Olympus OER-Elite Operation Manual

INSTRUCTIONS

ENDOSCOPE REPROCESSOR

OER-Elite¥

Labels and Symbols 1

Important Information — Please Read Before

Use 7

Chapter 1 Checking the Package Contents 19

Chapter 2 Nomenclature and Functions 23

Chapter 3 Basic Operation 35

Chapter 4 Settings 75

Chapter 5 Inspection and Preparation

Before Use 127

Chapter 6 Reprocessing Operations 147

Chapter 7 Functions 239

Chapter 8 Replacement of Consumable

Items 339

Chapter 9 Routine Maintenance 423

Chapter 10 End-of-Day Checks 451

Chapter 11 Log Management 463

Chapter 12 Information Menu Screen 589

Chapter 13 Troubleshooting and Repair 599

Appendix 647

For details on installation and setup, refer to “Instructions - Installation Manual”.

OPERATION MANUAL

Contents

i

OER-Elite OPERATION MANUAL

Contents

Labels and Symbols .......................................................................................................... 1

Important Information — Please Read Before Use ......................................................... 7

Intended use .......................................................................................................................... 7

Instruction manuals ............................................................................................................... 7

Terms used in these manuals ................................................................................................ 8

User qualifications ................................................................................................................ 11

Ensuring the safety of reprocessing personnel ................................................................... 12

Equipment compatibility ....................................................................................................... 13

Care and storage ................................................................................................................. 13

Maintenance and Inspection ................................................................................................ 13

Repair and modification ....................................................................................................... 13

Disposal of disinfectant solution .......................................................................................... 14

Disposal of this reprocessor ................................................................................................ 14

Signal words ........................................................................................................................ 14

Warnings and cautions ........................................................................................................ 14

Outline of Functions ........................................................................................................ 16

Chapter 1 Checking the Package Contents ....................................... 19

1.1 Checking the package contents ............................................................................ 19

Chapter 2 Nomenclature and Functions ............................................ 23

2.1 Front panel .............................................................................................................. 23

2.2 Top panel ................................................................................................................. 24

2.3 Inside ....................................................................................................................... 25

2.4 Rear panel ............................................................................................................... 26

2.5 Side panel ................................................................................................................ 27

2.6 Reprocessing basin ............................................................................................... 28

2.7 Control panels ........................................................................................................ 30

2.8 Consumable accessories (Optional) .................................................................... 31

Chapter 3 Basic Operation .................................................................. 35

3.1 Turning power ON .................................................................................................. 35

3.2 Alarm indicator ....................................................................................................... 37

3.3 Control panel operation ......................................................................................... 40

3.4 Menu screen ........................................................................................................... 41

3.5 LCG Info. screen ..................................................................................................... 42

ii

Contents

OER-Elite OPERATION MANUAL

3.6 Entering ID .............................................................................................................. 44

Entering through the RFID reader ....................................................................................... 45

Entering by the software keyboard ...................................................................................... 48

Entering the patient ID by the optional bar code ................................................................. 65

3.7 Checking the MRC level and entering the check result ...................................... 69

Required items .................................................................................................................... 70

Checking the MRC level ...................................................................................................... 70

Chapter 4 Settings ................................................................................ 75

4.1 Setting menu ........................................................................................................... 75

4.2 Auto leak test setting ............................................................................................. 79

4.3 MRC check setting ................................................................................................. 81

4.4 Manual cleaning and leak test setting .................................................................. 82

4.5 User ID Setting ........................................................................................................ 83

User ID setting (reprocessing) ............................................................................................. 84

User ID setting (functions and replacement) ....................................................................... 86

User ID setting (Heat LCG Timer) ....................................................................................... 87

4.6 Physician ID setting ............................................................................................... 88

4.7 Patient ID setting .................................................................................................... 89

4.8 Patient ID security setting ..................................................................................... 90

4.9 Procedure ID setting .............................................................................................. 91

4.10 Detergent replacement indicator .......................................................................... 92

4.11 Detergent lot number and shelf-life management ............................................... 94

4.12 LCG replacement indicator .................................................................................... 95

4.13 LCG lot number and shelf-life management ........................................................ 98

4.14 Filter replacement indicator .................................................................................. 99

4.15 Filter lot number management ............................................................................ 103

4.16 Auxiliary water tube cleaning setting ................................................................. 104

4.17 Print option ........................................................................................................... 106

Print format setting ............................................................................................................ 107

Auto Print Setting ............................................................................................................... 108

4.18 Start screen ........................................................................................................... 109

4.19 Connection guide ................................................................................................. 110

4.20 Volume and brightness ........................................................................................ 111

4.21 Date and time ........................................................................................................ 112

4.22 Temperature scale ................................................................................................ 115

4.23 Network setting ..................................................................................................... 116

4.24 Network security ................................................................................................... 121

Contents

iii

OER-Elite OPERATION MANUAL

Chapter 5 Inspection and Preparation Before Use .......................... 127

5.1 Inspection before use .......................................................................................... 127

5.2 Flow of inspection ................................................................................................ 128

5.3 Inspecting the power activation .......................................................................... 129

5.4 Inspecting for fluid leaks ..................................................................................... 132

5.5 Inspecting the lid and lid packing ....................................................................... 133

5.6 Inspecting the connectors ................................................................................... 134

5.7 Inspecting the connecting tubes and leak test air tube ................................... 137

5.8 Inspecting the remaining detergent ................................................................... 138

5.9 Inspecting and replenishing alcohol .................................................................. 139

Inspection of the amount of alcohol ................................................................................... 140

Replenishing of alcohol ..................................................................................................... 140

5.10 Inspecting the mesh filters .................................................................................. 143

5.11 Inspecting the washing case (MAJ-2121) .......................................................... 144

5.12 Inspecting the labels on the reprocessing basin .............................................. 145

5.13 Inspecting for disinfectant solution odor ........................................................... 145

Chapter 6 Reprocessing Operations ................................................ 147

6.1 General flow of endoscope reprocessing using OER-Elite .............................. 147

6.2 Precleaning, leak testing, and manual cleaning ................................................ 148

Modified manual cleaning process for preparing endoscopes for processing in the

OER-Elite ........................................................................................................................... 149

Endoscope precleaning

(Procedure performed at bedside immediately after patient examination) ........................ 149

Endoscope precleaning continued

(Procedure performed at bedside immediately after patient examination) ........................ 150

Leakage testing ................................................................................................................. 152

Manual cleaning (procedure performed in reprocessing area) .......................................... 152

Loading the endoscope and their accessories into the OER-Elite .................................... 154

6.3 Reprocessing operation in the OER-Elite .......................................................... 155

Warnings ............................................................................................................................ 155

Outline of reprocessing operation in the OER-Elite ........................................................... 157

6.4 Worst case load condition of endoscopes and accessories ........................... 158

6.5 Basic operation for reprocessing ....................................................................... 160

Reprocessing standby screen ........................................................................................... 160

Reprocessing program ...................................................................................................... 162

iv

Contents

OER-Elite OPERATION MANUAL

6.6 Loading of endoscopes and accessories .......................................................... 163

Outline of loading operation of endoscopes and accessories ........................................... 163

Input scope ID of first endoscope ...................................................................................... 165

Loading of first endoscopes in the reprocessing basin ...................................................... 166

Loading of the accessories of first endoscope (valves, etc.) ............................................. 173

Attaching the connecting tubes loading to first endoscope ............................................... 177

Loading of auxiliary water tube of first endoscope ............................................................ 186

Attaching the Leak test air tube loading to first endoscope ............................................... 189

Input connection information of first endoscope ................................................................ 194

Input results of manual cleaning and leak test of first endoscope ..................................... 195

Inputs user ID, physician ID, patient ID, and procedure ID of first endoscope .................. 196

Input scope ID of second endoscope ................................................................................ 197

Loading of second endoscopes in the reprocessing basin ................................................ 197

Loading of the accessories of second endoscope (valves, etc.) ....................................... 202

Attaching the connecting tubes loading to second endoscope .......................................... 205

Loading of auxiliary water tube of second endoscope ........................................................ 211

Attaching the Leak test air tube loading to second endoscope ......................................... 213

Input connection information of second endoscope .......................................................... 214

Input results of manual cleaning and leak test of second endoscope ............................... 214

Inputs user ID, physician ID, patient ID, and procedure ID of second endoscope ............ 214

Loading the stylus pen ....................................................................................................... 215

6.7 Inspection before starting reprocessing process ............................................. 216

6.8 Reprocessing ........................................................................................................ 220

Auto leak test ..................................................................................................................... 221

Channel monitoring ........................................................................................................... 223

Reprocessing operation ..................................................................................................... 225

6.9 Removing the endoscopes and accessories ..................................................... 228

6.10 Printing of the reprocessing records ................................................................. 232

Printing reprocessing results after completion of reprocessing ......................................... 234

Printing error code details in case of error ......................................................................... 237

Chapter 7 Functions ........................................................................... 239

7.1 Function menu ...................................................................................................... 239

Function menu ................................................................................................................... 239

7.2 Heat LCG ............................................................................................................... 242

7.3 Heat LCG Timer ..................................................................................................... 244

Flow of Heat LCG Timer .................................................................................................... 245

Starting the Heat LCG Timer ............................................................................................. 245

Standing by and starting the Heat LCG Timer ................................................................... 253

Finishing the Heat LCG Timer ........................................................................................... 254

7.4 Mix LCG ................................................................................................................. 255

7.5 Rinse ...................................................................................................................... 258

7.6 Air purge ................................................................................................................ 260

Contents

v

OER-Elite OPERATION MANUAL

7.7 Water line disinfection ......................................................................................... 262

Workflow of water line disinfection ..................................................................................... 263

Required items .................................................................................................................. 264

Checking the MRC level and entering the check result ..................................................... 264

Water line disinfection ........................................................................................................ 266

7.8 Self-disinfection and water sampling ................................................................. 274

Workflow of self-disinfection .............................................................................................. 274

Required items .................................................................................................................. 275

Checking the MRC level and entering the check result ..................................................... 275

Performing the self-disinfection ......................................................................................... 277

Microbiological Surveillance .............................................................................................. 281

7.9 Detergent line disinfection .................................................................................. 282

Required items .................................................................................................................. 283

Detergent line disinfection ................................................................................................. 283

7.10 Alcohol line disinfection ...................................................................................... 293

Required items .................................................................................................................. 294

Alcohol line disinfection ..................................................................................................... 294

7.11 Manual leak test .................................................................................................... 303

Workflow of manual leak test ............................................................................................. 304

Performing manual leak test .............................................................................................. 305

7.12 Auto leak test ........................................................................................................ 310

Workflow of auto leak test .................................................................................................. 312

Performing auto leak test ................................................................................................... 313

7.13 Self-check of auto leak test ................................................................................. 321

7.14 Alcohol flush ......................................................................................................... 323

7.15 Leaking scope decontamination ......................................................................... 326

Workflow of leaking scope decontamination ...................................................................... 328

Required items .................................................................................................................. 328

Performing leaking scope decontamination ....................................................................... 329

Chapter 8 Replacement of Consumable Items ................................ 339

8.1 Replacement of consumable items menu .......................................................... 339

8.2 Replacing the disinfectant solution .................................................................... 340

Workflow of replacement the disinfectant solution ............................................................. 341

Draining the disinfectant solution ....................................................................................... 342

Load the disinfectant solution ............................................................................................ 354

Required items .................................................................................................................. 355

Setting the disinfectant solution ......................................................................................... 356

8.3 Replacing the detergent tank .............................................................................. 364

Required item .................................................................................................................... 365

Replacing the detergent tank ............................................................................................. 366

vi

Contents

OER-Elite OPERATION MANUAL

8.4 Replacing the water filter (MAJ-824 or MAJ-2318) ............................................ 375

Replacing the water filter workflow (when performing the water line disinfection followed by the

replacement of the water filter) .......................................................................................... 377

Required items .................................................................................................................. 377

MRC check, check result input .......................................................................................... 378

Replacing the water filter ................................................................................................... 380

Draining air in the water filter housing ............................................................................... 389

Disinfecting the water line .................................................................................................. 392

8.5 Replacing the air filter (MAJ-823) ........................................................................ 402

Workflow of replacement of the air filter ............................................................................ 402

Required items .................................................................................................................. 402

Replacing the air filter ........................................................................................................ 403

Inspecting air leakage from the air filter connectors .......................................................... 408

8.6 Replacing the gas filter (MAJ-822) ...................................................................... 411

Required items .................................................................................................................. 412

Replacing the gas filter on the lid ...................................................................................... 412

Replacing the gas filter on the disinfectant solution tank ................................................... 416

Chapter 9 Routine Maintenance ........................................................ 423

9.1 Periodic inspection .............................................................................................. 423

9.2 Cleaning the detergent/alcohol drawer .............................................................. 425

9.3 Cleaning the accessories and accessory holder .............................................. 426

Required items .................................................................................................................. 426

Cleaning the accessories and accessory holder ............................................................... 426

9.4 Cleaning the alcohol tank .................................................................................... 428

9.5 Checking cassette cutters ................................................................................... 429

9.6 Cleaning the disinfectant bottle drawer ............................................................. 429

9.7 Cleaning the mesh filter in the water supply hose connector .......................... 430

Required items .................................................................................................................. 430

Cleaning the mesh filter in the water supply hose connector ............................................ 430

9.8 Replacing the fuse ................................................................................................ 434

9.9 Preparing the reprocessor for long-term storage ............................................. 436

Workflow of Preparing the reprocessor for long-term storage ........................................... 437

Required items .................................................................................................................. 437

Preparing the reprocessor for long-term storage ............................................................... 438

9.10 Care and maintenance after long-term storage ................................................. 448

Chapter 10 End-of-Day Checks ........................................................... 451

10.1 Inspection at the end of every working day ....................................................... 451

10.2 Turning the power OFF and closing the water faucet ....................................... 452

10.3 Cleaning the mesh filters ..................................................................................... 453

10.4 Cleaning the float switches ................................................................................. 454

10.5 Cleaning the fluid level sensor ............................................................................ 458

Contents

vii

OER-Elite OPERATION MANUAL

10.6 Cleaning the stylus pen ....................................................................................... 460

Wiping the stylus pen with alcohol ..................................................................................... 460

Reprocessing together with endoscopes ........................................................................... 460

10.7 Cleaning the outer surface .................................................................................. 461

Chapter 11 Log Management .............................................................. 463

11.1 Log menu .............................................................................................................. 463

11.2 Log display and output ........................................................................................ 464

Information recorded in each record .................................................................................. 470

11.3 Log management with PC ................................................................................... 533

Flow of electronic log management ................................................................................... 534

Required item .................................................................................................................... 534

Output of recorded data to the portable memory ............................................................... 535

Log management on PC .................................................................................................... 541

11.4 Printing records .................................................................................................... 575

Printing .............................................................................................................................. 575

Print format ........................................................................................................................ 579

Chapter 12 Information Menu Screen ................................................. 589

12.1 RFID data check .................................................................................................... 589

12.2 Reprocessor information check ......................................................................... 592

12.3 List management .................................................................................................. 595

Chapter 13 Troubleshooting and Repair ............................................ 599

13.1 Emergency stop and automatic processing after stopping ............................. 599

13.2 Troubleshooting guide ......................................................................................... 600

When the error code [E024] is displayed during the reprocessing process ...................... 614

When any leaks are detected ............................................................................................ 617

When the message screen “Message 087” is displayed ................................................... 627

When the “Message 093” is displayed .............................................................................. 635

Other problems and remedial actions ................................................................................ 642

13.3 OER-Elite return ................................................................................................... 645

Appendix ............................................................................................... 647

System chart .................................................................................................................. 647

Specifications ................................................................................................................ 649

Shipping environment ........................................................................................................ 649

Operating environment ...................................................................................................... 649

Specifications ..................................................................................................................... 650

EMC information ............................................................................................................ 653

License information of Open Source Software ........................................................... 658

License information of Open Source Software ........................................................... 670

viii

Contents

OER-Elite OPERATION MANUAL

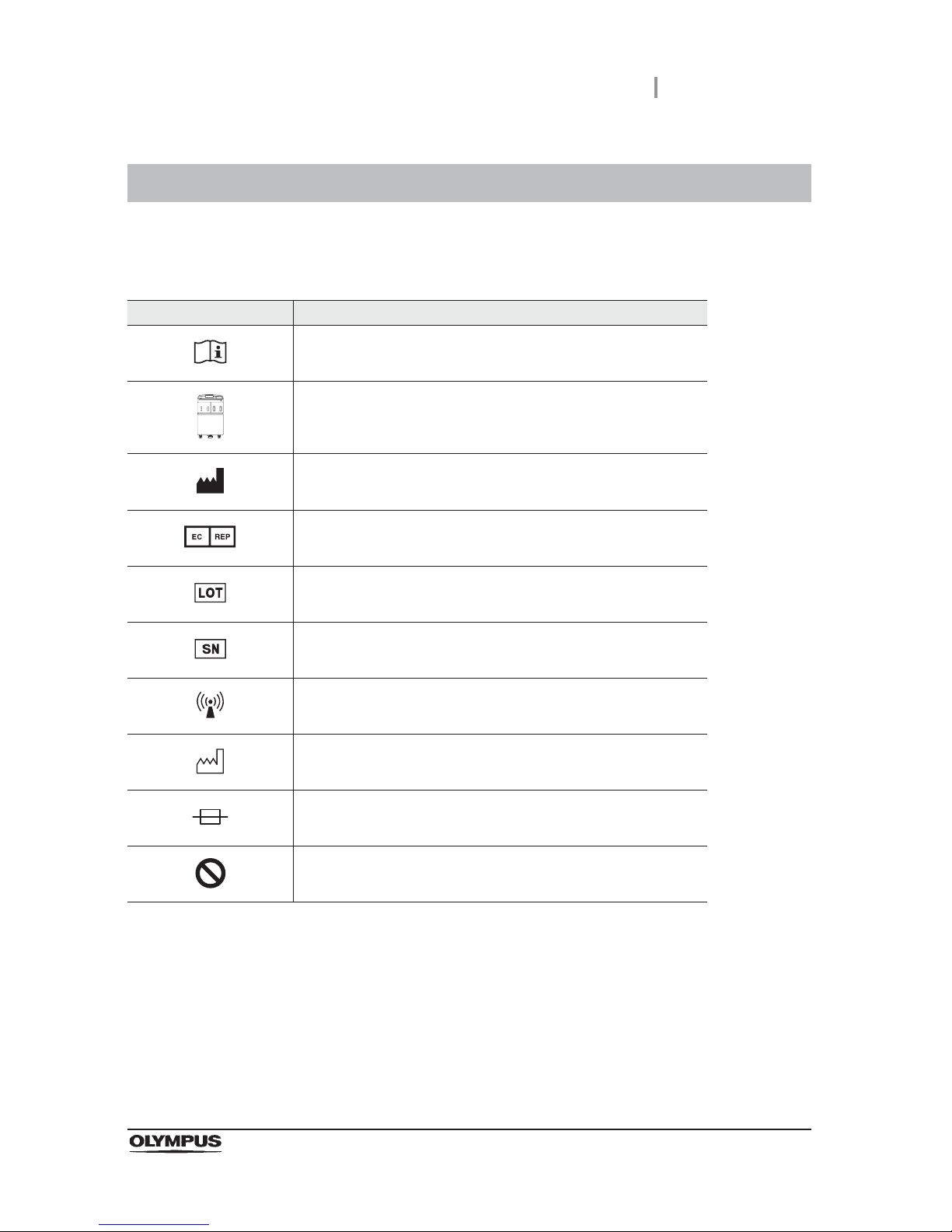

Labels and Symbols

1

OER-Elite OPERATION MANUAL

The meaning(s) of the symbol(s) shown on the component packaging, the back cover of this instruction

manual and/or this reprocessor are as follows:

For US Customers only

For a Symbols Glossary, visit us:

http://www.olympus-global.com/en/common/pdf/symbolsglossary.pdf

Safety-related labels and symbols are attached to the reprocessor at the locations shown next page. If

labels or symbols are missing or illegible, contact Olympus.

Labels and Symbols

Symbol Description

Refer to instructions.

Endoscope reprocessor

Manufacturer

Authorized representative in the European Community

Lot number

Serial number

Non-ionizing electromagnetic radiation

Date of manufacture

Fuse

General prohibition sign

2

Labels and Symbols

OER-Elite OPERATION MANUAL

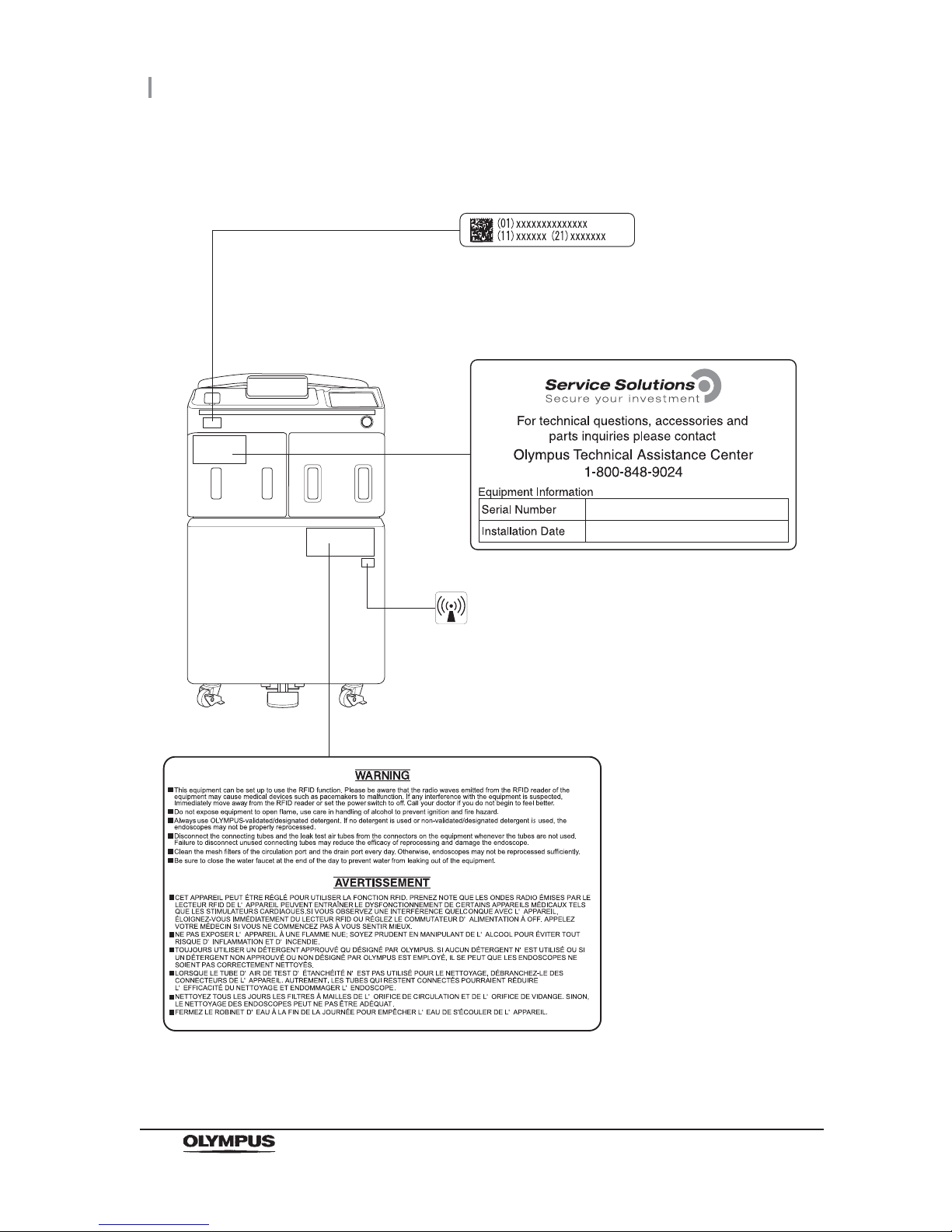

Front panel

RFID marking

UDI label

A label required by some countries’

regulations regarding identification of

medical device also known as Unique

Device Identification (UDI).

Labels and Symbols

3

OER-Elite OPERATION MANUAL

Inner side

Rotation direction indicator label

Indicates the rotation direction for locking

and releasing gas filter case (tank).

Rating plate

Shows the product model, power rating,

and serial number.

FRA

FRA

Date of manufacture

4

Labels and Symbols

OER-Elite OPERATION MANUAL

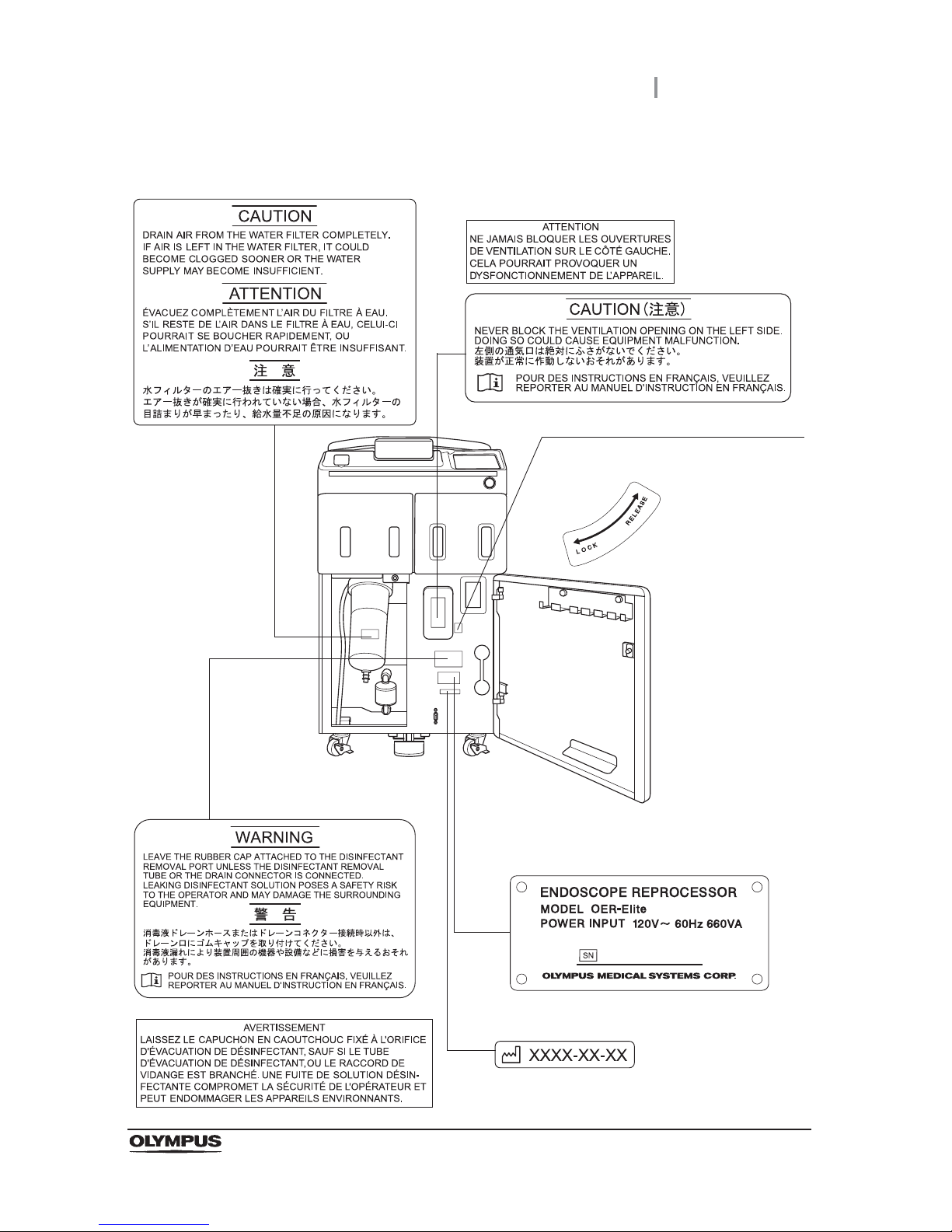

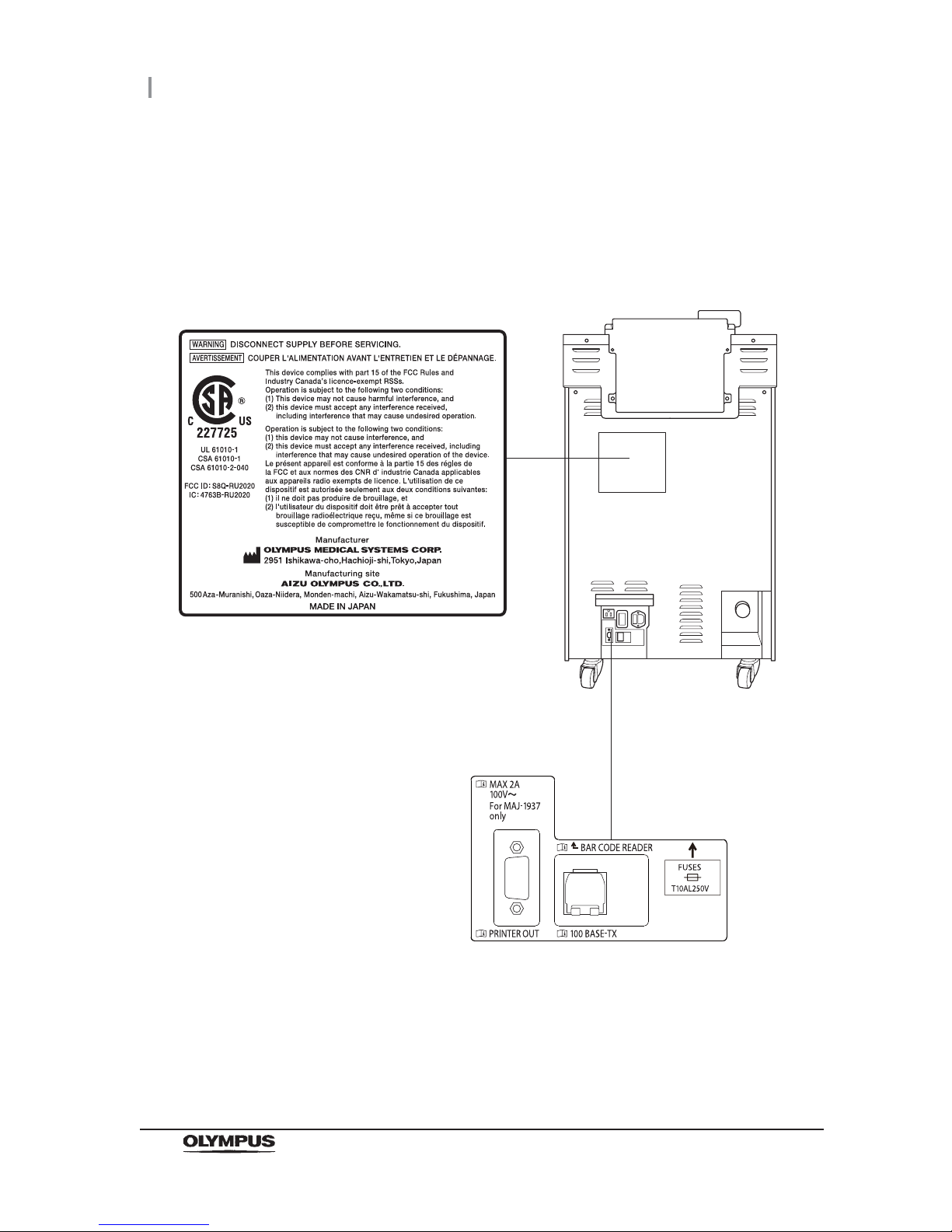

Rear panel

CSA/UL MARKING

Labels and Symbols

5

OER-Elite OPERATION MANUAL

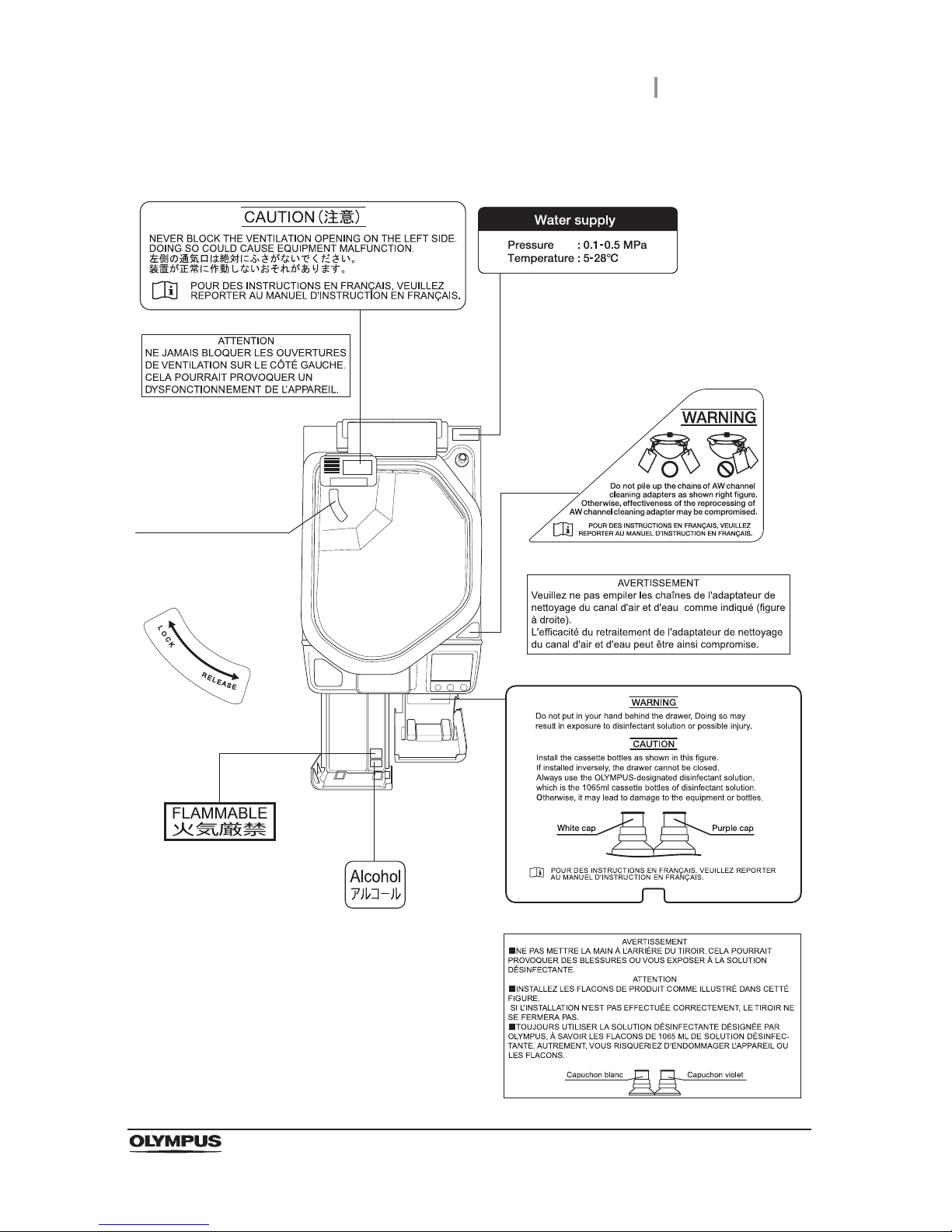

Top panel

Rotation direction

indicator label

Indicates the rotation

directions for locking

and releasing gas filter

case (lid).

FRA

FRA

FRA

6

Labels and Symbols

OER-Elite OPERATION MANUAL

Reprocessing basin

Fonts displayed on the touch screen

Ricoh bitmap fonts designed by RICOH Company, Ltd. are used.

Important Information — Please Read Before Use

7

OER-Elite OPERATION MANUAL

Intended use

The OER-Elite is intended for use in cleaning and high-level disinfection of heat sensitive Olympus

flexible endoscopes, their accessories, and endoscope reprocessor accessories. Safe use requires

detergent and an FDA-cleared high-level disinfectant/sterilant that Olympus has validated to be

efficacious and compatible with the materials of the OER-Elite and Olympus flexible endoscopes, their

accessories, and endoscope reprocessor accessories. Use of a detergent or high-level

disinfectant/sterilant that has not been validated by Olympus may be ineffective and can damage the

OER-Elite components and the endoscopes being reprocessed. Endoscopes must be cleaned by the

user prior to reprocessing; however, use of the OER-Elite enables the user to perform modified manual

cleaning of some endoscopes prior to automated cleaning and high-level disinfection in the OER-Elite.

Instruction manuals

The instructions for this reprocessor are divided into two volumes: “Instructions-Installation Manual”,

and “Instructions-Operation Manual”.

Instructions regarding the preparation of endoscopes prior to placing them in the OER-Elite are found

in “Instructions-Operation Manual”.

Each of these manuals contains essential information for using this reprocessor safely and effectively.

The “Instructions-Installation Manual” describes how to install the reprocessor. The

“Instructions-Operation Manual” describes how to operate and maintain the reprocessor and describes

modifications to the manual endoscope cleaning process that can save the user time and

inconvenience, if the endoscope is going to be subsequently reprocessed using the OER-Elite.

The “List of Compatible Endoscopes/Connecting Tubes <OER-Elite>” identifies all Olympus model

endoscopes that are compatible with the OER-Elite, plus the specific connecting tube(s) required for

each of these endoscope models.

The descriptions in these manuals assume that all endoscopes are reprocessed in the OER-Elite using

both an Olympus-validated detergent and disinfectant. Contact Olympus to obtain the list of both

Olympus-validated disinfectant solutions and detergents.

Before using this reprocessor, be sure to review all of the above-mentioned manuals, the safety

information provided with Olympus-validated detergents and disinfectants, and the manuals for all

other equipment used in the process. Always use this reprocessor as instructed. It might cause

unexpected danger if you do not follow the installation and operation manual. Keep these and all

related instruction manuals and documents in a safe and accessible location.

If you have any questions or comments about any information in these manuals, contact Olympus.

Important Information — Please Read Before Use

8

Important Information — Please Read Before Use

OER-Elite OPERATION MANUAL

Terms used in these manuals

ALT

Stands for Auto Leak Test.

Air purge

In this operation, air is fed into an endoscope channel to blow out residual fluid. This

operation is usually performed automatically during a process, but it can also be activated

independently. Air purge is also used to drain cleaning fluid or disinfectant solution from

inside the reprocessor when the operation has stopped due to an error code, etc.

Alcohol

70% ethyl alcohol or 70% isopropyl alcohol.

Alcohol flush

To assist in drying the channels after reprocessing, alcohol is flushed through the

endoscope channels followed by air. This operation can be performed as the last step of

the reprocessing program or as an independent operation.

Automatic processing

When the reprocessor is stopped by the operator or due to an error, it identifies its status

and executes the optimum operation automatically. For example, if the reprocessor stops

in the middle of the disinfection process, it terminates the disinfection process and

removes the disinfectant solution.

Channel blockage monitoring

This function monitors the channel blockage of endoscope’s suction channel due to a

foreign object, etc., during a reprocessing program.

Channel connectivity monitoring

This function monitors the connection status of the connecting tubes during a

reprocessing program.

Channel monitoring

“Channel monitoring” will be used as a generic term meaning “Channel connectivity

monitoring” and “Channel blockage monitoring”.

Cleaning fluid

Refers to filtered water with detergent that is used during the cleaning process.

Cleaning process

A series of operations programmed into the reprocessor that enable it to perform

ultrasonic cleaning and detergent cleaning of endoscopes.

Important Information — Please Read Before Use

9

OER-Elite OPERATION MANUAL

Detergent

Olympus-validated detergent. Refer to Section 2.8, “Consumable accessories (Optional)”

for details.

Disinfectant solution

Olympus-validated disinfectant solution. Refer to Section 2.8, “Consumable accessories

(Optional)” for details.

Disinfection process

A series of operations programmed into the reprocessor that enable it to perform

disinfection of endoscopes.

Error code

A code consisting of [E] and a three-digit number. This code is displayed on the touch

screen if there is a problem with the reprocessor. When an error code is displayed, check

the troubleshooting guide.

LCG

Liquid Chemical Germicide. It refers to disinfectant solution displayed on GUI.

Leak test

A test to confirm that an endoscope is free of leaks. This reprocessor is capable of both

the auto leak test and the manual leak test.

Manual cleaning

Cleaning of an endoscope by hand.

Modified precleaning and manual cleaning

A precleaning and manual cleaning method that is simplified due to subsequent use of the

OER-Elite which automates cleaning steps in the process.

MRC

Minimum Recommended Concentration.

Patient ID

Identity information specific to each patient. It can be recorded in the histories of

reprocessing, etc. For the patient ID input method, refer to Section 3.6, “Entering ID”.

Physician ID

Identity information specific to each endoscopist. It can be recorded in the histories of

reprocessing, etc. For the physician ID input method, refer to Section 3.6, “Entering ID”.

Portable memory

A digital medium for storage.

10

Important Information — Please Read Before Use

OER-Elite OPERATION MANUAL

Precleaning

Cleaning of an endoscope performed after each procedure at the bedside in the

endoscopy room.

Procedure ID

Identity information specific to each procedure of the patient. It can be recorded in the

histories of reprocessing, etc. For the procedure ID input method, refer to Section 3.6,

“Entering ID”.

Process

Generic term for any operation, including cleaning and disinfection that is performed

automatically by this reprocessor.

Reprocessing process

A series of operations for ultrasonic cleaning, detergent cleaning, disinfection, rinse, air

purge, and alcohol flush of the outer surface or channels of endoscopes that run in a

specified sequence and for a specified time. Reprocessing programs [1] to [4] can be

selected by the user. Programs [1] to [4] have a fixed cleaning process time and

disinfection process time. They also have different patterns of auto leak test and channel

monitoring respectively.

Scope ID

Identity information specific to each endoscope. It can be recorded in the historical data of

reprocessing, etc. For the scope ID input method, refer to Section 3.6, “Entering ID”.

Shelf life

The date of expiration of the effectiveness of a detergent or disinfectant before it is

opened.

Test strip

Device used to test if the concentration of disinfectant solution is effective for disinfection.

Refer to Section 2.8, “Consumable accessories (Optional)” for details. (i.e., the minimum

recommended concentration (MRC) specified by the disinfectant manufacturer)

User ID

Identity information specific to each reprocessing operator. It can be recorded in the

histories of reprocessing, etc. For the user ID input method, refer to Section 3.6, “Entering

ID”.

Important Information — Please Read Before Use

11

OER-Elite OPERATION MANUAL

User qualifications

The operator of this reprocessor must be sufficiently trained in reprocessing of endoscopes. The

medical literature reports cases of infections due to inappropriate cleaning, disinfection, and /or

sterilization. Thoroughly review and understand the following items before use:

Cleaning, disinfection, and sterilization procedures described in the instruction manuals for

the endoscope and ancillary equipment.

Professional health and safety standards.

Applicable guidelines on cleaning, disinfection, and sterilization of endoscopy equipment.

Structure and handling of endoscopic equipment.

Personal protective equipment requirements to minimize exposure to chemicals and

infectious materials.

These manuals do not explain or discuss detailed cleaning, disinfection, and sterilization procedures.

For more details, consult your facility’s procedures, professional guidelines, and regulatory

requirements for reprocessing endoscopes.

12

Important Information — Please Read Before Use

OER-Elite OPERATION MANUAL

Ensuring the safety of reprocessing personnel

• Disinfectant solution and detergent may irritate the mucous membranes in the eyes and

respiratory organs. If disinfectant solution contacts the skin directly and eyes, it may cause

irritation or damage. Therefore, before handling high-level disinfectant solution and detergent,

carefully read the instructions for use and the safety data sheet. For further details, contact

Olympus.

• While using chemicals, wear appropriate personal protective gear to prevent contact with or

inhalation of chemicals or infectious substances. Personal protective gear includes eyewear,

face mask, moisture-resistant clothing, and chemical-resistant gloves that fit properly and are

long enough so that your skin and eyes is not exposed. All personal protective gear should be

inspected before use and replaced periodically before it is damaged.

• When using disinfectant solution and alcohol, Olympus recommends the use of gas filters and

running this reprocessor in well-ventilated areas.

Wear a face mask, gloves, and protective clothes to minimize aspiration and skin contact.

Wear goggles for eye protection.

Refer to the following association’s guidelines related to ventilation:

If the person operating the reprocessor exhibits an allergic reaction or symptoms, no matter

how slight, they should discontinue the task they are performing and vacate the room.

• Before handling the detergent or disinfectant, read the SDS (material safety data sheets) and

learn what measures to take in the event of exposure.

• Operators who exhibit symptoms of an allergic reaction or sensitivity to the reprocessing

chemicals should not operate this reprocessor.

• This reprocessor can be set up to use the RFID (Radio Frequency Identification) function. Be

aware that the radio waves emitted from the RFID reader of the reprocessor may cause

medical devices such as pacemakers to malfunction. If any interference with the equipment is

found, immediately move away from the RFID reader or set the power switch to OFF. Contact

a medical professional immediately if symptoms persist.

SGNA (Society of Gastroenterology Nurses and Associates)

ASGE (American Society of Gastroenterological Endoscopy)

APIC (Association for Professionals of Infection Control and Epidemiology)

AORN (Association of Preoperative Registered Nurses)

ASTM (American Society for Testing and Materials)

OSHA (Occupational Safety and Health Administration)

ACGIH (American Conference of Governmental Industrial Hygienists)

NIOSH (National Institute for Occupational Safety and Health)

AIA (American Institute of Architects)

Important Information — Please Read Before Use

13

OER-Elite OPERATION MANUAL

Equipment compatibility

Use the OER-Elite in combination with ancillary equipment listed in “System chart” on page 647. Using

incompatible equipment may result in patient or operator injury and equipment damage and/or

malfunction.

Olympus has not tested the efficacy of reprocessing on the OER-Elite in combination with endoscopes

that are not listed on the “List of compatible Endoscopes/Connecting Tubes <OER-Elite>”.

If using endoscopes that are not listed on the “List of compatible Endoscopes/Connecting Tubes

<OER-Elite>”, reprocessing of endoscopes may be insufficient.

Care and storage

After use, reprocess and store this reprocessor referring to the instructions in Chapter 10, “End-of-Day

Checks” in this manual. Inappropriate care and storage could present an infection control risk and/or

cause reprocessor damage or malfunction.

Maintenance and Inspection

• The OER-Elite requires routine maintenance and inspection. In addition to checks before use,

the person in charge of maintenance and administration of the medical equipment at the

facility should periodically check all of the items described in this manual. If any irregularity is

found, do not use the reprocessor and inspect it as described in Section 13.2,

“Troubleshooting guide”. If the irregularity is still present, the reprocessor must be repaired

prior to next use.

• If the PERIODIC MAINTENANCE indicator starts to indicate on the touch screen, described

in Section 2.7, “Control panels”, the time for regularly scheduled maintenance is near. Contact

Olympus to perform the maintenance.

Repair and modification

Do not disassemble, modify, or attempt to repair this reprocessor and its accessories. Doing so could

result in operator or patient injury and/or equipment damage or malfunction. Some problems that

appear to be malfunctions may be corrected by referring to Chapter 13, “Troubleshooting and Repair”.

If the problem cannot be resolved using the information in Chapter 13, “Troubleshooting and Repair”,

contact Olympus.

14

Important Information — Please Read Before Use

OER-Elite OPERATION MANUAL

Disposal of disinfectant solution

Expired disinfectant solution for this reprocessor should be handled as directed in the

Olympus-validated disinfectant product label and instructions. Follow all applicable national, state, and

local guidelines.

Disposal of this reprocessor

When disposing of this reprocessor and accessories, follow all applicable national, state, and local

regulations and guidelines.

Signal words

The following signal words are used throughout these manuals:

Warnings and cautions

Follow the warnings and cautions given below when handling this reprocessor. This information is

supplemented by warnings given in each chapter.

WARNING

• Do not insert an EndoTherapy accessory or other object through an opening

including the air vent of the reprocessor.

• Do not allow any liquid (including water or disinfectant solution) to flow into an

opening. Contact with an electrical part inside the reprocessor could cause an

electric shock or reprocessor failure.

• Always remove the tank from the detergent/alcohol drawer before putting detergent

or alcohol in the tank. If detergent or alcohol is spilled on the detergent/alcohol

drawer, it could get inside the reprocessor and contact an electrical part inside,

causing an electric shock or fire hazard.

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert against unsafe practices or potential

equipment damage.

Indicates additional helpful information.

WARNING

CAUTION

NOTE

Important Information — Please Read Before Use

15

OER-Elite OPERATION MANUAL

WARNING

• Do not install this reprocessor in any place where any of the following are present.

High oxygen concentration

Oxidizing substance such as Nitrous Oxide (N

2

O)

Flammable anesthetic gas

This reprocessor is not explosion-proof and may explode or cause a fire under

these conditions.

• Always use the power cord provided with this reprocessor. Otherwise, reprocessor

failure or power cord burnout may result. Also, remember that the provided power

cord is for use only with this reprocessor and should not be used with any other

equipment.

CAUTION

• Do not press any of the switches on the control panel of this reprocessor with a

pointed or hard object. Otherwise, the switch may be damaged.

• Be sure to turn off the water faucet and the power switch of the reprocessor at the

end of the day to avoid potential water leaks.

• To avoid malfunctions, do not use this reprocessor in a dusty environment.

• To avoid electromagnetic interference from other equipment, do not install any

other electrical devices in close proximity to this reprocessor (aside from ancillary

devices used with this reprocessor).

• This equipment enables radio communication by RFID and emits RF (radio

frequency: 13.56 MHz) energy to perform the said intended functions. It may cause

electromagnetic interference in nearby electronic equipment, and is labeled with

the symbol below. If electromagnetic interference occurs, mitigation measures may

be necessary, such as moving the electronic equipment away, reorienting or

relocating this instrument, or shielding the location. An electromagnetic

interference with other devices may shorten the communications distance of the

designated ID tag and cause signals to become unreadable. Try to take mitigation

measures such as keeping the affecting device away from this equipment.

16

Outline of Functions

OER-Elite OPERATION MANUAL

Following functions are available in this reprocessor.

Reprocessing

A series of operations that enable the reprocessor to perform ultrasonic cleaning, detergent

cleaning, disinfection, rinse, air purge, and alcohol flush. A series of operations for ultrasonic

cleaning, detergent cleaning, disinfection, rinse, air purge, and alcohol flush of the outer surface

and channels of endoscopes in a specified sequence and for a specified time. Reprocessing

programs [1] to [4] can be selected by the user. Programs [1] to [4] have a fixed cleaning

process time and disinfection process time. They also have different patterns of auto leak test

and channel monitoring respectively. For details, refer to Chapter 6, “Reprocessing Operations”.

Heat LCG

A process for heating disinfectant solution until it reaches the specified temperature (22q, 72qF).

This process is performed automatically during the reprocessing program. It can also be

performed as an independent operation. For details, refer to Section 7.2, “Heat LCG”.

Heat LCG Timer

The function for heating the disinfectant solution until the specified temperature (22q, 72qF) by

the specified time. For details, refer to Section 7.3, “Heat LCG Timer”.

Drain LCG

This function drains the disinfectant solution from the disinfectant tank. For details, refer to

Section 8.2, “Replacing the disinfectant solution”.

Load LCG

This function loads the disinfectant solution after inserting a new disinfectant bottle. For details,

refer to Section 8.2, “Replacing the disinfectant solution”.

Mix LCG

This function mixs the disinfectant solution to the appropriate concentration and enables

accurate concentration check.

Outline of Functions

Outline of Functions

17

OER-Elite OPERATION MANUAL

Water line disinfection

This function disinfects the water supply line and other lines inside the reprocessor. For details,

refer to Section 7.7, “Water line disinfection”.

Self disinfection and water sampling

This function disinfects the basin and internal piping of the reprocessor. End of the process,

sampling of rinse water can be performed for microbiological surveillance. For details, refer to

Section 7.8, “Self-disinfection and water sampling”.

Detergent/Alcohol line disinfection

This function disinfects the detergent line and alcohol line of the reprocessor. For details, refer to

Section 7.9, “Detergent line disinfection” and Section 7.10, “Alcohol line disinfection”.

Auto leak test

The endoscope leak test can be executed automatically by programming it in a user-configured

reprocessing process. It can also be performed as an independent operation. For details, refer

to Section 7.12, “Auto leak test”.

Manual leak test

Manual inspection for endoscope leakage during immersion of water can be performed as an

independent operation. For details, refer to Section 7.11, “Manual leak test”.

Alcohol flush

To assist in drying the channel after reprocessing, alcohol is flushed through the endoscope

channels followed by air. This function performs alcohol flush into the endoscope channels. The

alcohol flush can be executed automatically in a reprocessing process. It can also be performed

as an independent operation. For details, refer to Section 7.14, “Alcohol flush”.

Air purge

This function drains the remaining fluid from the basin after an irregularity occurs, or if the

process is stopped before it completes. Air purge also eliminates residual fluid from the

endoscope channels. For details, refer to Section 7.6, “Air purge”.

18

Outline of Functions

OER-Elite OPERATION MANUAL

Rinse

This function performs the rinsing process if the fluid remains in the basin or in the endoscopes

after an irregularity occurs or the process is stopped midway. For details, refer to Section 7.5,

“Rinse”.

Leaking scope decontamination

This function decontaminates a leaking endoscope prior to repair. During the decontamination,

positive pressure is applied to the leaking endoscope to avoid fluid invasion and damage to the

endoscope. For details, refer to Section 7.15, “Leaking scope decontamination”.

ALT self-check

This function checks the auto leak test function of the reprocessor. It is performed automatically

at the end of Load LCG function or as an independent operation. For details, refer to

Section 7.13, “Self-check of auto leak test”.

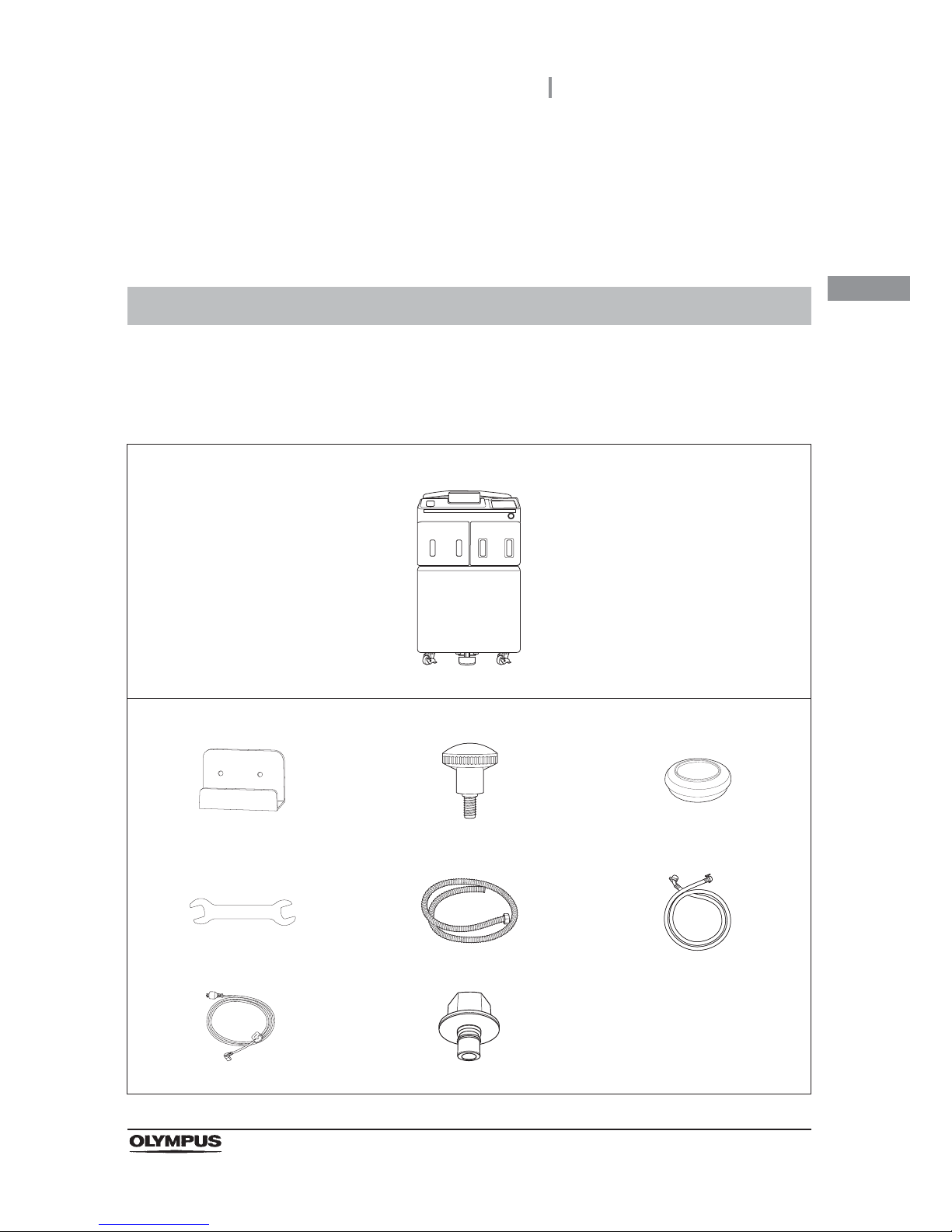

1.1 Checking the package contents

19

OER-Elite OPERATION MANUAL

Ch.1

Chapter 1 Checking the Package

Contents

Check that the package contains all the items listed below. Inspect each item for damage. If the device

is damaged, a component is missing, or there is any question regarding items, do not use the device

and contact Olympus immediately.

1.1 Checking the package contents

Endoscope reprocessor

Endoscope reprocessor OER-Elite

Accessories for use in installation

Buckling guard (GT970400) Buckling guard retaining screw

(GC783700, 2 pcs)

Grommet (GC784100, 4 pcs)

Wrench (GC748400) Drain hose (GJ853400) Water supply hose (GC416500)

Power cord (RL545000) Water supply plug (GN573800)

20

1.1 Checking the package contents

OER-Elite OPERATION MANUAL

Ch.1

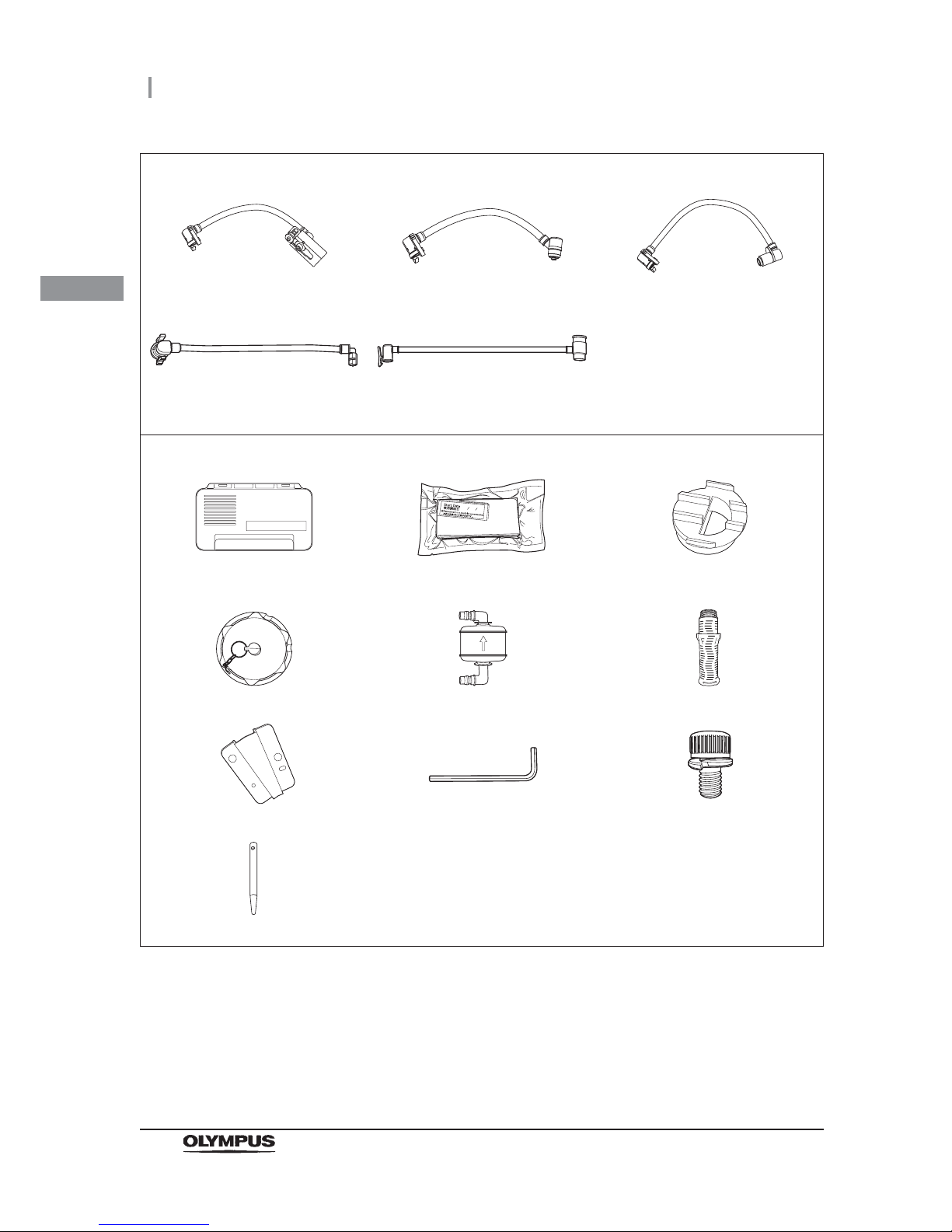

Accessories for use in reprocessing

Connecting tube (MAJ-2110, 2 pcs) Connecting tube (MAJ-2111, 2 pcs) Connecting tube (MAJ-2112, 2 pcs)

Connecting tube (MAJ-2113, 2 pcs) Leak test air tube

(MAJ-2127, 2 pcs)

Accessories to be attached to the reprocessor

Gas filter case (GJ460700) Gas filter (2 pcs) (MAJ-822) Gas filter adapter (splash guard)

(GC949900)

Washing case (MAJ-2121) Air filter (MAJ-823) Water filter (MAJ-824 or MAJ-2318)

Stylus pen holder (RA016500) Hex wrench (GT804300) M4 × 10 mm cap bolt (2 pcs)

Stylus pen (GT944200)

Loading...

Loading...