Page 1

User Manual

Surveyor 4B

Référence : NPS4BGB

Révision : E.0

The Fixed Gas Detection Experts

Page 2

ii

Surveyor 4B

User Manual

Copyright November 2018 by Oldham S.A.S.

All rights reserved. The reproduction of all or any section of this document in

any form whatsoever without the written permission of Oldham S.A.S. is

forbidden.

The information contained in this manual is accurate to our knowledge.

As a result of continuous research and development, the specifications of this

product may be modified at any time without prior notice.

Oldham S.A.S.

Rue Orfila

Z.I. Est – CS 20417

62027 ARRAS Cedex

Tel.: +33 (0)3 21 60 80 80

Fax: +33 (0)3 21 60 80 00

Website: https://gasdetection.3M.com

Page 3

Table of contents

iii

Table of contents

Chapter 1│ General Information ..................................................... 1

User Manual ................................ ................................................................ 1

Symbols used .............................................................................................. 1

Safety Instructions ....................................................................................... 2

Important Information .................................................................................. 2

Liability Limits .............................................................................................. 2

Warranty ...................................................................................................... 2

Chapter 2│ Description ................................................................... 3

Chapter 3│ Mounting of the SURVEYOR 4B ................................... 5

Chapter 4│ Connections ................................................................. 7

Alternative power supply.............................................................................. 7

DC power supply ......................................................................................... 8

Explosimetric detectors ............................................................................... 8

External components ................................................................................... 9

Examples of installation ............................................................................. 11

Chapter 5│ Operating instructions ............................................... 13

Switching on ................................ .............................................................. 13

Switching off ................................ .............................................................. 13

Alarms ....................................................................................................... 13

Chapter 6│ Technical specifications ............................................ 21

Chapter 7│ Disposal ...................................................................... 23

Chapter 8│ Main Part Numbers ..................................................... 25

Chapter 9│ Maintenance ............................................................... 27

Fuse replacement ...................................................................................... 27

Chapter 10│ Certificate of Compliance .......................................... 29

Page 4

iv

Surveyor 4B

User Manual

Page 5

1 - General Information 1

Chapter 1│ General Information

User Manual

The instructions given in this manual must be read thoroughly before

installation and start-up, particularly those concerning the points related to the

safety of the end-user. This user manual must be made available to every

person involved in the activation, use, maintenance, and repair of the unit.

The information, technical data, and diagrams contained in this manual are

based on the information that is available at a given time. In case of doubt,

contact Oldham for additional information.

The aim of this manual is to supply simple and accurate information to the

user. Oldham cannot be held liable for any misinterpretations in the reading of

this manual. In spite of our efforts to produce an error-free manual, it may

nonetheless contain some unintentional technical inaccuracies.

In the client’s interest, Oldham reserves the right to modify the technical

characteristics of its equipment to increase their performance without prior

notice.

The present instructions and their content are the inalienable property of

Oldham.

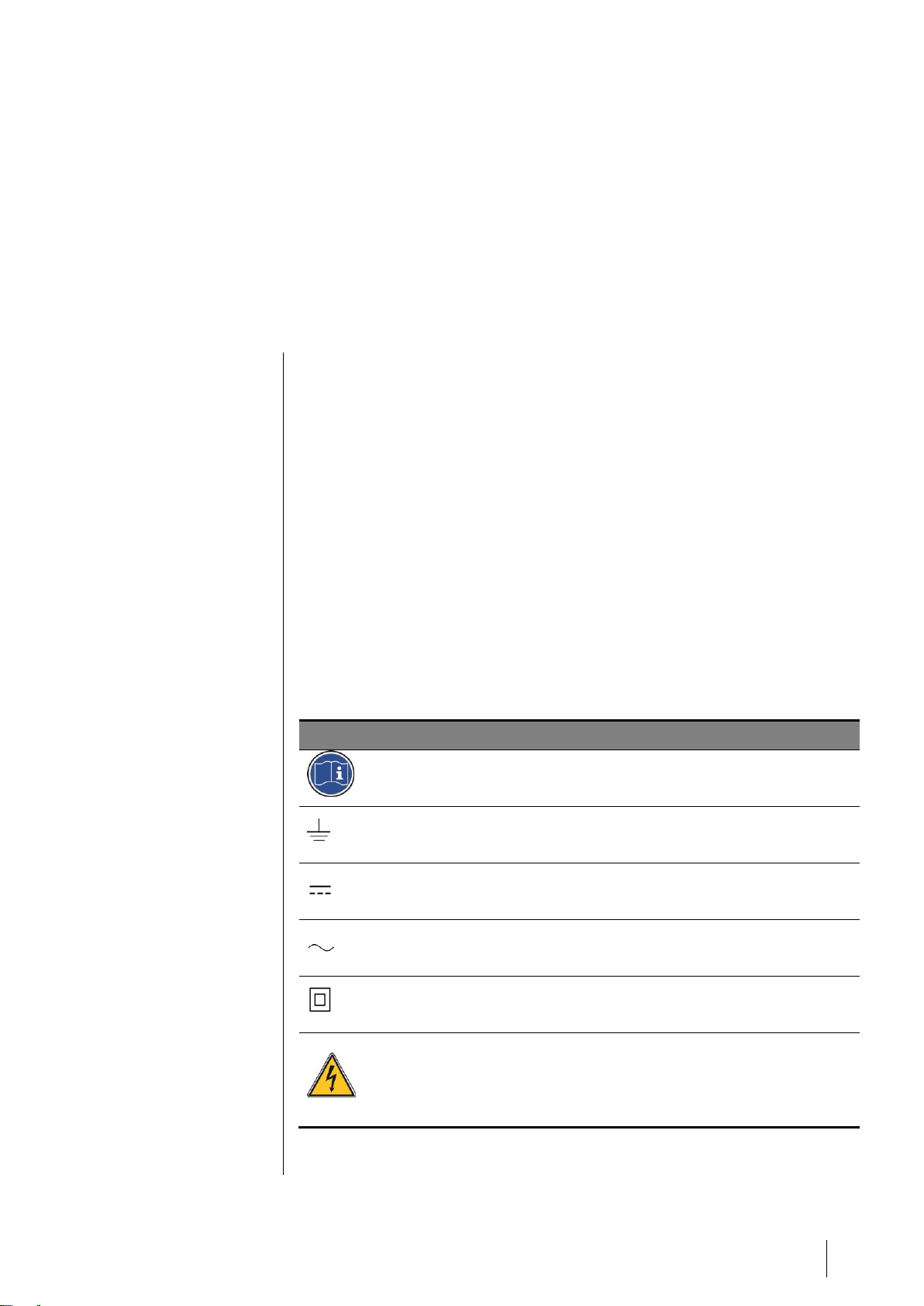

Symbols used

Icon

Significance

This symbol indicates useful additional information.

This symbol indicates:

Earth ground connection.

This symbol indicates:

DC voltage

This symbol indicates:

AC voltage

This symbol indicates:

Double insulated

This symbol denotes:

Attention! In the present mode of use, failure to adhere to the

instructions preceded by this symbol can result in a risk of

electric shock and/or death.

Page 6

2

Surveyor 4B

User Manual

This symbol indicates:

You must refer to the instructions.

European Union (and EEA) only. This symbol indicates that this

product must not be discarded with household waste, as per the

EEA directive (2002/96/EC) and your own national regulations.

This product must be disposed of at a collection point that is

reserved for this purpose, for example, an official site for the

collection of electrical and electronic equipment (EEE) in view of

their recycling, or a point of exchange for authorized products that

is accessible when you acquire a new product of the same type.

Safety Instructions

Labels intended to remind you of the principal precautions of use have been

placed on the unit in the form of pictograms. These labels are considered an

integral part of the unit. If a label falls off or becomes illegible, please ensure it

is replaced. The significance of the labels is detailed below.

The installation and electrical connections must be carried out by

qualified personnel according to the instructions of the manufacturer

and the standards of the competent authorities.

Failure to adhere to the instructions can have serious consequences

on the safety of persons. Please be extremely rigorous as regards

electricity and assembly (coupling, network connections).

Cables with an operating temperature of 60°C minimum (140 °F)

must be used because the temperature inside the controller can

reach 65°C (149 °F).

Important Information

The modification of the material and the use of parts of an unspecified origin

shall entail the cancellation of any form of warranty.

The use of the unit has been projected for the applications specified in the

technical characteristics. Exceeding the indicated values cannot in any case

be authorized.

Liability Limits

Neither Oldham nor any other associated company under any circumstances

can be held liable for any damage, including, without limitations, damages for

loss or interruption of manufacture, loss of information, defect of the Surveyor

4B controller, injuries, loss of time, financial or material loss, or any direct or

indirect consequence of loss occurring in the context of the use or

impossibility of use of the product, even in the event that Oldham has been

informed of such damage.

Warranty

Under normal conditions of use and on return to the factory, parts and

workmanship carry a one year warranty, excluding consumables such as

backup power supplies, audio and visible alarms, etc.

Page 7

2 – Description

3

Chapter 2│ Description

This controller is intended for the continuous measurement and control of the

gases present in the atmosphere.

The Surveyor 4B is intended for indoor use only and shall be installed in

premises without explosive atmospheres.

The central controller is intended for use in areas that meet the Class II

requirements for overvoltage and degree of pollution 2. Surveyor 4B is Class

II equipment.

Surveyor 4B is equipped with a small "NORMAL" box (58 x 105 x 90 mm). It

can be snap-fastened onto a standard symmetrical DIN rail and should

imperatively be integrated in a closed electrical equipment cabinet.

Page 8

4

Surveyor 4B

User Manual

The components used in operation are located on the front of the appliance:

- adjustments and tests on the top (Item 1, Figure 1),

- indicator lights on the FRONT face (Item 2,Figure 1),

- connections at the bottom (Item 3, Figure 1).

Figure 1

Item 1

Item 2

Item

Item 3

Page 9

3 - Mounting of the SURVEYOR 4B

5

Chapter 3│ Mounting of the SURVEYOR 4B

The surveyor 4B appliance fitted on its symmetrical DIN rail must be

installed in a closed electrical equipment cabinet.

A space of 100 mm is necessary around of the Surveyor 4B.

The Surveyor 4B should preferably be located in a monitored

location (such as a guardhouse, control room or instrumentation

room).

Page 10

6

Surveyor 4B

User Manual

Page 11

5 - Connections 7

Chapter 4│ Connections

The Surveyor 4B does not have a start/stop switch.

Certain voltage levels are capable of causing serious injuries or even

death. It is advised to install the material and cabling before applying

live voltage.

Since an incorrect or poor installation may cause measurement

errors or system failures, it is necessary to strictly follow all the

instructions in this manual in order to guarantee the proper operation

of the system.

Cables with an operating temperature of 60°C minimum (140 °F)

must be used because the temperature inside the controller can

reach 65°C (149 °F).

The electrical connections must be carried out by qualified personnel in

compliance with the different directives in force in the country of installation.

The nature of the current and line voltage must be checked. The line voltage

must match the voltage specified on the plate fitted on the Surveyor 4B. The

voltage is configured in the factory.

The wires to be connected to the Surveyor 4B must have a minimum cross

section of 1.5 mm².

The Surveyor 4B appliance can be supplied with either 230 Vac1 or 12 Vcc2.

Alternative power supply

230 volt AC power supply

The Surveyor 4B must be protected on the upstream side by a two-pole earth

leakage circuit breaker (1A) installed near the Surveyor 4B and is considered

as main cut-off device.

The response curve must be of type D.

The mains power supply must be wired on the two points marked N (Neutral)

and P (Phase) on the Surveyor 4B terminal block (see Figure 2, Item 1).

The wires to be connected to the Surveyor 4B must have a minimum cross

section of 1.5 mm²

Power consumption: 5.8 W max. (detector connected).

1

from 207 to 253 Vac

2

from 11.5 to 14 Vdc

Page 12

8

Surveyor 4B

User Manual

DC power supply

12-volt power supply

The 12 volt power supply can be connected to the points marked 0 and 12 V

on the Surveyor 4B terminal block (see Figure 2, Item2).

The Surveyor 4B must be protected on the upstream side by a fuse (630mA)

with time-delay.

The cable must have a minimum cross section of 1.5 mm².

Power consumption: 5.8 W max. (detector connected).

Explosimetric detectors

• Only explosimetric detectors of the "bridge" type can be connected to

the SV 4B.

• Surveyor 4B and the detector are connected together b y a shielded

cable with three active conductors. The shielded cable is to be

connected to the earth to EMC constraints at one end only.

• Terminals C1, C2 and C3 of Surveyor 4B and the detector are to be

connected in opposite mode (Figure 3).

Figure 3 : Detector connections

Figure 2 : power supply connections

Item 1

Item 2

Page 13

5 - Connections 9

• The maximum loop resistance is 1.4 ohms.

For example: the maximum distance between Surveyor 4B and the detector

will be 40 m with conductors with a cross section of 1.5 mm².

External components

Surveyor 4B is equipped with the following two relays:

• Relay 1 (REL 1), which is in mode, corresponds to the first gas alarm

threshold and to the "FAULT" alarm.

This relay is equipped with SPDT contacts available on the SV 4B

terminal block (Item 3, Figure 4).

• Relay 2 (REL 2), which is "negative safety" mode, corresponds to the

second gas threshold only. This relay is also equipped with SPDT

contacts available on the SV 4B terminal block (item 4, Figure 4).

• These both relays could be configured in positive and negative

security (programmation by welding slots on the printed circuit board:

made only by OLDHAM or a skilled personal).

N.B. : The relay contacts are dry contacts, corresponding to the appliance

without power supply.

3

2

1

Detector terminal

Item 3

Item 4

Figure 4 : relays terminals

Page 14

10

Surveyor 4B

User Manual

Caution: The high-power solenoid valves cannot be directly remote

controlled

3

. A power relay is required.

3

The maximum current through the relay contacts will be 2 A and the maximum voltage will be

250 Vac ou 30 Vdc.

Page 15

5 - Connections

11

Examples of installation

Example of installation set up of a SV 4B with TWO OLC 10 TWIN

detectors

* Breaking capacity of rating relays switch contact: 2A / 250Vca - 30Vdc

Important :

The relay's contacts are shown on the SV 4B label, unit switch off.

The AL1/ DEF relays are normally energized and the AL2 relay is

unenergized.

Figure 5 Example of installation set up of a SV 4B with TWO OLC 10 TWIN detectors

Page 16

12

Surveyor 4B

User Manual

Example of installation set up of a SV 4B with a single

detector

* Breaking capacity of rating relays switch contact : 2A / 250Vca – 30Vcc

Important :

The relay's contacts are shown on the SV 4B label, unit switch off.

The AL1/ DEF relays are normally energized and the AL2 relay is

unenergized.

Figure 6: Exemple d'installation d'un Surveyor 4B avec un capteur

Page 17

5 - Operating instructions

13

Chapter 5│ Operating instructions

Switching on

It is assumed that all the necessary connections have been made and that the

whole installation complies with the standards currently in force.

As soon as the SV 4B is supplied with power, it is ready to use and the

GREEN light-emitting diode lights up (rep 1, Figure 7).

Relay 1 is operated ("positive safety" position).

Switching off

The SV 4B is switched off by cutting off the power supply on an electrical

equipment cabinet.

Alarms

GAS alarm

The SV 4B has two adjustable GAS alarm thresholds but the second threshold

(AL 2) must be twice the first (AL 1).

Therefore, the red light-emitting diodes "AL1" and "AL2" (rep 3, Figure 7)

come on as soon as the alarm thresholds are exceeded (time delay of 7

seconds): LED flashing. The audio alarm (buzzer) is activated and the

corresponding relays are tripped.

Figure 7

item 4

item 1

item 2

item 3

Page 18

14

Surveyor 4B

User Manual

FAULT alarms

The SV 4B is equipped with a fault alarm (visual alarm (rep 2, Figure 7), audio

alarm and relay 1) which is activated in the following cases:

• One or more wires of the telemetry line interrupted

• One or more wires of the telemetry line short-circuited or with

excessive power consumption.

NB : The ALARM LEDs may also be activated depending on the

circumstances of the interruption or the short circuit.

Adjustments

The operations and adjustments described in this chapter must

be performed by authorized personnel only as they can affect the

appliance's reliability in detection.

Gas detectors are safety devices. OLDHAM recommends the regular testing

of fixed gas detection installations. This type of test consists of injecting the

calibration gas into the detector at a sufficient concentration to activate the

pre-set alarms. It is to be understood that this test is in no way a replacement

for a detector calibration.

The frequency of gas tests depends on the industrial application where the

detector is in use. Frequent inspections should be made in the months

following the commissioning of the installation, and should then become more

widely spaced provided that no significant deviation is observed. If a detector

should fail to react in contact with the gas, calibration is essential. The

frequency of calibrations shall be appropriate according to the results of the

tests (humidity, temperature, dust, etc.); however, it must not exceed one

year.

The general manager should put safety procedures in place on-site. OLDHAM

cannot be held responsible for their enforcement.

Page 19

5 - Operating instructions

15

Adjusting the "gas alarm" thresholds

Using a "reference gas kit" (gas cylinder + pressure regulator, etc.), inject the

reference gas with a content level higher than the first threshold desired. (For

example, threshold 1 will be 20% LEL, so a minimum of 25% LEL should be

injected).

Adjust the alarm potentiometer (rep 1, Figure 8) to trigger the first threshold

(AL1): the red LED (AL1) flashes (for 7 seconds) and then remains on in

steady mode, trip the corresponding alarm relay.

If you stop at this point, alarm 2 will be set to twice the level of alarm 1.

If you continue until alarm 2 is triggered: alarm 1 will be set to half the level of

alarm 2.

If you wish to lock the alarm relays (inhibiting the relays) during these alarm

threshold adjustments: set the maintenance switch to the high position (item

2, Figure 8).

Figure 8

Maintenance

( ↑ up)

Normal

item 3

item 1

item 2

item 4

MV

item 5

Page 20

16

Surveyor 4B

User Manual

When the adjustments have been made, do not forget to place

the switch back in its normal position.

Terminal posts item 3, Figure 8) are used to connect up a voltmeter for the

reading of a signal (in mV) corresponding to the content level of the injected

gas.

Then, using a rule of three, it is possible to calculate and adjust another signal

(in mV) for an alarm threshold (potentiometer: item 1, Figure 8) corresponding

to a different gas content level.

For example : when you inject 1% methane, you read 1,000 mV (for

instance).

If you set the alarm potentiometer to read 1,500 mV, the alarm is triggered at

1.5% methane.

Signal =

mV

mV

mVx

1500

1000

%11000

Or

Threshold (%) =

1% 1500

1000

15%

x mV

mV

.

Acknowledgement of gas alarms

A switch (item 4, Figure 8) is used to acknowledge gas alarms in manual

mode 4 or automatic mode 5

4

manuel : Manual mode: When a gas alarm is triggered, it must be cleared manually even if the

content level has fallen to zero (or to below the threshold). This is done by pressing the Ack. key

(item 5, Figure 8).

5

Automatic mode: When a gas alarm is triggered, it is cleared automatically as soon as the

content level falls below the alarm threshold.

Automatic ack.

( ↑ Up)

Manuel ack.

Page 21

5 - Operating instructions

17

As long as there is a high enough concentration of gas to

trigger an alarm, it is impossible to clear that alarm manually

(with the Ack. button).

Page 22

18

Surveyor 4B

User Manual

Adjusting the ZERO

- Necessary when a cell is replaced

- At least twice a year

- Connect a voltmeter to the two terminal posts provided for that purpose (MF

and MES), as shown below:

Figure 9

- Be sure to be in pure atmosphere (without gas) (If not, inject air)

- Adjust the ZERO (0 mV) with the potentiometer, item 1.Figure 9.

Checking the sensitivity

- Necessary when a cell is replaced.

- At least twice a year.

- Prepare the calibration kit and secure the gas input pipe to the detector.

- Adjust the flow rate of the reference gas6 to 60 l/h before injecting.

- Allow to stabilize for at least 10 seconds.

- Check that the alarm or alarms are triggered (as applicable 6) and carry out

the following procedure.

6

La valeur du gaz étalon sera supérieure au moins au premier seuil d'alarme.

item 1

item 2

MV

Page 23

5 - Operating instructions

19

Page 24

20

Surveyor 4B

User Manual

Replacing the fuse

It is mandatory that spare parts must be guaranteed original

OLDHAM parts as, otherwise, the reliability of the equipment

could be adversely affected.

The fuse (Figure 10, item 1) must be replaced by qualified personnel only.

The fuse is, and must be, in compliance with CEI 127, with time-delay, low

breaking capacity and a voltage of 250 V ~.

- Fuse 5x20- T125 mA 250 V- OLDHAM reference = 6154701

Figure 10

item 1

Page 25

6 – Technical specifications

21

Chapter 6│ Technical specifications

Manufacturer

OLDHAM

Type

SURVEYOR 4 B

Function

Control station for explosive gas detectors

Capacity

1 measurement chanel

1 detector type CEX 300 or OLC10/100 or 2

OLC 10Twin detectors

Measurement

Measurement

Display unit

Continious

None

Visual alarms

Failure: yellow

Gas, 1st threshold: red

Gas, 2nd threshold: red

Audio alarm

Integrated

Alarm Acknowledgement

Manual ou automatic

Electric power supplies

Alternative

Continue

230 VCA (207 à 253 V) – 50Hz

Accepts category II transient overvoltages

and pollution degree 2

12 VCC (11.5 à 14 V)

Power consumption

5.8 W (detector connected) @230Vac

0.4A (detector connected) @12 Vdc

Electrical protection

Fuse

Relays

Relay 1

Relay 2

Common to gas (alarm 1) and fault

Gas alarm 2

Contact

SPDT, relay 1 (positive safety)

SPDT, relay 2

Max. breaking capacity

2A sous 250Vca ou 30Vcc

Measuring line

Cable

Maximum line length

Maximum loop resistance

3 conductors

40 m (with conductor 1.5 mm²)

1.4 ohms

Mounting

On symmetrical DIN rail and into a

closed cabinet

Miscellaneous

Technology

Mains visual indicator

Housing

Warranty

SMC (surface mounted component)

Green LED

NORYL

1 year

Dimensions

58 x 105 x 90 mm

Weight

0.360 kg

Cable inlets/outlets

Screw type terminal block

Ingress Protection

IP 20

Mecanical protection

IK 08

Operating conditions

Ambient temperature

Relative humidity

Altitude

+ 10 °C to + 45 °C

5 % to 95 % non-condensed

≤2000m

Page 26

22

Surveyor 4B

User Manual

Page 27

7 – Disposal

23

Chapter 7│ Disposal

Concerning the conservation, of the protection and the improvement of the

quality of the environment, as well as for the protection of the health of the

persons and the careful and rational use of natural resources, SV 4B has to

be the object of a selective collection for the elec tronic equipments and

cannot be scrapped with the normal domestic waste. The user

thus has the obligation to separate the SV 4B of the other waste

so as to guarantee that it is recycled in a sure way at the

environmental level. For more details of the existing sites of

collection, contact the local administration or the distributor of this

product.

Page 28

24

Surveyor 4B

User Manual

Page 29

8 – Main Part Numbers

25

Chapter 8│ Main Part Numbers

Désignation

Reference

Surveyor 4B controller for 340mA wheatstone bridge

sensor

6 514 807

Fuse 5x20 - T125 mA 250 V

6 154 701

Page 30

26

Surveyor 4B

User Manual

Page 31

9 – Maintenance

27

Chapter 9│ Maintenance

Fuse replacement

Fuse replacement should only be performed by qualified personnel

and power must be first switched off.

Fuses shall comply with IEC 60127 standard (time-delay fuse, low breaking

capacity, 250Vac). Please see Chapter 8│.

Oldham does not allow any other repairs than those listed here

above.

Page 32

28

Surveyor 4B

Manuel utilisateur

Page 33

10 – Certificate of Compliance

29

Chapter 10│ Certificate of Compliance

The document hereafter (1 page) reproduces the EU declaration of

conformity.

Page 34

30

Surveyor 4B

Manuel utilisateur

Page 35

Page 36

10 – Certificate of Compliance

32

The Fixed Gas Detection Experts

EUROPEAN PLANT AND OFFICES

Z.I. Est – rue Orfila CS 20417 – 62027 ARRAS Cedex FRANCE

Tél.: +33 (0)3 21 60 80 80 – Fax: +33 (0)3 21 60 80 00

Web site: https://gasdetection.3M.com

AMERICAS

Tel : +1-713-559-9280

Fax : +1-281-292-2860

americas@oldhamgas.com

ASIA PACIFIC

Tel : +86-21-3127-6373

Fax : +86-21-3127-6365

sales@oldhamgas.com

EUROPE

Tel : +33-321-608-080

Fax : +33-321-608-000

info@oldhamgas.com

gasandflamedetection@mmm.com

Loading...

Loading...