Oliver MODEL 619-MDP Instruction Manual

Walker, Michigan, U.S.A. 49534

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 619-MDP

DOUGH PRESS

0619S20000-CV3

619-MDP DOUGH PRESS

INDEX

Section Description Document No. Page No.

SAFETY INSTRUCTIONS -------------------------------------- 0619S20141 --------------------------- 1-1

DESCRIPTION/SPECIFICATIONS --------------------------- 0619S20130---------------------------- 2-1

Description -------------------------------------------------------------------------------------------------- 2-1

Physical Specifications----------------------------------------------------------------------------------- 2-1

Electrical Specifications---------------------------------------------------------------------------------- 2-2

Electrical Wiring Diagrams ----------------------------------------------------------------------------- 2-1

OPERATING INSTRUCTIONS -------------------------------- 0619S20131 --------------------------- 3-1

Before You Start ------------------------------------------------------------------------------------------- 3-1

Basic Operation -------------------------------------------------------------------------------------------- 3-1

MAINTENANCE --------------------------------------------------- 0619S20148 --------------------------- 4-1

Cleaning ------------------------------------------------------------------------------------------------------4-1

Cleaning ---------------------------------------------------------------------------------------------------- 4-1

Lubrication ------------------------------------------------------------------------------------------------- 4-3

Hydraulic Oil Specification ----------------------------------------------------------------------------- 4-3

Hydraulic Filter Replacement -------------------------------------------------------------------------- 4-3

Removing the Lid ---------------------------------------------------------------------------------------- 4-3

Replacing the Locking Hook or Cam ---------------------------------------------------------------- 4-4

Replacing a Pressing Plate ---------------------------------------------------------------------------- 4-4

Removing the Backing Plate --------------------------------------------------------------------------- 4-4

Replacing the Hydraulic Cylinder --------------------------------------------------------------------- 4-5

Removing the Motor -------------------------------------------------------------------------------------- 4-5

Changing the Pump or Coupling ---------------------------------------------------------------------- 4-6

Replacing the Control Valve ---------------------------------------------------------------------------- 4-6

TROUBLESHOOTING ------------------------------------------- 0619S20133 --------------------------- 5-1

The Ram up Light Does Not Come On -------------------------------------------------------------- 5-1

The Motor Hums but Will Not Start ------------------------------------------------------------------- 5-1

The Motor Runs but Stalls at Either End of the Cylinder’s Travel ---------------------------- 5-1

The Motor Runs Slowly but Stalls Easily before Completion of its Stroke ----------------- 5-1

The Motor Has Stalled and Can Not be Restarted ----------------------------------------------- 5-2

The Overload Relay Continually Trips --------------------------------------------------------------- 5-2

The Dough Press is Not Pressing Properly -------------------------------------------------------- 5-2

RECOMMENDED SPARE PARTS -------------------------- 0619S20134 --------------------------- 6-1

REPLACEMENT PARTS SECTION

MAIN FRAME ASSEMBLY ------------------------------------ 0619S20135 --------------------------- 7-1

Drawing ------------------------------------------------------------------------------------------------- 7-1

Parts List ----------------------------------------------------------------------------------------------- 7-2

Continued

0619S20129

REV 10/12/10

0-1

INDEX (Continued)

REPLACEMENT PARTS SECTION (Continued)

Section Description Document No. Page No.

COVER ASSEMBLY --------------------------------------------- 0619S20144 --------------------------- 8-1

Drawing ------------------------------------------------------------------------------------------------ 8-1

Parts List ----------------------------------------------------------------------------------------------- 8-2

Parts List ----------------------------------------------------------------------------------------------- 8-3

HYDRAULIC ASSEMBLY -------------------------------------- 0619S20137 --------------------------- 9-1

Drawing ------------------------------------------------------------------------------------------------ 9-1

Parts List ----------------------------------------------------------------------------------------------- 9-2

LID ASSEMBLY -------------------------------------------------- 0619S20138 -------------------------- 10-1

Drawing ----------------------------------------------------------------------------------------------- 10-1

Parts List ---------------------------------------------------------------------------------------------- 10-2

PUSHER ASSEMBLY ------------------------------------------ 0619S20139-------------------------- 11-1

Drawing ----------------------------------------------------------------------------------------------- 11-1

Parts List ---------------------------------------------------------------------------------------------- 11-2

ELECTRICAL ASSEMBLY ------------------------------------ 0619S20140 -------------------------- 12-1

Drawing ----------------------------------------------------------------------------------------------- 12-1

Parts List ---------------------------------------------------------------------------------------------- 12-2

WARRANTY ------------------------------------------------------- GEN 040225

WARRANTY PROCEDURE------------------------------------ GEN 040226

RETURNED PARTS POLICY --------------------------------- GEN 040227

0619S20129

REV 10/12/10

0-2

619-MDP DOUGH PRESS

SAFETY INSTRUCTIONS

Every effort has been made by Oliver Products Company to provide you with a safe

machine. It is essential, however, that machine operators and maintenance personnel

observe the following safety precautions.

1. Before attempting to operate your dough press read this manual. Never allow an

untrained person to operate this machine.

2. Make sure that the machine is only connected to a properly grounded electrical

supply source of sufficient capacity for the load the divider will put on it. Always

unplug the machine when it is not in use.

3. Always make sure the machine has been disconnected and locked-out from the

power supply before cleaning or servicing.

4. All guards must be in place before starting the machine.

5. Keep your hands away from the moving parts of the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing. Shirt tails should be tucked in.

8. In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the machine in the operating instructions.

0619S20141 1-1

THIS PAGE WAS INTENTIONALLY

LEFT BLANK.

GEN020319

619-MDP DOUGH PRESS

DESCRIPTION/SPECIFICATION

Description

The Oliver dough press consists of a hopper which can be loaded with dough from an

approximate minimum of ten and one half pounds up to forty pounds, (depending on the

density of the dough). The lid and sides of the hopper are made of hard anodized and

Teflon impregnated cast aluminum. The pressing plate located at the bottom of the

hopper is manufactured of a food grade plastic and is raised by hydraulic pressure to

compress the dough. This makes the machine ideal for puff and fine pastries and

products requiring dough lamination.

The hydraulic pump is powered by a two horsepower, totally enclosed motor. The

system has a built-in four and one half gallon hydraulic oil tank making the machine

totally self-contained and is provided with casters to allow for easy movement about the

work area.

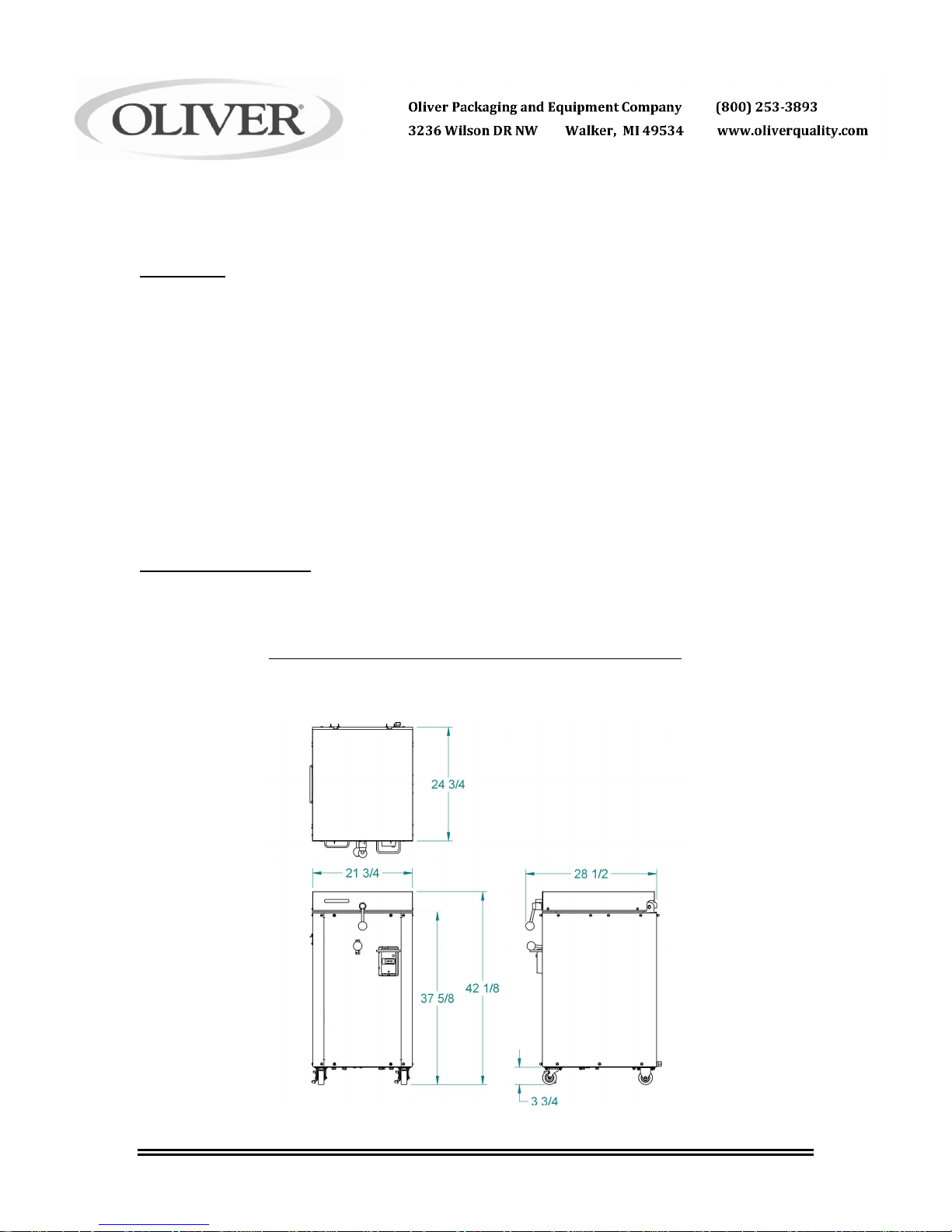

Physical specifications

OVERALL MACHINE DIMENSIONS

0619S20130 2-1

Physical specifications (continued)

Net Weight:

Approximately 455 pounds.

Shipping Weight:

Approximately 500 pounds.

Product Capacities:

Fill Capacity (approximate) = 10-1/2 to 40 pounds

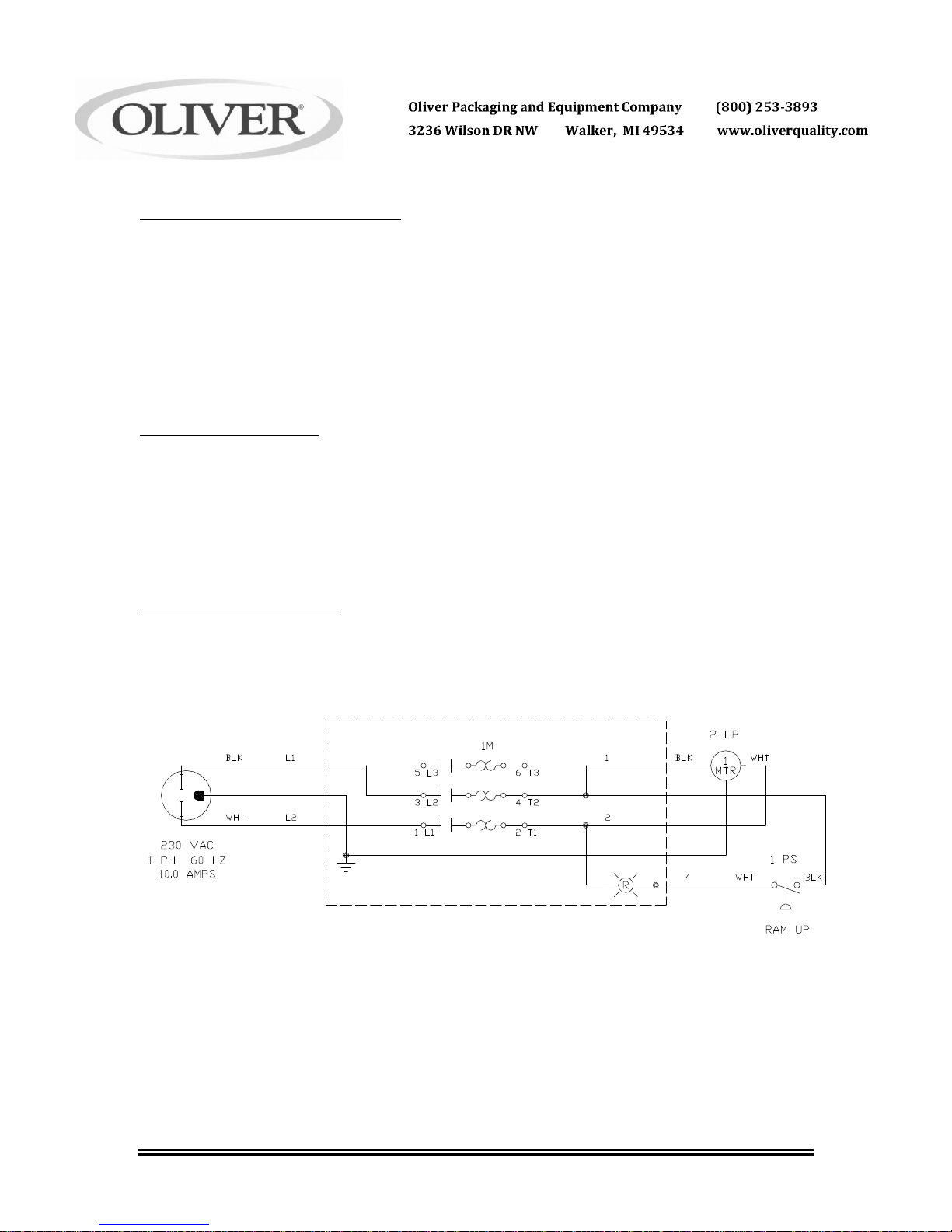

Electrical Specifications

2 Horse Power, 1 phase, 60 hertz, 230 Volts AC, 10 Amps.

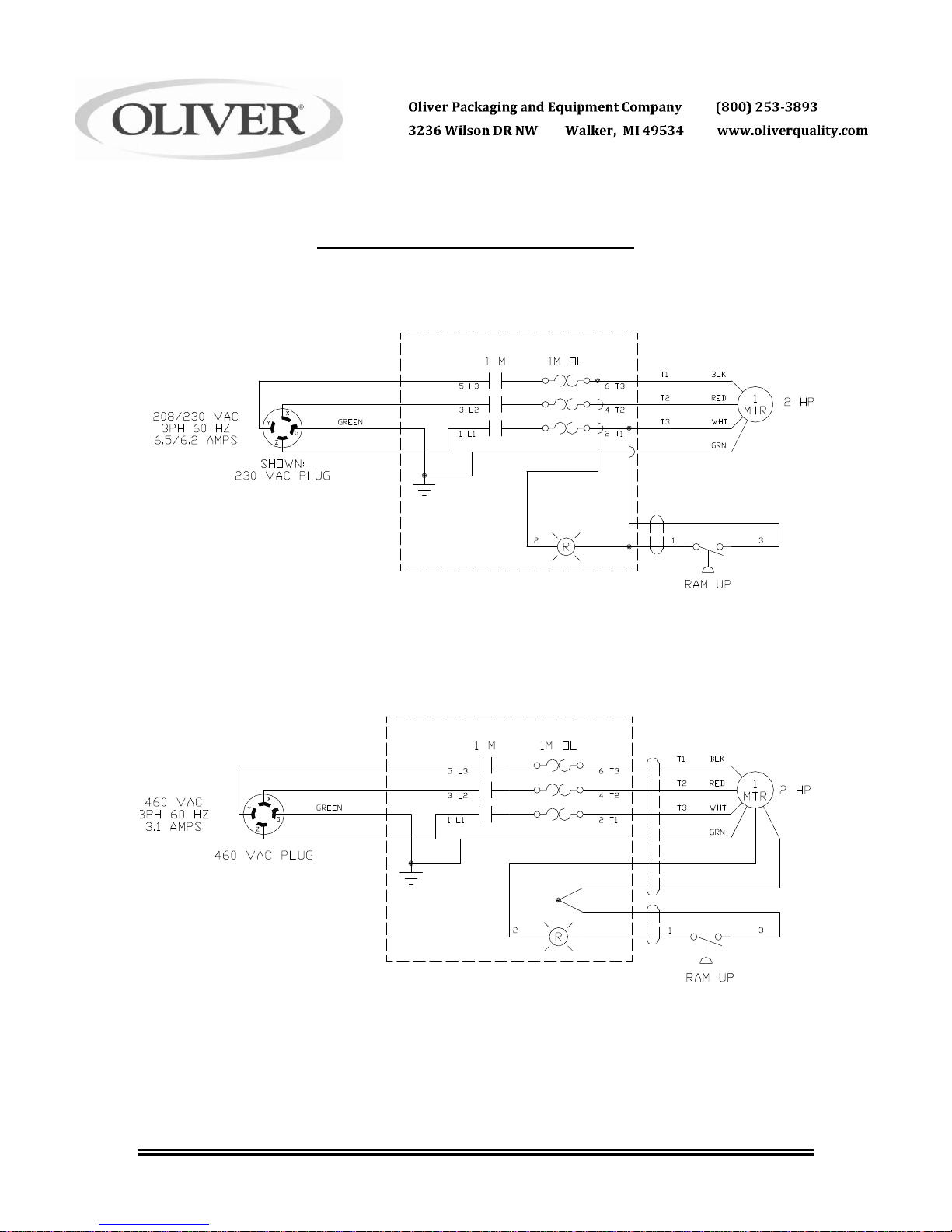

2 Horse Power, 3 phase, 60 hertz, 208 Volts AC, 6.5 Amps.

2 Horse Power, 3 phase, 60 hertz, 230 Volts AC, 6.2 Amps.

2 Horse Power, 3 phase, 60 hertz, 460 Volts AC, 3.1 Amps.

Others consult factory

Electrical Wiring Diagrams

1 ph, 60 hz, 230 VAC

0619S20130 2-2

Electrical Wiring Diagrams (Continued)

3 ph, 60 hz, 208/230 VAC

3 ph, 60 hz, 460 VAC

0619S20130 2-3

619-MDP DOUGH PRESS

OPERATING INSTRUCTIONS

Before You Start

CAUTION

THE DOUGH PRESS SHOULD ONLY BE PLUGGED INTO AN OUTLET

WITH THE SAME VOLTAGE AS STATED ON THE NAMEPLATE

Before starting a new dough press with THREE PHASE electrical power for the first time

you should check to see if the motor is running in the correct direction. Remove the front

cover by removing the four thumbscrews which secure it; you will also have to remove

the handle from the directional control lever before removing the front cover. Once the

cover has been removed you should be able to see the fan end of the motor on your

dough press, this fan MUST rotate in a clockwise direction.

CAUTION

EXTENDED RUNNING OF A DOUGH PRESS WITH THE MOTOR

ROTATING IN THE INCORRECT DIRECTION WILL SEVERELY

DAMAGE THE HYDRAULIC PUMP OF YOUR MACHINE.

If the motor is rotating in the incorrect direction turn the machine off, disconnect it from

the power supply and have a qualified electrician reverse two of the three power wires in

the plug at the end of the power cord. DO NOT move the ground, (green), wire.

WARNING

ALWAYS HAVE ELECTRICAL WORK DONE BY QUALIFIED

ELECTRICIANS ONLY.

Recheck the dough press making sure that it is now running in the correct direction,

(clockwise looking at the fan end of the motor). Each time the machine is moved to a

different power supply or has electrical work done which could alter the motor rotation,

the motor must be rechecked for proper rotation.

Basic Operation

· Make sure the floor of the hopper has been lowered before attempting to open the lid

of the divider.

· Open the lid and load the dough into the hopper. Spread the dough over the floor of

the hopper making it approximately the same height, this is done to eliminate large

air pockets.

0619S20131 3-1

Basic Operation (Continued)

· Close the lid and turn the handle in a clockwise direction making sure it is secure.

· With the machine running grasp the control valve handle and lift it to start the floor of

the hopper up. Hold it in this position until the light on the starter switch box comes

on, the light indicates that the preset pressing pressure has been achieved. Let

loose of the valve handle when you see that the light is on.

· Press the control valve handle down slightly to release the pressure on the lid so it

can be opened. Open the lid.

· The dough can now be removed and the above process repeated.

WARNING

NEVER LEAVE DOUGH IN A MACHINE WITHOUT OPENING THE LID;

RISING DOUGH MAY CAUSE EXPLOSIVE PRESSURES TO DEVELOP.

WARNING

NEVER FORCE THE LID HANDLE OPEN

· If dough has been left in the machine and the lid handle is difficult to turn,

recompress the dough by lifting the control valve handle until the light come on. This

will raise the floor of the hopper, after doing so lower the hopper floor by pressing

down on the control valve handle. This may have to be done more than once if

dough has been left in the machine for quite awhile. With the hopper floor all the

way down try to open the lid again. The handle should turn easily, if it does not,

recompress the dough and try again.

· The dough press is designed so that if dough is left in the hopper it will eventually

force the hopper’s floor to the bottom, thus allowing the dough to vent to the outside

of the machine through openings on the left side. If dough is coming out of these

openings follow the steps above, recompressing the dough a number of times before

attempting to open the lid.

0619S20131 3-2

619-MDP DOUGH PRESS

MAINTENANCE

WARNING

ALWAYS MAKE SURE THE MACHINE HAS BEEN DISCONNECTED

FROM THE POWER SUPPLY BEFORE CLEANING OR SERVICING

Cleaning

Remove- all scraps from lower pan. Open side doors and brushing out all scraps. Wash

all interior surfaces; Knives, pusher plates, hopper, lid surface with a damp rag and mild

soap solution. The exterior and contact surfaces should be cleaned daily using common

cleaners. The knives should be extended for easier cleaning. This can be done by

placing the cleaning separator, furnished with the machine, IN THE CENTER OF THE

HOPPER straddling the knives. Close the lid and bring the floor of the hopper up until

the light on the manual starter is on, lower the floor slightly. Open the lid and

disconnect the divider from the power supply. Clean the knives and plastic

compartment floors of all dough build-up. Rinse all interior surfaces with a damp rag and

clean water. Sanitize all interior surfaces with a damp rag and sanitizing solution. Air

Dry, leave divider lid open and allow interior to air dry before using.

Occasionally, or as required, remove the front and rear covers to allow access to the

drive chamber. There you should remove any build up of flour and dough particles in the

base of the machine and from around the motor. When finished replace the covers.

CLEANING INSTRUCTIONS FOR THE 619

RUN PRESS ALL THE WAY UP

0619S20148 4-1

******W A R N I N G******

UNPLUG MACHINE

USING THE ACCESS DOORS ON BOTH SIDES OF THE

UNIT

PULL DOOR UP, USE ONE HAND TO HOLD DOOR UP

WIPE DOWN MACHINE WITH OTHER, USING A RAG

OR A BRUSH

0619S20148 4-2

Loading...

Loading...