Contents

Introduction 1

Using the Online CD-ROM 1

Unpacking 2

Selecting a Location 2

Control Locations and Functions 3

Front View 3

Rear View 4

Inside 4

Installing the Toner Cartridge 5

Loading Paper 6

Connecting to Your Computer 8

Using Parallel Port 8

Using The USB Port 9

Powering On the Printer 10

Installing Software 11

Installing Printer Driver 12

System Requirement 12

Windows 95/98/NT 4.0 Installation 12

Windows 95/98 Plug and Play 13

If Windows Does Not Run the CD-ROM 13

Windows 3.1x Installation 14

Uninstalling the Printer Driver 15

Installing Printer Utilities 15

Windows 3.1x Installation 15

Windows 95/98/NT 4.0 Installation 15

DOS Installation 15

Printing on Network Printer 16

Setting Up Host PC Printer 16

Client PC Sharing Setup 16

Setting Up Your Printer

Operator’s manual

QUICK START-UP

ENGLISH

Selecting Paper Types and Feed Source 17

Loading Print Material 18

Feeding Manually 22

Using Face-up Stacker 23

Paper Guidelines 24

Paper Handling

Operating Your Printer

Operator Panel 25

Indicator Lights 25

Button Function 26

Selecting Your Printer 27

Windows 95/98/3.1x/NT 4.0 27

Printing a Document 28

Print Settings 28

Accessories 30

ENGLISH

Introduction

This Operator ’s Manual is intended as a quick introduction into working with the printer

and also to enable inexperienced users to operate the device properly. It describes the most

important functions of the printer and contains the essential information for your everyday

work with the printer. A more detailed description of the printer, its characteristic features,

and further information is contained in the Reference Manual on the Online CD-ROM,

which is inserted at the back of this manual.

Using the Online CD-ROM

First install the Adobe Acrobat Reader on your hard disk, unless the program has already

been installed. To install it, follow the steps described in the README file in the READER

directory.

To start the online documentation, call the File Manager (Windows 3.1) or Explorer

(Windows 95/ 98, Windows NT3.51/ NT4) and double click on the START. PDF file. Then

follow the instructions and menus on the screen.

1

Setting Up Your Printer

2

Setting Up Your Printer

Setting Up Your Printer

Unpacking

Remove the printer and all accessories from the packing carton. Save the carton and

packing materials in case you need to repack the printer.

Make sure you have the following items:

• Toner cartridge (Please, refer to page 4 and page 5)

• Power cord

• Setup CD-ROM

• Quick Install Guide

Notes:

• If you need help during setup, or if any items are missing or damaged, notify your dealer

immediately.

• You need a Centronics-compatible parallel printer cable. The cable is not shipped with your

printer. You can purchase this cable from your dealer or retailer. Make sure the cable is IEEE

1284-compliant. Ask your dealer for assistance if you need help selecting the right cable.

Selecting a Location

Place your printer on a flat, stable surface near your workstation. Leave enough space

around the printer, so that you can easily:

• open the printer cover

• load the paper

• retrieve the paper

• open the front output tray and retrieve the paper from the front output tray

• allow air circulation around the vents to prevent the printer from overheating

Do not place the printer:

• In direct sunlight

• Near heat sources or air conditioners

• In dusty or dirty environments

3

Setting Up Your Printer

ENGLISH

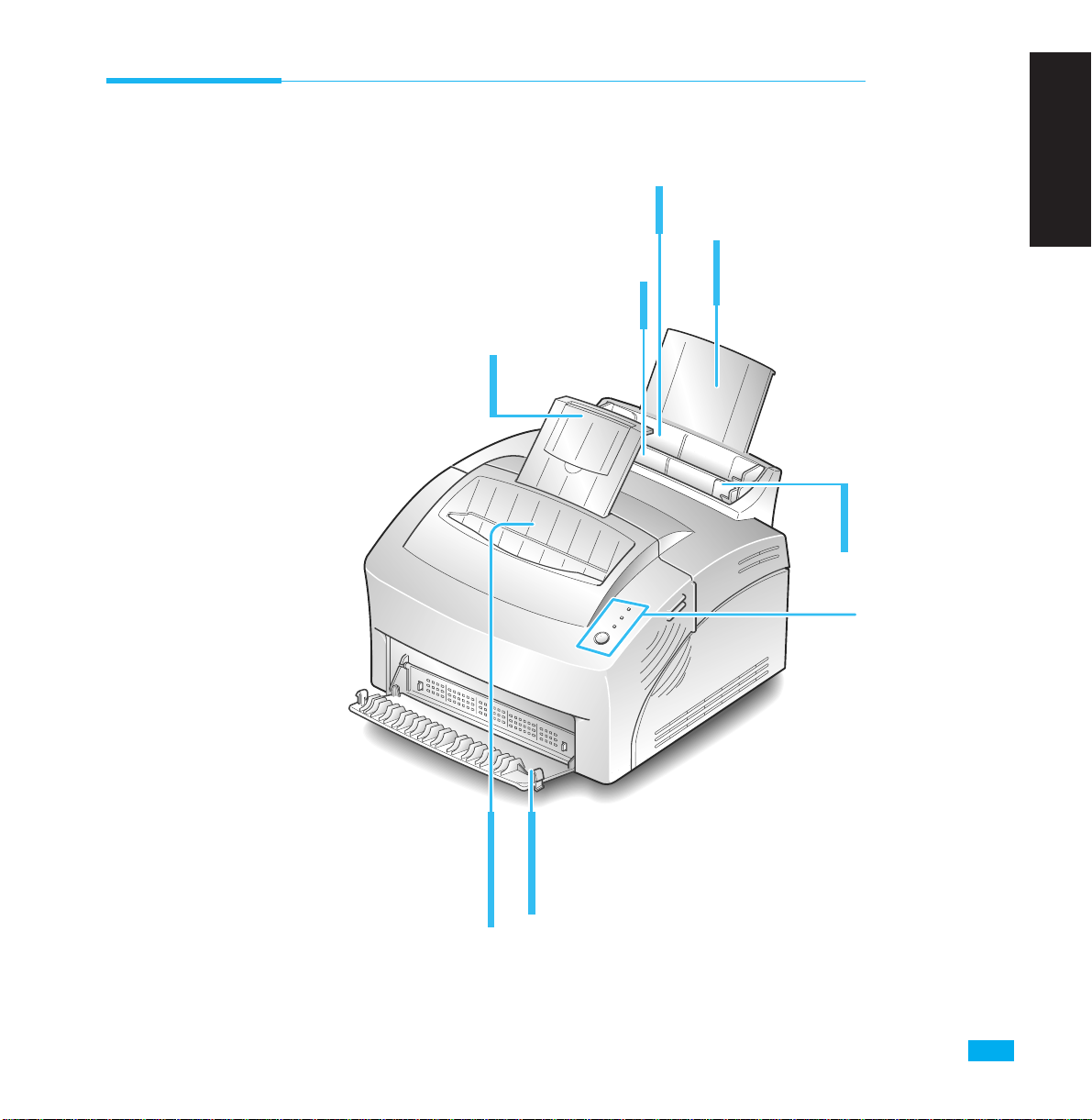

Automatic Paper Feeder

Holds 150 sheets of paper.

Paper Guides

Adjust to the

width of paper.

Face-down Stacker

Holds printed documents.

If printed on plain paper,

a maximum of 100 sheets

can be held.

Stacker Extender

Supports paper stacked in the

paper output bin.

Face-up Stacker

Holds a single sheet of special media (transparency,

label, envelope, and heavy weight paper) with print

side facing up.

Operator Panel

Tray Extender

Supports paper stacked in the

automatic paper feeder.

Manual Paper Feeder

Used to feed a single sheet of paper.

Control Locations and Functions

Front View

4

Setting Up Your Printer

Rear View

Inside

Power Switch

Power Cord Connector

USB Port

Printer Cable

Connector

Front Cover

Toner Cartridge

5

Setting Up Your Printer

ENGLISH

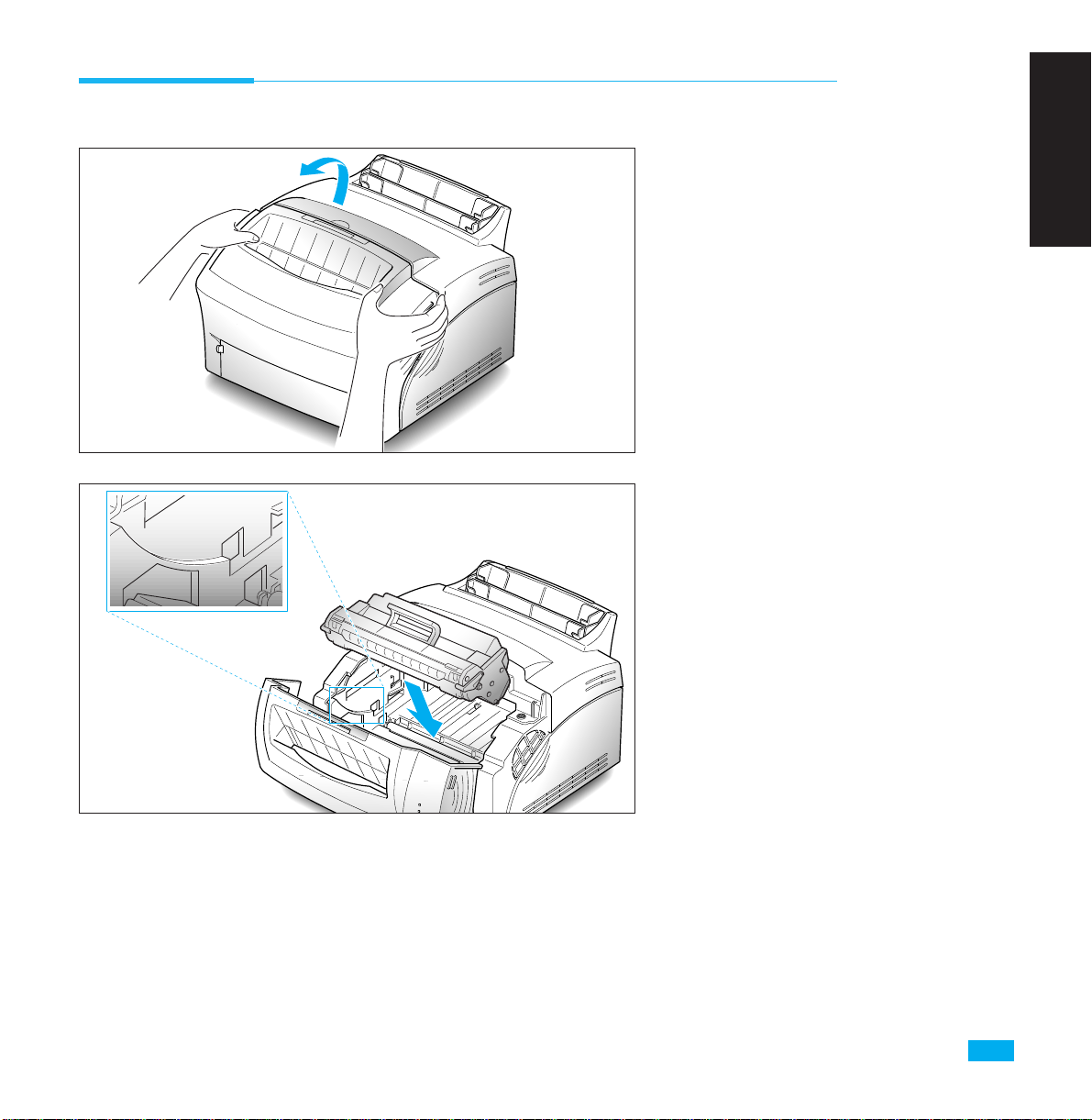

Installing the Toner Cartridge

2. Unpack the Toner Cartridge.

Carefully remove the sealing tape.

3. Rock the Cartridge 5 or 6 times to

distribute the toner.

4. Find the cartridge slots inside the

printer, one on each side.

5. Grasp the handle and slide the

Cartridge down between the toner

cartridge slots, until it drops into

place.

6. Close the cover.

1. To open the printer cover, hold the

cover using both hands and pull it

toward you.

6

Setting Up Your Printer

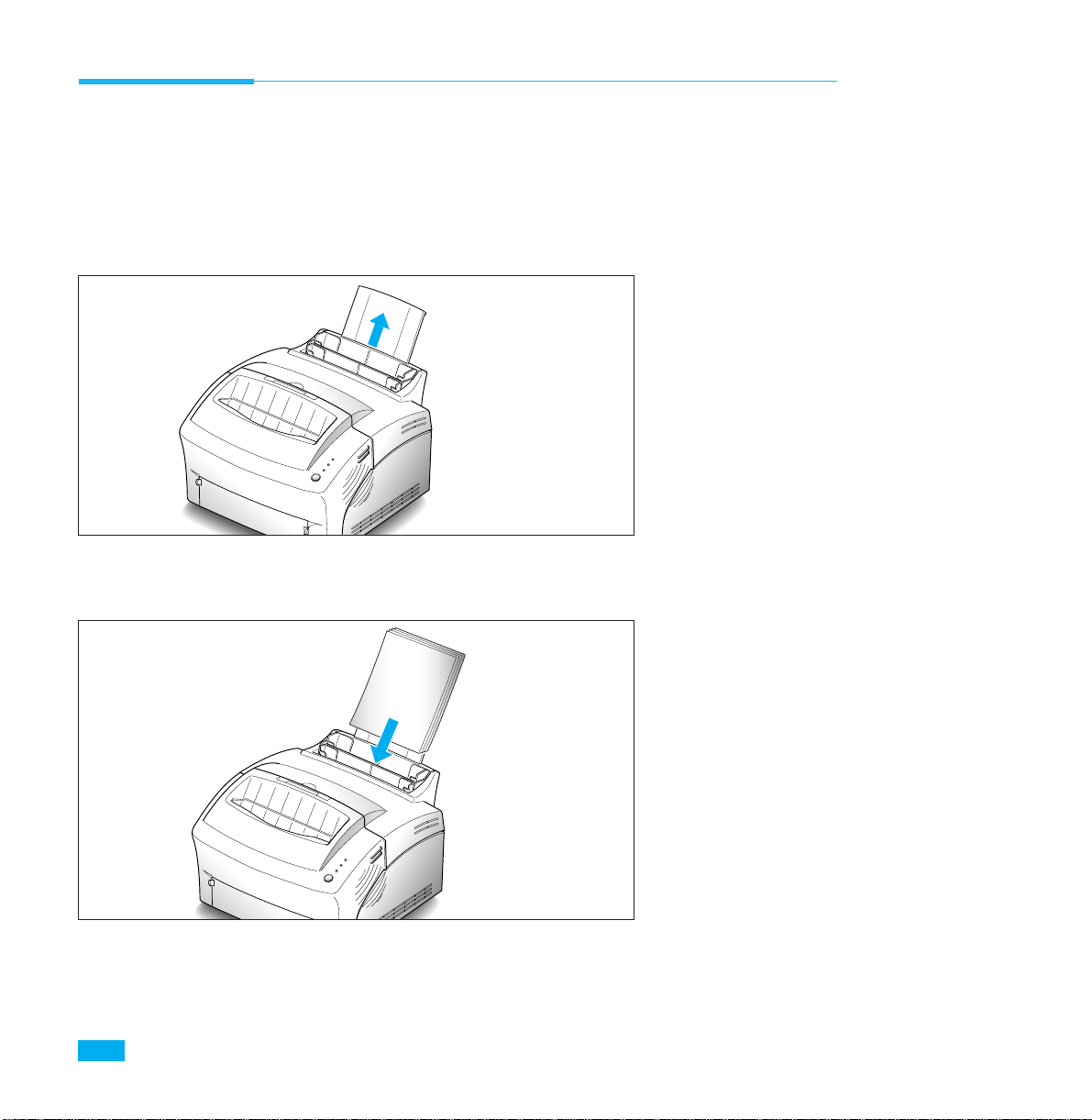

3. Insert the paper in the paper feeder.

If the paper has a preferred print side,

place the print side facing you. If you

use letterhead paper, load the paper

with the letter-head edge down and

facing you.

Loading Paper

For best results, use high quality 75g/m2 (20 lb) xerographic paper.

Note: For more information on loading paper and other print material, refer

to ‘Loading Print Material’ on page 18.

1. Pull the extender on the automatic

paper feeder up, until it stops.

2. Before loading the paper, flex the

sheets back and forth to loosen them,

then fan them. Tap the edges on a

table top to straighten them. Doing

this before you load paper helps

prevent paper jams.

Don’t load too much. This feeder

holds up to 150 sheets.

7

Setting Up Your Printer

ENGLISH

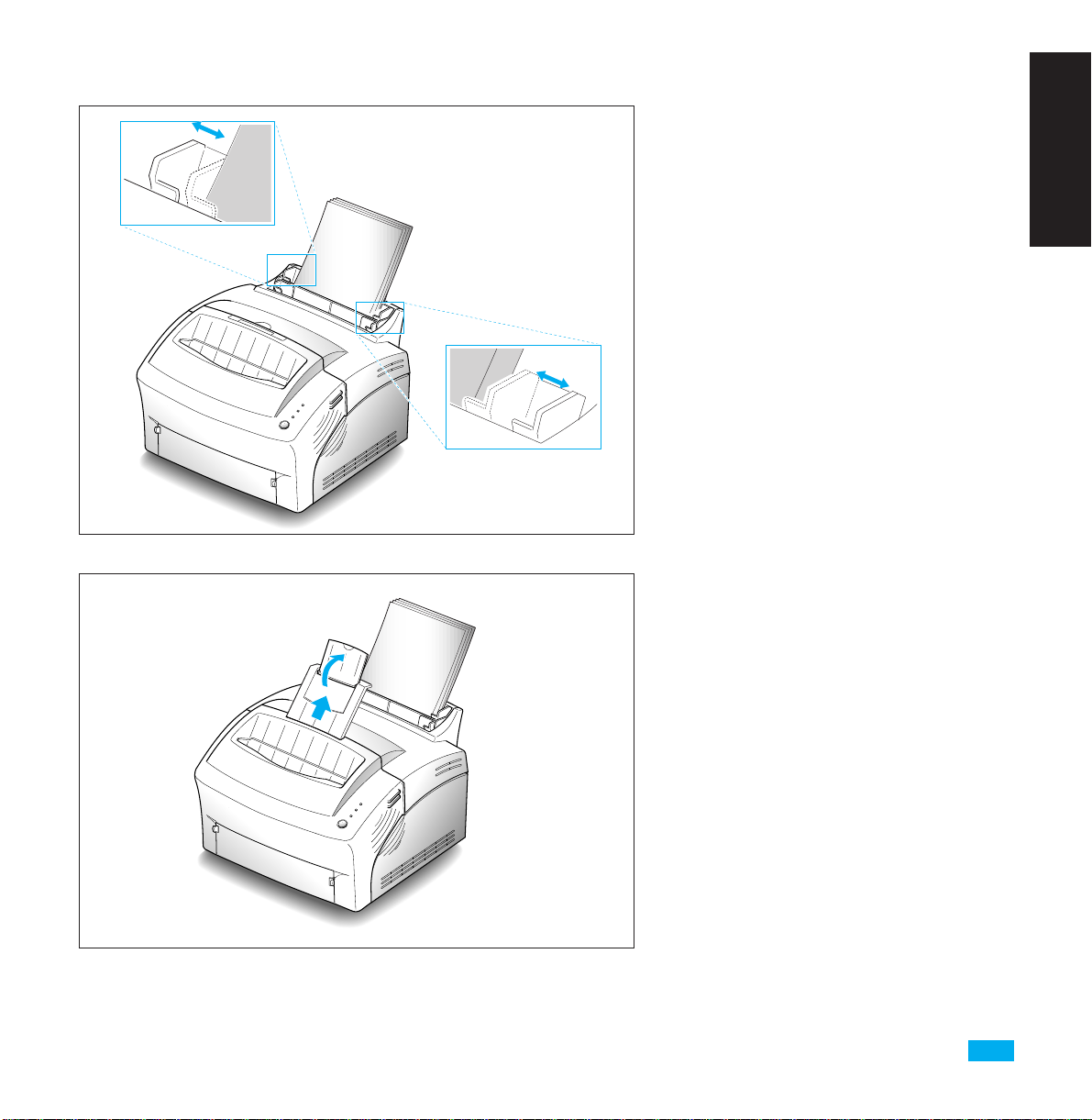

5. Pull up the extender on the facedown stacker. The face-down stacker

can hold up to 100 printed pages.

4. Adjust the paper guides to the width

of the paper.

8

Setting Up Your Printer

Note: Make sure the printer power is off when you connect it to the

computer.

Connecting to Your Computer

Your printer has parallel interface port, which allows you to use it with IBM PCs and

compatible computers. You have to purchase a Centronics compatible parallel interface

cable that supports bi-directional communications (IEEE standard 1284). Ask your dealer

for assistance if you need help selecting the right cable.

Your printer also has Universal Serial Bus (USB) port. The Universal Serial Bus is an

interface which allows the printer to be connected to multiple peripheral devices. If your

PC has USB port, you can connect your printer to your PC by using USB interface.

Using Parallel Port

1. Plug the parallel interface cable into

the connector on the back of the

printer. Push the clips at each end of

the connector into the notches on the

printer cable. The clips snap when

pushed into the notches.

2. Attach the other end of the parallel

cable to your computer.

9

Setting Up Your Printer

Using The USB Port

The USB port requires USB v1.0-compliant cable. Ask your dealer for assistance if you need

help selecting the right cable.

1. Make sure that both the printer and computer are turned off.

Note: To print using USB interface, you must install the USB driver. See page 15.

2. Plug the USB cable into the

connector on the back of the printer.

3. Connect the other end of the cable to

the USB port on your computer. See

your computer documentation if you

need help.

ENGLISH

10

Setting Up Your Printer

Powering On the Printer

2. Turn the printer on. As the printer

powers up, all control panel lights

turn on briefly.

1. Plug one end of the power cord into

the connector at the back of the

printer, and the other end into a wall

outlet.

11

Setting Up Your Printer

ENGLISH

Installing Software

Included with your printer is a CD-ROM containing printer drivers for some of the most

popular Windows software applications. To operate your printer, you must install a printer

driver, which translates data from your application into data the printer understands.

(Installation procedures follow this section.)

The CD-ROM shipped with your printer contains the following printer drivers and utilities.

• PCL printer driver for Windows NT 4.0.

• PCL 6 printer driver for Windows 95/98 and Windows 3.1x.

• Status Monitor enables you to monitor the status of print jobs.

• Remote Control Panel, which allows you to set up your printer to work properly with

Window applications run inside a Windows 3.1x/95/98 or NT Windows.

• USB driver, which allows your printer to connect USB peripheral.

3. When only the READY light is steadily

on, press and hold the button for about

3 seconds. All the indicators blink. Then

let it go. Atest page should print out.

ERROR

PAPER

READY

12

Setting Up Your Printer

Installing Printer Driver

System Requirement

Before you start, make sure you have the following computer setup. (These are the

minimum requirements.)

• IBM or compatible with a 386 or higher processor

• Windows 95, Windows 98, Windows 3.1x, or Windows NT

• 4 MB of available hard disk space

• 4 MB of RAM

• Centronics-compatible parallel cable (IEEE 1284-compliant)

Windows 95/98/NT 4.0 Installation

1. Turn on the computer and start Windows.

If Windows 95/98 recognizes the new printer, go to the section “Windows 95/98 Plug and

Play” on page 13.

2. Insert the setup CD-ROM into your CD-ROM drive.

If Windows does not automatically run the CD-ROM, go to the section “If Windows Does

Not Run the CD-ROM” on page 13.

3. Click the language you want.

13

Setting Up Your Printer

ENGLISH

Windows 95/98 Plug and Play

1. At the ‘New Hardware Found’ dialog box, click on the OK button.

2. Insert the setup CD-ROM into your CD-ROM drive.

3. Follow the instructions on the screen.

If Windows Does Not Run the CD-ROM

1. Select Run from the Start menu.

2. Type d:\setup.exe on the command line (where “d” is your

CD-ROM drive letter), then click OK.

3. Follow the instructions on the screen.

4. Click the Item you want to install.

5. Follow the instructions on the screen.

14

Setting Up Your Printer

Windows 3.1x Installation

1. Make sure the printer is plugged and connected to your computer. Turn on your

printer and computer.

2. Insert the CD-ROM disk into your CD-ROM drive.

3. From the Program Manager window, double-click Main, and File Manager.

4. From the File Manager window, select your CDROM drive, execute setup16.exe and click the

language you want.

5. Click the Item you want to install.

6. Follow the instructions on the screen.

15

Setting Up Your Printer

Uninstalling the Printer Driver

An uninstall utility is supplied with the printer driver to enable you to remove the driver

and all associated files from your hard disk, if so required.

To uninstall the driver, proceed as follows:

Windows 95/98/NT 4.0: From the Start menu, select Programs, Olivetti PG L8en,

Uninstall Olivetti PG L8en Driver.

Installing Printer Utilities (USB & Remote Control Panel)

Windows 3.1x Installation

1. From the Program Manager window, double-click Main, and File Manager.

2. From the File Manager window, select your CD-ROM drive, execute setup16.exe and

click the language you want.

3. Select the Item you want to install.

4. Follow the instructions on the screen.

Windows 95/98/NT 4.0 Installation

1. Select Run from the Start menu.

2. Type d:\setup.exe on the command line (where ‘d’ is your CD-ROM drive letter), and

click the language you want.

3. Select the Item you want to install.

4. Follow the instructions on the screen.

DOS Installation

1. Go to e:\dosutl in the CD-ROM and select the language you want.

2. Copy dosrcp.exe in the selected language to your HDD.

ENGLISH

Printing on Network Printer

Setting Up Host PC Printer

1. Start Windows.

2. Click Start, select Control Panel, and double-click on the Network icon.

3. Click File and Print Sharing, check box(es), then click OK.

Close the window.

4. Click Start and select Printers from Settings, then double-click your printer name

(Olivetti PG L8en).

5. Select Properties in Printer menu.

6. Click the Sharing tab, then check Shared As, fill in the Shared Name field, and click

OK.

Client PC Sharing Setup

1. Right-click the Start button, and select Explore.

2. Open your network folder in the left column.

3. Right-click the shared name, and select Capture Printer Port.

4. Select the port you want, click Reconnect at log on check box, the click OK button.

5. From the Start menu, select Settings, then Printers.

6. Double-click your printer icon (Olivetti PG L8en).

7. From the Printer menu, select Properties.

8. Press the Details tab, select the printer port, then press OK button.

16

Setting Up Your Printer

ENGLISH

Capacity

150 sheets

(Approx.)

1 sheet

10 envelopes

(Approx.)

1 envelope

10 items

(Approx.)

1 item

Notes:

•When you print, select the correct paper size and source in your application.

•Depending on paper thickness, the maximum capacity may be reduced.

Paper Handling

Selecting Paper Types and Feed Source

One of the most important things you can do to assure the best possible print quality from

your printer is to select the correct paper. Your printer produces letter quality output on

most plain bond papers, including cotton bond and photocopying papers; it does not

require special papers. However, the print quality varies with different paper types. Be sure

to test a small quantity of paper before you purchase a large quantity.

You can print on any of the following paper types:

Type

Plain paper

(20 to 30 Ib)

Envelopes

Transparency

Film Paper

Labels

Size

Letter: 8

1/2

x 11”

Legal: 8

1/2

x 14”

Executive: 7

1/4

x 10

1/2

”

A4: 210 x 297 mm

A5: 148 x 210 mm

B5: 182 x 257 mm

Folio: 8

1/2

x 13”

Custom size

COM-10: 4

1/8

x 9

1/2

”

Monarch: 3

7/8

x 7

1/2

”

C5: 162 x 229 mm

C6: 114 x 162 mm

DL: 110 x 220 mm

Feed Source

Automatic feeder

Manual feeder

Automatic feeder

Manual feeder

Automatic feeder

Manual feeder

17

Paper Handling

18

Paper Handling

2. Prepare the print material for

loading.

• For paper and envelopes:

- Flex paper or fan envelopes back

and forth. Do not fold or crease the

paper. Straighten the edges on a

level surface.

Note: If envelopes jam while printing, try reducing the number of envelopes in the automatic feeder.

Loading Print Material

You can stack paper, envelopes, card stocks, labels, or transparencies in the automatic paper

feeder to feed automatically. The automatic feeder can hold a maximum of 150 sheets of

plain paper, or 10 envelopes or other print media. The maximum capacity may reduce,

depending on the thickness.

Note: If you experience feeding problems, try printing one at a time from the manual feeder. See

page 22.

Extender

Automatic feeder

Manual feeder

1. Pull the extender on the automatic

feeder up until it stops.

19

Paper Handling

ENGLISH

3. Load the print material in the

automatic feeder. Do not load too

much print material. Do not mix

types. See the following directions to

load each type of print material.

• Load paper or transparencies with

the print side facing you.

• For transparencies:

- Hold the transparencies by the

edges and avoid touching the

print side.

- Fan the stack of transparencies to

prevent feeding failures. Be careful

not to scratch or leave fingerprints

on the print sides.

Place the print side

facing you.

20

Paper Handling

• Load envelopes with the flap side

facing away from you. The stamp area

is on the right side. The end of the

envelope with the stamp area enters

the feeder first.

• Load letterhead paper with the design

facing you. The top edge of the sheet

with the logo should enter the printer

first.

Notes:

• Do not feed stamped envelopes. The stamp is shown for placement only.

• Never use envelopes with clasps, snaps, windows, coated lining, or self-stick adhesives.

• These envelopes may severely damage the printer.

LETTERHEAD

21

Paper Handling

ENGLISH

5. Pull up the extender on the face-

down stacker. The face-down stacker

can hold a maximum of 100 printed

pages.

6. Before starting your print job, make

sure you select the correct paper size

and feed source in your application.

4. Adjust the guides to the width of

the print material. Slide the

guides until they lightly touch the

stack of print material. Do not

bend the print material.

Paper guide

Paper guide

Face-down

stacker

22

Paper Handling

Feeding Manually

Use the manual feeder to feed one sheet at a time into your printer.

1. If necessary, open the face-up

stacker. See page 23.

2. Load the print material in the

manual feeder and adjust the paper

guides to the width of the print

material.

See the instructions to load each type

of material on page 17.

3. Push it all the way in.

4. Before starting your print job, make sure you select the correct paper size and feed

source in your application.

5. Press the button on the operator panel. Printing starts.

6. If you have more than one page to print, the PAPER indicator blinks to alert you to

feed the next sheet each time the printer is ready to print the next page. Press and hold

the button for about 2 seconds until the printer pulls in the paper, and starts printing.

Note: If you press the button without paper in the manual feeder, the printer will

automatically use paper into the automatic paper feeder.

Automatic paper feeder

Paper guide

Paper guide

Manual paper feeder

The manual feeder is in front of the

automatic feeder.

23

Paper Handling

ENGLISH

2. If you use the face-up stacker, printed

pages exit through the front output

path, with the printed side up.

Using Face-up Stacker

Notes:

• The face-up stacker may not hold the printed materials properly.

• The printed pages will not stack in the standard face-down stacker unless you close the face-up

stacker. The face-down stacker can hold up to 100 printed pages. When you finish using the faceup stacker, you must close the face-up stacker.

1. Push both sides of the stacker marked

, and the stacker will open.

24

Paper Handling

Paper Guidelines

When selecting or loading paper, envelopes, or other special media, keep these guidelines

in mind:

• Attempting to print on damp, curled, wrinkled, or torn paper can cause paper jams and

poor print quality.

• Use cut-sheet paper only. You cannot use multipart paper.

• Use only high quality, copier grade paper. Avoid paper with embossed lettering,

perforations, or texture that is too smooth or too rough.

• Colored paper should be of the same high quality as white photocopy paper. The

pigments must withstand the printer ’s fusing temperature of 392 oF (200 oC) for 0.1

second without deterioration. Do not use paper with a colored coating that was added

after the paper was produced.

• Pre-printed forms must be printed with non-flammable, heat-resistant inks that do not

melt, vaporize, or release hazardous emissions when subject to the printer’s

approximately

392 oF (200 oC) fusing temperature for 0.1 second.

• Store paper in its ream wrapper until ready to use. Place cartons on pallets or shelves, not

on the floor. Do not place heavy objects on top of the paper, whether it is packaged or

unpackaged. Keep it away from moisture, or other conditions that can cause it to wrinkle

or curl.

• During storage, moisture-proof wrap (any plastic container or bag) should be used to

prevent dust and moisture from contaminating your paper.

• Always use paper and other media that conform with those listed under ‘Specifications’

on page 58.

• When you choose envelopes, use only well-constructed envelopes with sharp, and well

creased folds.

- DO NOT use envelopes with clasps and snaps.

- DO NOT use envelopes with windows, coated lining, self-stick adhesives, or other

synthetic materials.

- DO NOT use damaged or poorly made envelopes.

ENGLISH

INDICATOR DESCRIPTION

READY (on) The printer is ready to receive and process data.

READY (blink) The printer is receiving or processing data, or the print engine is

running.

READY (off) The printer is off-line.

ERROR (on) • There is no image cartridge installed, or the cover is open

• Print error occurs.

• If PAPER light is also on, there is a paper jammed.

ERROR (blink) The printer memory is insufficient for printing.

PAPER (on) The paper bin is empty.

PAPER (blink) The printer is in manual feed mode and waiting you to feed paper

into the manual feeder.

All lights Blinking System error occurs.

Operating Your Printer

Operator Panel

The operator panel has the indicator lights and one button. Depending on the light

sequence, pressing the button activates different printer functions, such as resetting the

printer, or running self-test. See page 26.

ERROR

PAPER

READY

Indicator Lights

25

Operating Your Printer

26

Operating Your Printer

Button Function

Image Cartridge

Cleaning

When you print a file if you have selected `Manual Feed’ source, the printer waits you to

feed paper into the manual feeder. When you are ready, press and hold down the button

for about 2 seconds.

The printer pulls in the page, and starts printing.

Press the button each time you feed paper manually.

FUNCTION USAGE

On-line/Off-line Pressing the button toggles the printer between on-line (READY light on) and off-line

(READY light off) status.

Manual Feed Start

Reset To clear all data from the printer ’s memory except permanent fonts and macros, and

then restore the user default settings:

Press the button to turn the printer off-line. With the READY light off, press and hold

down the button until all lights are blinking (approximately four seconds), then release the

button.

Self-test To perform a printer self-test:

While the printer is on-line (READY light on), press and hold down the button until all

three lights are blinking (approximately four seconds), then release the button. A one-page

printer status sheet will be printed.

To remove excess toner from the image cartridge: While the printer is on-line (READY

light on), press and hold down the button until all three lights remain lit (not blinking;

approximately seven seconds) and the printer begins to cycle up (starts feeding paper),

then release the button. One sheet will be printed.

27

Operating Your Printer

ENGLISH

Selecting Your Printer

To use all of the features of your Olivetti PG L8en printer, make sure it is selected as the

default printer. When you install the printer driver, Olivetti PG L8en is automatically set as

the default printer. If you use more than one printer, select PG L8en as the default printer as

follows:

Windows 95/98

1. Select Start, Settings, then Printers.

2. Double-click Olivetti PG L8en PCL 6.

3. Select Set As Default from the Printer menu.

Windows 3.1x

1. Double-click the Control Panel icon from the Main program group.

2. Double-click the Printers icon.

3. Select Olivetti PG L8en PCL 6.

4. Click Set As Default Printer.

Windows NT 4.0

1. Select Start, Settings, then Printers.

2. Double-click Olivetti PG L8en PCL.

3. Select Set As Default from the Printer menu.

28

Operating Your Printer

Printing a Document

This procedure describes the general steps required for printing from various Windows

applications. The exact steps for printing a document may vary depending on the

application you are using. Refer to your application’s documentation for the exact printing

procedure.

1. Start the program you are using to create the document, and/or open the document you

want to print.

2. Choose Print or Print Setup from the File menu. The Print or Print Setup dialog

appears to make changes to the printer setting.

3. If you click on Properties, Setup, or Options in the dialog box, you’ll access the

printer driver and you can make any additional setting as appropriate for printing

your document. See ‘Print Settings’ in the reference manual on page 31. The settings you

can change depend on the printer you selected.

4. Select OK to close the dialog box.

5. After making any necessary changes to the print parameters, select OK to start the

print job.

Note: The way you access the printer driver varies depending on the programs you use.

Print Settings

Most Windows applications allow you to make changes to the printer settings. This

changes the number of copies, sequence of the pages, paper orientation, and margins.

If you click Properties, Setup, or Options in the Print dialog box, you’ll access the printer

driver ’s dialog box. It allows you to change additional printer settings.

Note: Most Windows applications will override settings you specify in the printer driver. Change all

printer settings available in the software application first, and any remaining settings with

the printer driver.

29

Operating Your Printer

ENGLISH

Overlays

Using this tab, you can create, delete and load over lay. For detailed information about each setting, click Help at

the bottom of the dialog box.

Watermarks

Using this tab, you can edit, save, delete and control watermartk. For detailed information about each setting,

click Help at the bottom of the dialog box.

About

This tab shows the software version and useful information about your printer.

Olivetti PG L8en PCL 6 driver includes 5 tabs.

Paper Options

Using this tab, you can change the number of copies, page

orientation, paper size, paper source, and so on. For

detailed information about each setting, click Help at the

bottom of the dialog box.

Graphics

Using this tab, you can change graphics mode, resolution,

text mode, toner saver, and so on. For detailed information

about each setting, click Help at the bottom of the dialog

box.

30

Accessories

4 Mbyte memory module

8 Mbyte memory module

16 Mbyte memory module

32 MByte memory module

Process unit B0 335

Drivers and documentation, CD-ROM

Operating Your Printer

Loading...

Loading...