the

manufacturers instructions.

2.18 Periodically inspect the fluid container for obvious signs of wear or damage and replace if necessary.

2.19 Always empty the fluid container before moving the equipment. Care should be taken to obtain a firm grip underneath the

body of the equipment before moving. The fluid container holder must never be used as a hand hold or carrying handle.

2.20 Store and use the OFP within the environmental conditions described in Section 8; failure to do so may lead to equipment

malfunction or failure.

2.21 Only use replacement parts as specified in Section 7. Failure to do so may lead to equipment malfunction or failure.

3

FLUSHING PUMP OFP

Page 7

2.22 Confirm that the hospital grade wall power outlet has adequate electrical capacity to power the equipment connected to it.

Failure to do so may cause fire or power failure to all equipment connected to the same power circuit.

2.23 There are no operator--serviceable components inside the OFP. Refer servicing to qualified service personnel.

2.24 In accordance with the instructions supplied with the endoscope, ensure that the auxiliary water channel is patent and free

from blockages before starting a procedure.

2.25 At the beginning of each day of use, check that the pump head safety switch is operating correctly as follows:

With no tube fitted, operate the pump at maximum speed and, taking care to keep fingers clear of the rollers, lift the

pump head cover. The rollers should promptly stop rotating. If they do not, switch off the pump, disconnect it from the

electrical power supply and contact your Olympus representative.

3 INSTRUCTIONS FOR USE

WARNING

The OFP has been designed to be used with Olympus EVIS EXERA series gastrointestinal videoscopes

having an auxiliary water inlet as part of an Olympus endoscopic imaging system to facilitate washing of gastric

and colonic mucosa to remove blood, faeces and other organic matter, enabling improved visualisation,

diagnosis and therapy dur ing endoscopic procedures. Do not use for any purpose other than this intended use.

Ensure the OFP is switched off before installation or removal of the irrigation tube.

The operator must assess the condition of the patient and use clinical judgement to set the flow rate from the

pump to a suitable level to avoid patient trauma. The flow control should always be set to MIN at the start of the

procedure and be increased progressively to a level ‘commensurate with’ the clinical condition of the patient

and degree of washing r equired.

Note that when the flow control is set to MAX, the flow rate through the washing channel of the endoscope will

be in excess of that which can be delivered when using a 50ml syringe.

If there is NO fluid flow during use, stop the OFP immediately and identify and correct the cause, otherwise the

patient may be insufflated with air or damage to the unit may occur.

The irrigation tube, filter and fluid container are supplied in a non--sterile condition and MUST be autoclaved

before use (see Section 4) .

CAUTION

The OFP should not be positioned where the fluid container is directly exposed to heat emitted from adjacent

equipment, otherwise fluid in the container may become hot after a period of time and scald the patient.

Reprocess the MAJ--855 following each use according to the manufacturer’s instructions supplied with the

product.

Check the “USE BY” date of the tubing as indicated on the packaging label. Do not use any tubes beyond the

specified “USE BY” date.

Only sterilised water is to be used in conjunction with the OFP during operation. Use of irrigation fluid other

than sterile water may cause an infection risk to the patient.

The unit contains a safety device which will sound an audible alarm in the event of the pump operating without

the footswitch or remote control being activated. If the alarm is heard, switch the unit OFF immediately and

contact Olympus for service/repair.

FLUSHING PUMP OFP

4

Page 8

3.1 Remove the cap from the fluid container and sterilise both items by autoclaving before use. The irrigation tube and filter

must also be autoclaved before use (see Section 4).

NOTE

Remove the cap from the fluid container and autoclave separately. Otherwise, effective autoclaving will not be

possible, which could pose an infection control risk or cause tissue irritation.

The irrigation tube should be kept as straight as possible during autoclaving to avoid a permanent set forming.

A colour change in the irrigation tubing is normal after autoclaving, this will not affect performance and will

recover if left to rest.

3.2 Place the OFP on a level flat surface below patient level, ensuring the fluid container is not exposed to heat emitted from

adjacent equipment, such as a light sour ce.

3.3 Insert the footswitch tube into the footswitch connection port on the front panel (Figure 3-1) .

FIGURE 3-1

Footswitch connection port

Footswitch

3.4 Fillthe fluid container with sterile water and replace the cap. Place the fluid container in the space provided (see Figure 3-2)

and secure with the Velcro s trap.

CAUTION

Use of irrigation fluid other than sterile water may cause an infection risk to the patient.

FIGURE 3-2

Velcro strap

Fluid container holder

3.5 Thread the irrigation tube through the hole in the fluid container cap until it reaches the base of the fluid container.

5

FLUSHING PUMP OFP

Page 9

3.6 Referringto Figure 3-3, open the pump cover (a), feed the irrigation tubing around the peristalticpump rollers (b), then close

the cover (c) to secure the tube.

NOTE

To prevent inadvertent operation of the pump while fitting/changing the tube, the pump cover is fitted with a

microswitch which isolates the power supply when the cover is opened.

Ensure the tube is threaded correctly in the pump head to prevent damaging the tube and that the direction of

flow is correct.

(a) (b) (c)

3.7 Referring to Figure 3-4 , connect the filter to the irrigationtube Luer lock connector (a), then connect theauxiliary water tube

(MAJ--855) to the filter (b) and auxiliary water inlet on the endoscope.

CAUTION

Use only in conjunction with Olympus EVIS EXERA series endoscopes having an auxiliary water inlet and

MAJ--855 auxiliary water tube.

Ensure the MAJ--855 has the luer lock connector/one--way valve fitted.

Always ensure the filter is fitted in--line to maintain pump performance and safety.

FIGURE 3-3

(a)

3.8 Ensure the OFP power switch is OFF and connect the power cable into the IEC receptacle on the rear of the unit and a

suitably grounded AC wall outlet or isolation transformer socket. Set the flow control on the OFP to MIN.

WARNING

Do not allow the power cable plug to become wet, otherwise this may cause electric shock.

Ensure the power cable plug is properly connected to the power supply, otherwise the OFP may not function.

3.9 Turn the power supply switch ON and then the OFP power switch to ON.

(b)

FIGURE 3-4

FLUSHING PUMP OFP

6

Page 10

3.10 Depress and hold down the footswitch and adjust the flow control to activate the peristaltic pump. Confirm that water exits

from the endoscope water channel then release the footswitch to stop water flow.

NOTE

Ensure that no leaks are present from the irrigation tubing or any of its connections before use.

Take care not to spray equipment with water when operating the OFP with the endoscope outside the patient.

3.11 During the endoscopic procedure, depress the footswitch when mucosal lavage is required. Adjust the flow rate by means

of the flow control on the front panel.

WARNING

The operator must assess the condition of the patient and use clinical judgement to set the flow rate from the

pump to a suitable level to avoid patient trauma. The flow control should always be set to MIN at the start of the

procedure and be increased progressively to a level commensurate with the clinical condition of the patient and

degree of washing required.

Note that when the flow control is set to MAX, the flow rate through the washing channel of the endoscope will

be in excess of that which can be delivered when using a 50ml syringe.

CAUTION

NEVER allow the fluid container to run dry, otherwise air will be supplied to the patient.

3.12 To refill the fluid container during use, leave the pump cover closed so as not to disturb the irrigation tube. Lift the irrigation

tube from the fluid container and remove the container from the unit. Unscrew the cap, fill the container with sterile water

then replace the cap. Place the container back on the unit and secure with the Velcro strap. Insert the irrigation tube into

the container through the lid.

3.13 The remotecontrol cable connector mustonly be used with the optionalRemote Control CableMAJ--920. When connected,

this enables the OFP to be remotely controlled from the Olympus EVIS EXERA series endoscopes. Refer to MAJ--920

instructions for setting endoscope remote switch functions.

Using the remote control switch or footswitch

D When the switch is pressed, the pump will begin to operate, when the switch is pressed again, the pump will

stop operating.

D If the switch is not re--pressed, the pump will stop operating after 20 seconds ± 3 seconds.

Using the footswitch (supplied with OFP)

D When the footswitch is pr essed continuously, the pump will operate up to a maximum of 20 seconds.

D If you want to operate the pump again, release your foot from the footswitch and press it again.

7

FLUSHING PUMP OFP

Page 11

3.14 After each procedure, when the endoscope has been removed from the patient, the MAJ--855 and endoscope must be

disconnected from the filter/irrigation tube and reprocessed in accordance with the manufacturers instructions.

At the end of use and after removal of the endoscope from the patient, disconnect the irrigation tubing as follows:

(i) switch off the power supply.

(ii) with the endoscope still connected, open the pump cover and r emove the tube (Figure 3-5a).

(iii) hold the tubing above the fluid container and disconnect the endoscope luer connector (Figure 3-5b).

(iv) allow any fluid in the tube to return to the fluid container, then remove the tube from the container.

(v) discard the irrigation tubing and filter at the end of the day.

NOTE

Disconnecting the irrigation tube below the level of the fluid container may result in fluid siphoning from the

container.

(a) (b)

FIGURE 3-5

3.15 If sterility will be maintained by packaging, the fluid container should be removed from the OFP after use and autoclaved

prior to reuse. Always remove the cap from the fluid container and autoclave the fluid container and the cap separately,

otherwise effective autoclaving will not be possible, which could pose an infection control risk or cause tissue irritation.

FLUSHING PUMP OFP

8

Page 12

4 STEAM STERILIZATION (AUTOCLAVING)

Use biological indicators as recommended by your hospital’s policy and follow the sterilizer manufacturer’s instructions,

plus any relevant national and local hospital guidelines and policies. Such guidelines include AAMI TIR12:1994 and

ANSI/AAMI ST79:2006 (USA), EN 285:2006 and HTM 2010:1994 (Europe).

Olympus has validated the efficacy of steam sterilization (autoclaving) in a pre--vacuum sterilizer at the temperatures

and durations in the table below.

Items must be meticulously cleaned and dried prior to sterilization. Thorough cleaning removes both micro--organisms

and organic soil. Failure to adequately clean can decrease the effectiveness of the sterilization procedure.

Always leave space between the packages in the autoclave. If packages are placed too close together, effective

sterilization may be compromised.

Allow the packages to dry within the autoclave using the autoclave’s drying cycle (if applicable) or by opening the door

of the autoclave and allowing the packages to air dry.

Handling a wet package can compromise its sterility.

For details on operation of the autoclave, refer to the instruction manual for the autoclave.

Typical parameters for pre--v acuum autoclaves for wrapped instruments, according to national guidelines/standards:

Minimum Hold

Temperature

121--124˚C 15 mins EN 285: 2006, HTM 2010:1994

126--129˚C 10 mins EN 285: 2006, HTM 2010:1994

132˚C 4 mins ANSI/AAMI ST79:2006

134--137˚C 3 mins ANSI/AAMI ST79:2006, EN 285:2006, HTM 2010:1994

Do not exceed a temperature of 137˚C during autoclaving, otherwise equipment damage or accelerated deterioration

may result.

The items included with the OFP that are designated as ‘autoclavable’ may be sterilised using ‘flash’ steam sterilization

cycles utilized for sterilizing unwrapped instruments in emergency situations. Olympus recommends gradual air cooling

after a flash cycle – use of liquids for rapid cooling could result in equipment damage or accelerated deterioration. The

US Association of Operating Room Nurses (AORN) and the US Association for the Advancement of Medical

Instrumentation (AAMI) caution that flash--sterilized items must be used immediately, since sterility assurance of

unwrapped items cannot be maintained.

Exposure Time Guideline/Standard Reference

9

FLUSHING PUMP OFP

Page 13

5 CARE AND STORAGE

5.1 Care

(1) Clean the OFP with a soft cloth or gauze moistened with a neutral pH detergent, rinse with clean water, then wipe

over with a cloth dampened with 70% alcohol.

CAUTION

Do not use harsh or abrasive cleaning materials on the OFP as damage may result.

Ensure all surfaces are thoroughly dried before reusing the OFP.

Ensure footswitch is removed from the floor and stored safely to prevent it being damaged.

(2) Inspect the fluid container and fluid container cap before each session of use for obvious signs of damage, replace

if necessary.

(3) The fluid container and fluid container cap may be washed with a neutral pH detergent, then thoroughly rinsed

prior to autoclaving.

(4) Reprocess the MAJ--855 following each patient use according to the manufacturer’s instructions supplied with the

product.

(5) The fluid container and fluid container cap should be autoclaved at the end of the day (see Section 4).

5.2 Storage

(1) Remove the irrigation tubing and filter from the peristaltic pump and discard. Disconnect the power lead. Empty the

fluid container and autoclave prior to storage.

(2) The OFP should be stored within the environmental conditions given in Section 8.

6 MAINTENANCE AND REPAIR

6.1 Routine Maintenance

The following routine maintenance should be performed at the intervals specified:

User - Daily:

At the beginning of each day of use, check that the pump head safety switch is operating correctly as follows:

With no tube fitted, operate the pump at maximum speed and, taking care to keep fingers clear of the rollers, lift the

pump head cover. The rollers should promptly stop rotating. If they do not, switch off the pump, disconnect it from the

electrical power supply and contact your Olympus representative.

User - Monthly:

Check the pump head and rollers for damage.

Check that the power cable is in good condition.

Hospital Engineer or Olympus - Annually:

WARNING

Lethal electrical hazard -- ensure the unit is disconnected from the power supply before attempting to enter the

unit for inspection. This routine maintenance procedure must only be performed by a suitably qualified

technician or authorized Olympus service personnel.

Check that the power cable is in good condition.

Inspect the unit externally and perform safety checks as detailed in the maintenance & repair manual.

FLUSHING PUMP OFP

10

Page 14

6.2 Repair

The OFP must only be serviced/repaired by suitably qualified technical personnel. If repair is required, contact

Olympus.

Olympus will not be responsible for damage or injury to equipment or personnel caused by unauthorised repair or

modification to this unit.

If the pump fails to operate:

D Check the items detailed in Section 11 Troubleshooting.

D Check the condition of both fuses located at the rear of the unit and the fuse in the power cable plug as appr opriate.

CAUTION

The fuse must always be replaced with one of the correct rating. If the fuse continues to blow, stop using the

unit and contact Olympus or hospital engineer.

Always ensure the fuse drawer is pushed fully home following maintenance/repair, as failure to do so may

cause the mains power outlet to overheat.

Hold the unit with one hand to prevent it from moving, then insert the fuse drawer into the OFP mains power

inlet and push in until it clicks into position.

11

FLUSHING PUMP OFP

Page 15

7 SPARES & ACCESSORIES

Classificatio

n

NOTE

To maintain standards compliance, use only the following Spares and Accessories with this product.

7.1 Spares

Instructions 5070135...............................

Fluid container 7501352............................

Fluid container strap 7501353........................

Irrigation tube (pack of 10) 7501669....................

Filter ( pack of 10) 7501355..........................

Footswitch 7501357...............................

Fuse T1A (pack of 5) 7501356.......................

Fuse T2A (pack of 5) 7501404.......................

Power cable (UK) 7145454..........................

Power cable (USA) 7318766.........................

Power cable (Europe) 7145462.......................

Power cable (RoW) 7318561.........................

MAJ--855 endoscope tube 1113054 (UK part number only)....................

7.2 Accessories

Remote control cable MAJ--920

8 SPECIFICATIONS

Items Specifications

Product name Olympus Flushing Pump OFP

Standards

compliance

This product complies with the requirements of EN IEC 60601-1-2 for emissions and

immunity, and as such, its operation is unlikely to be affected by, or cause interference

with, equipment meeting appropriate EMC standards. As a precaution, equipment which

may be sensitive to interference outside the limits specified by EN IEC 60601--1--2 should

not be placed in close proximity to the OFP.

220-240V model

Classification according to EN IEC 60601-1: Class I Type BF.

110-120V model

Classification according to UL 2601-1: Class I Type BF

In accordance with EN IEC 60601-1 and UL 2601--1, the OFP is marked with the

symbol to indicate the provision of an adequate degree of protection against electrical

shock and that it has an applied part isolated from all other parts of the equipment.

None: the Olympus OFP must NOT be used in the zone of risk of flammable anaesthetic

gases.

(electromedical

equipment)

Electro-magnetic

compatibility

Type of protection

against electrical

shock

Degree of protection

against electrical

shock

Degree of protection

against explosion

Mode of operation Continuous

This symbol on the 110--120V version indicates it is listed by

Intertek Testing Services as meeting the requirements of UL

2601--1 and CAN/CSA C22.2 601.1--M90.

3024005

FLUSHING PUMP OFP

12

Page 16

Regulatory

Dimensionsand

Power

condition

s

status

European Economic

Area (EEA)

End of life

Dimensions and

weight

Power switch Marking The power switch is marked: l - on, O -off.

Power

requirements

Environmental

Fluid ingress Ordinary equipment in accordance with EN IEC 60601-1 and UL 2601--1.

Resistance to

chemicals

Pump type Peristaltic

Pump operation

Fluid container The fluid container supplied with the unit has a 1 litre capacity and will withstand steam sterilisation up to 137˚C.

Dimensions Height: 220 mm Width: 270 mm Depth: 350 mm

Weight 8kg

Power supply Frequency Fusing Power rating

220-240V~ 50/60Hz 2 x T1A 240V A

110-120V~ 50/60Hz 2 x T2A 240V A

Marking: The mark ~ on the product indicates the requirement for an AC power supply.

Ambient

temperature

Relative humidity Maximum: 93% at 40˚C relative non-condensing

Atmospheric

pressure

The external surfaces of the Olympus OFP are resistant to: 2% aqueous neutral pH detergent, 70% ethyl alcohol,

isopropyl alcohol, water.

Water feed: controlled by pneumatic footswitch

Flow rate: variable, controlled from front panel

Flow rate delivery from the pump will depend on the length and type of Olympus EVIS EXERA gastrointestinal

videoscope attached. At minimum setting, the pump will not produce any flow; at maximum setting, the pump will

deliver up to 350 ml/min in free--flow to atmospheric air from the end of the pump irrigation tube and filter.

When attached to an Olympus EVIS EXERA gastrointestinal videoscope, the flow from the distal end will

increase with decreasing endoscope length and the force of the water jet contacting the patient will increase. The

operator must therefore assess the condition of the patient and use clinical judgement to set the flow rate from

the pump to avoid causing patient trauma.

If the pump is connected to any other endoscope or device other than those specified in these instructions, then

damage to the pump or attached device, or injury to to the patient or user may result.

This mark on the product (220-240V model) indicates compliance with Directive

93/42/EEC relating to medical devices, Class IIa. The year of manufacture is

0086

given in the first two digits of the serial number.

In accordance with European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment, this symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be collected separately.

Refer to your local Olympus distributor for return and/or collection systems

available in your country.

Operational: +10˚Cto+40˚C(+50˚F to +104˚F)

Storage: -40˚Cto+70˚C (-40˚F to +158˚F)

Operational: 70-106 kPa

Storage: 23.5-106 kPa

Olympus is continually developing its product range and reserv es the right to alter the above specification without notice. The

Olympus OFP is manufactured in the UK by KeyMed (Medical & Industrial Equipment) Ltd.

9 TECHNICAL DESCRIPTION

Technical information regarding this product is available on request to assist suitably qualified personnel with repairs.

Contact Olympus regarding this information.

10 ENVIRONMENTAL PROTECTION

There are no known risks associated with disposal of irrigation tubing, filters, or the OFP itself at the end of its working

life.

13

FLUSHING PUMP OFP

Page 17

11 TROUBLESHOOTING

Problem Possible cause Action

No power to the unit when switched ON. Power cable not connected properly. Check power cable is fully connected.

Fuse blown. Check fuses and replace as necessary.

Ensure fuse drawer is fully home by

pushing drawer until it clicks into

position.

No power from power supply. Check power supply.

Unit ON but no fluid flow. Footswitch tube is disconnected or

poorly fitted.

Fluid container empty. Refill with sterile water.

Irrigation tube kinked or blocked. Replace with new tube.

Irrigation tube not fitted to pump

properly.

Endoscope blocked. Check endoscope and correct.

Endoscope tube kinked or blocked. Replace with new tube.

Incorrect tubing fitted. Check tubing and replace if necessary

Pump head or tube rollers damaged. Switch unit OFF, open pump cover and

Check that the footswitch tube is fully

connected.

Check and correct (Section 3.6).

with specified tube (see Section 7).

check for signs of damage. If damage is

evident,

refer to qualified service

personnel for repair.

Unit ON but poor fluid flow. Endoscope tube kinked or blocked. Replace with new tube.

Irrigation tube kinked or blocked. Replace with new tube.

Filter blocked. Replace filter.

Irrigation tube worn. Replace with new tube.

Timeout safety function invoked. Release footswitch and re--press to

re--start.

For remote control, press endoscope

switch twice to re--start.

Remote control function not operating. Remote control cable (MAJ--920) fitted

incorrectly.

Endoscope / processor function set

incorrectly.

Audible alarm sounds while pump is

running.

Internal fault has occurred.

FLUSHING PUMP OFP

Check connection according to MAJ--920

instructions.

Check endoscope / processor settings

according to manufactures instructions.

Switch unit OFF and refer to qualified

service personnel for repair.

14

Page 18

Page 19

Page 20

OLYMPUS MEDICAL SYSTEMS CORP.

2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan

Fax: (0426) 46-2429 Telephone: (0426) 42-2111

OLYMPUS MEDICAL SYSTEMS EUROPA GMBH

(Premises/Goods delivery) Wendenstrasse 14-18, D-20097 Hamburg, Germany

(Letters) Postfach 10 49 08, D-20034 Hamburg, Germany Telephone: (040) 237730

OLYMPUS AMERICA INC.

3500 Corporate Parkway, P.O. Box 610 Center Valley, PA 18034-0610, U.S.A.

Fax: (484) 896-7128 Telephone: (484) 896-5000

OLYMPUS SURGICAL & INDUSTRIAL AMERICA INC.

One Corporate Drive, Orangeburg, N.Y. 10962, U.S.A.

Fax: (845) 398-9444 Telephone: (845) 398-9400

KEYMED LTD.

KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom

Fax: (01702) 465677 Telephone: (01702) 616333

OLYMPUS SINGAPORE PTE LTD.

491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373

Fax: 6834-2438 Telephone: 6834-0010

OLYMPUS (BEIJING) SALES & SERVICE CO,. LTD.

No.6 GongYuanXijie, Jian Guo Men Nei, DongCheng District, Beijing, 100005, China

Room 1406 E Tower, GongYuan No. 6 Royal Palace,

Fax: (10) 6518-0865 Telephone: (10) 6518-8080

OLYMPUS MOSCOW LIMITED LIABILITY COMPANY

117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia

Fax: (095) 958-2277 Telephone: (095) 958-2245

Issue 19

March 2009

OLYMPUS AUSTRALIA PTY. LTD.

31 Gilby Road, Mount Waverley, Victoria 3149, Australia

Fax: (03) 9543-1350 Telephone: (03) 9265-5400

OLYMPUS LATIN AMERICA INC.

6100 Blue Lagoon Drive, Suite 390 Miami, FL 33126-2087, U.S.A.

Fax: (305) 261-4421 Telephone: (305) 266-2332

OLYMPUS KOREA CO,. LTD.

8F, Hyundai Marines Bldg., 646-1 Yeoksam-Dong, Kangnam-Gu, Seoul 135-080 Korea

Fax: (02) 6255-3499 Telephone: (02) 1544-3200

EKeyMed 2009

PrintedinUK

KT 5070135/309

Loading...

Loading...