Olympus GLIDER User Manual

GLIDER

Two-Axis Flat Panel Scanner

User’s Manual

DMTA029-01EN — Rev. E

December 2017

This instruction manual contains essential information on how to use this Olympus product safely and effectively.

Before using this product, thoroughly review this instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Olympus Scientific Solutions Americas, 48 Woerd Avenue, Waltham, MA 02453, USA

Copyright © 2007, 2014, 2016, 2017 by Olympus. All rights reserved. No part of this

publication may be reproduced, translated, or distributed without the express written

permission of Olympus.

This document was prepared with particular attention to usage to ensure the accuracy of the

information contained therein, and corresponds to the version of the product manufactured

prior to the date appearing on the title page. There could, however, be some differences

between the manual and the product if the product was modified thereafter.

The information contained in this document is subject to change without notice.

Part number: DMTA029-01EN

Rev. E

December 2017

Printed in Canada

All brands are trademarks or registered trademarks of their respective owners and third

party entities.

DMTA029-01EN, Rev. E, December 2017

Table of Contents

Labels and Symbols ........................................................................................... 1

Important Information — Please Read Before Use ..................................... 3

Intended Use .......................................................................................................................... 3

Instruction Manual ................................................................................................................ 3

Loose Parts .............................................................................................................................. 4

Scanner Compatibility .......................................................................................................... 4

Presence of Visual Interferences or Phantom Spots ......................................................... 5

Safety Symbols ....................................................................................................................... 5

Safety Signal Words ............................................................................................................... 6

Note Signal Words ................................................................................................................. 7

Safety ....................................................................................................................................... 7

Warnings ................................................................................................................................. 7

Equipment Disposal .............................................................................................................. 8

CE (European Community) ................................................................................................. 8

WEEE Directive ...................................................................................................................... 8

Warranty Information ........................................................................................................... 9

Technical Support .................................................................................................................. 9

Introduction ...................................................................................................... 11

1. Overview ..................................................................................................... 13

2. Scanner Assembly and Setup .................................................................. 17

2.1 Assembling the Scanner ........................................................................................... 17

2.2 Part Replacement and Adjustment ........................................................................ 18

2.2.1 Replacing a Mounting Pod ........................................................................... 18

2.2.2 Installing a Vacuum Generator with Pods ................................................. 19

2.2.3 Adjusting the Orientation of the Probe Holder ......................................... 28

Table of Contents iii

DMTA029-01EN, Rev. E, December 2017

2.2.4 Installing Springs on the Bearing Arm ........................................................ 30

2.2.5 Replacing a Conventional Ultrasonic Transducer ..................................... 33

2.2.6 Replacing a Phased Array Probe ................................................................. 35

2.2.7 Changing an Encoder .................................................................................... 37

2.2.8 Changing the Length of an Axis .................................................................. 38

2.3 Scanner Installation on the Inspection Surface ..................................................... 41

2.3.1 Installing a Scanner with Suction-Cup Pods .............................................. 41

2.3.2 Installing a Scanner with Magnetic Pods .................................................... 44

2.4 Setting Up the Scanner for Inspection .................................................................... 46

3. Operating the Scanner .............................................................................. 49

4. Specifications .............................................................................................. 53

5. Accessories and Spare Parts ..................................................................... 57

5.1 Yokes ........................................................................................................................... 57

5.2 Couplant-Feed Units ................................................................................................ 58

5.3 Connector Reference ................................................................................................. 59

5.4 Spare Parts .................................................................................................................. 59

6. Maintenance ................................................................................................ 65

6.1 Preventive Maintenance ........................................................................................... 65

6.2 Unit Cleaning ............................................................................................................. 65

List of Figures ................................................................................................... 67

List of Tables ..................................................................................................... 69

Index ................................................................................................................... 71

Table of Contentsiv

List of Abbreviations

A.M. according to model

CE European Community

EC eddy current

ECA eddy current array

FSW friction stir weld

ID internal diameter

N/A not applicable

NL normal liters

OD outside diameter

OEM original equipment manufacturer

P/N part number

PA phased array

SCFM standard cubic feet per minute

UT ultrasonic testing

WEEE waste electrical and electronic equipment

DMTA029-01EN, Rev. E, December 2017

List of Abbreviations v

DMTA029-01EN, Rev. E, December 2017

List of Abbreviationsvi

DMTA029-01EN, Rev. E, December 2017

Rating label

Labels and Symbols

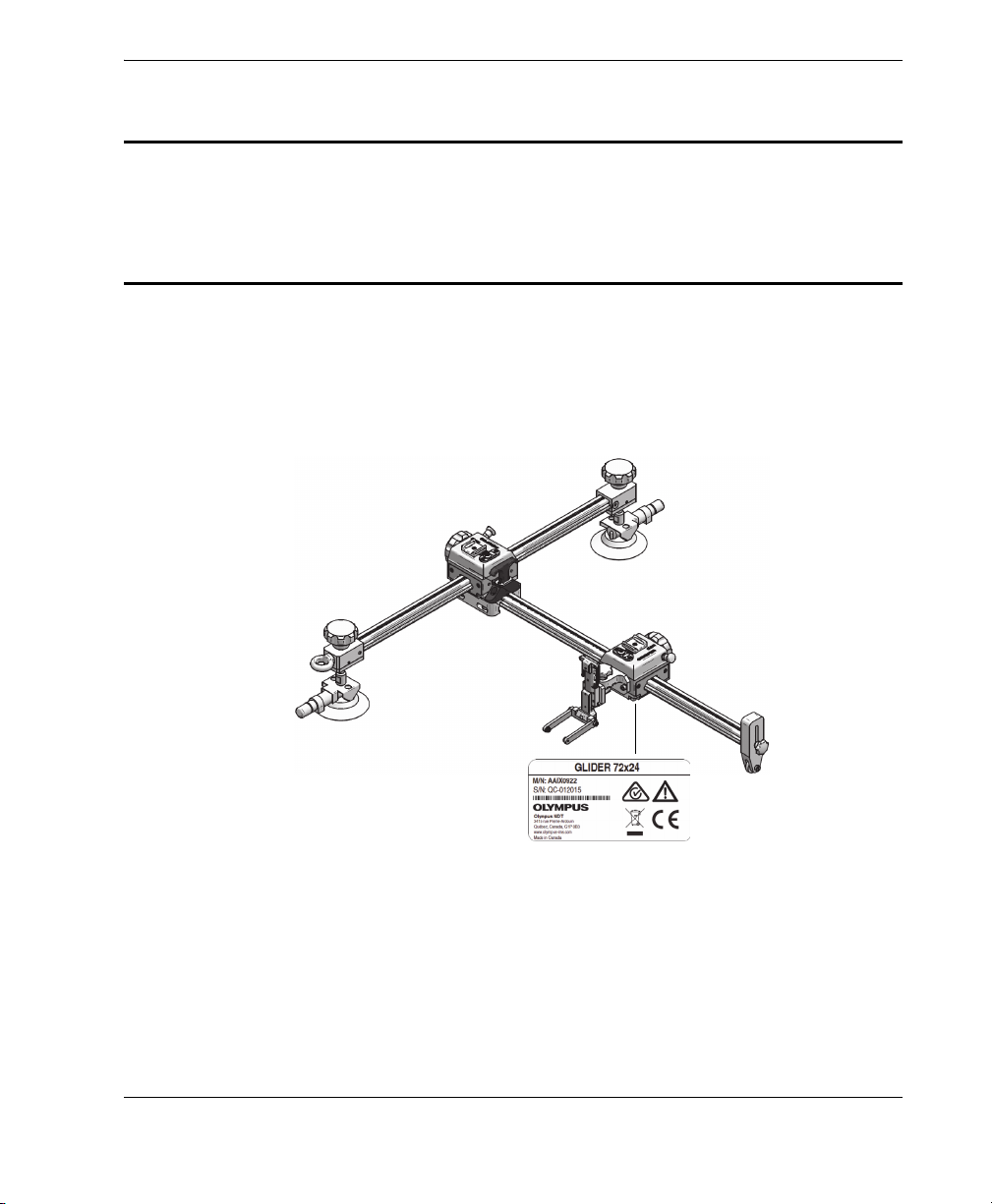

Safety-related labels and symbols are attached to the GLIDER scanner at the location

shown in Figure i-1 on page 1, with contents listed in Table 1 on page 2. If any or all of

the labels or symbols are missing or illegible, please contact Olympus.

Figure i‑1 Location of label on the GLIDER scanner

Labels and Symbols 1

DMTA029-01EN, Rev. E, December 2017

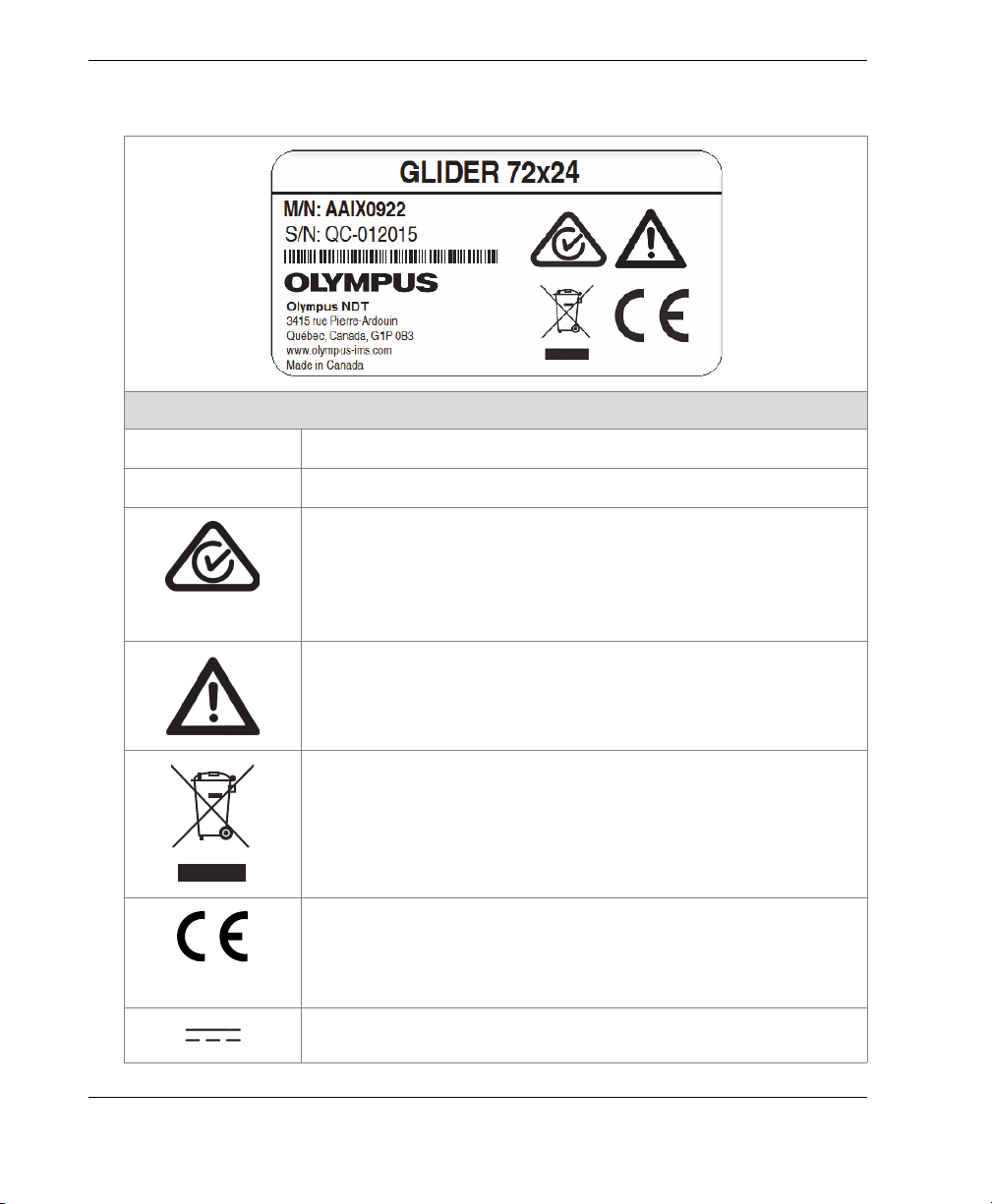

Table 1 Content of the rating label

Content

M/N

S/N

The model number is an eight (8) digit number.

The serial number is an eight (8) digit number.

The regulatory compliance mark (RCM) label indicates that

the product complies with all applicable standards, and has

been registered with the Australian Communications and

Media Authority (ACMA) for placement on the Australian

market.

The warning symbol indicates that the user must read the

user’s manual in order to find out the nature of the potential

hazards and any actions to avoid them.

The WEEE symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be

collected separately.

The CE marking is a declaration that this product conforms to

all the applicable directives of the European Community. See

the Declaration of Conformity for details. Contact your Olympus

representative for more information.

The direct current symbol.

Labels and Symbols2

DMTA029-01EN, Rev. E, December 2017

WARNING

IMPORTANT

Important Information — Please Read Before Use

Intended Use

The GLIDER scanner is designed to perform nondestructive inspections on industrial

and commercial materials.

Do not use the GLIDER scanner for any purpose other than its intended use. It must

never be used to inspect or examine human or animal body parts.

Instruction Manual

This instruction manual contains essential information on how to use this Olympus

product safely and effectively. Before using this product, thoroughly review this

instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Some of the details of components illustrated in this manual may differ from the

components installed on your instrument. However, the principles remain the same.

Important Information — Please Read Before Use 3

DMTA029-01EN, Rev. E, December 2017

WARNING

CAUTION

Loose Parts

The user is responsible for ensuring that no scanner parts have come loose or are lost

in critical mechanisms being inspected or maintained, especially in the case of aircraft.

Conduct a proper inspection before and after use to prevent foreign-object debris

(FOD) that could potentially cause equipment damage, injuries, or loss of life.

Scanner Compatibility

The GLIDER scanner is compatible with the Olympus ancillary equipment listed in

Table 2 on page 4.

Always use equipment and accessories that meet Olympus specifications. Using

incompatible equipment could cause equipment malfunction and/or damage, or

human injury.

Table 2 Ancillary equipment

Equipment Description

OmniScan PA and FOCUS LT Several types of phased array instrument model

can be used (may require one of the encoder cable

adaptors listed below).

Phased array probe and wedge Several models used. See Table 6 on page 57 for

optional holder models required according to

wedge models.

Important Information — Please Read Before Use4

DMTA029-01EN, Rev. E, December 2017

IMPORTANT

Table 2 Ancillary equipment (continued)

Equipment Description

P/N: U8775201 Scanner interface adaptor to connect scanner

encoder cables with DE15 connector to OmniScan

MX2, SX and FOCUS PX with LEMO connector

scanner interface.

P/N: U8780329 Scanner interface adaptor to connect scanner

encoder cables with LEMO connector to OmniScan

MX with DE15 connector scanner interface.

P/N: U8769010 0.3 m long adaptor LEMO female to Bendix male

linking LEMO encoder cable to FOCUS LT.

P/N: U8767107 0.3 m long adaptor DE15 female to Bendix male

linking DE15 encoder cable to FOCUS LT.

Presence of Visual Interferences or Phantom Spots

In a situation of physical proximity to powerful electromagnetic radiators, visual

interferences or phantom spots may be present. These interferences are temporary

and their persistence is not permanent in comparison with physical features of the

inspected part.

Safety Symbols

The following safety symbols might appear on the product and in the instruction

manual:

General warning symbol

This symbol is used to alert the user to potential hazards. All safety messages that

follow this symbol shall be obeyed to avoid possible harm or material damage.

Important Information — Please Read Before Use 5

DMTA029-01EN, Rev. E, December 2017

DANGER

WARNING

CAUTION

Shock hazard caution symbol

This symbol is used to alert the user to potential electric shock hazards. All safety

messages that follow this symbol shall be obeyed to avoid possible harm.

Magnetic field warning symbol

This symbol is used to alert the user to potentially strong magnetic fields. All

safety messages that follow this symbol shall be obeyed to avoid possible harm.

Safety Signal Words

The following safety signal words might appear in the documentation of the product:

The DANGER signal word indicates an imminently hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to will result in death or serious personal injury. Do not proceed beyond a

DANGER signal word until the indicated conditions are fully understood and met.

The WARNING signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to could result in death or serious personal injury. Do not proceed beyond a

WARNING signal word until the indicated conditions are fully understood and met.

The CAUTION signal word indicates a potentially hazardous situation. It calls

attention to an operating procedure, practice, or the like that if not correctly

performed or adhered to may result in minor or moderate personal injury, material

damage, particularly to the product, destruction of part or all of the product, or loss of

data. Do not proceed beyond a CAUTION signal word until the indicated conditions

are fully understood and met.

Important Information — Please Read Before Use6

DMTA029-01EN, Rev. E, December 2017

IMPORTANT

NOTE

TIP

WARNING

Note Signal Words

The following note signal words could appear in the documentation of the product:

The IMPORTANT signal word calls attention to a note that provides important

information, or information essential to the completion of a task.

The NOTE signal word calls attention to an operating procedure, practice, or the like,

which requires special attention. A note also denotes related parenthetical

information that is useful, but not imperative.

The TIP signal word calls attention to a type of note that helps you apply the

techniques and procedures described in the manual to your specific needs, or

provides hints on how to effectively use the capabilities of the product.

Safety

Before turning on the instrument, verify that the correct safety precautions have been

taken (see the following warnings). In addition, note the external markings on the

instrument, which are described under “Safety Symbols”.

Warnings

General Warnings

• Carefully read the instructions contained in this instruction manual prior to

• Keep this instruction manual in a safe place for further reference.

turning on the instrument.

Important Information — Please Read Before Use 7

DMTA029-01EN, Rev. E, December 2017

• Follow the installation and operation procedures.

• It is imperative to respect the safety warnings on the instrument and in this

instruction manual.

• If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment could be impaired.

• Do not install substitute parts or perform any unauthorized modification to the

instrument.

Equipment Disposal

Before disposing of the GLIDER scanner, check your local laws, rules, and

regulations, and follow them accordingly.

CE (European Community)

This device complies with the requirements of both directive

2014/30/EU concerning electromagnetic compatibility and directive

2014/35/EU concerning low voltage. The CE marking indicates

compliance with the above directives.

WEEE Directive

Important Information — Please Read Before Use8

In accordance with European Directive 2012/19/EU on Waste Electrical

and Electronic Equipment (WEEE), this symbol indicates that the

product must not be disposed of as unsorted municipal waste, but

should be collected separately. Refer to your local Olympus distributor

for return and/or collection systems available in your country.

DMTA029-01EN, Rev. E, December 2017

Warranty Information

Olympus guarantees your Olympus product to be free from defects in materials and

workmanship for a specific period, and in accordance with conditions specified in the

Olympus Scientific Solutions Americas Inc. Terms and Conditions available at

http://www.olympus-ims.com/en/terms/.

The Olympus warranty only covers equipment that has been used in a proper

manner, as described in this instruction manual, and that has not been subjected to

excessive abuse, attempted unauthorized repair, or modification.

Inspect materials thoroughly on receipt for evidence of external or internal damage

that might have occurred during shipment. Immediately notify the carrier making the

delivery of any damage, because the carrier is normally liable for damage during

shipment. Retain packing materials, waybills, and other shipping documentation

needed in order to file a damage claim. After notifying the carrier, contact Olympus

for assistance with the damage claim and equipment replacement, if necessary.

This instruction manual explains the proper operation of your Olympus product. The

information contained herein is intended solely as a teaching aid, and shall not be

used in any particular application without independent testing and/or verification by

the operator or the supervisor. Such independent verification of procedures becomes

increasingly important as the criticality of the application increases. For this reason,

Olympus makes no warranty, expressed or implied, that the techniques, examples, or

procedures described herein are consistent with industry standards, nor that they

meet the requirements of any particular application.

Olympus reserves the right to modify any product without incurring the

responsibility for modifying previously manufactured products.

Technical Support

Olympus is firmly committed to providing the highest level of customer service and

product support. If you experience any difficulties when using our product, or if it

fails to operate as described in the documentation, first consult the user’s manual, and

then, if you are still in need of assistance, contact our After-Sales Service. To locate the

nearest service center, visit the Service Centers page at: http://www.olympusims.com.

Important Information — Please Read Before Use 9

DMTA029-01EN, Rev. E, December 2017

Important Information — Please Read Before Use10

DMTA029-01EN, Rev. E, December 2017

Introduction

This manual contains instructions on assembling, installing, and operating the

GLIDER scanner.

The GLIDER scanner has two axes of motion: the X-axis and the Y-axis. Encoders, one

on each axis, provide precise position information. The scanner is used for inspecting

slightly curved and flat surfaces. It uses a single probe or transducer, which can vary

in type:

• A conventional ultrasonic (UT) transducer or phased array ultrasonic (PA) probe.

• An eddy current (EC) probe or eddy current array (ECA) probe. The probe holder

for the eddy current type of probe is not included with the scanner, however.

Typical applications include the inspection of plates and airplane fuselages for

delamination, cracks, and corrosion, as well as the inspection of friction stir welds

(FSW) on aluminum. The scanner is well suited for raster scanning with a single probe

or transducer.

Commonly inspected materials include composites, aluminum, and carbon steel.

Suction-cup mounting pods are used to hold the scanner against the inspection

surface. On ferromagnetic materials such as steel, however, optional magnetic

mounting pods are used to hold the scanner.

To help users understand and safely use the scanner, this manual provides the

following subject matter:

• An overview of main components

• Setup and operation

•Maintenance

• Specifications

Introduction 11

DMTA029-01EN, Rev. E, December 2017

Introduction12

DMTA029-01EN, Rev. E, December 2017

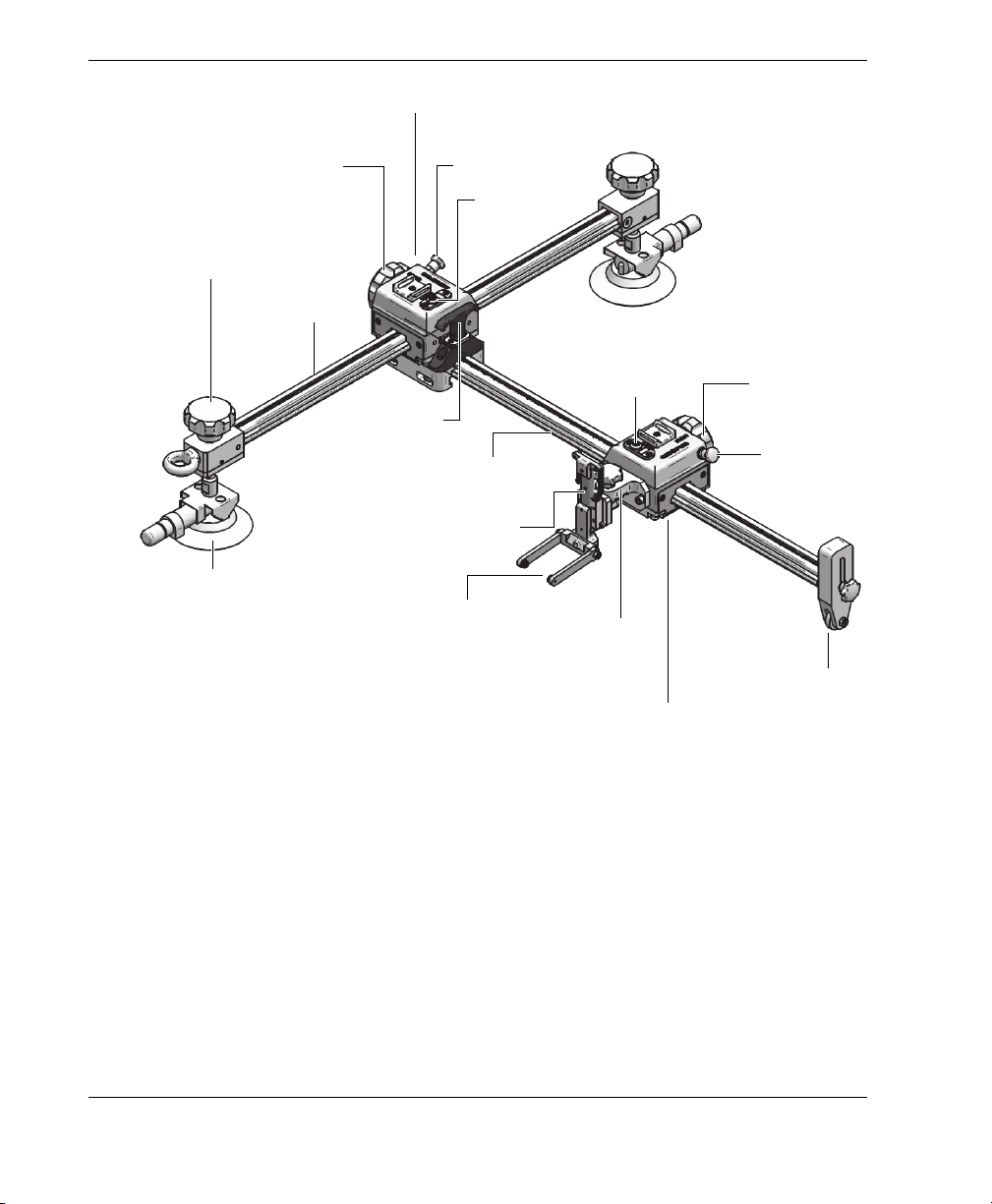

1. Overview

This chapter provides an overview of the components on the GLIDER scanner.

The scanner’s X-axis is secured to the inspection surface by either suction cups or

magnetic pods (sold separately). The probe (or transducer) holder moves along the Yaxis. Between inspection passes along one of the axes, the probe or transducer can be

either incremented in fixed steps or moved freely along the other axis to perform a

raster scan.

The GLIDER scanner is made up of three main component groups:

• Mounting pods (either suction-cup pods or magnetic pods)

• X-axis encoder module

• Y-axis encoder module

The elements of these main groups are illustrated in Figure 1-1 on page 14; a detailed

description follows.

Overview 13

DMTA029-01EN, Rev. E, December 2017

Mounting pod

X-axis encoder module

Y-axis encoder module

Pivot lock for mounting

pod

X-axis

X-axis increment knob

X-axis lock

Y- ax is

Y- ax is

increment knob

Y- ax is

lock

Y-a xi s

support

Probe or transducer

holder

Mounting bracket for

probe or transducer

holder

Encoder 1

Encoder 2

Y-axis quick release

Bearing arm

Mounting pods

Chapter 114

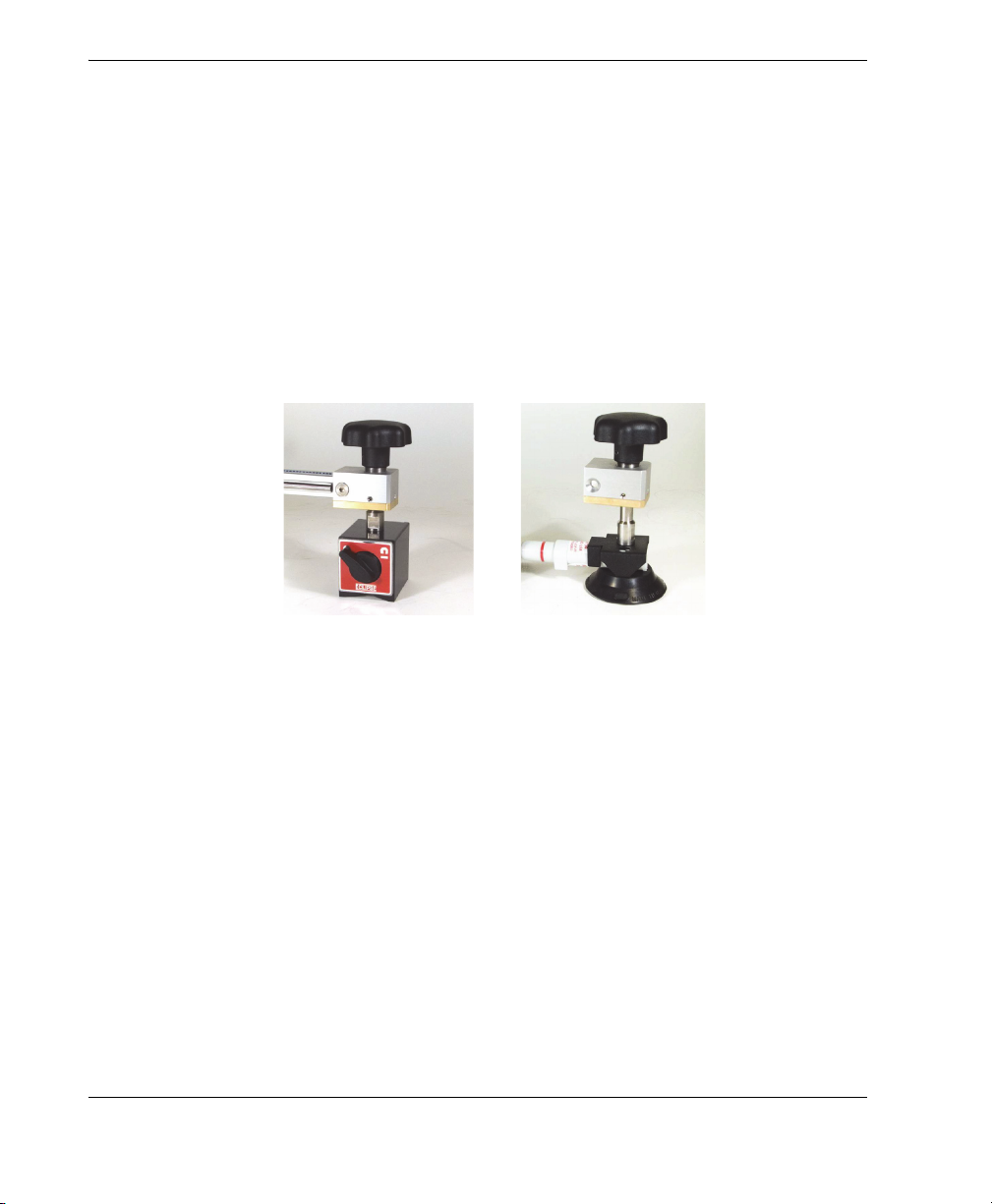

The X-axis is attached to two mounting pods that hold the scanner against the

inspection surface. Depending on the material to inspect, one of the following pod

types can be used (see Figure 1-2 on page 15): suction-cup pods (manual type

included) or magnetic pods (optional).

An optional vacuum generator with special suction cups is also available (for

more details, see “Installing a Vacuum Generator with Pods” on page 19).

Figure 1‑1 Scanner components

DMTA029-01EN, Rev. E, December 2017

Figure 1‑2 Mounting pod models: optional magnetic (left) and manual suction

cup (right)

The following features are common to both the X-axis and the Y-axis encoder

modules:

• Wheels, which are mounted on bearings that provide a smooth movement during

the entire axis stroke.

• Encoders, which measure the probe position along the axes (encoder resolution is

marked on the module).

• Locking devices, which allow each axis to be locked.

• Increment knobs, which can be set to either increment the axes in 4 mm steps, or

to provide a free-running motion (see Figure 1-3 on page 15).

Figure 1‑3 Increment‑knob positions: incrementing (left) and free‑running (right)

Overview 15

DMTA029-01EN, Rev. E, December 2017

X-axis encoder module

In addition to the common features listed above, the X-axis encoder module is

equipped with a quick-release device for the Y-axis, which allows you to

position the Y-axis with respect to the X-axis.

Y-axis encoder module

In addition to the common features listed above, the Y-axis encoder module

includes a mounting surface for the probe (or transducer) holder.

To help stabilize the Y-axis, one end rests on a height-adjustable support that

is equipped with a wheel.

The scanner components are stored in a custom case (see Figure 1-4 on page 16).

Figure 1‑4 Scanner components stored in the case

Chapter 116

DMTA029-01EN, Rev. E, December 2017

2. Scanner Assembly and Setup

The GLIDER scanner is designed for ease of assembly, servicing, installation, and

setup.

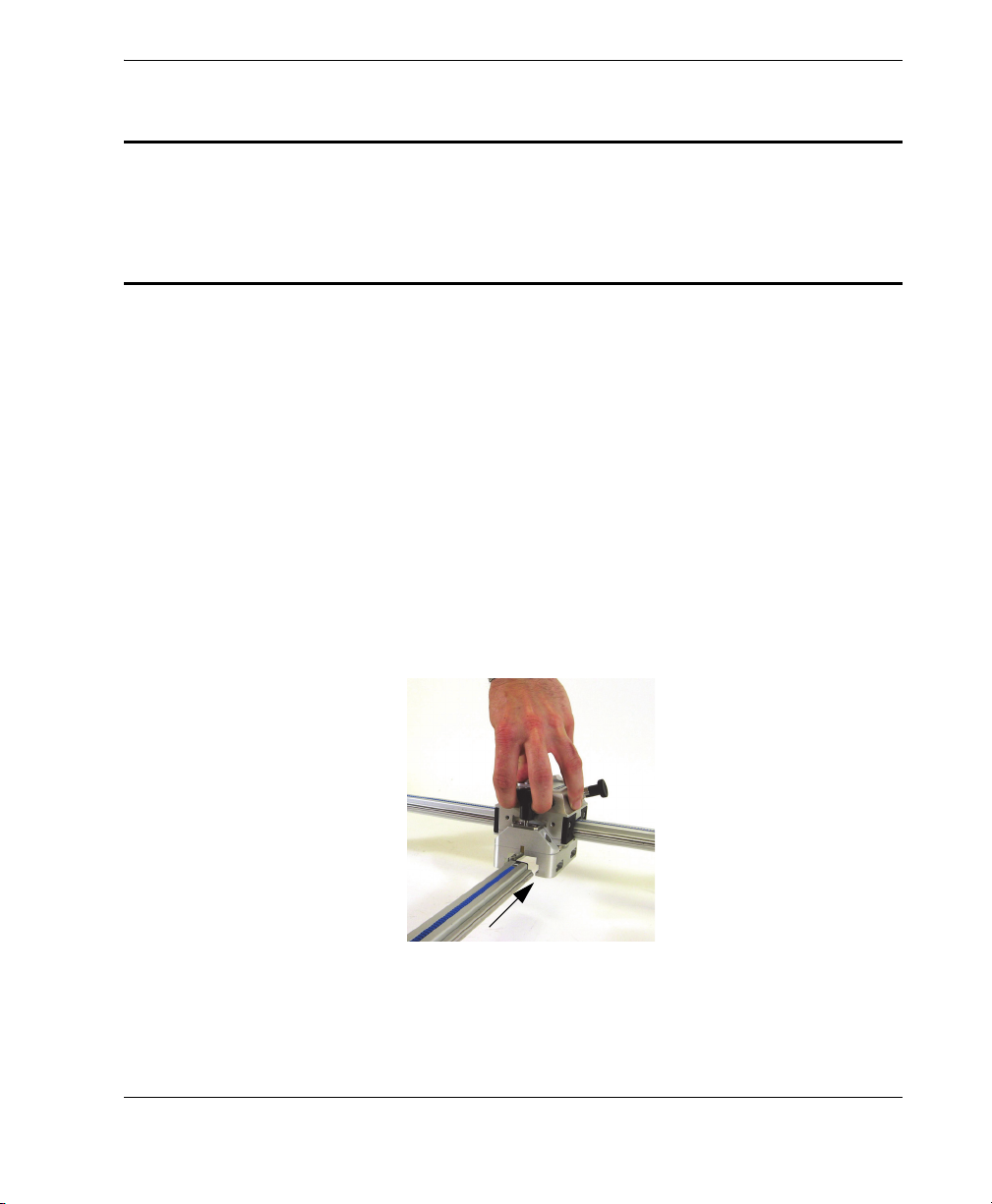

2.1 Assembling the Scanner

To assemble the scanner, simply insert the Y-axis into the X-axis module.

To insert the Y-axis into the X-axis module

1. Pull up on the Y-axis quick release device (see Figure 2-1 on page 17).

2. Slide the Y-axis into the X-axis module.

Figure 2‑1 Inserting the Y‑axis into the X‑axis module

3. Release the quick-release device.

Scanner Assembly and Setup 17

DMTA029-01EN, Rev. E, December 2017

2.2 Part Replacement and Adjustment

This section contains procedures for replacing or adjusting the bearing arm springs,

the mounting pods, the probe or transducer holders, and the encoders.

2.2.1 Replacing a Mounting Pod

The following procedure is valid for both the manual suction-cup model and the

magnetic-pod model (see Figure 2-2 on page 18). For details on mounting pods used

with an optional vacuum generator, see “Installing a Vacuum Generator with Pods”

on page 19.

Figure 2‑2 Mounting pod models: optional magnetic (left) and manual suction

cup (right)

To replace a mounting pod

1. Remove the screws at the locations shown in Figure 2-3 on page 19.

Chapter 218

Loading...

Loading...