INDEX

Chap. 1

Chap. 2

GENERAL INFORMATION

1.1 General information page 26

1.2 Symbols page 27

1.2.1 Editorial pictograms page 27

1.2.2 Safety pictograms page 27

1.3 Technical data page28

1.3.1 Overall dimensions page 28

1.3.2 Technical features page 28

1.3.3 Technical notes page 28

1.3.4 Proper use page 28

1.4 List of accessories supplied page 29

1.4.1 Storage page 29

1.4.2 Receipt and unpacking page 29

INSTALLATION

2.1 Instructions for installation page 30

2.2 Selection of position of the unit page 30

2.2.1 Choice of best position for installing the air conditioner page 30

2.2.2 Dimensions and features of site where air conditioner is installed page 30

2.3 Installation of the unit page 31

2.3.1 Drilling the wall page 31

2.3.2 Provision for draining condensate for machines with heat pump page 33

2.3.3 Installation of air pipes and external gratings page 33

2.3.4 Power supply connection page 34

2.3.5 Fitting the unit on bracket page 35

2.4 Preparation for assembly/installation wall top part page 35

2.4.1 Introduction page 35

2.4.2 Removal of front casing page 35

2.4.3 Preparation of unit page 36

2.5 Working tests and identification of possible malfunction page 36

2.5.1 Evacuation of condensation water in case of emergency page 38

2.6 Periodical maintenance page 38

Chap. 3

USE AND MAINTENANCE (for the user)

3.1 Important Recommendations page 39

3.2 Names of parts page 39

3.2.1 List of Units page 39

3.2.2 Description of signal console page 39

3.3 Control of Air Conditioner using the remote control unit page 40

3.3.1 Remote control p age 40

3.3.2 Insertion of batteries page 40

3.4 Remote control page 40

3.4.1 Description of the remote control page 40

3.4.2 Switching on and control of operation page 41

3.4.3 Switching the unit on and off (button T1) page 41

3.4.4 Automatic Operation (button T2) page 41

3.4.5 Cooling function page 41

3.4.6 Dehumidifier only page 42

3.4.7 Fan only page 42

3.4.8 Heating function (only models with heat pump) page 42

3.4.9 Control of air flow direction page 42

3.4.10 Control of fan speed page 43

3.4.11 External air intake page 43

3.4.12 Night operation page 44

3.4.13 Setting programs for operation page 44

3.4.14 Setting of correct time page 44

3.4.15 Setting of time schedules for 1st and 2nd Operating Program (PROGR. 1 and PROGR. 2) page 45

3.4.16 Starting and stopping operating programs page 45

3.4.17 Resetting all functions of remote control page 46

3.4.18 Control of Air Conditioner if remote control is not available page 46

3.5 Maintenance page 46

3.5.1 Cleaning air filter page 46

3.6 Troubleshooting page 47

3.6.1 Functional aspects that should not be mistaken for malfunctions page 47

3.7 Recommendations for energy savings page 47

3.8 Troubleshooting page 48

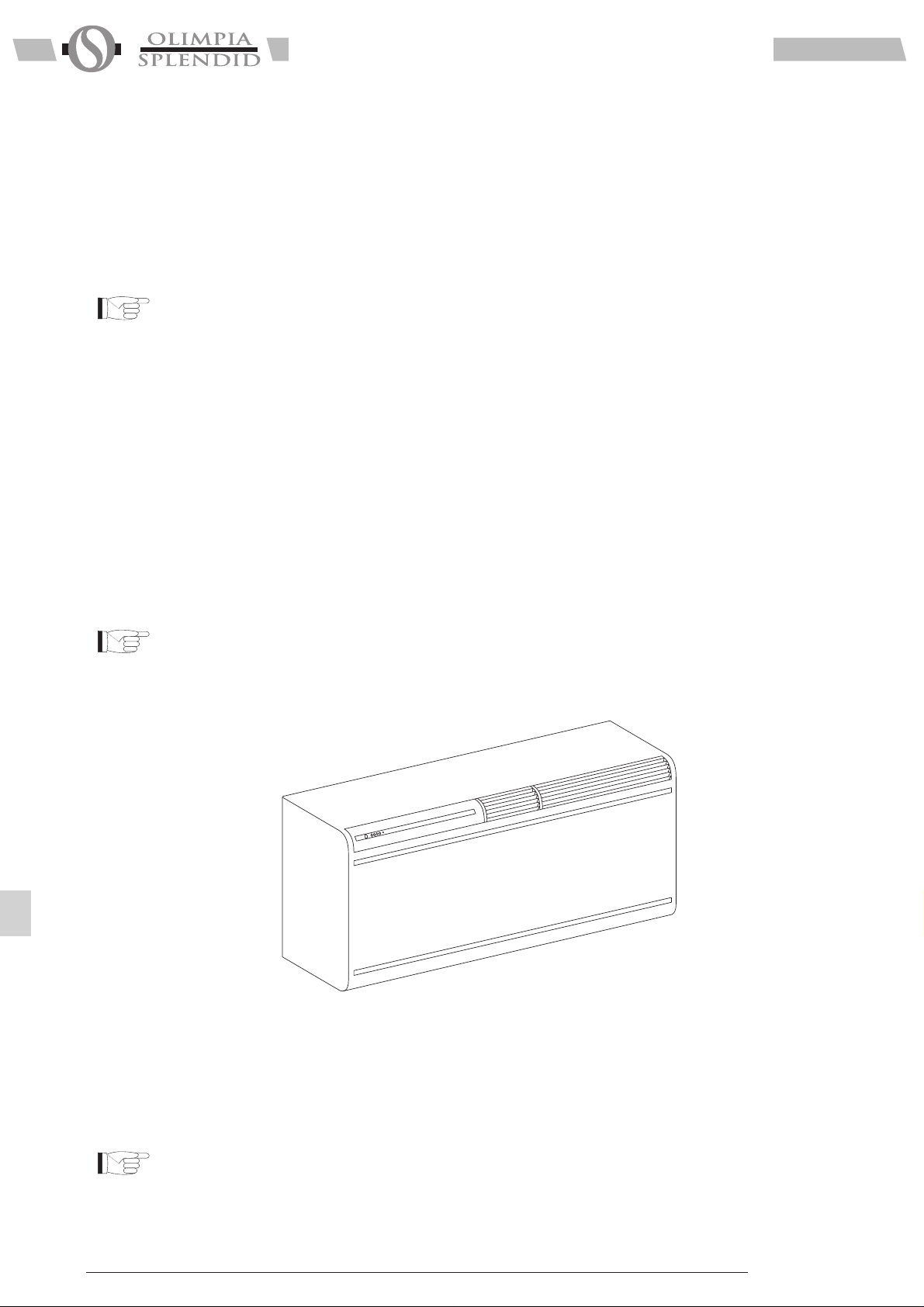

UNICO-HE

25

CHAP. 1 GENERAL INFORMATION

CHAP. 1.1

GENERAL INFORMATION

We wish to thank you, first of all, for purchasing an air-conditioner produced by our company.

We are sure you will be happy with it because it represents the state of the art in the technology of home air conditioning.

This manual serves to provide you with the instructions and explanations you need to make the best possible use of your

air-conditioner.

We suggest that you read it carefully before starting to use the appliance.

By following the instructions and suggestions provided in the manual, your air-conditioner will give you years of smooth

operation and comfort at the lowest cost in terms of power consumption.

ATTENTION

The manual is divided into 4 sections or chapters:

CHAP. 1 GENERAL INFORMATION

Contains information for the specialized installer and end user.

The information, technical data and important warnings must be known before installing and using the air-conditioner.

CHAP. 2 INSTALLATION

Contains information exclusively intended for the specialized installer.

The information contained in this chapter is necessary for installation of the air conditioner.

If the air-conditioner is installed by personnel lacking the necessary qualifications and specialization this invalidates the

warranty.

CHAP. 3 USE AND MAINTENANCE (by user)

Contains all information and instructions for proper use and programming of the air-conditioner, as well as instructions for

simple maintenance.

CHAP. 4 TROUBLESHOOTING

Helps user in case of malfunctions.

This document is restricted in use to the terms of the law and may not be copied or transferred to third parties without the express

authorization of the manufacturer, OLIMPIA SPLENDID.

Our machines are subject to change and some parts may appear different from the ones shown here, without this affecting the text of

the manual in any way.

Read this manual carefully before performing any operation (installation, maintenance, use) and follow the

instructions contained in each chapter.

26

THE MANUFACTURER IS NOT RESPONSIBLE FOR DAMAGES TO PERSONS OR PROPERTY CAUSED BY F AILURE

TO FOLLOW THE INSTRUCTIONS IN THIS MANUAL.

The manufacturer reserves the right to make any changes it deems advisable to its models, although the essential

features described in this manual remain the same.

The installation and maintenance of air-conditioners like this one may be hazardous as they contain a cooling

gas under pressure as well as powered parts.

Therefore, the installation, first startup and subsequent maintenance should be carried out exclusively by

authorized, qualified personnel.

UNICO-HE

Routine maintenance of the filters and general external cleaning can be done by the user as these operations are not

difficult or dangerous.

During installation and maintenance, respect the precautions indicated in the manual, and on the labels applied inside the

units, as well as all the precautions suggested by good sense and by the safety regulations in effect in your country.

Always wear gloves and protective goggles when performing any operations on the refrigerating side of the

units.

Air conditioners must not be installed in places containing inflammable gasses, explosive gasses, or in very

humid environments (laundries, greenhouses, etc.), or in places where there are machines that generate very

great heat.

In case of replacement of parts, use only original OLIMPIA SPLENDID parts.

IMPORTANT!

To prevent any risk of electrocution, always disconnect the main circuit breaker before making electric connections or

performing any maintenance on the units.

The following instructions must be made known to all personnel involved in the machine’s transport and installation.

CHAP. 1.2

1.2.1

Editorial

pictograms

1.2.2

Safety

pictograms

SYMBOLS

The pictograms in the next chapter provide the necessary information for correct, safe use of the machine in a rapid,

unmistakable way.

Service

- Refers to situations in which you should inform the SERVICE department in the company:

CUSTOMER TECHNICAL SERVICE.

Index

- Paragraphs marked with this symbol contain very important information and recommendations, particularly as regards

safety.

Failure to comply with them may result in:

- danger of injury to the operators

- loss of the warranty

- refusal of liability by the manufacturer.

Raised hand

- Refers to actions that absolutely must not be performed.

UNICO-HE

Danger of high voltage

- Signals to the personnel that the operation described could cause electrocution if not performed according to the safety

rules.

Generic danger

- Signals to the personnel that the operation described could cause physical injury if not performed according to the

safety rules.

Danger due to heat

- Signals to the personnel that the operation described could cause burns if not performed according to the safety rules.

27

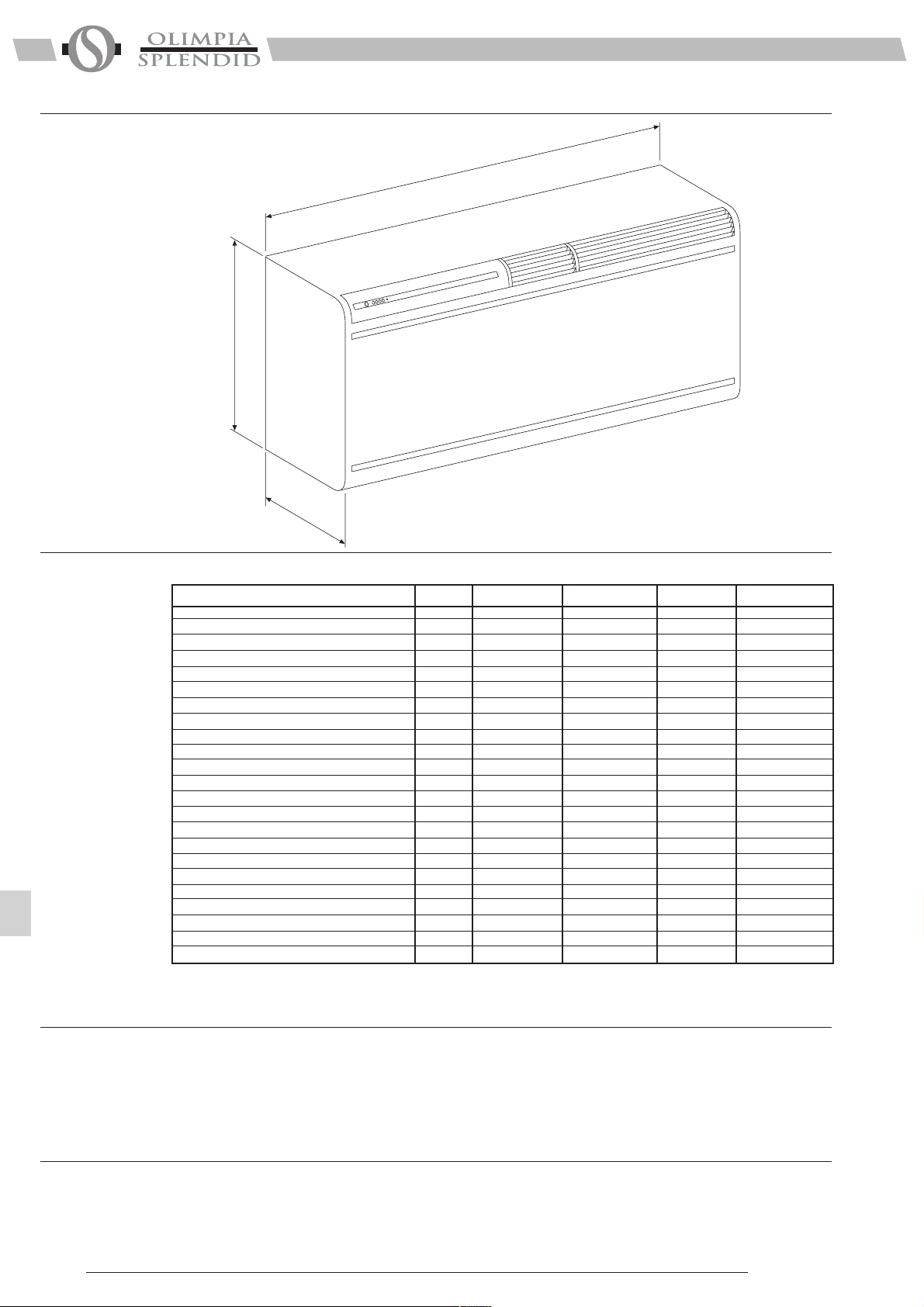

CHAP. 1.3

1.3.1

Overall

dimensions

TECHNICAL DATA

870

400

280

1.3.2

Technical

features

UNICO 8.5 HE UNICO 8.5 HP HE UNICO 11 HE UNICO 11 HP HE

Cooling capacity kW 2,1 2,1 2,45 2,45

Heating capacity kW -- 1,9 -- 2,035

Capacity absorbed during cooling W 790 790 1100 1100

Absorption during cooling A 3,47 3,47 4,83 4,83

Absorbed power during heating W -- 720 -- 1080

Absorption during heating A -- 3,16 -- 4,75

Max. absorbed power (*) W 930 930 1320 1320

Maximum absorption (*) A 4,12 4,12 5,85 5,85

E.E.R. (during cooling) 2,66 2,66 2,23 2,23

Energy efficiency class during cooling A A C C

C.O.P. (during heating) -- 2,64 -- 1,88

Energy efficiency class during heating -- C -- F

Annual energy consumption in cooling mode kWx500h 395 395 550 550

Dehumidification capacity

Cooling Gas R410a R410a R410a R410a

Power supply voltage V-Hz 230-50 230-50 230-50 230-50

Internal unit ventilation speed Num. 3 3 3 3

Maximum delivery of air during cooling (indoor unit) m3/h 350 350 390 390

Maximum air delivery OUTDOOR UNIIT m3/h 480 480 550 550

Dimensions of indoorl unit (Lxhxw) mm 870x400x280 870x400x280 870x400x280 870x400x280

Weight of indoor unit k g 43 43 46 46

Weight of outdoor unit kg -- -- -- -Maximum range of remote control m 8 8 8 8

l/h 1 1 1,2 1,2

(*) Maximum text conditions at high load

1.3.3

Technical notes

1.3.4

Proper use

28

The powers indicated refer to the following conditions (ISO reference standards):

in cooling and dehumidifying mode:

Air entering the inside unit at 27°C b.s. and 19°C b.u. with air entering the outside unit at 35°C b.s.

in heating mode:

Air entering the inside unit at 21°C b.s. and 19°C b.u. with air entering the outside unit at 7°C b.s. and 6°C b.u.

The air-conditioner should be used for the exclusive purpose of producing hot or cool air (on demand) for the sole purpose

of obtaining a comfortable temperature in the room.

Improper use of the machine (outside and inside units) causing damage to persons, property or animals relieve OLIMPIA

SPLENDID of any liability.

UNICO-HE

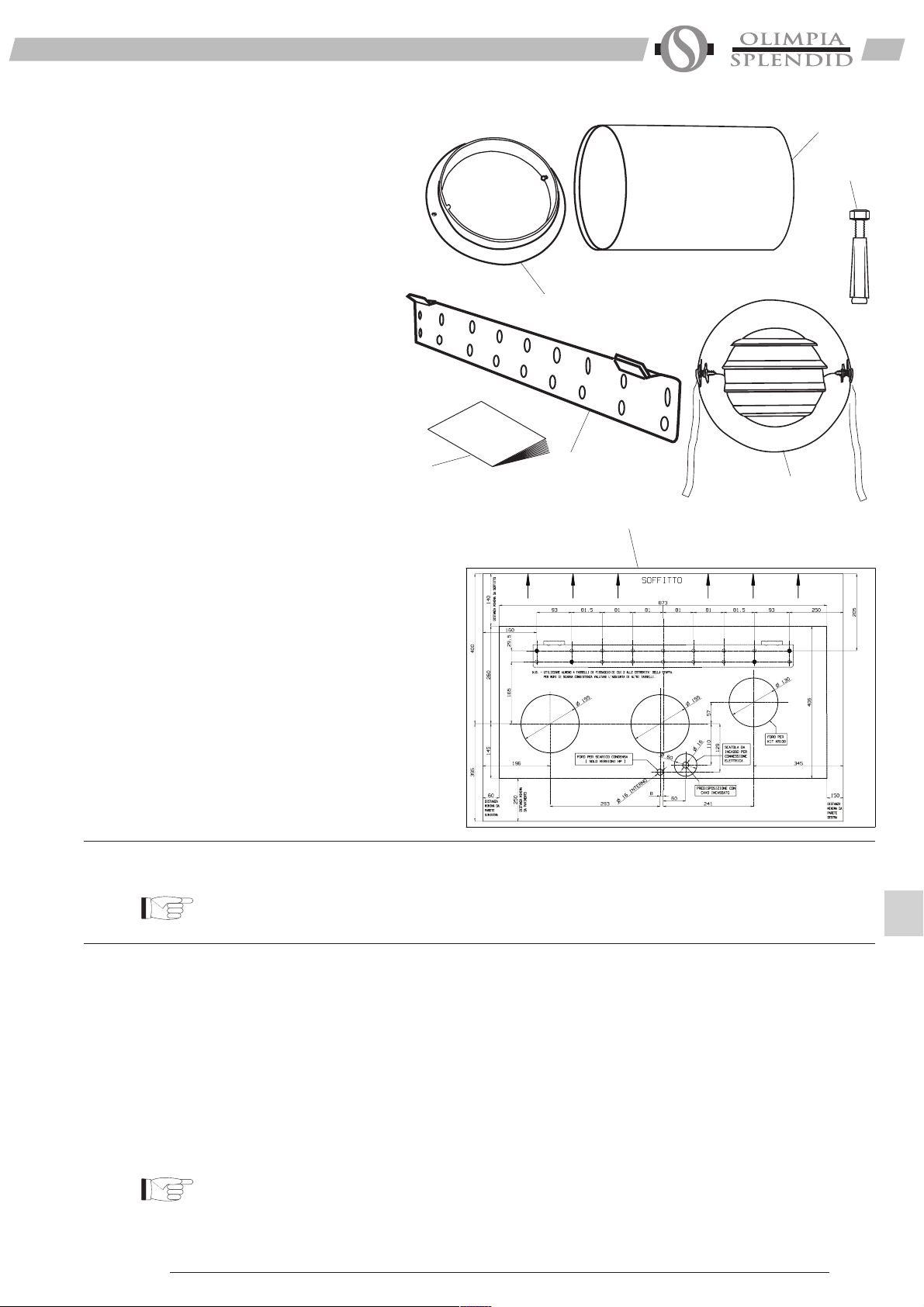

CHAP. 1.4

LIST OF ACCESSORIES SUPPLIED

The two units that make up the airconditioner are packed separately

in cartons.

Packaging may be transported per

single units, by hand by two

authorized persons, or loaded on

a trolley, even piling up to a

maximum of three packs.

The supply includes the parts

listed in the table below. Before

beginning to assemble the unit,

make sure all the parts are within

easy reach.

A - Wall fastening bracket 1

B - 2 external grids for air intake

and outlet including rubber

laces

C - 2 tubes to insert into holes on

wall, 50 cm long

D - Pipe fastening inner flange 2

E - Kit of screws and anchor

bolts

F - Manual of instructions for

use and maintenance, and

warranty

G - Paper template to make holes

F

C

E

D

MANUALE

A

B

G

Storage

Receipt and

unpacking

UNICO-HE

1.4.1

1.4.2

Store the cartons in a closed environment protected against atmospheric agents and raised off the floor by planks or a pallet.

TO NOT TURN THE CARTON UPSIDE DOWN.

The packing is made of suitable material and is done by expert personnel.

The units are delivered complete and in perfect condition, however we suggest that you perform the following controls of

the quality of the shipping service:

- on receipt of the cartons check them for any damage and, if any is found, accept the goods with reservation, and keep

photographic evidence of any damage found.

- unpack and check the contents against the packing list.

- make sure none of the parts have been damaged during shipment; in case of damage you must report it to the shipping

company within 3 days of receipt, by registered letter with return receipt,

presenting photographic documentation.

Copy of notice should also be sent by fax to OLIMPIA SPLENDID.

No notice of damage will be accepted after 3 days from delivery.

Important note:

Keep the packing at least through the warranty period, in case you need to ship the air-conditioner to the service centre for

repair.

Dispose of the packing materials in compliance with the rules in effect for waste disposal.

29

CHAP. 2 INSTALLATION

CHAP. 2.1

CHAP. 2.2

INSTRUCTIONS FOR INSTALLATION

To obtain the best results and optimum performance,

follow the instructions for correct installation provided in

this manual. Failure to follow the instructions and apply

the rules indicated may cause malfunction of the appliance

and relieves the manufacturer, OLIMPIA SPLENDID of

any form of guarantee and liability for damages to persons,

animals or property.

The electrical system must comply with the regulations

and rating data in the technical sheet, with good

grounding.

SELECTION OF POSITION OF THE UNIT

The position for installation of the inside unit, to obtain the

best performance and prevent breakdowns or hazards, must

have the following requisites:

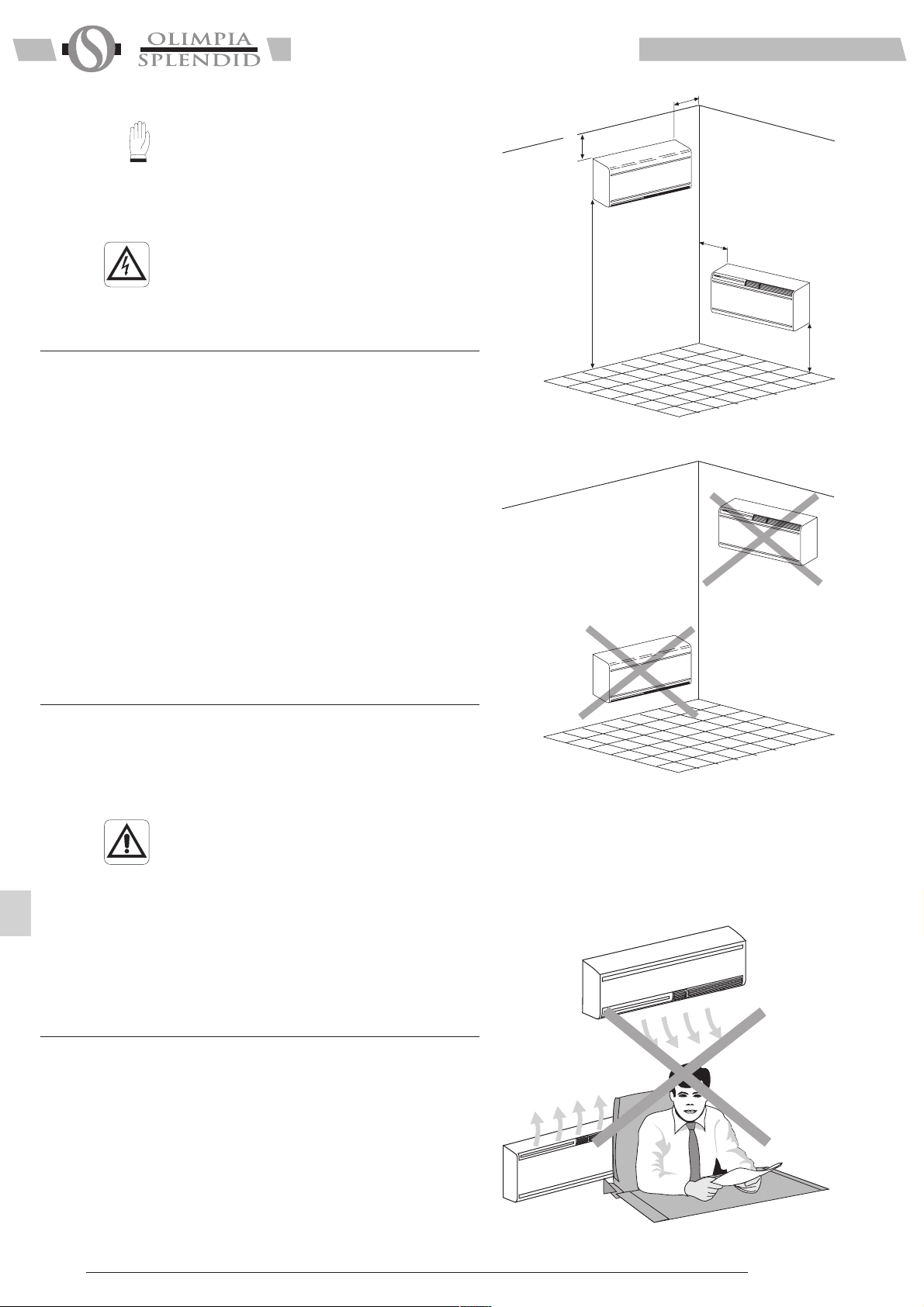

- The bottom of the inside unit must be at least 2 meters

off the floor and no more than 3 (fig. 1)

- The wall on which the inside unit is installed must be

sturdy and able to withstand its weight.

- It must be possible to leave room around the unit for any

maintenance operations that may be necessary.

- There should be no obstacles to the free circulation of air on

the intake side and, especially, on the air outlet side; on this side,

in particular, there should be no obstacles closer than 2 m.

This could cause turbulence that would interfere with correct

operation of the unit.

150 mm

2 m (min)

3 m (max)

150 mm

OK

150 mm

OK

300 mm

NO

2.2.1

Choice of best

position for

installing the air

conditioner

2.2.2

Dimensions and

features of site

where air

conditioner is

installed

NO

The air conditioner must be installed on a wall that

communicates with the outside.

Fig.1

Caution: After determining the best place for

installation as described above, check to make sure

that the wall can be drilled in that point without

interfering with other structures or installations

(beams, piers, pipes, wires, etc.).

Check again to make sure there are no obstacles to

air circulation through the holes to be drilled due to

plants and their leaves, slats or panelling, blinds,

gratings or grids too dense, etc.).

Before installing the air conditioner, it is essential to make

an accurate calculation of the heat load in summer (and

cold load in winter for models with heating pump) at the

site of installation.

The more accurate this calculation is made the better the

air conditioner will be able to do its job.

T o make these calculations, refer directly to the regulations

in effect (UNI ref. Law 10/91) or to the tables, both printed

and computerized, based on those regulations.

For particularly significant applications, we recommend

contacting expert heating engineers.

30

Fig. 2

UNICO-HE

As far as possible, in any case, it is important to try and

reduce major thermal loads by the following means:

Large glass panes exposed to sunlight should be provided

with curtains on the inside or shades on the outside

(Venetian blinds, verandas, refracting films, etc.)

The air-conditioned room should be closed as much of

the time as possible.

Halogen spotlights or other electrical equipment with high

power consumption should not be used in the room

(toasters, steam irons, hot plates for cooking, etc.).

- It should not be installed in a position where the air flow

can strike the people underneath directly (fig. 2).

- It should not be directly over another appliance (television

set, radio, refrigerator, etc.), or over a source of heat

(fig. 3).

- There should be no obstacles for reception of signals

emitted by the remote control (fig. 4).

Fig. 3

CHAP. 2.3

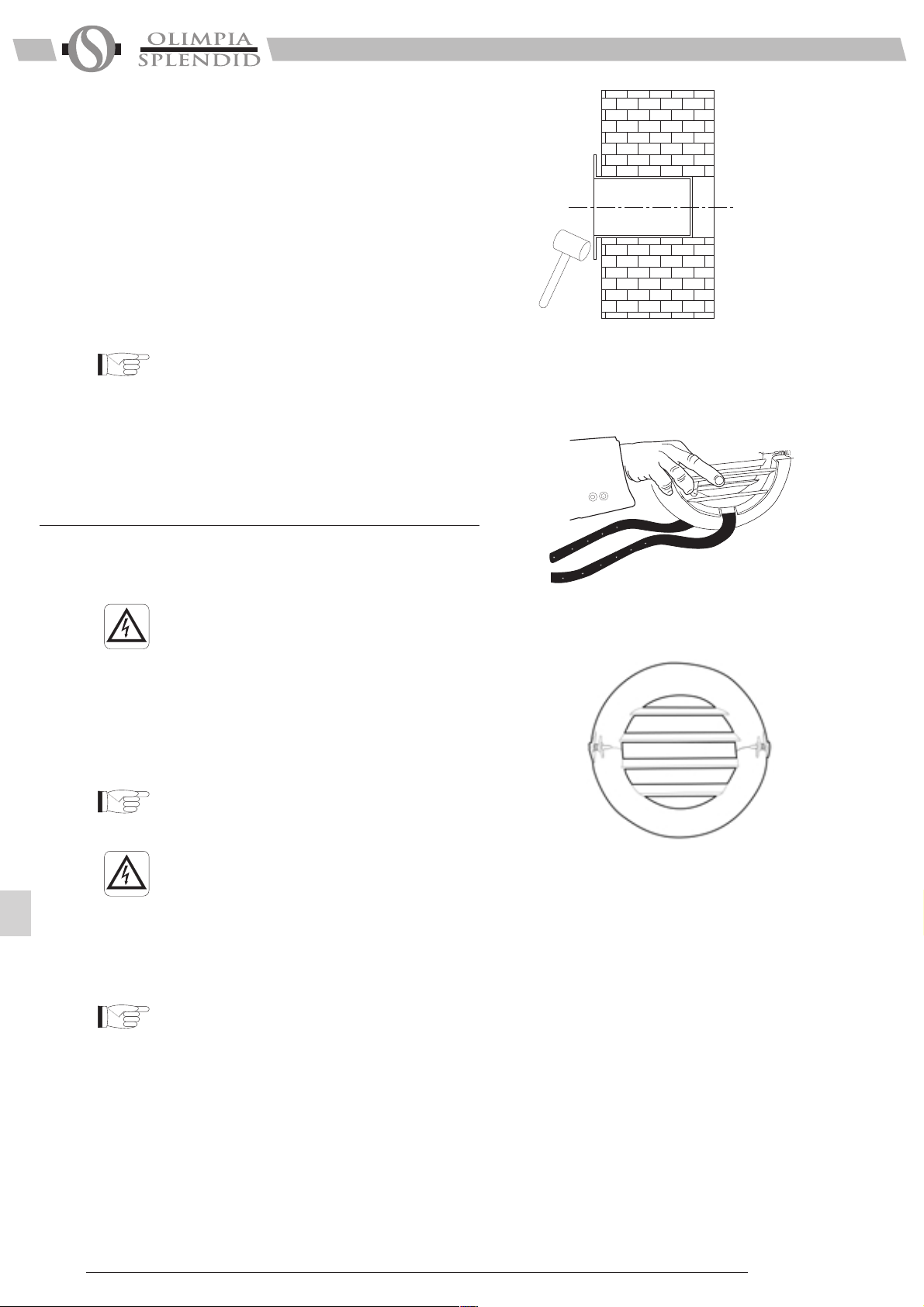

2.3.1

Drilling the wall

INSTALLATION OF THE UNIT

This operation should be carried out using the proper tools

to facilitate your work and prevent excess damage or

disturbance to your client.

The best tools for drilling large holes in walls are special

drills called core borers with very high twisting torque and

adjustable rotation speed depending on the diameter of

the hole to be drilled.

T o prevent the creation of large amounts of dust and rubble

due to drilling, the core borer can be fitted with a vacuum

system applied by means of suction cups to the drilling

zone.

Our Service Department can give you all necessary

information to enable you to find these devices.

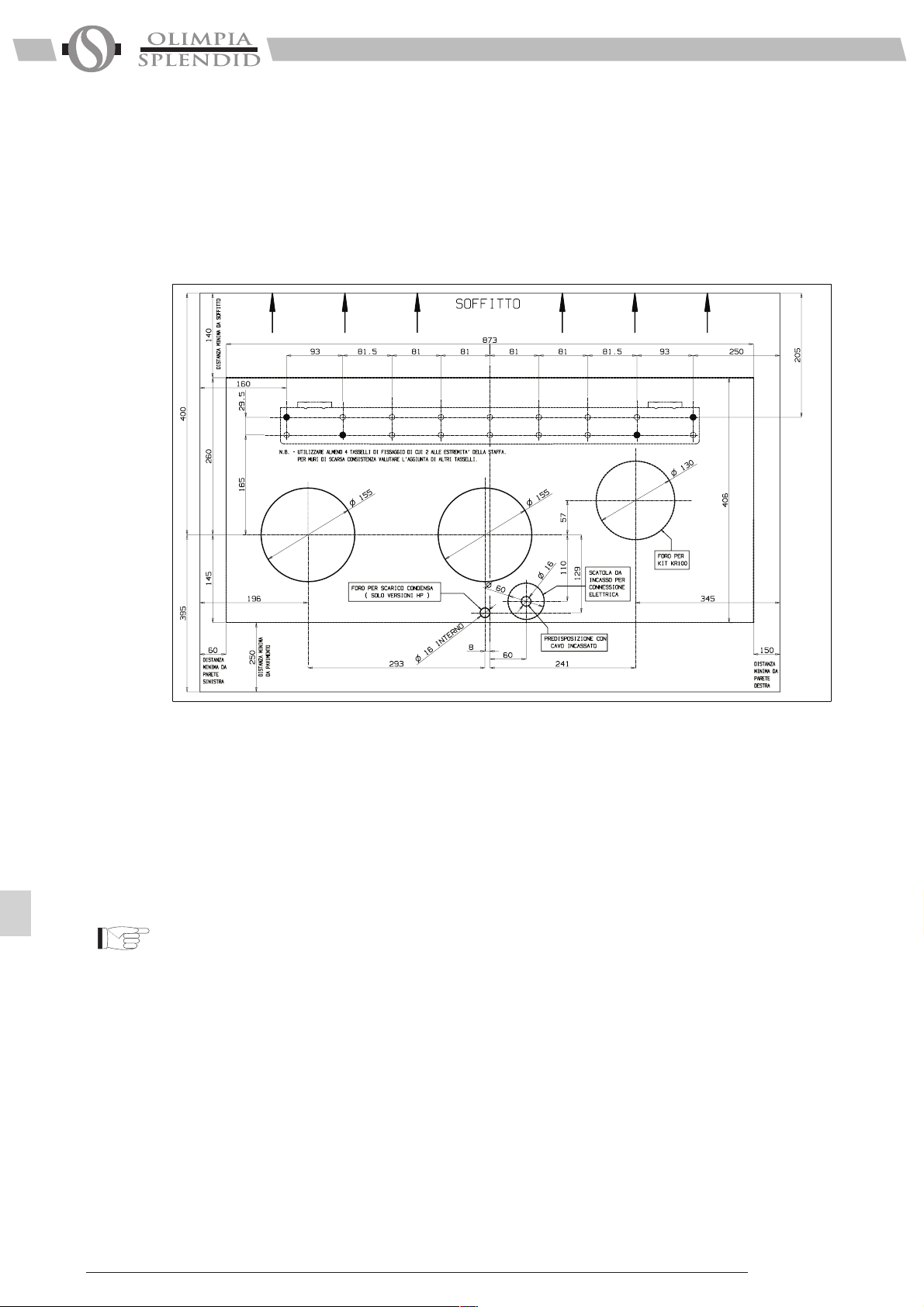

To drill the holes, proceed as follows:

Fasten the drilling template to the wall leaving the

necessary space from the ceiling, floor and side walls as

shown on the template. Use adhesive tape to fasten it in

place.

Use a small drill or punch to mark, with extreme care, the

exact centre of each of the holes to be drilled.

Using a core boring head measuring at least 154 mm to

drill the two holes for entry and exit of the air.

Note: The holes should have a slight outward

inclination to prevent any backflow of water from the

pipes (see fig.1).

T

E

C

S

T

U

A

A

R

U

O

H

1

AUT

R

U

O

H

N

O

UT

A

F

F

P

O

M

E

T

F

F

O

/

N

O

R

H

1

R

E

W

O

P

H

G

I

H

T

E

C

S

T

U

A

A

R

U

O

H

1

T

U

A

R

U

O

H

N

O

T

U

A

F

F

P

O

M

E

T

F

F

/O

N

O

R

H

1

R

E

W

O

P

H

G

I

H

Fig. 4

UNICO-HE

Most of the removed material is expelled outwards,

therefore make sure that it does not hit any person or

object when it falls out.

In order to avoid as much as possible outer plaster

breaking, it is necessary to proceed carefully with the

last part of hole execution, decreasing pressure on core

borers.

Fig. 5

31

Next, drill the holes for anchoring the fastening brackets to

the wall using as a first option the 4 holes on the ends of

the bracket as shown on the drilling template (see fig. 6).

If the wall is not very solid, it is advisable to use some

extra anchor bolts.

As you can see, the bracket can be fastened in a number

of different ways and positions. The air conditioner is

heavier on the left-hand side, so it is best to make sure of

a solid anchorage on that side. The anchor bolts provided

require holes with a diameter of 10 mm. In any case, the

wall should be inspected carefully to determine the best

possible anchorage and type of bolts suitable for particular

situations.

Warning: The manufacturer is not liable in case of

underestimation of the structural consistency of the

anchorage made at the time of installation. We

therefore recommend that you perform this operation

with the maximum care as, if not done properly, it

can cause serious damage to persons and property.

When installing models equipped with heating pump, if

no drainage well for condensate has been provided built

into the wall (see paragraph 2.3.2), it will be necessary,

to allow for drainage of the condensate, to drill a hole

through the wall measuring 16 mm in diameter in the

position shown on the template (see fig.6).

Fig. 6

32

UNICO-HE

2.3.2

Provision for

draining con-

densate for

machines with

heat pump.

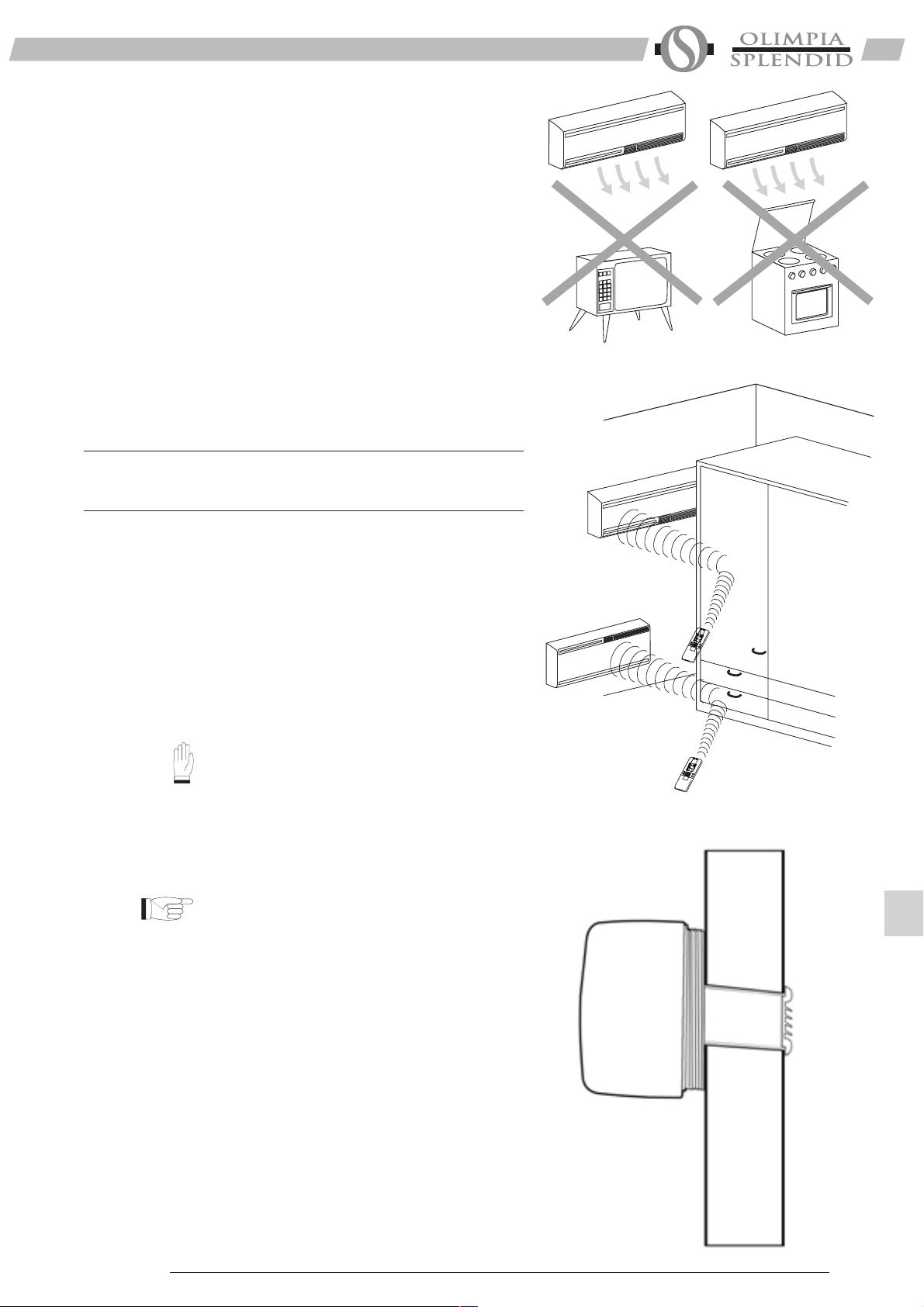

When the machine is heating, it produces condensate

that has to be eliminated through a specific drain line,

otherwise the machine will not work. Drainage occurs by

gravity . For this reason, it is essential for the drain line to

have a minimum inclination of at least 3% throughout its

length. The pipe can be rigid or not, with a minimum

internal diameter of 16 mm.

If the line drains into a sewer system, it should be provided

with a trap ahead of the main outlet.

The trap should be at least 300 mm lower than the inlet

opening on the air conditioner (fig. 7).

2.3.3

Installation of air

pipes and

external

gratings

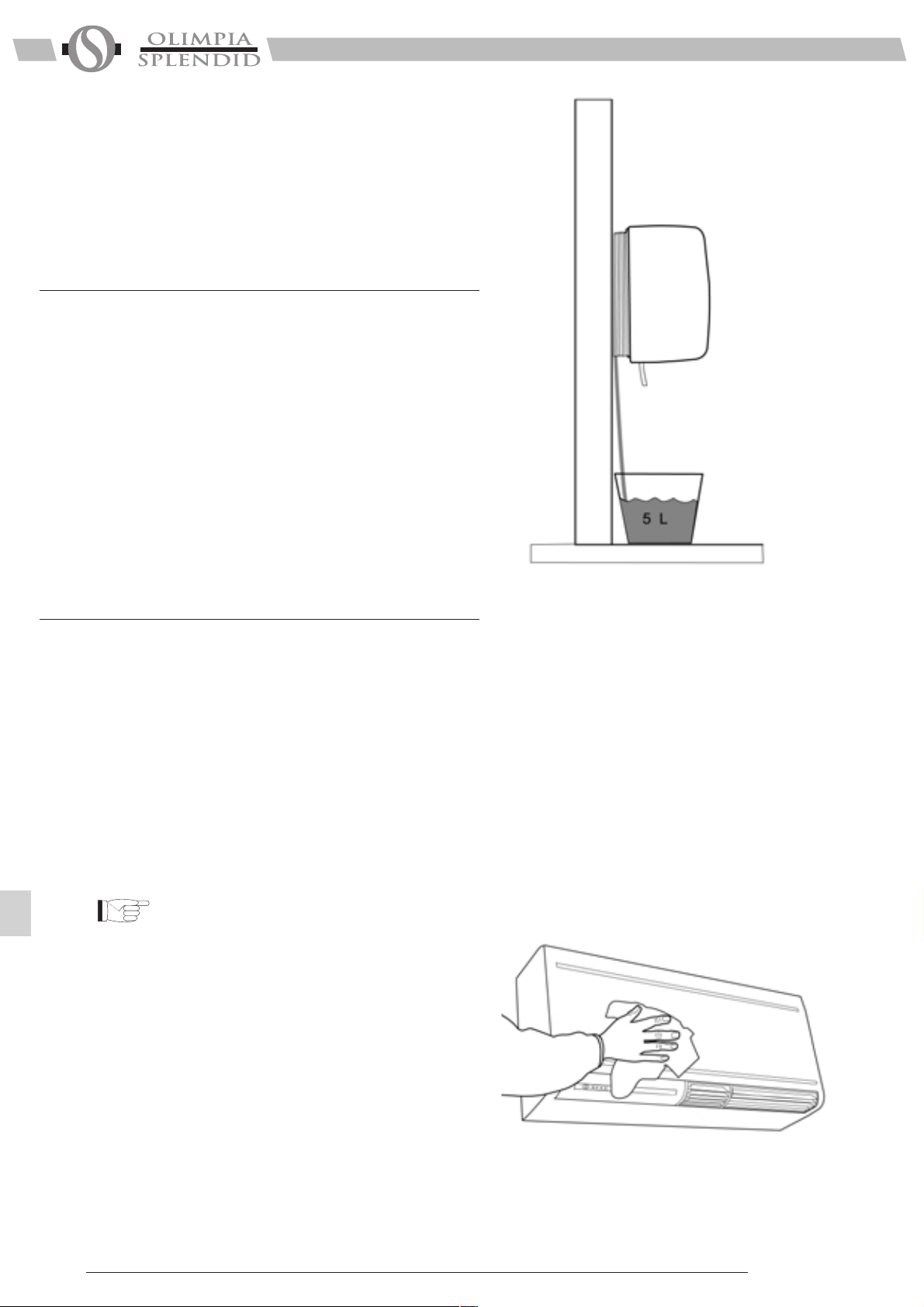

If the drainpipe drains into a vessel (tank or other

container), this container should not be sealed and the

drainpipe should not remain immersed in the water (see

fig. 8).

The correct position for the pipe inlet on the machine is

shown on the template for drilling and positioning the

machine (see also fig. 6).

The air conditioner is equipped with a pipe with an external

diameter of 14 mm for drainage of condensate.

This pipe protrudes from the machine for a length of about

400 mm.

The pipe should be fitted inside the one provided by you

for a distance of at least 200 mm, without any sharp bends

that could obstruct it.

When draining toward the outside, the pipe can be

inserted through the wall (always making sure to give it a

suitable inclination) (see fig. 5).

Caution: make sure, in this case, that the water expelled

outward does not damage or disturb persons or

property. During the winter this type of drainage may

cause sheets of ice to form.

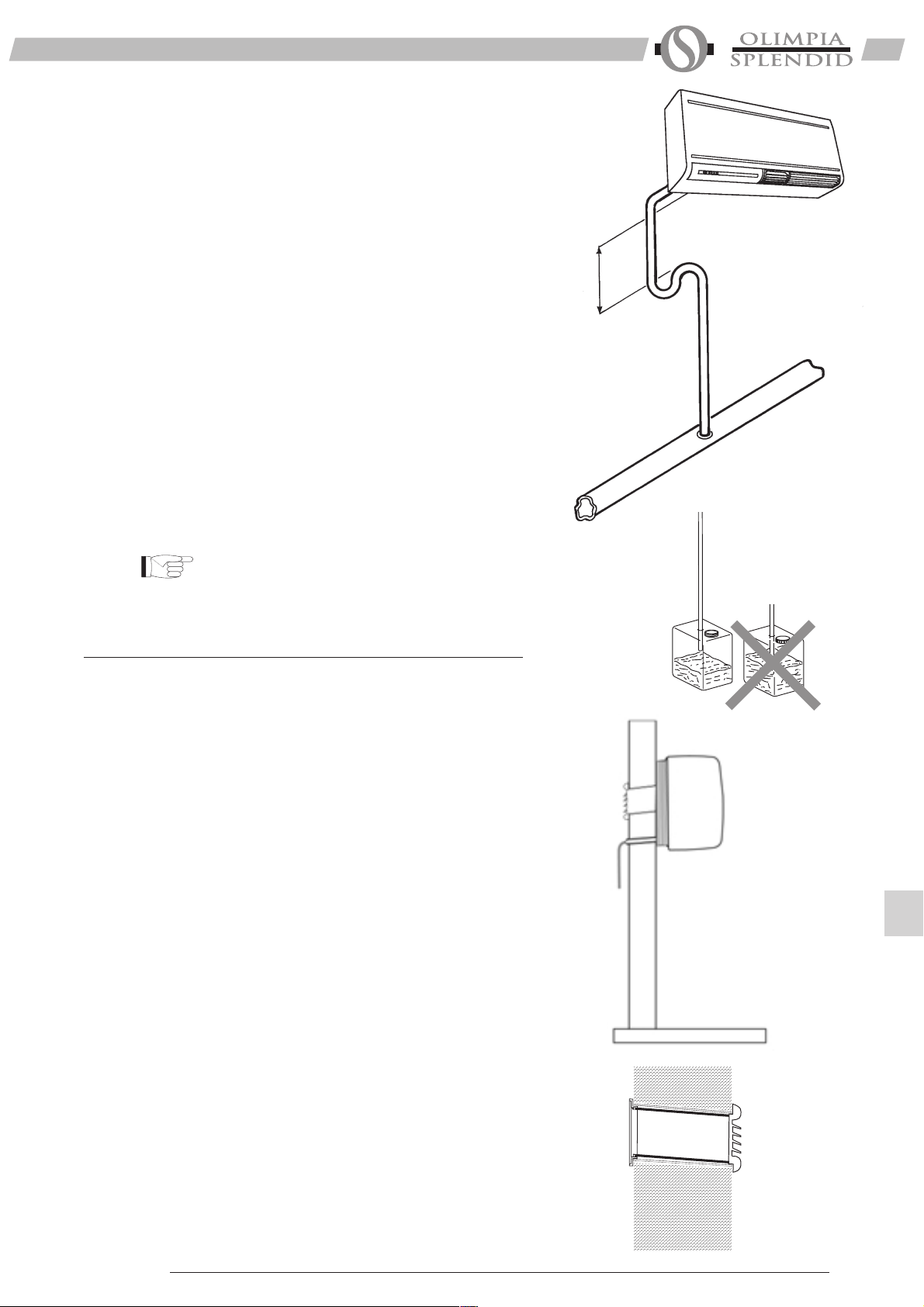

After drilling the holes, the plastic pipes supplied with the

air conditioner have to be fitted through them. The pipe

with insulation on the inside has to be fitted in the righthand hole with the insulated part toward the inside as

indicated on the label applied to it. The length of the pipes

should be 55 mm less than that of the wall. To cut the

pipe, a normal handsaw can be used. After cutting the

pipes, fit the ends into the two internal anchoring flanges

(fig. 10).

300 mm

Fig. 7

Fig. 8

UNICO-HE

The tube diameter is nearly the same as those carried

out using the 152/154 mm nominal diameter core drill. In

order to introduce the tubes, they must therefore be forced

slightly using, in the most difficult cases, a normal rubber

hammer (fig. 10/1). Having the hole internal diameter

extremely similar to the tube external diameter avoids

dangerous slacks which may generate humidity

infiltrations or air noises. Should the insertion prove to be

too difficult, we suggest you drill using the core bit inside

the hole so as to widen the internal diameter slightly.

Next, fit the pipes into the holes in the wall and fasten the

flanges with 4 anchor bolts with diameter 6, taking care

to keep the two fastening holes in a horizontal position.

Fig. 9

Fig. 10

33

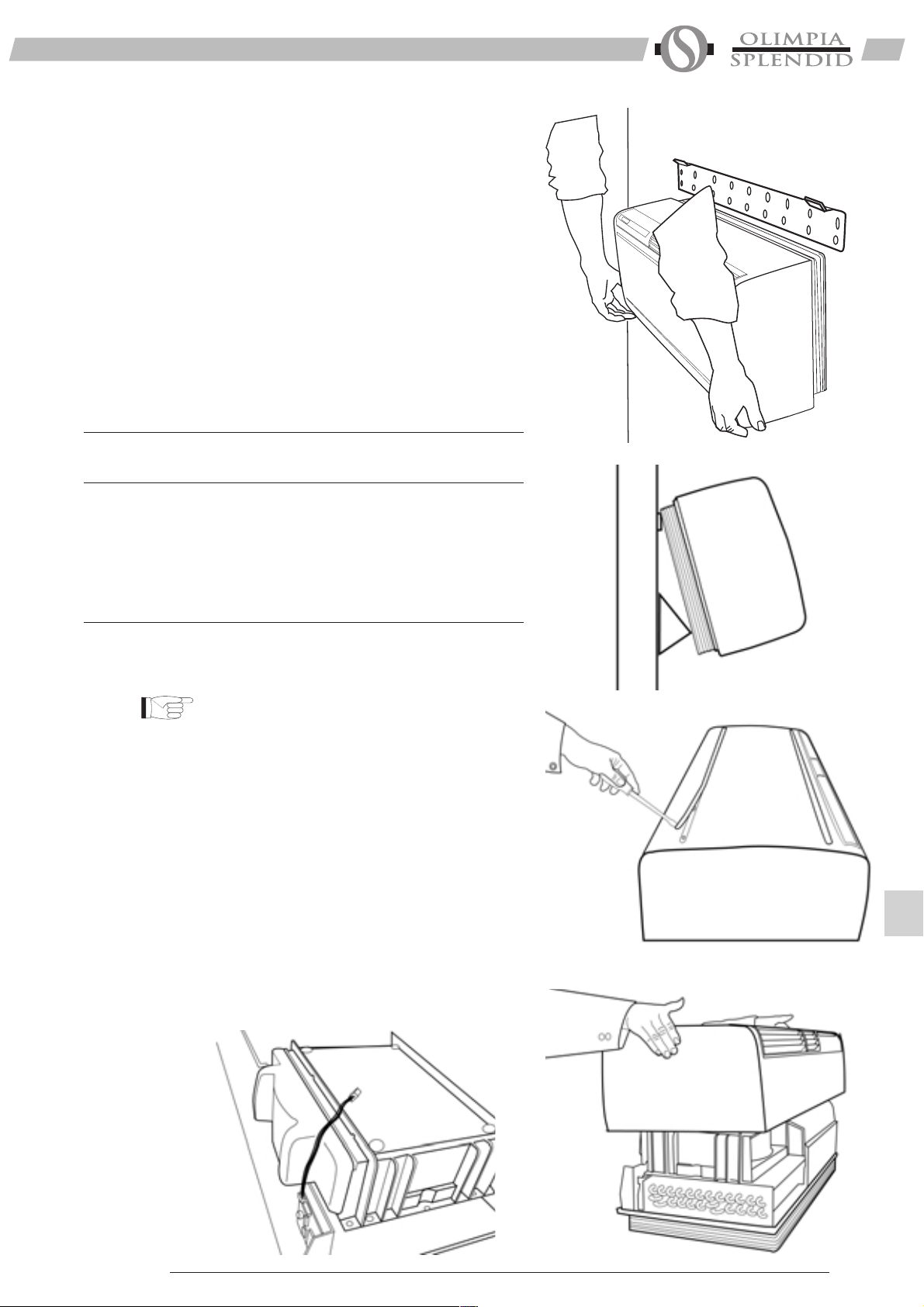

To position the external grating, proceed as follows:

- Grasp the two rubber belts attached to the grating in

one hand.

- Fold the outer gratings in half by grasping them with

your free hand along the fold line and inserting your

fingers inside the fins (fig. 11).

Insert your arm inside the pipe until the grating

protrudes all the way outside.

- Let the grating open, but keep your fingers inside the

fins.

- Turn the grating so that the fins are perfectly horizontal

with the inclination toward the outside (fig. 12).

- Pull the grating toward you.

- Tighten the rubber belts and fasten them to the two

pins on the inner flange.

- Cut the excess part of the belt.

Warning: If the external grating is accessible, to

prevent the hazards resulting from its possible

removal (insertion of the hands into the pipes and

touching moving or powered parts) it is absolutely

essential to fasten it to the wall with 4 anchor bolts

with a diameter of 6 mm.

Fig. 10/1

2.3.4

Power supply

connection

The air conditioner is equipped with a power supply cable

and plug.

If it is installed near an outlet, you need only plug it in.

In this case, it is important to make sure the outlet to

which you are plugged in is effectively grounded and

connected to the mains by wiring of adequate size

(minimum 1.5 sq.mm. cross section).

T o make an electrical connection with the shielded cable

(recommended for installations high on the wall) proceed

as follows:

Install a shunt box in the wall in the position shown on

the installation template (fig. 6), where you should provide

a power cable with a cross-section (two poles plus ground

wire) of 2,5 sq.mm.

Warning: The external power line should be provided

with an overload circuit breaker with suitable capacity

for the rating of the machine.

Make all connections in compliance with the laws in

effect.

Close the shunt box with its cover after drilling a hole in it

for passage of the cable.

Alternatively , you can use a cable in the wall in the position

shown on the template, for making the connection. In

this case, remove the casing (as described in paragraph

2.4.2) and connect the cable to the power terminal board.

Fig. 11

Fig. 12

34

Caution: these operations should be performed with

the machine already positioned on the bracket. Read

the instructions carefully before completely the

electric connection.

UNICO-HE

2.3.5

Fitting the unit

on bracket

CHAP. 2.4

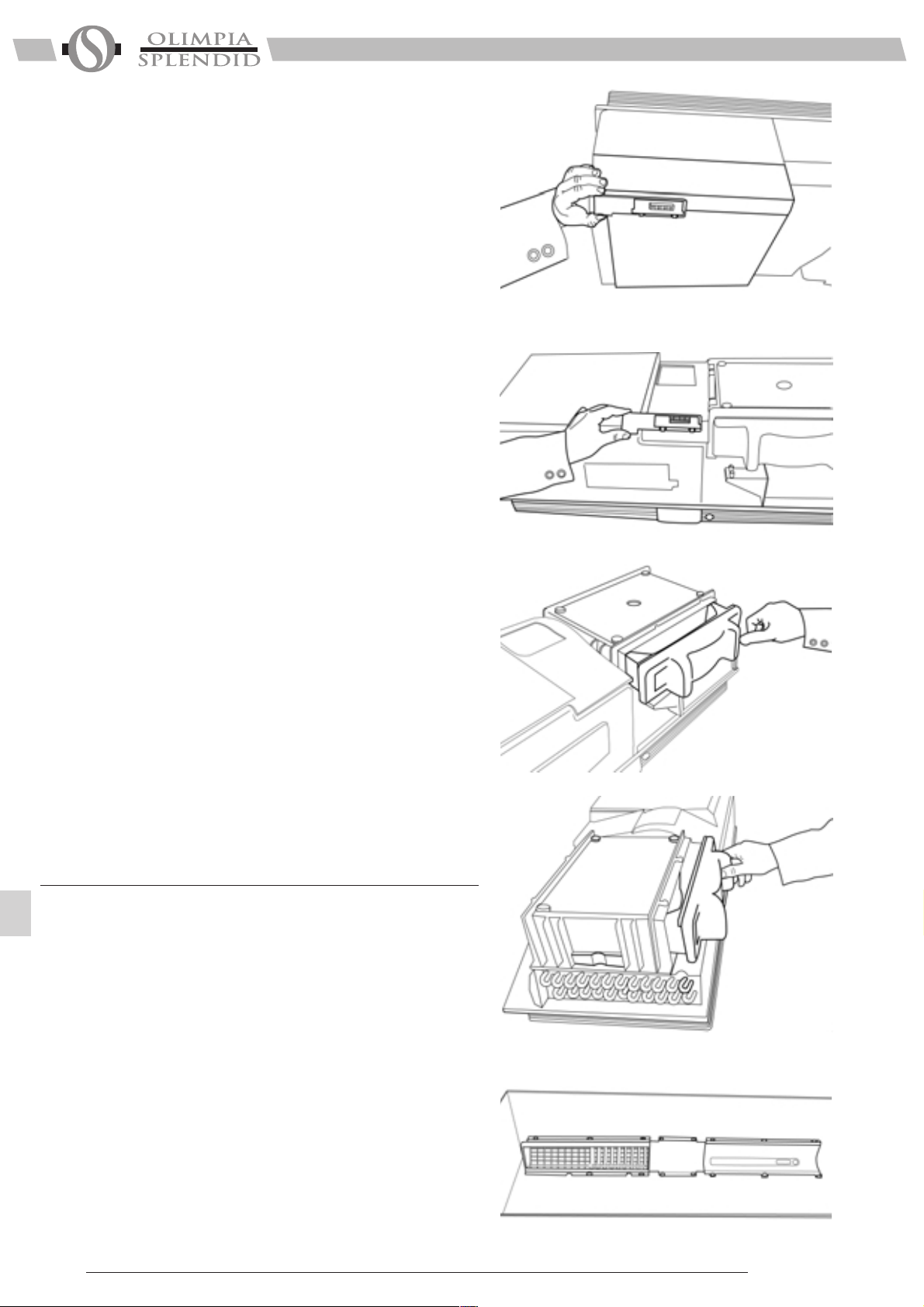

After checking again that the fastening bracket is securely

fastened to the wall, and that any necessary preparations

for electric connection and condensate drainage have

been made, you can fasten the air conditioner to its

supporting bracket. Lift it up holding the sides of the bottom

(see fig. 13).

To facilitate the operation of fastening it to the bracket, tilt

it slightly toward you.

T o make the electrical connection and fasten the drainpipe,

place a wedge between the air conditioner and the wall

(see fig. 14).

After these operations have been carried out, the air

conditioner can be pushed firmly against the wall so that

the bottom hook catches.

When you have finished, inspect carefully to make sure

there are no fissures at the back of the air conditioner

(the insulating gasket must fit firmly against the wall)

particularly in the zone where air enters and leaves the

machine.

Fig. 13

PREPARATION FOR ASSEMBLY/INSTALLATION

WALL TOP PART

2.4.1

Introduction

2.4.2

Removal of front

casing

The air conditioner is assembled in the factory ready to

be installed low on the wall.

The air outlet, in this case, is at the top of the air conditioner

with the recycle grating and control panel.

In order to prepare the product for installation on the top

part of the wall, follow the instructions below.

Note: if the air conditioner has not been installed on

the wall yet, place it on its back. To not apply heavy

pressure to the bottom of the device as this could

dent or scratch the casing.

Use a small blade screwdriver to remove the horizontal

strips on the casing, applying gentle leverage in the slits

along the sides. (see fig. 15).

Take care not to scratch the strips or casing with the

screwdriver point.

Unscrew the 8 self-threading screws that fasten the casing

to the air conditioner.

Lift the casing off carefully , pulling it toward you by about

50 cm (see fig. 16).

Disconnect the fastener on the right that fastens the wires to

the airflow deviation baffle adjustment motor (see fig. 17).

Now you can remove the casing completely.

Fig. 14

Fig. 15

UNICO-HE

Fig. 16Fig. 17

35

2.4.3

Preparation of

unit

Unscrew the bracket supporting the small circuit board with

display leds and reinstall it on the bottom opposite, where

you will find two holes on the base (see fig. 18-19).

Make sure the connection plate is securely fastened on

the inside of the air conditioner, and apply some insulating

tape if necessary. Remove the styrofoam enclosure on

the lower right-hand side under the air recycle fan and fit

it against the opening above the fan (see fig. 20-21).

Remove the air outlet grating by removing the fastening

screws. Remove the control panel (see fig. 22).

When performing this operation place the casing on a

secure surface so as not to scratch or dent it. Remove

the plastic plate with the logo and transparent screen for

display of the leds from the control panel by pressing on

the hooks at the rear. Turn it over (rotate by 180°) and

reinstall it on the panel.

Reassemble the parts in the opposite position from the

original installation, reversing the air outlet grating with

the control panel grating.

Turn the casing over so that the air outlet grating is on

the lower right-hand side of the device.

Connect the plug on the step-step motor of the grating.

Fit the casing back on the air conditioner carefully, t aking

care to hold the wires for the step-step motor to one side

so that they do not interfere with the inner part of the air

outlet grating.

Check that all the coupling references of the casing with

the rear frame are fully inserted so that the casing is

fitted smoothly and evenly all around.

Fasten the casing with its eight screws and replace the

strips in their slots.

After completing installation, the electronic parts of the

air conditioner have to be configured so as to take into

account the stratification of heat in the room. This procedure is outlined in paragraph 2.5 (Operating tests and

diagnosis of possible malfunctions).

Fig. 18

Fig. 19

CHAP. 2.5

WORKING TESTS AND IDENTIFICATION

OF POSSIBLE MALFUNCTIONS

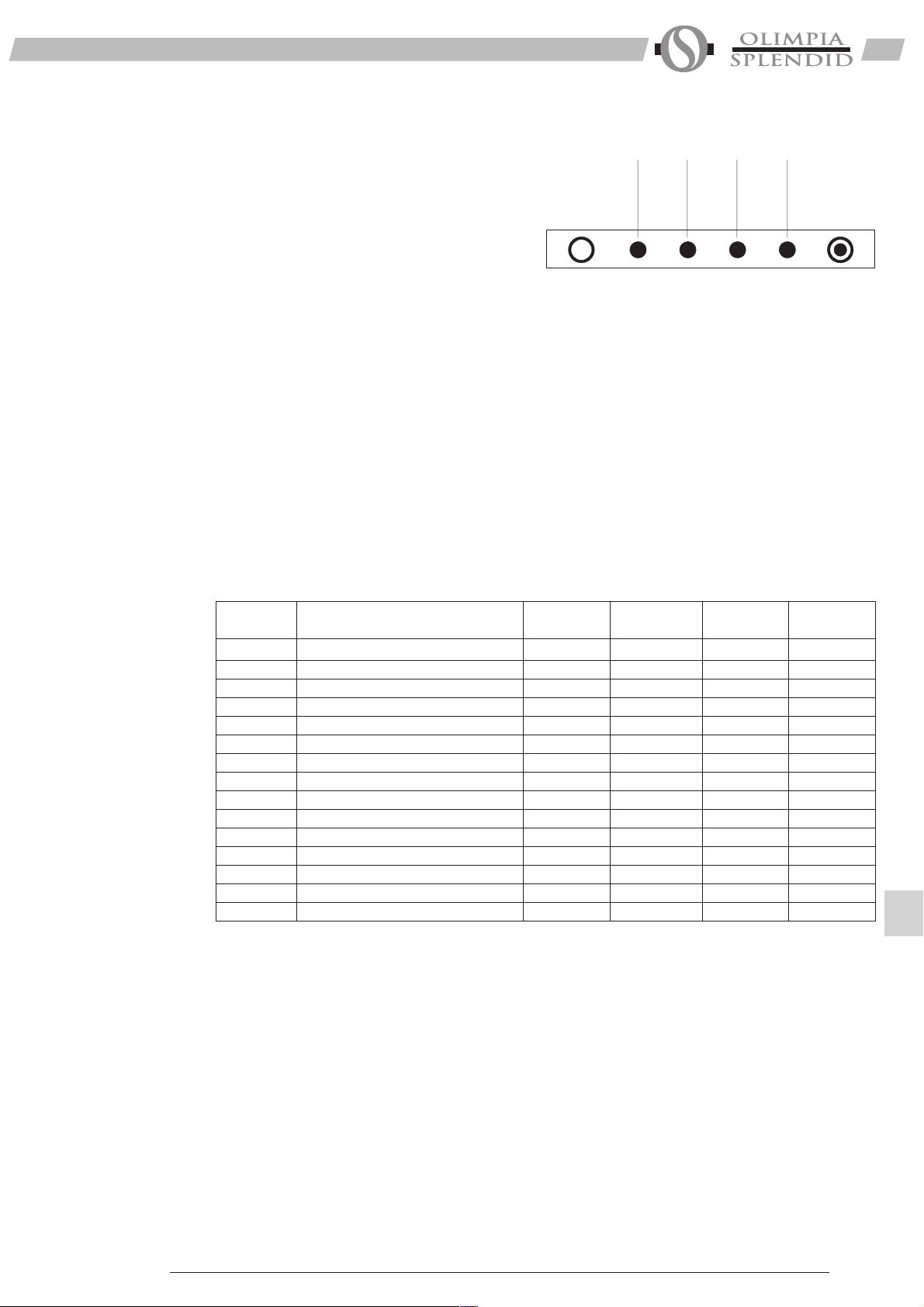

The program introduced in the microprocessor of this

device makes it possible to run a brief self-test to ensure

that the machine functions normally by starting each of

its internal components.

To run the self-test, proceed as follows:

- Power the air conditioner and make sure it is on stand-by.

- Use a sharp object to press the microkey located under

the hole on the left of the control panel for at least 10

sec.

- At the beginning and end of the self-test procedure the

status of configuration of the machine will be displayed

for a few seconds as follows:

Fig. 20

Fig. 21

36

Fig. 22

UNICO-HE

red led (filter): off = UNICO

on = UNICO HP (with heat

pump)

green led (compr.): off = with correction of room tem-

perature

on = without correction of room

temperature

orange led (timer): off = without correction of room

temperature

on = with correction of room tem-

perature

green led (power): off = stand-by in case of black-

out

on = restart in case of black-out

- Check after a few seconds to see whether the

equipment heats normally (if equipped with heat pump

function) for about 2 minutes and then, after a few

seconds, that it cools for another 2 minutes.

Before concluding the self-test, the electronic part tests

the temperature probes to make sure they are operating

normally. If any of these should not be working, the

corresponding signal led remains lit for 20 sec. (see

table on next page).

Should there be a jam in the air-conditioning system with

alarm signals according to the table here following, please

be ready to refer to the Service Centre which leds are

blinking in order to simplify their intervention.

green orange green red

Starting from the left:

CODE DESCRIPTION green LED orange LED green LED red LED

ALARM POWER TIMER COMPR. FILTER

1-FS dirty filter O

2-HTI internal battery overheat O

3-HTE external battery overheat O O

4-LT internal battery low temp. O

5 pump working continuously O O

6-CF/RL

batt. temp. not reached O O

7-OF water level O O O

8-CKS eeprom parameters not valid O

9- O O

10-TSF short on room sensor O O

1 1-TSF room sensor disconnected O O O

12-TSF short on evaporator sensor O O

13-TSF evap. sensor disconnected O O O

14-TSF short on condenser sensor O O O

15-TSF condenser sensor O O O O

The end of the self-test will be signalled by all the leds

lighting up at once and blinking ten times, as well as by

an acoustic signal.

At this time, you can adjust the temperature reading on

the room temperature sensor. This correction is importan t

if the air conditioner is installed high on the wall in a room

where the warm air tends to stratify upward (as in rooms

with high ceilings or other sources of heat besides the air

conditioner). The sensor will read a temperature 3°C lower

than the effective one, in this case, to compensate for

the difference between the lower inhabited part of the

room and the temperature at the height of the sensor.

To enter or remove this correction proceed as follows:

1 Check the status of the machine as described

previously, and if no correction has been made, press

the button on the console while the acoustic signal is

on at the end of the self-test.

2 To remove the correction, press the button while the

acoustic signal is on at the end of the self-test.

UNICO-HE

37

The machine is set in the factory without correction of

the temperature.

In addition to the self-test (that can be made under any

conditions of room temperature) we recommend that you

also test the product in the various operating modes

accessible to the user (see the user manual). One

important test you should make concerns regular

evacuation of condensation water on the models with heat

pump. To check this, keep the machine running for at

least 4-5 hours in the heating mode. If the water does not

drain, there should be an “overflow” alarm.

Evacuation of

2.5.1

condensation

water in case of

emergency

CHAP. 2.6

If there should be a malfunction in the condensation water

drain system, the air conditioner stops working and

signals, with flashing orange, green and red lights (the

second and third leds from the left), the alarm status.

T o enable the air conditioner to work temporarily until the

service personnel arrives, you can drain the water out by

following these simple instructions:

- Grasp the rubber cap on the bottom centre of the air

conditioner behind the edge of the frame facing the wall

between your thumb and forefinger.

- Pull the rubber tube closed by the cap out by a few

centimetres.

- Remove the cap after placing a bucket or other container

underneath it (at least five litter capacity) to collect the

water (see fig. 23).

- After eliminating the malfunction the service personnel

will take care of closing the evacuation tube.

PERIODICAL MAINTENANCE

Air conditioners of this type do not require any particular

routine maintenance except:

- Cleaning or washing the room air filter when the red

led lights up (see user manual).

- Cleaning of “external air” battery, to be done as needed,

depending on the amount of dirt in the external air,

once or twice a year. To do this, you must, of course,

open the air conditioner by removing its casing and

the noise insulation on the inside.

- Cleaning can be done using a vacuum cleaner or soft

brush, taking particular care not to damage the

aluminium heat exchanger baffles. It may be necessary

to use water and detergents to remove heavily

encrusted dirt.

Fig. 23

38

Note: after cleaning the battery replace the noise

insulation carefully matching the edges and gaskets

with their reference markings.

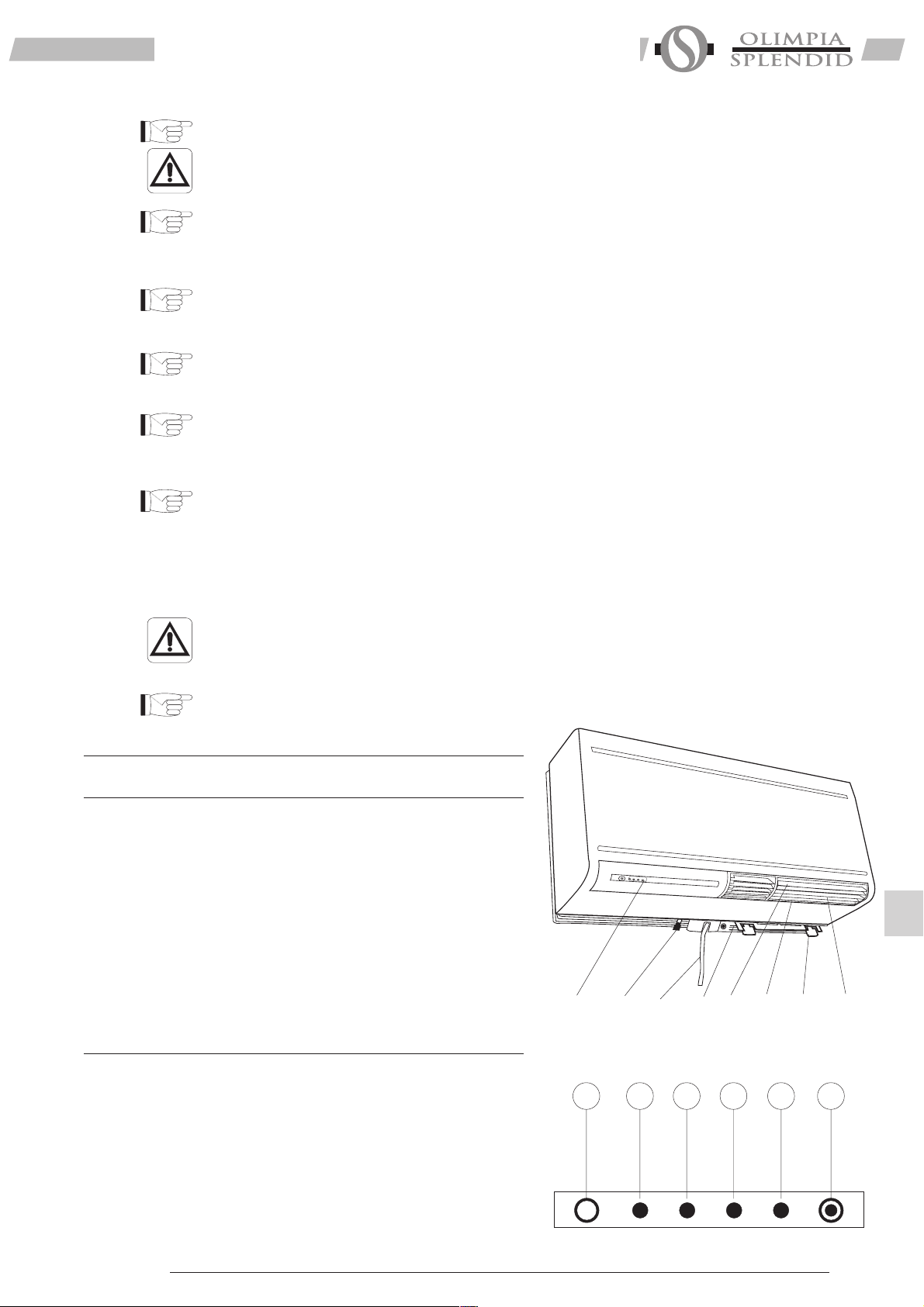

Before you leave the site of installation you should gather

up all packing material and use a damp cloth to remove

any traces of dust that may have deposited on the

machine during assembly (fig. 24).

These operations, though certainly not essential, have a

beneficial effect as they enhance the professional image

of the installer in the eyes of the client.

T o prevent unnecessary calls by the user , before you leave

the site of installation it is also a good idea to:

- Explain the contents of the Instruction Manual to the user.

- Show him how to clean the filter.

- Explain when and how he should contact the Service

Department

Fig. 24

UNICO-HE

CHAP. 3 USE AND MAINTENANCE (for the user)

CHAP. 3.1

Important Recommendations

Installation and connection of the air conditioner should

be carried out by specialized personnel in possession

of the qualifications specified in Law 46/90.

The instructions for installation are provided in the

specific manual.

No structural object (furniture, curtains, plants, leaves,

blinds, etc.) should ever obstruct the normal flow of

air from either the internal or external gratings.

Never lean or, worse yet, sit on the casing of the air

conditioner as this could cause serious damage to

the external parts.

Do not turn the horizontal airflow baffles by hand.

Always use the remote control to adjust baffle

position.

If the unit leaks water, switch it off immediately and

disconnect it from the power mains. Call the nearest

service centre.

When the air conditioner is heating, it has to

periodically eliminate any ice that could form on the

external battery. While it is doing this, the machine

keeps running but does not heat the room. This lasts

for a brief period of time, from 3 to a maximum of 10

minutes.

3.2

3.2.1

List of Units

3.2.2

Description of

signal console

The air conditioner must not be installed in rooms

where explosive gasses develop or where there are

conditions of heat and humidity beyond the maximum

limits indicated in the installation manual.

Clean the air filter periodically, as described in the

specific paragraph.

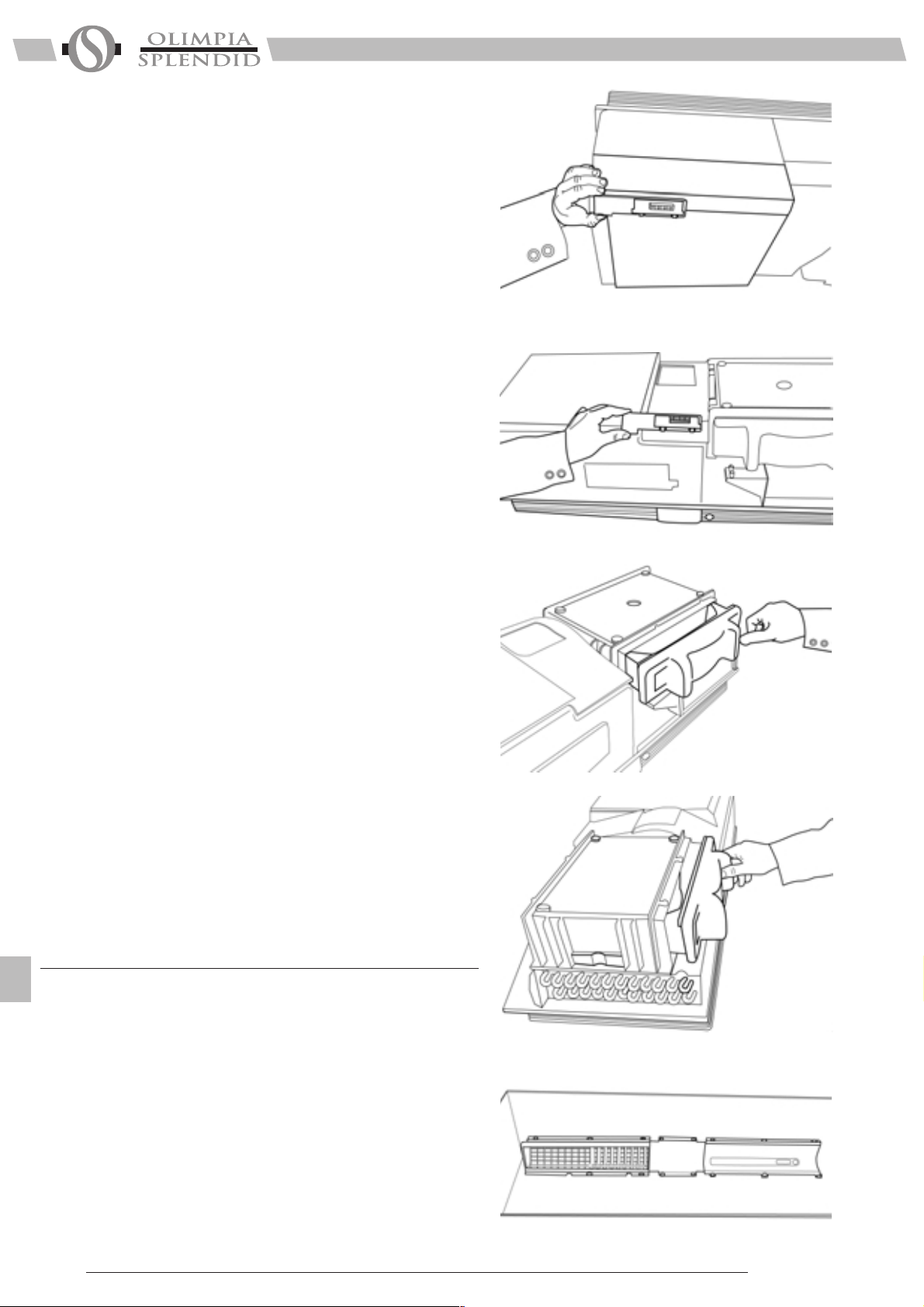

NAMES OF PARTS

1) Air outlet grating..

2) Cursors for lateral adjustment of airflow.

3) Motor-operated air baffles for upward airflow

4) Alarm display console.

5) Air intake grating.

6) Grips for removal of air filter.

7) Rubber hose with cap on end for evacuation of

condensation water in case of emergency.

8) Power cable

1) Transparent zone of receipt of remote control signal.

2) Green led indicating machine is running (When the

machine is on stand-by this light is off).

3) Orange led indicates on/off programming is in use.

4) Green led indicates cooling compressor is on.

5) Red led indicates air filter clogged.

6) Service microkey (RESET)

4

165432

7

5

8

Fig. 25

261

3

UNICO-HE

Fig. 26

39

3.3

CONTROL OF AIR CONDITIONER

USING THE REMOTE CONTROL UNIT

3.3.1

Remote control

3.3.2

Insertion of

batteries

The remote control supplied with the air conditioner is

designed to be extremely sturdy and to ensure excellent

performance in use, but it should nevertheless be handled

with some care.

For example, do not:

- leave it out in the rain, spill water on its keyboard

or drop it into water.

- subject it to impacts or drop it onto hard surfaces.

- leave it exposed to direct sunlight.

- place obstacles between the remote control and

the air conditioner while using it.

Furthermore:

- if other devices operated by remote control (TV , radio,

stereo systems, etc.) are located in the same room as

the air conditioner, there may be interference,

- electronic and fluorescent lighting may interfere with

communications between the remote control and the

air conditioner,

- remove the batteries in case of prolonged disuse of

the remote control.

Use only 2 dry cell batteries type LR03 with 1,5 V (supplied

with the remote control unit). Dispose of used batteries

only at the special collection points provided by the local

authorities for this type of waste.

Replace both batteries at the same time.

D3

+

-

-

+

D4

3.4

3.4.1

Description of

the remote

control

To insert the batteries remove the spring-latch cover on

the back of the remote control.

The batteries have to be inserted according to the positive and negative pole markings in the bottom of the battery

compartment.

Close the spring-latch cover after inserting the batteries.

REMOTE CONTROL

The remote control is the interface between the user and

the air conditioner. It is therefore particularly important to

familiarize yourself with the parts of the remote control

that relate to this interface.

T1 On/Off.

T2 Well being mode (Automatic)

T3 Night well-being mode

T4 Operating mode selector.

T5 Fan speed selector.

T6 Button for setting timer and programs.

T7 Button for increasing (+) or decreasing (-) the tem-

perature/time settings.

T8 Button to start external air intake (functions only if

the air conditioner is equipped with this accessory).

T9 Movable baffle adjustment On/Off button.

T10 Reset button.

T11 Program start button.

D Display: shows operating status and settings as

they are made.

D1 Fan speed or automatic operating mode indicator

(AUTO).

D2 Heating.

D3 Cooling.

D4 Dehumidifier only.

D2

D1

D8

D9

T1

T4

T5

T8

T9

AUTO

1

2

D5

D6

AUTO

H

M

D7

D10

T2

T3

F

S

A

N

+

E

T

T7

-

T6

T11

T10

40

UNICO-HE

D5 External air intake switch.

AUTO

AUTO

F

A

N

S

E

T

+

-

AUTO

F

A

N

S

E

T

+

-

D6 Night operation switch.

D7 Automatic operation switch.

D8 First operating program switch.

D9 Second operating program switch.

D10 Temperature indicator (thermometer) or time

indicator (H M).

The remote control is also equipped with a cover with a

cursor that can be positioned so as to permit access only

to the ON/OFF, AUT O M ATIC MODE and NIGHT MODE

buttons.

With the cover in this position the air conditioner can be

used but none of the settings can be tampered with.

Switching on

3.4.2

and control of

operation

3.4.3

Switching the

unit on and off

(button T1)

In order to command the machine via the remote control,

the main switch on the electric line (ask the technician

who installed the machine about the main switch position)

must be on and the mains plug of the machine must be

plugged in.

Once these operations have been carried out, the

machine may be regulated using the remote control.

To send commands to the air conditioner, point the front

of the remote control toward the air conditioner control

panel.

The device emits a beep when it receives a command.

The maximum distance for transmission of commands is

about 8 meters.

This button turns the machine on or off.

The machine’s control system has a memory, therefore

any setting will not be lost when it is turned off.

This button serves to switch the air conditioner on or off

for brief periods of time.

In case of prolonged stop of the machine, it must be

deactivated turning the main switch off or unplugging the

machine from the mains.

T1

Switching the unit on and off

AUTO

AUTO

F

A

N

Fig. 28

S

+

E

T

3.4.4

Well being mode

(Automatic)

(button T2)

3.4.5

Cooling function

UNICO-HE

By means of this button the machine is automatically

regulated in order to create an optimal comfort temperature in the air-conditioned room.

The machine’s temperature is automatically regulated

according to the room’s temperature.

The fan speed is also automatically regulated according

to the set temperature (except in dehumidification use).

When used in this mode, the air conditioner dehumidifies

and cools the room.

Button T4 is used to select the operating mode.

Press until the snowflake symbol appears on the display.

First set the desired temperature and fan speed (see the

relative paragraphs).

After three minutes (maximum time), the compressor

should start up and the air conditioner should start cooling

the room.

When the compressor starts you will see a green LED

light up on the control panel.

Fig. 29

T2

Well being mode (Automatic)

T4

Fig. 30

Cooling function

41

3.4.6

Dehumidifier only

When used in this mode, the air conditioner only

eliminates the humidity in the room, practically without

changing the temperature.

This function can be extremely useful between

seasons, particularly on rainy days when the temperature is not uncomfortable but the excess humidity

feels unpleasant.

When used in this mode, the air conditioner ignores

the temperature and fan speed settings, which are

not shown on the display in this case.

To operate the air conditioner in this mode, press

Button T4 until the droplet symbol appears on the

display with automatic ventilation.

In this operating mode it is normal for the air

conditioner to function intermittently.

T4

Fig. 31

Dehumidifier only

AUTO

F

S

A

N

+

E

T

-

3.4.7

Fan only

3.4.8

Heating function

(only models with

heat pump)

When used in the mode the air conditioner does not act

on the either the temperature or the humidity in the room,

but only keeps the air in circulation.

This operating mode is selected by pressing button T4

until the fan symbol appears on the display.

At this stage you can select the fan speed (see

paragraph 3.4.10).

When used in this mode the air conditioner heats the

room. This function is only available on models with a

heating pump (HP).

To select this mode press button T4 (operating mode

selection switch) until the sun symbol appears on the

display. First set the desired temperature and fan speed

(see the specific paragraphs). After three minutes

(maximum time) the compressor should start and the air

conditioner starts heating the room. When the compressor

starts you will see a green LED light up on the control

panel.

Note: The air conditioner has to defrost its battery

periodically (about once every half hour). During this

operation (about 3-8 minutes) the air conditioner does

not heat the room, though its internal parts remain

on except for the room air fan. When the outdoor temperature is very low, there may be a slight delay (about

three minutes) for passage from the minimum to the

medium or maximum speed from when the command

is sent to the machine with the remote control.

F

S

A

E

N

T

T4

Fig. 32

Fan only

AUTO

F

S

A

E

N

T

T4

Heating function (only models with heat pump)

Fig. 33

+

-

+

-

3.4.9

Control of air flow

direction

42

The airflow can be controlled in both its horizontal and

vertical direction. Control of the horizontal direction cannot

be carried out with the remote control and must be made

manually by adjusting the position of the fins on the outlet

opening.

IMPORT ANT : Adjustment of horizont al airflow should

only be made when the movable grating is not m

oving.

Fig. 34

Control of air flow direction

UNICO-HE

F

A

N

S

E

T

+

-

F

A

N

S

E

T

+

-

To adjust vertical airflow you can operate in two ways:

- continuous oscillation of airflow, obtained by pressing

button T9 which starts and stops the movable grating.

This enables the fins on the grating to turn completely

around.

- stop the movable grating in the desired position by

pressing button T9 again while the fins are in motion.

Pressing button T9 will start automatic turning of the baffle.

3.4.10

Control of fan

speed

IMPORT ANT: The baffle must not be turned by hand.

Fan speed is controlled by button T5.

Pressing this button gives the following sequence:

once=Low, twice=Medium, three times=High, four

times=Automatic.

The higher the speed setting, the greater the output of

the air conditioner but also the louder its operation.

If you select Automatic mode, the microprocessor in the

air conditioner adjusts the speed automatically, keeping

it as high as needed to reach the temperature setting

with respect to the effective room temperature.

As the room temperature nears the setting, fan speed

is reduced automatically.

When the unit is operating in dehumidification mode,

fan speed adjustment is not possible as it can only

function at low speed.

T9

T5

External air intake

3.4.11

UNICO-HE

This function is available only on devices equipped with

the optional external air intake, that is an exclusive

feature for this type of air conditioner.

Press button T8 once to start the microfan on the

external air intake and open the shutter to refresh the

air in the room.

Press button T8 again to close the shutter.

It should be borne in mind that opening the external

air intake reduces the cooling effect of the air

conditioner.

This is also true of the heating effect for machines

equipped with a heat pump.

For this reason, if you want to maintain a constant flow

of external air with the air conditioner in operation, you

should first make sure your unit is powerful enough to

operate this way.

If not, you should close the external air intake when

the temperature outside is extreme.

Fig. 35

Control of fan speed

T8

Fig. 36

External air intake

F

S

A

N

+

E

T

-

43

3.4.12

F

A

N

S

E

T

+

-

Night well-being

mode

Use button T3 to select Night well-being Mode, which

includes the following functions:

- Gradual increase of the temperature set for cooling.

- Gradual reduction of the temperature set for heating

(only HP models).

- Reduction of noise level.

- Lower energy consumption at night.

To select Night well-being mode press button T3 af ter

selecting the operating mode using button T4 and

setting the temperature using button T7.

Ideally, you should start night well-being mode

operation just before you fall asleep.

In cooling mode, the set temperature is held for one hour

after starting Night well-being mode operation.

For the next hour, the setting is allowed to increase

gradually up to 2°C over the original setting, while the fan

speed setting is low.

After the second hour, the temperature and fan speed

settings are not changed.

In heating mode, the set temperature is held for one hour

after starting Night well-being mode operation.

For the next hour the setting is lowered gradually to 4°C

below the original while the fan speed setting is low.

After the second hour, the temperature and fan speed

settings are not changed.

Night well-being mode operation is not available for

dehumidifying only.

Night well-being mode operation can be halted at any

time (ideally when you wake up in the morning) by

pressing button T3 again.

At this stage the temperature and fan speed settings

made prior to starting Night well-being mode operation

go back into effect.

T4

T3

T7

Fig. 37

Night well-being mode

3.4.13

Setting programs

for operation

3.4.14

Setting of correct

time

44

The air conditioner logic provides the user with a choice

of two operating programs that can be set to start and

stop at programmed times, for example you might want

the air conditioner to start shortly before you return home

so that it is cool when you get there.

T o use these functions it is first necessary to set the exact

time on the remote control and then set the time for the

programs to start.

To set the exact time proceed as follows:

a) Press button T6 T ime and Program Setting, as many

times as necessary to display the hour indicator (H).

b) Press the toggle button T7 to increase or decrease

the numerical display until it shows the exact hour.

c) Press button T6 again to display the minute

indicator (M).

d) Press toggle button T7 to increase or decrease the

numerical display until it shows the exact time in

minutes.

T6

H

F

S

A

N

+

E

T

-

T7

Setting of correct time

Fig. 38

M

F

S

A

N

+

E

T

-

T6

T7

UNICO-HE

3.4.15

2

1

2

A

1

F

A

N

S

E

T

+

-

2

F

A

N

S

E

T

+

-

2

F

A

N

S

E

T

+

-

2

F

A

N

S

E

T

+

-

Setting of time

schedules for 1st

and 2nd

Operating

Program

(PROGR. 1 and

PROGR. 2)

To set the times for starting and stopping the two air

conditioner programs, proceed as follows:

a) Press button Time and Program Setting, as many

times as necessary to display the PROGR. 1 ON

indicator (Time to start 1st program).

b) Press toggle button T7 to increase or decrease the

numerical display of the time when you want program

1 to start.

Every time you press one end of the toggle button

the time setting increases or decreases by 30

minutes.

c) Press button T6 Time and Program Setting, as many

times as necessary to display the PROGR. 1 OFF

indicator (Time to stop 1st program).

d) Press toggle button T7 to increase or decrease the

numerical display of the time when you want program

1 to stop. Every time you press one end of the toggle

button the time setting increases or decreases by 30

minutes.

e) Press button Time and Program Setting, as many

times as necessary to display the PROGR. 2 ON

indicator (Time to start 2nd program).

f) Press toggle button T7 to increase or decrease the

numerical display of the time when you want program

2 to start.

Every time you press one end of the toggle button

the time setting increases or decreases by 30

minutes.

g) Press button T6 T ime and Program Setting, as many

times as necessary to display the PROGR. 2 OFF

indicator (Time to stop 2nd program).

h) Press toggle button T7 to increase or decrease the

numerical display of the time when you want program

1 to stop. Every time you press one end of the toggle

button the time setting increases or decreases by 30

minutes.

i) To return to the normal operating mode just press

button T6 as many times as necessary to cancel the

program indications from the display.

T6

T6

Setting of time schedules for 1st and 2nd Operating

Program (PROGR. 1 and PROGR. 2)

T7

T7

T6

T6

Fig. 39

T7

T7

Starting and

3.4.16

stopping

operating

programs

After making the settings for the operating programs, they

can be used or not, as needed.

Either or both of the programs can be used.

In particular, when you press T11 to run the programs,

the following things occur:

Use of Program no. 1 only

1

T11

F

S

A

N

+

E

T

-

Use of Program no. 2 only

Use of Programs 1 and 2

Disuse of both programs.

UNICO-HE

Starting and stopping operating programs

Fig. 40

45

3.4.17

Resetting all

functions of

remote control

3.4.18

Control of Air

Conditioner if

remote control

is not available

Press button T10 to reset all the settings on the remote

control.

This will cancel all the settings of the timer and the remote control will use the default settings.

In addition, by pressing T10 you will display all possible

indications so that you can verify the proper conditions

of the display.

If you lose the remote control unit, or the batteries are dead

or it is not working for any other reason, you can still control

the air conditioner in the automatic mode using the

microswitch on the console, that is the same switch that has

to be used to reset the clogged filter alarm light.

To do this, proceed as follows:

- Make sure the red clogged filter alarm LED is not on.

If it is on, clean the filters and reset the indicator light as

described in paragraph 3.5.1 Cleaning of air filter.

- Use a sharp object to press the microswitch located under

the hole on the console.

- The air conditioner will function in “AUTO” mode.

To restore normal operation under the control of the remote control unit, you need only give any command with

the remote control unit when it becomes available again.

T10

AUTO

AUTO

1

2

F

A

N

H

M

S

+

E

T

-

Resetting all functions of remote control

Fig. 41

3.5

3.5.1

Cleaning air

filter

MAINTENANCE

Your air conditioner has been designed to reduce

operations of routine maintenance to a minimum and

ensure that they can be performed easily by any user.

The only operations required are the three types of

cleaning illustrated below.

To ensure effective internal air filtration and satisfactory

operation of your air conditioner, the air filter has to be

cleaned periodically.

The need to perform this important operation is signalled

after a prolonged period of use by a red led lighting up on

the control panel (see fig. 26).

The filter is located on the front of the air intake grating

on the back of the machine.

To remove it, press on the two fastening hooks and pull

the filter toward you (see fig. 42).

Wash the filter by forcing a jet of water in the opposite

direction from that of dust accumulation.

In case of dirt that is hard to remove (such as grease or

other encrusted dirt) you may have to soak the filter first

in a solution of water and neutral detergent.

Before replacing the filter shake it to eliminate the wash

water.

The last part of this operation consists of briefly pressing,

with a sharp object, the microkey located on the control

panel.

The red led goes off and lights up again after the air

conditioner has been in operation for a few days.

Fig. 42

Cleaning air filter

46

UNICO-HE

3.6

TROUBLESHOOTING

It is extremely important for the user to know when

behaviour that seems like a malfunction really isn’t.

Among these are some (that we will indicate) that the

user can easily correct following our simple instructions,

while in other cases it is necessary to get in touch with

our service personnel.

We also wish to remind you that any attempts to repair

the equipment made by unauthorized personnel will

immediately invalidate the warranty.

3.6.1

Functional

aspects that

should not be

mistaken for

malfunctions

CHAP. 3.7

The compressor does not start up again immediately after

a stop (it takes about three minutes to start again).

The operating logic of the device provides for a delay

between stoppage of the compressor and starting up

again.

This is to safeguard the compressor.

- When heating, on versions with the heating pump, the

machine does not start emitting heat until a few minutes

after the compressor starts.

If the fan should go into operation at the same time as

the compressor, for the first few minutes it would emit

cold air into the room (and this could disturb the

occupants) as the heating function needs some time

to warm up.

This is why the fan startup is delayed until after the

compressor has started.

RECOMMENDATIONS FOR

ENERGY SAVINGS

- Always keep the filters clean (see chapter on

maintenance and cleaning).

- Keep the doors and windows closed in the air-

conditioned rooms.

- Keep sunlight out of the room by using curtains, lowering

the shades or closing the shutters.

- Do not obstruct the air flow (intake and outlet) on the

units; this in addition to reducing the performance of the

system, will jeopardize correct operation and could

cause irreparable damage.

UNICO-HE

47

CHAP. 3.8

TROUBLESHOOTING

In case of malfunctions of the air-conditioner, check the items in the table below

If, after making the suggested check the problem is not solved, contact you authorized service centre.

- The air conditioner does not switch on. This may be due to:

- lack of power;

what to do:

- Make sure power is being supplied (by switching on a light in the house, for example).

- Make sure the main circuit breaker is closed and the fuse is not burnt out (replace the fuse if necessary.

If instead of a circuit breaker you have installed a cutoff switch, make sure it has not been tripped (reset it if necessary).

If the problem persists, contact our Service Department and do not try to start the air conditioner.

- The batteries in the remote control are dead.

If the batteries are dead you will notice the absence of indications on the display and the failure of the air conditioner to beep

when you try to send it a command. In this case, replace the batteries.

- The device no longer cools satisfactorily, this could be due to:

- The temperature set on the remote control being too high or too low (for models with heat pump);

what to do:

- check and, if necessary, correct the temperature setting on the remote control.

- The air filter is clogged before the alarm indicator lights up.

what to do:

- check and clean if necessary..

- Something is obstructing the airflow to the inside or to the outside;

what to do:

- remove anything that could obstruct airflow.

- There has been an increase in the heating or cooling load (for example a door or window has been left open or a device

that dissipates a large amount of heat has been installed in the room);

what to do:

- make sure the doors and windows are closed; if a heat source has been installed in the room that raises the temperature

excessively and for which the air conditioner is unable to compensate, the only solution is to install another air conditioner

or replace the existing one with a more powerful model.

- The air conditioner stops and the second and third led from the left on the control panel (orange, green and red lights)

start flashing;

If there should be a malfunction in the condensation water drain system, the air conditioner stops working and signals,

with flashing orange, green and red lights (the second and third leds from the left), the alarm status.

To enable the air conditioner to work temporarily until the service personnel arrives, you can drain the water out by following

these simple instructions:

- Grasp the rubber cap on the bottom centre of the air conditioner behind the edge of the frame facing the wall between

your thumb and forefinger.

- Pull the rubber tube closed by the cap out by a few centimetres.

- Remove the cap after placing a bucket or other container underneath it (at least five litter capacity) to collect the water.

- After eliminating the malfunction the service personnel will take care of closing the evacuation tube.

IMPORTANT: If you are unable to classify the problem as one of those described above, you should immediately

get in touch with our Service Department without attempting to make any repairs yourself.

48

UNICO-HE

SOMMAIRE

Chap. 1

Chap. 2

GENERALITES

1.1 Informations générales page 50

1.2 Symbologie page 51

1.2.1 Pictogrammes rédactionnels page 51

1.2.2 Pictogrammes concernant la sécurité page 51

1.3 Données techniques page 52

1.3.1 Dimensions d’encombrement page 52

1.3.2 Caractéristiques techniques page 52

1.3.3 Notes techniques page 52

1.3.4 Utilisation prévue page 52

1.4 Liste des composants nécessaires fournis page 53

1.4.1 Stockage page 53

1.4.2 Réception et déballage page 53

INSTALLATION

2.1 Mode d’installation page 54

2.2 Choix de la position de l’unité page 54

2.2.1 Choix de la position où installer le climatiseur page 54

2.2.2 Dimensions et caractéristiques de la pièce où le cli matiseur doit être installé page 54

2.3 Montage de l’unité page 55

2.3.1 Perçage du mur page 55

2.3.2 Préparation d'un système d'évacuation du condensat pour les machines

avec pompe à chaleur page 57

2.3.3 Montage des conduits d'air et des grilles extérieures page 57

2.3.4 Branchement électrique page 58

2.3.5 Fixation de l'appareil sur la bride page 59

2.4 Preparation de l'installation dans la partie superieure du mur page 59

2.4.1 Introduction page 59

2.4.2 Démontage de la coque avant page 59

2.4.3 Préparation de l’appareil page 60

2.5 Essais de fonctionnement et diagnostics d'éventuelles anomalies page 60

2.5.1 Evacuation de l'eau de condensation en cas d'urgence page 62

2.6 Entretien périodique page 62

Chap. 3

MODE D’EMPLOI ET ENTRETIEN (partie utilisateur)

3.1 Avertissements page 63

3.2 Dénomination des composants page 63

3.2.1 Liste unités page 63

3.2.2 Description de la console de signalisation page 63

3.3 Gestion de l’appareil avec la télécommande page 64

3.3.1 Télécommande page 64

3.3.2 Introduction des piles page 64

3.4 Télécommande page 64

3.4.1 Description de la télécommande page 64

3.4.2 Mise en marche générale et gestion du fonctionnement page 65

3.4.3 Activation/Désactivation de l’appareil (touche T1) page 65

3.4.4 Fonctionnement automatique (touche T2) page 65

3.4.5 Fonctionnement en mode refroidissement page 65

3.4.6 Fonctionnement en mode déshumidification seulement page 66

3.4.7 Fonctionnement en mode ventilation seulement page 66

3.4.8 Fonctionnement en mode chauffage (uniquement modèles avec pompe à chaleur) page 66

3.4.9 Contrôle de la direction du soufflage d’air page 66

3.4.10 Contrôle de la vitesse du ventilateur page 67

3.4.11 Entrée d’air de l’extérieur page 67

3.4.12 Fonctionnement nocturne page 68

3.4.13 Établissement des programmes de fonctionnement page 68

3.4.14 Configuration de l’horaire exact page 69

3.4.15 Programmation des horaires du 1° et du 2° Programme de Fonctionnement

(PROGR. 1 et PROGR. 2) page 69

3.4.16 Activation et désactivation des programmes de fonctionnement page 69

3.4.17 Réinitialisation de toutes les fonctions de la télécommande page 70

3.4.18 Gestion de l’appareil en cas de non disponibilité de la télécommande page 70

3.5 Entretien page 70

3.5.1 Nettoyage du filtre à air page 70

3.6 Diagnostic des inconvénients page 71

3.6.1 Aspects fonctionnels à ne pas interpréter comme des inconvénients page 71

3.7 Conseils pour l'economie d'energie page 71

3.8 Anomalies et solutions page 72

UNICO-HE

49

CHAP. 1 GENERALITES

CHAP. 1.1

INFORMATIONS GENERALES

Nous désirons avant tout vous remercier pour avoir accordé la préférence à un climatiseur de notre production.

Comme vous pourrez le constater, vous avez effectué un choix gagnant en achetant un produit qui représente ce qu’il y

a de plus avancé dans la technologie de la climatisation domestique.

Ce manuel a été conçu afin de vous fournir toutes les explications qui vous permettrons de gérer au mieux votre système

de climatisation.

Nous vous invitons donc à le lire attentivement avant de mettre votre appareil en marche.

En suivant les instructions qui sont contenues dans ce manuel, vous pourrez profiter pendant des années et sans

problèmes, grâce au climatiseur que vous venez d’acheter, de conditions ambiantes optimales avec un minimum

d’investissement en termes énergétiques.

ATTENTION

Le manuel est divisé en 4 sections ou chapitres:

CHAP. 1 GENERALITES

Il s’adresse à l’installateur qualifié et à l’utilisateur final.

Il contient des informations, des données techniques et des instructions importantes qui doivent être connues avant

d’installer et d’utiliser le climatiseur.

CHAP. 2 INSTALLATION

Il s’adresse uniquement et exclusivement à l’installateur qualifié. Il contient toutes les informations nécessaires à

l’emplacement et au montage du climatiseur à l’endroit où il doit être installé. L’installation du climatiseur par un personnel

non qualifié entraîne la perte d’effet des conditions de garantie.

CHAP. 3 MODE D’EMPLOI ET ENTRETIEN (partie utilisateur)

Il contient les informations utiles pour comprendre le mode d’emploi et la programmation du climatiseur ainsi que les

interventions d’entretien les plus courantes.

CHAP. 4 ANOMALIES ET LEURS SOLUTIONS

Il conseille et aide l’utilisateur en cas d’anomalies de fonctionnement qui pourraient se vérifier au cours du temps.

Document réservé aux termes de la loi avec interdiction de reproduction ou de transmission à tiers sans l’autorisation expresse de la

société OLIMPIA SPLENDID.

Les machines peuvent subir des mises à jour et par conséquent présenter des éléments différents de ceux qui sont représentés, sans

que cela constitue pour autant un préjudice pour les textes contenus dans ce manuel.

Lire attentivement le présent manuel avant de procéder à toute opération (installation, entretien, utilisation) et

suivre scrupuleusement ce qui est décrit dans chacun des chapitres.

50

LE FABRICANT DECLINE T OUTE RESPONSABILITE EN CAS DE DOMMAGES AUX PERSONNES OU AUX BIENS

DERIVANT DU NON-RESPECT DES NORMES CONTENUES DANS LE PRESENT LIVRET.

Le fabricant se réserve le droit d’apporter à tout moment des modifications à ces modèles, tout en conservant les

caractéristiques essentielles décrites dans le présent manuel.

L’installation et l’entretien d’app areils pour la climatisation comme celui qui est décrit dans ce manuel pourraient

être dangereux étant donné qu’il se trouve à l’intérieur de ces appareils un gaz frigorigène sous pression ainsi

que des composants électriques sous tension.

Par conséquent l’installation, la première mise en route et les phases successives d’entretien doivent être effectuées

exclusivement par un personnel agréé et qualifié.

UNICO-HE

L’entretien courant des filtres, le nettoyage général extérieur peuvent être effectués même

par l’utilisateur, étant donné que ces opérations ne comportent pas de difficulté ou de danger.

Lors du montage, et à chaque opération d’entretien, il faut observer les précautions citées dans le présent manuel et sur

les étiquettes mises à l’intérieur des appareils, ainsi qu’adopter toute les précautions suggérées par le bon sens commun

et par les Normes de Sécurité en vigueur sur le lieu de l’installation.

Il faut toujours mettre des gants et chausser des lunettes de protection pour effectuer les interventions sur le

côté réfrigérant des appareils.

CHAP. 1.2

1.2.1

Pictogrammes

rédactionnels

Les climatiseurs

explosifs, dans des endroits très humides (buanderies, serres, etc.), ou dans des locaux où se trouvent d’autres

machines produisant une importante source de chaleur.

En cas de remplacement de composants, utiliser exclusivement des pièces de rechange originales OLIMPIA SPLENDID.

IMPORTANT!

Afin de prévenir tout risque d’électrocution, il est indispensable de couper le courant au disjoncteur principal avant d’effectuer

des branchements électriques et toute opération d’entretien sur les appareils.

Communiquer ces instructions à tout le personnel concerné par le transport et l’installation de la machine.

SYMBOLOGIE

Les pictogrammes reportés au chapitre suivant permettent de fournir rapidement et de manière univoque les informations

nécessaires pour une utilisation correcte de la machine dans des conditions de sécurité.

Service

- Indique des situations où il faut informer le SERVICE interne de la société:

SERVICE APRES-VENTE CLIENTS.

Index

- Les paragraphes précédés par ce symbole contiennent des informations et des prescriptions très importantes, notamment

pour ce qui concerne la sécurité.

Le non-respect peut comporter:

- danger pour la sécurité des opérateurs.

- perte de la garantie du contrat.

- dégagement de la responsabilité du fabricant.

NE DOIVENT PAS être installés dans des pièces où il y a présence de gaz inflammables, gaz

1.2.2

Pictogrammes

concernant la

sécurité

Main levée

- Indique les actions qu’il ne faut absolument pas accomplir.

Tension électrique dangereuse

- Signale au personnel concerné que l’opération décrite présente, si elle n’est pas effectuée conformément aux normes

de sécurité, le risque de provoquer une décharge électrique.

Danger général

- Signale au personnel concerné que l’opération décrite présente, si elle n’est pas effectuée conformément aux normes

de sécurité, le risque de provoquer des dommages physiques.

Danger de température élevée

- Signale au personnel concerné que l’opération décrite présente, si elle n’est pas effectuée conformément aux normes

de sécurité, le risque de provoquer des brûlures par contact avec des composants à température élevée.

UNICO-HE

51

CHAP. 1.3

1.3.1

Dimensions

d’encombrement