Page 1

NORTEC 600

Eddy Current Flaw Detector

User’s Manual

DMTA-10040-01EN — Rev. E

February 2018

This instruction manual contains essential information on how to use this Olympus product safely and effectively.

Before using this product, thoroughly review this instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Page 2

Olympus Scientific Solutions Americas, 48 Woerd Avenue, Waltham, MA 02453, USA

Copyright © 2014, 2015, 2017, 2018 by Olympus. All rights reserved. No part of this

publication may be reproduced, translated, or distributed without the express written

permission of Olympus.

This document was prepared with particular attention to usage to ensure the accuracy of the

information contained therein, and corresponds to the version of the product manufactured

prior to the date appearing on the title page. There could, however, be some differences

between the manual and the product if the product was modified thereafter.

The information contained in this document is subject to change without notice.

Part number: DMTA-10040-01EN

Rev. E

February 2018

Printed in the United States of America

The microSD logo is a trademark of SD-3D, LLC.

All brands are trademarks or registered trademarks of their respective owners and third

party entities.

Page 3

DMTA-10040-01EN, Rev. E, February 2018

Table of Contents

List of Abbreviations ....................................................................................... ix

Labels and Symbols ........................................................................................... 1

Important Information — Please Read Before Use ..................................... 7

Intended Use .......................................................................................................................... 7

Instruction Manual ................................................................................................................ 7

Instrument Compatibility ..................................................................................................... 8

Repair and Modification ....................................................................................................... 9

Patent Rights Protection ....................................................................................................... 9

Safety Symbols ..................................................................................................................... 10

Safety Signal Words ............................................................................................................. 10

Note Signal Words ............................................................................................................... 11

Safety ..................................................................................................................................... 11

Warnings ............................................................................................................................... 12

Battery Precautions .............................................................................................................. 13

Equipment Disposal ............................................................................................................ 14

CE (European Community) ............................................................................................... 14

WEEE Directive .................................................................................................................... 14

China RoHS .......................................................................................................................... 15

Korea Communications Commission (KCC) ................................................................... 16

EMC Directive Compliance ................................................................................................ 16

FCC (USA) Compliance ...................................................................................................... 16

ICES-001 (Canada) Compliance ........................................................................................ 17

Warranty Information ......................................................................................................... 17

Technical Support ................................................................................................................ 18

Introduction ...................................................................................................... 19

Table of Contents iii

Page 4

DMTA-10040-01EN, Rev. E, February 2018

1. Instrument Overview ................................................................................ 21

1.1 Operating Principle ................................................................................................... 21

1.2 Contents of the Case ................................................................................................. 22

1.3 Connectors ................................................................................................................. 23

1.4 Power Requirements ................................................................................................. 26

1.4.1 Charger/Adaptor ............................................................................................ 27

1.4.2 Battery Compartment .................................................................................... 30

1.4.3 Lithium-Ion Battery ....................................................................................... 31

1.4.4 Alkaline Batteries ........................................................................................... 32

1.5 Optional microSD Card Installation ....................................................................... 33

1.6 NORTEC 600 Hardware Features .......................................................................... 34

1.6.1 Hardware Overview ...................................................................................... 35

1.6.1.1 Front Panel and SmartKnob ............................................................... 36

1.6.1.2 Keypad .................................................................................................. 37

1.6.2 Connectors ....................................................................................................... 42

1.6.2.1 Probe and BNC Connectors ............................................................... 42

1.6.2.2 Input/Output (I/O) and VGA OUT Connectors .............................. 42

1.6.2.3 microSD and USB Port ........................................................................ 44

1.6.3 Various Hardware Features .......................................................................... 45

1.6.3.1 Instrument Stand ................................................................................. 45

1.6.3.2 O-Ring Gasket and Membrane Seals ................................................ 46

1.6.3.3 Display Protection ............................................................................... 46

1.6.4 Environmental Ratings .................................................................................. 46

2. Software User Interface ............................................................................ 49

2.1 Starting Up the Instrument ...................................................................................... 49

2.1.1 Navigating the Application Menu ............................................................... 50

2.1.2 Main Inspection Screen ................................................................................. 51

2.2 Selecting from the Menus ........................................................................................ 54

2.3 Displaying All Functions Simultaneously — ALL SETTINGS Menu ............... 54

2.3.1 Using the ALL SETTINGS Menu ................................................................. 55

2.3.2 Special Functions in the ALL SETTINGS Menu ........................................ 56

2.4 Displaying Real-Time Readings ............................................................................. 56

2.4.1 Enabling Real-Time Readings on the Main Inspection Screen ................ 59

2.4.2 Enabling the Real-Time Readings in Full-Screen Mode — FULL NEXT

key .................................................................................................................... 60

3. Initial Setup ................................................................................................ 63

3.1 Setting the User Interface Language and the Decimal Symbol .......................... 63

3.2 Setting the Clock ....................................................................................................... 64

3.3 Changing the Location of Saved Files .................................................................... 64

Table of Contentsiv

Page 5

DMTA-10040-01EN, Rev. E, February 2018

3.4 Changing the Display Settings ................................................................................ 65

3.5 Changing the Display Brightness ........................................................................... 66

3.6 Adjusting Auto Erase ............................................................................................... 67

3.7 Selecting the Startup Screen .................................................................................... 67

3.8 Enabling Knobless Entry for Harsh Environments ............................................. 68

4. Control Functions ...................................................................................... 69

4.1 PowerLink .................................................................................................................. 69

4.2 Instrument Controls ................................................................................................. 70

4.2.1 Display ............................................................................................................. 71

4.2.2 Power and Lock Buttons ............................................................................... 71

4.2.3 Direct-Function Keys ..................................................................................... 71

4.2.4 Menu Keys ...................................................................................................... 77

4.2.5 Knob ................................................................................................................. 78

4.2.6 Hidden Function — Screen Capture ........................................................... 78

4.2.7 Knobless Entry ............................................................................................... 78

4.2.8 Ambidextrous Controls ................................................................................. 79

4.2.9 FULL NEXT key ............................................................................................. 80

4.3 Menus ......................................................................................................................... 82

4.3.1 Frequency (FREQ 1) Menu — MAIN FILTER Key ................................... 82

4.3.2 Filter Menu — MAIN FILTER Key .............................................................. 84

4.3.3 Special Menu — MAIN FILTER Key ........................................................... 85

4.3.4 Display Menu — DISP Key .......................................................................... 87

4.3.5 Alarm Menu — ALARM Key ...................................................................... 91

4.3.6 Memory Menu — MEM Key ........................................................................ 92

4.3.7 Memory Text Editor ....................................................................................... 96

4.3.8 Advanced Setup Menu — ADV SETUP Menu Key .................................. 99

4.4 Dual Frequency Menus .......................................................................................... 109

4.4.1 Frequency (FREQ 1) Menu — MAIN FILTER Key ................................. 109

4.4.2 Frequency (FREQ 2) Menu — MAIN FILTER Key ................................. 111

4.4.3 MIX Menu in Dual Frequency — MAIN FILTER Key ........................... 113

4.4.4 Filter Menu in Dual Frequency — MAIN FILTER Key .......................... 114

4.4.5 Special Menu in Dual Frequency — MAIN FILTER Key ....................... 114

4.4.6 Display Menu in Dual Frequency — DISP Key ...................................... 116

4.4.7 ALARM Menu in Dual Frequency — ALARM Key ............................... 118

5. Using the Instrument .............................................................................. 119

5.1 Common NORTEC 600 Applications .................................................................. 120

5.1.1 Detecting Surface-Breaking Cracks — General Purpose Procedure for All

NORTEC 600 Models .................................................................................. 120

Table of Contents v

Page 6

DMTA-10040-01EN, Rev. E, February 2018

5.1.2 Inspecting Fastener Holes with a Rotating Scanner — NORTEC 600S and

NORTEC 600D Models ................................................................................ 126

5.1.3 Detecting Sub-Surface Cracks at Very Low Frequency — All

NORTEC 600 Models ................................................................................... 135

5.1.4 Inspecting Welds on Ferromagnetic Materials — All NORTEC 600

Models ........................................................................................................... 141

5.1.5 Evaluating Paint Thickness on Ferromagnetic Material — All

NORTEC 600 Models ................................................................................... 148

5.1.6 Measuring Conductivity and Nonconductive Coating Thickness —

NORTEC 600C, NORTEC 600S, and NORTEC 600D Models ............... 154

5.1.7 Inspecting Aircraft Wheels — All NORTEC 600 Models ....................... 160

5.1.8 Inspecting Critical Fastener Holes with a Controlled Translation

(Indexing) Scanner — NORTEC 600S and NORTEC 600D Models ..... 166

5.2 Special and Educational Applications ................................................................. 173

5.2.1 Using the Impedance Plane Theory and Display — All NORTEC 600

Models ........................................................................................................... 174

5.2.2 Sorting Metals by Evaluating Conductivity — All NORTEC 600

Models ........................................................................................................... 177

5.2.3 Evaluating Nonconductive Coating (Paint) Thickness — All NORTEC 600

Models ........................................................................................................... 181

5.2.4 Evaluating Metal Thickness and Using Thickness Curve Theory — All

NORTEC 600 Models ................................................................................... 185

5.3 Advanced Dual Frequency Applications ............................................................ 189

5.3.1 Detecting Corrosion Using Dual Frequency to Reduce the Pillowing

Effect — NORTEC 600D Model ................................................................. 190

5.3.2 Detecting Sub-Surface Cracks Using Dual Frequency in a Lap Splice with

Anodized and Alodine Rivets — NORTEC 600D Model ....................... 201

5.3.3 Inspecting Heat Exchanger Tubing Using Dual Frequency —

NORTEC 600D Model ................................................................................. 215

5.4 Heat Exchanger Tubing Applications .................................................................. 228

5.4.1 ECT Pitting, Wear, and Cracks — NORTEC 600D Model ...................... 230

5.4.1.1 Using the Application ....................................................................... 233

5.4.1.2 Displaying Reference Signals .......................................................... 248

5.4.1.3 Using the ALL-IN-1 (Strip Chart) Display .................................... 249

5.4.2 ECT Erosion and Corrosion — NORTEC 600D Model .......................... 251

5.4.3 RFT Pitting and Wear — NORTEC 600D Model ..................................... 256

5.4.3.1 Using the Application ....................................................................... 259

5.4.3.2 Enhancing the Signal with the LO PASS Filter ............................. 268

5.4.3.3 Using the ALL-IN-1 Display ............................................................ 269

5.4.4 RFT Erosion and Corrosion — NORTEC 600D Model ........................... 271

5.4.4.1 Using the Application ....................................................................... 272

5.4.4.2 Using the Overlay Display ............................................................... 277

Table of Contentsvi

Page 7

DMTA-10040-01EN, Rev. E, February 2018

5.4.4.3 Optimizing the Frequency ............................................................... 278

5.4.5 NFT Pitting (Differential) — NORTEC 600D Model .............................. 279

5.4.6 NFT Erosion and Corrosion (Absolute) — NORTEC 600D Model ...... 286

5.5 Alarm Menus ........................................................................................................... 292

5.5.1 Alarm DEFINE Menu .................................................................................. 292

5.5.2 Selecting the Alarm Shape and Position — Alarm 1, 2, and 3 Menus .. 294

5.5.3 SWEEP alarm ................................................................................................ 295

6. NORTEC PC Software ............................................................................ 297

6.1 Importing Files ........................................................................................................ 297

6.2 Capturing a Screen Image Using NORTEC PC .................................................. 300

6.3 Upgrading the Instrument Software Using NORTEC PC ................................ 302

6.4 Upgrading the Instrument Software without NORTEC PC ............................. 305

6.5 Creating a PDF ........................................................................................................ 307

6.6 Issuing Remote Commands to the NORTEC 600 from a PC ............................ 308

6.7 Remotely Controlling the NORTEC 600 from a PC ........................................... 318

6.8 Managing Files on the NORTEC 600 from your PC .......................................... 320

6.9 Unlocking NORTEC 600 Upgrade Options with your PC ............................... 323

6.10 Backing Up the NORTEC 600 Files ...................................................................... 325

6.11 Restoring or Cloning the NORTEC 600 Files ...................................................... 327

7. Maintenance and Troubleshooting ...................................................... 329

7.1 Lithium-Ion Battery ................................................................................................ 329

7.2 Error Messages ........................................................................................................ 330

7.3 Probe Care and Diagnostics .................................................................................. 331

Appendix A: Specifications ......................................................................... 333

A.1 General and Environmental Specifications ......................................................... 333

A.2 Input/Output Specifications .................................................................................. 338

Appendix B: Accessories, Replacement Parts, and Upgrades ............... 341

List of Figures ................................................................................................. 347

List of Tables ................................................................................................... 357

Index ................................................................................................................. 359

Table of Contents vii

Page 8

DMTA-10040-01EN, Rev. E, February 2018

Table of Contentsviii

Page 9

List of Abbreviations

A/C air conditioner

AC alternating current

CD-ROM compact disc read-only memory

DC direct current

ECT eddy current testing

EFUP environment-friendly use period

GB gigabyte

I/O input-output

ID identification

ID internal diameter

IP ingress protection

LCD liquid crystal display

LED light-emitting diode

Li-ion lithium-ion

MIL military

mil one-thousandths of one inch (0.0254 mm)

N/A not applicable

NFT near-field testing

OD outside diameter

OEM original equipment manufacturer

P/N part number

PC personal computer

RFT remote-field testing

SD secure digital (card)

DMTA-10040-01EN, Rev. E, February 2018

List of Abbreviations ix

Page 10

DMTA-10040-01EN, Rev. E, February 2018

SPC statistical process control

USB universal serial bus

VGA video graphics array

WEEE waste electrical and electronic equipment

WT wall thickness

List of Abbreviationsx

Page 11

DMTA-10040-01EN, Rev. E, February 2018

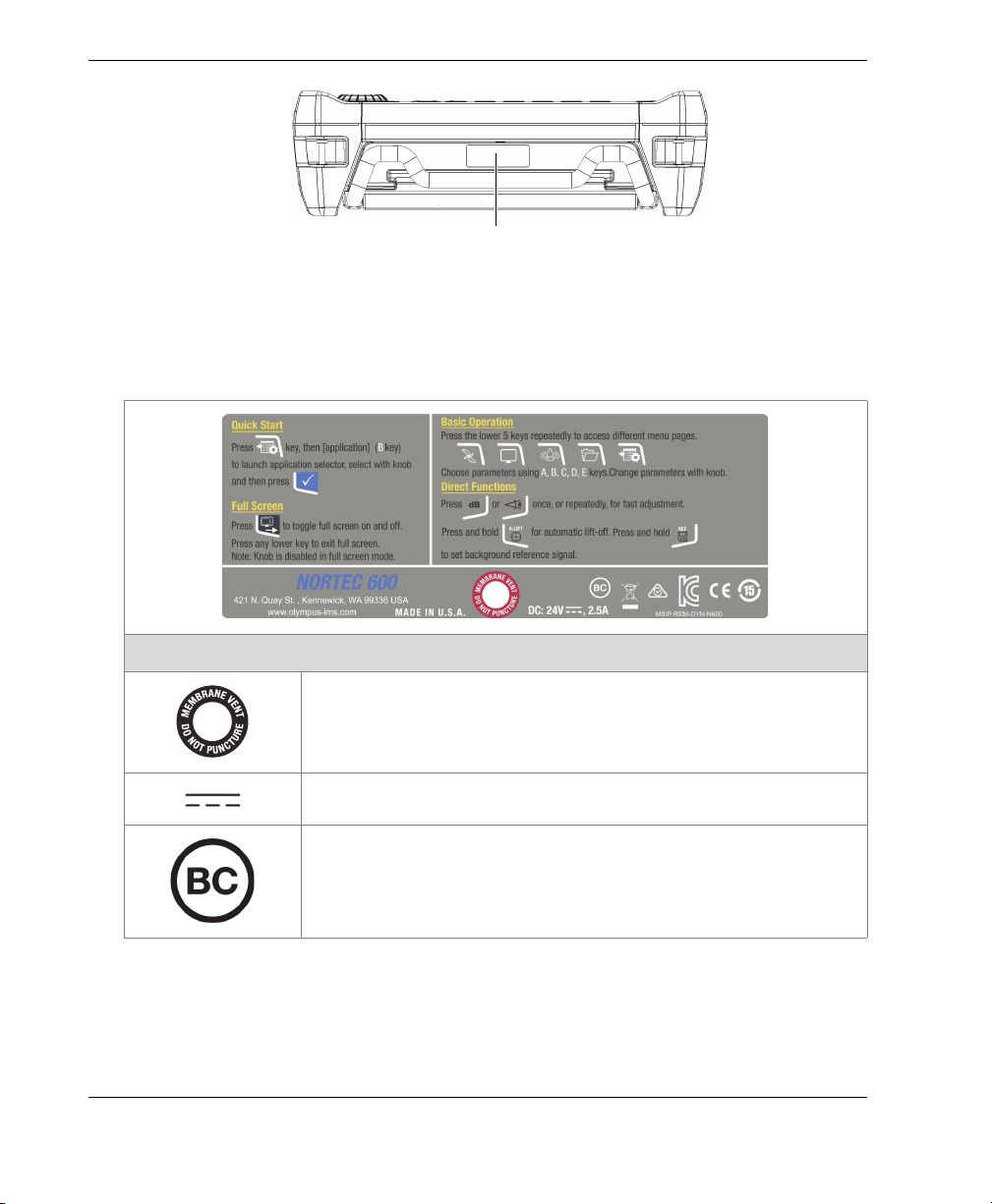

Instruction and rating label (see Table 1 on page 2)

Labels and Symbols

Safety-related labels and symbols are attached to the instrument at the locations

shown in Figure i-1 on page 1. If any or all of the labels or symbols are missing or

illegible, please contact Olympus.

Figure i‑1 Label attached to the back of the instrument

Labels and Symbols 1

Page 12

DMTA-10040-01EN, Rev. E, February 2018

Serial number location (see Table 1 on page 2)

Figure i‑2 Location of the serial number

Table 1 Content of the rating label

This symbol indicates the location of the membrane vent.

The direct current symbol.

Efficiency of battery chargers specific to California, USA.

Labels and Symbols2

Content

Page 13

DMTA-10040-01EN, Rev. E, February 2018

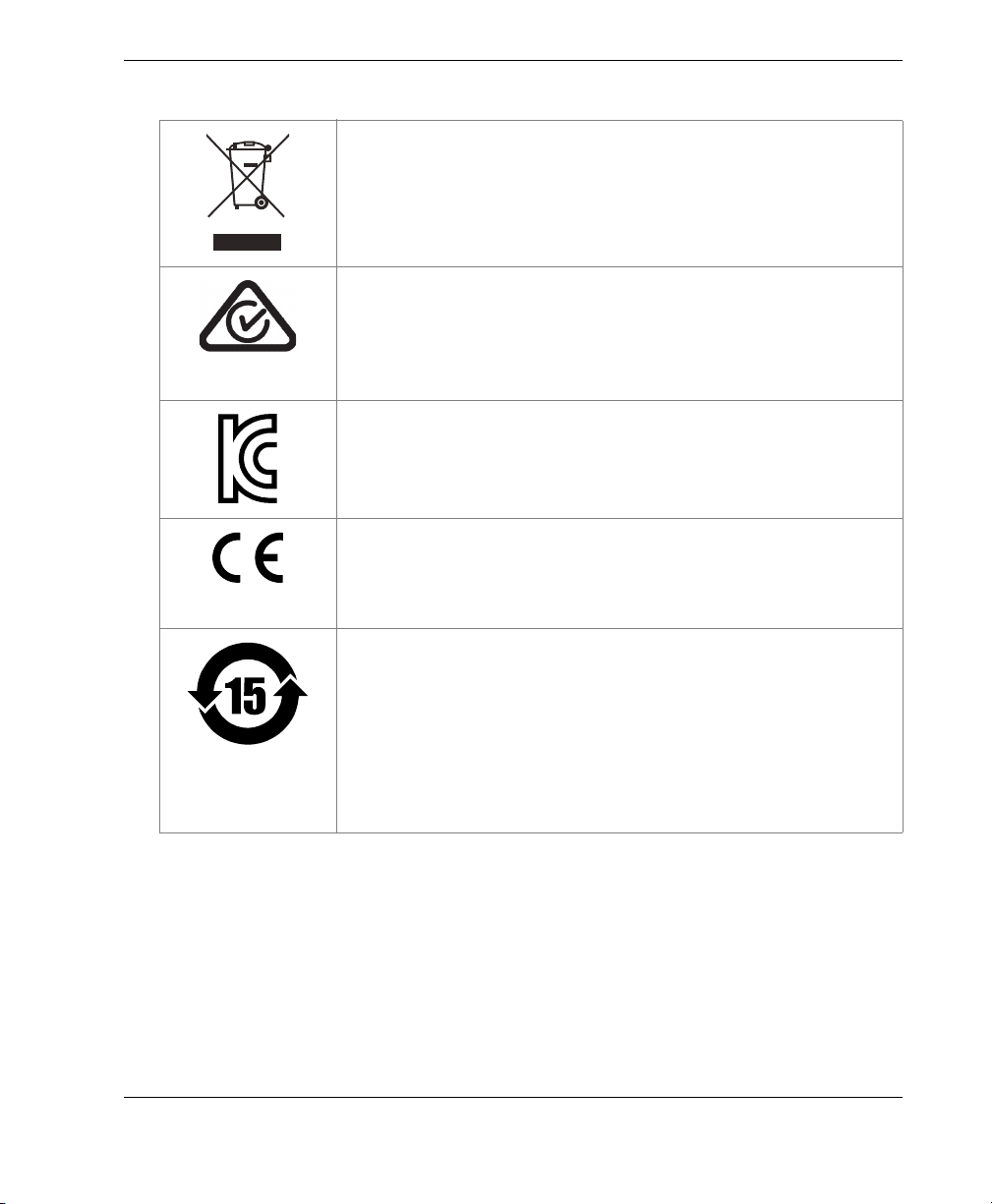

Table 1 Content of the rating label (continued)

The WEEE symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be

collected separately.

The regulatory compliance mark (RCM) label indicates that

the product complies with all applicable standards, and has

been registered with the Australian Communications and

Media Authority (ACMA) for placement on the Australian

market.

Seller and user shall be noticed that this equipment is suitable

for electromagnetic equipment for office work (class A) and it

can be used outside home. The MSIP code for the

NORTEC 600 is the following: MSIP-REM-OYN-N600.

The CE marking is a declaration that this product conforms to

all the applicable directives of the European Community. See

the Declaration of Conformity for details. Contact your Olympus

representative for more information.

The China RoHS mark indicates the product’s EnvironmentFriendly Use Period (EFUP). The EFUP is defined as the

number of years for which listed controlled substances will not

leak or chemically deteriorate while in the product. The EFUP

for the NORTEC 600 has been determined to be 15 years. Note:

The Environment-Friendly Use Period (EFUP) is not meant to

be interpreted as the period assuring functionality and

product performance.

Labels and Symbols 3

Page 14

DMTA-10040-01EN, Rev. E, February 2018

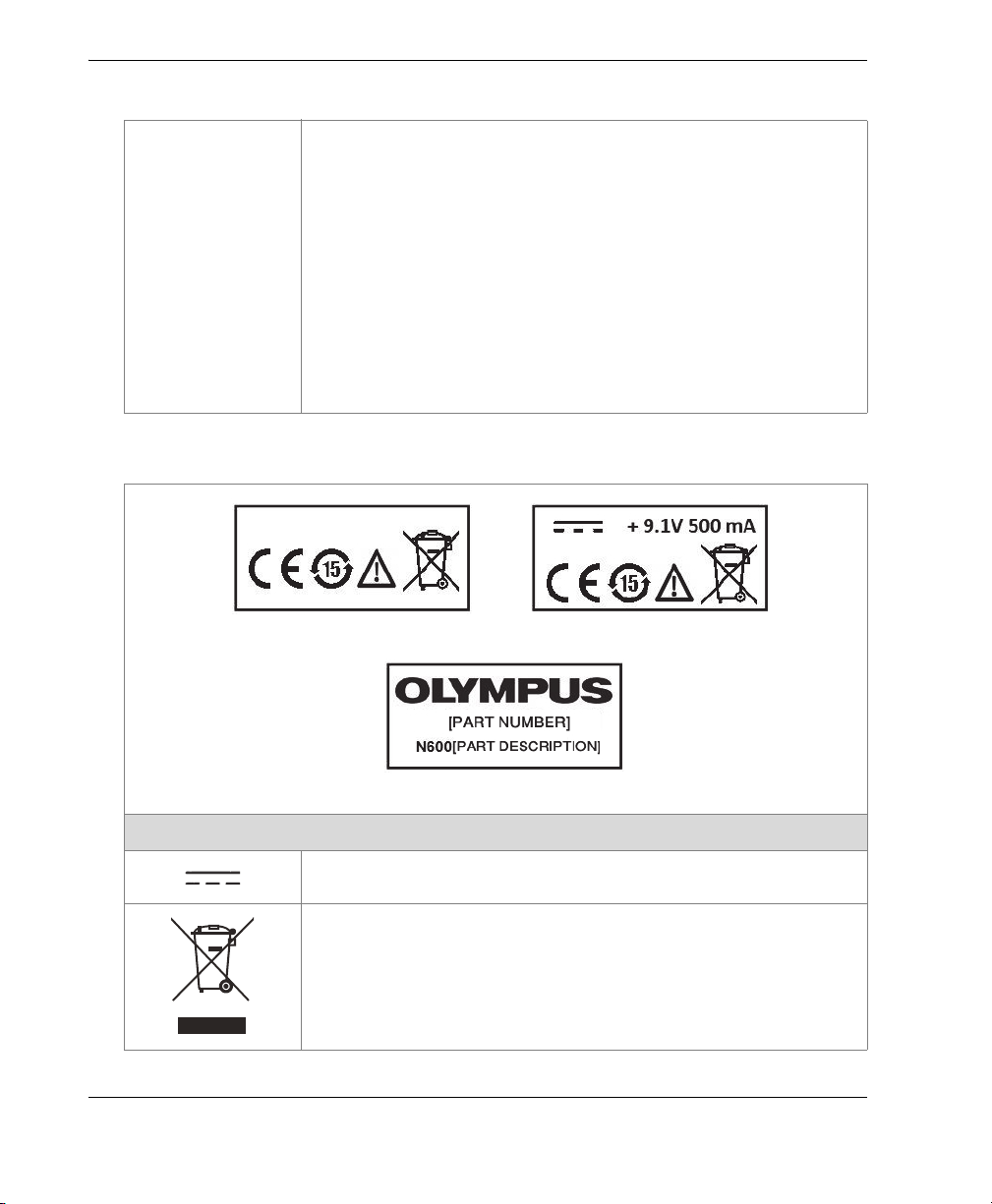

RFT adaptor label

ECT and NFT adaptor label

Part identification label

Table 1 Content of the rating label (continued)

SERIAL The serial number is a nine (9) digit number in the following

format:

yynnnddmm

where:

yy Production year

nnn Unit number manufactured that day

dd Production day

mm Production month

For example, the 130050609 serial number indicates that the

fifth unit (005) was produced on 6 September 2013.

Table 2 Content of the probe adaptor labels

Labels and Symbols4

Content

The direct current symbol.

The WEEE symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be

collected separately.

Page 15

Table 2 Content of the probe adaptor labels (continued)

Part

identification

information

DMTA-10040-01EN, Rev. E, February 2018

The CE marking is a declaration that this product conforms to

all the applicable directives of the European Community. See

the Declaration of Conformity for details. Contact your Olympus

representative for more information.

The China RoHS mark indicates the product’s EnvironmentFriendly Use Period (EFUP). The EFUP is defined as the

number of years for which listed controlled substances will not

leak or chemically deteriorate while in the product. The EFUP

for the NORTEC 600 probe cable has been determined to be

15 years. Note: The Environment-Friendly Use Period (EFUP)

is not meant to be interpreted as the period assuring

functionality and product performance.

The warning symbol indicates that the user must read the

user’s manual in order to find out the nature of the potential

hazards and any actions to avoid them.

The product’s part number and description.

Labels and Symbols 5

Page 16

DMTA-10040-01EN, Rev. E, February 2018

Labels and Symbols6

Page 17

DMTA-10040-01EN, Rev. E, February 2018

WARNING

Important Information — Please Read Before Use

Intended Use

The NORTEC 600 is designed to perform nondestructive inspections on industrial

and commercial materials.

Do not use the NORTEC 600 for any purpose other than its intended use. It must

never be used to inspect or examine human or animal body parts.

Instruction Manual

This instruction manual contains essential information on how to use this Olympus

product safely and effectively. Before using this product, thoroughly review this

instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Important Information — Please Read Before Use 7

Page 18

DMTA-10040-01EN, Rev. E, February 2018

IMPORTANT

NOTE

CAUTION

Some of the details of components illustrated in this manual may differ from the

components installed on your instrument. However, the operating principles remain

the same.

Instrument Compatibility

Only use the NORTEC 600 instrument with the following ancillary equipment:

• Rechargeable lithium-ion (Li-ion) battery pack (Olympus P/N: 600-BAT-L-2

[U8760058])

• Optional stand-alone external battery charger (Olympus P/N: EPXT-EC-X

[U8767043]), where “X” denotes the power cord type (see Table 12 on page 342).

• Charger/adaptor (Olympus P/N: EP-MCA-X), where “X” denotes the power cord

type (see Table 14 on page 343).

See “Accessories, Replacement Parts, and Upgrades” on page 341 for more details

about accessories.

Always use equipment and accessories that meet Olympus specifications. Using

incompatible equipment could cause equipment malfunction and/or damage, or

human injury.

The following rotating scanners are compatible with the NORTEC 600S and

NORTEC 600D instrument models:

• MiniMite

•Spitfire

Important Information — Please Read Before Use8

Page 19

DMTA-10040-01EN, Rev. E, February 2018

IMPORTANT

CAUTION

• RA-2000 (replaces the RA-19 scanner, which became obsoleted in 2002. The RA-19

scanner is NOT

series)

•PS5

• GE Hocking MiniDrive

• Rohmann Elotest MR3 scanner

ANY other scanner not listed here has not been tested and is NOT supported at the

time of publication of this manual.

compatible with the NORTEC 500 or NORTEC 600 instrument

Repair and Modification

The NORTEC 600 does not contain any user-serviceable parts. Opening the

instrument might void the warranty.

In order to prevent human injury and/or equipment damage, do not disassemble,

modify, or attempt to repair the instrument.

Patent Rights Protection

Certain components of Olympus products are patented. For more details, see the

About > Legal Info menu on the NORTEC 600 instrument display.

Important Information — Please Read Before Use 9

Page 20

DMTA-10040-01EN, Rev. E, February 2018

DANGER

WARNING

Safety Symbols

The following safety symbols might appear on the instrument and in the instruction

manual:

General warning symbol

This symbol is used to alert the user to potential hazards. All safety messages that

follow this symbol shall be obeyed to avoid possible harm or material damage.

Shock hazard caution symbol

This symbol is used to alert the user to potential laser hazards. All safety

messages that follow this symbol shall be obeyed to avoid possible harm or

material damage.

Safety Signal Words

The following safety signal words might appear in the documentation of the

instrument:

The DANGER signal word indicates an imminently hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to will result in death or serious personal injury. Do not proceed beyond a

DANGER signal word until the indicated conditions are fully understood and met.

The WARNING signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to could result in death or serious personal injury. Do not proceed beyond a

WARNING signal word until the indicated conditions are fully understood and met.

Important Information — Please Read Before Use10

Page 21

DMTA-10040-01EN, Rev. E, February 2018

CAUTION

IMPORTANT

NOTE

TIP

The CAUTION signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to may result in minor or moderate personal injury, material damage,

particularly to the product, destruction of part or all of the product, or loss of data. Do

not proceed beyond a CAUTION signal word until the indicated conditions are fully

understood and met.

Note Signal Words

The following note signal words could appear in the documentation of the

instrument:

The IMPORTANT signal word calls attention to a note that provides important

information, or information essential to the completion of a task.

The NOTE signal word calls attention to an operating procedure, practice, or the like,

which requires special attention. A note also denotes related parenthetical

information that is useful, but not imperative.

The TIP signal word calls attention to a type of note that helps you apply the

techniques and procedures described in the manual to your specific needs, or

provides hints on how to effectively use the capabilities of the product.

Safety

Before turning on the instrument, verify that the correct safety precautions have been

taken (see the following warnings). In addition, note the external markings on the

instrument, which are described under “Safety Symbols.”

Important Information — Please Read Before Use 11

Page 22

DMTA-10040-01EN, Rev. E, February 2018

WARNING

WARNING

Warnings

General Warnings

• Carefully read the instructions contained in this instruction manual prior to

turning on the instrument.

• Keep this instruction manual in a safe place for further reference.

• Follow the installation and operation procedures.

• It is imperative to respect the safety warnings on the instrument and in this

instruction manual.

• If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment could be impaired.

• Do not install substitute parts or perform any unauthorized modification to the

instrument.

• Service instructions, when applicable, are for trained service personnel. To avoid

the risk of electric shock, do not perform any work on the instrument unless

qualified to do so. For any problem or question regarding this instrument, contact

Olympus or an authorized Olympus representative.

• Do not touch the connectors directly by hand. Otherwise, a malfunction or electric

shock may result.

• Do not allow metallic or foreign objects to enter the device through connectors or

any other openings. Otherwise, a malfunction or electric shock may result.

Electrical Warning

The instrument must only be connected to a power source corresponding to the type

indicated on the rating label.

Important Information — Please Read Before Use12

Page 23

DMTA-10040-01EN, Rev. E, February 2018

CAUTION

CAUTION

If a nonapproved power supply cord not dedicated to Olympus products is used,

Olympus will not be able to ensure the electrical safety of the equipment.

Battery Precautions

• Before disposing of a battery, check your local laws, rules, and regulations, and

follow them accordingly.

• Transportation of lithium-ion batteries is regulated by the United Nations under

the United Nations Recommendations on the Transport of Dangerous Goods. It is

expected that governments, intergovernmental organizations, and other

international organizations shall conform to the principles laid down in these

regulations, thus contributing to worldwide harmonization in this field. These

international organizations include the International Civil Aviation organization

(ICAO), the International Air Transport Association (IATA), the International

Maritime Organization (IMO), the US Department of Transportation (USDOT),

Transport Canada (TC), and others. Please contact the transporter and confirm

current regulations before transportation of lithium-ion batteries.

• Do not open, crush, or perforate batteries; doing so could cause injury.

• Do not incinerate batteries. Keep batteries away from fire and other sources of

extreme heat. Exposing batteries to extreme heat (over 80 °C) could result in an

explosion or personal injury.

• Do not drop, hit, or otherwise abuse a battery, as doing so could expose the cell

contents, which are corrosive and explosive.

• Do not short-circuit the battery terminals. A short circuit could cause injury and

severe damage to a battery making it unusable.

• Do not expose a battery to moisture or rain; doing so could cause an electric

shock.

• Only use the NORTEC 600 unit or an external charger approved by Olympus to

charge the batteries.

• Only use batteries supplied by Olympus.

• Do not store batteries that have less than 40 % remaining charge. Recharge

batteries to between 40 % and 80 % capacity before storing them.

Important Information — Please Read Before Use 13

Page 24

DMTA-10040-01EN, Rev. E, February 2018

IMPORTANT

• During storage, keep the battery charge between 40 % and 80 %.

• Do not leave batteries in the NORTEC 600 unit during instrument storage.

Equipment Disposal

Before disposing of the NORTEC 600, check your local laws, rules, and regulations,

and follow them accordingly.

CE (European Community)

This device complies with the requirements of directive 2014/30/EU

concerning electromagnetic compatibility, directive 2014/35/EU

concerning low voltage, and directive 2011/65/EU concerning

restriction of hazardous substances (RoHS). The CE marking indicates

compliance with the above directives.

Tubing probes (with cables) that are 25 m (82 ft) in length or under are CE compliant

when used with the NORTEC 600 instrument. Probes (with cables) over 25 m (82 ft) in

length are not CE compliant.

WEEE Directive

Important Information — Please Read Before Use14

In accordance with European Directive 2012/19/EU on Waste Electrical

and Electronic Equipment (WEEE), this symbol indicates that the

product must not be disposed of as unsorted municipal waste, but

should be collected separately. Refer to your local Olympus distributor

for return and/or collection systems available in your country.

Page 25

DMTA-10040-01EN, Rev. E, February 2018

China RoHS

China RoHS is the term used by industry generally to describe legislation

implemented by the Ministry of Information Industry (MII) in the People’s Republic

of China for the control of pollution by electronic information products (EIP).

The China RoHS mark indicates the product’s EnvironmentFriendly Use Period (EFUP). The EFUP is defined as the number of

years for which listed controlled substances will not leak or

chemically deteriorate while in the product. The EFUP for the

NORTEC 600 has been determined to be 15 years.

Note: The Environment-Friendly Use Period (EFUP) is not meant

to be interpreted as the period assuring functionality and product

performance.

“ 中国 RoHS” 是一个工业术语,一般用于描述中华人民共和国信息工业部 (MII)针

对控制电子信息产品 (EIP)的污染所实行的法令。

中国 RoHS 标识是根据 “ 电器电子产品有害物质限制使用管理办

法 ” 以及 “ 电子电气产品有害物质限制使用标识要求 ” 的规定,适

用于在中国销售的电气电子产品上的电气电子产品有害物质限制使

用标识。

电气电子产品

有害物质

限制使用标识

注意:电气电子产品有害物质限制使用标识内的数字为在正常的使

用条件下有害物质不会泄漏的年限,不是保证产品功能性的年限。

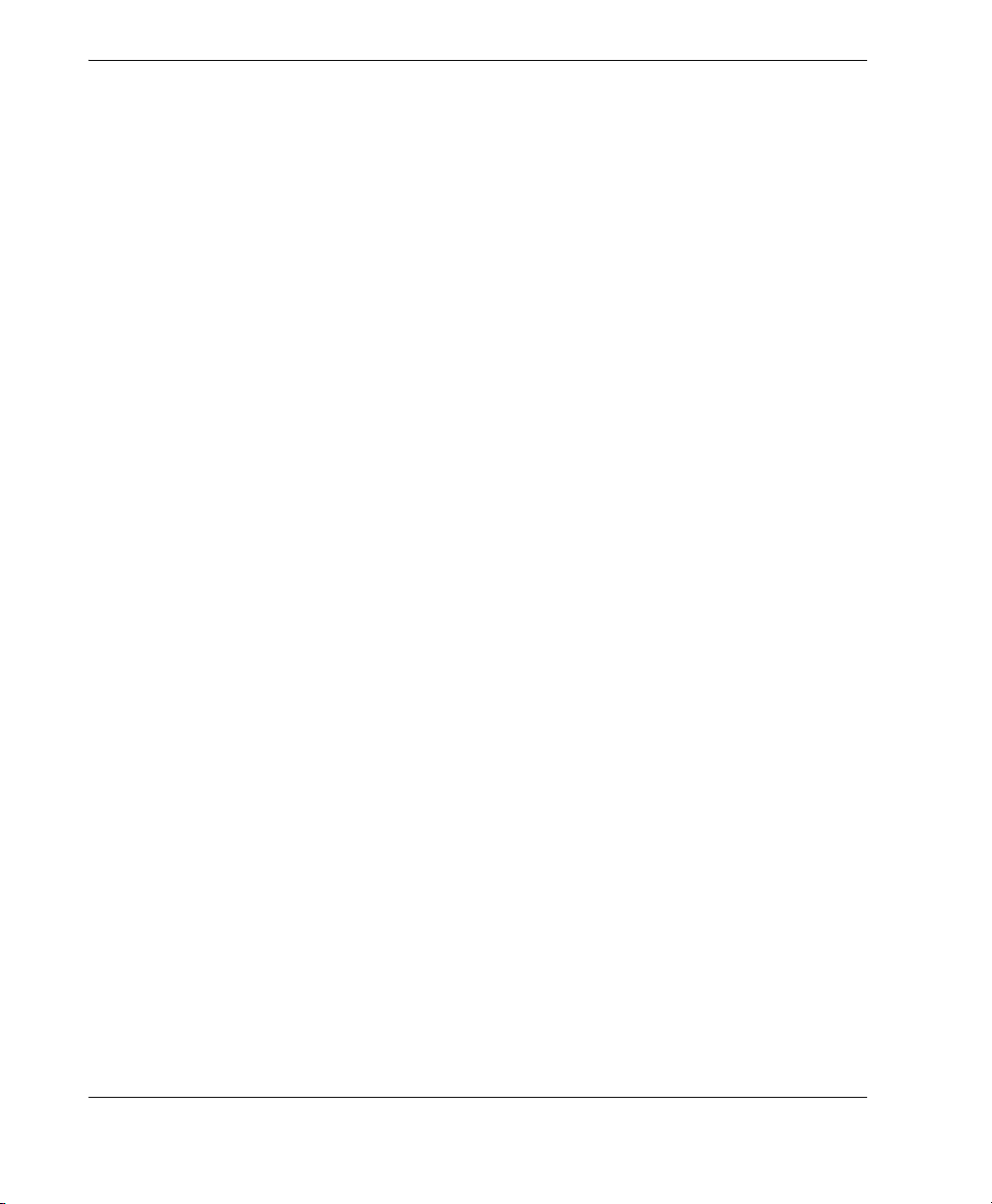

部件名称 铅及其

机构部件

主体 光学部件

电气部件

产品中有害物质的名称及含量

有害物质

汞及其

化合物

(Pb) (Hg) (Cd)

× ○○○○○

× ○○○○○

× ○○○○○

化合物

镉及其

化合物

六价铬及

其化合物

(Cr( Ⅵ ))

多溴联苯 多溴

二苯醚

(PBB) (PBDE)

Important Information — Please Read Before Use 15

Page 26

DMTA-10040-01EN, Rev. E, February 2018

产品中有害物质的名称及含量

有害物质

部件名称 铅及其

化合物

(Pb) (Hg) (Cd)

附件

本表格依据 SJ/T 11364 的规定编制。

○:表示该有害物质在该部件所有均质材料中的含量均在 GB/T26572 规定的限量要求以下。

×:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T26572 规定的限量要求。

× ○○○○○

汞及其

化合物

镉及其

化合物

六价铬及

其化合物

(Cr( Ⅵ ))

多溴联苯 多溴

(PBB) (PBDE)

Korea Communications Commission (KCC)

이 기기는 업무용 환경에서 사용할 목적으로 적합성평가를 받은 기기로서 가정용 환

경에서 사용하는 경우 전파간섭의 우려가 있습니다 .

EMC Directive Compliance

This equipment generates and uses radio-frequency energy and, if not installed and

used properly (that is, in strict accordance with the manufacturer’s instructions), may

cause interference. The NORTEC 600 has been tested and found to comply with the

limits for an industrial device in accordance with the specifications of the EMC

directive.

二苯醚

FCC (USA) Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that

may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Important Information — Please Read Before Use16

Page 27

DMTA-10040-01EN, Rev. E, February 2018

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy, and if not installed and used in accordance with the

instruction manual, might cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case you will be required to correct the interference at your own

expense.

ICES-001 (Canada) Compliance

This Class A digital apparatus complies with Canadian ICES-001.

Cet appareil numérique de la classe A est conforme à la norme NMB-001 du Canada.

Warranty Information

Olympus guarantees your Olympus product to be free from defects in materials and

workmanship for a specific period, and in accordance with conditions specified in the

Olympus Scientific Solutions Americas Inc. Terms and Conditions available at

http://www.olympus-ims.com/en/terms/.

The Olympus warranty only covers equipment that has been used in a proper

manner, as described in this instruction manual, and that has not been subjected to

excessive abuse, attempted unauthorized repair, or modification.

Inspect materials thoroughly on receipt for evidence of external or internal damage

that might have occurred during shipment. Immediately notify the carrier making the

delivery of any damage, because the carrier is normally liable for damage during

shipment. Retain packing materials, waybills, and other shipping documentation

needed in order to file a damage claim. After notifying the carrier, contact Olympus

for assistance with the damage claim and equipment replacement, if necessary.

This instruction manual explains the proper operation of your Olympus product. The

information contained herein is intended solely as a teaching aid, and shall not be

used in any particular application without independent testing and/or verification by

the operator or the supervisor. Such independent verification of procedures becomes

increasingly important as the criticality of the application increases. For this reason,

Important Information — Please Read Before Use 17

Page 28

DMTA-10040-01EN, Rev. E, February 2018

Olympus makes no warranty, expressed or implied, that the techniques, examples, or

procedures described herein are consistent with industry standards, nor that they

meet the requirements of any particular application.

Olympus reserves the right to modify any product without incurring the

responsibility for modifying previously manufactured products.

Technical Support

Olympus is firmly committed to providing the highest level of customer service and

product support. If you experience any difficulties when using our product, or if it

fails to operate as described in the documentation, first consult the user’s manual, and

then, if you are still in need of assistance, contact our After-Sales Service. To locate the

nearest service center, visit the Service Centers page at: http://www.olympusims.com.

Important Information — Please Read Before Use18

Page 29

DMTA-10040-01EN, Rev. E, February 2018

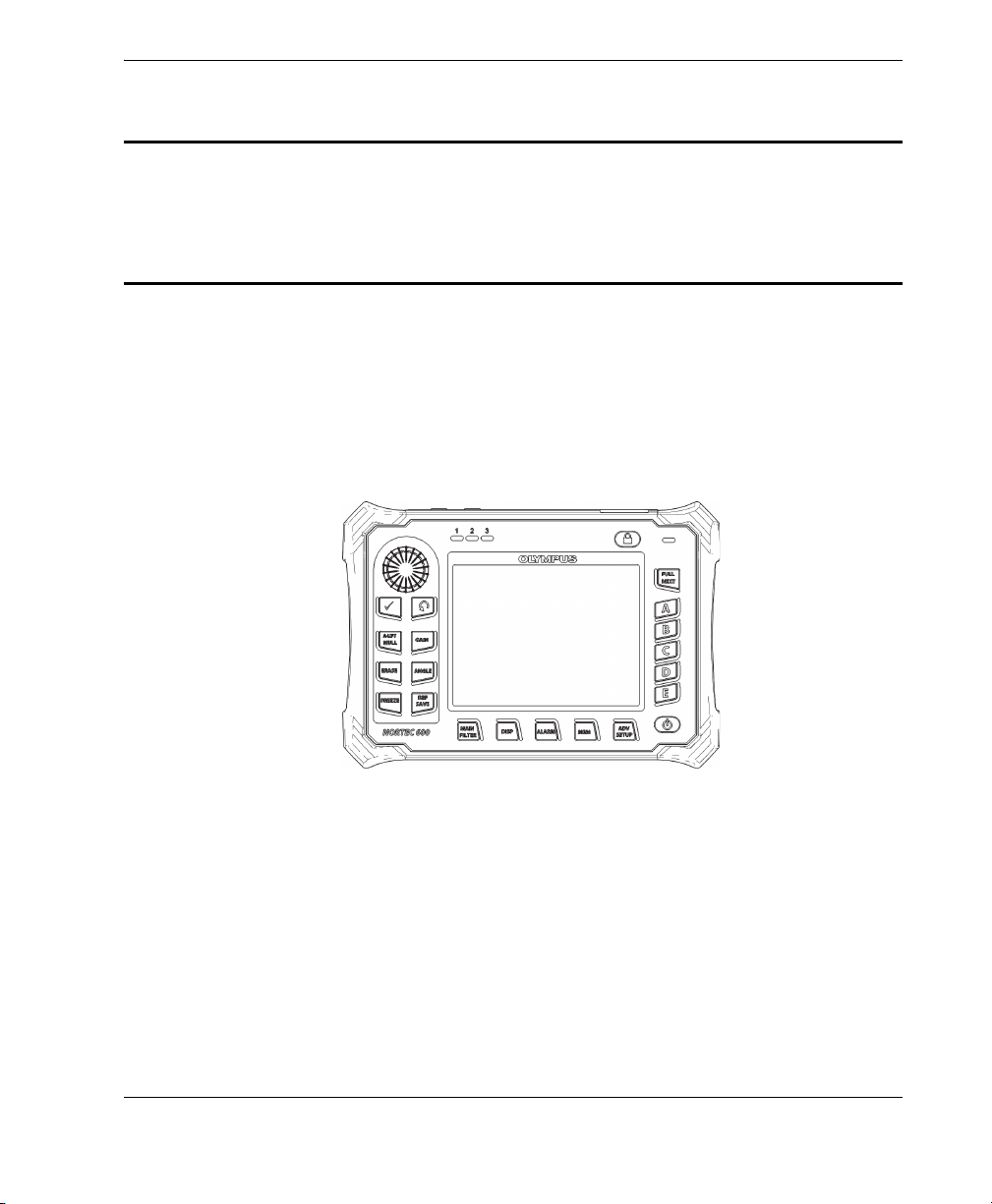

Introduction

This user’s manual provides operating instructions for the Olympus NORTEC 600

instrument, which uses eddy currents to detect surface flaws in various types of

metals (see Figure i-3 on page 19). The information in this manual is organized to

explain the technology, safety details, hardware, and software. Practical inspection

examples help the user become familiar with the instrument’s capabilities.

Figure i‑3 The NORTEC 600 instrument

Introduction 19

Page 30

DMTA-10040-01EN, Rev. E, February 2018

Introduction20

Page 31

DMTA-10040-01EN, Rev. E, February 2018

1. Instrument Overview

This chapter provides a brief overview of the Olympus NORTEC 600 eddy current

flaw detector, and includes the principle of operation, accessories, and all common

operational requirements.

1.1 Operating Principle

The NORTEC 600 is a small, lightweight flaw detector designed to make fast,

accurate, and repeatable measurements on conductive materials such as aluminum,

copper, stainless steel, steel, and titanium.

The NORTEC 600 uses electromagnetic induction to detect flaws in conductive

materials. Electromagnetic induction is achieved with a coil that carries a current and

that is placed in proximity to the test material. The alternating current in the coil

generates a changing magnetic field that interacts with the test material and causes

eddy currents. Variations in the phase and magnitude of these eddy currents are

monitored. Variations in the electrical conductivity or magnetic permeability of the

test object, or the presence of any flaws, will cause a change in eddy current and a

corresponding change in the phase and amplitude of the measured current.

Eddy current testing can detect very small cracks in or near the surface of non-ferrous

material, and it is also useful for making electrical conductivity and coating thickness

measurements. The surfaces being tested need minimal preparation.

Instrument Overview 21

Page 32

DMTA-10040-01EN, Rev. E, February 2018

1.2 Contents of the Case

The NORTEC 600 comes with several key accessories (see Figure 1-1 on page 23):

• ISO-15548 certificate or calibration certificate (short form of the ISO-15548)

(Olympus P/N: 7922035 [U8030145]).

• Charger/adaptor (Olympus P/N: EP-MCA-X), where “X” denotes the AC power

cord type (see Table 14 on page 343).

• AC power cord

• Getting Started leaflet (Olympus P/N: DMTA-10039-01YY), where “YY” denotes

the language (see Table 17 on page 344 for order numbers).

•NORTEC600 User’s Manual and PC interface program on CD-ROM (Olympus

P/N: N600-CD [U8030151])

• Instrument transport case (P/N: 600-TC [U8780294])

• Universal PowerLink eddy current probe cable (Olympus P/N: 9122083

[U8800073]). Although in some countries this item may be included, for most

countries it is optional and must be purchased separately. Please contact your

Olympus representative for more details.

• microSD memory card 2 GB (1 internal, 1 external) (Olympus P/N: MICROSDADP-2GB [U8779307])

• USB 2.0 (mini-AB) to PC cable (Olympus P/N: EPLTC-C-USB-A-6 [U8840031])

• 73 watt-hour battery for 600 Series products; 10.8 V, 6.8 Ah, 73 Wh (Olympus

P/N: 600-BAT-L-2 [U8760058])

• AA battery holder (tray) for emergency use (Olympus P/N: 600-BAT-AA

[U8780295])

• Factory-installed hand strap on left side of NORTEC 600 instrument

(Olympus P/N: 38DLP-HS [U8779371])

Chapter 122

Page 33

DMTA-10040-01EN, Rev. E, February 2018

Charger/adaptor

AC power cord and

probe cable

Getting Started leaflet and calibration

certificate

NORTEC 600 unit

Transport case (may

differ from your model,

depending on image

available at time of

publication)

User’s manual and PC interface program

on CD-ROM

Li-ion battery

microSD memory card

and USB to PC cable

A list of optional accessories available from Olympus can be found in “Accessories,

Replacement Parts, and Upgrades” on page 341.

1.3 Connectors

Figure 1-2 on page 24 illustrates the connections of the NORTEC 600 instrument with

the charger/adaptor, the microSD card, and a PC.

Figure 1‑1 Transport case contents

Instrument Overview 23

Page 34

DMTA-10040-01EN, Rev. E, February 2018

To po we r

outlet

DC power plug

EP-MCA-X

charger/adaptor

AC power cord

USB to PC

microSD card

WARNING

DC power connector

PROBE connector

(16-pin LEMO)

BNC connector

Figure 1‑2 The NORTEC 600 connections

Use only the AC power cord supplied with your instrument, unless specifically

instructed in the manual. Using an unauthorized power cord may result in damage to

instruments or serious injury to the user.

The DC power, PROBE, and BNC connectors are located on the top end of the

NORTEC 600 (see Figure 1-3 on page 24).

Figure 1‑3 The top end connectors

Chapter 124

Page 35

DMTA-10040-01EN, Rev. E, February 2018

CAUTION

USB port

microSD card slot

I/O door

Removable

microSD card

Do not allow metallic or foreign objects to enter the device through connectors or any

other openings. Otherwise, an electric shock or malfunction may result.

The USB port and the removable microSD memory card slot are located on the righthand side of the instrument, hidden behind the input/output (I/O) door (see

Figure 1-4 on page 25).

Figure 1‑4 The connectors behind the input/output (I/O) door

The I/O and the VGA OUT connectors are located at the back of the instrument, in the

upper section (see Figure 1-5 on page 26). A rubber cover protects each connector.

Instrument Overview 25

Page 36

DMTA-10040-01EN, Rev. E, February 2018

VGA OUT connector

I/O connector

Figure 1‑5 The VGA OUT and I/O connectors

1.4 Power Requirements

The NORTEC 600 is designed to operate using three power supply methods:

• Directly from the NORTEC 600 charger/adaptor

• Internal lithium-ion battery

• Internal alkaline battery holder

Press the power button ( ) to turn on the NORTEC 600 (see Figure 1-6 on page 27).

Pressing this button once causes an initial beep, which is followed by the instrument

startup screen, and then a second beep approximately five seconds later.

Chapter 126

Page 37

DMTA-10040-01EN, Rev. E, February 2018

Charger/adaptor

indicator light

Power button

WARNING

Figure 1‑6 Location of the NORTEC 600 power button and indicator light

1.4.1 Charger/Adaptor

A NORTEC 600 charger/adaptor is provided with every instrument. This

charger/adaptor is the primary method for powering the NORTEC 600, with or

without a battery installed. It is also used to charge the lithium-ion rechargeable

battery when it is installed in the instrument. A charger/adaptor indicator light on the

front panel of the unit displays the current status of the charger/adaptor (see

Figure 1-6 on page 27 and Figure 1-7 on page 27).

Figure 1‑7 The charger/adaptor indicator light on the front panel

Use only the power cord supplied with your instrument, unless specifically instructed

in the manual. Using an unauthorized power cord may result in damage to

instruments or serious injury to the user.

Instrument Overview 27

Page 38

DMTA-10040-01EN, Rev. E, February 2018

WARNING

To power outlet

DC power connector

EP-MCA-X

charger/adaptor

AC power cord

The NORTEC 600 charger/adaptor (P/N: EP-MCA-X) is designed to power the

NORTEC 600 and charge the lithium-ion battery only (P/N: 600-BAT-L-2 [U8760058]).

Do not attempt to charge any other types of batteries, including alkaline batteries in

the battery holder (P/N: 600-BAT-AA [U8780295]), and do not attempt to use any

other charger/adaptor. Doing so might cause an explosion or injury.

Do not attempt to power or charge other electronic equipment with the

charger/adaptor (P/N: EP-MCA-X), unless specifically instructed in the manual.

Misuse of the charger/adaptor can cause other batteries and/or instruments to

explode, which could lead to serious injury or death.

To connect the charger/adaptor

1. Connect the AC power cord to the charger/adaptor and to an appropriate power

outlet (see Figure 1-8 on page 28).

Chapter 128

Figure 1‑8 Connecting the charger/adaptor

Page 39

DMTA-10040-01EN, Rev. E, February 2018

DC power cable from the

charger/adaptor

DC power connector

(rubber seal not shown)

2. Lift the rubber seal that covers the DC connector on top of the NORTEC 600.

3. Connect the DC output power cable from the charger/adaptor to the DC power

connector on top of the NORTEC 600 (see Figure 1-9 on page 29).

Figure 1‑9 Connecting the DC power cable

Table 3 on page 29 explains the indicators for the power status of the charger/adaptor

and the battery charge condition, which are visible at the top of the front panel and in

the user interface.

Table 3 Charger/adaptor and battery indicators

Charger/adaptor

indicator light

Red Yes Internal battery is charging.

Off No Charger/adaptor is not connected.

AC line power

connected

Indicator meaning

Battery

indicator

Instrument Overview 29

Page 40

DMTA-10040-01EN, Rev. E, February 2018

Membrane vent

hole

Thumb screws (two)

Battery compartment

cover

Table 3 Charger/adaptor and battery indicators (continued)

Charger/adaptor

indicator light

Green Yes

AC line power

connected

Indicator meaning

Charger/adaptor is connected, but

no battery is installed.

OR

Internal battery is fully charged.

Battery

indicator

1.4.2 Battery Compartment

The NORTEC 600 battery compartment cover allows you to quickly access the battery

(or AA batteries in the alkaline battery holder) without the need for tools. Two thumb

screws on the battery compartment cover secure it to the instrument case and ensure

the compartment is sealed.

The battery compartment cover also has a small hole in the bottom center area that is

covered on the inside by an environmentally sealed membrane vent. This vent is a

safety feature that is required in the event that the instrument battery fails and emits

gas. This vent must not be punctured.

Figure 1‑10 The battery compartment

Chapter 130

Page 41

DMTA-10040-01EN, Rev. E, February 2018

WARNING

IMPORTANT

The NORTEC 600 accepts one rechargeable lithium-ion battery pack (Olympus

P/N: 600-BAT-L-2 [U8760058]) that can be recharged inside the instrument or on the

optional external charging base (Olympus P/N: EPXT-EC-X [U8767043]). You can also

use the NORTEC 600 with eight standard AA-size alkaline batteries installed in an

alkaline battery holder (Olympus P/N: 600-BAT-AA [U8780295]) for extended

portable use.

If the NORTEC 600 is to be used with a rechargeable battery, only use the Olympus

battery, P/N: 600-BAT-L-2 [U8760058]. Using any other type of battery might cause an

explosion and injury.

1.4.3 Lithium-Ion Battery

The NORTEC 600 is normally used as a portable instrument powered by the lithiumion battery and recharged via the charger/adaptor (both are supplied with the

NORTEC 600). When properly maintained, and when the instrument is operated

under typical inspection conditions, the lithium-ion battery should provide between 8

and 10 hours of continuous operation if a rotating scanner is not connected. If an

Olympus rotating scanner is connected, the NORTEC 600 should provide between 6

and 8 hours of continuous operation.

The lithium-ion battery is not fully charged when the instrument is shipped. You

must charge the battery for two to three hours before using battery power to operate

the instrument (see “Charger/Adaptor” on page 27).

To install or replace the lithium-ion battery

1. Unfold the instrument stand (see Figure 1-11 on page 32).

2. At the back of the instrument, loosen the two thumb screws securing the battery

3. Remove the battery compartment cover.

compartment cover.

Instrument Overview 31

Page 42

DMTA-10040-01EN, Rev. E, February 2018

Battery

compartment

cover

Thumb screws

(two)

Battery

Stand

4. Remove the battery and/or install the new battery in the battery compartment.

5. Check the cover gasket to make sure it is clean and in good condition.

6. Install the battery compartment cover at the back of the instrument, and then

tighten the two thumb screws to complete the installation.

Figure 1‑11 Removing the lithium‑ion battery

1.4.4 Alkaline Batteries

The NORTEC 600 includes a battery holder (Olympus P/N: 600-BAT-AA [U8780295]).

This holder accommodates eight AA-size alkaline batteries for situations where an

AC power source is not available and the internal Li-ion battery is discharged. When

operated under typical inspection conditions, the alkaline batteries typically provide

three hours of continuous operation.

To install the alkaline battery holder

1. Unfold the instrument stand (see Figure 1-12 on page 33).

2. Loosen the two thumb screws securing the battery compartment cover at the back

of the instrument, and then remove the battery compartment cover.

3. Remove the lithium-ion battery, if installed.

4. Install eight AA-size alkaline batteries into the alkaline battery holder.

5. Connect the alkaline battery holder connector to the instrument.

Chapter 132

Page 43

DMTA-10040-01EN, Rev. E, February 2018

Battery holder

with alkaline

batteries (eight)

Battery holder

connector

Battery compartment cover

Thumb screws

(two)

Stand

NOTE

6. Position the alkaline battery holder in the battery compartment.

Figure 1‑12 The alkaline battery holder

7. Install the battery compartment cover at the back of the instrument, and then

tighten the two thumb screws.

When alkaline batteries are installed in the instrument, the battery indicator in the

user interface displays ALK. The charger/adaptor does not recharge the batteries

installed in the alkaline battery holder.

1.5 Optional microSD Card Installation

A 2 GB microSD card (Olympus P/N: MICROSD-ADP-2GB [U8779307]) can be

installed in the NORTEC 600 instrument.

To install the microSD removable memory card

1. Remove the card from its packaging.

Instrument Overview 33

Page 44

DMTA-10040-01EN, Rev. E, February 2018

USB port

Thumb screws (two)

microSD card slot

microSD card

NOTE

2. Loosen the two thumb screws, and then open the NORTEC 600 I/O door (see

Figure 1-13 on page 34).

Figure 1‑13 Installing the microSD card

3. Hold the card so that the microSD label faces toward the rear of the instrument.

4. Gently slide the card into the microSD slot until it clicks.

To remove the microSD card, gently push the card into the instrument and release. A

spring-loaded mechanism will partially eject the card, and then you can grasp the

card and remove it from the instrument.

1.6 NORTEC 600 Hardware Features

The NORTEC 600 instrument has many physical features that are either completely

new or improvements of features on older NORTEC 500 models. It is important to

become familiar with the use and maintenance of these items.

Chapter 134

Page 45

DMTA-10040-01EN, Rev. E, February 2018

Protective rubber bumpers

D-rings to attach the

optional chest harness

(at the four corners)

Display window

(screen)

Keypad

Knob (SmartKnob)

1.6.1 Hardware Overview

Figure 1-14 on page 35 and Figure 1-15 on page 36 show the main components on the

NORTEC 600 instrument.

Figure 1‑14 Overview of the NORTEC 600 hardware — Front view

Instrument Overview 35

Page 46

DMTA-10040-01EN, Rev. E, February 2018

DC power connector

VGA OUT connector

Stand

Battery compartment

cover

BNC connector

PROBE connector

Membrane vent

I/O door

I/O connector

Figure 1‑15 Overview of the NORTEC 600 hardware — Back view

1.6.1.1 Front Panel and SmartKnob

The SmartKnob is an important feature of the NORTEC 600 instrument, and it is the

primary method used to change different parameters within a menu. In this manual,

the term “knob” is also used to refer to the SmartKnob.

The NORTEC 600 front panel features direct-function keys that are used in

combination with the SmartKnob to provide direct access to menus and common

parameters, and to enable easy adjustment of values (see Figure 1-16 on page 37).

Chapter 136

Page 47

DMTA-10040-01EN, Rev. E, February 2018

Direct-function

keys

Function keys

Charger/adaptor

indicator

Power button

Display window (screen)

SmartKnob

Menu keys

FULL NEXT key

Figure 1‑16 The NORTEC 600 front panel with SmartKnob and keypad

1.6.1.2 Keypad

The NORTEC 600 is available with an English, Chinese, Japanese, or international

keypad configuration (see Figure 1-17 on page 38 to Figure 1-20 on page 39, and

Table 4 on page 40). The text labels on some keys may be replaced by pictograms,

depending on the keypad configuration. In this document, keys are referred to using

the English label, which indicates its function. The keys are used to select menu items

or screen parameters and to change parameter values.

Instrument Overview 37

Page 48

DMTA-10040-01EN, Rev. E, February 2018

Figure 1‑17 The NORTEC 600 English keypad

Figure 1‑18 The NORTEC 600 Chinese keypad

Chapter 138

Page 49

DMTA-10040-01EN, Rev. E, February 2018

Figure 1‑19 The NORTEC 600 Japanese keypad

Figure 1‑20 The NORTEC 600 international keypad

Instrument Overview 39

Page 50

DMTA-10040-01EN, Rev. E, February 2018

Table 4 Keypad functions

Function

name

International

keypad

symbol

Function description

Enter The Enter key is used to make selections.

Return The Return (or Back) key is used to exit a

menu and return to a previous screen.

A-LIFT NULL If this direct-function key is pressed once, it

nulls (zeros) the instrument. If this key is

pressed and held, the Auto Liftoff is set.

GAIN Direct-function key used to display either

the instrument’s combined horizontal and

vertical gain settings, horizontal gain only,

or vertical gain only.

ERASE Direct-function key used to erase the

currently displayed image.

ANGLE Direct-function key used to display the

angle.

FREEZE Direct-function key used to freeze the

image displayed on the instrument for

further evaluation. When the image is

frozen, the NORTEC 600 also allows

calibrating the eddy current signals, and

changing the gains or angle.

REF SAVE Direct-function key used to save images

and settings in the instrument’s memory.

When this key is pressed once (and

released), the currently displayed image

and settings are saved. When this key is

pressed and held, the current instrument

image is set as the reference memory

display.

Chapter 140

Page 51

DMTA-10040-01EN, Rev. E, February 2018

Table 4 Keypad functions (continued)

Function

name

International

keypad

symbol

Function description

MAIN FILTER Provides access to the main menu, which

controls functions such as frequency, gain,

angle, and filters.

DISP Provides access to the display menu, which

controls functions such as display mode,

position, trace, and grid.

ALARM Provides access to the alarm menu, which

controls functions such as alarm type,

dwell time, horn volume, and alarm

position.

MEM Provides access to the memory menu,

which controls functions such as

previewing stored memory files, recalling

and editing stored files, capture mode,

capture time, and user information.

ADV SETUP Provides access to the instrument’s

advanced settings, including the

application selection menu, the ALL

SETTINGS menu, frequency mode, colors,

password, systems setup, reset, unlock

options, and legal/regulatory information.

FULL NEXT Used to expand the instrument display to

full screen, or to select items in the menu.

A A Function key

B B Function key

C C Function key

D D Function key

E E Function key

Instrument Overview 41

Page 52

DMTA-10040-01EN, Rev. E, February 2018

BNC connector

PROBE connector

CAUTION

1.6.2 Connectors

The NORTEC 600 instrument contains several types of connectors for hardware

components.

1.6.2.1 Probe and BNC Connectors

The NORTEC 600 instrument is supplied with a 16-pin LEMO (PROBE) connector

and a BNC connector.

The PROBE (LEMO) and BNC connectors are located at the top of the instrument, on

the left-hand side. The two connectors are easily accessible from the front of the

instrument (see Figure 1-21 on page 42).

Figure 1‑21 Location of the PROBE (LEMO) and BNC connectors

Do not allow metallic or foreign objects to enter the device through connectors or any

other openings. Otherwise, an electric shock or malfunction may result.

1.6.2.2 Input/Output (I/O) and VGA OUT Connectors

The I/O and the VGA OUT connectors are located at the back of the instrument, in the

upper section (see Figure 1-22 on page 43). A rubber cover protects each connector.

Chapter 142

Page 53

DMTA-10040-01EN, Rev. E, February 2018

VGA OUT connector

I/O connector

CAUTION

Figure 1‑22 The VGA OUT and I/O connectors

The VGA OUT connector allows the user to connect the instrument to a standard

analog computer monitor. The I/O connector is used to connect an external horn or, if

necessary, to connect an external control for integrating the NORTEC 600 into a

system. For PC communication details, see “microSD and USB Port” on page 44.

Do not expose the instrument to harsh and wet environments while the I/O or the

VGA OUT connectors are not protected by their rubber covers. To prevent connector

corrosion and damage to the instrument, keep the rubber protective covers on the

connectors when no cable is connected.

Instrument Overview 43

Page 54

DMTA-10040-01EN, Rev. E, February 2018

USB port

Thumb screws (two)

microSD card slot

1.6.2.3 microSD and USB Port

On the right-hand side of the NORTEC 600, a door covers the microSD slot and the

USB port (see Figure 1-23 on page 44). The I/O door closes against an integral

membrane seal to keep liquids away from the unsealed connectors behind the door.

The NORTEC 600 utilizes 2 GB microSD memory cards for both onboard and

removable memory. The onboard 2 GB microSD card is mounted on the PC board

inside the instrument, and is responsible for all onboard data storage. In the event the

instrument is damaged beyond repair, this microSD card can be removed at an

authorized service center, allowing you to recover critical data from the damaged

instrument.

The NORTEC 600 allows the user to connect the instrument to a PC via the USB port.

PC communication requires the interface program (Olympus P/N: N600-CD

[U8030151]) provided with the instrument for file transfers. The NORTEC 600 can

also communicate directly with other SPC programs.

The I/O door is kept closed by two thumb screws. You can also use a coin or a

screwdriver to manipulate these thumb screws as needed.

Chapter 144

Figure 1‑23 The microSD slot and USB port

Page 55

DMTA-10040-01EN, Rev. E, February 2018

CAUTION

Do not expose the instrument to harsh and wet environments while the I/O door is

open. To prevent connector corrosion and damage to the instrument, keep the I/O

door closed and sealed when no cable is connected.

1.6.3 Various Hardware Features

The NORTEC 600 instrument’s physical features make it suitable for a variety of

operating environments.

1.6.3.1 Instrument Stand

The NORTEC 600 features an articulating stand for variable viewing angles (see

Figure 1-24 on page 45). The stand is attached to the back of the instrument with two

hard pivot blocks. There is a high-friction coating on the stand surface to help prevent

it from sliding. The stand is bent in the center to easily accommodate being placed on

a curved surface.

Figure 1‑24 Instrument stand

Instrument Overview 45

Page 56

DMTA-10040-01EN, Rev. E, February 2018

CAUTION

1.6.3.2 O-Ring Gasket and Membrane Seals

The NORTEC 600 contains seals that protect the instrument’s internal hardware from

the environment:

• Battery compartment cover seal

• I/O door seal

• Membrane vent

These seals must be properly maintained to assure environmental durability.

Instrument seals are evaluated and replaced as needed during the instrument annual

calibration. This should be performed at an authorized Olympus service center.

1.6.3.3 Display Protection

The NORTEC 600 includes a clear plastic sheet protecting the instrument display

window. Olympus strongly recommends leaving this protection sheet in place.

Replacements are available in packages of ten sheets (Olympus P/N: 600-DP

[U8780297]).

The display window is permanently bonded to the instrument case to fully seal the

instrument. If the display window becomes damaged, the front part of the case must

be replaced, along with the instrument’s keypad.

1.6.4 Environmental Ratings

The NORTEC 600 is an extremely rugged and durable instrument that can be used in

harsh environments. To classify the instrument’s durability in wet or damp

environments, Olympus has adopted the IP (ingress protection) system to rate how

well the instrument is sealed.

The NORTEC 600 is designed and manufactured to meet the requirements of the IP66

ingress protection rating. To maintain this level of protection, you are responsible for

the proper care of all routinely exposed membrane seals. Additionally, you are

responsible for returning the instrument to an authorized Olympus service center

each year to ensure that the instrument seals are properly maintained. Olympus

Chapter 146

Page 57

DMTA-10040-01EN, Rev. E, February 2018

cannot guarantee any level of ingress protection performance once the instrument

seals have been manipulated. You must use sound judgment and take proper

precautions before exposing the instrument to harsh environments.

The NORTEC 600 adheres to the environmental standards listed in Table 8 on

page 333.

Instrument Overview 47

Page 58

DMTA-10040-01EN, Rev. E, February 2018

Chapter 148

Page 59

DMTA-10040-01EN, Rev. E, February 2018

2. Software User Interface

This chapter explains the main software screens and menus on the NORTEC 600

instrument. The back of the NORTEC 600 contains a quick guide to the instrument

keypad and functions (see Figure 2-1 on page 49).

Figure 2‑1 The instrument label showing keypad functions

2.1 Starting Up the Instrument

When power is turned on, the NORTEC 600 starts up in one of two modes, depending

on what is connected to the instrument.

If no probe is connected, or if a probe that is not a PowerLink type of probe is

connected, the first screen displayed by the NORTEC 600 software is the application

quick-setup menu (see Figure 2-2 on page 50). Choose from among the basic

applications on this menu to automatically configure the appropriate instruments

settings. For more details on the application quick-setup menu, see “Common

NORTEC 600 Applications” on page 120.

Software User Interface 49

Page 60

DMTA-10040-01EN, Rev. E, February 2018

NOTE

Figure 2‑2 Application choices on the quick‑setup menu

The NORTEC 600 applications are designed for quick setup of the instrument.

However, always follow published maintenance procedures when inspecting.

2.1.1 Navigating the Application Menu

Navigating the menu is designed to be intuitive, and the settings for each application

will permit immediate inspection; little or no additional instrument setup is needed.

To navigate the application menu

1. Rotate the knob to highlight one of the eight applications.

2. Press the Enter key ( ) to select the application.

OR

Press the Return key ( ) to go back to the NORTEC 600 main screen.

Alternatively, if a PowerLink probe is connected to the instrument when it is turned

on, the NORTEC 600 starts up in the PowerLink recognition screen (see Figure 2-3 on

page 51).

Chapter 250

Page 61

DMTA-10040-01EN, Rev. E, February 2018

Figure 2‑3 The PowerLink recognition screen

To navigate the application menu for PowerLink

In the PowerLink recognition screen, load the program stored in the PowerLink

probe by pressing the A key.

You can use the KEEP LAST SETTINGS function to load the previous

parameters if they are compatible with the probe or accessory that is detected.

This automatically sets up the instrument.

OR

Bypass the stored program in the probe and gain access to the instrument’s main

inspection screen by pressing the Return key ( ).

2.1.2 Main Inspection Screen

After the initial steps are completed through the quick-setup menu or PowerLink

menu, the main inspection screen is displayed (see Figure 2-4 on page 52).

Software User Interface 51

Page 62

DMTA-10040-01EN, Rev. E, February 2018

Figure 2‑4 The main inspection screen

The battery power indicator remains visible at the top of the screen, except when in

full-screen mode (see Table 3 on page 29 for details). The time and date also remain

visible, except when in full-screen mode.

The rectangular readout in the top-left corner of the screen is called the quick-access

bar (see Figure 2-5 on page 53). It displays either the instrument combined horizontal

and vertical gain settings, horizontal gain only, vertical gain only, or angle setting

when the GAIN ( ) or ANGLE ( ) direct-function keys are pressed. The

quick-access bar remains visible until any other key is pressed.

Chapter 252

Page 63

DMTA-10040-01EN, Rev. E, February 2018

Direct-function

keys

Function keys

Real-time readings bar

Menu keys

Quick-access bar

Operation menu

(instrument settings)

FULL NEXT key

Figure 2‑5 The NORTEC 600 front panel and main inspection screen

The real-time readings bar displays user-configurable readings (measurements) [see

Figure 2-5 on page 53]. It can display a maximum of two real-time readings from

among the available choices. The real-time readings bar can be set to display one or

two readings, or it can be disabled. For more information, see “Displaying Real-Time

Readings” on page 56.

The instrument settings are displayed on the right hand side of the main screen. The

displayed settings information can change, depending on the menu key that is

pressed. The menu keys are the five keys located at the bottom of the front panel:

MAIN FILTER ( ), DISP ( ), ALARM ( ), MEM ( ), and ADV SETUP

( ), as shown in Figure 2-5 on page 53.

The microSD memory card can be inserted into a slot that is located behind the I/O

door on the right-hand side of the instrument (see Figure 1-23 on page 44). Depending

on the context and on the available functions and options, various indicators and

numeric values appear on the screen and around the main measurement value (see

Figure 2-5 on page 53).

Software User Interface 53

Page 64

DMTA-10040-01EN, Rev. E, February 2018

2.2 Selecting from the Menus

The NORTEC 600 menu keys at the bottom of the front panel are MAIN FILTER

( ), DISP ( ), ALARM ( ), MEM ( ), and ADV SETUP ( ). These

keys provide access to the operation menu. This menu appears at the right-hand side

of the screen (see Figure 2-5 on page 53). If applicable, pressing a menu key again will

display a secondary menu with parameters available for that key.

To select from a menu

1. Press one of the menu keys located at the bottom of the front panel to display a

menu: MAIN FILTER ( ), DISP ( ), ALARM ( ), MEM ( ), or

ADV SETUP ( ).

Pressing the same menu key again will cycle through the available options and

update the available functions which can then be adjusted.