Page 1

86(5b60$18$/

[HARDWARE]

FLUOVIEW

FV10i-LIV

Confocal Laser Scanning Biological Microscope

Note

؞This instruction manual is for the Olympus Confocal Laser Scanning Microscope Model

FLUOVIEW FV10i-LIV.

To ensure the safety, obtain optimum performance and familiarize yourself fully with the

use of this microscope, we recommend that you study this manual thoroughly before

RSHUDWLQJWKH PLFURVFRSH)RUVDIHW\ZHDOVRUHFRPPHQG WKDW\RXUHDG DWWDFKHG86(5b6

MANUAL [SAFETY] together with this manual.

؞ For the operating procedures for observation and acquisition, please also read separate

YROXPH>6LPSOLrHG2SHUDWLRQ0DQXDO@DQGWKH2QOLQH+HOSRIWKHVRIWZDUH

؞ Retain this instruction manual in an easily accessible place near the work desk for future

reference.

A X 8 0 1 7 [TYPE 3]

Page 2

Page 3

CONTENTS

FLUOVIEW FV10i-LIV

IMPORTANT

1 SYSTEM AND MAIN CONTROL

2 ASSEMBLY

1 Connecting the Cables ................................................................................................................................................................ 5

2 Connecting the Tubes .............................................................................................................................................................. 6,7

3 Preparation before Placing the Specimen ................................................................................................. 8,9

4 Placing the Specimen ............................................................................................................................................................ 9,10

3 ROUTINE MAINTENANCE

1 Cleaning the Objective.............................................................................................................................................................. 11

2 Refilling/Draining Water in the Incubator ....................................................................................................... 11

1

2-4

5-10

11,12

3 Refilling Water in the Objective Water Tank ............................................................................................... 11

4 Draining Water from the Water Tray ....................................................................................................................... 11

5 Disinfection and Sterilization ............................................................................................................................................ 12

PROPER SELECTION OF THE POWER SUPPLY CORD .................................................................................. 13,14

Page 4

IMPORTANT

For safety precautions, please refer to attached USER’S MANUAL

[ SAFETY ].

Getting Ready

1

1. Always use ultrapure water with the incubator and water tank.

2. Four forms of specimen (containers) can be used including a

cover glass chamber (8 compartments) and well slide (8 compartments). The standard thickness of the cover glass is

0.17 mm, but the range from 0.13 to 0.21 mm is acceptable.

3. After starting up the system, reserve a warm-up period of about 3 hours (When the use environment temperature is 25°C)

until the internal temperature of the incubator stabilizes. When the setting of the internal temperature of the incubator is

not necessary, hold the main switched pressed (for 3 seconds), and the system can be used right away.

4. The operating period warranted for the LD light source is the shorter period of 2000 hours or one (1) year after the delivery

inspection.

5. Depending on the fluctuation of the temperature in the usage environment, a drift may occur in the X, Y or Z direction.

6. Do not apply strong impact to the equipment.

7. Install this product on the flat (Tilt : less than 2°) and durable table.

8. Reserve clearances of 15 cm or more in front of the air inlet and outlet.

9. Be sure to clean or replace as required the filter connected to the water tank that stores the ultrapure water supplied to the

objective front.

10. Refill the ultrapure water to be supplied to the objective front whenever the display shows the warning message.

11. When a specimen holder for

specimens in the unused specimen positions.

12. If water drops are left on the inner side of the top cover of the

image may be degraded.

13. When a high-power objective is switched to a low-power objective, the image quality may be degraded if water is

attached at the bottom side of the specimen.

14. The Z-stack image can be obtained only in the direction from the position distant to the specimen toward the position

closer to it.

15. When the equipment is not to be used for a long period (more than 2 weeks), be sure to drain ultrapure water from the

tank for the ultrapure water supplied to the objective front.

16. If the inside of the water pump is dried, the failure may occur in the product performances. Refill the water tank with water

at least once a year (P. 8, 11) and drain water from the water pump (P. 9).

17. Long-period oscillations (20 Hz or less) may affect the image quality.

18. Oscillations may be noticeable during zooming. This is due to the fan of the incubator and can be reduced by increasing

the Karman integration count.

19. When disposing of the microscope, be sure to observe the regulations or rules of your local government.

35 mm dish is used and the number of specimens is 1 or 2, be sure to place dummy

35 mm glass-bottom dish, slide glass (76 mm x 26 mm),

35 mm glass-bottom dish, the quality of the transmitted

1

Caution

2

If the equipment is used in a manner not specified by this manual, the safety of the user may be imperiled. In addition, the

equipment may also be damaged. Always use the equipment as outlined in this instruction manual.

Page 5

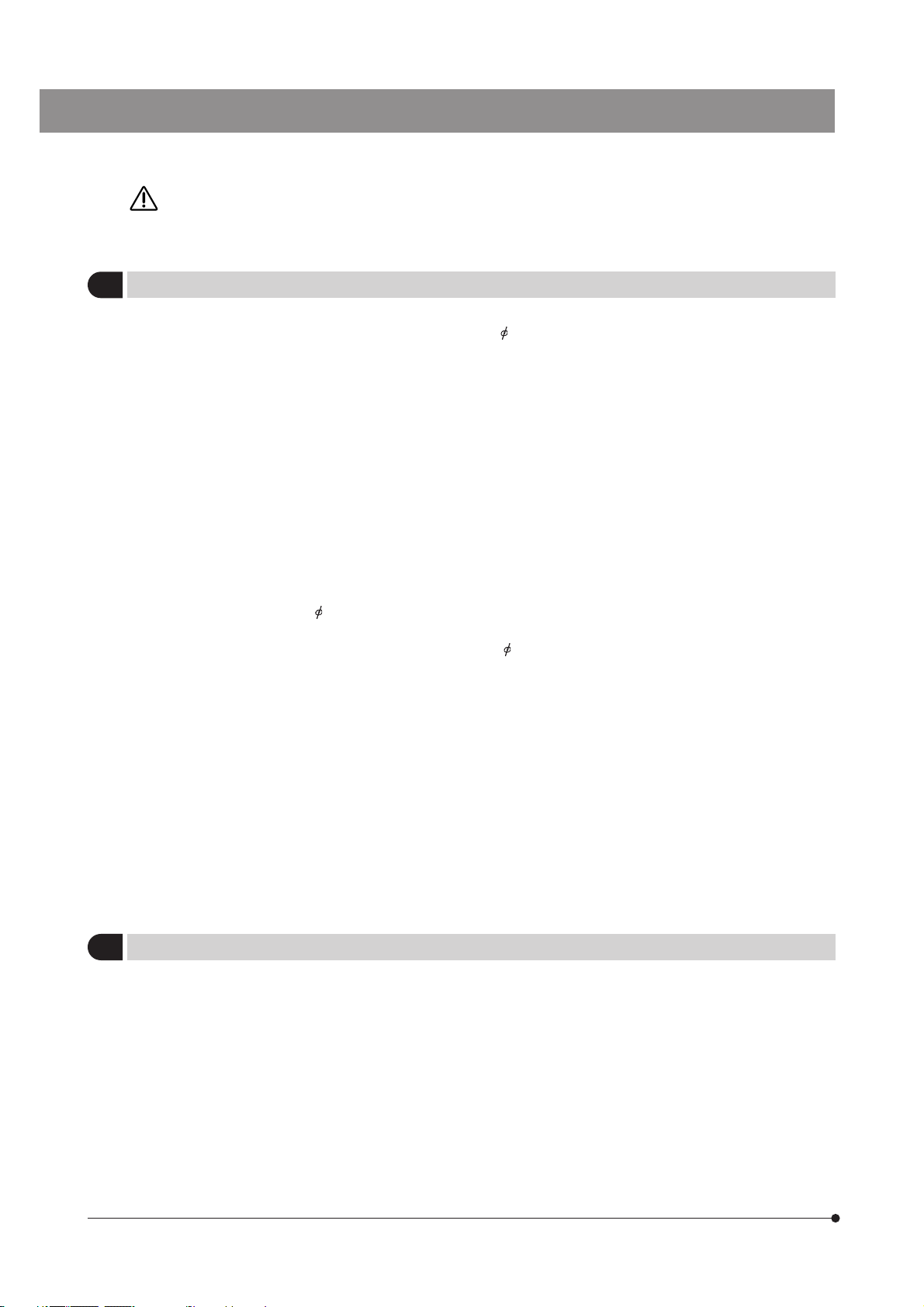

1

SYSTEM AND MAIN CONTROLS

Main Unit: FV10C-W3

FLUOVIEW FV10i-LIV

Cover

Close lever

Water tank cover

Water tank for

immersed objective

(Approx. 200 ml) is

built in.

Water stop valve

Water tray

View when the water tank cover is

opened

Incubator temperature

· Blinks during warmup.

· “- -” is displayed when

the temperature setting is OFF.

CO2 inlet port

Cover lock buttons

Push the botton to open the cover.

When setting the sub-switch to ON

· Press it shortly to start up the main unit with the heater

ON.

· Press and hold it until a short beep is generated (about

3 seconds) to start up the main unit with the heater

OFF.

Sub-switch OFF

· Press and hold for 3 sec.

}Status LEDs when both the main and sub switches are ON.

LEDs

Left Right

Green

blinking

Green

lighting

Green

lighting

· The left LED lights in red when the main switch is set to “ ”

(ON).

· Both the left LED (green) and right LED (orange) blink when

the cover is open.

Orange

lighting

Orange

lighting

Orange

blinking

Laser Software

Initializing

Standby Not run

Standby Running

indicator

Sub-switch

Status LEDs

Water level

window

Water inlet

With a cap and filter.

2

Page 6

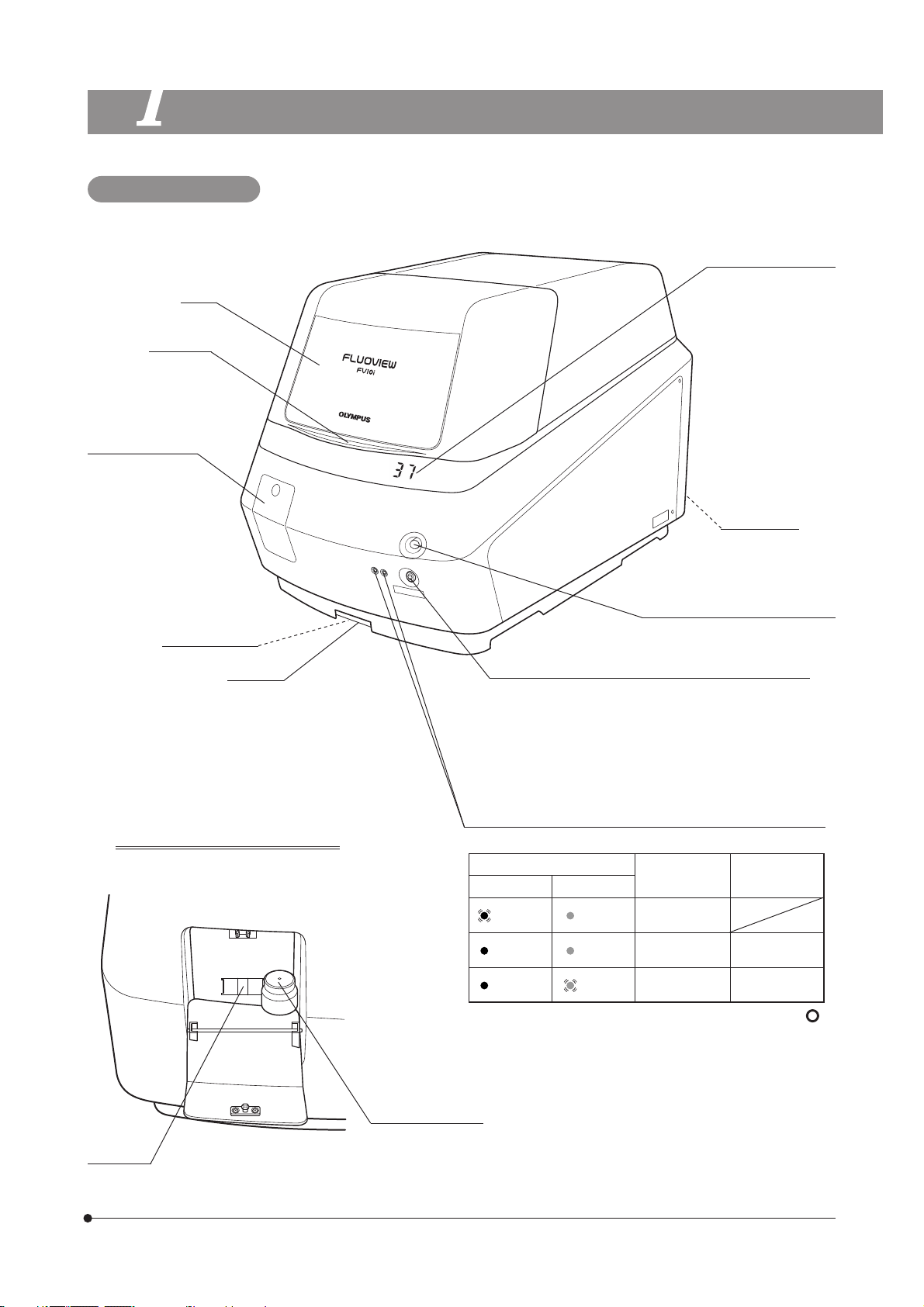

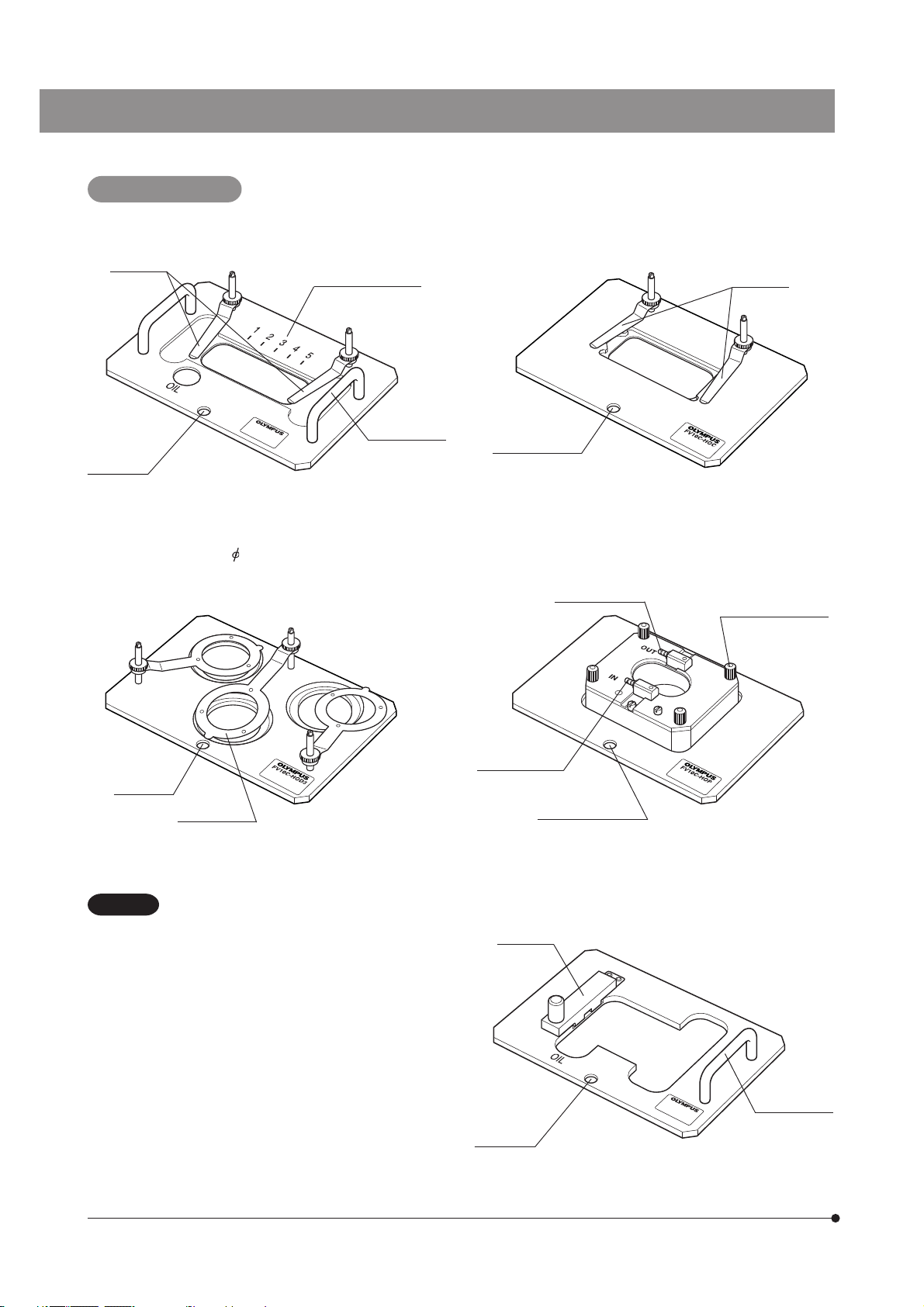

Specimen Holders

1. Specimen holder for slide glass: FV10C-HOS-2

Specimen

stoppers

Positioning

hole

Map area indicator

Holder handle

3. Specimen holder for 35 mm dish: FV10C-HOD3

2. Specimen holder for chamber: FV10C-HOC

Chamber

stopper

Positioning hole

4. Specimen holder for culture pod: FV10C-HOP

Culture solution

outlet

Top cover clamping

screws

x 4 pcs.

Positioning

hole

Dish stopper

CAUTION

To keep the internal temperature and humidity of

the incubator stable, be sure to place dummy

specimens in the unused specimen positions

when the number of specimens used is 1 or 2.

Culture solution

inlet

Positioning holes

5. Specimen holder for well slide: FV10C-HOW

Slide glass

stopper

Holder handle

Positioning

hole

3

Page 7

Power Supply Unit: FV10C-PSU

Main switch

Power cord

connector

FLUOVIEW FV10i-LIV

Output connector

Controller: FV10C-CU

}The software is pre-installed.

Software: FV10i-SW

}The display is not provided. Please prepare

a WUXGA (1920 x 1200 pixels) display.

Main switch

Dongle

4

Page 8

ASSEMBLY

Connecting the Cables

1

CAUTION

Be sure to set the main switches of the power supply unit and controller to “ ” (OFF) before connecting the

cables.

Attach the dongle

to the USB port.

Rear panel of the

FV10C-CU controller unit

Communication cable

Main switch

“ ” (OFF)

Rear panel of the

FV10C-W3

Power input cord

5

Power cord

}For the connection of the display, refer to the instruction manual for your display.

@²

Fig. 1

CAUTION

CAUTION

· Cables and cords are vulnerable to bend or twist. Do not apply

excessive force to them.

· Always use the power cord provided by Olympus. If no power

cord is provided, please select the power cord by referring to

the section “PROPER SELECTION OF THE POWER SUPPLY

CORD” at the end of this manual. If the proper power cord is

not used, Olympus can no longer warrant the electrical safety

performance of the equipment.

1. Insert the connector of the power cord to the connector on the power

supply unit.

Always ensure that the grounding terminal is safety grounded/

earthed. If the equipment is not grounded/earthed, Olympus

can no longer warrant the electrical safety performance of the

equipment.

2. Insert the power cord plug @ into the wall power outlet ².

Rear panel

of the FV10C-PSU

power supply unit

Page 9

Connecting the Tubes

2

FLUOVIEW FV10i-LIV

CAUTION

The tubes, CO2 gas cylinder and CO2 mixer are not included in the FV10i-LIV package. Please purchase

these accessories separately.

100% CO2 gas cylinder**

CO2 mixer*

Tube

Tube

Rear panel of

FV10C-W3

Diameter converter

Tube

Inner dia. 2 x Outer dia. 4 mm

Tube

Inner dia. 2 x Outer

dia. 4 mm

nipple

Ultrapure water

}As the CO2 concentration is reduced due to the incubator structure, please supply 6% CO2 gas. It will be turned into 5%

CO

2 gas inside the incubator.

* Recommended CO

**

When a 6% CO2 gas cylinder is used, connect a flow meter in place of the CO2 mixer.

2 mixer output flow: 150 ml/min. of 6% CO2 gas.

6

Page 10

Connecting the culture perfusion tubes to the culture pod

²

³

Peristaltic

pump

Tube

Inner dia. 2 x Outer

dia. 4 mm

Fig. 2

4

Cap @

1. Remove the cap @ provided on the left side of main body (Fig. 3).

Use the allen wrench included in the product. Loosen the stopper screw

from inside and remove the cap by bringing the stopper in horizontal

position.

2. Remove the cover ² of the incubator.

3. Remove the screw ³ by the allen wrench and remove the cap | provided

on the side of the cover (Fig. 2).

4. Connect the tubes to culture pod as illustrated in the Fig. 3.

}Connect the tube on the side of the peristaltic pump to OUT.

Connect the tube on the side of culture solution to IN.

5. Place the cover on the incubator. Use the space for the cap | to take out

the tubes.

Incubator

7

Culture solution

Fig. 3

Connecting the chemical stimulation tube to the culture pod

CAUTION

Be sure to connect to the OUT side make the amount of the culture solution 2 ml in order to prevent

bubble production in the culture solution.

Chemical syringe

Inner dia. 2 x Outer dia. 4 mm

Tube

FV10C-W3

OUT

IN

Culture pod

Culture pod

Page 11

Preparation Before Placing the Specimen

3

²

³

FLUOVIEW FV10i-LIV

Water Injection in the Incubator (Fig. 4)

}Water injection is not necessary when the internal temperature of the

incubator is not set (OFF).

1. Push and hold the cover button @, and lift the cover.

2. Remove the cover ² from the incubator.

3. Take out the rubber CO

pour ultrapure water until it fills about 70% of the water reservoir.

4. Re-place the rubber CO

tube is immersed underwater.

5. The cover of the incubator is to be placed after having placed the

specimen.

2 feed tube holder ³ from the water reservoir and

2 feed tube holder to that the extremity of the

@

Fig. 4

Fig. 5

²

@

Water Injection in the Objective Water Tank (Fig. 5)

}Confirm that the drain cock is closed before filling water. Please refer to

“Refilling Water in the Objective Water Tank” in P.11 for the detail information

of the drain cock.

1. Push the dented portion of the water tank cover to open it.

2. Remove the cap from the water inlet @ and pour ultrapure water gently

(so that the filter can pass the water).

3. Fill the water tank while observing the water level window ².

The water level is not visible until the water approaches the full capacity

of 200 ml.

}Be sure to fill the water tank completely when the time-lapse operation is

to be performed.

The amount of water injected into the objective tip is 0.1 ml per time.

When the tank is full, water injection is possible for about 2,000 times.

}The water inlet has a filter inserted in the way. If the water feed is extremely

slow, take out the filter and clean* or change it.

* Clean the filter frame with ultrapure water after taking it out and reversing

it.

8

Page 12

Draining of Water Pump (Fig. 6)

The water pump for the objective lens contains water to prevent dryness. At the first startup of FV10i-LIV, or after emptying

and refilling the objective water tank with water, drain water from the water pump according to the procedures below.

1. Open the body cover and remove the sample holder.

2. Start Software and Logon.

3. Click on the button. Water feeding starts and the color

of the button changes to red.

Fig. 6

4. Wait for the color of the

gray.

5 minutes later, water feeding stops and the color of the button returns

automatically to gray.

5. Return the sample holder and the body cover back to the original position.

button to return automatically to

Placing the Specimen

4

CAUTION

NOTE

· If you attempt to place the specimen directly on the specimen holder installed in the main unit, it may drop

inside the main unit.

Be sure to take out the specimen holder and place the specimen on it outside the main unit.

· If the sample falls within the device, pick up the sample with the tweezers made of bamboo or plastic, or the

stick wrapped by the adhesive tape.

If you open the cover, the temperature within the incubator drops. When you replace samples, etc., do so

quickly. After you open the cover, wait for a while to stabilize the temperature within the incubator.

(When the use environment temperature is 25°C and the cover open time is less than 3 minutes, wait for

approx.30 minutes.)

Place a dummy specimen until the internal temperature of the incubator rises to the optimum temperature (35 to

37°C).

When the specimen holder for

Without specimens placed, the internal temperature of the incubator may become unstable.

a

²

8

³

9

8

@

(Figs. 7 to 9)

35 mm dish is used, place dummy specimens in all of the three positions.

1. Push and hold the cover buttons @, and lift the cover.

2. Remove the cover of the incubator.

3. Place the specimen.

} When using a culture pod, it is necessary to remove its top cover, set the

35 mm dish and connect the tubes (see page 7).

Specimen other than well slide/culture pod specimen

· Place the specimen in the specified specimen holder ² and fix the

specimen with the specimen stopper ³ (Fig. 7).

A slide glass specimen should be placed with the cover glass facing

downward.

9

Fig. 7

Page 13

4

Fig. 8

5

7

FLUOVIEW FV10i-LIV

Well slide specimen (Fig. 8)

Remove media chamber from the slide and cover glass on top

surface. Shield it with proper method.

Place the slide with cover glass facing downward for imaging.

· Loosen the knob | of the slide glass stopper and lift it.

· Place the well slide 5 along the left edge, lower the slide glass stopper

and tighten the knob |.

}When using the specimen holder for slide glass, memorize the map area

indicator number 7 aligned with the position of the observation target 6

and use the same position in later observation/acquisition (Fig. 9).

6

Fig. 9

4. Hold the specimen holder ² horizontally by the holder handle 8 or

pillars of the specimen stoppers and place the specimen holder on the

specimen holder mount so that the positioning hole 9 of the specimen

holder comes on the front (Fig. 7).

5. Re-place the cover of the incubator.

6. Push down the close lever a and confirm that a click sound is generated

(Fig. 7).

}If the cover is not closed completely, the internal temperature of the

incubator may become unstable and the laser beam will not be output,

making observation impossible.

10

Page 14

ROUTINE MAINTENANCE

Cleaning the Objective

1

}Clean the object front after completing observation and acquisition.

1. Remove the specimen holder and wipe water attached to the object front using a piece of cleaning paper or clean cloth.

2. If the object front is stained, moisten the cleaning paper or cloth with commercially available absolute alcohol.

Refilling/Draining Water in the Incubator

2

· Check the amount of water in the incubator at proper timing, for example when replacing the specimen, and refill water

as required.

· After completing observation/acquisition, take out the rubber tube from the water reservoir of the incubator without

stopping the CO

After this, drain water from the water reservoir.

Refilling Water in the Objective Water Tank

3

2 feed (in order to drain water from inside the rubber tube).

· Check the water level of the water tank periodically through the water level window, and refill water as required.

· The display shows an alarm when the water amount gets insufficient.

Draining Water from the Water Tank (Figs. 10 & 11)

}When the system is not to be used for more than two weeks, drain the

water because the water quality would degrade.

}For safety in transportation, shut down the software and turn the sub-

switch of the main unit to OFF.

1. Slide out the water tray @.

2. Attach the drain tube ² at the drain outlet.

3. Prepare the relatively large bucket, and place it so that water from the

drain tube enters into the bucket.

4. Twist the drain cock ³ to start draining.

@

Fig. 10

²

5. When draining is finished, return the drain cock ³ to the original position.

6. Remove the drain tube ² and return the water tray @ to the original

position.

CAUTION

4

Be sure to use the drain tube provided by Olympus.

Draining Water from the Water Tray

· The water tray @ pools excess water in the main unit. Slide out the tray

periodically and drain water from it.

(Fig. 10)

11

3

Fig. 11

Page 15

FLUOVIEW FV10i-LIV

Disinfection and Sterilization

5

}If a hazardous specimen is attached to or splashed in the specimen holder or the incubator, immediately disinfect or

sterilize it.

Do not leave the attached substance, for it will harden and become hard to remove.

Disinfection

· Applicable position: Inside the incubatorand on various specimen holders. (excluding the rubber part @ of the

FV10C-HOW).

· Procedure: Moisten a clean cloth with disinfecting alcohol and wipe with it.

Do not rub the name plate with a strong force to prevent it from being peeled off.

Sterilization

@

· Applicable position: Cover on the culture pod.

· Procedure: Use autoclaving (high-pressure steam sterilization)

at 121°C for 20 minutes.

After sterilization, dry the specimen holder before reuse.

12

Page 16

PROPER SELECTION OF THE POWER SUPPLY CORD

If no power supply cord is provided, please select the proper power supply cord for the equipment by referring to “ Specifications ” and

“ Certified Cord ” below:

CAUTION:

In case you use a non-approved power supply cord for Olympus products, Olympus can no longer warrant the

electrical safety of the equipment.

Specifications

Voltage Rating

Current Rating

Temperature Rating

Length

Fittings Configuration

125V AC (for 100-120V AC area) or, 250V AC (for 220-240V AC area)

6A minimum

60°C minimum

3.05 m maximum

Grounding type attachment plug cap. Opposite terminates in molded-on IEC configuration appliance coupling.

Table 1 Certified Cord

A power supply cord should be certified by one of the agencies listed in Table 1 , or comprised of cordage marked with an

agency marking per Table 1 or marked per Table 2. The fittings are to be marked with at least one of agencies listed in

Table 1. In case you are unable to buy locally in your country the power supply cord which is approved by one of the

agencies mentioned in Table 1, please use replacements approved by any other equivalent and authorized agencies in

your country.

Country Agency

Argentina

Australia

IRAM

SAA

Certification

Mark

Country Agency

Italy

Japan

IMQ

JET, JQA, TÜV,

UL Japan / METI

Certification

Mark

13

Austria

Belgium

Canada

Denmark

Finland

France

Germany

Ireland

ÖVE

CEBEC

CSA

DEMKO

FEI

UTE

VDE

NSAI

Netherlands

Norway

Spain

Sweden

Switzerland

United

Kingdom

U.S.A.

KEMA

NEMKO

AEE

SEMKO

SEV

ASTA

BSI

UL

Page 17

FLUOVIEW FV10i-LIV

Table 2 HAR Flexible Cord

APPROVAL ORGANIZATIONS AND CORDAGE HARMONIZATION MARKING METHODS

Approval Organization

Comite Electrotechnique Belge

(CEBEC)

Verband Deutscher Elektrotechniker

(VDE) e.V. Prüfstelle

Union Technique de l´Electricite´

(UTE)

Instituto Italiano del Marchio di

Qualita´ (IMQ)

British Approvals Service for Electric

Cables (BASEC)

N.V. KEMA

SEMKO AB Svenska Elektriska

Materielkontrollanstalter

Österreichischer Verband für

Elektrotechnik (ÖVE)

Danmarks Elektriske Materialkontroll

(DEMKO)

Printed or Embossed Harmonization Marking (May be located on

jacket or insulation of internal wiring)

CEBEC <HAR>

<VDE> <HAR>

USE <HAR>

IEMMEQU <HAR>

BASEC <HAR>

KEMA-KEUR <HAR>

SEMKO <HAR>

<ÖVE> <HAR>

<DEMKO> <HAR>

Alternative Marking Utilizing

Black-Red-Yellow Thread (Length

of color section in mm)

Black Red Yellow

10 30 10

30 10 10

30 10 30

10 30 50

10 10 30

10 30 30

10 10 50

30 10 50

30 10 30

National Standards Authority of Ireland

(NSAI)

Norges Elektriske Materiellkontroll

(NEMKO)

Asociacion Electrotecnica Y

Electronica Espanola (AEE)

Hellenic Organization for

Standardization (ELOT)

Instituto Portages da Qualidade

(IPQ)

Schweizerischer Elektro

Technischer Verein (SEV)

Elektriska Inspektoratet

Underwriters Laboratories Inc. (UL) SV, SVT, SJ or SJT, 3 X 18AWG

Canadian Standards Association (CSA) SV, SVT, SJ or SJT, 3 X 18AWG

<NSAI> <HAR>

NEMKO <HAR>

<UNED> <HAR>

ELOT <HAR>

np <HAR>

SEV <HAR>

SETI <HAR>

30 30 50

10 10 70

30 10 70

30 30 70

10 10 90

10 30 90

10 30 90

14

Page 18

MEMO

Page 19

Page 20

Shinjuku Monolith, 3-1, Nishi Shinjuku 2-chome, Shinjuku-ku, Tokyo, Japan

Wendenstrasse 14-18, 20097 Hamburg, Germany

3500 Corporate Parkway, Center Valley, Pennsylvania 18034-0610, U.S.A.

491B River Valley Road, #12-01/04 Valley Point Office Tower, Singapore 248373

31 Gilby Road, Mount Waverley, VIC., 3149, Melbourne, Australia

Blue Lagoon Drive, Suite 290 Miami, FL 33126, U.S.A.

5301

Printed in Japan on June 01, 2011 M 002–04

Loading...

Loading...