Page 1

INSTRUCTIONS

MAINTENANCE UNIT

MU-1

USA: CAUTION: Federal law restricts this device to sale by or on the order of a physician.

Page 2

Page 3

Contents

Contents

Labels and Symbols..................................................................... 1

Important Information — Please Read Before Use.................... 3

Intended Use ............................................................................................ 3

Instruction Manual .................................................................................... 3

User Qualifications ................................................................................... 3

Instrument Compatibility............................................................................ 4

Repair and Modification ........................................................................... 4

Signal Words ............................................................................................ 4

Dangers, Warnings and Cautions ............................................................. 5

Chapter 1 Checking the Package Contents............................ 6

1.1 Checking the Package Contents..................................................... 6

Chapter 2 Instrument Nomenclature....................................... 7

2.1 Instrument Nomenclature................................................................ 7

Chapter 3 Preparation and Inspection .................................... 9

3.1 Preparation of the Equipment ......................................................... 9

3.2 Preparation and Inspection of the Maintenance Unit ...................... 11

3.3 Preparation and Inspection of the Endoscope and Disinfectant Container

15

Chapter 4 Operation ................................................................. 17

4.1 Leakage Testing ............................................................................. 17

4.2 Remove water from the Air/Water Channel (For endoscope with Air/Water

channel only) ............................................. 18

Chapter 5 Care, Storage and Disposal.................................... 20

5.1 Care ................................................................................................ 20

5.2 Storage ........................................................................................... 21

5.3 Disposal .......................................................................................... 21

Chapter 6 Troubleshooting ...................................................... 22

6.1 Troubleshooting Guide.................................................................... 22

6.2 Returning the Maintenance Unit for Repair..................................... 23

Appendix ....................................................................................... 24

System Chart ........................................................................................... 24

Transportation, Storage and Operating Environments.............................. 26

MAINTENANCE UNIT MU-1

i

Page 4

Contents

Specifications ........................................................................................... 26

ii

MAINTENANCE UNIT MU-1

Page 5

Labels and Symbols

Electrical Rating Plate

Product name,rated voltage,

and serial number are

described.

1.2 A

1.2 A

Electrical Rating Plate

Safety-related labels are attached to the instrument at the locations shown

below. If labels are missing or illegible, contact Olympus.

Rear side

Labels and Symbols

MAINTENANCE UNIT MU-1

1

Page 6

Labels and Symbols

Back cover of this instruction manual

Manufacturer

Authorized representative in the European Community

2

MAINTENANCE UNIT MU-1

Page 7

Important Information — Please Read Before Use

Important Information — Please Read

Before Use

Intended Use

This instrument has been designed to be used with an Olympus endoscope and

other ancillary equipment for Leakage Testing and Remove water from the

Air/Water Channel.

When combined with the optional MB-264 Disinfectant Container, the

endoscope’s Air/Water Channel can be irrigated with 70% ethyl or isopropyl

alcohol to dry the channel.

Do not use this instrument for any purpose other than its intended use.

Instruction Manual

This instruction manual contains essential information on using this instrument

safely and effectively. Before use, thoroughly review this manual and the

manuals of all equipment which will be used during the procedure and use the

instruments as instructed.

Keep this and all related instruction manuals in a safe, accessible location.

If you have any questions or comments about any information in this manual,

please contact Olympus.

Terms Used in This Manual

Wall Mains Outlet

An electrical outlet that has a terminal used exclusively for grounding.

User Qualifications

The operator of this instrument must be a physician or medical personnel under

the supervision of a physician and must have received sufficient training in

clinical endoscopic technique. This manual, therefore, does not explain or

discuss clinical endoscopic procedures.

MAINTENANCE UNIT MU-1

3

Page 8

Important Information — Please Read Before Use

Instrument Compatibility

Refer to the “System Chart” in Appendix to confirm that this instrument is

compatible with the ancillary equipment being used. Using incompatible

equipment can result in patient or equipment damage.

Repair and Modification

This instrument does not contains any user-serviceable parts. Do not

disassemble, modify or attempt to repair it; patient or user injury and/or

equipment damage can result. If the problems appears minor, refer to Chapter 6,

“Troubleshooting”.

If the problem cannot be resolved by using Chapter 6, contact Olympus.

Signal Words

The following signal words are used throughout this manual:

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices or potential

equipment damage.

Indicates additional helpful information.

4

MAINTENANCE UNIT MU-1

Page 9

Important Information — Please Read Before Use

Dangers, Warnings and Cautions

Follow the dangers, warnings and cautions described below when handling this

instrument. This information is supplemented by the dangers, warnings and

cautions described in each chapter.

• Follow the following precautions strictly. Failure to do so may

place the patient and medical personnel in danger of an

electrical shock.

Keep liquids away from all electrical equipment. If spilled

fluids enter the unit, stop operation of the equipment at

once and contact Olympus.

Do not prepare, inspect or use this instrument with wet

hands.

• Never use the Maintenance Unit in a flammable or

high-concentration oxygen environment and keep all

flammable gases and liquids or high-concentration oxygen

away from the Maintenance Unit while it is being used.

Explosion or fire may result because the instrument is not

designed to be explosion-proof.

• Be sure to connect the Power Plug of the Power Cord directly

to a grounded Wall Mains Outlet. If the Maintenance Unit is

not grounded properly, it can cause an electric shock or/and

fire.

Do not bend, pull or twist the Power Cord. Electrical shock,

equipment damage or fire can result.

• Alcohol is flammable. Handle with care.

• Do not connect the power cord of the MU-1 to a different

voltage electrical outlet. Fire and smoke may result.

MAINTENANCE UNIT MU-1

5

Page 10

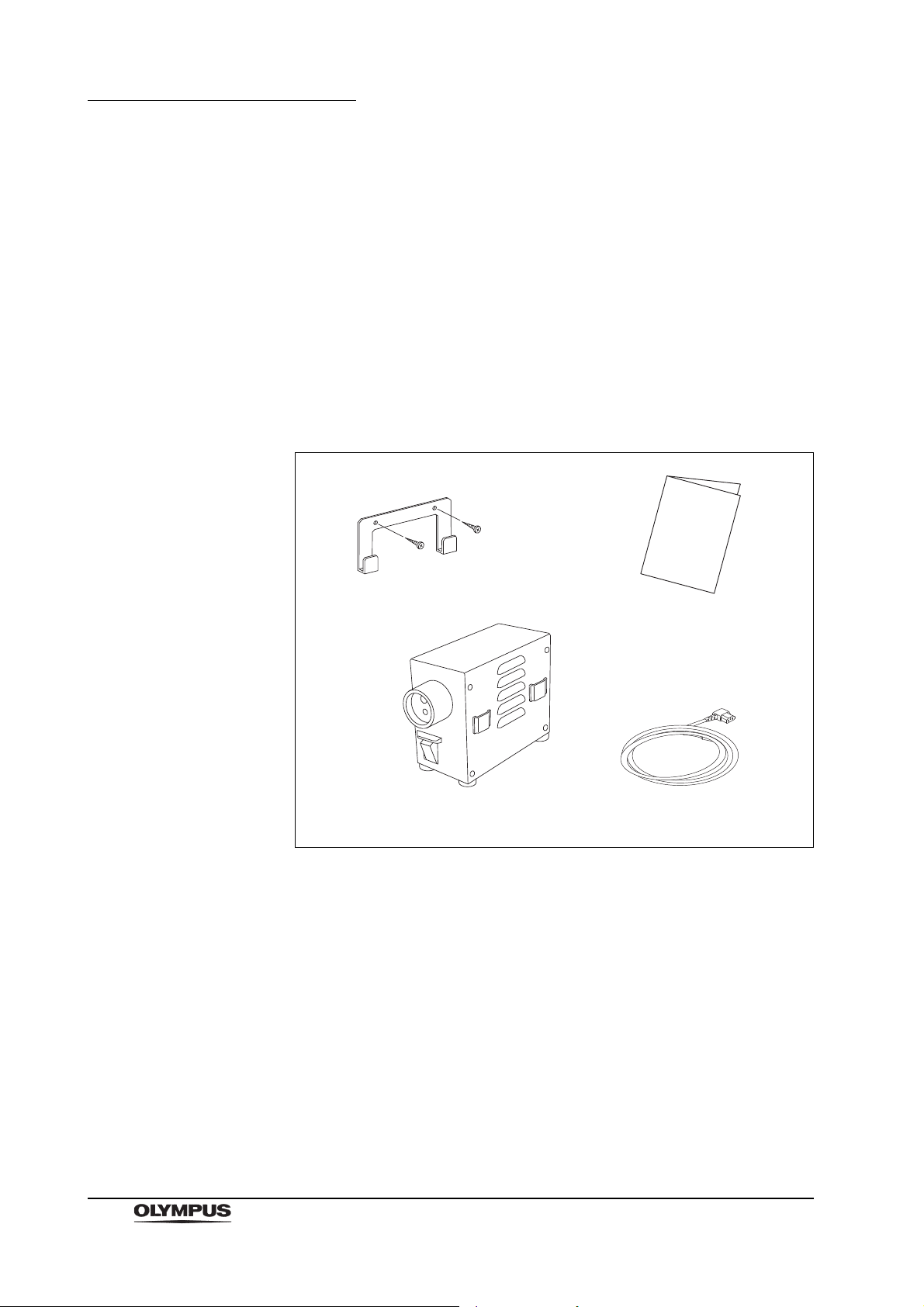

Chapter 1 Checking the Package Contents

Screw

Hook

Maintenance Unit (MU-1) Power Cord

Instruction Manual

Chapter 1 Checking the Package

Contents

1.1 Checking the Package Contents

Match all items in the package with the components shown below. Inspect each

item for damage. If the instrument is damaged, a component is missing or you

have any questions, do not use the instrument; immediately contact Olympus.

6

MAINTENANCE UNIT MU-1

Page 11

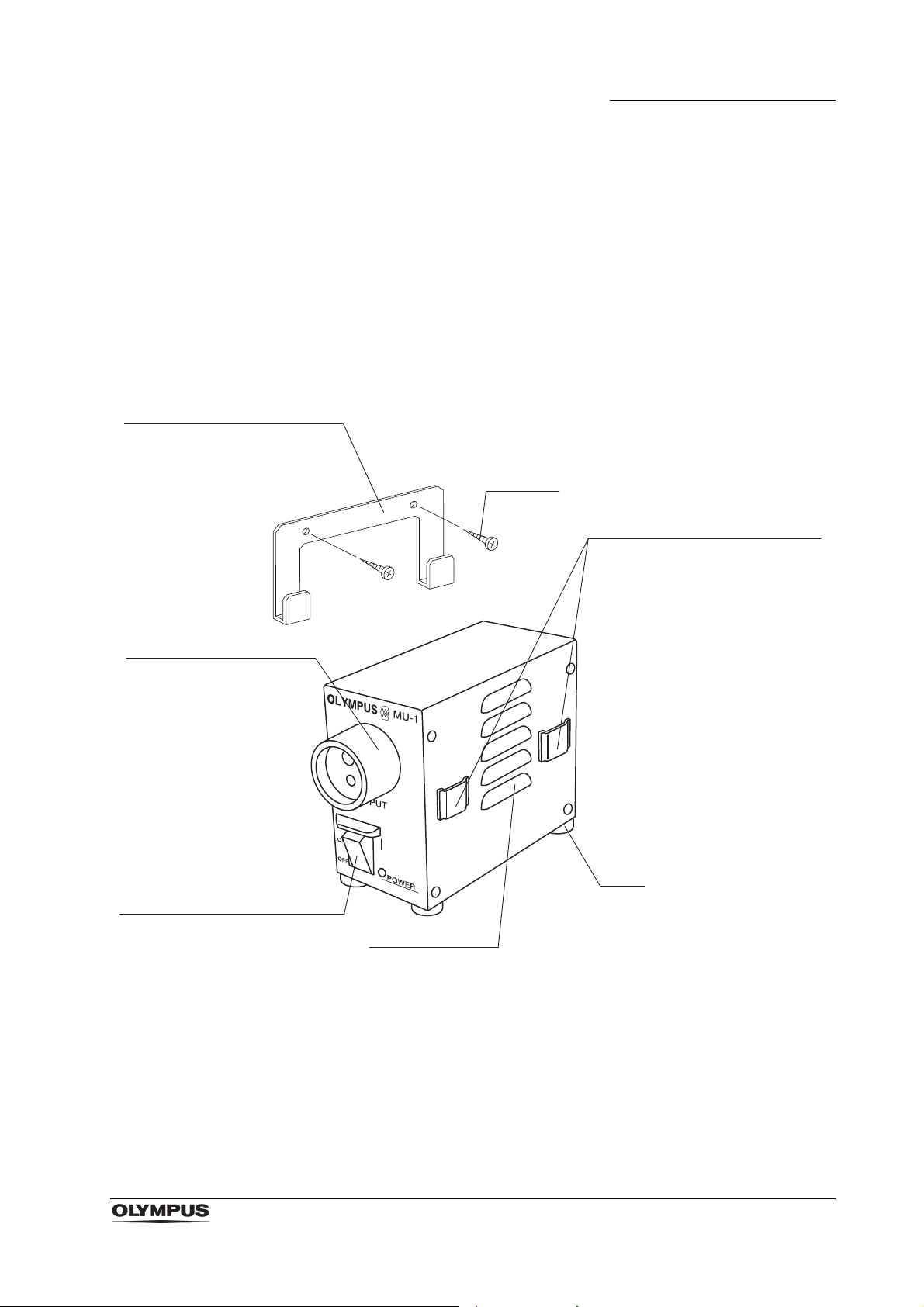

Chapter 2 Instrument Nomenclature

Hook

Used to attach the Maintenance

Unit to a wall. Use the screws to

attach the Hook to a wall near a

sink.

Output Socket

Accepts the endoscope or

leakage tester and feeds air.

Screw ×2

Power Switch

Switches the power ON and OFF.

The power switch lamp will

illuminate and the unit emits air

from the air pipe in the output

socket when the power is on.

Ventilation Grills

Feet

Attaches the Maintenance Unit to

the hooks or attaches the MB-264

Alcohol Container to the

Maintenance Unit. Brackets are

provided on both sides of the unit.

Attachment Brackets

(provided on both sides)

Chapter 2 Instrument Nomenclature

2.1 Instrument Nomenclature

Front Panel and Side Panel

MAINTENANCE UNIT MU-1

7

Page 12

Chapter 2 Instrument Nomenclature

Power Cord Receptacle

Circuit Breakers

Protects the Maintenance Unit

and other equipment from

electrical surges.

Rear Panel

Symbols and Descriptions

Power Switch

ON

OFF

8

MAINTENANCE UNIT MU-1

Page 13

Chapter 3 Preparation and Inspection

Chapter 3 Preparation and Inspection

Before each case, prepare and inspect this instrument as

instructed below. Inspect other equipment that are used with

this instrument as instructed in their respective instruction

manuals. Should the slightest irregularity be suspected, do

not use the instrument and see Chapter 6, “Troubleshooting”.

If the irregularity is still suspected after consulting Chapter 6,

contact Olympus.

Damage or irregularity may compromise patient or user

safety and may result in more-severe equipment damage.

Do not connect the power cord of the MU-1 to a different

voltage electrical outlet. Fire and smoke may result.

According to the “System Chart” in the Appendix, prepare this instrument, other

equipment that are used with this instrument, paper towels, basin, gauze and

protective equipment, such as eye wear, a face mask, moisture-resistant clothing

and chemical-resistant gloves, for the procedure.

Refer to the respective instruction manual for each piece of equipment.

3.1 Preparation of the Equipment

Use 70% ethyl or isopropyl alcohol as directed on the

container’s label. Store 70% ethyl or isopropyl alcohol in an

air-tight container. 70% ethyl or isopropyl alcohol stored in an

open container may cause fires and will lose its efficacy due

to evaporation.

Use basins which are at least 40 cm by 40 cm (16” by 16”) in

size and deep enough to allow the endoscope to be

completely immersed. Do not coil the endoscope’s insertion

tube or universal cord with a diameter less than 40 cm.

The endoscope can be damaged if coiled too tightly.

MAINTENANCE UNIT MU-1

9

Page 14

Chapter 3 Preparation and Inspection

Prepare the following equipment:

Leakage Testing

• Personal Protective Equipment

• Water Container

• Maintenance Unit (MU-1)

• Endoscope

• Leakage Tester (MB-155 Optional)

• Water-resistant Cap

(provided with the endoscope,

EVIS Videoscope only)

Remove water from the Air/Water Channel (For endoscope

with Air/Water channel only)

• Personal Protective Equipment

• Maintenance Unit (MU-1)

• Endoscope

• AW Channel Cleaning Adapter

(provided with the endoscope)

• Alcohol Container

(only when irrigating with 70% ethyl

or isopropyl alcohol)

• 70% ethyl or isopropyl alcohol

(only when irrigating with 70% ethyl

or isopropyl alcohol)

(MB-264 Optional)

10

MAINTENANCE UNIT MU-1

Page 15

Chapter 3 Preparation and Inspection

3.2 Preparation and Inspection of the Maintenance Unit

Confirm that the Wall Mains Outlet that you connect the

Maintenance Unit to has more capacity than the total power

consumption of all connected equipment (including this

Maintenance Unit). If the capacity is inadequate, fire can

result or the Circuit Breaker may trip and turn OFF the

Maintenance Unit and all other instruments connected to the

same breaker.

• Do not place the Maintenance Unit on its side or upside

down.

• When installing the Maintenance Unit on the hooks, confirm

that the screws which attach the hooks to the wall are not

loose and that the Maintenance Unit is stable when attached

to the hooks . When a hook comes off, the Maintenance Unit

drops and is damaged, and there is a fear that a user hurt by

the Maintenance Unit which dropped.

• The Maintenance Unit’s Ventilation Grills should be clear of

ancillary equipment. Blockage can cause overheating and

equipment damage.

• Do not connect the power cord of the MU-1 to a different

voltage electrical outlet. Fire and smoke may result.

MAINTENANCE UNIT MU-1

11

Page 16

Chapter 3 Preparation and Inspection

Affix Hook to the wall using

fixing screws provided.

Place unit onto Hook ensuring

brackets are full located.

Installation

Install the Maintenance Unit on the Hook or place the unit on a stable surface in

an area where the unit will not be exposed to the water splashed during

operation. When installing the unit using the feet, confirm that the feet stick firmly

to the installation surface, when attaching the unit to the Hook, confirm that the

screws that attach the Hook to the wall are not loose, and that the Hook does not

move when the unit is attached to it (see Figure 3.1).

Connecting the Power Supply

1. Confirm the Power Switch is OFF “ ”.

2. Connect the Power Cord to the Power Cord Receptacle.

3. Insert the other end of the Power Cord directly into a Wall Mains Outlet (see

Figure 3.1

The plug of the power cord that follows the equipment may

vary from this drawing, as in each country the

commercialized cable is in accordance to the local applicable

norm.

Figure 3.2).

12

MAINTENANCE UNIT MU-1

Page 17

Figure 3.2

Inspecting the Operation

1.

Turn the Power Switch ON “ ”.

Chapter 3 Preparation and Inspection

2. Confirm that the Power Switch lamp lights and that the pump starts

operating.

3. Confirm that air comes out of the lower hole in the Output Socket (see

Figure 3.3).

4. Turn the Power Switch OFF “ ”.

Figure 3.3

MAINTENANCE UNIT MU-1

13

Page 18

Chapter 3 Preparation and Inspection

If Power Fails to Come on

If power fails to come on, inspect the system as follows:

1. Confirm that the Power Cord is connected securely to a Wall Mains Outlet

and the Power Cord Receptacle on the Maintenance Unit.

2. Confirm that the Circuit Breakers have not tripped by checking that the

breaker buttons have not popped up. If the buttons have popped up, reset

the breakers according to the following procedure 3. and 4.

Reset the Circuit Breakers only once. If the power is still not

supplied to the Maintenance Unit after resetting the Circuit

Breakers, immediately turn the Power Switch OFF “ ”

disconnect the Power Cord from a Wall Mains Outlet and

contact Olympus. This condition can result in electrical shock

and/or fire.

When the Circuit Breakers trips, do not reset the Circuit

Breakers immediately. Turn the Power Switch OFF “ ”. Wait

at least 15 seconds before resetting the Circuit Breakers to

prevent Circuit Breaker damage.

3. Turn the Power Switch OFF “ ”, disconnect the Power Cord and depress

the Circuit Breaker buttons until it stops with a click.

4. Reconnect the Power Cord and turn the Power Switch ON “ ”. Confirm

that power is being supplied to the Maintenance Unit.

14

MAINTENANCE UNIT MU-1

Page 19

Chapter 3 Preparation and Inspection

3.3 Preparation and Inspection of the Endoscope and Disinfectant Container

The Fiberscope Adapter (AC10-S) is not waterproof. Ensure

it is removed before immersing the OES Fiberscope in a

solution.

Leakage Testing

Refer to the instruction manuals of the Leakage Tester and endoscope for

directions on Leakage Testing.

Remove water from the Air/Water Channel (For endoscope with Air/Water channel only)

1.

When using the OES Fiberscope, remove the Fiberscope Adapter from the

Light Guide Connector (if used).

2. Remove the Air/Water Valve from the endoscope and replace it with the AW

Channel Cleaning Adapter (see Figure 3.4).

Figure 3.4

MAINTENANCE UNIT MU-1

15

Page 20

Chapter 3 Preparation and Inspection

3. Insert the Light Guide Connector as far as it will go into the Output Socket

on the front panel of the Maintenance Unit (see Figure 3.5).

Figure 3.5

Perform the following procedures only when irrigating the channel with 70% ethyl

or isopropyl alcohol. Operate to the Alcohol Container (MB-264) according to the

directions given in it’s instruction manual.

4. Fill the Alcohol Container 70% ethyl or isopropyl alcohol and close the cap.

5. Attach the Alcohol Container to the MU-1’s Container Hanger.

6. Insert the Alcohol Container’s nozzle into the Water Container Connector on

the Light Guide Connector (see Figure 3.6).

Figure 3.6

16

MAINTENANCE UNIT MU-1

Page 21

Chapter 4 Operation

The operator of this instrument must be a physician or medical personnel under

the supervision of a physician and must have received sufficient training in

clinical endoscopic technique. This manual, therefore, does not explain or

discuss clinical endoscopic procedures. It only describes basic operation and

precautions related to the operation of this instrument.

Do not allow the Power Cord to become wet. A wet Power

Cord may cause electrical shock.

Use personal protective equipment to guard against

dangerous chemicals and infectious material. During

operation, wear appropriate protective equipment, such as

eye wear, a face mask, moisture-resistant clothing and

chemical-resistant gloves that fit properly and are long

enough so that your skin is not exposed.

Chapter 4 Operation

4.1 Leakage Testing

When reprocessing the endoscope, perform leakage testing to ensure that the

endoscope is waterproof.

Refer to the instruction manuals of the Leakage Tester and endoscope for

directions on Leakage Testing.

Only perform insufflation after drying the channel with 70%

ethyl or isopropyl alcohol. Otherwise the 70% ethyl or

isopropyl alcohol may remain inside the endoscope’s

channel.

MAINTENANCE UNIT MU-1

17

Page 22

Chapter 4 Operation

4.2 Remove water from the Air/Water Channel (For endoscope with Air/Water channel only)

Do not remove the AW Channel Cleaning Adapter and the

Alcohol Container’s nozzle until the Power Switch is OFF

“ ”. If the AW Channel Cleaning Adapter or Alcohol

Container’s nozzle are removed from the endoscope while

the Power Switch is ON “ ”, water or 70% ethyl or isopropyl

alcohol will splatter.

Flushing the channels with 70% ethyl or isopropyl alcohol

facilitates drying inside the Air/Water channel.

When Irrigating With 70% Ethyl or Isopropyl Alcohol

1.

Turn the Power Switch ON “ ”.

2. Depress the button on the AW Channel Cleaning Adapter for approximately

10 seconds to irrigate the channel with 70% ethyl or isopropyl alcohol (see

Figure 4.1).

3. Release the button and perform insufflation for approximately 10 seconds

until no more 70% ethyl or isopropyl alcohol exits the endoscope.

4. Turn the Power Switch OFF “ ”.

5. Remove the Alcohol Container’s nozzle from the Air/Water Port on the Light

Guide Connector.

6. Perform drying the Air/Water channel according to the next page.

18

Figure 4.1

MAINTENANCE UNIT MU-1

Page 23

Dry the Air/Water Channel

1.

Turn the Power Switch ON “ ”.

2. Close the irrigation port of the endoscope with your finger. Press the AW

Channel Cleaning Adapter button and release it. Repeat this procedure at

intervals of approximately 30 seconds until no more water or 70% ethyl or

isopropyl alcohol exit the Distal End of the endoscope (see Figure 4.2).

3. Turn the Power Switch OFF “ ”.

4. Remove the Light Guide Connector from the Output Socket.

Chapter 4 Operation

Figure 4.2

MAINTENANCE UNIT MU-1

19

Page 24

Chapter 5 Care, Storage and Disposal

Chapter 5 Care, Storage and Disposal

5.1 Care

• Use only dry gauze to wipe the Power Switch. Do not

moisten the gauze as this could cause the switches to fail, as

well as producing an electric shock.

• After wiping with a gauze moistened in liquid, dry the

Maintenance Unit thoroughly before using it again. If it is

used while still wet, there is risk of electrical shock.

• When performing care of the Maintenance Unit, always wear

appropriate personal protection equipment.

Blood, mucous and other infection material tuck on the

Maintenance Unit could pose an infection control risk.

• Do not steam sterilize (autoclave) or gas sterilize the

equipment, the Maintenance Unit will be damaged.

• Do not wipe the outside surface with hard or abrasive wiping

material. The surface will be scratched.

If the Maintenance Unit becomes soiled, perform the following cleaning

procedure immediately after use. Stains caused by organic substances solidify

after a certain amount of time has passed and are very difficult to clean. The

equipment should also be cleaned routinely.

1. Turn the Maintenance Unit Power Switch OFF “ ” and disconnect the

Power Cord.

2. Wipe the equipment using soft, lint-free cloth moistened with 70% ethyl or

isopropyl alcohol remove dust, dirt and non-patient debris.

3. Should the equipment become soiled with blood or other potentially

infectious materials, first wipe off all gross debris using detergent and then

decontaminate the equipment a surface using lint-free cloth moistened with

70% ethyl or isopropyl alcohol. The equipment is compatible with 70% ethyl

or isopropyl alcohol.

20

4. Confirm that the equipment is completely dry before use.

MAINTENANCE UNIT MU-1

Page 25

5.2 Storage

Chapter 5 Care, Storage and Disposal

Do not store the Maintenance Unit in a location exposed to

direct sunlight, X rays, radioactivity or strong electromagnetic

radiation (near microwave medical treatment equipment,

short-wave medical treatment equipment, MRI equipment or

radio). Damage to the Maintenance Unit may result.

Store the equipment in the horizontal position in a clean, dry and stable location.

5.3 Disposal

When disposing of this product, or any of its components, follow all applicable

national laws and guidelines.

Figure 5.1

MAINTENANCE UNIT MU-1

21

Page 26

Chapter 6 Troubleshooting

Chapter 6 Troubleshooting

If the instrument is visibly damaged, does not function as expected or is found to

have other irregularities during the inspection described in Chapter 3,

“Preparation and Inspection”, do not use the instrument. Contact Olympus.

Problems that appear not to be malfunctions may be correctable by referring to

Section 6.1, “Troubleshooting Guide”. Should you fail to correct the problem

even after taking the described remedial action, stop using the instrument and

send it to Olympus for repair. Olympus does not repair accessory parts. If an

accessory part becomes damaged, contact Olympus to purchase a replacement.

6.1 Troubleshooting Guide

Irregularity

Description

The pump does not

work.

The pump works but no

air comes out.

Insufflation pressure is

weak.

Possible Cause Solution

The Power Cord is not

connected.

The Power Switch is not

turned ON.

The endoscope is not

correctly connected to

the unit.

The unit is not correctly

connected to the

leakage tester, or the

leakage tester is not

correctly connected to

the endoscope.

Air leaks from a

connection section.

Connect the Power Cord to a Wall

Mains Outlet.

Turn the Power Switch ON “ ”.

Connect the endoscope to the unit

correctly.

Connect the unit to the leakage

tester correctly, and connect the

leakage tester to the endoscope

correctly.

Confirm no air leaks from any

connection section.

22

MAINTENANCE UNIT MU-1

Page 27

Chapter 6 Troubleshooting

6.2 Returning the Maintenance Unit for Repair

Olympus is not liable for any injury or damage which occurs

as a result of repairs attempted by non-Olympus personnel.

When returning the Maintenance Unit for repair, include a description of the

Maintenance Unit malfunction or damage and the name and telephone number

of the individual at your location who is most familiar with the Maintenance Unit

problem. Also include a repair purchase order.

If a Maintenance Unit accessory (Power Cord, Hook, Screw,

Instruction Manual) needs to be replaced, contact Olympus

to obtain a new one.

MAINTENANCE UNIT MU-1

23

Page 28

Appendix

Appendix

System Chart

The recommended combinations of equipment and accessories that can be

used with this instrument are listed below. New products released after the

introduction of this instrument may also be compatible for use in combination

with this instrument. For further details, contact Olympus.

If combinations of equipment other than those shown below

are used, the full responsibility is assumed by the medical

treatment facility.

24

MAINTENANCE UNIT MU-1

Page 29

Water-resistant Cap

EVIS Videoscope

AW Channel

Cleaning Adapter

Maintenance Unit

(MU-1)

Alcohol Container

(MB-264)

only

EVIS Videoscope

100/200 series

OES Fiberscope

10/20/30 series

OES Fiberscope

LeakageTester

(MB-155)

Appendix

MAINTENANCE UNIT MU-1

25

Page 30

Appendix

Transportation, Storage and Operating Environments

Specifications

Transportation

and Storage

Environment

Operating

Environment

Power Supply Voltage 120 V AC

Ambient

Temperature

Relative Humidity

Atmospheric

Pressure

Ambient

Temperature

Relative Humidity

Air Pressure

Item Specification

Voltage Fluctuation

-25 to +70

10‐90%

700‐1060 hPa

10‐40

C (50 to 104F)

30‐85%(without condensation)

700‐1060 hPa

(0.7‐1.1 kgf/cm

(10.2‐15.4 psia)

Within 10%

C (-13 to +158F)

2

)

Frequency 50/60 Hz

Frequency

Fluctuation

Input Current 0.4 A

Size Dimensions 85 (W) × 157 (H) × 170 (D) mm

Weight 1.8 kg

Compatible

Endoscopes

Insufflation

function

Pump Electromagnetic Vibrator

Performance At scope socket:

Within 1Hz

(maximum)

OES Fiberscope

EVIS Videoscope

2000 ml/min

0ml/min

4

1.76 × 10

higher

2.84 × 104Pa and

higher

Pa and

26

MAINTENANCE UNIT MU-1

Page 31

Appendix

Classification

(Medical

Electrical

Equipment)

Year of

Manufacture

EMC Applied standard ;

Type of Protection

against Electric

Shock

Degree of Protection

against Electric

Shock of Applied

part

Degree of Protection

against Explosion

12345

77

IEC 60601-1-2:2001

Class Ⅰ

TYPE BF

This instrument should be kept away

from flammable gases

The last digit of the year of manufacture

is the second digit of the serial number.

This instrument complies with the

standards listed in the left column.

CISPR 11 of emission:Group 1,Class B

This instrument complies with the EMC

standard for medical electrical

equipment; edition 2(IEC 60601-1-2:

2001). However, when connecting to an

instrument that complies with the EMC

standard for medical electrical

equipment; edition 1 (IEC 60601-1-2:

1993), the whole system complies with

edition 1.

MAINTENANCE UNIT MU-1

27

Page 32

Page 33

Page 34

Page 35

©1997 OLYMPUS MEDICAL SYSTEMS CORP. All rights reserved.

No part of this publication may be reproduced or distributed without the

express written permission of OLYMPUS MEDICAL SYSTEMS CORP.

OLYMPUS is a registered trademark of OLYMPUS CORPORATION.

Trademarks, product names, logos, or trade names used in this

document are generally registered trademarks or trademarks of each

company.

Page 36

Manufactured by

2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan

Fax: (042)646-2429 Telephone: (042)642-2111

Distributed by

3500 Corporate Parkway, P.O. Box 610, Center Valley, PA

Fax: (484)896-7128 Telephone: (484)896-5000

5301 Blue Lagoon Drive, Suite 290 Miami, FL 33126-2097, U.S.A.

Fax: (305)261-4421 Telephone: (305)266-2332

(Premises/Goods delivery) Wendenstrasse 14-18, 20097 Hamburg, Germany

(Letters) Postfach 10 49 08, 20034 Hamburg, Germany

Fax: (040)23773-4656 Telephone: (040)23773-0

KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom

Fax: (01702)465677 Telephone: (01702)616333

117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia

Fax: (095)958-2277 Telephone: (095)958-2245

A8F, Ping An International Financial Center, No. 1-3, Xinyuan South Road,

Chaoyang District, Beijing, 100027 P.R.C.

Fax: (86)10-5976-1299 Telephone: (86)10-5819-9000

Olympus Tower 9F, 446, Bongeunsa-ro, Gangnam-gu, Seoul, Korea 135-509

Fax: (02)6255-3494 Telephone: (02)6255-3210

18034-0610, U.S.A.

GC4807 21

491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373

Fax: 6834-2438 Telephone: 6834-0010

3 Acacia Place, Notting Hill, VIC 3168, Australia

Fax: (03)9543-1350 Telephone: (03)9265-5400

Printed in Japan 20140430 *0000

Loading...

Loading...