INDEX

Chap. 1

Chap. 2

GENERAL INFORMATION

1.1 General information page 26

1.2 Symbols page 27

1.2.1 Editorial pictograms page 27

1.2.2 Safety pictograms page 27

1.3 Technical data page28

1.3.1 Overall dimensions page 28

1.3.2 Technical features page 28

1.3.3 Technical notes page 28

1.3.4 Proper use page 28

1.4 List of accessories supplied page 29

1.4.1 Storage page 29

1.4.2 Receipt and unpacking page 29

INSTALLATION

2.1 Instructions for installation page 30

2.2 Selection of position of the unit page 30

2.2.1 Choice of best position for installing the air conditioner page 30

2.2.2 Dimensions and features of site where air conditioner is installed page 30

2.3 Installation of the unit page 31

2.3.1 Drilling the wall page 31

2.3.2 Provision for draining condensate for machines with heat pump page 33

2.3.3 Installation of air pipes and external gratings page 33

2.3.4 Power supply connection page 34

2.3.5 Fitting the unit on bracket page 35

2.4 Preparation for assembly/installation wall top part page 35

2.4.1 Introduction page 35

2.4.2 Removal of front casing page 35

2.4.3 Preparation of unit page 36

2.5 Working tests and identification of possible malfunction page 36

2.5.1 Evacuation of condensation water in case of emergency page 38

2.6 Periodical maintenance page 38

Chap. 3

USE AND MAINTENANCE (for the user)

3.1 Important Recommendations page 39

3.2 Names of parts page 39

3.2.1 List of Units page 39

3.2.2 Description of signal console page 39

3.3 Control of Air Conditioner using the remote control unit page 40

3.3.1 Remote control p age 40

3.3.2 Insertion of batteries page 40

3.4 Remote control page 40

3.4.1 Description of the remote control page 40

3.4.2 Switching on and control of operation page 41

3.4.3 Switching the unit on and off (button T1) page 41

3.4.4 Automatic Operation (button T2) page 41

3.4.5 Cooling function page 41

3.4.6 Dehumidifier only page 42

3.4.7 Fan only page 42

3.4.8 Heating function (only models with heat pump) page 42

3.4.9 Control of air flow direction page 42

3.4.10 Control of fan speed page 43

3.4.11 External air intake page 43

3.4.12 Night operation page 44

3.4.13 Setting programs for operation page 44

3.4.14 Setting of correct time page 44

3.4.15 Setting of time schedules for 1st and 2nd Operating Program (PROGR. 1 and PROGR. 2) page 45

3.4.16 Starting and stopping operating programs page 45

3.4.17 Resetting all functions of remote control page 46

3.4.18 Control of Air Conditioner if remote control is not available page 46

3.5 Maintenance page 46

3.5.1 Cleaning air filter page 46

3.6 Troubleshooting page 47

3.6.1 Functional aspects that should not be mistaken for malfunctions page 47

3.7 Recommendations for energy savings page 47

3.8 Troubleshooting page 48

UNICO-HE

25

CHAP. 1 GENERAL INFORMATION

CHAP. 1.1

GENERAL INFORMATION

We wish to thank you, first of all, for purchasing an air-conditioner produced by our company.

We are sure you will be happy with it because it represents the state of the art in the technology of home air conditioning.

This manual serves to provide you with the instructions and explanations you need to make the best possible use of your

air-conditioner.

We suggest that you read it carefully before starting to use the appliance.

By following the instructions and suggestions provided in the manual, your air-conditioner will give you years of smooth

operation and comfort at the lowest cost in terms of power consumption.

ATTENTION

The manual is divided into 4 sections or chapters:

CHAP. 1 GENERAL INFORMATION

Contains information for the specialized installer and end user.

The information, technical data and important warnings must be known before installing and using the air-conditioner.

CHAP. 2 INSTALLATION

Contains information exclusively intended for the specialized installer.

The information contained in this chapter is necessary for installation of the air conditioner.

If the air-conditioner is installed by personnel lacking the necessary qualifications and specialization this invalidates the

warranty.

CHAP. 3 USE AND MAINTENANCE (by user)

Contains all information and instructions for proper use and programming of the air-conditioner, as well as instructions for

simple maintenance.

CHAP. 4 TROUBLESHOOTING

Helps user in case of malfunctions.

This document is restricted in use to the terms of the law and may not be copied or transferred to third parties without the express

authorization of the manufacturer, OLIMPIA SPLENDID.

Our machines are subject to change and some parts may appear different from the ones shown here, without this affecting the text of

the manual in any way.

Read this manual carefully before performing any operation (installation, maintenance, use) and follow the

instructions contained in each chapter.

26

THE MANUFACTURER IS NOT RESPONSIBLE FOR DAMAGES TO PERSONS OR PROPERTY CAUSED BY F AILURE

TO FOLLOW THE INSTRUCTIONS IN THIS MANUAL.

The manufacturer reserves the right to make any changes it deems advisable to its models, although the essential

features described in this manual remain the same.

The installation and maintenance of air-conditioners like this one may be hazardous as they contain a cooling

gas under pressure as well as powered parts.

Therefore, the installation, first startup and subsequent maintenance should be carried out exclusively by

authorized, qualified personnel.

UNICO-HE

Routine maintenance of the filters and general external cleaning can be done by the user as these operations are not

difficult or dangerous.

During installation and maintenance, respect the precautions indicated in the manual, and on the labels applied inside the

units, as well as all the precautions suggested by good sense and by the safety regulations in effect in your country.

Always wear gloves and protective goggles when performing any operations on the refrigerating side of the

units.

Air conditioners must not be installed in places containing inflammable gasses, explosive gasses, or in very

humid environments (laundries, greenhouses, etc.), or in places where there are machines that generate very

great heat.

In case of replacement of parts, use only original OLIMPIA SPLENDID parts.

IMPORTANT!

To prevent any risk of electrocution, always disconnect the main circuit breaker before making electric connections or

performing any maintenance on the units.

The following instructions must be made known to all personnel involved in the machine’s transport and installation.

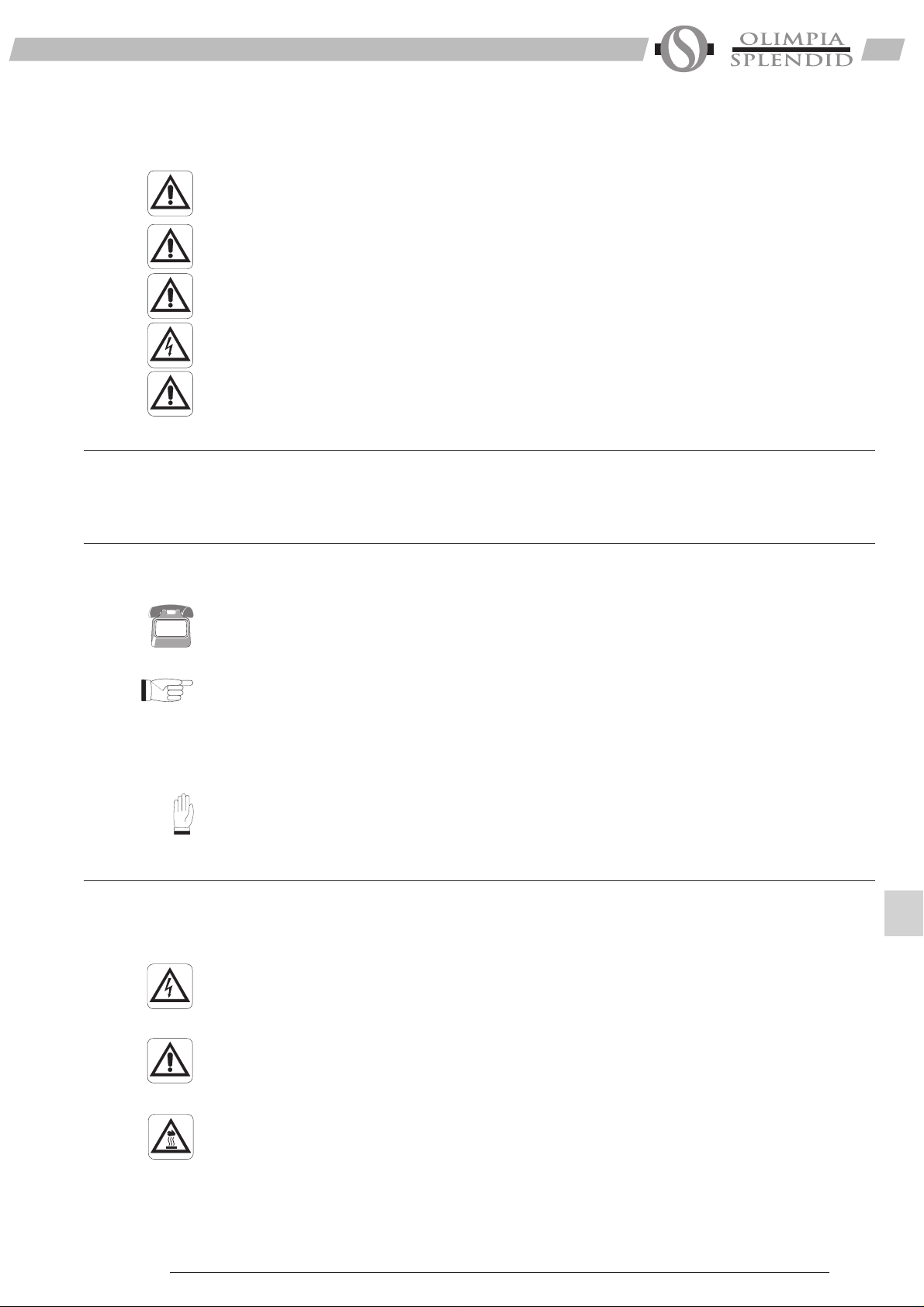

CHAP. 1.2

1.2.1

Editorial

pictograms

1.2.2

Safety

pictograms

SYMBOLS

The pictograms in the next chapter provide the necessary information for correct, safe use of the machine in a rapid,

unmistakable way.

Service

- Refers to situations in which you should inform the SERVICE department in the company:

CUSTOMER TECHNICAL SERVICE.

Index

- Paragraphs marked with this symbol contain very important information and recommendations, particularly as regards

safety.

Failure to comply with them may result in:

- danger of injury to the operators

- loss of the warranty

- refusal of liability by the manufacturer.

Raised hand

- Refers to actions that absolutely must not be performed.

UNICO-HE

Danger of high voltage

- Signals to the personnel that the operation described could cause electrocution if not performed according to the safety

rules.

Generic danger

- Signals to the personnel that the operation described could cause physical injury if not performed according to the

safety rules.

Danger due to heat

- Signals to the personnel that the operation described could cause burns if not performed according to the safety rules.

27

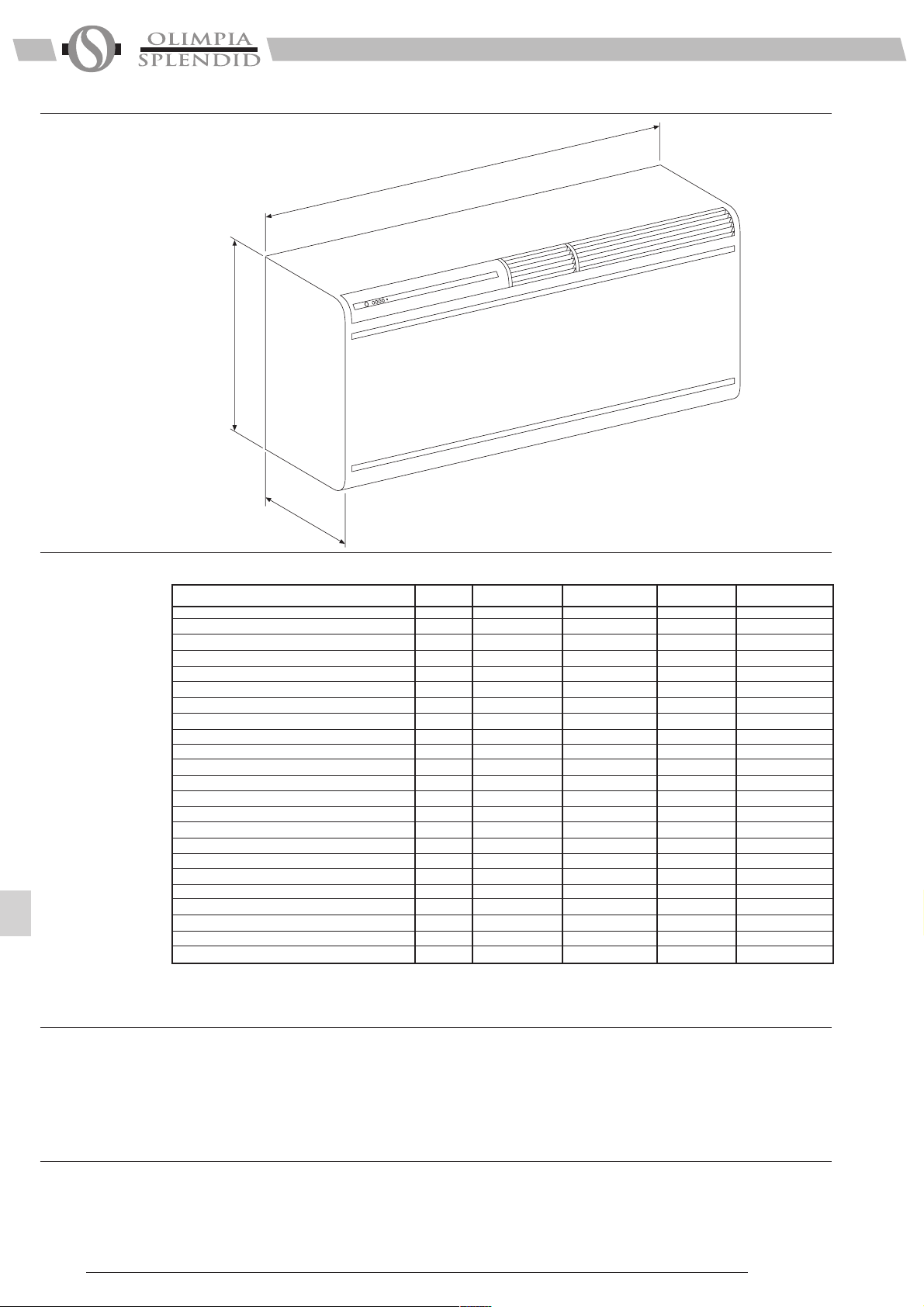

CHAP. 1.3

1.3.1

Overall

dimensions

TECHNICAL DATA

870

400

280

1.3.2

Technical

features

UNICO 8.5 HE UNICO 8.5 HP HE UNICO 11 HE UNICO 11 HP HE

Cooling capacity kW 2,1 2,1 2,45 2,45

Heating capacity kW -- 1,9 -- 2,035

Capacity absorbed during cooling W 790 790 1100 1100

Absorption during cooling A 3,47 3,47 4,83 4,83

Absorbed power during heating W -- 720 -- 1080

Absorption during heating A -- 3,16 -- 4,75

Max. absorbed power (*) W 930 930 1320 1320

Maximum absorption (*) A 4,12 4,12 5,85 5,85

E.E.R. (during cooling) 2,66 2,66 2,23 2,23

Energy efficiency class during cooling A A C C

C.O.P. (during heating) -- 2,64 -- 1,88

Energy efficiency class during heating -- C -- F

Annual energy consumption in cooling mode kWx500h 395 395 550 550

Dehumidification capacity

Cooling Gas R410a R410a R410a R410a

Power supply voltage V-Hz 230-50 230-50 230-50 230-50

Internal unit ventilation speed Num. 3 3 3 3

Maximum delivery of air during cooling (indoor unit) m3/h 350 350 390 390

Maximum air delivery OUTDOOR UNIIT m3/h 480 480 550 550

Dimensions of indoorl unit (Lxhxw) mm 870x400x280 870x400x280 870x400x280 870x400x280

Weight of indoor unit k g 43 43 46 46

Weight of outdoor unit kg -- -- -- -Maximum range of remote control m 8 8 8 8

l/h 1 1 1,2 1,2

(*) Maximum text conditions at high load

1.3.3

Technical notes

1.3.4

Proper use

28

The powers indicated refer to the following conditions (ISO reference standards):

in cooling and dehumidifying mode:

Air entering the inside unit at 27°C b.s. and 19°C b.u. with air entering the outside unit at 35°C b.s.

in heating mode:

Air entering the inside unit at 21°C b.s. and 19°C b.u. with air entering the outside unit at 7°C b.s. and 6°C b.u.

The air-conditioner should be used for the exclusive purpose of producing hot or cool air (on demand) for the sole purpose

of obtaining a comfortable temperature in the room.

Improper use of the machine (outside and inside units) causing damage to persons, property or animals relieve OLIMPIA

SPLENDID of any liability.

UNICO-HE

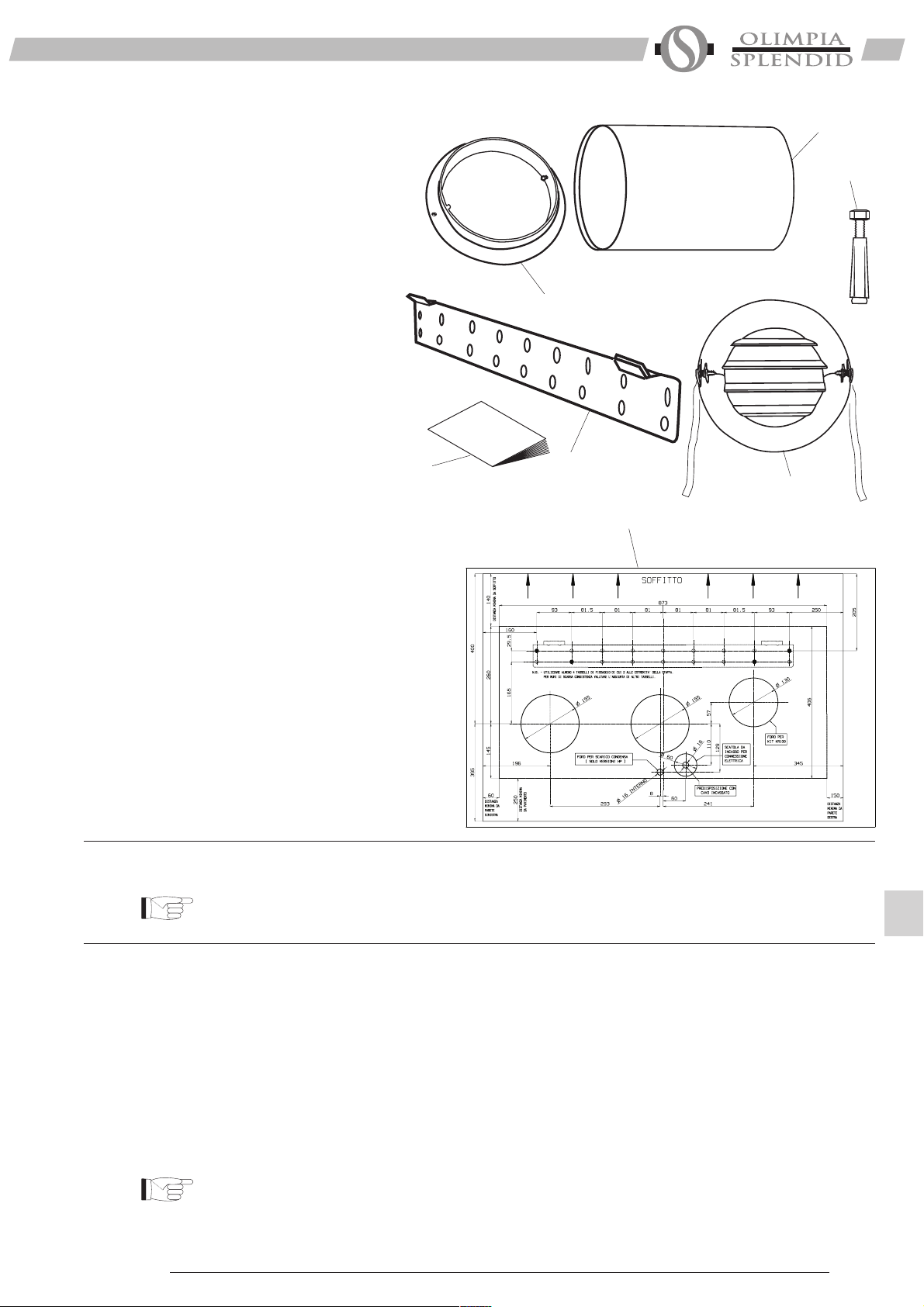

CHAP. 1.4

LIST OF ACCESSORIES SUPPLIED

The two units that make up the airconditioner are packed separately

in cartons.

Packaging may be transported per

single units, by hand by two

authorized persons, or loaded on

a trolley, even piling up to a

maximum of three packs.

The supply includes the parts

listed in the table below. Before

beginning to assemble the unit,

make sure all the parts are within

easy reach.

A - Wall fastening bracket 1

B - 2 external grids for air intake

and outlet including rubber

laces

C - 2 tubes to insert into holes on

wall, 50 cm long

D - Pipe fastening inner flange 2

E - Kit of screws and anchor

bolts

F - Manual of instructions for

use and maintenance, and

warranty

G - Paper template to make holes

F

C

E

D

MANUALE

A

B

G

Storage

Receipt and

unpacking

UNICO-HE

1.4.1

1.4.2

Store the cartons in a closed environment protected against atmospheric agents and raised off the floor by planks or a pallet.

TO NOT TURN THE CARTON UPSIDE DOWN.

The packing is made of suitable material and is done by expert personnel.

The units are delivered complete and in perfect condition, however we suggest that you perform the following controls of

the quality of the shipping service:

- on receipt of the cartons check them for any damage and, if any is found, accept the goods with reservation, and keep

photographic evidence of any damage found.

- unpack and check the contents against the packing list.

- make sure none of the parts have been damaged during shipment; in case of damage you must report it to the shipping

company within 3 days of receipt, by registered letter with return receipt,

presenting photographic documentation.

Copy of notice should also be sent by fax to OLIMPIA SPLENDID.

No notice of damage will be accepted after 3 days from delivery.

Important note:

Keep the packing at least through the warranty period, in case you need to ship the air-conditioner to the service centre for

repair.

Dispose of the packing materials in compliance with the rules in effect for waste disposal.

29

CHAP. 2 INSTALLATION

CHAP. 2.1

CHAP. 2.2

INSTRUCTIONS FOR INSTALLATION

To obtain the best results and optimum performance,

follow the instructions for correct installation provided in

this manual. Failure to follow the instructions and apply

the rules indicated may cause malfunction of the appliance

and relieves the manufacturer, OLIMPIA SPLENDID of

any form of guarantee and liability for damages to persons,

animals or property.

The electrical system must comply with the regulations

and rating data in the technical sheet, with good

grounding.

SELECTION OF POSITION OF THE UNIT

The position for installation of the inside unit, to obtain the

best performance and prevent breakdowns or hazards, must

have the following requisites:

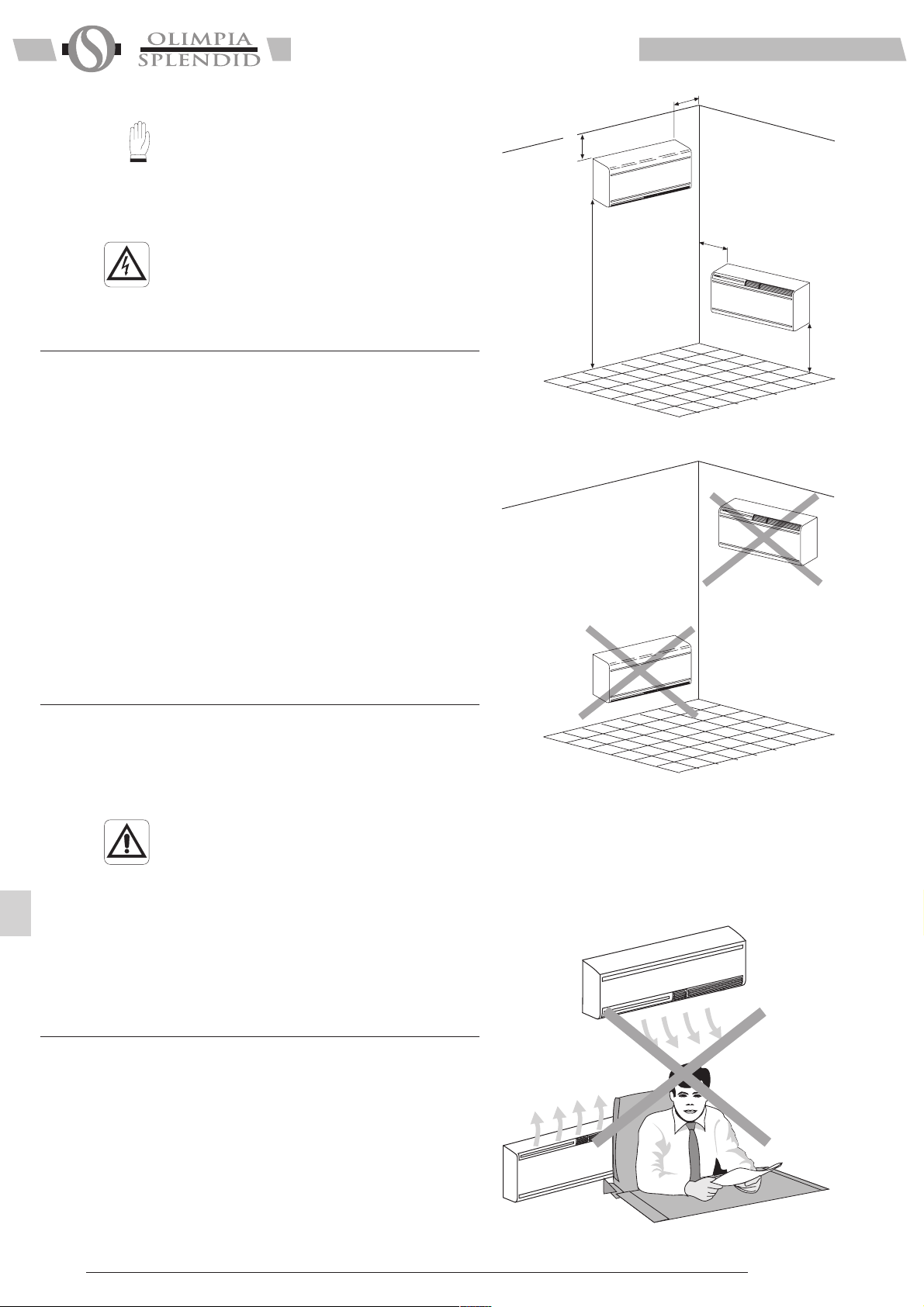

- The bottom of the inside unit must be at least 2 meters

off the floor and no more than 3 (fig. 1)

- The wall on which the inside unit is installed must be

sturdy and able to withstand its weight.

- It must be possible to leave room around the unit for any

maintenance operations that may be necessary.

- There should be no obstacles to the free circulation of air on

the intake side and, especially, on the air outlet side; on this side,

in particular, there should be no obstacles closer than 2 m.

This could cause turbulence that would interfere with correct

operation of the unit.

150 mm

2 m (min)

3 m (max)

150 mm

OK

150 mm

OK

300 mm

NO

2.2.1

Choice of best

position for

installing the air

conditioner

2.2.2

Dimensions and

features of site

where air

conditioner is

installed

NO

The air conditioner must be installed on a wall that

communicates with the outside.

Fig.1

Caution: After determining the best place for

installation as described above, check to make sure

that the wall can be drilled in that point without

interfering with other structures or installations

(beams, piers, pipes, wires, etc.).

Check again to make sure there are no obstacles to

air circulation through the holes to be drilled due to

plants and their leaves, slats or panelling, blinds,

gratings or grids too dense, etc.).

Before installing the air conditioner, it is essential to make

an accurate calculation of the heat load in summer (and

cold load in winter for models with heating pump) at the

site of installation.

The more accurate this calculation is made the better the

air conditioner will be able to do its job.

T o make these calculations, refer directly to the regulations

in effect (UNI ref. Law 10/91) or to the tables, both printed

and computerized, based on those regulations.

For particularly significant applications, we recommend

contacting expert heating engineers.

30

Fig. 2

UNICO-HE

As far as possible, in any case, it is important to try and

reduce major thermal loads by the following means:

Large glass panes exposed to sunlight should be provided

with curtains on the inside or shades on the outside

(Venetian blinds, verandas, refracting films, etc.)

The air-conditioned room should be closed as much of

the time as possible.

Halogen spotlights or other electrical equipment with high

power consumption should not be used in the room

(toasters, steam irons, hot plates for cooking, etc.).

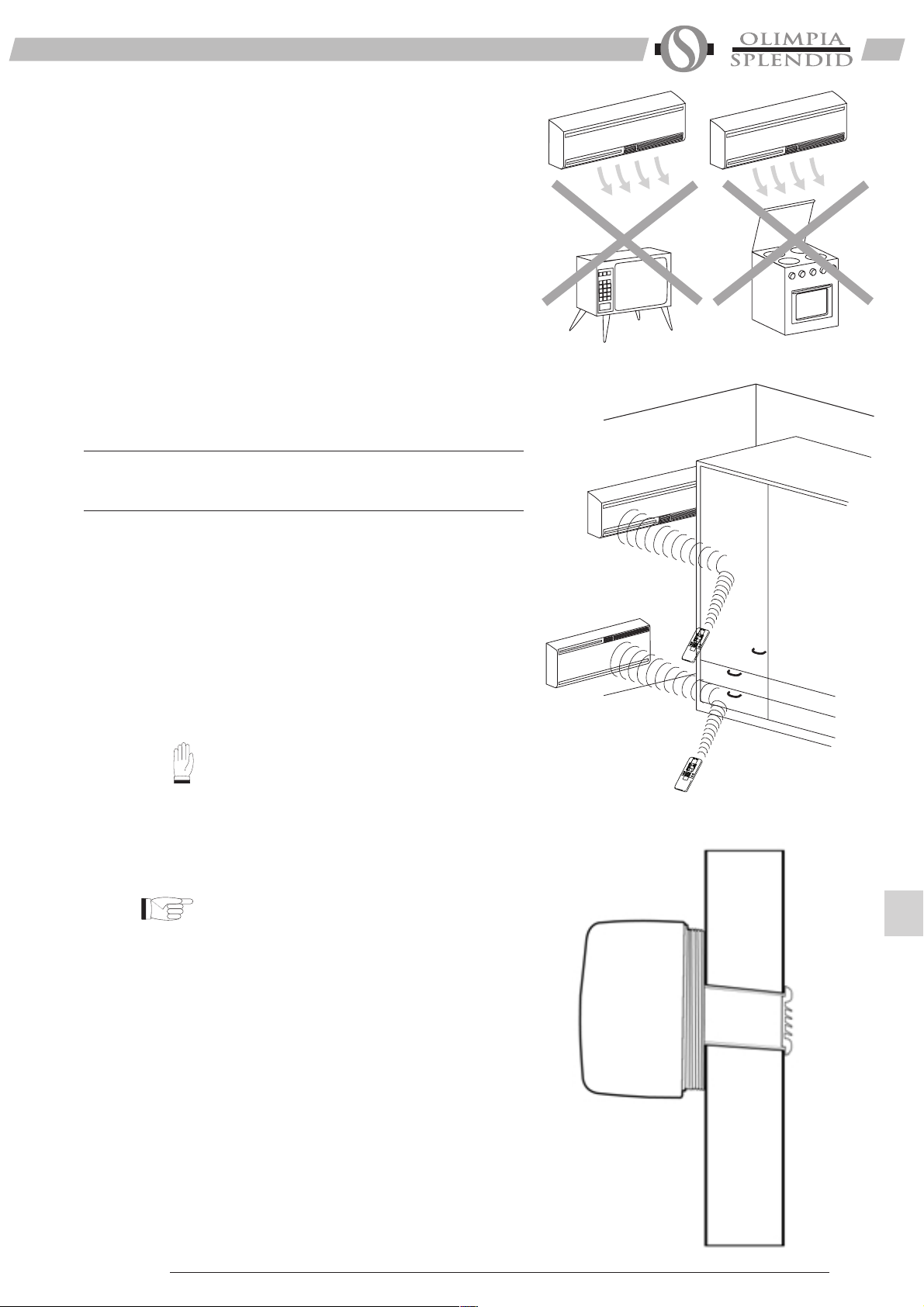

- It should not be installed in a position where the air flow

can strike the people underneath directly (fig. 2).

- It should not be directly over another appliance (television

set, radio, refrigerator, etc.), or over a source of heat

(fig. 3).

- There should be no obstacles for reception of signals

emitted by the remote control (fig. 4).

Fig. 3

CHAP. 2.3

2.3.1

Drilling the wall

INSTALLATION OF THE UNIT

This operation should be carried out using the proper tools

to facilitate your work and prevent excess damage or

disturbance to your client.

The best tools for drilling large holes in walls are special

drills called core borers with very high twisting torque and

adjustable rotation speed depending on the diameter of

the hole to be drilled.

T o prevent the creation of large amounts of dust and rubble

due to drilling, the core borer can be fitted with a vacuum

system applied by means of suction cups to the drilling

zone.

Our Service Department can give you all necessary

information to enable you to find these devices.

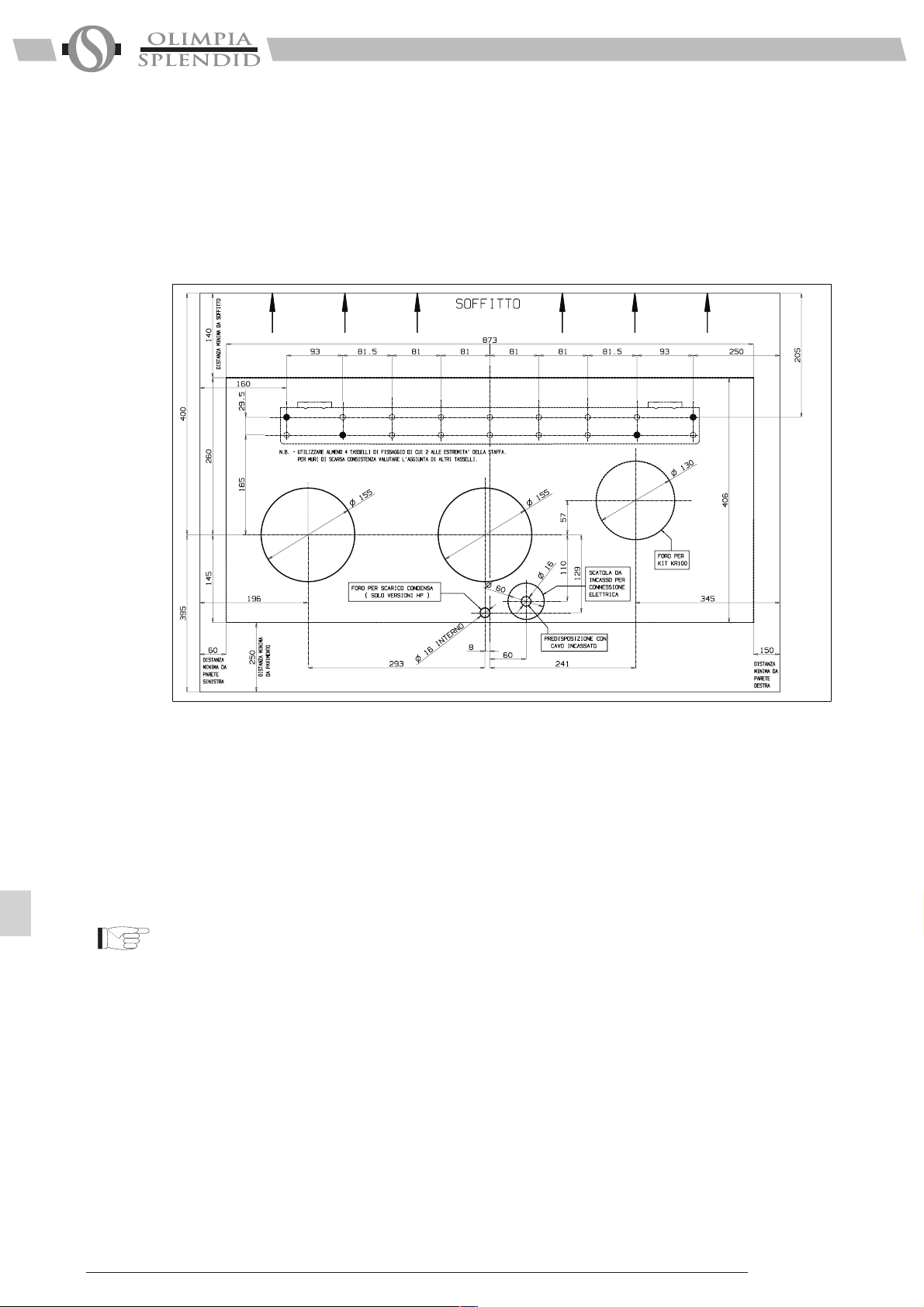

To drill the holes, proceed as follows:

Fasten the drilling template to the wall leaving the

necessary space from the ceiling, floor and side walls as

shown on the template. Use adhesive tape to fasten it in

place.

Use a small drill or punch to mark, with extreme care, the

exact centre of each of the holes to be drilled.

Using a core boring head measuring at least 154 mm to

drill the two holes for entry and exit of the air.

Note: The holes should have a slight outward

inclination to prevent any backflow of water from the

pipes (see fig.1).

T

E

C

S

T

U

A

A

R

U

O

H

1

AUT

R

U

O

H

N

O

UT

A

F

F

P

O

M

E

T

F

F

O

/

N

O

R

H

1

R

E

W

O

P

H

G

I

H

T

E

C

S

T

U

A

A

R

U

O

H

1

T

U

A

R

U

O

H

N

O

T

U

A

F

F

P

O

M

E

T

F

F

/O

N

O

R

H

1

R

E

W

O

P

H

G

I

H

Fig. 4

UNICO-HE

Most of the removed material is expelled outwards,

therefore make sure that it does not hit any person or

object when it falls out.

In order to avoid as much as possible outer plaster

breaking, it is necessary to proceed carefully with the

last part of hole execution, decreasing pressure on core

borers.

Fig. 5

31

Next, drill the holes for anchoring the fastening brackets to

the wall using as a first option the 4 holes on the ends of

the bracket as shown on the drilling template (see fig. 6).

If the wall is not very solid, it is advisable to use some

extra anchor bolts.

As you can see, the bracket can be fastened in a number

of different ways and positions. The air conditioner is

heavier on the left-hand side, so it is best to make sure of

a solid anchorage on that side. The anchor bolts provided

require holes with a diameter of 10 mm. In any case, the

wall should be inspected carefully to determine the best

possible anchorage and type of bolts suitable for particular

situations.

Warning: The manufacturer is not liable in case of

underestimation of the structural consistency of the

anchorage made at the time of installation. We

therefore recommend that you perform this operation

with the maximum care as, if not done properly, it

can cause serious damage to persons and property.

When installing models equipped with heating pump, if

no drainage well for condensate has been provided built

into the wall (see paragraph 2.3.2), it will be necessary,

to allow for drainage of the condensate, to drill a hole

through the wall measuring 16 mm in diameter in the

position shown on the template (see fig.6).

Fig. 6

32

UNICO-HE

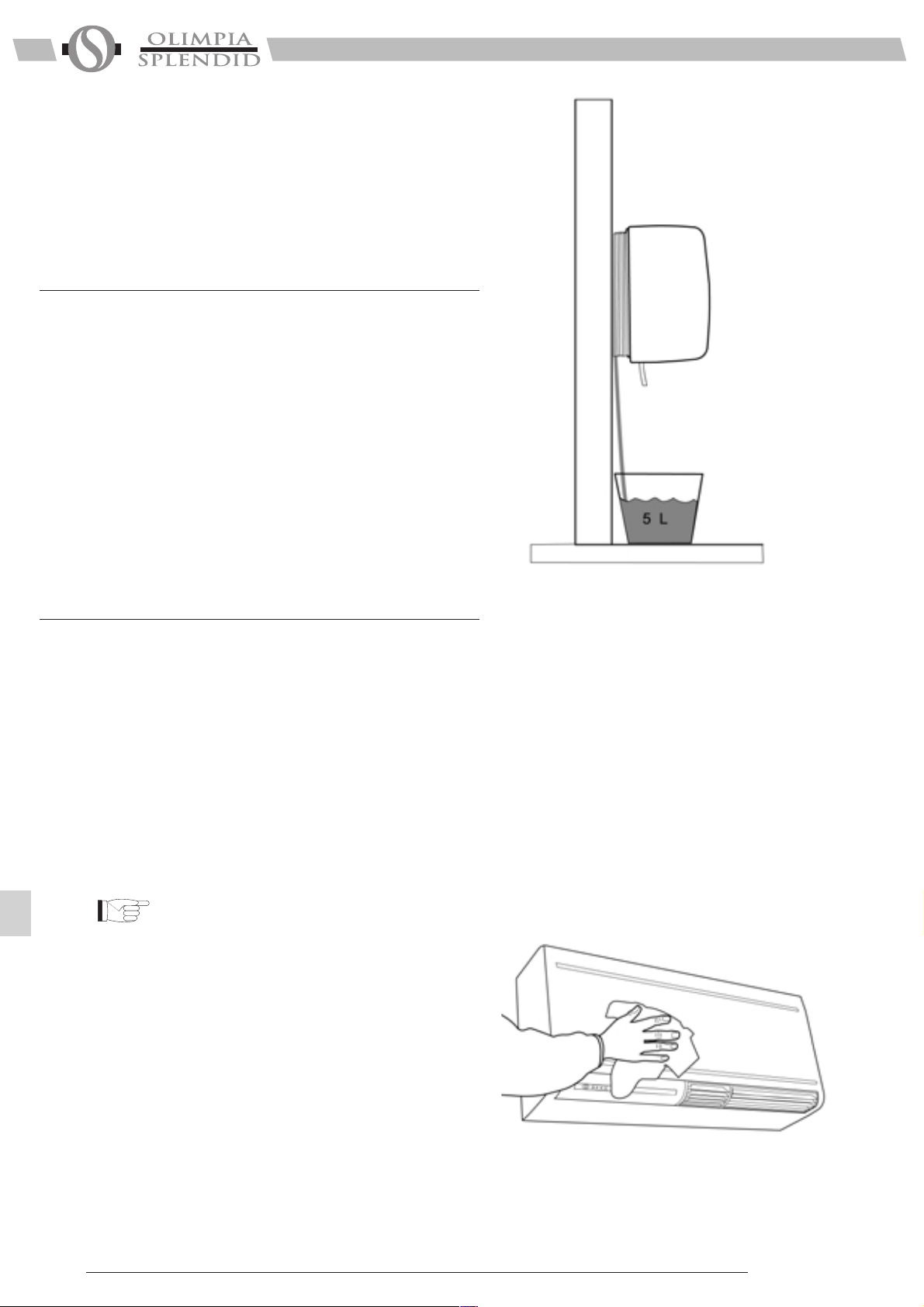

2.3.2

Provision for

draining con-

densate for

machines with

heat pump.

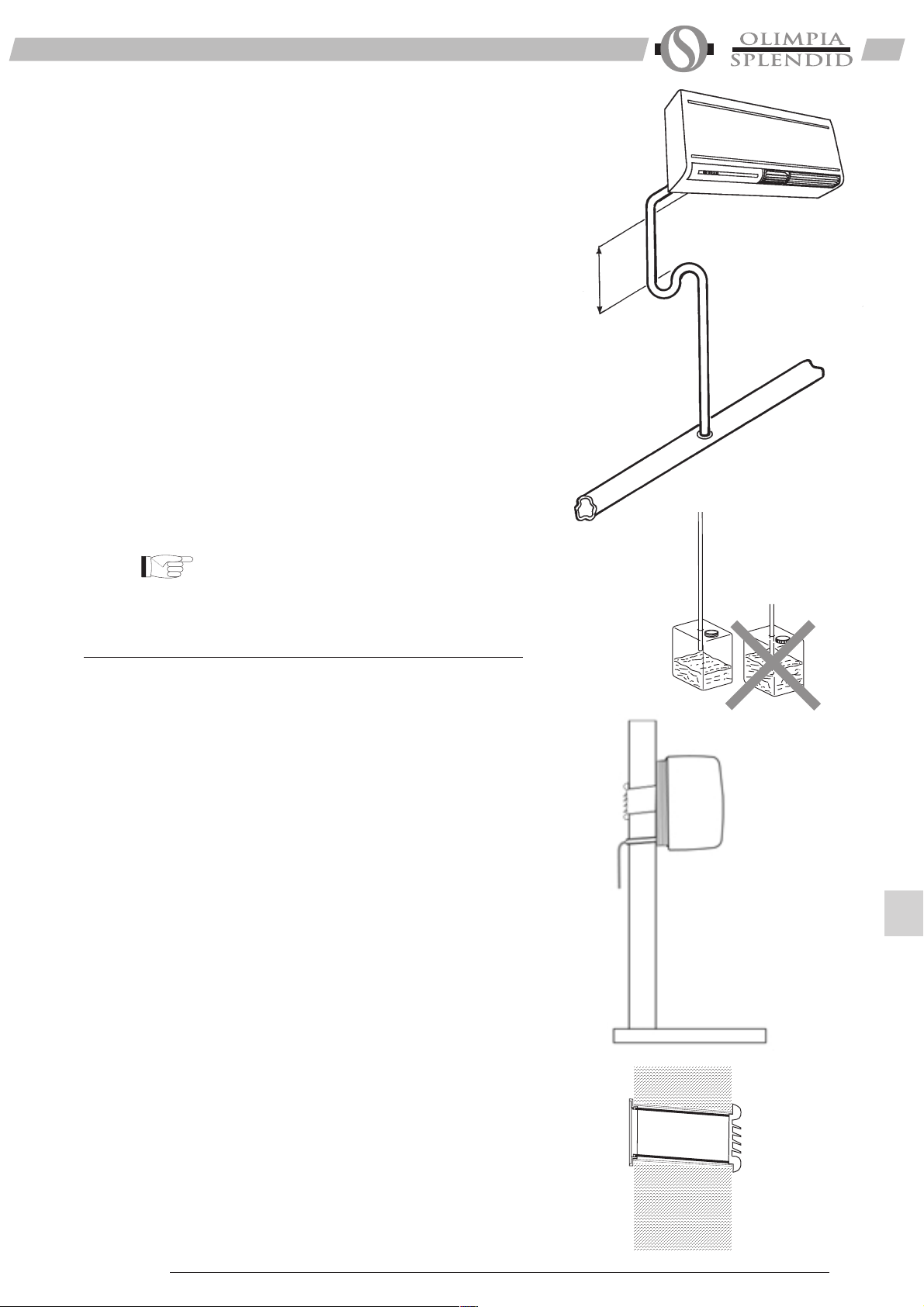

When the machine is heating, it produces condensate

that has to be eliminated through a specific drain line,

otherwise the machine will not work. Drainage occurs by

gravity . For this reason, it is essential for the drain line to

have a minimum inclination of at least 3% throughout its

length. The pipe can be rigid or not, with a minimum

internal diameter of 16 mm.

If the line drains into a sewer system, it should be provided

with a trap ahead of the main outlet.

The trap should be at least 300 mm lower than the inlet

opening on the air conditioner (fig. 7).

2.3.3

Installation of air

pipes and

external

gratings

If the drainpipe drains into a vessel (tank or other

container), this container should not be sealed and the

drainpipe should not remain immersed in the water (see

fig. 8).

The correct position for the pipe inlet on the machine is

shown on the template for drilling and positioning the

machine (see also fig. 6).

The air conditioner is equipped with a pipe with an external

diameter of 14 mm for drainage of condensate.

This pipe protrudes from the machine for a length of about

400 mm.

The pipe should be fitted inside the one provided by you

for a distance of at least 200 mm, without any sharp bends

that could obstruct it.

When draining toward the outside, the pipe can be

inserted through the wall (always making sure to give it a

suitable inclination) (see fig. 5).

Caution: make sure, in this case, that the water expelled

outward does not damage or disturb persons or

property. During the winter this type of drainage may

cause sheets of ice to form.

After drilling the holes, the plastic pipes supplied with the

air conditioner have to be fitted through them. The pipe

with insulation on the inside has to be fitted in the righthand hole with the insulated part toward the inside as

indicated on the label applied to it. The length of the pipes

should be 55 mm less than that of the wall. To cut the

pipe, a normal handsaw can be used. After cutting the

pipes, fit the ends into the two internal anchoring flanges

(fig. 10).

300 mm

Fig. 7

Fig. 8

UNICO-HE

The tube diameter is nearly the same as those carried

out using the 152/154 mm nominal diameter core drill. In

order to introduce the tubes, they must therefore be forced

slightly using, in the most difficult cases, a normal rubber

hammer (fig. 10/1). Having the hole internal diameter

extremely similar to the tube external diameter avoids

dangerous slacks which may generate humidity

infiltrations or air noises. Should the insertion prove to be

too difficult, we suggest you drill using the core bit inside

the hole so as to widen the internal diameter slightly.

Next, fit the pipes into the holes in the wall and fasten the

flanges with 4 anchor bolts with diameter 6, taking care

to keep the two fastening holes in a horizontal position.

Fig. 9

Fig. 10

33

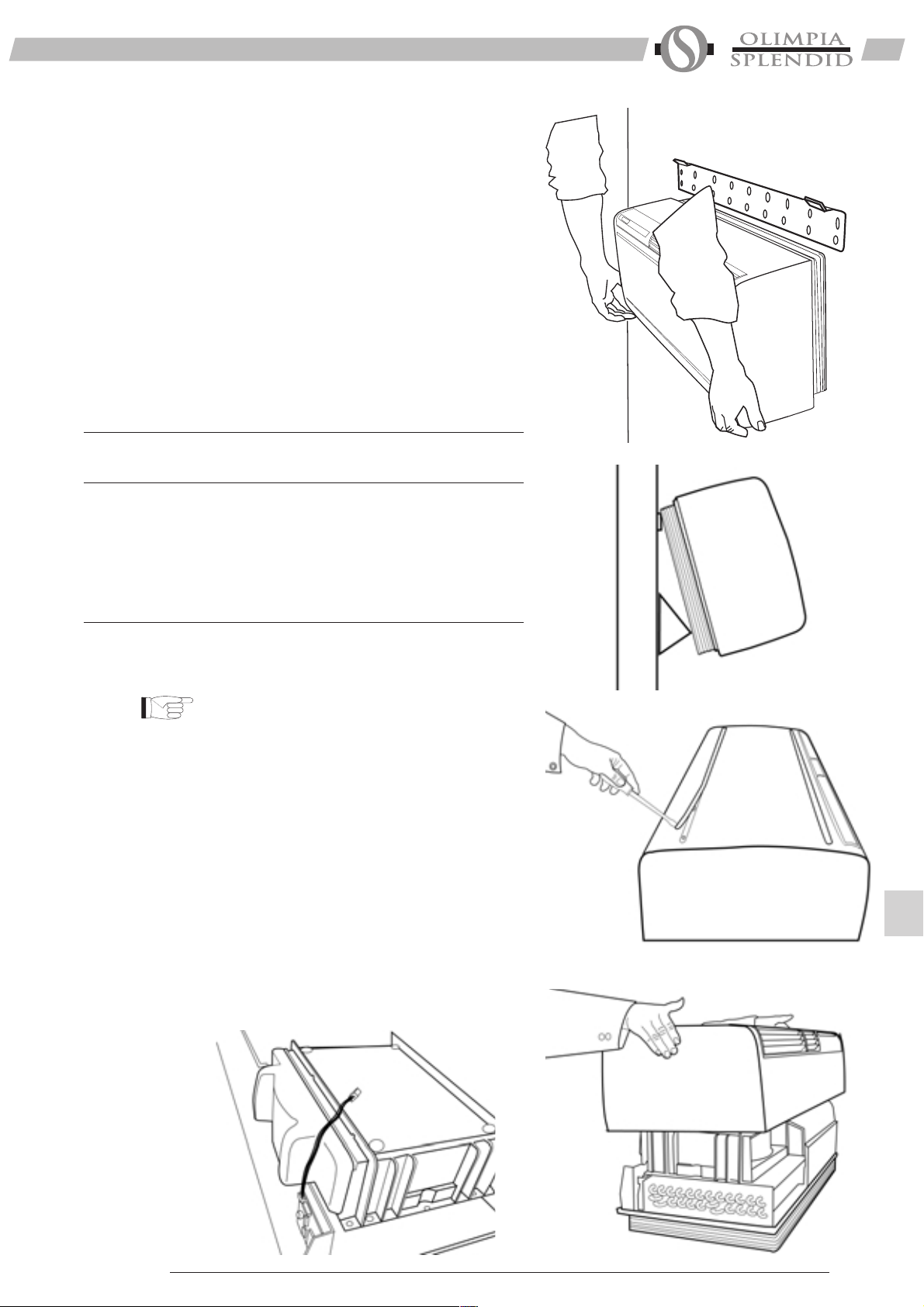

To position the external grating, proceed as follows:

- Grasp the two rubber belts attached to the grating in

one hand.

- Fold the outer gratings in half by grasping them with

your free hand along the fold line and inserting your

fingers inside the fins (fig. 11).

Insert your arm inside the pipe until the grating

protrudes all the way outside.

- Let the grating open, but keep your fingers inside the

fins.

- Turn the grating so that the fins are perfectly horizontal

with the inclination toward the outside (fig. 12).

- Pull the grating toward you.

- Tighten the rubber belts and fasten them to the two

pins on the inner flange.

- Cut the excess part of the belt.

Warning: If the external grating is accessible, to

prevent the hazards resulting from its possible

removal (insertion of the hands into the pipes and

touching moving or powered parts) it is absolutely

essential to fasten it to the wall with 4 anchor bolts

with a diameter of 6 mm.

Fig. 10/1

2.3.4

Power supply

connection

The air conditioner is equipped with a power supply cable

and plug.

If it is installed near an outlet, you need only plug it in.

In this case, it is important to make sure the outlet to

which you are plugged in is effectively grounded and

connected to the mains by wiring of adequate size

(minimum 1.5 sq.mm. cross section).

T o make an electrical connection with the shielded cable

(recommended for installations high on the wall) proceed

as follows:

Install a shunt box in the wall in the position shown on

the installation template (fig. 6), where you should provide

a power cable with a cross-section (two poles plus ground

wire) of 2,5 sq.mm.

Warning: The external power line should be provided

with an overload circuit breaker with suitable capacity

for the rating of the machine.

Make all connections in compliance with the laws in

effect.

Close the shunt box with its cover after drilling a hole in it

for passage of the cable.

Alternatively , you can use a cable in the wall in the position

shown on the template, for making the connection. In

this case, remove the casing (as described in paragraph

2.4.2) and connect the cable to the power terminal board.

Fig. 11

Fig. 12

34

Caution: these operations should be performed with

the machine already positioned on the bracket. Read

the instructions carefully before completely the

electric connection.

UNICO-HE

2.3.5

Fitting the unit

on bracket

CHAP. 2.4

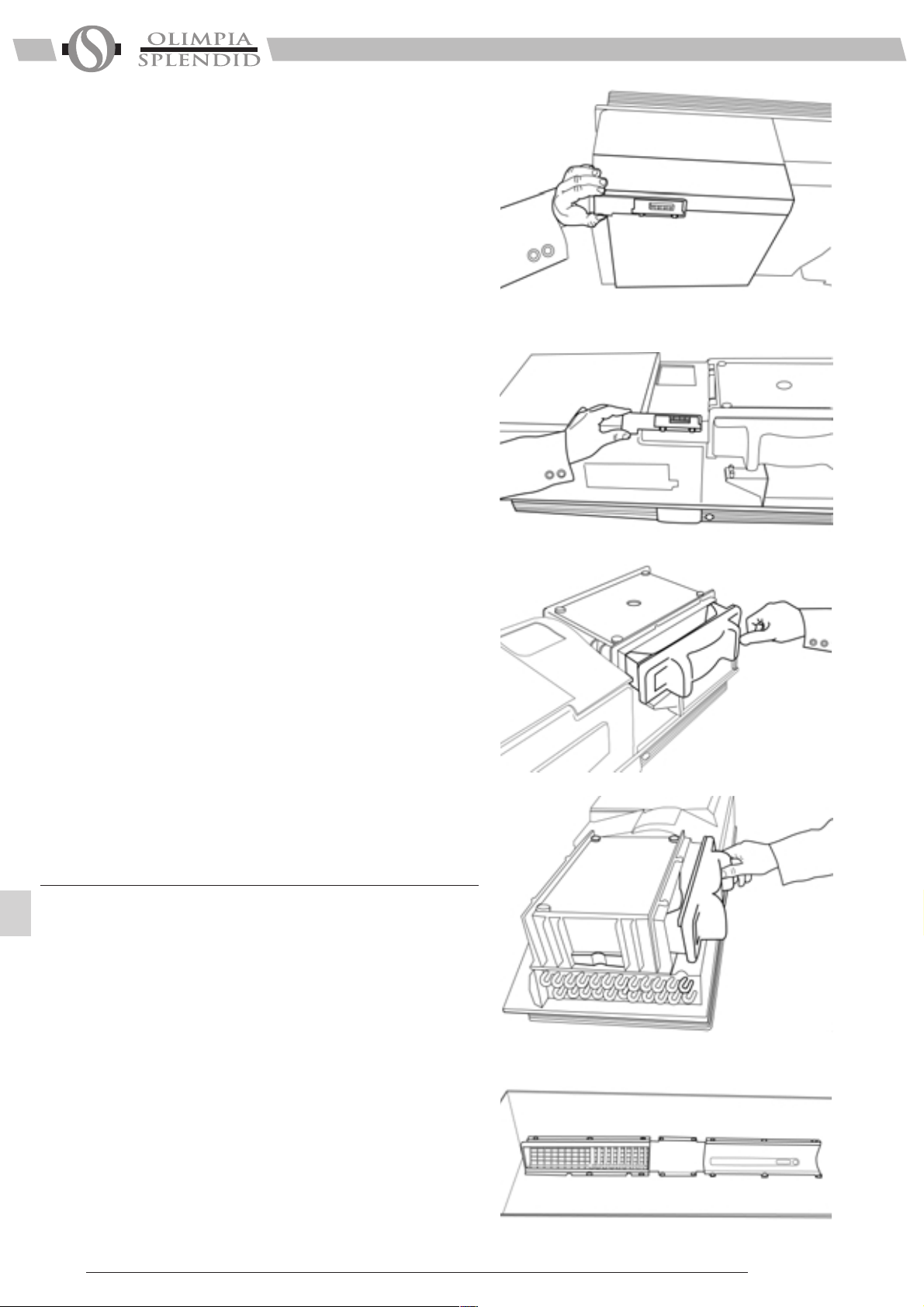

After checking again that the fastening bracket is securely

fastened to the wall, and that any necessary preparations

for electric connection and condensate drainage have

been made, you can fasten the air conditioner to its

supporting bracket. Lift it up holding the sides of the bottom

(see fig. 13).

To facilitate the operation of fastening it to the bracket, tilt

it slightly toward you.

T o make the electrical connection and fasten the drainpipe,

place a wedge between the air conditioner and the wall

(see fig. 14).

After these operations have been carried out, the air

conditioner can be pushed firmly against the wall so that

the bottom hook catches.

When you have finished, inspect carefully to make sure

there are no fissures at the back of the air conditioner

(the insulating gasket must fit firmly against the wall)

particularly in the zone where air enters and leaves the

machine.

Fig. 13

PREPARATION FOR ASSEMBLY/INSTALLATION

WALL TOP PART

2.4.1

Introduction

2.4.2

Removal of front

casing

The air conditioner is assembled in the factory ready to

be installed low on the wall.

The air outlet, in this case, is at the top of the air conditioner

with the recycle grating and control panel.

In order to prepare the product for installation on the top

part of the wall, follow the instructions below.

Note: if the air conditioner has not been installed on

the wall yet, place it on its back. To not apply heavy

pressure to the bottom of the device as this could

dent or scratch the casing.

Use a small blade screwdriver to remove the horizontal

strips on the casing, applying gentle leverage in the slits

along the sides. (see fig. 15).

Take care not to scratch the strips or casing with the

screwdriver point.

Unscrew the 8 self-threading screws that fasten the casing

to the air conditioner.

Lift the casing off carefully , pulling it toward you by about

50 cm (see fig. 16).

Disconnect the fastener on the right that fastens the wires to

the airflow deviation baffle adjustment motor (see fig. 17).

Now you can remove the casing completely.

Fig. 14

Fig. 15

UNICO-HE

Fig. 16Fig. 17

35

2.4.3

Preparation of

unit

Unscrew the bracket supporting the small circuit board with

display leds and reinstall it on the bottom opposite, where

you will find two holes on the base (see fig. 18-19).

Make sure the connection plate is securely fastened on

the inside of the air conditioner, and apply some insulating

tape if necessary. Remove the styrofoam enclosure on

the lower right-hand side under the air recycle fan and fit

it against the opening above the fan (see fig. 20-21).

Remove the air outlet grating by removing the fastening

screws. Remove the control panel (see fig. 22).

When performing this operation place the casing on a

secure surface so as not to scratch or dent it. Remove

the plastic plate with the logo and transparent screen for

display of the leds from the control panel by pressing on

the hooks at the rear. Turn it over (rotate by 180°) and

reinstall it on the panel.

Reassemble the parts in the opposite position from the

original installation, reversing the air outlet grating with

the control panel grating.

Turn the casing over so that the air outlet grating is on

the lower right-hand side of the device.

Connect the plug on the step-step motor of the grating.

Fit the casing back on the air conditioner carefully, t aking

care to hold the wires for the step-step motor to one side

so that they do not interfere with the inner part of the air

outlet grating.

Check that all the coupling references of the casing with

the rear frame are fully inserted so that the casing is

fitted smoothly and evenly all around.

Fasten the casing with its eight screws and replace the

strips in their slots.

After completing installation, the electronic parts of the

air conditioner have to be configured so as to take into

account the stratification of heat in the room. This procedure is outlined in paragraph 2.5 (Operating tests and

diagnosis of possible malfunctions).

Fig. 18

Fig. 19

CHAP. 2.5

WORKING TESTS AND IDENTIFICATION

OF POSSIBLE MALFUNCTIONS

The program introduced in the microprocessor of this

device makes it possible to run a brief self-test to ensure

that the machine functions normally by starting each of

its internal components.

To run the self-test, proceed as follows:

- Power the air conditioner and make sure it is on stand-by.

- Use a sharp object to press the microkey located under

the hole on the left of the control panel for at least 10

sec.

- At the beginning and end of the self-test procedure the

status of configuration of the machine will be displayed

for a few seconds as follows:

Fig. 20

Fig. 21

36

Fig. 22

UNICO-HE

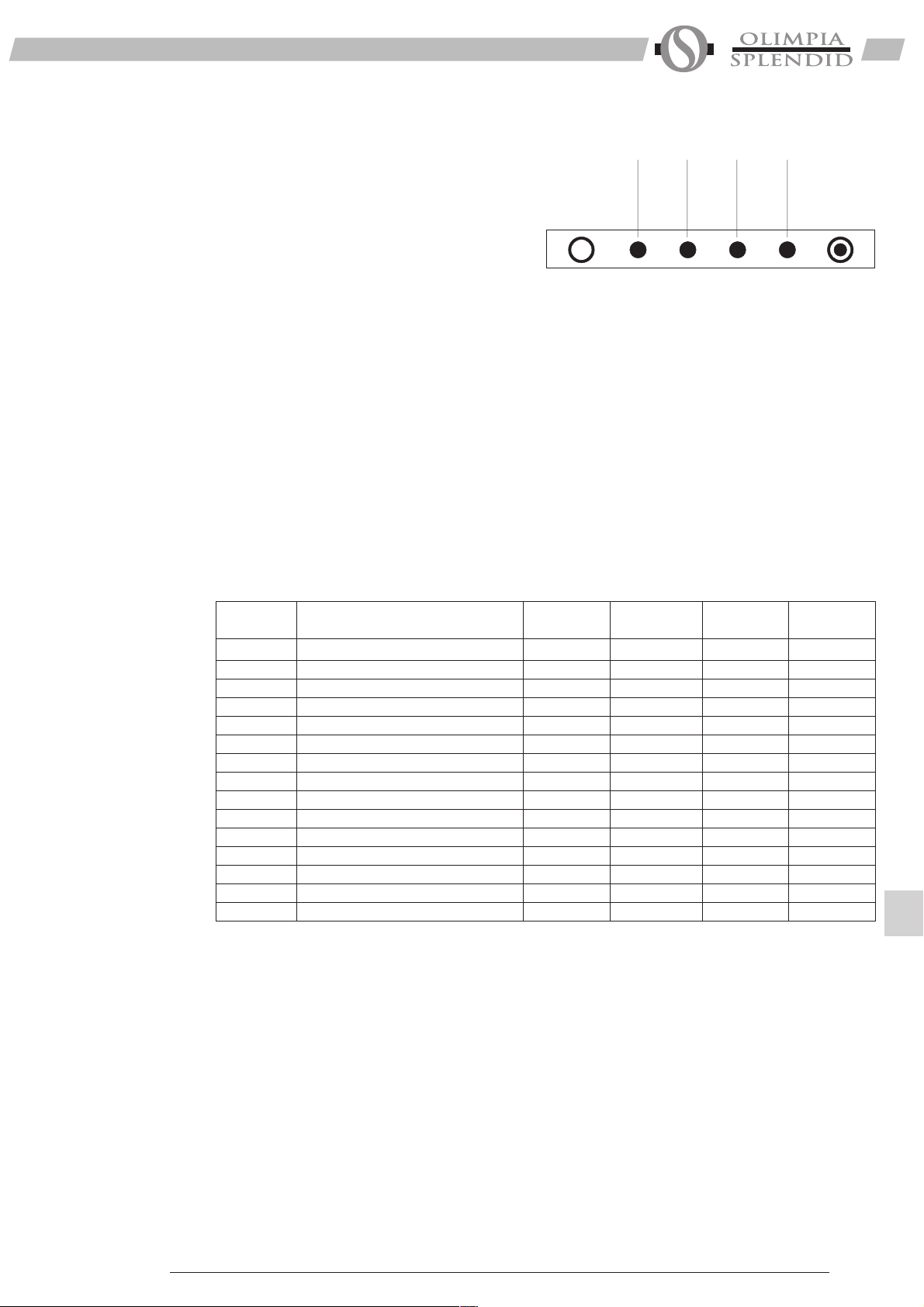

red led (filter): off = UNICO

on = UNICO HP (with heat

pump)

green led (compr.): off = with correction of room tem-

perature

on = without correction of room

temperature

orange led (timer): off = without correction of room

temperature

on = with correction of room tem-

perature

green led (power): off = stand-by in case of black-

out

on = restart in case of black-out

- Check after a few seconds to see whether the

equipment heats normally (if equipped with heat pump

function) for about 2 minutes and then, after a few

seconds, that it cools for another 2 minutes.

Before concluding the self-test, the electronic part tests

the temperature probes to make sure they are operating

normally. If any of these should not be working, the

corresponding signal led remains lit for 20 sec. (see

table on next page).

Should there be a jam in the air-conditioning system with

alarm signals according to the table here following, please

be ready to refer to the Service Centre which leds are

blinking in order to simplify their intervention.

green orange green red

Starting from the left:

CODE DESCRIPTION green LED orange LED green LED red LED

ALARM POWER TIMER COMPR. FILTER

1-FS dirty filter O

2-HTI internal battery overheat O

3-HTE external battery overheat O O

4-LT internal battery low temp. O

5 pump working continuously O O

6-CF/RL

batt. temp. not reached O O

7-OF water level O O O

8-CKS eeprom parameters not valid O

9- O O

10-TSF short on room sensor O O

1 1-TSF room sensor disconnected O O O

12-TSF short on evaporator sensor O O

13-TSF evap. sensor disconnected O O O

14-TSF short on condenser sensor O O O

15-TSF condenser sensor O O O O

The end of the self-test will be signalled by all the leds

lighting up at once and blinking ten times, as well as by

an acoustic signal.

At this time, you can adjust the temperature reading on

the room temperature sensor. This correction is importan t

if the air conditioner is installed high on the wall in a room

where the warm air tends to stratify upward (as in rooms

with high ceilings or other sources of heat besides the air

conditioner). The sensor will read a temperature 3°C lower

than the effective one, in this case, to compensate for

the difference between the lower inhabited part of the

room and the temperature at the height of the sensor.

To enter or remove this correction proceed as follows:

1 Check the status of the machine as described

previously, and if no correction has been made, press

the button on the console while the acoustic signal is

on at the end of the self-test.

2 To remove the correction, press the button while the

acoustic signal is on at the end of the self-test.

UNICO-HE

37

The machine is set in the factory without correction of

the temperature.

In addition to the self-test (that can be made under any

conditions of room temperature) we recommend that you

also test the product in the various operating modes

accessible to the user (see the user manual). One

important test you should make concerns regular

evacuation of condensation water on the models with heat

pump. To check this, keep the machine running for at

least 4-5 hours in the heating mode. If the water does not

drain, there should be an “overflow” alarm.

Evacuation of

2.5.1

condensation

water in case of

emergency

CHAP. 2.6

If there should be a malfunction in the condensation water

drain system, the air conditioner stops working and

signals, with flashing orange, green and red lights (the

second and third leds from the left), the alarm status.

T o enable the air conditioner to work temporarily until the

service personnel arrives, you can drain the water out by

following these simple instructions:

- Grasp the rubber cap on the bottom centre of the air

conditioner behind the edge of the frame facing the wall

between your thumb and forefinger.

- Pull the rubber tube closed by the cap out by a few

centimetres.

- Remove the cap after placing a bucket or other container

underneath it (at least five litter capacity) to collect the

water (see fig. 23).

- After eliminating the malfunction the service personnel

will take care of closing the evacuation tube.

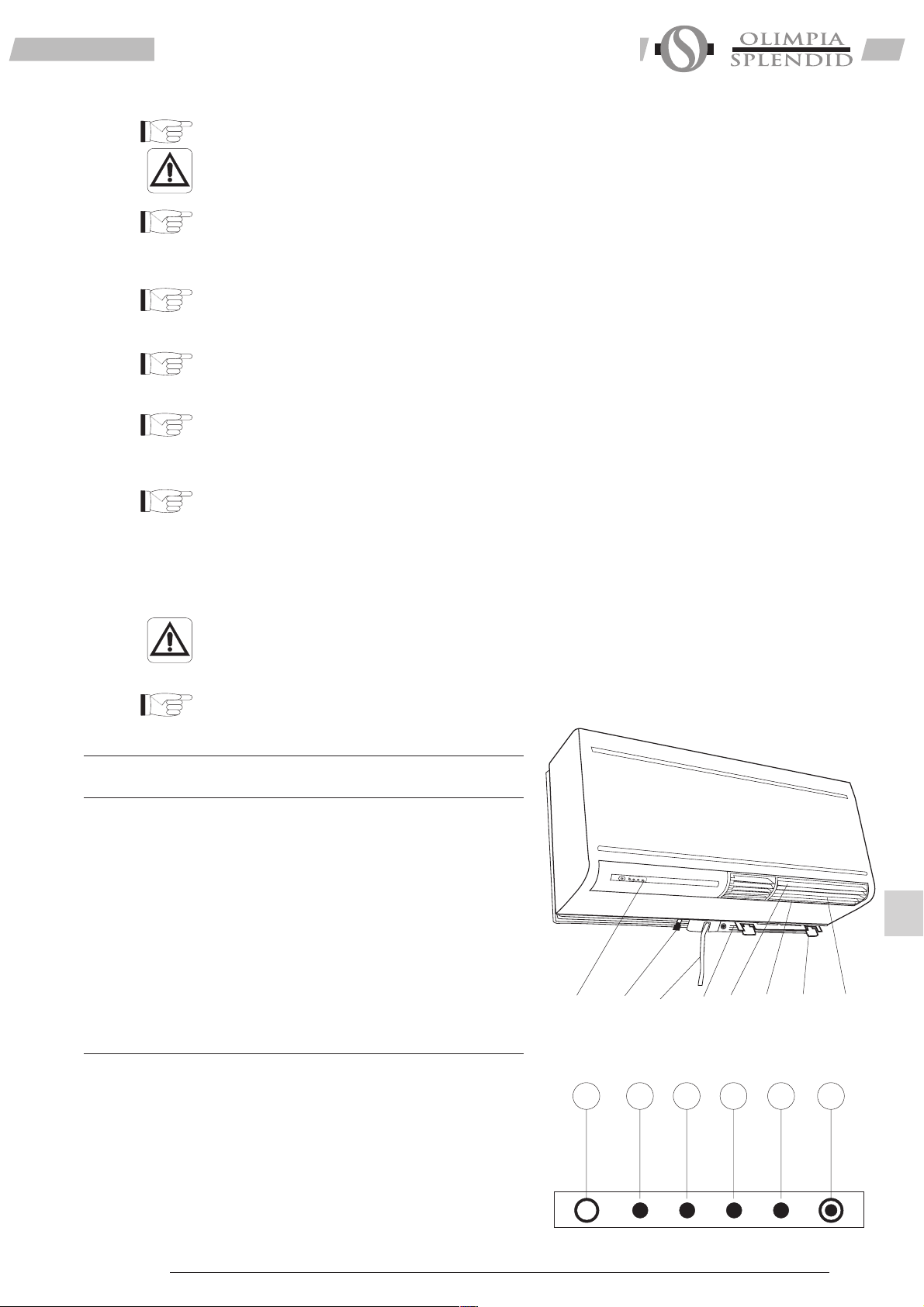

PERIODICAL MAINTENANCE

Air conditioners of this type do not require any particular

routine maintenance except:

- Cleaning or washing the room air filter when the red

led lights up (see user manual).

- Cleaning of “external air” battery, to be done as needed,

depending on the amount of dirt in the external air,

once or twice a year. To do this, you must, of course,

open the air conditioner by removing its casing and

the noise insulation on the inside.

- Cleaning can be done using a vacuum cleaner or soft

brush, taking particular care not to damage the

aluminium heat exchanger baffles. It may be necessary

to use water and detergents to remove heavily

encrusted dirt.

Fig. 23

38

Note: after cleaning the battery replace the noise

insulation carefully matching the edges and gaskets

with their reference markings.

Before you leave the site of installation you should gather

up all packing material and use a damp cloth to remove

any traces of dust that may have deposited on the

machine during assembly (fig. 24).

These operations, though certainly not essential, have a

beneficial effect as they enhance the professional image

of the installer in the eyes of the client.

T o prevent unnecessary calls by the user , before you leave

the site of installation it is also a good idea to:

- Explain the contents of the Instruction Manual to the user.

- Show him how to clean the filter.

- Explain when and how he should contact the Service

Department

Fig. 24

UNICO-HE

CHAP. 3 USE AND MAINTENANCE (for the user)

CHAP. 3.1

Important Recommendations

Installation and connection of the air conditioner should

be carried out by specialized personnel in possession

of the qualifications specified in Law 46/90.

The instructions for installation are provided in the

specific manual.

No structural object (furniture, curtains, plants, leaves,

blinds, etc.) should ever obstruct the normal flow of

air from either the internal or external gratings.

Never lean or, worse yet, sit on the casing of the air

conditioner as this could cause serious damage to

the external parts.

Do not turn the horizontal airflow baffles by hand.

Always use the remote control to adjust baffle

position.

If the unit leaks water, switch it off immediately and

disconnect it from the power mains. Call the nearest

service centre.

When the air conditioner is heating, it has to

periodically eliminate any ice that could form on the

external battery. While it is doing this, the machine

keeps running but does not heat the room. This lasts

for a brief period of time, from 3 to a maximum of 10

minutes.

3.2

3.2.1

List of Units

3.2.2

Description of

signal console

The air conditioner must not be installed in rooms

where explosive gasses develop or where there are

conditions of heat and humidity beyond the maximum

limits indicated in the installation manual.

Clean the air filter periodically, as described in the

specific paragraph.

NAMES OF PARTS

1) Air outlet grating..

2) Cursors for lateral adjustment of airflow.

3) Motor-operated air baffles for upward airflow

4) Alarm display console.

5) Air intake grating.

6) Grips for removal of air filter.

7) Rubber hose with cap on end for evacuation of

condensation water in case of emergency.

8) Power cable

1) Transparent zone of receipt of remote control signal.

2) Green led indicating machine is running (When the

machine is on stand-by this light is off).

3) Orange led indicates on/off programming is in use.

4) Green led indicates cooling compressor is on.

5) Red led indicates air filter clogged.

6) Service microkey (RESET)

4

165432

7

5

8

Fig. 25

261

3

UNICO-HE

Fig. 26

39

Loading...

Loading...