Page 1

HST-Lite Scanner

User’s Manual

DMTA-20045-01EN — Revision A

October 2012

Page 2

Olympus NDT, 48 Woerd Avenue, Waltham, MA 02453, USA

© 2012 Olympus NDT, Inc. All rights reserved. No part of this publication may be

reproduced, translated, or distributed without the express written permission of

Olympus NDT, Inc.

This document was prepared with particular attention to usage to ensure the

accuracy of the information contained therein, and corresponds to the version of

the product manufactured prior to the date appearing on the title page. There

could, however, be some differences between the manual and the product if the

product was modified thereafter.

The information contained in this document is subject to change without notice.

Part number: DMTA-20045-01EN

Revision A

October 2012

Printed in Canada

All brands are trademarks or registered trademarks of their respective owners and

third party entities.

Page 3

DMTA-20045-01EN, Rev. A, October 2012

Table of Contents

Labels and Symbols ........................................................................................... 1

Important Information — Please Read Before Use ..................................... 3

Intended Use .......................................................................................................................... 3

Instruction Manual ................................................................................................................ 3

Instrument Compatibility ..................................................................................................... 4

Safety Symbols ....................................................................................................................... 4

Safety Signal Words ............................................................................................................... 5

Note Signal Words ................................................................................................................. 6

Warnings ................................................................................................................................. 6

WEEE Directive ...................................................................................................................... 7

Warranty Information ........................................................................................................... 7

Technical Support .................................................................................................................. 8

1. HST-Lite Scanner ......................................................................................... 9

1.1 Positioning the Frame Bar ....................................................................................... 10

1.2 Installing a Probe and a Wedge in a Probe Holder .............................................. 11

1.3 Setting the Distance Between Beam Exit Points ................................................... 13

1.4 Positioning the Wheel Encoder ............................................................................... 16

1.5 Installing Tubing and Cables .................................................................................. 16

1.6 Installing the Cable Sheath ...................................................................................... 19

1.7 Scanner Wheels ......................................................................................................... 22

1.8 Installing a Preamplifier .......................................................................................... 24

1.9 Offset Probe Configuration ..................................................................................... 26

2. Parts and Accessories ................................................................................ 29

2.1 Standard Accessories ................................................................................................ 29

2.2 Optional Accessories ................................................................................................ 30

Table of Contents iii

Page 4

DMTA-20045-01EN, Rev. A, October 2012

3. Specifications .............................................................................................. 31

List of Figures ................................................................................................... 33

List of Tables ..................................................................................................... 35

Index ................................................................................................................... 37

iv Table of Contents

Page 5

DMTA-20045-01EN, Rev. A, October 2012

Location of marking

(see Table 1 on

page 2).

Labels and Symbols

Marking of the HST-Lite Scanner is shown in Figure i-1 on page 1. If the marking is

illegible, please contact Olympus.

Figure i-1 Marking location

Labels and Symbols 1

Page 6

DMTA-20045-01EN, Rev. A, October 2012

Table 1 Content of the marking

Marking:

Contains:

S/N The serial number.

The CE marking is a declaration that this product conforms to

all the applicable directives of the European Community. See

the Declaration of Conformity for details.

2 Labels and Symbols

The WEEE symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be

collected separately.

Page 7

DMTA-20045-01EN, Rev. A, October 2012

Important Information — Please Read Before Use

Intended Use

The HST-Lite Scanner is designed to perform nondestructive inspections on industrial

and commercial materials.

Do not use the HST-Lite Scanner for any purpose other than its intended use. It must

never be used to inspect or examine human or animal body parts.

Instruction Manual

This instruction manual contains essential information on how to use this Olympus

product safely and effectively. Before using this product, thoroughly review this

instruction manual, and use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Important Information — Please Read Before Use 3

Page 8

DMTA-20045-01EN, Rev. A, October 2012

Instrument Compatibility

The HST-Lite Scanner is compatible with the ancillary Olympus equipment listed in

Table 2 on page 4. For a list of other compatible parts and accessories, refer to chapter

2 on page 29.

Using incompatible equipment could cause malfunction and/or equipment damage.

Table 2 Ancillary equipment

Equipment Description

OmniScan MX Phased array instrument

TomoScan FOCUS LT Phased array instrument (using the optional

C1-DE15F-BXM-0.30M [U8767107] encoder adaptor)

OmniScan MXU OmniScan software

OmniScan MX2 Phased array instrument (using the adaptor

OMNI-A2-ADP20 [U8775201] supplied with the

instrument)

TOFD wedges ST1 and ST2 type

Safety Symbols

The following safety symbols might appear on the instrument and in the instruction

manual:

General warning symbol:

This symbol is used to alert the user to potential hazards. All safety messages that

follow this symbol shall be obeyed to avoid possible harm.

4 Important Information — Please Read Before Use

Page 9

DMTA-20045-01EN, Rev. A, October 2012

High voltage warning symbol:

This symbol is used to alert the user to potential electric shock hazards greater

than 1000 volts. All safety messages that follow this symbol shall be obeyed to

avoid possible harm.

Safety Signal Words

The following safety symbols might appear in the documentation of the instrument:

The DANGER signal word indicates an imminently hazardous situation. It calls

attention to a procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in death or serious personal injury. Do not proceed beyond a

DANGER signal word until the indicated conditions are fully understood and met.

The WARNING signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in death or serious personal injury. Do not proceed beyond a

WARNING signal word until the indicated conditions are fully understood and met.

The CAUTION signal word indicates a potentially hazardous situation. It calls

attention to an operating procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in minor or moderate personal injury, material

damage, particularly to the product, destruction of part or all of the product, or loss of

data. Do not proceed beyond a

fully understood and met.

CAUTION signal word until the indicated conditions are

Important Information — Please Read Before Use 5

Page 10

DMTA-20045-01EN, Rev. A, October 2012

Note Signal Words

The following safety symbols could appear in the documentation of the instrument:

The IMPORTANT signal word calls attention to a note that provides important

information, or information essential to the completion of a task.

The NOTE signal word calls attention to an operating procedure, practice, or the like,

which requires special attention. A note also denotes related parenthetical

information that is useful, but not imperative.

The TIP signal word calls attention to a type of note that helps you apply the

techniques and procedures described in the manual to your specific needs, or

provides hints on how to effectively use the capabilities of the product.

Warnings

General Warnings

• Carefully read the instructions contained in this instruction manual prior to using

the instrument.

• Keep this instruction manual in a safe place for further reference.

• Follow the installation and operation procedures.

• It is imperative to respect the safety warnings on the instrument and in this

instruction manual.

• If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment could be impaired.

• Do not install substitute parts or perform any unauthorized modification to the

instrument.

6 Important Information — Please Read Before Use

Page 11

DMTA-20045-01EN, Rev. A, October 2012

WEEE Directive

In accordance with European Directive 2002/96/EC on Waste Electrical

and Electronic Equipment (WEEE), this symbol indicates that the

product must not be disposed of as unsorted municipal waste, but

should be collected separately. Refer to your local Olympus distributor

for return and/or collection systems available in your country.

Warranty Information

Olympus guarantees your Olympus product to be free from defects in materials and

workmanship for a specific period, and in accordance with conditions specified in the

Olympus NDT Terms and Conditions available at http://www.olympusims.com/en/terms/.

The Olympus warranty only covers equipment that has been used in a proper

manner, as described in this instruction manual, and that has not been subjected to

excessive abuse, attempted unauthorized repair, or modification.

Inspect materials thoroughly on receipt for evidence of external or internal damage

that might have occurred during shipment. Immediately notify the carrier making the

delivery of any damage, because the carrier is normally liable for damage during

shipment. Retain packing materials, waybills, and other shipping documentation

needed in order to file a damage claim. After notifying the carrier, contact Olympus

for assistance with the damage claim and equipment replacement, if necessary.

This instruction manual explains the proper operation of your Olympus product. The

information contained herein is intended solely as a teaching aid, and shall not be

used in any particular application without independent testing and/or verification by

the operator or the supervisor. Such independent verification of procedures becomes

increasingly important as the criticality of the application increases. For this reason,

Olympus makes no warranty, expressed or implied, that the techniques, examples, or

procedures described herein are consistent with industry standards, nor that they

meet the requirements of any particular application.

Olympus reserves the right to modify any product without incurring the

responsibility for modifying previously manufactured products.

Important Information — Please Read Before Use 7

Page 12

DMTA-20045-01EN, Rev. A, October 2012

Technical Support

Olympus is firmly committed to providing the highest level of customer service and

product support. If you experience any difficulties when using our product, or if it

fails to operate as described in the documentation, first consult the user’s manual, and

then, if you are still in need of assistance, contact our After-Sales Service. To locate the

nearest service center, visit the Service Centers page at: http://www.olympusims.com.

8 Important Information — Please Read Before Use

Page 13

DMTA-20045-01EN, Rev. A, October 2012

Frame bar

Handle

Dovetail nuts (2)

Probe holder (2)

Wheel encoder

Wheel block (2)

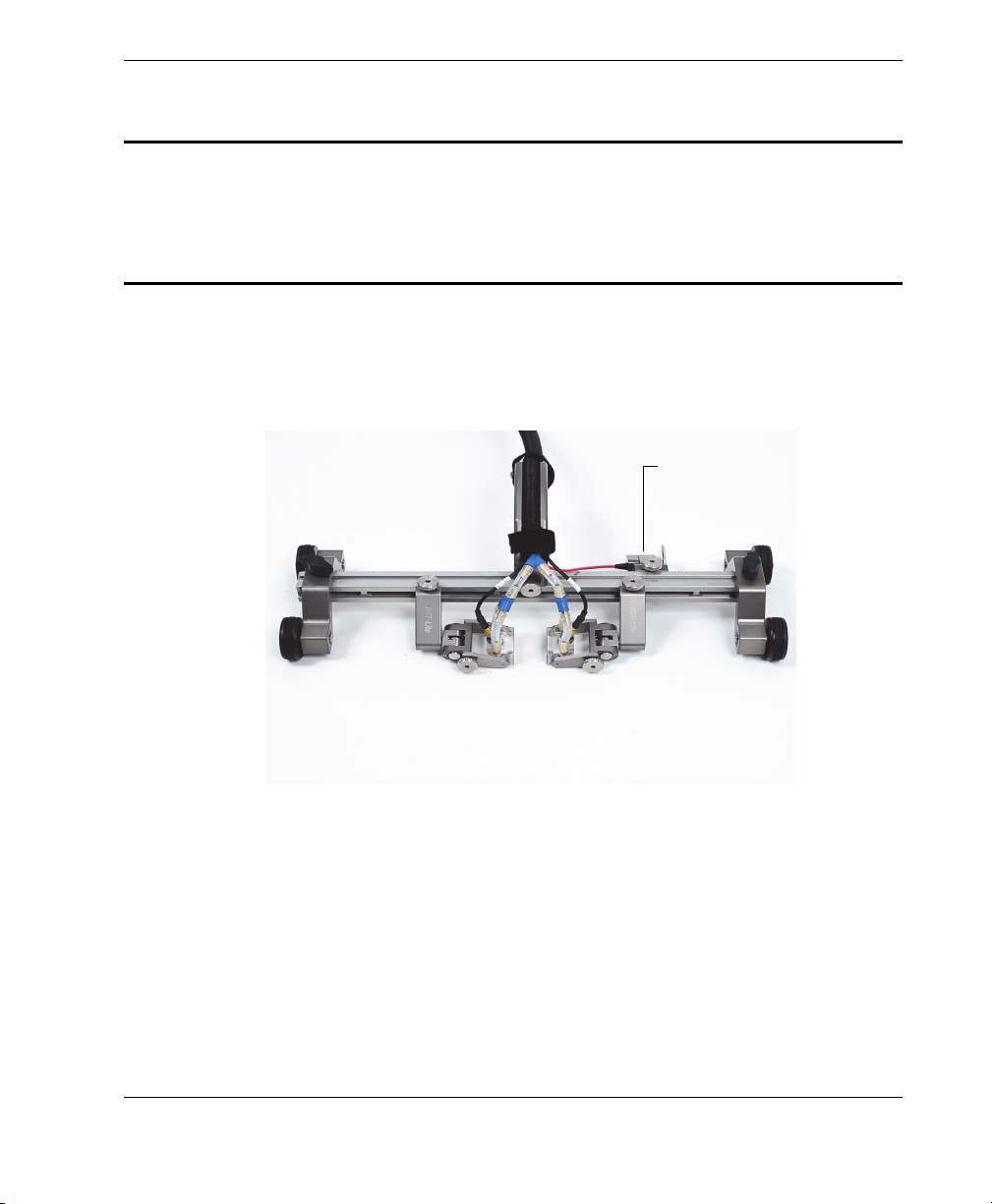

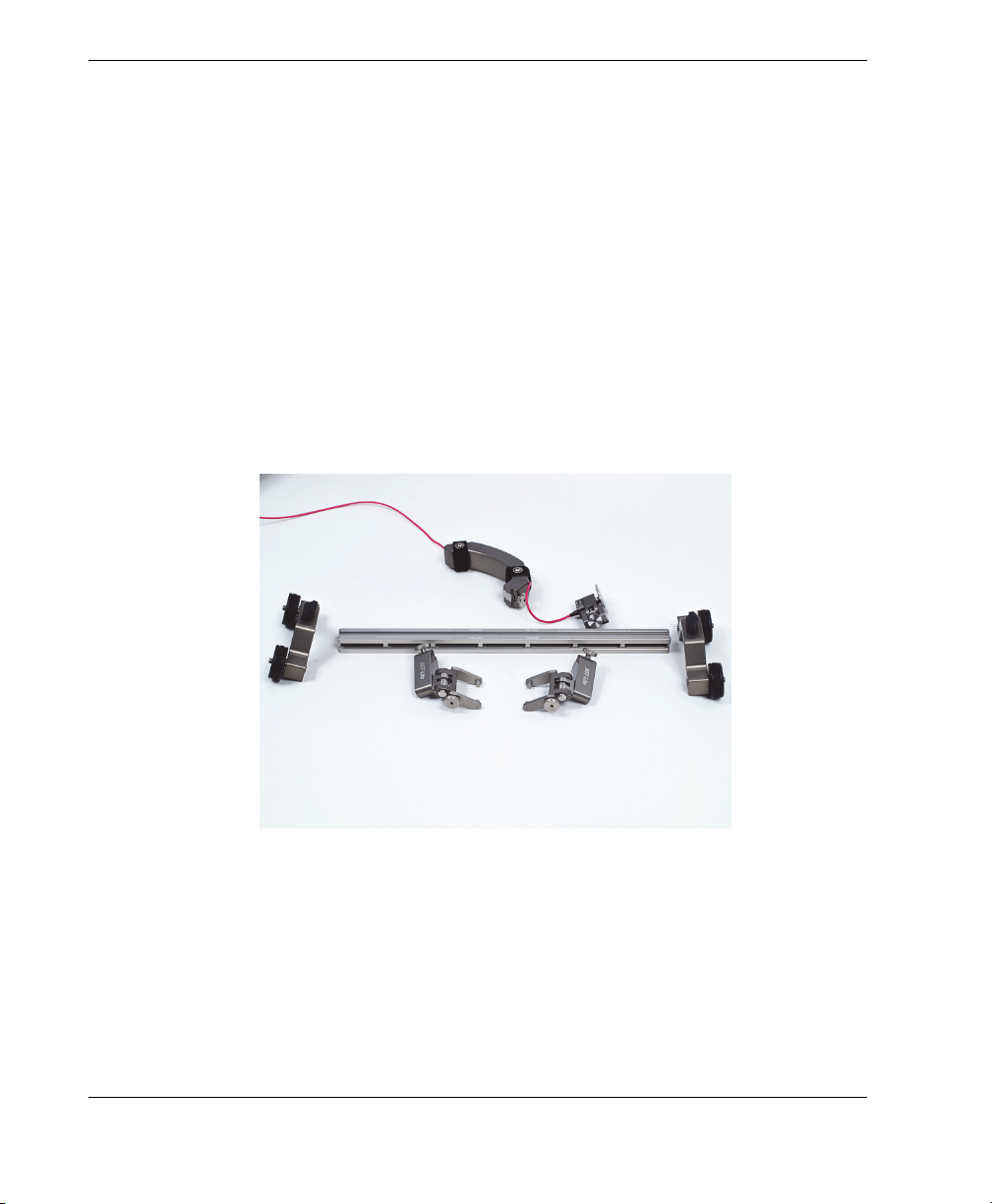

1. HST-Lite Scanner

The HST-Lite Scanner is a versatile pipe and plate scanner, which can be used to

inspect welds using TOFD and pulse-echo techniques.

The HST-Lite Scanner is composed of the following items (see Figure 1-1 on page 9):

Figure 1-1 The HST-Lite Scanner components

HST-Lite Scanner 9

Page 14

DMTA-20045-01EN, Rev. A, October 2012

1.1 Positioning the Frame Bar

The frame bar must be positioned differently according to the wedge model used:

• Stainless steel wedges (IHS)

• Rexolite wedges (IHC)

The engraving corresponding to the wedge model used must be facing upward. If it is

not the case, perform the following procedure.

To position the frame bar

1. Loosen the wheel block, the probe holder, the handle, and the wheel encoder

thumbscrews, and then remove all the components from the frame bar (see

Figure 1-2 on page 10).

Figure 1-2 Disassembled scanner

2. Position the frame bar so the engraving corresponding to the wedge model used

IHS TOFD WEDGES or IHC TOFD WEDGES) is facing upward (see Figure 1-3 on

(

page 11).

10 HST-Lite Scanner

Page 15

DMTA-20045-01EN, Rev. A, October 2012

Engraving

corresponding to

the wedge model

Figure 1-3 Engraving on the frame bar

3. Reassemble the scanner.

1.2 Installing a Probe and a Wedge in a Probe Holder

To install a probe and a wedge in a probe holder

Before installing a new probe into a probe holder, make sure that there is enough

couplant between the probe face and the wedge.

1. Apply couplant on the probe face (see Figure 1-4 on page 12).

HST-Lite Scanner 11

Page 16

DMTA-20045-01EN, Rev. A, October 2012

Figure 1-4 Applying couplant on probe face

2. Install the probe on the wedge.

3. Loosen the yoke thumbscrew (see Figure 1-5 on page 12).

12 Chapter 1

Figure 1-5 Loosening yoke thumbscrew

Page 17

DMTA-20045-01EN, Rev. A, October 2012

Wedge Yoke arm guiding

pin

4. Install the probe and wedge assembly between the two yoke arms (see Figure 1-6

on page 13).

Figure 1-6 Wedge installed

5. Push the yoke arm in order to place the yoke arm guiding pin into the wedge side

hole (see Figure 1-6 on page 13).

6. Tighten the thumbscrew until it holds the yoke arm tight against the holder.

7. Repeat the procedure to install the other wedge.

1.3 Setting the Distance Between Beam Exit Points

To set the distance between beam exit points

1. According to the scan plan, determine the distance between the beam exit points

(for example, 40 mm).

2. Divide the distance value by two (for example, 20 mm).

3. Position the probe holders so their indicators point to the half value (for example,

20 mm) on the left- and right-hand side frame rulers (see Figure 1-7 on page 14

and Figure 1-8 on page 15).

HST-Lite Scanner 13

Page 18

DMTA-20045-01EN, Rev. A, October 2012

Indicator

Figure 1-7 Probe holder indicator

A millimeter appears as the distance between two short lines. The distance between

two long lines is 5 mm.

4. To make sure that the distance between beam exit points is properly set:

When using Rexolite wedges, measure the distance between the dots

engraved on yoke arms (see Figure 1-8 on page 15).

OR

When using stainless steel wedges, measure the distance between the vertical

lines engraved on wedges (see Figure 1-9 on page 15).

14 Chapter 1

Page 19

DMTA-20045-01EN, Rev. A, October 2012

Probe holder pointing to the half

value (for example, 20 mm)

Probe holder pointing to the half

value (for example, 20 mm)

Distance between beam exit

points (for example, 40 mm)

Dot on yoke armDot on yoke arm

Vertical line used to

measure distance between

beam exit points.

Figure 1-8 Distance between beam exit points (Rexolite wedges shown)

Figure 1-9 Vertical lines engraved on stainless steel wedges

HST-Lite Scanner 15

Page 20

DMTA-20045-01EN, Rev. A, October 2012

Wheel encoder thumbscrew

Slide the encoder

1.4 Positioning the Wheel Encoder

To position the wheel encoder

1. Loosen the wheel encoder thumbscrew (see Figure 1-10 on page 16).

2. Slide the wheel encoder to the desired position (see Figure 1-10 on page 16).

3. Tighten the wheel encoder thumbscrew.

Figure 1-10 Positioning the wheel encoder

1.5 Installing Tubing and Cables

To install tubing and cables

1. If you plan to use the offset probe configuration, assemble the HST-Lite Scanner

according to section 1.9 on page 26.

2. If required, install the preamplifier (see section 1.8 on page 24).

3. Connect the probe cables to the probes.

4. Cut four pieces of transparent tube. They should measure about 3.8 cm (1.5 in.)

long.

5. Install the four transparent tubes on the wedges (see Figure 1-11 on page 17).

6. Install a Y-fitting on each pair of transparent tubes (see Figure 1-11 on page 17).

16 Chapter 1

Page 21

DMTA-20045-01EN, Rev. A, October 2012

Y-fitting installed on wedge

tubes

Probe cable

Transparent tube

Figure 1-11 Transparent tubes installed on the wedges

7. Insert a Y-fitting in the blue irrigation tube (see Figure 1-12 on page 17).

Figure 1-12 Y-fitting inserted in the irrigation tube

HST-Lite Scanner 17

Page 22

DMTA-20045-01EN, Rev. A, October 2012

Hook and loop

strip

Y-fitting outside

the handle

8. Install the irrigation tube in the scanner handle, and then temporarily secure the

irrigation tube using the hook and loop strips (see Figure 1-13 on page 18).

Make sure the Y-fitting of the irrigation tube is outside the handle (see Figure 1-13 on

page 18).

18 Chapter 1

Figure 1-13 Securing the irrigation tube

9. Link the wedges to the irrigation tube using pieces of transparent tubes cut to the

required length (see Figure 1-14 on page 19).

Page 23

Figure 1-14 Irrigation tube linked to the wedges

1.6 Installing the Cable Sheath

DMTA-20045-01EN, Rev. A, October 2012

To install the cable sheath

1. Unfasten the handle hook and loop strips.

2. Bundle up the probe cables, wheel encoder cable, irrigation tube, and

preamplifier cables (if installed).

3. Install the draw-in tool on the cable and tube bundle. The pointed end of the

draw-in tool should point away from the scanner (see Figure 1-15 on page 20).

HST-Lite Scanner 19

Page 24

DMTA-20045-01EN, Rev. A, October 2012

Pointed end pointing away

from the scanner

Figure 1-15 Draw-in tool installed on cable and tube bundle

4. Install the cable sheath over the draw-in tool, and then slide the tool to install the

cable sheath (see Figure 1-16 on page 20).

20 Chapter 1

Figure 1-16 Cable sheath installed on the draw-in tool

Page 25

DMTA-20045-01EN, Rev. A, October 2012

To prevent the draw-in tool from slipping out of the cable sheath, place your fingers

under the tool and the sheathing (see Figure 1-17 on page 21).

Figure 1-17 Fingers placed under the draw-in tool

5. Position the cable and tube bundle in the scanner handle, and then fasten the

hook and loop strips (see Figure 1-18 on page 22).

HST-Lite Scanner 21

Page 26

DMTA-20045-01EN, Rev. A, October 2012

Figure 1-18 Cable and tube bundle in the scanner handle

1.7 Scanner Wheels

The HST-Lite Scanner is equipped with four wheels. Two additional wheels can be

installed for offset configuration. For more details about offset configuration, see

section 1.9 on page 26.

To replace a scanner wheel

1. Block the wheel shaft using the hexagonal key (see Figure 1-19 on page 23).

22 Chapter 1

Page 27

DMTA-20045-01EN, Rev. A, October 2012

Blocking the

wheel shaft

Non-threaded flange

Figure 1-19 Blocking the wheel shaft

2. Unscrew the wheel manually, and then remove the wheel (see Figure 1-20 on

page 23).

Figure 1-20 Installing a replacement wheel

HST-Lite Scanner 23

Page 28

DMTA-20045-01EN, Rev. A, October 2012

Dovetail nut (2)

Back channel

When installing a replacement wheel, make sure that the non-threaded flange faces

the wheel block. If the wheel is not installed properly, the wheel threads will be

damaged.

3. Block the wheel shaft with your fingers, and then manually screw on the

replacement wheel.

4. Hold the wheel shaft in place using the hexagonal key, and then slightly tighten

the wheel.

1.8 Installing a Preamplifier

Perform the following procedure to install the optional preamplifier (P/N: 5682-KIT02

[U8779091]).

To install a preamplifier

1. Remove one of the wheel blocks.

2. Remove both dovetail nuts from the frame bar, and then insert them in the back

channel (see Figure 1-21 on page 24).

24 Chapter 1

Figure 1-21 Inserting dovetail nuts in the frame bar back channel

Page 29

DMTA-20045-01EN, Rev. A, October 2012

Lock washer on

thumbscrew

Preamplifier

bracket HSMT-ABRK5682

[U8779089]

(included in 5682KIT02 package)

3. Reinstall the wheel block.

4. Insert a lock washer on each preamplifier bracket thumbscrew (see Figure 1-22 on

page 25).

To prevent thread damage, do not overtighten the preamplifier bracket thumbscrews.

5. Secure the preamplifier bracket to the dovetail nuts using the thumbscrews (see

Figure 1-22 on page 25).

Figure 1-22 Securing the preamplifier bracket

6. Install the preamplifier in the bracket, and then secure the preamplifier using the

hook and loop strips (see Figure 1-23 on page 26).

HST-Lite Scanner 25

Page 30

DMTA-20045-01EN, Rev. A, October 2012

Figure 1-23 Preamplifier installed

1.9 Offset Probe Configuration

When an obstacle prevents you from placing the weld to be inspected between the

wheels, we suggest you use the offset configuration.

To configure the scanner for offset inspection

1. Install the scanner components as shown in Figure 1-24 on page 27.

26 Chapter 1

Page 31

DMTA-20045-01EN, Rev. A, October 2012

Two wheels installed

Figure 1-24 Offset configuration

2. Adjust the distance between beam exit points according to step 4 on page 14.

To prevent the scanner from falling off during the inspection, you must add two

magnetic wheels to the inner wheel block. Additional magnetic wheels are sold

separately.

When installing an additional wheel on a shaft, make sure that the threaded flange of

the second wheel faces the wheel block.

3. Install the additional wheels (see Figure 1-25 on page 28):

HST-Lite Scanner 27

Page 32

DMTA-20045-01EN, Rev. A, October 2012

Figure 1-25 Installing an additional wheel

a) Block the wheel shaft with your fingers, and then manually screw on the

wheel. The wheel threaded flange must face the wheel block.

b) Hold the shaft in place using the hexagonal key, and then slightly tighten the

wheel.

c) Repeat the step for the other wheel.

28 Chapter 1

Page 33

DMTA-20045-01EN, Rev. A, October 2012

2. Parts and Accessories

This chapter describes the accessories delivered with the HST-Lite Scanner and

presents a list of spare parts that can be used with the scanner.

2.1 Standard Accessories

The HST-Lite Scanner comes standard with:

• Frame bar with handle.

• Four magnetic wheels.

• OmniScan-compatible, waterproof, spring-loaded wheel encoder with 5 m cable.

• Two spring-loaded arms (SLA) with TOFD–P/E yokes (31.75 mm wide and 5 mm

diameter buttons).

• Irrigation tubing and accessories.

• Cable sheath.

• Carrying case.

Probes, wedges, and cables are not included with the basic HST-Lite Scanner.

Parts and Accessories 29

Page 34

DMTA-20045-01EN, Rev. A, October 2012

2.2 Optional Accessories

Table 3 HST-Lite Scanner optional accessories

Description Part number

5682 remote preamplifier kit 5682-KIT02 (U8779091)

Couplant-feed unit WTR-SPRAYER-8L (U8775001)

TomoScan FOCUS LT encoder

cable adaptor

Plastic wheel CHAINSCAN-A-PWHEEL (U8775189)

Magnetic wheel CHAINSCAN-A-MWHEEL (U8779383)

Replacement encoder HST-Lite-SP-ENC (U8775277)

Extra handle HST-Lite-A-Handle (U8775278)

Extra pair of spring loaded

probe holders for TOFD

inspection compatible with

HST-Lite Scanner. Yokes are

31.75 mm wide and 23.5 mm

long with 5 mm buttons.

Irrigation tubes and fittings for

HST-Lite Scanner. Same

content as in the basic HST-Lite

Scanner package.

C1-DE15F-BXM-0.30M (U8767107)

HST-Lite-A-PH-TOFD (U8775279)

HST-Lite-SP-IRRIGATION (U8775281)

30 Chapter 2

Page 35

DMTA-20045-01EN, Rev. A, October 2012

3. Specifications

This chapter presents the general specifications for the HST-Lite Scanner.

Table 4 HST-Lite Scanner specifications

Length in scan

axis (mm)

125 385

a. 67 mm without handle

Width

(mm)

Height

(mm)

a

100

Wei ght

(kg)

1.3 9

Encoder

resolution

(steps/mm)

Specifications 31

Page 36

DMTA-20045-01EN, Rev. A, October 2012

32 Chapter 3

Page 37

DMTA-20045-01EN, Rev. A, October 2012

List of Figures

Figure i-1 Marking location .................................................................................................. 1

Figure 1-1 The HST-Lite Scanner components ................................................................... 9

Figure 1-2 Disassembled scanner ....................................................................................... 10

Figure 1-3 Engraving on the frame bar ............................................................................. 11

Figure 1-4 Applying couplant on probe face .................................................................... 12

Figure 1-5 Loosening yoke thumbscrew ........................................................................... 12

Figure 1-6 Wedge installed .................................................................................................. 13

Figure 1-7 Probe holder indicator ...................................................................................... 14

Figure 1-8 Distance between beam exit points (Rexolite wedges shown) ................... 15

Figure 1-9 Vertical lines engraved on stainless steel wedges ......................................... 15

Figure 1-10 Positioning the wheel encoder ......................................................................... 16

Figure 1-11 Transparent tubes installed on the wedges .................................................... 17

Figure 1-12 Y-fitting inserted in the irrigation tube ........................................................... 17

Figure 1-13 Securing the irrigation tube ............................................................................. 18

Figure 1-14 Irrigation tube linked to the wedges ............................................................... 19

Figure 1-15 Draw-in tool installed on cable and tube bundle .......................................... 20

Figure 1-16 Cable sheath installed on the draw-in tool .................................................... 20

Figure 1-17 Fingers placed under the draw-in tool ........................................................... 21

Figure 1-18 Cable and tube bundle in the scanner handle ............................................... 22

Figure 1-19 Blocking the wheel shaft ................................................................................... 23

Figure 1-20 Installing a replacement wheel ........................................................................ 23

Figure 1-21 Inserting dovetail nuts in the frame bar back channel ................................. 24

Figure 1-22 Securing the preamplifier bracket ................................................................... 25

Figure 1-23 Preamplifier installed ........................................................................................ 26

Figure 1-24 Offset configuration .......................................................................................... 27

Figure 1-25 Installing an additional wheel ......................................................................... 28

List of Figures 33

Page 38

DMTA-20045-01EN, Rev. A, October 2012

34 List of Figures

Page 39

DMTA-20045-01EN, Rev. A, October 2012

List of Tables

Table 1 Content of the marking .......................................................................................... 2

Table 2 Ancillary equipment ............................................................................................... 4

Table 3 HST-Lite Scanner optional accessories ............................................................... 30

Table 4 HST-Lite Scanner specifications .......................................................................... 31

List of Tables 35

Page 40

DMTA-20045-01EN, Rev. A, October 2012

36 List of Tables

Page 41

Index

DMTA-20045-01EN, Rev. A, October 2012

A

accessories 29

optional accessories 30

standard accessories 29

additional wheels 27

ancillary equipment See compatibility, scanner

arm, yoke 13, 29

B

bar, frame 9, 29

engraving 11

positioning 10

rulers 13

beam exit points 15

distance 13

Rexolite wedges 14

stainless steel wedges 14

block, wheel 9

blue tube See irrigation tube

bracket, preamplifier 25

C

cable

installation 16

probe 17

sheath 19, 29

carrying case 29

caution notes

additional wheel installation 27

couplant on probe 11

incompatible equipment 4

wheel replacement 24

CE marking 2

compatibility, scanner 4

OmniScan MX 4

OmniScan MX2 4

OmniScan MXU 4

TOFD wedges 4

TomoScan FOCUS LT 4

components, scanner See scanner components

conduit See sheath, cable

configuration, offset probe 26, 27

couplant 11, 12

D

danger note, scanner intended use 3

distance, beam exit points 13, 15

dovetail nuts 9, 24

draw-in tool 19, 20

pointed end 20

E

encoder, wheel 9, 29

positioning 16

F

fittings, Y- 17, 18

frame bar 9, 29

engraving 11

positioning 10

rulers 13

G

guiding pin, yoke arm 13

H

handle 9

Index 37

Page 42

DMTA-20045-01EN, Rev. A, October 2012

hexagonal key 22

holder, probe 9

hook and loop strips 18

HST-Lite Scanner See scanner

I

IHC 10

IHS 10

installing

additional wheels 27

cable sheath 19

preamplifier 24

probe in probe holder 11

tubing and cables 16

instruction manual 3

instrument See scanner

intended use, scanner 3

irrigation tube 17, 29

K

key, hexagonal 22

L

lock washers 25

M

magnetic wheels See wheels

manual, instruction 3

marking

content 2

location 1

N

note signal words 6

notes

irrigation tube Y-fitting 18

probes and wedges not included 29

ruler reading 14

nuts, dovetail 9, 24

O

offset probe configuration 26, 27

Olympus technical support 8

optional accessories 30

P

parts 29

points, beam exit 15

distance 13

Rexolite wedges 14

stainless steel wedges 14

positioning

frame bar 10

wheel encoder 16

preamplifier 26

bracket 25

dovetail nuts 9, 24

installation 24

probe

cable 17

holder 9

installation 11

offset configuration 26, 27

R

removing a wheel 23

replacing scanner wheels 22

rulers 13

S

safety

signal words 5

symbols 4

scanner

compatibility 4

OmniScan MX 4

OmniScan MX2 4

OmniScan MXU 4

TOFD wedges 4

TomoScan FOCUS LT 4

components 9

dovetail nuts 9, 24

frame bar 9, 29

handle 9

probe holder 9

wheel block 9

wheel encoder 9, 29

description 9

intended use 3

marking

content 2

location 1

serial number 2

38 Index

Page 43

DMTA-20045-01EN, Rev. A, October 2012

specifications 31

wheels 22

removal 23

replacement 22

shaft 23

serial number 2

setting distance between beam exit points 13

sheath, cable 19, 29

signal words

note 6

safety 5

specifications 31

standard accessories 29

strips, hook and loop 18

support information 8

symbols

CE 2

WEEE 2

T

technical support 8

thumbscrews

lock washers 25

preamplifier bracket 25

yoke 12

tip, draw-in tool usage 21

tools

draw-in tool 19, 20

pointed end 20

hexagonal key 22

transparent tubes 17, 18, 19

tubing

installation 16

irrigation tube 17, 29

transparent tubes 17, 18, 19

U

use, scanner intended 3

V

velcro See hook and loop strips

W

warnings, general 6

warranty information 7

washers, lock 25

waste electrical and electronic equipment

(WEEE) 7

wedges

Rexolite (IHC) 10

stainless steel (IHS) 10

WEEE directive 2, 7

wheel block 9

wheel encoder 9, 29

positioning 16

wheels 22, 29

additional wheel installation 27

removal 23

replacement 22

shaft 23

Y

yellow tool See draw-in tool

Y-fittings 17, 18

yoke

arm 13, 29

guiding pin 13

thumbscrew 12

Index 39

Page 44

DMTA-20045-01EN, Rev. A, October 2012

40 Index

Loading...

Loading...