Page 1

BCH 25 - DSH 250

GB

OPERATOR’S INSTRUCTION BOOK

F

MANUEL D’UTILISATION ET D’ENTRETIEN

E

MANUAL DE USO Y MANTENIMIENTO

RUS

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИ

HR

BIH SRB MNE

UA

ПЕРЕКЛАД ОРИГІНАЛЬНИХ ІНСТРУКЦІЙ ВСТУП

UPUTSTVA ZA KORIŠTENJE I ODRŽAVANJE

(25.4 cm3)

Page 2

1

9

10

1 2

21

17

16

3

14

7

4

8

6

5

20

19A

C

19B

15

20

18

12

11

13

21

18

A

D

B

16

15

17

2

3

Page 3

4

5A

B

A

F

C

5B 5C

D

E

E

D

6 7

D

F

N

L

H

L

H

F

R

C

B

D

A

Page 4

8 9

10

11

A

CLOSE

B

OPEN

13 14

15

12

Page 5

4

5

6

16

T

19 20

A

B

17

21

5

9

BRUSHCUTTER

12

18

L8RTF

2019

8200000000

61450265

0,5 mm

13

11

1

4

2

3

10

7

4

14

6

8

Page 6

Page 7

English 2

Français 20

Español 40

Pуccкий 60

Hrvatski 80

Українська 99

Page 8

GB

TRANSLATION OF ORIGINAL INSTRUCTIONS

To our valued customers

Thank you for selecting an Emak product.

Our network of dealers and authorized

workshops will always be at your complete

disposal for any need you may have.

INTRODUCTION

For correct use of the machine and to avoid

accidents, do not start working until you have

read this manual carefully. You will find

explanations concerning the operation of the

various parts plus instructions for necessary

checks and relative maintenance.

NOTE: The descriptions and illustrations

contained in this manual are not binding. The

manufacturer reserves the right to

undertake any modifications it deems

necessary without revising this manual.

In addition to the operating instructions, this

manual contains paragraphs that require your

special attention. Such paragraphs are marked

with the symbols described below:

WARNING: where there is a risk of an accident

or personal, even fatal, injury or serious damage

to property.

CAUTION: where there is a risk of damaging the

machine or its individual components.

WARNING

RISK OF HEARING DAMAGE

IN NORMAL CONDITIONS OF USE, THIS

MACHINE MAY EXPOSE THE OPERATOR TO A

PERSONAL DAILY NOISE LEVEL EQUAL TO OR

HIGHER THAN

85 dB (A)

CONTENTS

1. SAFETY PRECAUTIONS (precautions

for using the machine safety)

2. SYMBOLS AND SAFETY WARNINGS

(explanations on how to identify the

machine and the meaning of the

symbols)

3. MAIN COMPONENTS (position of the

main parts that make up the machine)

4. ASSEMBLY (explanations on how to

remove the packaging and assemble

detached parts)

5. STARTING 5

6. STOPPING THE ENGINE 8

7. USING THE MACHINE 8

8. TRANSPORTING 11

9. MAINTENANCE (all information

required to keep the machine at peak

efficiency)

10. STORAGE 14

11. ENVIRONMENTAL PROTECTION

(advice on using the machine in ways

that respect the environment)

12. TECHNICAL DATA (a summary of the

main specifications of the machine)

13. DECLARATION OF CONFORMITY 18

14. WARRANTY CERTIFICATE (a summary

of the warranty conditions)

15. TROUBLESHOOTING (helps you to

quickly solve any problems you may encounter while using the machine)

1. SAFETY PRECAUTIONS

WARNING

- The machine, when used correctly, is a

useful and effective tool; if used

incorrectly or without the necessary

precautions, it can be dangerous. To

ensure your safety and comfort, always

observe the safety instructions given here

below and throughout this manual.

- Exposure to vibrations through

prolonged use of combustion enginedriven tools could cause blood vessel or

nerve damage in the fingers, hands, and

wrists of people prone to circulation

disorders or abnormal swellings.

Prolonged use in cold weather has been

linked to blood vessel damage in

otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

2

strength, change in skin colour or texture,

or loss of feeling in the fingers, hands, or

wrists, discontinue the use of this tool and

seek medical attention.

4

- The ignition system of your machine

4

produces an electromagnetic field of very

4

12

14

15

18

19

2

Page 9

low intensity. This field could interfere

with certain pacemakers. To reduce the

risk of serious or fatal injury, persons with

pacemakers should consult their doctor or

the manufacturer of the pacemaker

before using this machine.

WARNING: National regulations may limit

the use of the machine.

1 - Do not operate the machine unless you

have received specific instruction on its use.

First time users must familiarise themselves

thoroughly with the operation of the

machine before working in the field.

2 - The machine must only be used by adults

in good physical condition who are familiar

with the operating instructions.

3 - Never use the brush cutter when you are

tired or fatigued or if you have taken alcohol,

drugs or medication.

4 - Wear appropriate clothing and safety articles

such as: boots, heavy-duty trousers, gloves,

protective eyewear, ear protection and

protective helmet. Use clothing which is

close-fitting but comfortable.

5 - Do not allow children to use the brush cutter.

6 - Do not allow other people to remain within

15 metres during brush cutter use .

7 - Before using the brush cutter, make sure

that the blade fixing bolt is well-tightened.

8 - The brush cutter must be equipped with

the cutting accessories recommended by

the manufacturer (look pag. 16).

9 - Never use the brush cutter without the blade

guard or the head.

10 - Before starting the engine, make sure that

the blade is free to move and is not in contact

with any foreign objects.

11 - Every now and then while working, stop

the engine and check the blade. Replace it

at the first sign of cracks or breaks.

12 - Only use the machine in well-ventilated

places, do not use in explosive or flammable

atmospheres or in closed environments.

13 - Never touch the blade or attempt any

maintenance work while the engine is

running.

14 - It is prohibited to fit any device other than

that supplied by the manufacturer.

15 - Do not use a machine that has been

damaged, badly repaired, improperly

assembled or modified. Do not attempt to

remove or bypass any of the safety devices.

Only use cutting attachments indicated in

the table.

16 - All labels with health hazards must be kept

in good conditions. In case of damage or

deterioration, immediately substitute them

(Fig. 21).

17 - Do not utilize the machine for uses

different from the ones specified in the

manual (see pag. 8).

18 - Never leave the machine unattended with

the engine running.

19 - Do not start the engine with the arm not

mounted.

20 - Check the brush cutter daily to be sure that

components and safety devices are full

functioning properly.

21 - Do not attempt to carry out operations

or repairs that are not part of the normal

maintenance. See the authorised dealer.

22 - When disposing of the machine at the

end of its useful life, think of the

environment. Take your old unit to your

dealer who will be able to dispose of it in

a proper manner.

23 - Only experienced persons who are

familiar with the operation and safe use of

this machine should use it. If you lend the

blower to someone, also give them the

instruction manual and ensure that they

read it before using the machine.

24 - All saw service, other than the operations

shown in the present manual, should be

performed by competent personnel.

25 - Keep this manual on hand and consult it

before each use of the tool.

26 - Please note that the owner or the user is

responsible for any accidents or damage to

third parties or their property.

WARNING

- Never use a machine with faulty safety

equipment. The machine’s safety

equipment must be checked and

GB

3

Page 10

GB

maintained as described in this section. If

your machine fails any of these checks

contact an Authorised Service Centre to

get it repaired.

- Any use of the machine not expressly

envisaged in this manual is to be

considered improper and therefore a

source of risk to people and property.

PROTECTIVE CLOTHING

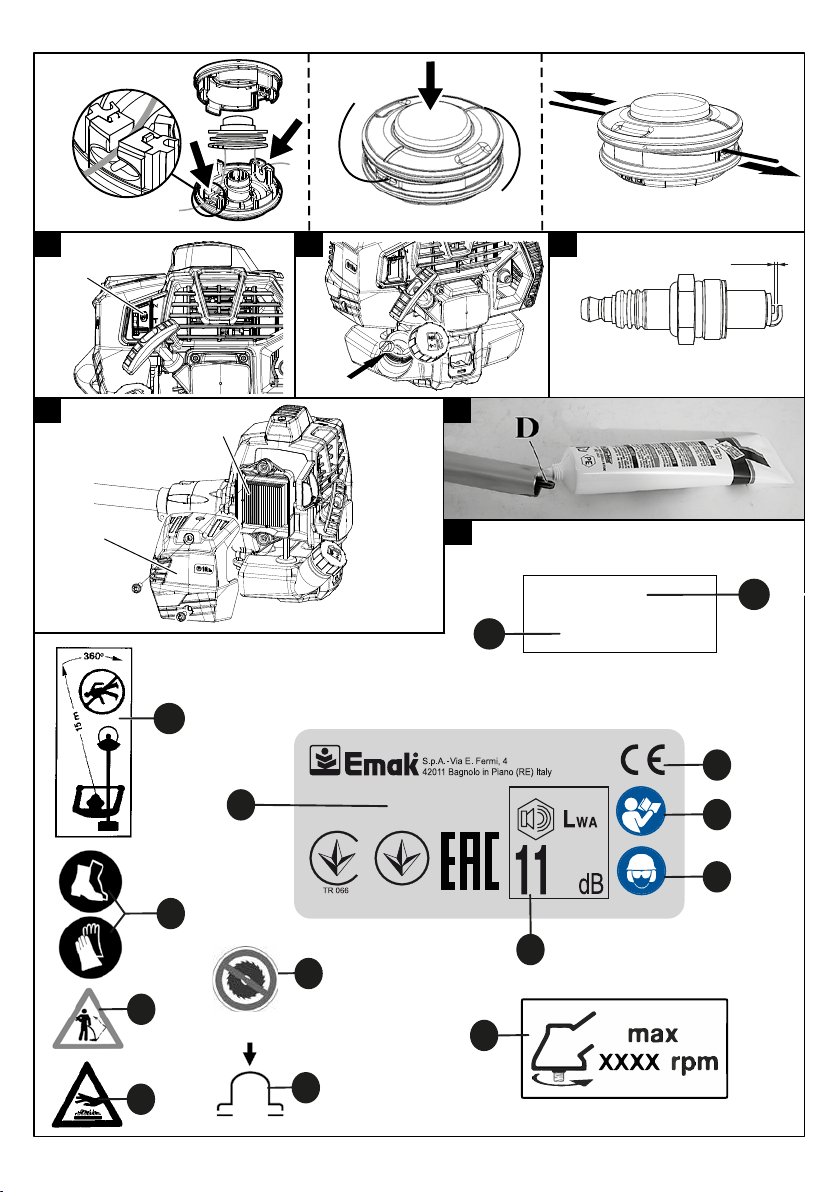

6 - WARNING! – The surface can be hot!

7 - Do not use the brushcutter with the wood

cutting disk.

8 - Purge Bulb.

9 - Type of machine: BRUSH CUTTER.

10 - Guaranteed sound power level.

11 - CE conformity marking.

12 - Serial number.

13 - Year of manufacture.

14 - Max. speed of output shaft, RPM

While working with the brushcutter,

always use safety protective approved

clothing. The use of protective clothing does

not eliminate injury risks, but reduces the injury

effects in case of accident. Consult your trusted

supplier to choose an adequate equipment.

The clothing must be proper and not an obstacle.

Wear adherent protective clothing. Protective

jackets and dungarees are ideal. Do not wear

clothes, scarfs, ties or bracelets that can stuck

into twigs. Tie up and protect long hair (example

with foulards, caps, helmets, etc.).

Safety shoes having skid-proof sole and antipiercing insert.

Wear protective goggles or face screens!

Use protections against noises; for example

noise reduction ear guards or earplugs. The

use of protections for the ear requests much

more attention and caution, because the

perception of danger audio signals (screamings,

alarms, etc.) is limited.

Wear gloves that permit the maximum

absorption of vibrations.

2. SYMBOLS AND SAFETY WARNINGS (Fig.21)

1 - Read operator’s instruction book before

operating this machine.

2 - Wear head, eye and ear protection.

3 - Wear strong boots and gloves when cutting

with metal or plastic blades.

4 - Be aware that objects can be thrown.

5 - Keep bystanders away 15 m.

4

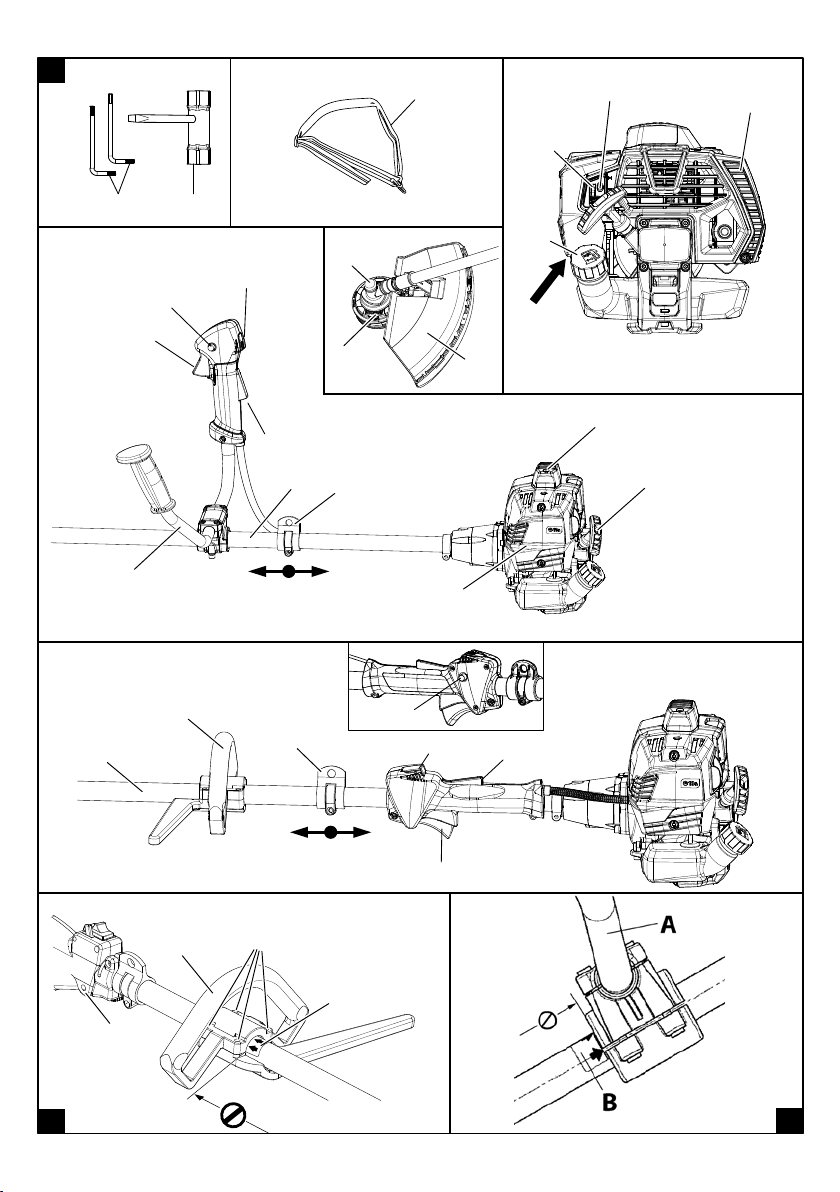

3. MAIN COMPONENTS (Fig.1)

1÷2 - Tools supplied

3 - Harness

4 - Bevel gear

5 - Curved guard

6 - Nylon line head

7 - Fuel tank cap

8 - Purge Bulb

9 - Carburettor adjustment screws

10 - Muffler guard

11 - Spark plug

12 - Air filter

13 - Starter Handle

14 - Choke Lever

15 - Throttle trigger lockout

16 - STOP button

17 - Throttle lever

18 - Harness attachment

19 - Handle

20 - Shaft arm

21 - Button half-throttle

4. ASSEMBLY

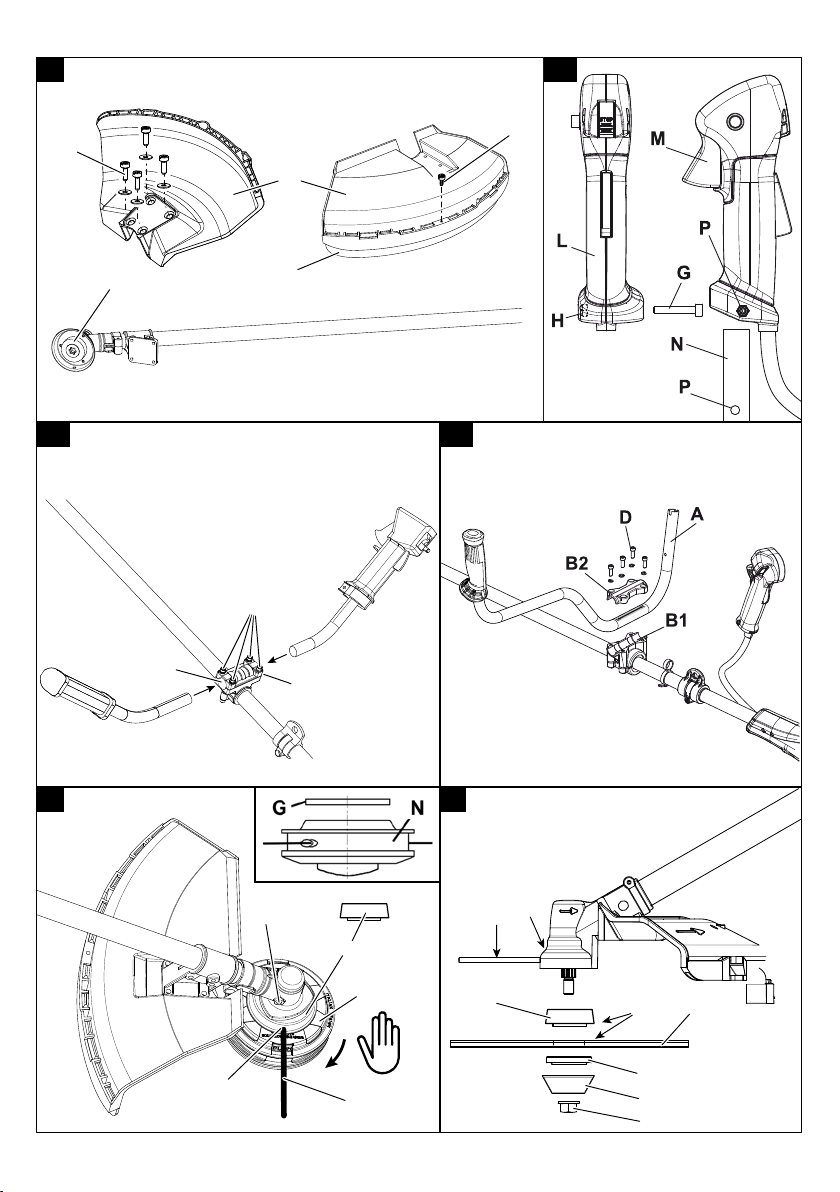

FITTING THE SAFETY GUARD (Fig.4)

Fit the blade guard (A) to the shaft arm with screws

in a position allowing the operator to work safely (B).

NOTE: use the guard (C) only with nylon head.

Secure the guard (C) to the protection (A) by

means of the screw (D).

FITTING THE NYLON LINE HEAD (Fig. 6)

Put the upper (F) flange in place. Put the head fixing

pin (H) in the appropriate hole (L) and tighten the

head (N) anti-clockwise by hand.

NOTE: when present, also fit the plastic spacer

(G, Fig.6).

Page 11

FITTING THE DISK (Fig. 7)

Fix the blade (R) onto the upper flange (F) making

sure that the rotation direction is correct.

Fix the lower flange (B), the cup (D) and tighten bolt

(A) anti-clockwise.

Put the pin provided in the appropriate hole (L)

to block the blade and allow the bolt (A) to be

tightened to 2.5 kgm (25 Nm).

WARNING – Collar (see arrows C, Fig.7)

must locate in blade’s mounting hole.

FITTING THE HANDLE (Fig. 2)

Fit the handle (A) onto the shaft arm and secure it

using screws (D). The handle position is calculated

depending on the requirements of the operator.

WARNING - Assemble the loop handle (A,

Fig.2-3) between label’s arrow (B) and rear

handle (C).

PREPARING TO WORK

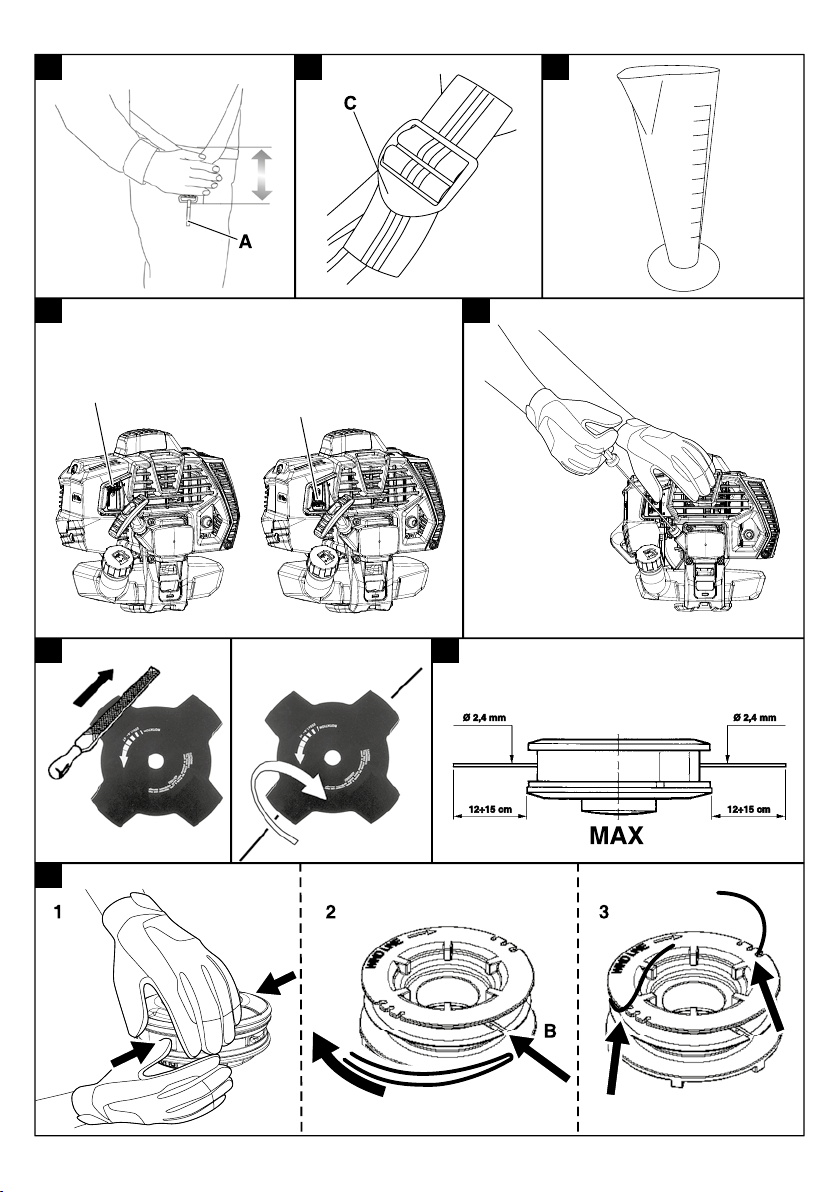

HARNESS (3, Fig. 1)

Correct adjustment of the harness permits the

brush cutter to be properly balanced and at an

appropriate height from the ground (Fig. 8).

- Put on the single harness.

- Hook the brush cutter to the harness using the

hook (A, Fig. 8).

- Position the hook (18, Fig. 1) to obtain the best

brush cutter balance.

- Position the buckle (C) to obtain the correct

brush cutter height (Fig.9).

5. STARTING

FUELING

GB

FITTING THE HANDLEBAR (FIG.5B)

- Loosen the clamp screws (D).

- Insert the 2 halves of the handlebar in the

respective sockets (E).

- Retighten the screws (D)

MOUNTING THE CONTROL HANDLES (Fig. 5A)

- Loosen the screw (G). The nut (H) remains in the

control handle (L).

- Push the control handle (L) (throttle trigger M

must point toward the gearbox) onto the bike

handle (N) so that the holes (P) line up.

- Insert screw (G) and tighten down firmly.

ASSEMBLING THE BIKE HANDLE (Fig. 5C)

- Place the bike handle (A, Fig.4) in the lower hub

(B1).

- Place the upper hub (B2) in position and tighten

the 4 screws (D), without finally tighten yet.

- Line up the handlebar at a right angle to the

drive tube.

- Tighten down the screws (D) firmly.

WARNING: Make sure that all

components are connected properly and all

screws tightened.

WARNING: Gasoline is an extremely

flammable fuel. Use extreme caution when

handling gasoline or fuel mix. Do not smoke

or bring any fire or flame near the fuel or the

unit.

· To reduce the risk of fire and burn injury,

handle fuel with care. It is highly flammable.

· Mix and store fuel in a container approved for

gasoline.

· Mix fuel outdoors where there are no sparks or

flames.

· Select bare ground, stop engine, and allow to

cool before refueling.

· Loosen fuel cap slowly to release pressure and

to keep fuel from escaping around the cap.

· Tighten fuel cap securely after refueling. Unit

vibration can cause an improperly tightened

fuel cap to loosen or come off and spill

quantities of fuel.

· Wipe spilled fuel from the unit. Move 3 metre

away from refueling site before starting

engine.

· Never attempt to burn off spilled fuel under

any circumstances.

· Do not smoke while handling fuel or while

operating the unit.

5

Page 12

GB

· Store fuel in a cool, dry, well ventilated place.

· Never place the machine in a combustible

area such as dry leaves, straw, paper, etc.

· Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

· Never take the cap off the tank when the

engine is running.

· Never use fuel for cleaning operations.

· Take care not to get fuel on your clothing

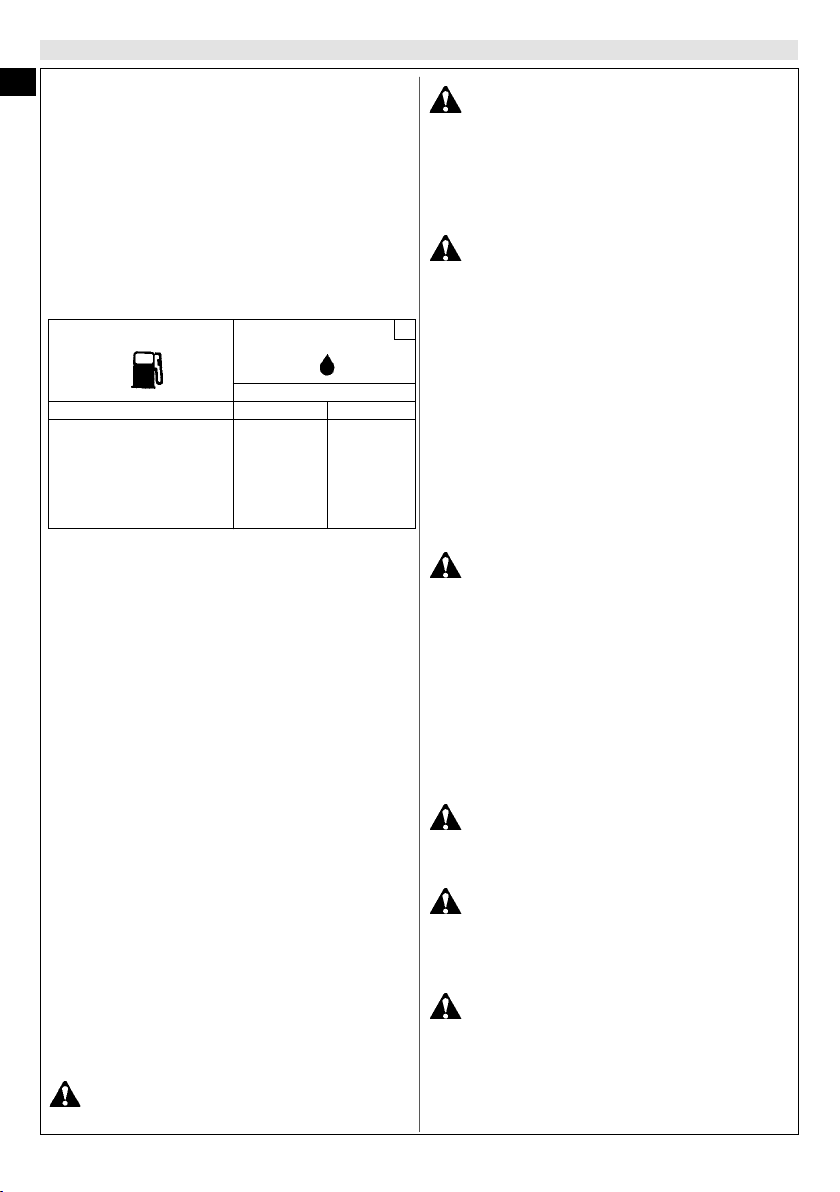

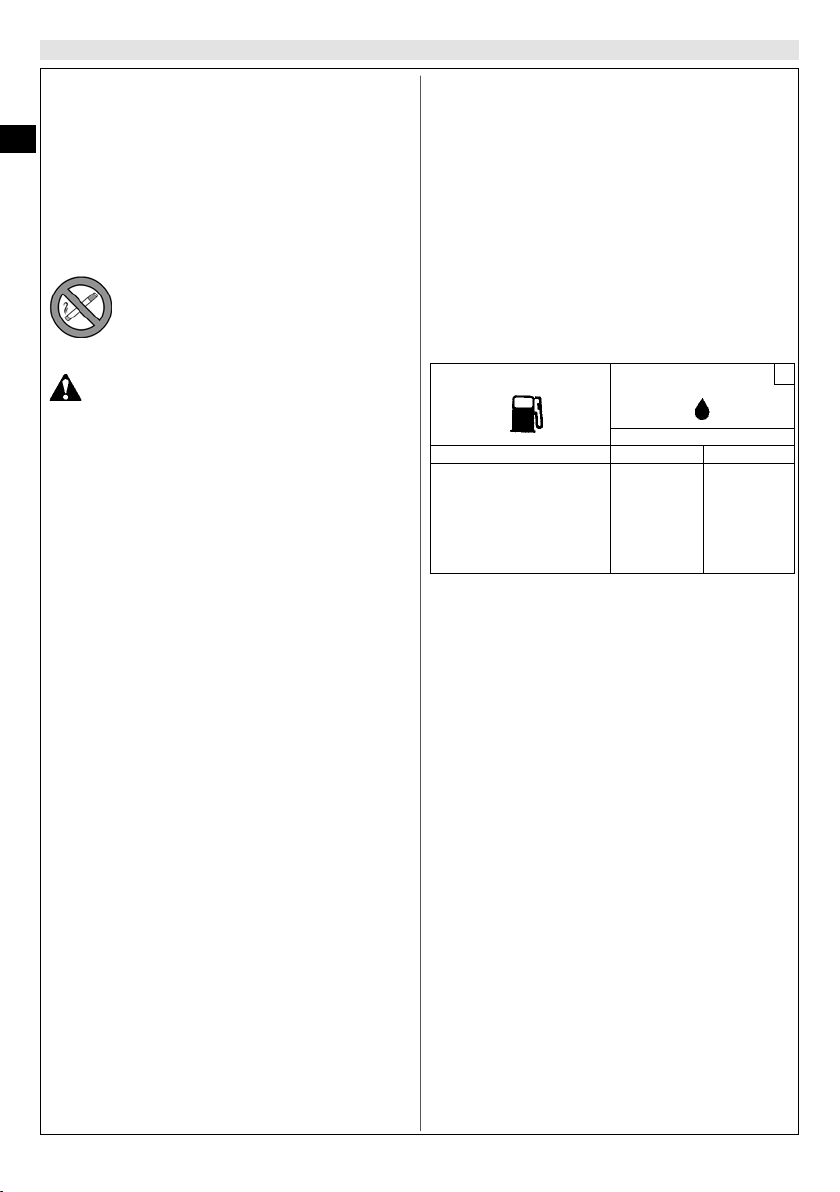

GASOLINE

OIL

CAUTION:

- Match your fuel purchases to your

consumption; don’t buy more than you will

use in one or two months;

- Store gasoline in a tightly-closed container

in a cool, dry place.

CAUTION - For the mixture, never use a

fuel with an ethanol percentage higher than

10%; gasohol (mixture of gasoline and

ethanol) up to 10% ethanol or E10 fuel are

A

acceptable.

2%-50 : 1

l

1

5

10

15

20

25

l

0,02 (20)

0,10 (100)

0,20 (200)

0,30 (300)

0,40 (400)

0,50 (500)

(cm3)

This product is powered by a 2-cycle engine and

requires pre-mixing gasoline and 2-cycle oil.

Pre-mix unleaded gasoline and 2-cycle engine

oil in a clean container approved for gasoline.

RECOMMENDED FUEL: THIS ENGINE IS

CERTIFIED TO OPERATE ON UNLEADED

GASOLINE INTENDED FOR AUTOMOTIVE USE

WITH AN OCTANE RATING OF 89 ([R + M] / 2) OR

HIGHER.

Mix 2-cycle engine oil with gasoline according to

the instructions on the package.

The oil / petrol mixture can be prepared with

the right amount of oil per liter, using the

graduated dispenser provided (Fig.10) and

referring to table A.

We strongly recommend the use of 2% (1:50)

Efco - Oleo-Mac two cycle engine oil, which is

specifically formulated for all air-cooled twostroke engines.

The correct oil / fuel proportions shown in the

table (Fig. A) are suitable when using the

PROSINT 2 and EUROSINT 2 or an equivalent

high-quality engine oil (JASO specification FD

or ISO specification L-EGD).

CAUTION: DO NOT USE AUTOMOTIVE

OIL OR 2-CYCLE OUTBOARD OIL.

6

NOTE - Prepare only the quantity of mixture

required for immediate use; do not leave fuel in

the tank or a container for a long time. Were

commend the use of the additive Emak ADDITIX

2000 code 001000972 if the mixture is to be

stored for 12 months.

Alkylate gasoline

CAUTIONS – Alkylate fuels have

different density than normal fuel. Therefore

engines, set with normal fuel, need different

H jet regulation to avoid critical issues. For

this operation it’s necessary turned at a

Licensed Service Dealer.

Filling the tank

stir the mixture well before refuelling.

STARTING

Before starting the engine, make sure

that the blade is free to move and is not in

contact with any foreign objects.

The cutting attachment must not rotate

when the engine is idling. Otherwise contact

an Authorized Service Center to carry out a

check and fix the problem.

WARNING: Hold the brush cutter firmly

with both hands. Always keep your body is to

the left of tube. Never use a cross-handed grip.

Left-handers should follow these instructions

too.

Keep a proper cutting stance.

Page 13

Over exposure to vibrations can result in

blood-vessel or nerve injury to persons

suffering with blood circulation problems. Seek

medical attention if you experience physical

symptoms such numbness, lack of feeling,

reduction in normal strength, changes in the

colour of the skin. These symptoms normally

appear in the fingers, hands or wrists.

Before starting the engine, make sure that the

throttle lever works freely.

WARNING: Follow safety instruction for

fuel handling. Always shut off engine before

fuelling. Never add fuel to a machine with a

running or hot engine. Move at least 3 m from

refuelling site before starting engine. DO

NOT SMOKE!

1. Clean surface around fuel cap to prevent

contamination.

2. Loosen fuel cap slowly.

3. Carefully pour fuel mixture into the tank.

Avoid spillage.

4. Prior to replacing the fuel cap, clean and

inspect the gasket.

5. Immediately replace fuel cap and hand

tighten. Wipe up any fuel spillage.

WARNING: Check for fuel leaks, if any

are found, correct before use. Contact a

Servicing Dealer if necessary.

Engine is Flooded

- Engage a suitable tool in the spark plug boot.

- Pry off the spark plug boot.

- Unscrew and dry off the spark plug.

- Open the throttle wide.

- Pull the starter rope several times to clear the

combustion chamber.

- Refit the spark plug and connect the spark

plug boot, press it down firmly.

- Set the choke lever to OPEN position – even

if engine is cold.

- Now start the engine.

2) Pull the choke lever (14, Fig.1) in the CLOSE

position (A, Fig.11)

3) Pull the throttle lever (17, Fig. 1) and stop it

at half-throttle by pressing the button (21),

then release the lever (17).

4) Place the brush cutter on the ground in a

stable position. Check that the blade is free.

Holding the brush cutter down (Fig.12), pull

the starter rope until the first kick over of the

engine is heard (no more than 3 pulls). A new

unit may require additional pulls.

5) Push the choke lever (14, Fig.1) in OPEN

position (B, Fig.11).

6) Pull the starter cord to start the engine. Once

the machine is started, warm up the machine

for about few seconds, without touch the

throttle lever. The machine could need more

seconds to warm up with cold weather or at

high altitudes. Finally, push the throttle lever

(17, Fig.1) for deactivate the half-throttle.

CAUTION:

- Never wrap the starter cord around your

hand.

- When pulling the starter rope, do not

use the full extent of the rope as this can

cause the rope to break.

- Do not let starter rope snap back. Hold the

starter handle (13, Fig.1) and let the rope

rewind slowly.

WARNING: Once the engine is warmed

up do not use the choke to start up again.

WARNING: Use the semi-acceleration

device only in the phase of starting the engine

to cold.

BREAKING-IN THE ENGINE

The engine reaches the maximum power after

5÷8 hours of activity.

During this period of breaking-in do not use the

engine at wide open throttle without load, to avoid

excessive functioning stress.

GB

STARTUP PROCEDURE

1) Slowly push the purge bulb 4 times (8, Fig.1).

WARNING! - During the breaking-in

period do not vary the carburetion to obtain a

7

Page 14

GB

presumed power increment; the engine can be

damaged.

NOTE: It is normal for smoke to be emitted

from a new engine during and after first use.

6. STOPPING THE ENGINE

Set the throttle lever to idle position (17, Fig. 1)

and wait a few seconds to let the engine cool off.

Turn off the engine, pushing the STOP button (16).

7. USING THE MACHINE

PROHIBITED USE

WARNING: Avoid kickout which can

result in serious injury. Kickout is the

sideward or sudden forward motion of the

machine occurring when the blade contacts

any object such as a log or stone. Contacting

a foreign object can also result in loss of

brush cutter control.

WARNING! - Always follow the safety

precautions. The brush cutter must only be

used to trim grass material. Do not cut metal,

plastics, masonry. Do not use the brush cutter

as a lever to lift, move or break objects, nor

lock it on fixed supports. It is forbidden to apply

tools or applications that are not the ones

indicated by the manufacturer onto the brush

cutter’s power take-off.

WARNING: When using rigid blades,

avoid cutting close to fences, sides of

buildings, tree trunks, stones or other such

objects that could cause the brush cutter to

kick out or could cause damage to the blade.

We recommends use of the nylon line heads

for such jobs. In addition, be alert to an

increased possibility of ricochets in such

situations.

WARNING: Never use of a brush cutter

with the cutting attachment perpendicular to

the ground. Never use the brushcutter for

trimming hedges.

WARNING: If the blade loosens after

being properly tightened, stop work

8

immediately. The retaining nut may be worn

or damaged and should be replaced. Never

use unauthorized parts to secure the blade. If

the blade continues to loosen, see your

dealer. Never use the brushcutter for

trimming hedges.

Work Area Precautions

• Always cut with both feet on solid ground to

prevent being pulled off balance.

• Make sure you can move and stand safely.

Check the area around you for possible

obstacles (roots, rocks, branches, ditches, etc.)

in case you have to move suddenly.

• Do not cut above chest height, as a brush

cutter held higher is difficult to control against

kickout forces.

• Do not work near electrical wires. Leave this

operation for professionals.

• Cut only when visibility and light are adequate

for you to see clearly.

• Do not cut from a ladder, this is extremely

dangerous.

• Stop the brush cutter if the blade strikes a

foreign object. Inspect the blade and brush

cutter; repair parts as necessary.

• Keep the blade out of dirt and sand. Even a

small amount of dirt will quickly dull a blade

and increase the possibility of kickout.

• Stop the engine before setting the brush

cutter down.

• Be particularly cautious and alert while

wearing hearing protection because such

equipment may restrict your ability to hear

sounds indicating danger (calls, signals,

warnings, etc).

• Be extremely cautious when working on

slopes or uneven ground.

WARNING: Never use rigid blades when

cutting in stony areas. Thrown objects or

damaged blades may result in serious or fatal

injury to the operator or bystanders. Watch

out for thrown objects. Always wear approved

eye protection. Never lean over the cutting

attachment guard. Stones, rubbish, etc. can

be thrown up into the eyes causing blindness

Page 15

or serious injury. Keep unauthorised persons

at a distance. Children, animals, onlookers

and helpers should be kept outside the safety

zone of 15 m. Stop the machine immediately

if anyone approaches. Never swing the

machine around without first checking

behind you to make sure no-one is within the

safety zone.

5. Never put the machine down with the engine

running.

• Always use the correct equipment.

• Make sure the equipment is well adjusted.

• Organise your work carefully.

• Always use full throttle when starting to cut

with the blade.

• Always use sharp blades.

GB

Working Techniques

General Working Instructions

WARNING: This section describes the

basic safety precautions for working with

clearing saws and trimmers. If you encounter

a situation where you are uncertain how to

proceed you should ask an expert. Contact

your dealer or your service workshop. Avoid

all usage which you consider to be beyond

your capability. You must understand the

difference between forestry clearing, grass

clearing and grass trimming before use.

Basic safety rules

1. Look around you:

• To ensure that people, animals or other things

cannot affect your control of the machine.

• To ensure that people, animals, etc., do not

come into contact with the cutting attachment

or loose objects that are thrown out by the

cutting attachment.

WARNING: Do not use the machine

unless you are able to call for help in the

event of an accident.

2. Do not use the machine in bad weather, such

as dense fog, heavy rain, strong wind, intense

cold, etc. Working in bad weather is tiring and

often brings added risks, such as icy ground,

etc.

3. Make sure you can move and stand safely.

Check the area around you for possible

obstacles (roots, rocks, branches, ditches, etc.)

in case you have to move suddenly. Take great

care when working on sloping ground.

4. Switch off the engine before moving to

another area.

WARNING: Neither the operator of the

machine nor anyone else may attempt to

remove the cut material while the engine is

running or the cutting equipment is rotating,

as this can result in serious injury. Stop the

engine and cutting equipment before you

remove material that has wound around the

blade as otherwise there is a risk of injury.

The bevel gear can get hot during use and

may remain so for a while afterwards. You

could get burnt if you touch it.

WARNING: Sometimes branches or

grass get caught between the guard and

cutting attachment. Always stop the engine

before cleaning.

Check before starting

• Check the blade to ensure that no cracks have

formed at the bottom of the teeth or by the

centre hole. Discard a blade if cracks are

found.

• Check that the support flange is not cracked

due to fatigue or due to being tightened too

much. Discard the support flange if it is

cracked.

• Ensure the locking nut has not lost its captive

force. The tightening torque of the locking nut

should be 25 Nm.

• Check that the blade guard is not damaged or

cracked. Replace the blade guard if it is

cracked.

WARNING: Never use the machine

without a guard or with a defective guard.

Never use the machine without the

transmission shaft.

Forestry clearing

9

Page 16

GB

• Before you start clearing, check the clearing

area, the type of terrain, the slope of the

ground, whether there are stones, hollows etc.

• Start at whichever end of the area is easiest,

and clear an open space from which to work.

• Work systematically to and fro across the area,

clearing a width of around 4-5 m on each pass.

This exploits the full reach of the machine in

both directions and gives the operator a

convenient and varied working area to work

in.

• Clear a strip around 75 m long. Move your fuel

can as work progresses.

• On sloping ground you should work along the

slope. It is much easier to work along a slope

than it is to work up and down it.

• You should plan the strip so that you avoid

going over ditches or other obstacles on the

ground. You should also orient the strip to

take advantage of wind conditions, so that

cleared stems fall in the cleared area of the

stand.

Grass clearing using a grass blade

• Grass blades and grass cutters must not be

used on woody stems.

• A grass blade is used for all types of tall or

coarse grass.

• The grass is cut down with a sideways,

swinging movement, where the movement

from right-to-left is the clearing stroke and the

movement from left-to-right is the return

stroke. Let the left-hand side of the blade

(between 8 and 12 o’clock) do the cutting.

• If the blade is angled to the left when clearing

grass, the grass will collect in a line, which

makes it easier to collect, e.g. by raking.

• Try to work rhythmically. Stand firmly with

your feet apart. Move forward after the return

stroke and stand firmly again.

• Let the support cup rest lightly against the

ground. It is used to protect the blade from

hitting the ground.

• Reduce the risk of material wrapping around

the blade by following these instructions:

1. Always work at full throttle.

2. Avoid the previously cut material during the

return stroke.

• Stop the engine, unclip the harness and place

the machine on the ground before you start to

collect the cut material.

Grass trimming with a trimmer head

CAUTION: Do not work with mowing

line longer than the intended diameter. With

a properly mounted guard, the built-in cutter

will automatically adjust the line to its proper

length. Overly long lines can overload the

engine, resulting in damage to the clutch

mechanism and nearby parts.

Trimming

• Hold the trimmer head just above the ground

at an angle. It is the end of the cord that does

the work. Let the cord work at its own pace.

Never press the cord into the area to be cut.

• The cord can easily remove grass and weeds

up against walls, fences, trees and borders,

however it can also damage sensitive bark on

trees and bushes, and damage fence posts.

• Reduce the risk of damaging plants by

shortening the cord to 10-12 cm and reducing

the engine speed.

Clearing

• The clearing technique removes all unwanted

vegetation. Keep the trimmer head just above

the ground and tilt it. Let the end of the cord

strike the ground around trees, posts, statues

and the like.

CAUTION: This technique increases the

wear on the cord.

• The cord wears quicker and must be fed

forward more often when working against

stones, brick, concrete, metal fences, etc., than

when coming into contact with trees and

wooden fences.

• When trimming and clearing you should use

less than full throttle so that the cord lasts

longer and to reduce the wear on the trimmer

head.

10

Page 17

Cutting

• The trimmer is ideal for cutting grass that is

difficult to reach using a normal lawn mower.

Keep the cord parallel to the ground when

cutting. Avoid pressing the trimmer head

against the ground as this can ruin the lawn

and damage the tool.

• Do not allow the trimmer head to constantly

come into contact with the ground during

normal cutting. Constant contact of this type

can cause damage and wear to the trimmer

head.

Sweeping

• The fan effect of the rotating cord can be used

for quick and easy clearing up. Hold the cord

parallel to and above the area to be swept and

move the tool to and fro.

• When cutting and sweeping you should use

full throttle to obtain the best results.

WARNING: Never cut, when visibility is

poor or in very high or low temperatures or in

freezing weather.

8. TRANSPORTING

TRANSPORTION

Carry the brush cutter with the engine off and with

the protective blade cover on (Fig. 3).

GB

ATTENTION: Fit the disk protection p.n.

4196086 as shown (Fig. 3) before transporting or

storing the brushcutter.

WARNING – When transporting the

machine in a vehicle, ensure that it is properly

secured using belts. The machine should be

transported in a horizontal position with the

tank empty, ensuring compliance with applicable

regulations for transport of such machines.

11

Page 18

GB

9. MAINTENANCE

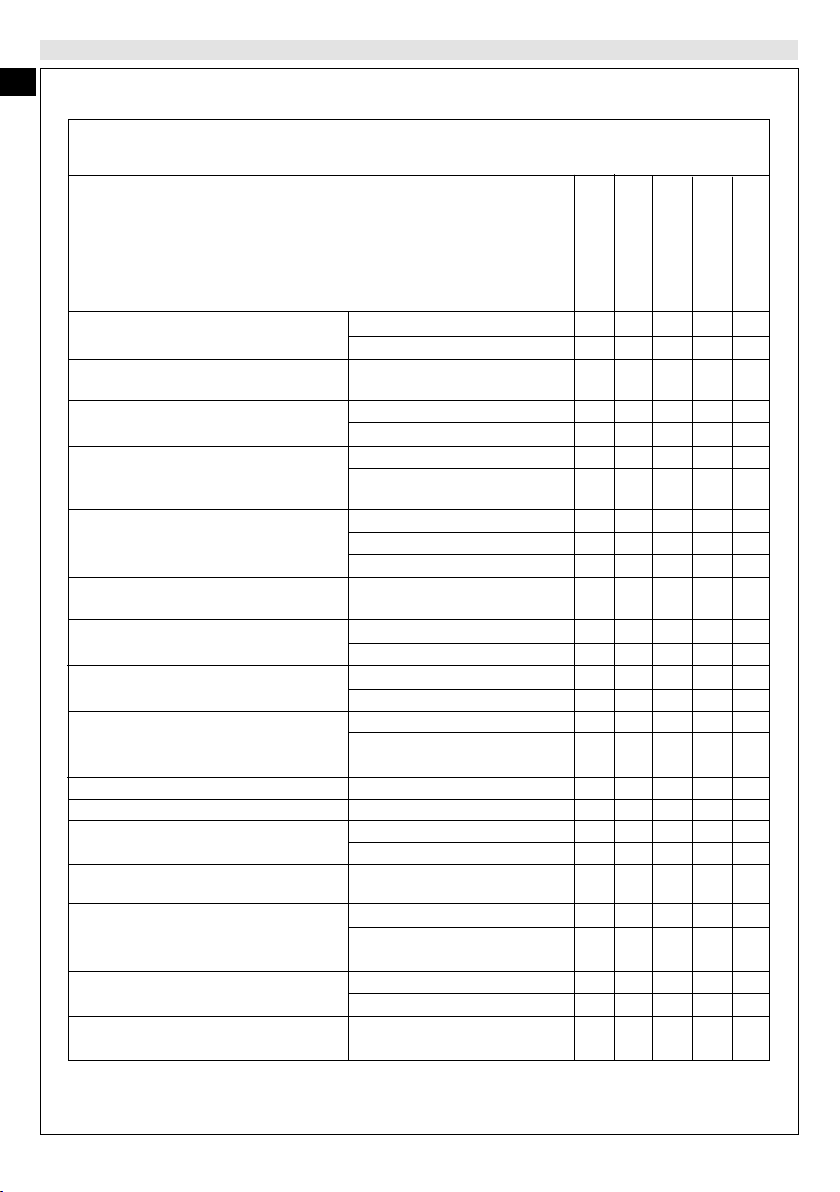

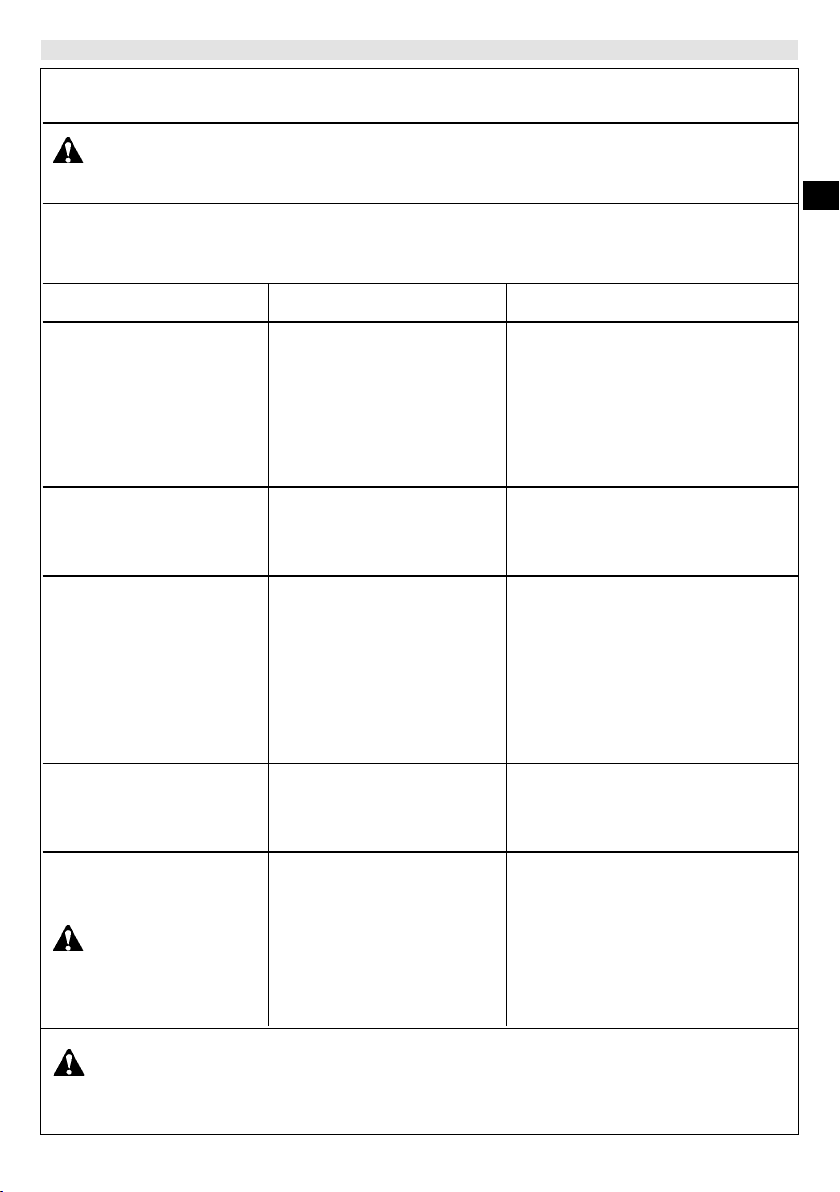

Maintenance Chart

Please note that the following maintenance intervals apply for normal operating conditions only. If your daily work

requires longer than normal or harsh cutting conditions are present, then the suggested intervals should be shortened

accordingly.

Complete Machine

Controls (STOP button, Choke Lever, Throttle

Trigger, Trigger interlock)

Fuel Tank

Fuel Filter and tube

Cutting Attachments

Bevel Gear

Cutting Attachments Guard

All Accessible Screws and Nuts (Not Adjusting Screws)

Air Filter

Cylinder Fins

Starter System Vents

Starter Rope

Carburetor

Spark Plug

Vibration Mounts

Cutting Attachments nuts and screws

Inspect (Leaks, Cracks, and Wear)

Clean after finishing daily work

Check Operation

Inspect (Leaks, Cracks, and Wear)

Clean

Inspect

Clean, Replace Filter Element

Inspect (Damage, Sharpness, and Wear)

Check Tension

Sharpen

Inspect (Damage, Wear and Grease Level)

Inspect (Damage, and Wear)

Replace

Inspect

Retighten

Clean

Replace

Clean

Clean after finishing daily work

Inspect (Damage, and Wear)

Replace

Check Idle (Cutting Attachments must not

rotate at idle)

Check Electrode Gap

Replace

Inspect (Damage, and Wear)

Replace by Dealer

Check that the locking nut of the cutting

equipment is tighten correctly

Faulty

Monthly

Before Each Use

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

As Required

If Damaged or

x

x

x

x

x

x

x

x

x

x

x

x

1 year or 100 hrs.

x

x

x

x

12

Page 19

BLADE SHARPENING 234 TOOTH

1. Blades are reversible: when one side is no

longer sharp, the blade can be turned over

and used on the other side (Fig. 13).

2. Blades are sharpened using a flat single-cut

file (Fig. 13).

3. To maintain the correct balance, file all cutting

edges uniformly.

4. If the blades are not sharpened correctly, this

can set up abnormal vibrations in the machine

and cause the blades themselves to break

ultimately.

WARNING! – The wrong type of cutter or

an incorrectly sharpened blade will increase the

risk of kickback. Check mower blades for

deterioration or cracks, and replace if damaged.

gloves during maintenance operations. Do not

carry out maintenance with the engine hot.

AIR FILTER

Every 8-10 working hours, remove the cover (A,

Fig. 19), clean the filter (B).

Blow with compressed air, at a distance.

Replace if dirty or damaged. The engine runs

irregularly if the filter is clogged, with consequent

higher consumption and lower performance.

FUEL FILTER

Check fuel filter periodically. A dirty filter can cause

difficult starting and lower engine performance.

To clean filter proceed as follows: remove it from

fuel filling hole. Replace it (Fig. 17) if too dirty.

GB

WARNING: Never repair damaged

cutting attachments by welding,

straightening or modifying the shape. This

may cause parts of the cutting tool to come

off and result in serious or fatal injuries.

NYLON LINE HEAD

Only use line of the same diameter as the original

to avoid overloading the engine (Fig. 14).

In order to get more line out of the cutting head,

tap it lightly on the ground while working.

Note: Never hit the nylon head against hard spots

such as concrete or stones, it could be dangerous.

Replacing the nylon line on the TAP&GO

trimmer head (Fig.15)

1 - Press the tab (1, Fig. 15) and remove the cover

and the internal spool.

2 - Double back the line, leaving one end 14 cm

longer than the other one. Lock the line in the

notch (2, Fig. 15). Wind the line in the direction

of the arrow, each end in its chink, regulary,

without crossing them.

3 - At the end of the winding, lock in the slits (3,

Fig. 15) Assemble the spring. Thread the line

through the eyelets (4) (fig.15), secure the

head with the cover (5) and then pull the line

outwards from the head (6).

WARNING! – Always wear protective

ENGINE

Clean cylinder fins with a brush or compressed

air periodically. Dangerous overheating of engine

may occur due to impurities on the cylinder.

SPARK PLUG

Clean spark plug and check electrode distance

periodically (Fig. 18). Use TORCH L8RTF or of other

brand with the same thermal grade.

GEAR HOUSING

Every 30 working hours, remove screw (D, Fig. 6)

on the gear housing and check the quantity of

grease. Do not use more than 10 grams. Use high

quality molybdenum bisulfide grease.

Never use fuel for cleaning operations.

TRASMISSION

Grease the joints of the rigid tube (D, Fig. 20) every

30 working hours with molybdenum disulfide.

CARBURETOR (Fig. 16)

Before adjusting the carburetor, clean the air filter

(B, Fig. 19) and warm up the engine.

Idle screw T is adjusted in order to ensure a good

safety margin between idle running and clutch

engagement.

13

Page 20

GB

WARNING: With the engine idling (3100

rpm), the blade should not rotate. We

recommend that you have your nearest

authorised dealer or service workshop carry

out any carburettor adjustments.

WARNING: Weather conditions and

altitude may affect carburation.

EXTRA MAINTANANCE ADVISABLE

It is advisable to inspect the machine by a

specialized technician at an authorized service

network at the end of season, if used

intensively, and every two years if with normal

use.

ATTENTION: All maintenance operations

not reported in this manual must be carried

out by an authorized Service Center.

To ensure steady and regular brush cutter

operation, remember that parts must only be

replaced with ORIGINAL SPARES.

Any unauthorized changes and/or use

of non-original replacement parts may result

in serious injury or death to the operator or

third parties.

10. STORAGE

If the machine is to be stored for long periods:

- Drain and clean the fuel tank in a well-ventilated

area. To drain the tank, start the engine and

wait until the fuel is exhausted and the engine

stops (leaving fuel mixture in the carburettor

could damage the membranes).

- The procedures for returning the machine to

service following winter storage are the same

as for starting up during everyday use (page 7).

- Follow all the maintenance regulations

previously described.

- Clean the brush cutter completely and lubricate

the metallic parts.

- Remove, clean and lubricate the blade to

prevent rusting.

- Remove the blade fixing flanges, clean, dry

and lubricate the bevel gear seat.

- Empty the fuel tank and put the cap back on.

- Thoroughly clean the cooling slots and the air

filter (B, Fig. 19).

- Store the brush cutter in a dry place, preferably

not in direct contact with the floor and away

from heat sources.

11. ENVIRONMENTAL PROTECTION

Environmental protection should be a priority of

considerable importance when using the

machine, for the benefit of both social cohesion

and the environment in which we live.

- Try not to cause any disturbance to the

surrounding area.

- Scrupulously comply with local regulations

and provisions for the disposal of waste

materials after mowing.

- Scrupulously comply with local regulations

and provisions for the disposal of oils, petrol,

batteries, filters, deteriorated parts or any

elements which have a strong impact on the

environment. This waste must not be

disposed of as normal waste, it must be

separated and taken to specified waste

disposal centres where the material will be

recycled.

Demolition and disposal

When the machine reaches the end of its service

life, do not dispose of it into the environment;

instead take it to a waste disposal centre.

Most materials used in the manufacture of the

machine are recyclable; all metals (steel,

aluminium, brass) can be delivered to a normal

recycling station. For information contact your

local waste recycling service. Waste disposal

must be carried out with respect for the

environment, avoiding soil, air and water

pollution.

In all cases, applicable local legislation must

be complied with.

When the machine is scrapped also the CE mark

label must be destroyed together with this

manual.

14

Page 21

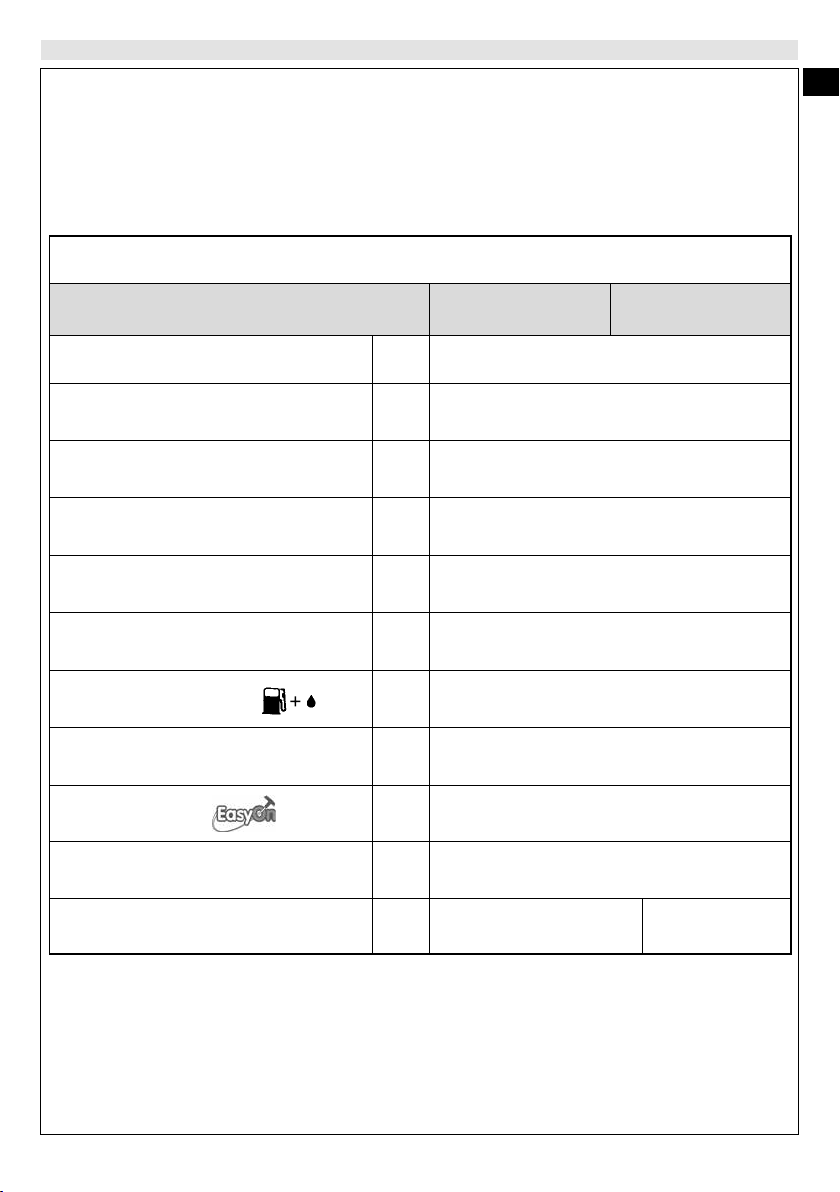

12. TECHNICAL DATA

GB

BCH 25 S - DSH 250 S BCH 25 T - DSH 250 T

Displacement

Engine

Power

Min. rpm

Maximum speed of output spindle

Engine speed at maximum output spindle speed

Fuel tank capacity

Primer carburetor

Starting system

Cutting width

Weight without cutting tool and guard

cm

kW

min

min

min

cm

cm

kg

3

25.4

2 stroke EMAK

0.9

-1

-1

-1

3

3.100

8.100

10.500

640 (0.64 l)

Yes

Yes

41

5.8

6.4

15

Page 22

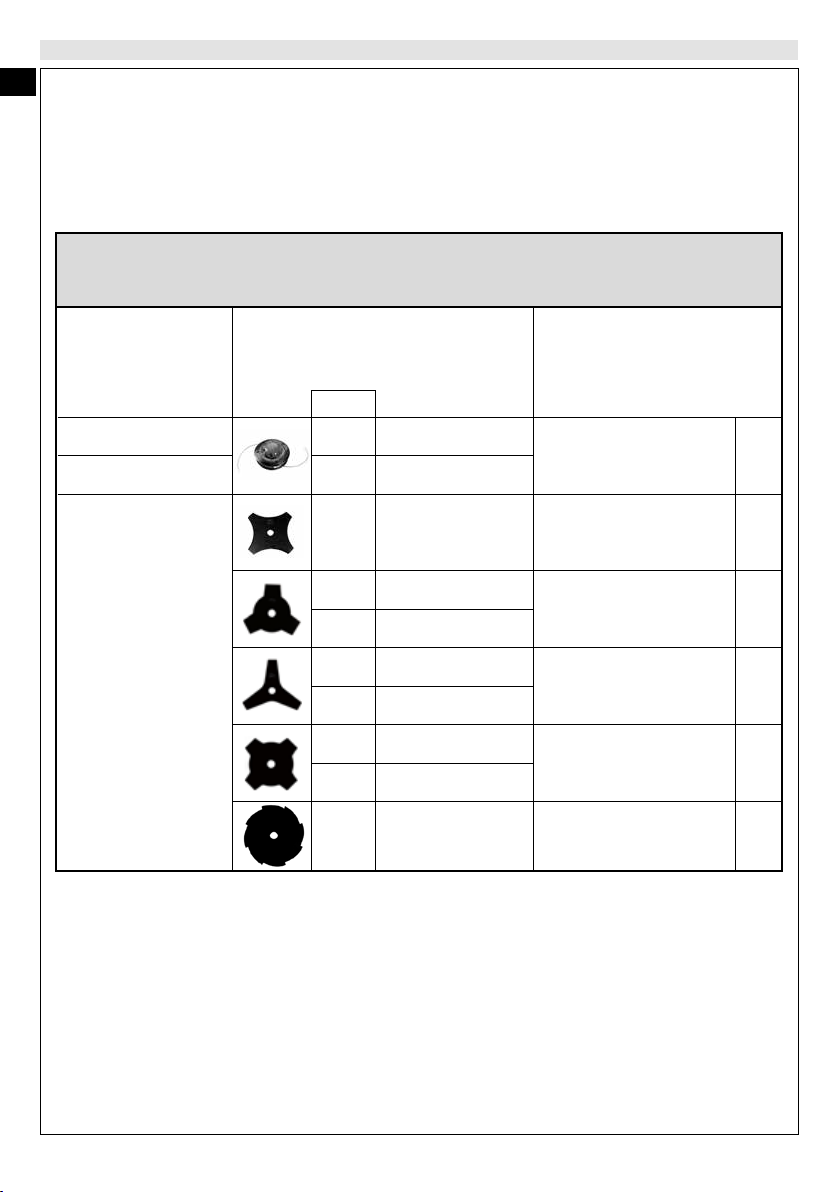

GB

BCH 25 S - BCH 25 T

DSH 250 S - DSH 250 T

Recommended cutting attachments

Model Cutting attachments Guards

Ø mm

110

110

P.N. 61469100

P.N. 61450295AR

P.N. 61469101

200 P.N. 4095681BR P.N. 61450295AR

230

255

BCH 25 - DSH 250

* Protection p. (C, Fig. 4) not needed. Metal cutting attachments.

WARNING!!!

Using an incorrect cutting attachment increases the risk of accidents! Only use the

recommended cutting attachments and guards and follow the manufacturer’s sharpening

instructions.

255

305

230

255

230 P.N. 4095565AR

P.N. 4095637AR

P.N. 61450295AR

P.N. 4095638AR

P.N. 4095673BR

P.N. 61450295AR

P.N. 4095674AR

P.N. 4095568AR

P.N. 61450295AR

P.N. 4095563AR

P.N. 61450295AR

*

*

*

*

*

16

Page 23

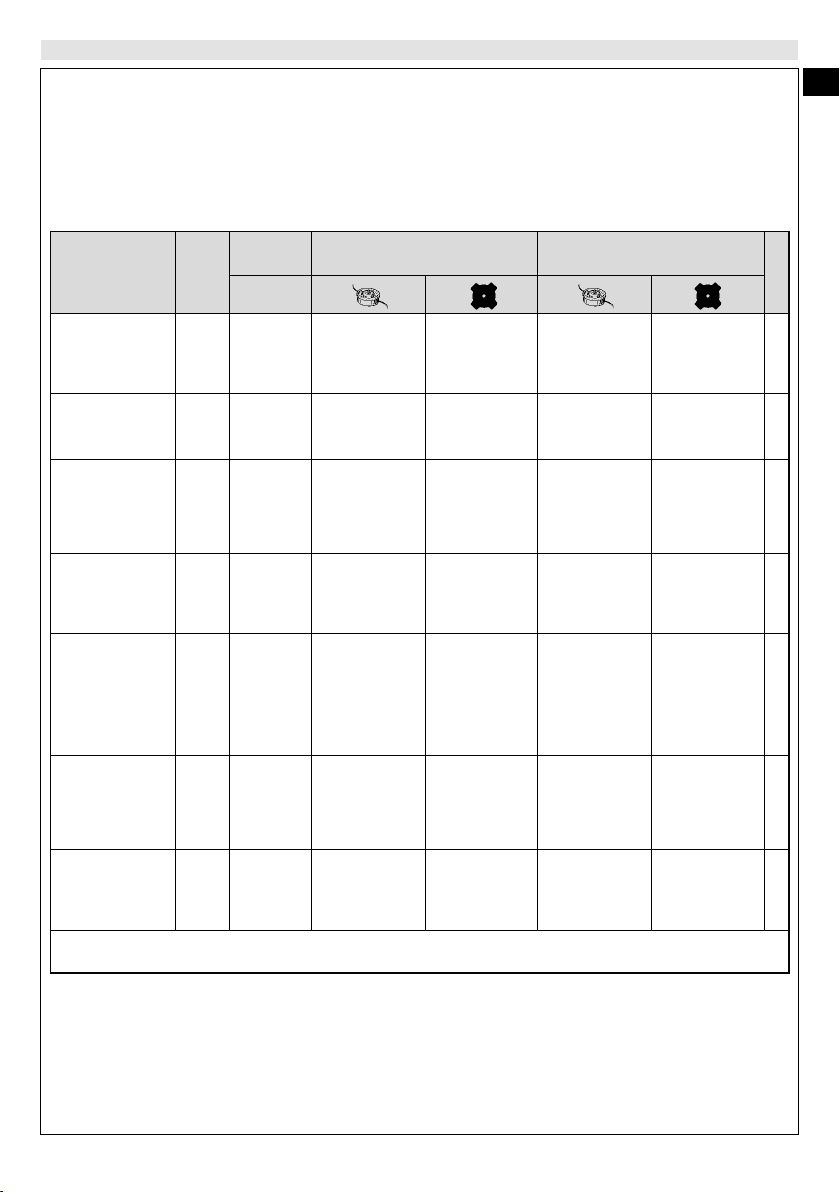

Pressure level

dB (A)

LpA av

EN 11806

EN 22868

BCH 25 S - DSH 250 S BCH 25 T - DSH 250 T

98.0 94.8 98.0 94.8

GB

*

Uncertainty

Measured sound

power level

Uncertainty

Guaranteed

sound power

level

Vibration level

Uncertainty

- Weighted average values: 1/2 minimum rpm, 1/2 at full load (head) or 1/2 racing (blade).

*

dB (A)

dB (A)

dB (A)

dB (A)

m/s

m/s

2000/14/EC

EN 22868

EN ISO 3744

2000/14/EC

EN 22868

EN ISO 3744

EN 11806

2

EN 22867

EN 12096

2

EN 12096

2.0 2.0 2.0 2.0

112.3 107.0 112.3 107.0

2.1 2.3 2.1 2.3

L

WA

114.0 110.0 114.0 110.0

5.3 (sx)

5.5 (dx)

1.2 (sx)

1.2 (dx)

5.5 (sx)

5.2 (dx)

1.4 (sx)

1.5 (dx)

3.5 (sx)

4.7 (dx)

1.3 (sx)

1.4 (dx)

2.9 (sx)

4.6 (dx)

1.3 (sx)

1.4 (dx)

*

17

Page 24

GB

13. DECLARATION OF CONFORMITY

The undersigned, Emak spa via Fermi, 4 - 42011 Bagnolo in

Piano (RE) ITALY declares under its own responsibility that

the machine:

1. Category: brushcutter/grass trimmer

2. Brand Efco, Type DSH 250 S - DSH 250 T

Brand Oleo-Mac, Type BCH 25 S - BCH 25 T

3. Serial ID 820 XXX 0001 ÷ 820 XXX 9999

Complies with the requirements established Directive /

Regulation 2006/42/CE - 2000/14/CE - 2014/30/EU - 2011/65/

EU, conforms to the provisions of the following harmonized

standards:

EN ISO 11806-1:2011 - EN 55012:2007 - EN 55012:2007/

A1:2009 - EN ISO 14982:2009

Procedures for evaluation of conformity followed:

Annex V - 2000/14/CE

14. WARRANTY CERTIFICATE

This machine has been designed and manufactured using the

most modern techniques. The manufacturer guarantees its

products for 24 months from the date of purchase, for private

and hobby use. The warranty is limited to 12 months in case

of professional use.

Limited warranty

1) The warranty period starts on the date of purchase. The

manufacturer, acting through the sales and technical

assistance network, shall replace free of charge any parts

proven defective in material, machining or

manufacturing. The warranty does not affect the

purchaser’s rights as established under legislation

governing the consequences of defects in the machine.

2) Technical personnel will undertake the necessary repairs

in the minimum time possible, compatible with

organisational needs.

3) To make any claim under the warranty, this certificate of

warranty, fully completed, bearing the dealer’s stamp

and accompanied by the invoice or receipt showing the

date of purchase, must be displayed to the personnel

authorised to approve work.

4) The warranty shall be null and void if:

- the machine has evidently not been serviced correctly

Measured sound power level: 112.3 dB (A)

Guaranteed sound power level: 114.0 dB (A)

Technical Documentation deposited with Administrative

Headquarter: Technical Department

Signed in Bagnolo in Piano (RE) Italy - via Fermi, 4

Date: 01/12/2019

Fausto Bellamico - President

- the machine has been used for improper purposes or

has been modified in any way,

- unsuitable lubricants and fuels have been used

- non-original spare parts and accessories have been

fitted

- work has been done on the machine by unauthorised

personnel

5) The warranty does not cover consumables or parts

subject to normal wear.

6) The warranty does not cover work to update or improve

the machine.

7) The warranty does not cover any preparation or

servicing work required during the warranty period.

8) Damage incurred during transport must be immediately

brought to the attention of the carrier: failure to do so

shall render the warranty null and void.

9) Engines of other manufacturers (Briggs & Stratton,

Subaru, Honda, Kipor, Lombardini, Kohler, etc.) fitted to

our machines are covered by the warranties of the

engine manufacturer.

10) The warranty does not cover injury or damage caused

directly or indirectly to persons or things by defects in

the machine or by periods of extended disuse of the

machine resulting from the said defects.

s.p.a.

MODEL

SERIAL No

BOUGHT BY Mr.

Do not send! Only attach to requests for technical warranties.

18

DAT E

DEALER

Page 25

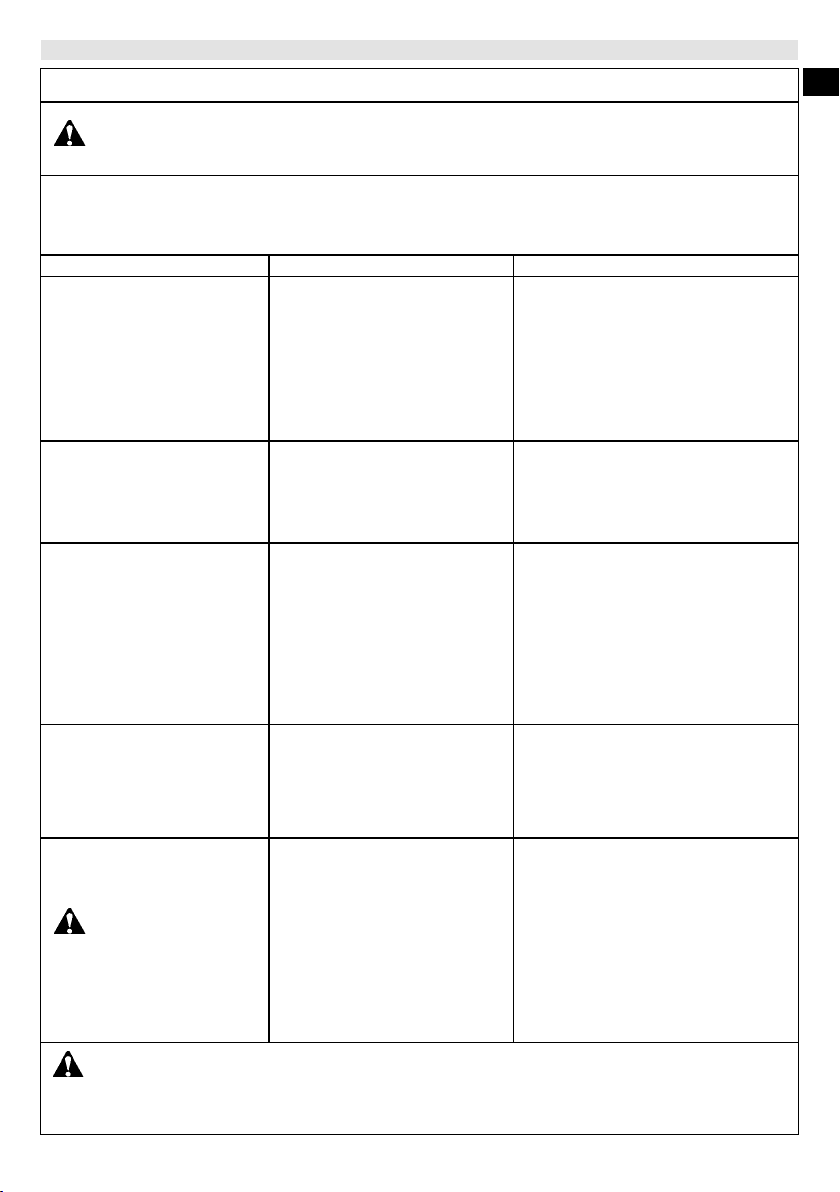

15. TROUBLESHOOTING

WARNING: Always stop unit and disconnect spark plug before performing all of the

recommended remedies below except remedies that require operation of the unit.

When all the possible causes have been checked and the problem is not resolved, consult an

Authorised Service Centre. If a problem occurs that is not listed in this table, consult an Authorised

Service Centre.

PROBLEM POSSIBLE CAUSES SOLUTION

Engine will not start or will

run only a few seconds

after starting.

Engine starts but will not

accelerate properly or will

not run properly at high

speed.

1. No spark

2. Flooded engine.

Carburetor requires

adjustment.

1. Watch for spark at spark plug

2. Follow procedure page 7. If

Contact a Servicing Dealer for

carburetor adjustment.

tip. If there is no spark, repeat

test with a new spark plug

(TORCH L8RTF).

engine still fails to start, repeat

procedure with a new spark

plug.

GB

Engine does not reach full

speed and / or emits

excessive smoke

Engine starts, runs and

accelerates but will not

idle.

Engine starts and runs, but

cutting attachment is not

rotating

WARNING: Never

touch the cutting

attachment while

the engine is

running.

WARNING: Do not attempt to carry out repairs without the necessary repairs and

technical expertise. Poorly executed repairs will automatically invalidate the warranty and

relieve the manufacturer of all liability.

1. Check oil fuel mixture.

2. Air filter dirty.

3. Carburetor requires

adjustment.

Carburetor requires

adjustment.

Clutch, bevel drive or

transmission shaft damaged

1. Use fresh fuel and the correct

2. Clean per instruction in

3. Contact a Servicing Dealer for

Turn idle speed screw “T ”

(Fig. 16) clockwise to increase idle

speed. See Operation-Carburetor

Adjustment.

Replace if necessary - contact a

Servicing Dealer.

2-cycle oil mix.

Maintenance-Air Filter Section.

carburetor adjustment.

19

Page 26

TRADUCTION DES INSTRUCTIONS

ORIGINALES

F

À notre aimable clientèle

Merci d’avoir choisi un produit Emak.

Notre réseau de distributeurs et d’assistance est

à votre disposition pour toute nécessité.

INTRODUCTION

Pour un emploi correct de la machine et pour

éviter tout accident, ne commencez pas le

travail sans avoir préalablement lu ce manuel

avec attention. Vous y trouverez les descriptions

du fonctionnement des différents composants,

ainsi que les instructions relatives aux contrôles

et aux procédures d’entretien requis.

N.B. Les descriptions et les illustrations

figurant dans le présent manuel ne sont pas

rigoureusement contractuelles. Le fabricant

se réserve le droit d’apporter d’éventuelles

modifications sans être tenu de mettre à jour

à chaque fois ce manuel.

Outre les instructions relatives au

fonctionnement, le présent manuel contient

des paragraphes requérant une attention

particulière de votre part. Ces paragraphes sont

signalés par les symboles décrits ci-dessous :

ATTENTION : lorsqu’il existe des risques

d’accidents, de blessures corporelles voire

mortelles, ou de graves dommages au matériel.

AVERTISSEMENT : lorsqu’il existe un risque de

dommages sur l’unité ou ses composants.

ATTENTION

RISQUE DE DOMMAGES AUDITIFS

EN CONDITIONS NORMALES D’UTILISATION,

CET ENGIN PEUT REPRÉSENTER POUR

L’OPÉRATEUR PRÉPOSÉ UN NIVEAU

D’EXPOSITION PERSONNELLE ET QUOTIDIENNE

AU BRUIT ÉGALE OU SUPÉRIEURE À

85 dB (A)

SOMMAIRE

1. RÈGLES DE SÉCURITÉ (contient les

consignes d’utilisation de la machine

en sécurité)

2. EXPLICATION DES SYMBOLES ET

AVERTISSEMENTS DE SÉCURITÉ

(comment identifier la machine et la

signification des symboles)

3. COMPOSANTS PRINCIPAUX

(emplacement des composants et

éléments principaux de la machine)

4. ASSEMBLAGE (comment retirer

l’emballage et terminer le montage

des éléments détachés)

5. MISE EN ROUTE 23

6. ARRET DU MOTEUR 26

7. UTILISATION DE LA MACHINE 26

8. TRANSPORT 30

9. ENTRETIEN (contient toutes les

informations pour maintenir la

machine en parfait état)

10. REMISSAGE 33

11. PROTECTION DE L’ENVIRONNEMENT

(conseils d’utilisation écologique de

la machine)

12. CARACTÉRISTIQUES TECHNIQUES

(résume les principales

caractéristiques techniques de la

machine)

13. DÉCLARATION DE CONFORMITÉ 38

14. CERTIFICAT DE GARANTIE (résume

les conditions de garantie)

15. GUIDE AU RÉSOLUTION DES

PANNES (pour résoudre rapidement

tout problème)

1. RÈGLES DE SÉCURITÉ

ATTENTION

- La machine, bien utilisée, est un outil de

travail rapide, commode et efficace ;

utilisée de façon incorrecte ou sans les

précautions dues, elle peut devenir un

outil dangereux. Pour rendre votre travail

agréable et sans risques, nous vous

invitons à respecter scrupuleusement les

mesures de sécurité libellées ci-après et

reprises dans le manuel.

- L’exposition aux vibrations dues à

20

l’utilisation prolongée des instruments

actionnés par des moteurs à combustion

interne peut engendrer des lésions aux

22

23

23

31

33

35

38

39

20

Page 27

vaisseaux sanguins ou aux nerfs des

doigts, des mains et des poignets des

personnes présentant des problèmes

circulatoires (enflures). En outre, il a été

démontré que l’utilisation prolongée par

temps froid entraînait des lésions des

vaisseaux sanguins chez les personnes

saines. En cas d’apparitions de symptômes

tels que des engourdissements douleurs,

pertes de force, changements de la couleur

ou de la texture de la peau ou pertes de

sensation au niveau des doigts, des mains

ou des poignets, interrompez

immédiatement l’utilisation de la machine

et consultez un médecin.

- Le système de mise en marche de l’unité

produit un champ électromagnétique de

très basse intensité. Ce champ peut créer

des interférences avec certains

pacemakers. Pour réduire le risque de

lésions graves ou mortelles, les porteurs

de pacemaker devraient consulter leur

médecin et le fabricant du pacemaker

avant d’utiliser cette machine.

ATTENTION: Certaines normes nationales

peuvent limiter l’utilisation de la machine.

1 - Ne pas utiliser la débroussailleuse avant de

s’être informé sur les modalités spécifiques

d’utilisation. L’opérateur inexpert devrait

s’exercer avant d’utiliser la machine sur le

terrain.

2 - La débroussailleuse ne peut être utilisée

que par des personnes majeures en bonne

condition physique et bien informées de son

mode d’emploi.

3 - N’utilisez pas la débroussailleuse si vous êtes

physiquement fatigué ou sous l’influence de

l’alcool, de drogues ou de médicaments.

4 - Portez des vêtements adéquats et sûrs comme

par exemple des bottes, un pantalon résistant,

des gants, des lunettes de protection, un

casque antichoc. Utilisez des vêtements

adhérents mais commodes.

5 - Ne laissez pas les enfants utiliser la

débroussailleuse.

6 - Veillez à ce que personne ne se trouve dans un

rayon de 15 mètres quand la débroussailleuse

est en marche.

7 - Avant d’utiliser une débroussailleuse vérifiez

si le boulon de fixage du disque est bien serré.

8 - La débroussailleuse doit être équipée des

outils de coupe conseillés par le fabricant

(voir pag. 36).

9 - N’utilisez pas la débroussailleuse sans la

protection du disque.

10 - Avant de mettre le moteur en marche vérifiez

si le disque tourne bien librement et s’il n’est

pas en contact avec des corps étrangers.

11 - Pendant le travail contrôlez souvent le disque

en arrêtant le moteur. Changez de disque

dès que vous remarquez des fissures ou des

cassures.

12 - Utiliser la débroussailleuse exclusivement

dans des endroits aérés, ne pas l’utiliser en

atmosphère explosive, inflammable ou dans

des zones confinées.

13 - Quand le moteur tourne n’effectuez aucun

entretien et ne touchez pas au disque.

14 - Il est interdit d’appliquer sur la prise de force

de la débroussailleuse des dispositifs non

fournis par le constructeur.

15 - Ne pas utiliser la débroussailleuse si elle est

endommagée, mal réparée, mal montée ou

modifiée de façon arbitraire. Ne pas enlever,

endommager ou rendre inefficace l’un des

dispositifs de sécurité. Utiliser exclusivement

les dispositifs de coupe indiqués dans le

tableau.

16 - Veillez à ce que les étiquettes portant les

signaux de danger et de sécurité soient

toujours en parfait état. Si elles sont

détériorées, remplacez-les sans délai (Fig. 21).

17 - N’utilisez pas la tronçonneuse dans un but

autre que ceux indiqués dans le manuel

(voir pag. 26).

18 - N’abandonnez pas la machine moteur en

marche.

19 - Ne faites pas démarrer le moteur sans que le

bras soit monté.

20 - Contrôlez tous les jours la débroussailleuse

et assurez-vous que tous les dispositifs, de

sécurité et autres, fonctionnent bien.

21 - N’effectuez pas d’opérations ou de

réparations qui ne soient pas d’entretien

normal. Adressez-vous plutôt à des ateliers

21

F

Page 28

autorisés.

22 - S’il s’avère nécessaire de mettre la

F

débroussailleuse hors service, ne pas

l’abandonner dans l’environnement mais la

remettre au Revendeur qui veillera ŕ son

évacuation.

23 - Ne confier ou prêter la débroussailleuse

qu’à des personnes qualifiées et au courant

du fonctionnement correct de l’appareil.

Remettre par la même occasion le manuel

contenant le mode d’emploi à lire avant de

commencer les travaux.

24 - S’adresser a un revendeur pour toutes

autres demandes ou pour une intervention

prioritaire.

25 - Conservez ce manuel soigneusement et

consultez-le à chaque foisque vous devrez

utiliser la machine.

26 - Se rappeler que le propriétaire ou

l’opérateur sont responsables des accidents

ou des dommages à tiers, aux biens de leur

propriété.

ATTENTION

- Ne jamais utiliser d’unité dont les

fonctions de sécurité sont défectueuses.

Les dispositifs de sécurité de la machine

doivent faire l’objet d’un contrôle et d’un

entretien spécifiques, comme décrit dans

la présente section. Si le résultat de ces

vérifications est insatisfaisant, contacter

le service après-vente pour faire réparer

votre machine.

- Chaque utilisation de la machine non

prévue expressément dans le manuel doit

être considérée comme une utilisation

impropre et, par conséquent, source de

danger potentielle.

VÊTEMENTS DE PROTECTION

Toujours porter des vêtements de

protection homologués pour utiliser une

débroussailleuse. Le port de vêtements de

protection n’élimine pas les risques de blessure

mais il peut en réduire les effets en cas d’accident.

Demandez conseil à votre revendeur habituel

pour choisir le vêtement qui répond le mieux à

vos exigences.

Assurez-vous que le vêtement choisi ne gêne

pas les mouvements. Portez un vêtement de

protection près du corps. La veste et la

salopette de protection sont l’idéal. Ne portez

pas de vêtements, écharpes, cravates ou bijoux

qui risqueraient de s’accrocher dans les buissons.

Nouez les cheveux longs et protégez-les (par

exemple avec un foulard, un béret, un casque,

etc...).

Portez des chaussures de protection avec

semelles antiglisse et pointes en acier.

Portez des lunettes ou une visière de

protection!

Utilisez des dispositifs protégeant contre les

émissions sonores; casque ou boules dans les

oreilles. Rappelez-vous d’être extrémement

prudents lorsque vous utilisez ce genre de

protection car la perception des signaux

acoustiques de danger (cris, alarmes, etc...) est

réduite.

Portez des gants qui absorbent le plus

possible les vibrations.

2. EXPLICATION DES SYMBOLES ET

AVERTISSEMENTS DE SÉCURITÉ (Fig.21)

1 - Lire le manuel avant d’utiliser cette machine.

2 - Vêtir casque, visière et protège-oreilles.

3 - Porter chaussures de protection et gants

quand on utilise disques métalliques ou de

plastique.

4 - Prêter d’attention au lancement d’objets.

5 - Personne doit approcher à moins de 15 m.

6 - ATTENTION! - La surface risque d’être très

chaude!.

7 - L’utilisation de la débroussailleuse avec le

disque en bois est interdite.

8 - Poire d’amorçage.

9 - Type de machine : DÉBROUSSAILLEUSE.

10 - Niveau de puissance acoustique garanti.

11 - Label CE de conformité.

22

Page 29

12 - Numéro de série.

13 - Année de fabrication.

14 - Vitesse maximale de l’arbre de sortie, en tr/

min.

3. COMPOSANTS PRINCIPAUX (Fig.1)

1÷2 - Outils fournis

3 - Harnais

4 - Pignon conique

5 - Protection de sécurité

6 - Tête a fils de nylon

7 - Bouchon du réservoir de carburant

8 - Poire d’amorçage

9 - Vis réglage carburateur

10 - Protection du pot d’échappement

11 - Bougie

12 - Filtre à air

13 - Poignée du lanceur

14 - Levier de starter

15 - Levier accélérateur bloqué

16 - Bouton de STOP

17 - Levier de l’accélérateur

18 - Sistème à courroie

19 - Poignée

20 - Tuyau de transmission

21 - Touche demi-régime

4. ASSEMBLAGE

MONTAGE PROTECTION-SECURITE (Fig. 4)

Fixer la protection (A) au tuyau de transmission à

l’aide des vis (B) en position telle à vous permettre

de travailler en toute sécurité.

NOTE: utiliser la protection (C) seulement avec la

tête fil nylon. Le protecteur (C) doit être fixé sur

le carter de protection (A) au moyen de la vis (D).

MONTAGE DE LA TETE AUX FILS DE NYLON

(Fig. 6)

Enfilez la bride supérieure (F). Enfilez le goujon

qui va bloquer la tête (H) dans son orifice (L) et

vissez à la main, dans le sens contraire des aiguilles

d’une montre, la tête (N).

NOTE: le cas échéant, montez également

l’entretoise en plastique (G, Fig.6).

Enfilez le goujon en dotation dans le trou approprié

(L) pour pouvoir bloquer le disque et serrer le

boulon (A) à 2.5 kgm (25 Nm).

ATTENTION – Installer le collier (voir

flèches C, Fig.7) dans l’orifice de montage du

disque.

MONTAGE DE LA POIGNEE (Fig. 2)

Montez la poignée (A) sur le tuyau de transmission

et fixez-la avec les vis (D). La position de la poignée

se règle selon les exigences de l’opérateur.

ATTENTION - Monter la poignée en

boucle (A, Fig.2-3) entre les flèches d’étiquettes

(B) et la poignée arrière (C).

MONTAGE DU GUIDON (FIG.5B)

- Desserrer les vis (D) du bloc de fixation.

- Introduire les 2 demi-poignées dans les

logements correspondants (E).

- Resserrer les vis (D).

MONTAGE DES POIGNÉES DE COMMANDE

(Fig.5A)

- Desserrer la vis (G). L’écrou (H) reste dans la

poignée de commande (L).

- Pousser la poignée de commande (L)

(l’accélérateur M doit être tourné vers le couple

conique) sur le guidon (N) de sorte que les

orifices (P) soient alignés.

- Introduire la vis (G) et serrer à fond.

MONTAGE DU GUIDON (Fig.5C)

- Installer le guidon (A) dans le bloc de fixation

inférieur (B1).

- Installer le bloc de fixation supérieur (B2) et

visser les 4 vis (D) sans les serrer à fond.

- Poser le guidon à angle droit par rapport au

tuyau de transmission.

- Serrer les vis (D) à fond.

ATTENTION: Veillez à ce que tous les

composants soient bien relié et les vis serrées.

REPARATION DE LA DEBROUSSAILLEUSE

F

MONTAGE DU DISQUE (Fig. 7)

Montez le disque (R) sur la bride supérieure (F), en

vérifiant le bon sens de rotation. Montez la bride

inférieure (B), le carter (D) et vissez le boulon (A)

dans le sens contraire des aiguilles d’une montre.

LES COURROIES (3, Fig. 1)

Un bon réglage du système de courroies permet

à la débroussailleuse d’avoir un bon équilibre et

d’être à une hauteur du sol adéquate (Fig. 8).

- Enfilez la courroie simple.

23

Page 30

- Accrochez la débroussailleuse à la courroie à

l’aide du crochet (A, Fig. 8).

- Positionnez le crochet (18, Fig. 1) de manière

F

à obtenir le meilleur équilibre pour la

débroussailleuse.

- Placez la boucle (C) de manière à ce que la

débroussailleuse soit à la bonne hauteur (Fig. 9).

5. MISE EN ROUTE

CARBURANT

ATTENTION : l’essence est un carburant

extrêmement inflammable. Manipulez

l’essence ou le mélange de carburant avec

une extrême précaution. Ne pas fumer ni

produire de flammes à proximité du carburant

ou de la débroussailleuse.

· Pour réduire le risque d’incendie et de

brûlures, manipulez le carburant avec

précaution. Il est extrêmement

inflammable.

· Secouez et mettez le carburant dans un

récipient homologué.

· Mélangez le carburant en plein air dans un

endroit sans risque d’étincelles ou de flammes.

· Placez au sol, coupez le moteur et laissez-le

refroidir avant de procéder au ravitaillement.

· Desserrez lentement le bouchon du carburant

pour évacuer la pression et pour éviter que le

carburant ne se déverse.

· Serrez fermement le bouchon après le

ravitaillement. Sous l’effet des vibrations, le

bouchon risque de se desserrer et le carburant

de s’échapper.

· Essuyez le carburant qui aurait pu s’échapper.

Écartez l’outil à 3 m du lieu de ravitaillement

avant de démarrer le moteur.

· Ne tentez en aucun cas de brûler le carburant

déversé.

· Ne pas fumer durant le ravitaillement ou

lorsque la débroussailleuse est en marche.

· Stockez le carburant dans un endroit frais, sec

et bien aéré.

· Ne stockez pas le carburant dans un endroit

présentant des feuilles sèches, de la paille, du

papier, etc.

· Conservez l’outil et le carburant dans un

endroit où les vapeurs de carburant

n’entreront pas en contact avec des étincelles

ou des flammes libres, des ballons d’eau pour

le chauffage, des moteurs électriques ou des

interrupteurs, des fours, etc.

· N’ôtez pas le bouchon du réservoir lorsque le

moteur tourne.

· N’utilisez pas de carburant pour les opérations

de nettoyage.

· Assurez-vous de ne pas déverser de carburant

sur vos vêtements.

ESSENCE

l

1

5

10

15

20

25

HUILE

2%-50 : 1

l

0,02 (20)

0,10 (100)

0,20 (200)

0,30 (300)

0,40 (400)

0,50 (500)

A

(cm3)

Cet appareil est actionné par un moteur 2 temps

et nécessite le prémélange d’essence et d’huile

pour moteurs 2 temps. Prémélangez l’essence

sans plomb et l’huile pour moteurs 2 temps dans

un récipient propre homologué pour contenir

de l’essence.

CARBURANT CONSEILLÉ : CE MOTEUR EST

CERTIFIÉ POUR ÊTRE ALIMENTÉ EN ESSENCE

SANS PLOMB POUR USAGE AUTOMOBILIE AVEC

NIVEAU D’OCTANES 89 ([R + M] / 2) OU

SUPÉRIEUR.

Mélangez l’huile pour moteurs 2 temps avec

l’essence en suivant les instructions sur

l’emballage.

Le mélange huile / essence peut être préparé

avec la bonne quantité d’huile par litre, en

utilisant le distributeur gradué fourni (Fig.10)

et en vous reportant au tableau A.

Il est conseillé d’utiliser de l’huile pour moteurs 2

temps Efco - Oleo-Mac à 2% (1:50) spécialement

formulée pour tous les moteurs 2 temps refroidis

par air.

Les proportions correctes huile/essence

illustrées dans la notice (Fig. A) sont adaptées à

24

Page 31

l’utilisation d’huile pour moteurs PROSINT 2 et

EUROSINT 2 ou d’huile moteur de haute qualité

équivalente (spécifications JASO FD ou ISO

L-EGD).

ATTENTION : NE PAS UTILISER D’HUILE

POUR AUTOMOBILES OU POUR MOTEURS

HORS-BORD 2 TEMPS.

ATTENTION :

- N’achetez que la quantité de carburant

nécessaire en fonction des consommations

personnelles ; n’en achetez pas plus qu’il

n’en sera utilisé en un ou deux mois ;

- Conservez l’essence dans un récipient

hermétique, dans un endroit frais et sec.

ATTENTION - Pour le mélange, ne jamais

utiliser un carburant dont le pourcentage

d’éthanol dépasse 10% ; sont admis le gazole

(mélange essence/éthanol) avec un

pourcentage d’éthanol jusqu’à 10% ou le

carburant E10.

NOTA - Ne préparer que la quantité requise de

mélange ; ne pas laisser le mélange dans le

réservoir ou dans le bidon trop longtemps. Il est

conseillé d’utiliser le stabilisateur pour carburant

Emak ADDITIX 2000 réf. 001000972 pour

conserver le mélange pendant 12 mois.

Essence alkylée

ATTENTION - L’essence alkylée ne

présente pas la même densité que l’essence

normale. Par conséquent, régler différemment

la vis H des moteurs mis au point avec l’essence

normale. Pour cette opération, s’adresser à un

centre après-vente agréé.

RAVITAILLEMENT

Secouez le jerrycan du mélange avant de

procéder au ravitaillement .

MISE EN ROUTE

Avant de mettre le moteur en marche

vérifiez si le disque tourne bien librement et s’il

n’est pas en contact avec des corps étrangers.

Moteur au ralenti, le dispositif de

coupe ne doit pas tourner. Sinon, contactez

un Centre de Service Agréé de procéder à

une vérification et corriger le problème.

AVERTISSEMENT: tenez toujours la

débroussailleuse à deux mains. Votre corps

doit toujours se tenir à gauche du tube. Vous

devez maintenir la débroussailleuse à deux

mains, sans jamais les croiser. Ces directives

s’appliquent également aux gauchers.

Conservez la position de coupe correcte.

L’exposition aux vibrations peut

entraîner des problèmes aux personnes

souffrant de troubles circulatoires ou de

nature nerveuse. Demander l’avis d’un

médecin en cas de symptômes physiques tels

qu’engourdissements, absence de

sensibilité, réduction de la force normale ou

variations de la couleur de la peau. Ces

symptômes se présentent normalement au

niveau des doigts, mains ou poignets.

Avant de faire démarrer le moteur vérifiez si le

levier de l’accélérateur fonctionne librement.

ATTENTION : respectez les consignes de

sécurité sur la manipulation du carburant.

Coupez toujours le moteur avant de procéder

au ravitaillement. Ne faites jamais l’appoint

de carburant lorsque le moteur tourne ou s’il

est encore chaud. Restez à au moins 3 m de la

zone de ravitaillement avant de démarrer le

moteur. NE FUMEZ PAS !

1. Nettoyez la surface autour du bouchon de

carburant afin d’éviter toute contamination.

2. Dévissez lentement le bouchon de carburant.

3. Versez soigneusement le mélange de

carburant dans le réservoir. Évitez de

renverser du carburant.

4. Avant de remonter le bouchon de carburant,

nettoyez et inspectez le joint d’étanchéité.

5. Remontez immédiatement le bouchon de

carburant et serrez-le manuellement. Essuyez

25

F

Page 32

tout déversement de carburant.

ATTENTION : vérifiez si le carburant fuit et, le

F

cas échéant, éliminez les fuites avant d’utiliser

la machine. Si nécessaire, faites appel au

service d’assistance auprès de votre revendeur.

Moteur noyé

- Insérez un outil adapté dans la coiffe de

bougie.

- Faites levier sur la coiffe de bougie et

retirezla.

- Dévissez et séchez la bougie.

- Ouvrez l’accélérateur à fond.

- Actionnez le lanceur à plusieurs reprises de

façon à vider la chambre de combustion.

- Remontez la bougie et connectez la coiffe en

l’enfonçant fermement.

- Passez le levier d’étrangleur sur la position

OPEN, même si le moteur est froid.

- Démarrez à présent le moteur.

Procédure de démarrage

1) Pousser lentement le primaire 4 fois (8, Fig.1).

2) Mettre le levier de démarreur (14, Fig.1) sur la

position CLOSE (A, Fig.11).

3) Tirez le levier de l’accélérateur (17, Fig. 1) et

appuyez sur le poussoir (21) pour bloquer en

demi-accélération, puis relâchez le levier (17).

4) S’assurer que la débroussailleuse est bien

stable sur le terrain. S’assurer que rien ne gêne

l’outil de coupe. Tenir la débroussailleuse

d’une main (Fig.12) et tirer sur la corde

de démarrage (pas plus de 3 fois) jusqu’à

obtenir la première explosion du moteur.

Lorsque la débroussailleuse est neuve, il sera

certainement nécessaire de tirer plusieurs fois

sur la corde.

5) Mettre le levier de démarreur (14, Fig.1) sur la

position OPEN (B, Fig.11).

6) Tirer sur la corde pour démarrer le moteur.

Lorsque la débroussailleuse s’est mise

en marche, attendre quelques secondes

qu’elle atteigne la température de service

sans toucher l’accélérateur. En hiver ou en

montagne, attendre quelques secondes de

plus pour que la débroussailleuse atteigne la

température de service. Après quoi, appuyer

sur l’accélérateur (17, Fig.1) pour désactiver la