Page 1

PUS

GIF

,,,,XP

OES

GASTROINTESTINAL

WARNING

The user of this equipment should be thoroughly trained in the applicable

procedure. Furthermore, failure to read and thoroughly understand the

contents of this instruction manual may result in

patient and/or user. It is essential to follow the instructions contained

this and other manuals which pertain to any equipment and accessories

used in conjunction with the procedures. Possible injuries related to

endoscopic procedures may include perforation,

shock, hemorrhage, infection, explosion, etc.

Failure to follow these instructions may also result in damage to

malfunction of the instrument.

FIBERSCOPE

sefious injury to the

in

eleflrical burns and

andlor

Page 2

IMPOR

The Olympus GIF-XPIO has been designed for endoscopic diagnosis and treatment within the upper digestive

tract including esophagus, stomach and duodenum. Do not use the instrument for any purpose other than its

intended application.

Please read this entire manual carefully before using the instrument. It contains pertinent information on

the proper care and handling of your new fiberscope. Although fiberscopes by nature are delicate instruments,

proper handling and cleaning, as described in this manual, will greatly reduce the need for costly repair and

prolong the life of your new instrument.

This manual describes the recommended procedure for preparing and inspecting the equipment prior to use,

It does not describe how an actual procedure is to be performed in detail.

a beginner with endoscopic technique and the medical aspects of

should be used only by physicians who have received thorough previous training in the art of flexible endoscopy.

TANT

Nor does it attempt to acquaint

gastroenterologicaI endoscopy. This instrument

The safety and performance of an endoscopic system depends not only on the fiberscope but also on any ancil-

it

lary equipment used with it. To insure compatibility,

with this fiberscope.

lf you have any questions about the operation, safety or any of the material contained in this manual, please

con tact your Olympus representative or the nearest Olympus office.

is recommended that you use only Olympus accessories

Page 3

UPON RECEIVING THE EQUIPMENT

Hold

fiberscope

with

both

hands.

Please check each item in the set against the list of standard components found in Section

if there are any missing or defective parts. Refer to the following sections on

MAIN SPECIFICATIONS AND

3.

Contact Olympus

NOMENCLATURE to become acquainted with the name and function of each part of the instrument. Review

the instrument preparation, inspection and

cleaning/disinfecting procedures carefully. The fiberscope should be

disinfected prior to its initial use.

The fiberscope and accessories should be removed from the carrying case and stored asdescribed in Section

Storage.

The carrying case is not intended to be used for storage of the equipment. Retain the carrying case

6-4

only for shipping or transporting the instrument.

.P$

Remove the

ETO

cap (venting cap) from the fiberscope and store in an appropriate place.

PRIOR TO USE

In addition to thoroughly reading this manual, refer also to the instruction manuals supplied with your light

source, electrosurgical unit, accessories and other ancillary equipment.

CAUTION:

The GIF-XP10 is a precision instrument. Its design incorporates many features to insure patient safety.

cular, the angulation system is constructed to provide smooth response and maximal angulation of the distal tip

when normal force is applied to the angulation control knobs. Excessive pressure applied to the angulation

control knobs will result in damage to the fiberscope and may cause patient injury.

Before introducing the instrument into the patient be certain that the angulation control locks are in the "Free"

("F")

position and that the distal tip moves without resistance. If abnormal resistance is encountered when

introducing the instrument or when operating the angulation mechanism, DO NOT USE THE INSTRUMENT.

Contact your Olympus representative or the nearest Olympus office.

In parti-

Page 4

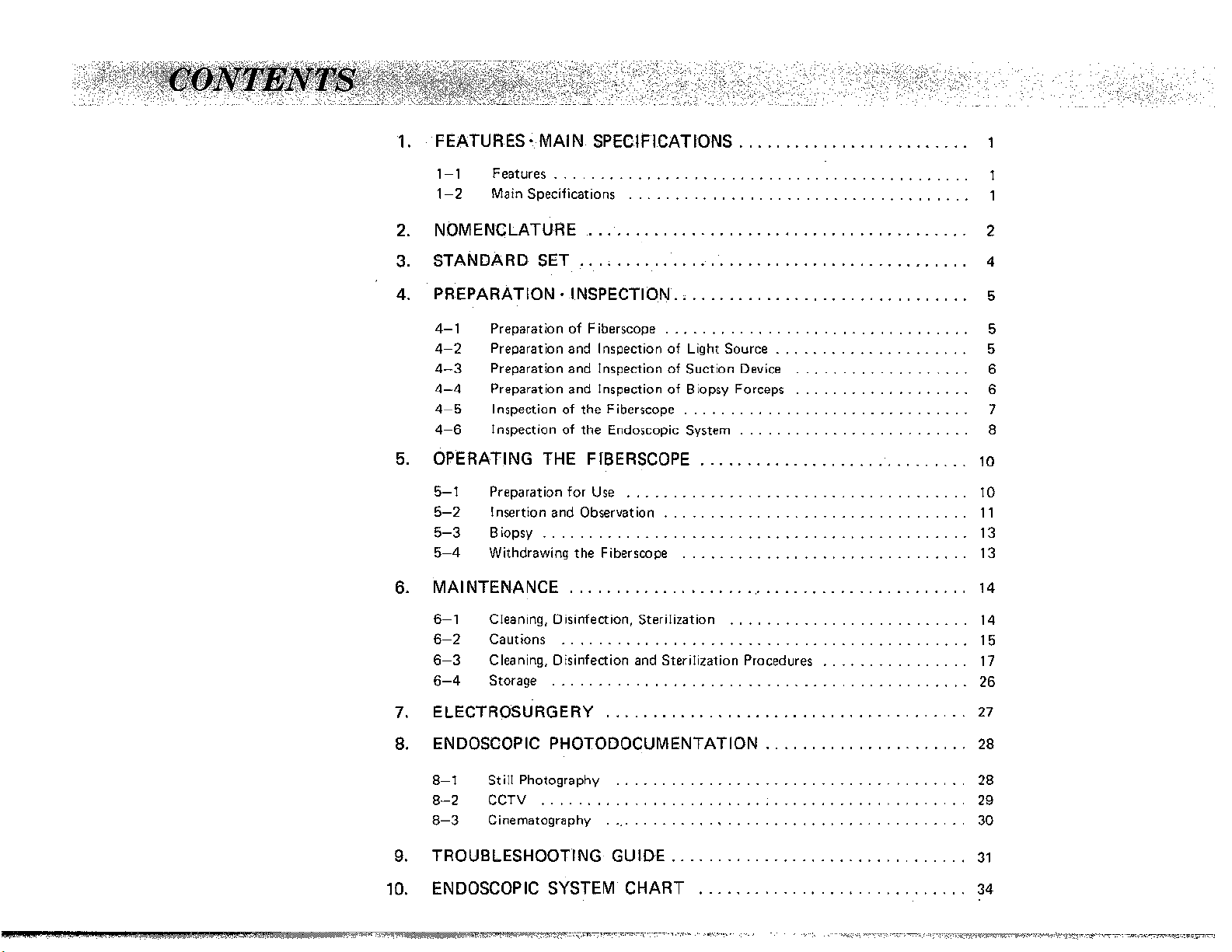

CONTENTS

1

.

FEATURES . MAIN SPECIFICATIONS

.........................

1

1-1

1-2

2

.

NOMENCLATURE

.

3

STANDARD SET

.

4

PREPARATION INSPECTION

4-1

4-2

4-3

4-4

4-5

4-6

5 .

OPERATING THE FIBERSCOPE

5-1

5-2

5-3

5-4

6-1

6-2

6-3

6-4

Features

Main Specifications

.............................................

.........................................

..........................................

.

Preparation of Fiberscope

Preparation and Inspection of Light Source

Preparation and Inspection of Suction Device

Preparation and Inspection of Biopsy Forceps

Inspection of the Fiberscope

Inspection of the Endoscopic System

Preparation for Use

l nsertion and Observation

Biopsy

Withdrawing the Fiberscope

Cleaning. Disinfection. Sterilization

Cautions

Cleaning. Disinfection and Sterilization Procedures

Storage

..............................................

............................................

............................................

1

.....................................

................................

.................................

.....................

...................

...................

...............................

.........................

.............................

.....................................

.................................

...............................

..........................

................

1

2

4

5

5

5

6

6

7

8

10

10

11

13

13

14

15

17

26

8 .

ENDOSCOPIC PHOTODOCUMENTATION

8-1

8-2

8-3

9

.

TROUBLESHOOTING GUIDE

.

10

ENDOSCOPIC SYSTEM CHART

Still Photography

CCTV

Cinematography

..............................................

......................

......................................

........................................

................................

.............................

28

28

29

30

31

34

Page 5

I

FEATURESeMAIN SPECIFICATIONS

I-1

Features

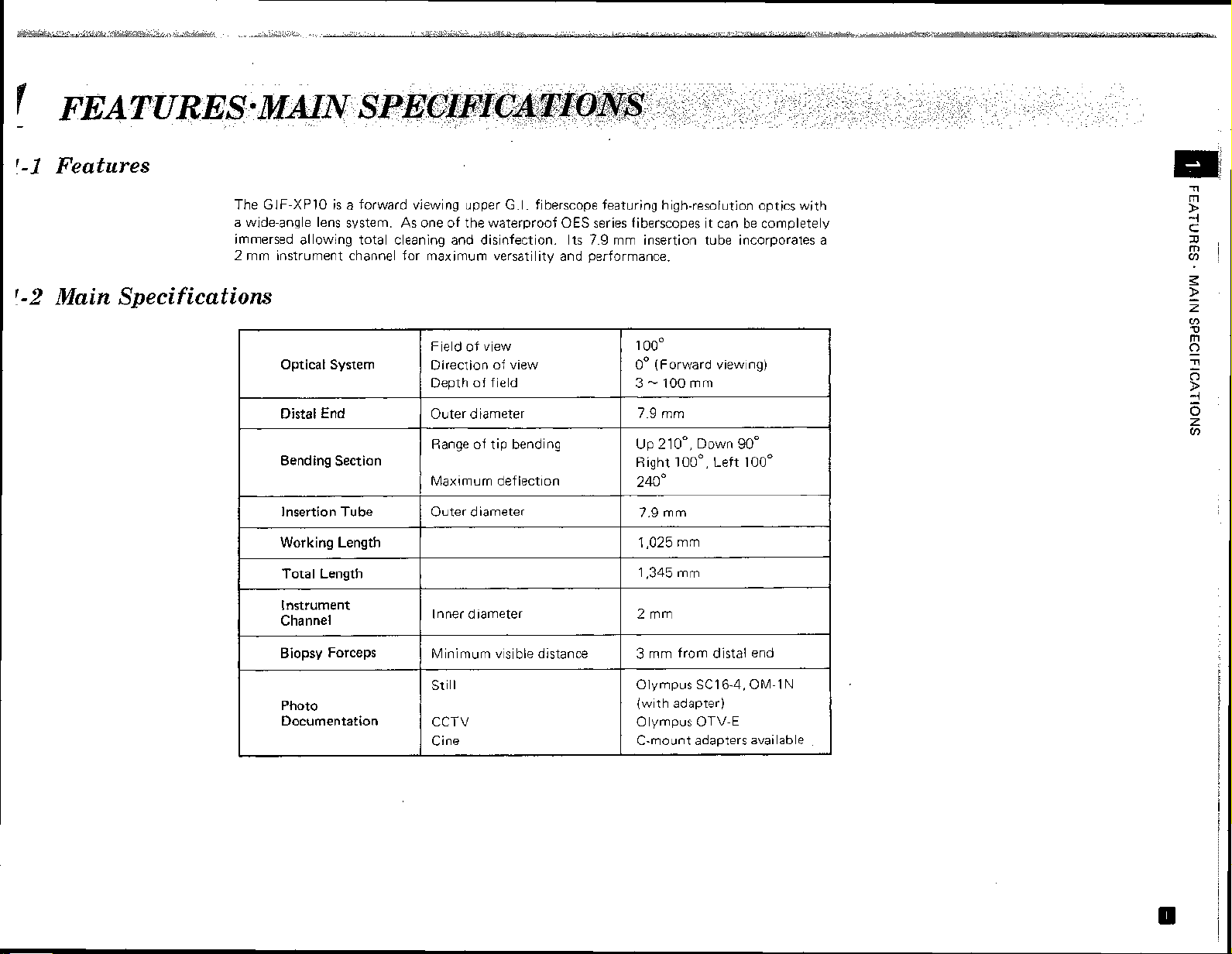

The

1-2

Main Specifications

GIF-XP10

a wide-angle lens system. As one of the waterproof OES series fiberscopes it can be completely

immersed allowing total cleaning and disinfection.

2

mm instrument channel for maximum versatility and performance.

is a forward viewing upper G.I. fiberscope featuring high-resolution optics with

mm insertion tube incorporates a

Its 7.9

Optical System

Distal End

Bending Section

Insertion Tube

Working Length

Total Length

l nstrument

Channel

Biopsy Forceps

Photo

Documentation

Field of view

Direction of view

Depth of field

Outer diameter 7.9 mm

Range of tip bending Up 21

Maximum deflection

Outer diameter 7.9 mm

Inner diameter

Minimum visible distance

Still

CCTV Olympus OTV-E

Cine C-mount adapters available

1

00°

0"

(Forward viewing)

3

-

100

mm

oO,

Down

90'

Right

loo0,

Left

100'

240'

1,025

mm

1,345 mm

2

mm

3

mm from distal end

Olympus SC16-4, OM-I

(with adapter)

N

Page 6

&

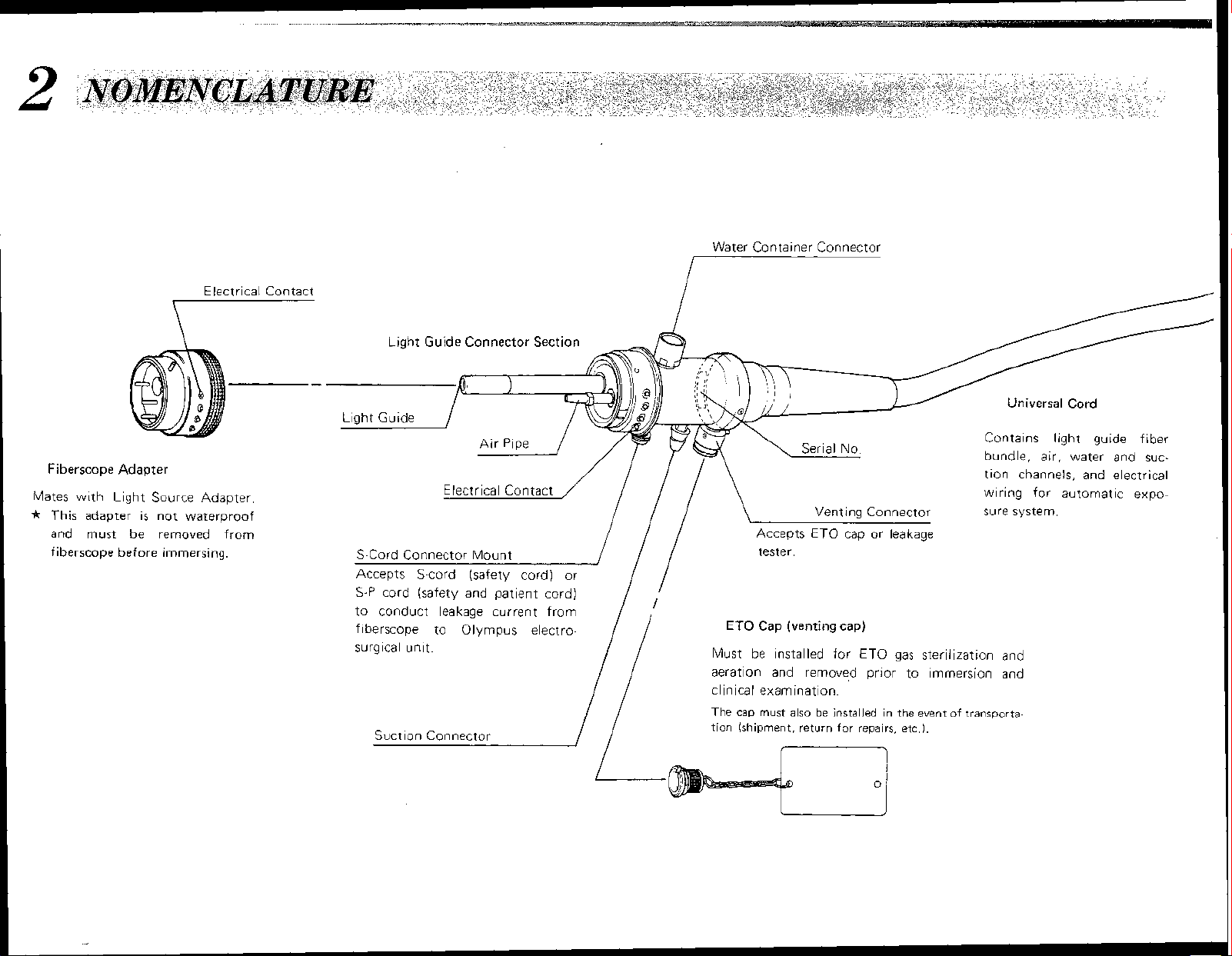

NOMENCLATURE

Water Container Connector

7

Electrical Contact

7

Fiberscope

Mates

*

This

and must be removed from

fiberscope before immersing.

Adapter

w~th Light Source Adapter

adapter

is

not waterproof

Light Guide Connector Section

Electrical Contact

S-Cord Connector Mount

Accepts S-cord (safety cord) or

S-P

cord (safety and patient cord)

to conduct leakage current from

fiberscope to

surgical unit.

Suction Connector

Olyrnpus electro-

/

!/

------/

/ /

/

\

Accepts

tester.

€TO

Cap

Must be installed for ETO gas sterilization and

aeration and removed prior to immersion and

clinical examination.

The cap must also be installed in the event

tion (shipment, return

Venting Connector

ETO

cap or leakage

(venting cap)

for

repairs, etc.).

of

\

Universal Cord

Contains light guide fiber

bundle, air, water and suction channels, and electrical

wiring for automatic exposure system

transporta-

Page 7

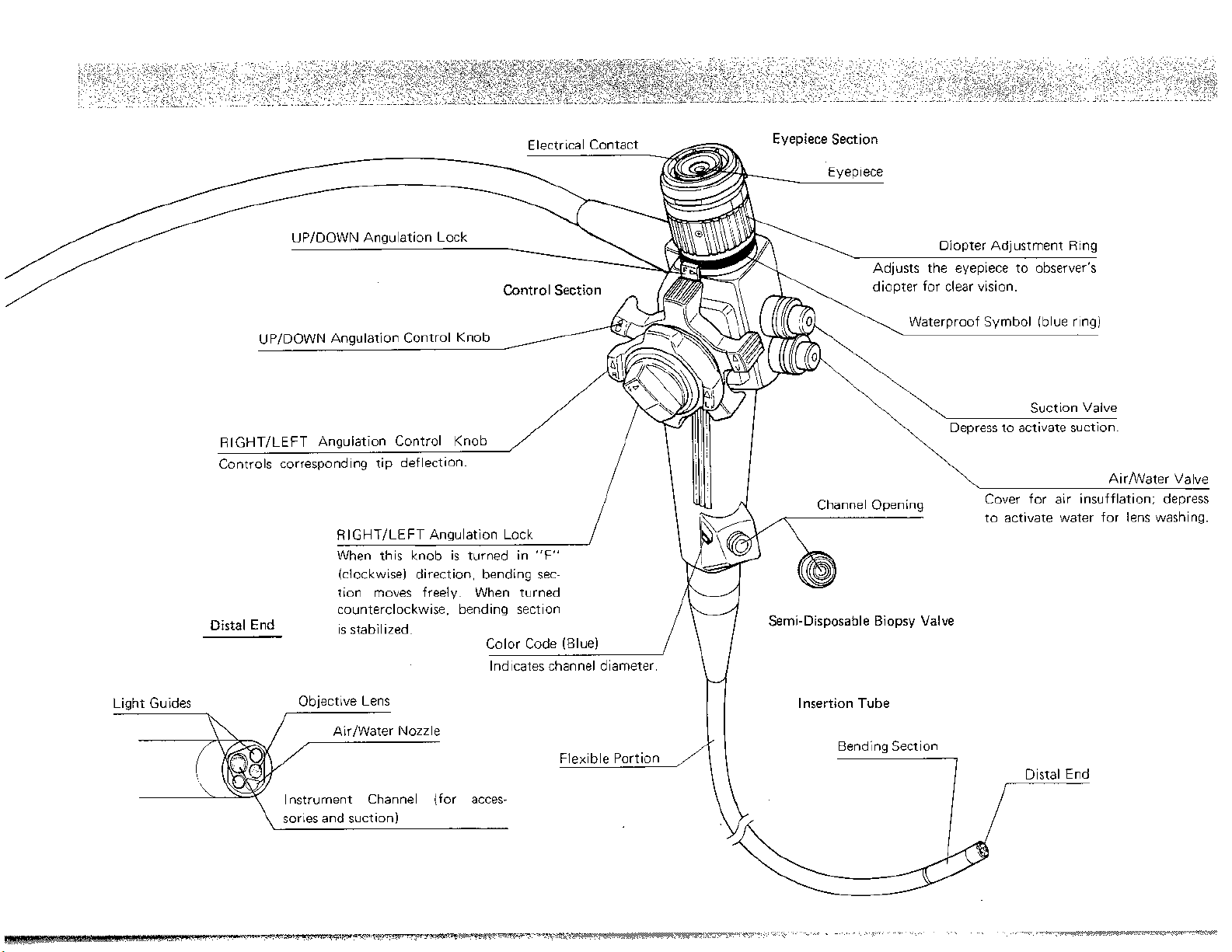

UPIDOWN Angulatio

Controls corresponding tip deflection.

Control Section

Eyepiece Section

Eyepiece

8

Diopter Adjustment Ring

Adjusts the eyepiece to observer's

diopter for clear vision.

Cover for air insufflation; depress

to activate water for lens washing.

When this knob is turned in

(clockwise) direction, bending sec-

tion moves freely. When turned

counterclockwise, bending section

Distal End

Light Guides Objective Lens

h

Instrument Channel (for acces-

\

sories and suction)

is stabilized.

"F"

Color Code (Blue)

Indicates channel diameter.

'

\

/

rl

Semi-Disposable Biopsy Valve

Insertion Tube

Page 8

3

O

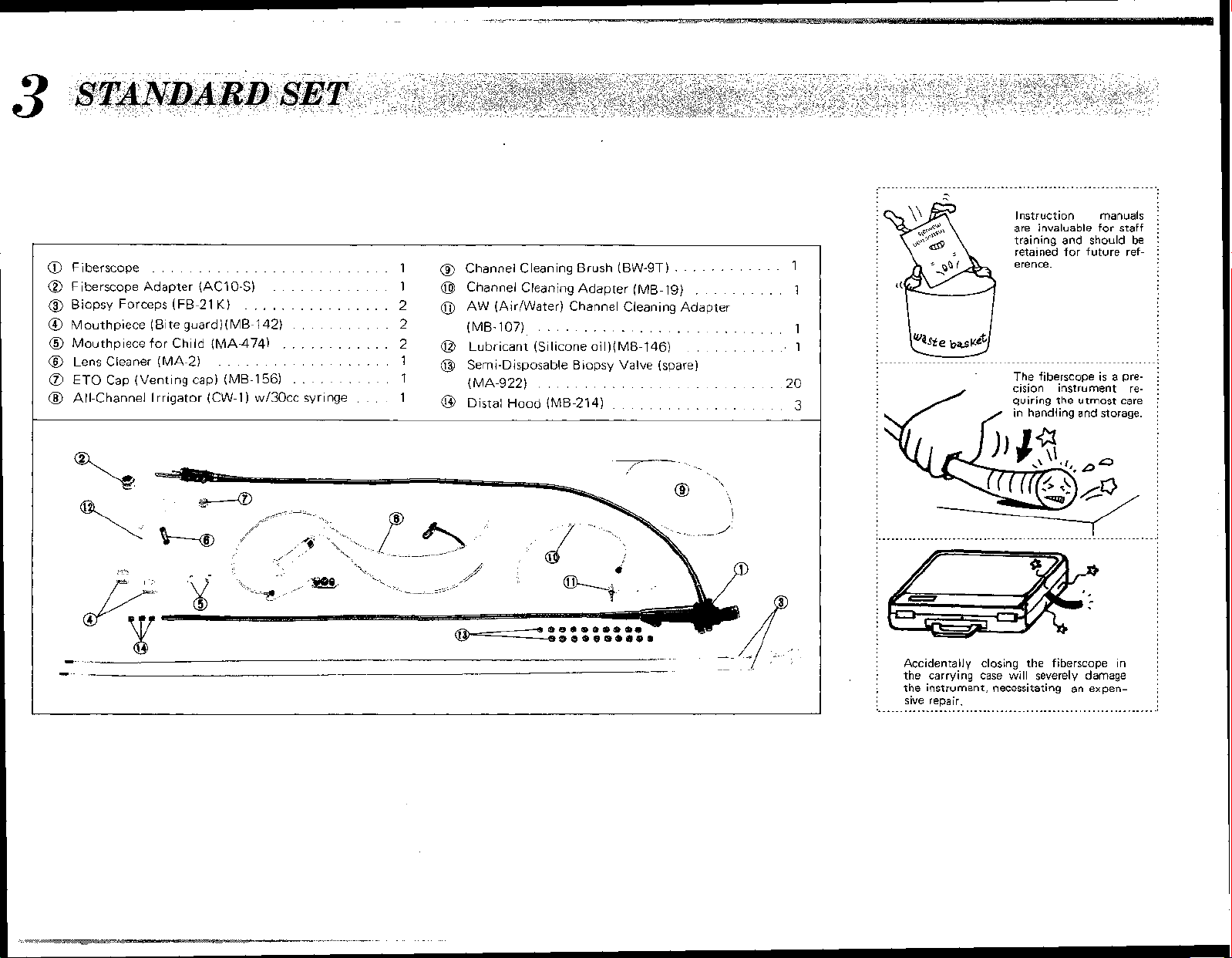

STANDARDSET

Fiberscope

@

Fiberscope Adapter (AC10-S)

@

Biopsy Forceps (FB-21

@

Mouthpiece (Bite guard) (MB-142)

@

Mouthpiece for Child (MA-474)

@

Lens Cleaner (MA-2)

a

ETO

@

All-Channel Irrigator (CW-1) wl30cc syringe

..........................

............

K)

................

............

..................

Cap (Venting cap) (ME-1

56)

..........

...........

...

1

@

Channel Cleaning Brush (BW-ST) 1

1

@

Channel Cleaning Adapter (MB-19)

2

0

AW (Air/Water) Channel Cleaning Adapter

2

2

1

1 (MA-922)

1

(MB-107)

@

Lubricant (Silicone oil)(MB-146)

@

Semi-Disposable Biopsy Valve (spare)

@

Distal ~~~d (MB-214)

............

..........

...........................

............

.........................

...................

1

1

1

.20

3

,*"aL*

';,,,.,\+'

I

Accidentally closing the fiberscope in

the carrying case

j

:

the instrument, necessitating an expen-

j

sive repair.

m

.............................................................

Instruction manuals

are invaluable for staff

training and should be

retained for future reference.

'

The fiberscope is a precision instrument requiring the utmost care

in handling and storage.

will

severely damage

Page 9

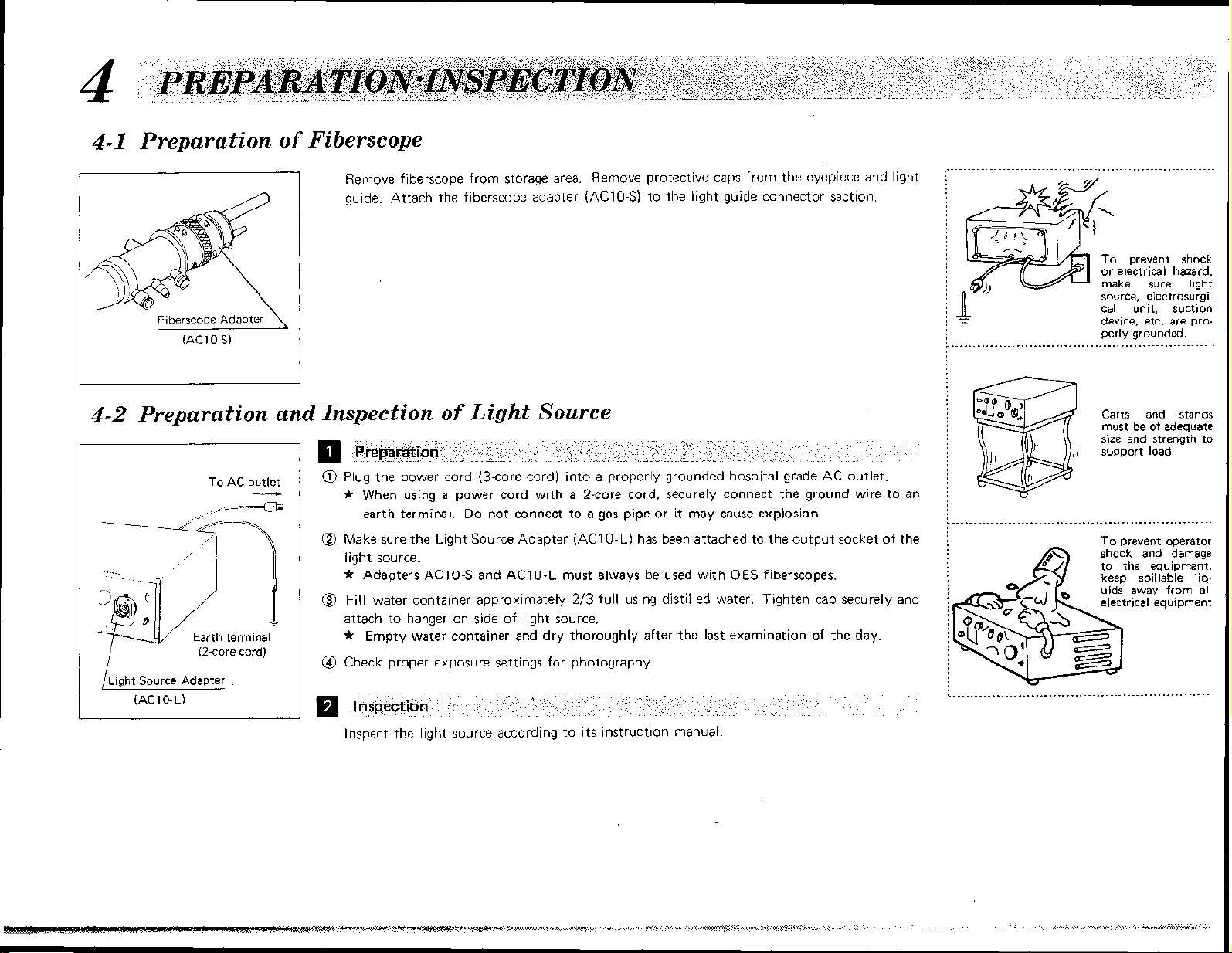

4-1

Preparation of Fiberscope

Remove fiberscope from storage area. Remove protective caps from the eyepiece and light

guide. Attach the fiberscope adapter

(AC10-S) to the light guide connector section.

n

To prevent shock

or electrical hazard,

make sure light

source, electrosurgical unit, suction

device, etc. are properly grounded.

4-2

Preparation and Inspection of Light Source

r

I

/Liclht Source Adapter

L

To AC outlet

__C

//====-EL=

Earth term~nal

(2-core cord)

-

Preparation

a

Plug the power cord (3-core cord) into a properly grounded hospital grade AC outlet.

t

When using a power cord with a 2-core cord, securely connect the ground wire to an

earth terminal. Do not connect to a gas pipe or it may cause explosion.

@

Make sure the Light Source Adapter (AC10-L) has been attached to the output socket of the

light source.

.r$

Adapters

@

Fill water container approximately 213 full using distilled water. Tighten cap securely and

attach to hanger on side of light source.

+

Empty water container and dry thoroughly after the last examination of the day.

Check proper exposure settings for photography

!

inspection

Inspect the light source according to its instruction manual.

AC10-S

and

AC10-L

must always be used with

OES

fiberscopes.

Carts and stands

must be of adequate

size and strength to

support load.

To prevent operator

shock and damage

he equipment,

Page 10

4-3

Preparation and Inspection of Suction Device

@

Connect the power cord of suction device to the

-

earth terminal

The suction device must be in safe and proper working condition.

@

lnspect the suction device following its operating manual.

@

Connect the suction tube to the suction device and to the suction connector on the light

guide section of the fiberscope.

@

Turn on suction device. Suction is controlled by the fiberscope's suction valve.

see page

5)

following its operating manual.

AZ

mains (and the ground wire to the

4-4

I

Preparation and Inspection of Biopsy Forceps

l

nspecting forceps operation

Open

-

-

Close

I)

Preparation

Select proper biopsy forceps for fiberscope being used. (Refer to the System Chart, page

*

Always have spare forceps available.

Inspection

Biopsy forceps should be inspected before each use

@

Form a loop in the biopsy forceps approximately 20cm in. diameter. Make sure that the

forceps cups open and close smoothly when the handle is lightly operated.

@

Inspect snares, etc., following individual instruction manuals.

@

If there

etc., the item should be replaced with a new one.

8

*

is

any irregularity in the operation or external appearance of a forceps, snare,

Replace bent or kinked accessories.

All Olympus accessories have been designed and manufactured with utmost care. Due

to the delicate nature of the

safe nor economical to repair endoscopic accessories. In the interest of patient safety,

policy

is

Olympus'

individuals should not be attempted.

to replace rather than repair these items. Repair by unauthorized

small precision parts involved,

!

it

is

considered neither

35.)

Any accessory which

its

along

will be difficult to pass through the

fiberscope, and must be replaced.

.............................................................

shaft will not operate smoothly,

is

kinked or bent

Page 11

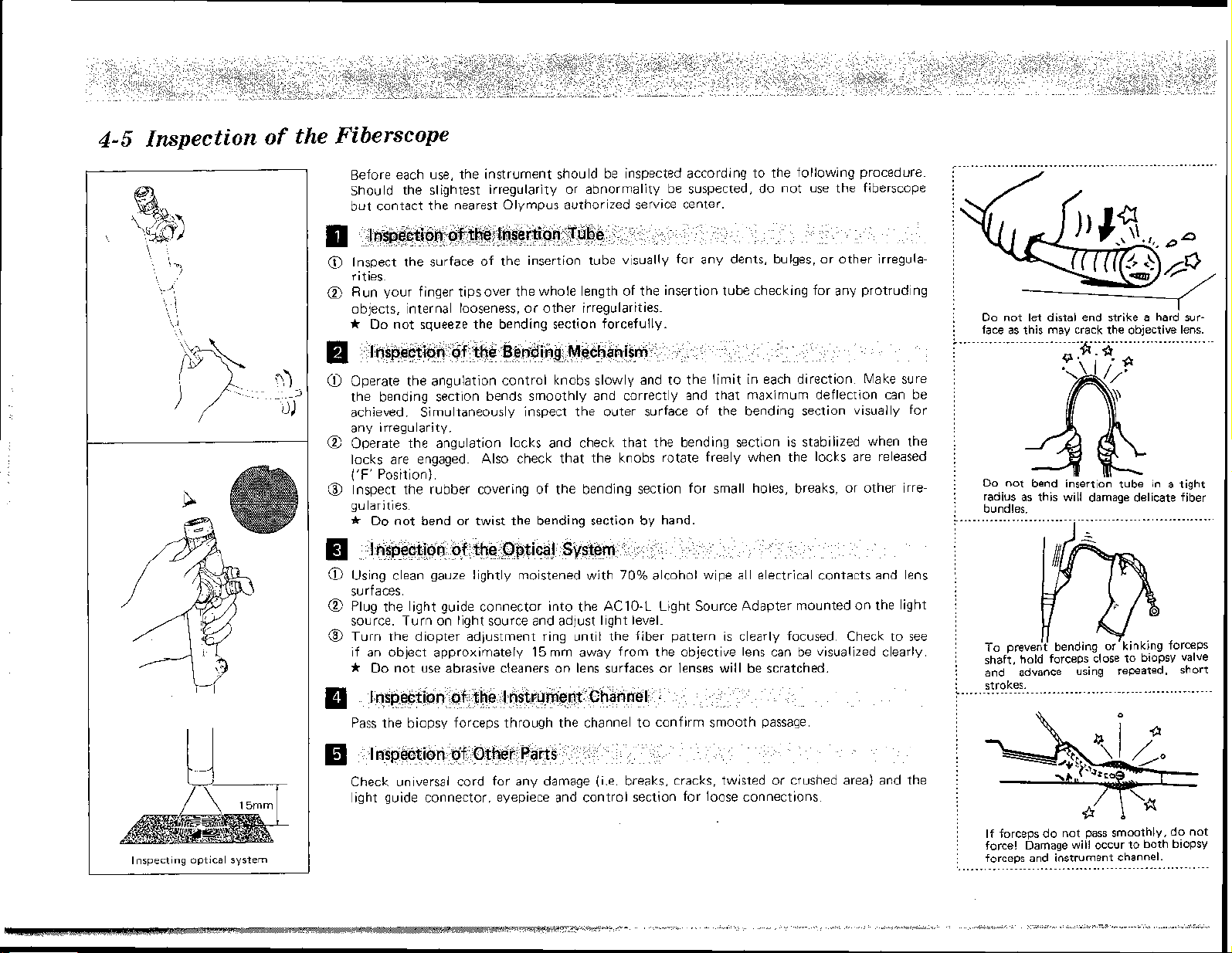

4-5

Inspection

of

the Fiberscope

Before each use, the instrument should be inspected according to the following procedure.

Should the slightest irregularity or abnormality be suspected, do not use the fibersco~e

but contact the nearest Olympus authorized service center.

El

@

Inspect the surface of the insertion tube visually for any dents, bulges, or other irregula-

rities.

@

Run your finger tips over the whole length of the insertion tube checking for any protruding

objects, internal looseness, or other irregularities.

@

Operate the angulation control knobs slowly and to the limit in each direction. Make sure

the bending section bends smoothly and correctly and that maximum deflection can be

achieved. Simultaneously

any irregularity.

@

Operate the angulation locks and

locks are engaged.

('F'

@

Position).

Inspect the rubber covering of the bending section for small holes, breaks, or other irregularities.

a$

Do not bend or twist the bending section by hand.

a

@

Using clean gauze lightly moistened with

surfaces.

@

Plug the light guide connector into the AC10-L Light Source Adapter mounted on the light

source. Turn on light source and adjust light level.

@

Turn the diopter adjustment ring until the fiber pattern

if an object approximately 15mm away from the objective lens can be visualized clearly.

-&

Do not use abrasive cleaners on lens surfaces or lenses will be scratched.

Inspection

p

Pass the biopsy forceps through the channel to confirm smooth passage.

inspect the outer surface of the bending section visually for

check that the bending section is stabilized when the

Also check that the knobs rotate freely when the locks are released

70%

alcohol wipe all electrical contacts and lens

is

clearly focused. Check to see

of

the Instrument Channel

...........................................................

j

:

j

Do not let distal end strike a hard sur-

j

face as this may crack the objective lens.

;

.

............................*...*.......................

9;

;

.a

:

bundles.

...........................................................

:

and advance using repeated, short

stroltes.

...........................................................

I

I

Inspecting optical system

Check universal cord for any damage (i.e. breaks, cracks, twisted or crushed area) and the

light guide connector, eyepiece and control section for loose connections

i

If

forceps do not pass smoothly, do not

I

1

force! Damage will occur to both biopsy

I

forceps and instrument channel.

..........................................................

Page 12

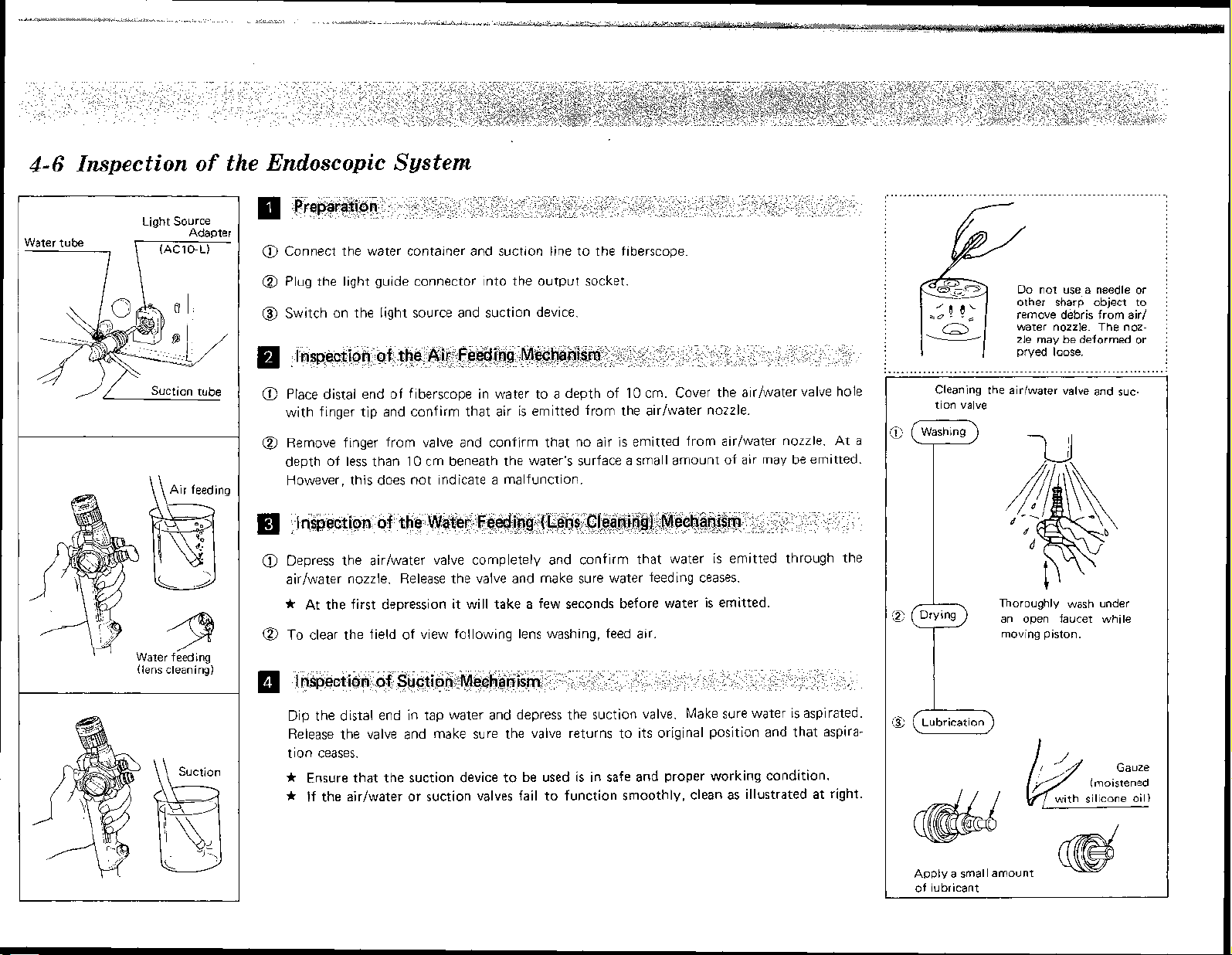

4-6

water tuh

Inspection

-7

~iant Source

,

Air feeding

9

Water feedincr

(lens cleanins)

of

the Endoscopic System

Preparation

a

Connect the water container and suction line to the fiberscope.

@

Plug the light guide connector into the output socket.

@

Switch on the light source and suction device.

lnspection of the Air Feeding Mechanism

a

Place distal end of fiberscope in water to a depth of

with finger tip and confirm that air is emitted from the airlwater nozzle.

@

Remove finger from valve and confirm that no air is emitted from airlwater nozzle. At a

depth of less than

However, this does not indicate a malfunction.

lnspection of the Water Feeding (Lens Cleaning) Mechanism

a

Depress the airlwater valve completely and confirm that water

airlwater nozzle. Release the valve and make sure water feeding ceases.

-i$

At the first depression it will take a few seconds before water is emitted.

@

To clear the field of view following lens washing, feed air

lnspection of Suction Mechanism

10

10

cm. Cover the airlwater valve hole

cm beneath the water's surface a small amount of air may be emitted.

is

emitted through the

................................................................

L-

Do not use-a needle or

other sharp object to

remove debris from

water nozzle. The noz-

rnav

1

...............................................................

Cleaning the airlwater valve

tion valve

Washing

I

zle

pryed ioose.

be deformed or

r

Thoroughly

an

open faucet while

moving piston.

wash

and

under

air/

suc-

L

Dip the distal end in tap water and depress the suction valve. Make sure water is aspirated.

Release the valve and make sure the valve returns to its original position and that aspira-

tion ceases.

.f$

Ensure that the suction device to be used

4

if

the airlwater or suction valves fail to function smoothly, clean as illustrated

is

in safe and proper working condition.

at

right.

@

(Lubrication)

Apply a small amount

of lubricant

Page 13

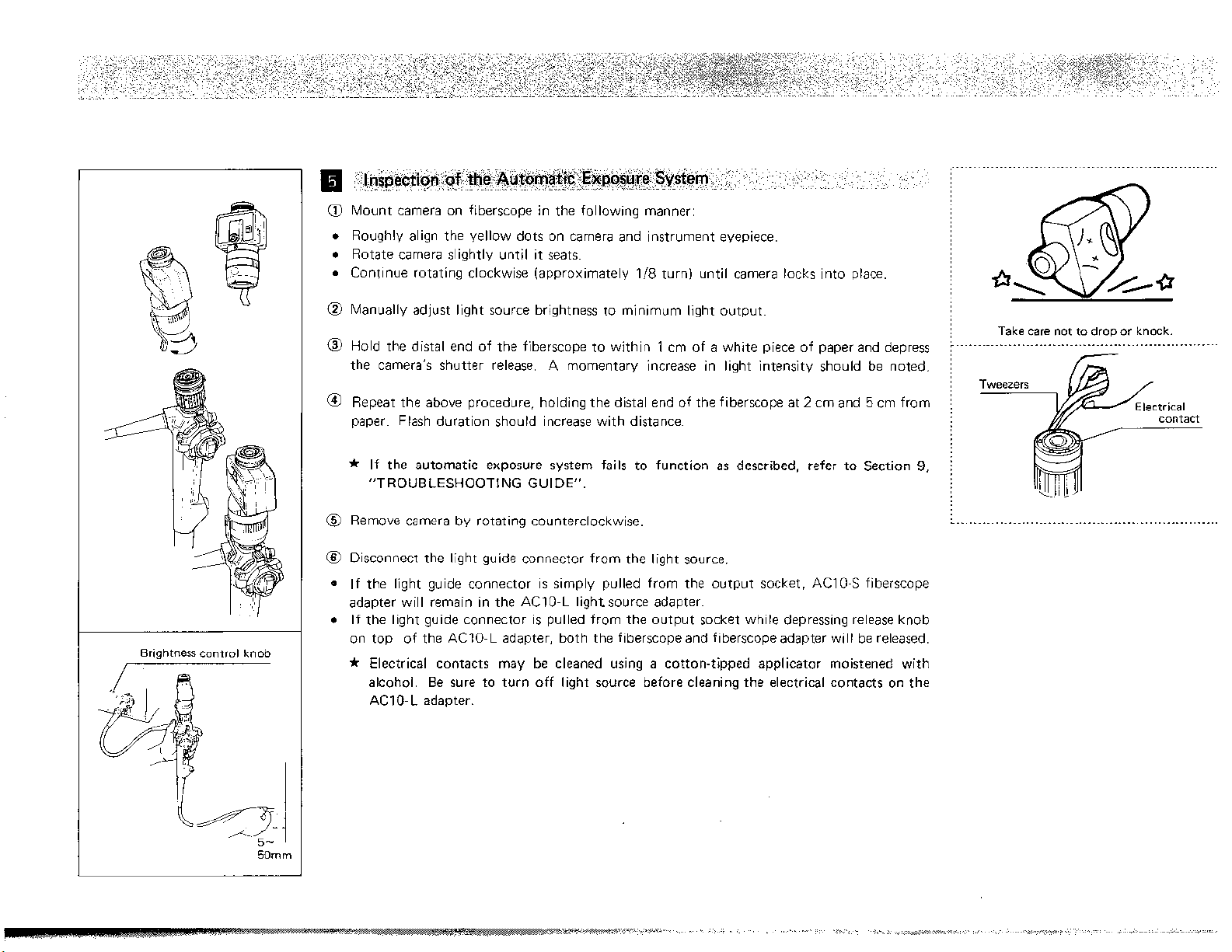

Brightness control knob

Inspection of the Automatic Exposure

@

Mount camera on fiberscope in the following manner:

o

Roughly align the yellow dots on camera and instrument eyepiece.

Rotate camera slightly until it seats.

Continue rotating clockwise (approximately

@

Manually adjust light source brightness to minimum light output

@

Hold the distal end of the fiberscope to within 1 cm of a white piece of paper and depress

the camera's shutter release. A momentary increase in light intensity should be noted.

@

Repeat the above procedure, holding the distal end of the fiberscope at 2 cm and 5 cm from

paper. Flash duration should increase with distance.

*

If the automatic exposure system fails to function as described, refer to Section

"TROUBLESHOOTING GUIDE".

@

Remove camera by rotating counterclockwise.

@

Disconnect the light guide connector from the light source.

s

If the light guide connector is simply pulled from the output socket, AC10-S fiberscope

adapter will remain in the

If the light guide connector is pulled from the output socket while depressing release knob

on top of the

Ibp

Electrical contacts may be cleaned using a cotton-tipped applicator moistened with

alcohol. Be sure to turn off light source before cleaning the electrical contacts on the

AC10-L

AC10-L adapter, both the fiberscope and fiberscope adapter will be released.

adapter.

AC10-L light source adapter.

System

118

turn) until camera locks into place.

.............................................................

Take care not to drop or knock.

9,

Page 14

5

OPERATING THE FIBERSCOPE

5-

P

Preparation for

r-P,-.

yi

17''

This section describes the basic operation

The endoscopist should carefully evaluate the clinical factors involved and decide on the technical details of the procedure.

To become more thoroughly acquainted with some of the potential hazards associated with flexible endoscopy,

the following are examples of possible complications resulting from improper technique.

Improper Technique

1.

Use of faulty fiberscope and/or accessory

2.

Forceful insertion without clear view of the lumen

3. Prolonged suction with distal tip in contact with

rnucosal surface

Prolonged close-up observation with intense illumination

Overinstifflation

Retroflexion of the fiberscope within the esophagus

or duodenal bulb

Blind or abrupt protrusion of accessory from distal tip

Electrosurgery without clear view

Withdrawal of fiberscope

locked position

Blind withdraw1 of fiberscope

Improperly

cleaned/disinfected instruments

wit,h angulation controls in

of

th; fiberscope and outlines a general procedure for endoscopy.

SPElClAL

NOTE

Possible Complication

Mucosal trauma, Perforation, Laceration,

Electrical shock, etc.

Perforation, etc.

Bleeding, Suction artifact, etc.

Thermal injury to mucosa, etc.

Pain, Rupture, etc.

Instrument impacted and cannot be withdrawn

Perforation, etc.

Mucosal burns, Perforation, etc.

Trauma, Perforation, Laceration, etc

Trauma, Perforation, Laceration, etc.

Cross-contamination, Infection, etc.

Use

'

0

Disinfection/Sterilization

Disinfect or sterilize the fiberscope and accessories as described in Section

I

1

Application

c,

Wipe moisture from objective lens.

a

Apply lens cleaner to a piece of clean gauze and lightly wipe the objective lens. Remove

af

Lens Cleaner (Anti-Fogging Agent)

of Instruments

6.

Do not occlude airfwater

nozzle when applying lens

cleaner.

\

?s4noeo

c'Iqe

t

When cleaning the objective lens, always wipe in a direction away from the airlwater

nozzle.

I

Attaching the Distal Hood

a

Attach the distal hood, with rounded edge facing outward, while holding the distal end of

the fiberscope firmly between finger tips. Gently press on hood.

To remove, hold the distal end of the fiberscope firmly.

the hood and gently pull off.

ft

To prevent accidental dislodgement of the hood, make sure mating surfaces of the hood

and distal end are clean and dry before attaching.

*

lf hood appears cracked or worn, do not use.

(if

required)

Using finger tips, grasp the edge of

Replace with a new one.

i

To prevent damage to bending section,

I

grasp insertion tube near the distal

j

when installing hood.

end

Page 15

Diopter Adjustment

Turn the diopter adjustment ring until the fiber pattern is clearly focused

*

Four color-coded index lines serve as a reference for repeated setting.

5-2

I

I

Insertion and Observation

Preparation for Insertion

$TI

Always use a mouthpiece (bite guard) to prevent the instrument from being bitten.

@

Lubricate the insertion tube wi.th a water soluble medical grade lubricant, taking care to

avoid the distal tip.

Holding the Fiberscope

The control section of the instrument is designed to be held in the left hand. The airlwater

and suction valves are activated by the index finger. The upldown angulation control knob

is operated by the thumb. The right hand is free to manipulate the insertion tube and the

ii

I I

'I

Mouthoiece

I

1

1

'

left/right angulation control knob.

Adjusting Brightness

Adjust the brightness control knob on the light source to a comfortable level of illumination.

*

Always use the minimum necessary light level to avoid thermal mucosal damage as well

to protect your eye.

Tip Deflection

Operate the angulation control knobs as necessary to guide the distal end for insertion and

observation.

t

If

the angle control mechanism ceases to function, or if any other irregularity is noticed

in the operation of the fiberscope, stop the examination immediately; free the angulation

locks and return the angulation control knobs to their neutral position. Carefully with-

draw the fiberscope while observing through

*

Always operate the angulation conrrol knobs slowly.

it.

as

Petroleum based lubricants will cause

stretching and deterioration of bending

section rubber.

Always use a mouthpiece to prevent

damage to the insertion tube.

Page 16

I

- - -

-_ - _

e4

!-

d

1.

_ . _ _

-

-

1

Aspiration

Fluid or foreign matter obscuring the visual field may be aspirated by depressing the suction

valve. Aspiration is also useful for removing excess air.

Cleaning the Objective Lens

@

Secretions and foreign matter adhering to the objective lens may be removed by simultane-

ously depressing the airiwater and suction valves.

(2'

Water drops remaining on the lens may be removed by feeding air.

1

I

,/'

Operating

airiwater

2%-

-

.

suction

and

valves as necessarv.

-yx,

Ilioprer

.

aai

.srmrnr

I

2

@

1

I

Adjusting Lumen lnsufflation

Maintain the proper level of lumen insufflation for observation by feeding and aspirating air

*

Overinsufflation

may

cause excessive patient discomfort and possible injury.

Using the Lecturescope (Teaching Attachment)

Either the LS-10 lecturescope or LS-2 lecturescope (with A10-L2 adapter) may be used with

the fiberscope

If des~red a camera may be attached to the prrmary eyeplece of the LS-10 lecturescope.

THERE IS A RISK OF THERMAL INJURY TO TISSUE FROM PROLONGED EXPOSURE TO THE INTENSE ILLUMINATION TRANSMITTED THROUGH

Because of the rncreased light carry lng capabillttes of OES endoscopes combrned wlth the

h~gh output of hrgh-rntensrty (Xenon) l~ght sources,

lrght energy and to concentrate this energy ~n a very small area (for example, when the

of

flberscope

result). Because

control, 'the level of

unless manually reduced

The risk of injury is increased under the following conditions:

1)

2)

3)

The following recommendations

1)

2)

To prevent

lamp on when not in use.

tip comes ~n close contact with the mucosa, thermal injury to the tlssue may

thls fiberscope does not contarn a photocell for automatic brightness,

~lluminatlon wlll become very great under close-viewing condrtions

Prolonged close contact or close stationary viewlng of the mucosa

Advanc~ng the flberscope through a narrow lumen (e g esophagus, pharynx, etc

Usrng a h~gh-rntensrty llght source (e g , CLV, CLX, CLX-F)

will

Use the minimum level of illumination necessary, for adequate v~sualiration. The

filter(BorC)built into

When possible, avoid close stationary viewing.

acc~dents, do not leave the flberscope plugged into the light source with the

high-intensity(Xenon)light

WARNlNG

it

IS

posstble to convey a large amount

reduce the rlsk of thermal Injury

sourcesmay be used for this purpose.

A

FIBERSCOPE

1

)

Page 17

INhen forceps cups

fail to close

5-4

Withdrawing the

Inserting Biopsy Forceps

a

While visualizing the area of interest, insert biopsy forceps into the instrument channel with

its cups closed.

4

If the forceps encounters resistance to passage through the bending section, decrease tip

angulation until smooth passage is possible. Application of a medical grade lubricant to

the forceps prior insertion into the fiberscope will enhance passage.

@

Slowly advance the forceps using repeated short strokes, grasping the forceps approximately

3

cm from the biopsy valve. When the tip protrudes approximately 3 mm from the distal

end, the forceps will come into view.

*

If the biopsy valve leaks fluid or air, replace with a new one.

Hold forceps

close to biops

valve and advance using

repeated shor

strokes.

Biopsy Procedure

Tissue samples are obtained by grasping the mucosa in the biopsy cups and then gently

pulling the forceps back until the specimen is removed.

*

Do not attempt to cut through the tissue by applying excessive force.

*

Withdraw forceps slowly with cups in a closed position

&

In the event the cups of forceps fail to close when the slider is operated making it impossible to withdraw the forceps, close the cups by winding proximal portion of the shaft

several times around your finger. If this fails to close the cups, withdraw the forceps as

as

possible

far

\

withdraw both fiberscope and forceps.

into channel opening. While viewing through the fiberscope, carefully

Fiberscope

If

resistance is encountered when passing

i

I

biopsy forceps. DO

:

tensive damage to both forceps and

j

fiberscope may result.

...........................................................

/

Advance forceps slowly.

jury or perforation, always view through

:

I

fiberscope when advancing forceps.

.........................................................

NOT

FORCE.

To prevent in-

Ex-

Before withdrawing the fiberscope, aspirate accumulated air and be sure that upldown and

rightheft angulation locks are in the "Free"

@

Always view through the fiberscope when withdrawing the instrument.

ft

The fiberscope must be cleaned immediately after withdrawal from the patient. (Refer

to

pp.

19-21.)

(F)

position.

!

Do not apply excessive force when

j

opening and closing biopsy forceps.

L......

Page 18

6

6

MAINTENANCE

6-1

Cleaning, Disinfection, Sterilization

Endoscopic instruments must be meticulously cleaned prior to disinfection or sterilization. The methods employed to achieve these conditions are left to the discretion of the endoscopist, hospital infection control

committee, etc.

Olympus instruments are made of materials and constructed in a manner which may not tolerate certain

methods of cleaning, disinfection or sterilization. Those procedures, as described on pages

manual, have been thoroughly tested and found to have no adverse effects. Strict adherence to these procedures is highly recommended.

17 - 25

of this

%

Only those fiberscopes identified by a Blue Ring on

'88

Only those accessories identified by a Green Color or marked "AUTOCLAVE" may be autoclaved.

the

Eyepiece may be totally immersed.

'

Non-OES fiberscopes

'..._____.....___.......--................................~......,

Page 19

6-2

Cautions

General Precaution

e

Before using any disinfectant solution not mentioned below, check with Olympus.

c

Removable parts (e.g. distal hood, biopsy valve, airlwater and suction valves), as well as the areas on which

these parts are mounted, should be thoroughly cleaned and disinfected (sterilized).

P,

The water container should be emptied, cleaned, and disinfected at the end of each day's procedures.

Disinfectant Solution

Reference herein to solutions for disinfection is not an endorsement of their germicidal effectiveness. Oual-

c

ified persons from the disinfectant manufacturer should be consulted if any questions exist on this subject.

e

When the disinfectant solution has been in contact with the instrument for the recommended time, remove the

instrument from the disinfectant and rinse thoroughly to remove all toxic residue and to prevent instrument

deterioration. The recommended dilution percentage and contact time listed below should not be exceeded.

c

Rubber gloves should be worn for protection against skin irritation, infection, etc

Disinfectant

Solution

MATERIAL

Alcohol

(Disinfectant

Ethanol)

Surgical scrub

soap solution

lodophor

Glutaraldehyde

70%

BRAND NAME

Wescodyne

Cidex (2%)

Sonacide (2%)

Glutarex (2%)

(

I

.6%)

Sporicidin

Alhydex Plus

(2.2%)

Aldehyde 28

(2%)

DISTRIBUTED BY

West Chemical Products

(USA)

Surgikos (USA)

Ayerst Labs (USA)

3-M Medical Products

Sporicidin Co. (USA)

Surgikos (West Europe)

Antiseptics Consultant

Service (Australia)'

CONDITIONS

Wipe using alcohol dampened gauze

I

Maximum

Dilution:

Max. Immersion: 20 Min.

Follow Manufacturer's Instructions

mmersion: 30 Minutes

100X (0.016%)

-

Page 20

Ethylene

Prior to sterilizing the f iberscope, the ETO Cap (venting cap) must be attached. 0 ES fiberscopes are completely sealed to rnake them watertight.

scope from escaping as a vacuum is created within the sterilization chamber. This will cause the rubber cover-

ing the bending section to rupture. After the ETO procedure is completed, the

order to reseal the fiberscope and insure watertightness.

e

Before sterilization, the instrument must be thoroughly cleaned and dried as described in pages 19 - 21 of

the manual. Failure to do

The instrument must be properly aerated after ETO sterilization to remove all residual toxic gas.

@

Always use a biological indicator and follow the manufacturer's instructions for the particular gas sterilizer

being used.

Oxide

Gas Sterilization

Failure to attach the ETO cap will prevent the air sealed inside the

so will inhibit sterilization.

ETO

Cap must be removed in

fiber-

Formalin

Anprolene

Gas

Ethylene Oxide

Gas

Gas sterilizer

gas

H.W. Andersen Products

I

To

be kept in sealed condition for 24

hours max.

Follow Manufaturer's Instructions

Temperature 55°C (131°F)

Pressure 1 .7kg/cm2

Humidity 50%

Gas Concentration 10%

Time 4 Hours

Aeration Time: 7 days at room temperature or

chamber between

57°C

I2 hours in an aeration

50"~ (122"~) and

(135°F)

Autoclave

@

Only those accessories identified by a Green Color or marked "AUTOCLAVE" may be autoclaved.

B)

Meticulous mechanical cleaning followed by 5 minutes of ultrasonic cleaning (at

datory prior to autoclaving. (Refer to Autoclavable Accessory Instruction Manual for details.)

@

Standard autoclave cycles, including "flash" may be used provided the temperature does not exceed 132OC.

I I

Heat

Boiling Water

Autoclave

(

Maximum Immersion: 30 Minutes

2 atmospheres of air pressure

for 5 minutes or 1 atmosphere (121"~ or

250°F) for 20 minutes

40

kHz or higher) is man-

(132°C or 270"~)

(24 psi)

I

Page 21

6-3

Cleaning, Disinfection and Sterilization Procedures

Supplies

Needed

Cleaning solution Disinfectant solution Large basin for water

Semi-disposable

biopsy valve

(MA-922)

Rubber gloves

ETO

cap (venting cap)

(MB-156)

Large basin for disinfectant

solution

All-channel irrigator (CW-1)

30cc syringe

with

j

o

To avoid extensive damage and costly

repair,

it

:

fiberscopes be tested for water leakage

i

prior to immersion in cleaning solutions.

j

@

To facilitate leak testing and cleaning procedures, the use of a leakage

tester, maintenance unit

i

endoscope washer

mended (optional items).

Refer to the operating manuals provided

with these units.

L..................

is recommended that

(EW-10)

............................................

OES

(MU-1 ) or

is- recorn-

Scrub brush (soft)

Gauze pads

A~rlwater channel cleaning adapter

(MB-I 07)

Channel cleaning brush

(BW-ST)

Channel cleaning adapter

(MB-19)

Leakage Tester (optional)

Page 22

LEAN IMMEDIATELY AFTER PROCEDURE

1. Wipe insertion tube with gauze.

2.

Turn off air pump. Remove AIRIWATER VALVE by slowly pulling out and place in cleaning solution.

3.

Insert AIRIWATER CHANNEL CLEANING ADAPTER (blue collar). Turn on air DumD.

4.

Alternately feed water and air for 10 seconds each. Turn off light source.

5.

Place distal tip in water and suction for approximately 10 seconds. Then alternate suctioning of water and air several times. Turn off

suction device.

6.

Remove AIRWATER CHANNEL CLEANING ADAPTER, SUCTION VALVE and BIOPSY VALVE. Place in cleaning solution.

7.

PERFORM LEAK TEST PROCEDURE.

8.

Immerse insertion tube in cleaning solution.

9.

Insert channel cleaning brush through insertion tube, universal cord and channel opening to brush the entire suction line.

10. Turn off suction device and remove suction line and channel cleaning adapter.

11. Immerse entire instrument in cleaning solution. Scrub all external surfaces.

12. Using a soft brush, gently wash and rinse all valves.

13. Install AW CHANNEL CLEANING ADAPTER and SUCTION

14. Connect suction tube to suction connector on the instrument. While holding the control section out of water, turn on suction device,

making certain free end of the channel cleaning adapter remains in water. Aspirate water for approximately 10 seconds.

15. Remove entire instrument from water. Continue to aspirate air for approximately

suction line.

16. Dry all external surfaces of the instrument.

17.

Turn off light source.

VALVE, and attach CHANNEL CLEANING ADAPTER.

,

.

Remove instrument, place in clean water and rinse.

30

seconds. Turn off suction device, and disconnect

1. Connect All-Channel lrrigator (CW-1

2. Immerse fiberscope and All-Channel

3.

Pump disinfectant solution through all channels. Gas Sterilization Cycle

4.

Disconnect All-Channel lrrigator (CW-1) and allow Instrument to

remaln in disinfectant solution for Recommended Period of Time.

5.

Following disinfection, remove the Instrument from dis~nfectant

solution and place in clean water.

6. Reattach All-Channel Irrigator. Place weighted end of blue intake

tube in water. 2. Remove ETO Cap.

7.

Flush all channels with clean water until thoroughly rlnsed.

Remove weighted end of blue intake tube from water and repeat and BIOPSY VALVE which have been sterilized

flushing process, forcing air through channels to expel water.

Rinse the outslde of the fiberscope under a running faucet. Remove All-

8.

Channel lrrigator from the fiberscope while rinsing.

9.

Plug

LG

until moisture has been expelled and channels are dry,

10.

Wipe dry outside surface of the Instrument

connector into light source and force air through all channels

DISINFECTION COMPLETED

)

to fiberscope

lrrlgator into dis~nfectant solut~on.

I

i

1

Aeration

3.

Install AIRIWATER VALVE, SUCTION VALVE

and dried.

II

STERl LlZATlON COMPLETED

Page 23

Detach airlwater valve and attach

AW

channel cleaning adapter.

Cleaning/Disinfecting/Sterilizing

the

Fi

berscope

CLEAN IMMEDIATELY AFTER PROCEDURE

Initiate the following cleaning procedure immediately after each examination. Failure

to do so may result in a malfunction of the instrument.

4

The light guide plug (chrome shaft extending from the light guide connector) may

be extremely hot immediately after removal from the light source.

DO NOT TOUCH!

Wipe insertion tube with gauze.

1.

+

Do not squeeze the bending section forcefully.

2.

Turn off air pump.

Remove

Insert AIR/WATER CHANNEL CLEANING ADAPTER (blue collar).

3.

Turn on air pump.

Alternately feed water and air for

4.

Turn off light source.

4

Place distal tip in water and suction for approximately

5.

tioning of water and air several times.

Turn off suction device.

*

6.

Remove AIR/WATER CHANNEL CLEANING ADAPTER, SUCTION VAVLE and

BIOPSY VALVE.

Place in cleaning solution.

AIR/WATER VALVE

The AirIWater Channel Cleaning Adapter will feed water through both the air channel

and water channel when depressed. It feeds air through both channels automafically

when the valve

Altern'ately insert and.remove distal end of the instrument.

is

released.

by

slowly pulling out and place in cleaning solution.

10

seconds each.

10

seconds. Then alternate suc-

Clean fiberscope immediately after each

j

j

examination.

........................................................

-....

j

AW

channel cleaning

/

adapter (blue collar)

use

in

Never

i

examination.

Remove fiberscope adapter before clean-

j

j

ingldisinfecting procedure.

L_______

.....................................................

clinica;&

(not waterproof)

Alternately feed

water and air.

Page 24

leakage

tester

Disconnect from light

source

r

wait

first

30

seconds.

and

\

connector

7.

Perform Leak Test Procedure.

@

Remove fiberscope from light source by simply pulling outward.

*

DO NOT DEPRESS Silver Button on top of the light source adpater (ACI

a

Be sure fiberscope adapter (AC10-S) remains in the light source adapter.

@

Detach water container and suction line from the light guide connector.

@

Insert black end of the leakage tester into output socket on the light source.

@

Turn on the light source.

t

Be sure air pump

tester, lightly depress the pin inside the connector cap.

@

Attach leakage tester to venting connector on the light guide connector.

*

Place the connector cap over the venting connector, aligning the pin on the connectoor

with the keywav on the cap. Depress and rotate cap clockwise (approximately

until no further .rotation is possible.

*

At this point, note expansion of the rubber covering of the bending section due to

increased internal pressure.

@

Immerse entire instrument in water.

Observe the instrument carefully for about

If no bubbling is observed from the instrument, the instrument is watertight. Proceed

to Step

If continuous bubbling is observed from a given area, this indicates a leak. Remove the

a

instrument from water immediately.

a

Turn off light source and disconnect leakage tester from light source.

Wait approximately

to its normal shape); then disconnect opposite end of leakage tester from the instrument.

DO NOT USE THE INSTRUMENT! Reattach all valves and distal hood (if used) and

send

,

@

Remove the entire instrument from the water and turn off the light source

Disconnect the leakage tester from the light source.,

e

Wait approximately

returns to its normal shape).

r

Disconnect the leakage tester from the venting connector on the light guide connector

by depressing and rotating counterclockwise.

*

-k

Immerse insertion tube in cleaning solution

8.

O.

Some initial bubbles may be observed due to air trapped in crevices on the fiberscope's outer surface. This is normal.

to

vour nearest Olvm~us Service Center.

Do not detach the leakage tester before the fiberscope has been removed from water.

When detaching the leakage tester, always disconnect from the light source first.

Failure to follow this exact procedure will not allow the instrument to depressurize

and damage will result.

Thoroughly dry the leakage tester.

is

also

"ON".

30

seconds (or until rubber which covers the bending section returns

30

seconds (or until the rubber which covers the bending section

To ensure that air is being emitted from the leakage

30

seconds.

0-L).

90

j

If

continuous bubbling

a

)

given area,

I

.................................................................

this

is

observed from

indicates a leak.

I

Page 25

Brushing the suction line

cleaning

Insert channel cleaning brush through insertion tube, universal cord and channel opening

9,

to brush the entire suction line.

5

Pass channel cleaning brush through suction valve housing at an angle of approximately 45'

until the brush extends from the distal end of the instrument. Brush channel several times.

Pazs the channel cleaning brush directly into the suction valve housing (approximately

90

)

brushing the entire length of the universal cord until the brush extends from the

su,ction connector. Brush several times.

Insert channel cleaning brush into channel opening approximately

10cm. Brush several

times.

* Use only the channel cleaning brush

(BW-ST)

supplied with the instrument.

Attach the suction line to the suction connector on the light guide. Attach channel cleaning adapter to channel opening and place the free end in cleaning solution. Turn on suction

10

device and cover suction valve housing with finger for approximately

Turn off suction device and remove suction line and channel cleaning adapter

10.

11.

Immerse entire instrument in cleaning solution. Scrub all external surfaces. Remove

seconds.

instrument, place in clean water and rinse.

Using a soft brush, gently wash and rinse all valves.

12.

Install AW channel cleaning adapter and suction valve, and attach channel cleaning

13.

adapter.

14.

Connect suction tube to the suction connector on the instrument. While holding the

control

section out of water, turn on suction device, making certain free end of the

channel cleaning adapter remains in water. Aspirate water for approximately 10 seconds.

15. Remove entire instrument from water. Continue to aspirate air for approximately

30

seconds. Turn off suction device, and disconnect suction line.

Dry all external surfaces of the instrument, especially the electrical contacts.

16.

e

Reconnect instrument to the light source.

e

Turn on light source and air pump.

s

Cover water container connector with finger and depress AW channel cleaning adapter

10

seconds to dry air and water channels. Then replace AW channel cleaning adapter

for

Airmater valve.

with

17. Turn off light source.

e

Disconnect instrument from light source.

e

Remove all valves and channel cleaning adapter.

e

Using a cotton-tipped applicator, dry airlwater valve housing, suction valve housing,

biopsy valve housing, distal end and eyepiece.

@

Dry, lubricate and reattach all valves.

B

Wash, Rinse and Dry all cleaning equipment

j

Do not attempt to pass channel cleaning

j

brush in reverse direction:

j

caught, making retrieval impossible.

To

prevent water leak

do not apply excessive

force when

j

Wet electrical contacts cause faulty

:

exoosure.

I

Feed air until no water comes out of

I

nozzle.

...........................................................

it

may get

washins

Page 26

Suction

CO,

(.

DISINFECTION

OES

fiberscopes (identified by a blue ring around the eyepiece) have been designed to

withstand complete

immersion in disinfectant solutions. Prior to immersion, the following

1

points must be noted

Attach tightly to each housing.

3-wav

stopcock

/ /

Be sure to rotate stopcock

to both positions

"B"

while

Intake tube

(with filter) Syringe

in

use.

Air

inlet

Fiubber plug

"A"

and

The fiberscope must be physically clean as outlined in steps

15

The disinfectant solutions listed on page

of this manual have been tested by Olympus

1-1

7

of the Cleaning Procedure.

and found to have no adverse effects on the instrument when used in accordance with the

disinfectant manufacturer's label instructions.

@

Remove all valves and place in disinfectant solution.

1.

Connect All-Channel lrrigator (CW-1) to fiberscope.

a

Firs:, wet the valve housing cover.

piece, attach to the suction valve and

Then, with the metal tab pointing toward the eye-

airlwater valve housings respectively. (The C02

cover is used only with C02 equipped instruments.)

e

Attach channel opening cover to channel opening.

o

Attach the opposite end of the tubing to the air inlet on the light guide connector.

a

lnsert rubber plug into water container connector.

e

lnsert white plastic male connector into hole beside the rubber plug.

e

lnsert connector on blue intake tube into 3-way stopcock.

e

lnsert 30 cc syringe into the top of the connector.

+

Replace 3-way stopcock when it develops cracks or other defect.

2.

Immerse fiberscope and All-Channel lrrigator into disinfectant solution

3. Pump disinfectant solution through all channels.

Be certain weighted end of blue intake tube is in solution.

e

Turn the handle on the 3-way stopcock to position "A".

e

Withdraw the plunger until syringe fills with disinfectant solution.

e

Depress plunger forcing solution through the air and water channels until air has been

expelled and solution comes out of the

airlwater nozzle at the distal end of the insertion

tube. Repeat several times.

a

Turn the handle on the 3-way stopcock to position "B".

Repeat the above procedure, forcing solution through the entire suction channel. Fluid

e

will exit through the channel opening at the distal end of the insertion tube and through

the suction connector on the universal cord.

Attach U-tube tightly to rubber plug.

........................................................

i

Page 27

1

Immersion in disinfectant solution

Light

Maintenance

1

Drying the airiwater channel

Electrical

Source or

4.

Disconnect All-Channel Irrigator and allow instrument to remain in disinfectant solution

for Recommended Period of Time.

5. Following disinfection, remove the instrument from disinfectant solution and place in

clean water.

6.

Reattach All-Channel Irrigator. Place weighted end of blue intake tube in water.

7.

FIUS~

all channels with clean water until thoroughly rinsed. Remove weighted end of blue

intake tube from water and repeat flushing process, forcing air through channels to expel

1

water.

8.

Rinse the outside of the fiberscope under a running faucet. Remove All-Channel Irrigator

from the fiberscope while rinsing.

9.

Plug

LG

connector into light source and force air through all channels until moisture has

been expelled and channels are dry.

a

Install AirIWater Channel Cleaning Adapter to airlwater valve housing. Closing water container connector, depress AirIWater Channel Cleaning Adapter for approximately 30 seconds

to force water through airlwater channel. Release Adapter and allow airlwater channel to

be thoroughly dried.

@

Install biopsy valve to channel opening. Connect suction line and turn on suction device.

Close suction valve housing with a fingertip and air-dry suction channel.

10. Wipe dry outside surface of the instrument.

c

Using a cotton-tipped applicator, dry the distal tip, eyepiece and valve housings.

c

Replace airlwater valve and suction valve which have been previously disinfected, rinsed,

1

dried and lubricated.

............................................................

I

i

.........

........................................

:

,

...........................................................

Thoroughly remove

toxic residual disinfect

ant solution.

Objective

1

~horoughly wipe dry above areas

lens

contacts

Cold sterilization

If absolutely necessary, the fiberscope may be left in glutaraldehyde solution for a maximum of 10 hours to achieve "Cold Sterilization". NEVER EXCEED

MAXIMUM. After four

reduce the level of internal humidity.

(4)

such extended immersions, the instrument MUST be aerated to

(ETO

cap must be attached during aeration.)

Aeration conditions:

Temperature

Time

50'~ (122'~)

15 hours

THE

I

10 HOURS

m

...........................................................

P

Do not use hard or a

rasive scrub brush.

After rinsing, thorouc

wipe dry.

Page 28

ETO

Cap

must

be

attached.

ETO

GAS STERILIZATION

OES frberscopes have been des~gned to w~thstand Ethylene Oxlde Gas Steril~zat~on provrded the

a

The flberscope must be

following

cond~t~ons are met prlor to ster~lrzat~on

physically

clean and thoroughly drred as outl~ned In steps

1-17

the Clean~ng Pro~edure

r

Air/Water, Suction and Biopsy Valves (as well as distal hood if used) must be removed from

the fiberscope prior to sterilization.

ETO Cap MUST be securely attached to the venting connector on the light guide connector

and must remain in place throughout the sterilization and aeration process. To attach the

ETO Cap; place cap over the connector, aligning the pin on the connector with the keyway

on the cap, depress and rotate cap clockwise (approximately

90')

until no further rotation

is possible. To remove, depress cap and rotate counterclockwise.

Sterilization and aeration must be performed under the conditions described in Section

6-2,

mof this manual.

To insure that sterilization has been accomplished, always use a biological indicator and

follow the manufacturer's instructions for the particular gas sterilizer being used.

In

Page 29

Cleaning/Disinfecting/Sterilizing

@

Manual Cleaning

Thoroughly wash the biopsy forceps in cleaning solution using a soft brush to remove

all debris. Particular care should be taken to remove all blood, stool and secretions from

difficult to clean areas such as the biopsy cups. After a thorough rinsing, wipe off all

moisture.

*

Do not kink the forceps shaft.

@

Ultrasonic cleaning (over

5

minutes rnin.1

Cleaning

'1

disinfectant

rl,

1

rlII

40kHz,

Preliminary

I

Fk';:",

,pG;?Gq

Autoclave

I

I

1

1

Ultrasonic Cleaning

The use of an ultrasonic cleaner is desirable to aid

Ultrasonic cleaning is mandatory if the biopsy forceps are to be autoclaved.

e

Clean the biopsy forceps immediately after use.

*

Immerse in an ultrasonic cleaner with 40 kHz or higher output for a minimum of 5 minutes.

r

Use only tap water in the ultrasonic cleaner. Some surfactants and other agents may cause

the forceps to operate sluggishly.

@

Disinfection

r

Prior to disinfection or sterilization, the biopsy forceps must be meticulously

r

Immerse in disinfectant solution for recommended time.

Rinse thoroughly and dry.

Lubricate cups with a medical grade silicone lubricant.

@

ETO

Gas Sterilization

Prior to ETO gas sterilization, the forceps must be meticulously cleaned and thoroughly

dried. Accessories with plastic parts must be aerated following ETO gas sterilization.

a

Lubricate forceps cups with a medical grade silicone lubricant.

*

Always use a biological indicator and follow the manufacturer's instructions for the

particular gas sterilizer being used.

@

Autoclave

D

Prior to steam autoclaving, the biopsy forceps must be mechanically cleaned and have

undergone a minimum of 5 minutes of ultrasonic cleaning.

Autoclave under the following conditions:

Temperature:

Pressure:

Time:

132'~ (270'~) or Temperature: 121°c (250'~)

2

atmospheres

5

minutes

the Biopsy Forceps

in the removal of particulate matter.

Pressure:

Time: 20 minutes

1

atmosphere

cleaned.

Green label

j

Only those accessories identified by

:

green color or marked "AUTOCLAVE'

/

may be autoclaved.

Do not apply excessive force.

Never autoclave or boil the fiberscope,

j

nor use ultrasonic cleaner with it.

j

8

..........................................................

2

r

Lubricate forceps cups with a medical grade silicone lubricant.

-k

Only those accessories identified by a green color

be autoclaved.

or

marked "AUTOCLAVE" may

Page 30

6-4

Storage

@

The fiberscope must be dried thoroughly prior to storing. Ta

tip, all lenses, and electrical contacts.

@

The storage location must be clean, dry, well ventilated and maintained at a normal temperature. Avoid direct sunlight, high temperature, high humidity and X-ray exposure.

The

fiberscope should be stored with the insertion tube as straight as possible. Release all

angulation control locks.

than its condition when in the instrument carrying case.

'g'

Do not use the carrying case for storage. The carrying case is designed for shipping purpose

only. Routine storage of the fiberscope in a humid, dark, non-ventilated environment, such

as the carrying case, may cause problem with infection control.

forceps) must also be dried thoroughly before storage. Do not coil tightly.

If it must be coiled for storage, do not coil insertion tube tighter

Accessor!es (e.g. biopsy

................................................................

,

!

Do not scratch electrical contacts

i

.................................................................

with sharp tools.

i

i

j

center in its original carrying case, along with a description of the instrument malfunction

or damage. Include the name and telephone number of the individual most familiar with the

instrument problem and a repair purchase order.

*

Attach the

&

Minor problem with the operation of the fiberscope may be correctable by the endoscopist

or assistant. Refer to Section 9 TROUBLESHOOTING GUIDE.

All other repair should be made only by an authorized Olympus service center. In no event

will Olympus be liable for any injury or damage due to repairs performed by non-Olympus

personnel.

ETO

cap (venting cap)

to

the venting connector.

..

i

i

hi.

................................................

!Pe?!t:

Do not sharply bend.

Do not store in the

carryins case.

Page 31

7

ELECTROSURGERY

Extensive training and experience in Endoscopic Electrosurgery is necessary before attempting electrosurgical procedures through the

technical, as well as clinical details of the procedure from a professional medical viewpoint.

improper technique, faulty equipment and the use of improper or incompatible ancillary

equipment can all result in electrosurgical accidents. Refer to the instruction manual per-

taining to each piece of equipment used.

The following Olympus equipment is safe and compatible with this fiberscope:

e

0

1

ly mpus electrosurgical accessories

Olympus Electosurgical Units

(PSD, PSD-2, PSD-3, UES, UES-2)

f

i berscope. The endoscopist must determine the

1

Physiological saline

/

Connecting Lead

or

conductive paste

B

/

Rubber gloves

Page 32

ENDOSCOPIC

PHO

TODOCUlMENTATION

8-1

I

Still

-

OM-I

N

Photogrqhg

-1

I

A10-MI

A1 0-M2

or

SC16-4 Camera

a

Refer to SC16-4 instruction manual for instructions on loading film and operating the

camera.

@

Attach camera to fiberscope eyepiece as explained in Section 4-6,

OM-1

N

Camera

a

Place

1-9

endoscopic focusing screen in camera viewfinder.

@

Set shutter speed at 114 second ("4").

Q

Set shutter speed sync switch to "X" (use "FP" with CLE-F light source).

@

Set meter switch to "OFF".

@

Attach proper OM adapter and connect sync cord to camera body:

Liqht Source

1

CLE. CLE-3. CLE-4U. CLE-5

CLV, CLS, CLS-F, CLX

CLX-F, CLE-F

t

Refer to camera instruction manual for instructions on loading film and operating camera.

+

Attach camera to fiberscope eyepiece

*

Confirm that the

eyepiece, camera and light guide connector.

LED

indicator light is illuminated.

/

A10-MI

A1 0-M2 (standard image)

A1 0-MI (reduced image)

as

explained in Section

Adapter

If

not, clean electrical contacts in

-@,

4-6,

s-0,

page

9.

1

page

EC-3 Polaroid Camera

a

Refer to EC-3 instruction manual for instructions on loading film and operating camera.

@

Use A10-E3 adapter to connect EC-3 camera to fiberscope eyepiece.

adapter from EC-3 camera, depress release button while rotating counterclockwise.)

@

Set shutter speed at 114 second

("4")

.

(To remove

9.

A10-E3

EC-3

A10-E.?

--

(A10-L2)

1

NOTE:

Camera

SC 1 6-4

OM-1

N

EC-3

Photographs may also be taken by attaching camera to the primary eyepiece of the

LS-10 Lecturescope. Refer to the LS-10 instruction manual for details. The

A10-L2 lecturescope adapter can also be used for manual exposure with EC-3.

1

Exposure Index

3

4

3

4

I

Film

1

604-D

1604-T

ISOIASA 200 Day light

ISOIASA 160 Tungsten

/

Polaroid

779

1

Page 33

8-2

CCTV

Refer to the instruction manuals provided with light source and OTV-E Medical TV System.

Connections

/

TV

Adapter

I

-

Do not let direct intense light into

camera.

Do not knock or drop.

1

Auto white adjustment

I

Light

Source Setting

Light Source

Camera

OTV-E

C-Mount Contact camera manufacturer for

I

TV

-

* Exposure index numbers are the standard setting. Adjust index depending on con-

*

camera

ditions.

Do not allow direct intense light to enter the TV Camera when it is not connected to

fiberscope; camera may be damaged.

1

Adapter

AS-TV04 + A1 0-E3 TV.CINE

A10-C2

CLV

S Switch:

~nstructions.

CLX-F, CLX

Exp. Index

L..........................................-...............

I

i

:

Do not put heavy objects.

TV

system is not waterproof. Do not

wet.

Page 34

ENDOSCOPIC pH0 TODOCUMENTATION

8-1

r----

I

Still Photography

-

OM-1

N

A10-MI

A1 O-M

-.

or

2

SC16-4 Camera

@

Refer to SC16-4 instruction manual for instructions on loading film and operating the

camera.

@

Attach camera to fiberscope eyepiece as explained in Section 4-6,

Place 1-9 endoscopic focusing screen in camera viewfinder.

@

Set shutter speed at 114 second ("4").

@

Set shutter speed sync switch to "Xu (use "FP" with CLE-F light source).

@

Set meter switch to "OFF".

@

Attach proper

1

1

t

Refer to camera instruction manual for instruct~ons on loading film and operating camera.

Attach camera to fiberscope eyepiece as explained in Section 4-6,

t

Confirm that the

eyepiece, camera and light guide connector.

OM

adapter and connect sync cord to camera body:

Liaht Source

CLE. CLE-3. CLE-4U. CLE-5

CLV, CLS, CLS-F, CLX

CLX-F, CLE-F

LED

indicator light is illuminated. If not, clean electrical contacts in

I

/

A10-MI

A1 0-M2 (standard image)

A10-MI (reduced image)

Adapter

-@,

-@,

page 9.

I

I

page

EC-3 Polaroid Camera

9.

Refer to EC-3

a

Use

A10-E3 adapter to connect EC-3 camera to fiberscope eyepiece. (To remove A10-E3

adapter from EC-3 camera, depress release button while rotating counterclockwise.)

@

Set shutter speed at 114 second ("4")

instruction manual for instructions on loading film and operating camera.

.

Light Source Setting

1

NOTE:

Camera

OM-lN

EC-3

Photographs may also be taken by attaching camera to the primary eyepiece of the

LS-10 Lecturescope. Refer to the LS-10 instruction manual for details. The

A10-L2 lecturescope adapter can also be used for manual exposure with EC-3.

I

1

Exposure Index

3

4

1

1

ISOIASA 200 Daylight

1

ISOIASA 160 Tunclsten

/

Polaroid 779

Film

I

I

Page 35

I

'I

i

I

.p

8-2

lIEc~~~

CCTV

0

Refer to the instruction manuals provided with light source and OTV-E Medical TV System.

~----~-~~~----.-~~~~~~~-~.-~--~----~-----~~--~-~~----~---~~

./

1

I

I

MANUAL

Auto white adjustment

C

LV

CLX-F

AUTO

Earth terminal

Light Source

Camera Adapter CLV CLX-F, CLX Exp. Index

A1

OTV-E

0-TV

AS-TV04

+

A10-E3

Switch: Switch:

AUTO TV.CINE

4

0'

5

1

r__...________.__..__________________._.________._______._

.................

J&

Do not let direct intense light into

camera.

Do not knock or

Do not put heavy objects.

\

'.,

(

drop.

fiberscope; camera may be damaged.

Contact camera manufacturer for

instructions.

..........................................................

Page 36

8-3

Cinematography

Refer to the instruction manuals provided with your light source and cinecamera.

................................................................

I

TNc

DEC

CLV

q

.

I

1

Camera

1

cmOunt

*

*

ye

Index

Make sure A10-C2 adapter is securely mounted to the camera.

Adapter

A10-c2

"4"

is

standard setting. Adjust index depending on conditions.

Liqht

C

LV

Swltch

AUTO

Exposure

Index:

Source

CLX-F, CLX

Exposure

4

Sw~tch

TV-Cine

Index:

1

Film~ng speed

24

4

fps

Film

Daylight

I SO/ASA

Development:

2X

160

push

Cinecamera and adapter are not water.

proof. Do not wet.

......

:

Hold cinecamera steady with your hand

:

and bodv, and shoot.

j

I

CLX-F

Page 37

9

TROUBLESHOOTING

GUIDE

s

c?

.s

g

u

~JY

'2

2

C

m

0:

O

Symptom

Fiberscope cannot be

connected to light source.

AC10-Sfiberscope

adapter cannot be re-

/

moved from output

socket.

Image is not clear.

lmage is too dark or too

bright.

Absent or insufficient air

or water feeding.

Possible Problem

AC10-S fiberscope adapter is missing.

AC10-S fiberscope adapter is defective.

AC10-L light source adapter installed incorrectly.

Failure to release latch.

1

Dirty objective lens.

Dirty eyepiece lens.

Optics not adjusted to operator's

eyesight.

Dirty camera or adapter lens

Internal fluid damage

Dirty light guide.

Improper light source settings.

Old or improperly installed light

source lamp.

Airlwater nozzle is clogged.

Airlwater nozzle missing or

deformed.

Airlwater valve is dirty.

Remedy

Install AC10-S adapter on fiberscope light

guide connector.

Check for bent electrical terminals. Re-

place if necessary.

Reinstall adapter.

Depress release button on top of

adapter.

AC10-L

I I

Feed water to remove mucus, etc. from

objective lens.

Clean with cotton swab moistened with

alcohol.

Rotate diopter adjustment ring until fiber

pattern is clear. (Applies to fiberscope

eyepiece, lecture scope and SC-16 camera.)

Carefully clean with cotton swab mois-

tened with alcohol.

Moisture within the instrument will permanently cloud the lenses in the distal

and/or eyepiece. Send the instrument

end

for reoair.

Clean light guide connector and distal tip

with gauze moistened with alcohol.

Adjust brightness control knob. Check

filter.

Properly install lamp.

Replace old lamp.

Soak distal end in warm soapy water. Use

all-channel irrigator (CW-1) and a small

syringe to flush debris from the

nozzle. Routine use of the airlwater chan-

nel cleaning adapter will eliminate this

problem.

Send instrument for repair

Remove valve. Clean and lubricate with

silicone oil.

airlwater

Page 38

Symptom

Absent or

ins~~fficient air

or water feeding.

No water feeding.

Air pump not operating

Water container cap is loose.

Water container either empty or

Possible Problem Remedy

Turn on switch on light source.

Tighten cap.

213 full.

Fill

too full.

Sticky

airlwater valve.

Valve is dirty.

Remove valve. Clean and lubricate with

silicone oil.

Constant air feeding

Airlwater valve is dirtv

Remove valve. Clean, lubricate with

silicone oil and replace.

Absent or insufficient

suction.

Suction channel obstructed.

Remove suction valve and pass cleaning

brush through suction channels in both

insertion tube and universal cord.

Dirtv suction valve. Remove valve. Clean and lubricate with

silicone oil.

Biopsy valve ieaks or is improperly

attached.

Suction pump is off or not connected.

Check and replace with new valve if necessary.

Turn on pump and check suction tube

connections.

Sticky suction valve Valve is dirtv Remove valve. Clean and lubricate with

silicone oil.

Resistance when rotating

angulation control knobs.

Tip deflection is not

normal.

-

--

No l~ght output. Turn on power switch. Check fuses and

Angulation locks engaged.

Internal problem.

Amount of tip deflection

than s~ecif ications.

Light source not operating.

is

less

Place locks in "Free" position.

Send instrument for repair.

Send instrument for

re~air

circuit breakers. Depress ignition switch

(if applicable). Replace burned out lamp.

Accessory does not pass

through channel

smooth-

IY.

Forceps shaft is bent or kinked.

Discard and replace with new forceps.