Page 1

1

User manual

OLCT 20

Part Number: NPO20GB

Revision: E.0

The Fixed Gas Detection Experts

Page 2

2

Copyright April 2018 by Oldham S.A.S

All rights reserved. No reproduction of all or part of this document, in any for mis

permitted without the written consent of Oldham S.A.S.

All information provided in this document is accurate to the best of our

knowledge.

As a result of continuous research and development, the specifications of this

product may be changed without prior notice.

Oldham S.A.S

Rue Orfila

Z.I. Est – CS 20417

F – 62027 ARRAS Cedex

Tel: +33 (0)3 21 60 80 80

Fax: +33 (0)3 21 60 80 00

Page 3

Table of Contents

iii

Table of Contents

| Overview.............................................................. 1

Limitation of Liability .........................................................................................1

Ownership clauses ...........................................................................................1

Warnings ...........................................................................................................1

Warranty ...........................................................................................................2

Important Information ........................................................................................2

Destruction of equipment ..................................................................................2

Symbols used ...................................................................................................3

| Description .......................................................... 5

Overview ...........................................................................................................5

Main characteristics of the various versions .....................................................5

Mechanical installation of the various versions ................................................6

| Wiring Arrangements ......................................... 7

3-wire version (OLC 20d, OLCT 20d) ...............................................................7

2-wire version (OLCT 20d) ...............................................................................7

2-wire Intrinsic Safety version (OLCT 20i) ........................................................8

| Installation ........................................................... 9

Regulations and operating conditions ..............................................................9

Equipment required ..........................................................................................9

Positioning the detector ....................................................................................9

Mounting the detector .................................................................................... 10

| Maintenance ...................................................... 11

Maintenance frequency ................................................................................. 11

Detector OLC 20 ............................................................................................ 12

Transmitters OLCT 20 ................................................................................... 12

Replacing a sensor on OLCT 20 ................................................................... 14

| Spare Parts ........................................................ 15

Flameproof approved replacement sensors .................................................. 15

Intrinsically-safe approved replacement sensors .......................................... 16

| Accessories ...................................................... 17

| Technical Specifications .................................. 19

Common ........................................................................................................ 19

OLC 20d ........................................................................................................ 19

OLCT 20d ...................................................................................................... 19

OLCT 20i ....................................................................................................... 19

Sensors .......................................................................................................... 20

Cross gas factors for combustible gases ....................................................... 21

Page 4

Table of Contents

iv

| EU Declaration of Conformity .......................... 25

| Special instructions for use in explosive

atmospheres and fonctional safety.......................................... 27

General comments ........................................................................................ 27

Warnings ........................................................................................................ 27

Requirements for use in dust explosive atmospheres ................................... 27

Cable entries .................................................................................................. 27

Threaded joints .............................................................................................. 28

Limitations of use ........................................................................................... 28

Transfer curve for OLCT20 gas detectors ..................................................... 29

Marking .......................................................................................................... 29

Page 5

1 – Overwiew 1

| Overview

Thank you for choosing this OLDHAM instrument.

All necessary actions have been taken to ensure your complete satisfaction

with this equipment.

It is important that you read this entire manual carefully and thoroughly.

Limitation of Liability

■ OLDHAM shall not be held responsible for any damage to the equipment or for any

physical injury or death resulting in whole or in part from the inappropriate use or

installation of the equipment, non-compliance with any and all instructions, warnings,

standards and/or regulations in force.

■ No business, person or legal entity may assume responsibility on behalf of OLDHAM,

even though they may be involved in the sale of OLDHAM products.

■ OLDHAM shall not be responsible for any direct or indirect damage, or any direct or

indirect consequence, resulting from the sale and use of any of its products UNLESS

SUCH PRODUCTS HAVE BEEN SELECTED BY OLDHAM ACCORDING TO THE

APPLICATION.

Ownership clauses

■ The drawings, specifications, and information herein contain confidential information

that is the property of OLDHAM.

■ This information shall not, either in whole or in part, by physical, electronic, or any

other means whatsoever, be reproduced, copied, divulged, translated, or used as the

basis for the manufacture or sale of OLDHAM equipment, or for any other reason

without the prior written consent of OLDHAM.

Warnings

■ This is not a contractual document. OLDHAM reserves the right to alter the technical

features of its equipment at any time and for any reason without prior notice.

■ READ THESE INSTRUCTIONS CAREFULLY BEFORE USING FOR THE FIRST

TIME: these instructions should be read by all persons who have or will have

responsibility for the use, maintenance, or repair of the instrument.

■ This instrument shall only be deemed to be in conformance with the published

performance if used, maintained, and repaired in accordance with the instructions of

OLDHAM, by OLDHAM personnel, or by personnel authorized by OLDHAM.

Page 6

1 – Overwiew 2

Warranty

Under normal conditions of use and on return to the factory, parts and workmanship are

guaranteed for 2 years, excluding consumables such as sensors, filters, etc.

Important Information

The modification of the material and the use of parts of an unspecified origin

shall entail the cancellation of any form of warranty.

The use of the unit has been projected for the applications specified in the

technical characteristics. Exceeding the indicated values cannot in any case

be authorized.

Catalytic sensors are susceptible to poisoning by traces of several

substances. This leads to an inhibition which can be permanent or temporary

depending on the contaminant, the concentration of the contaminant, the

duration of exposure to the contaminant.

Poisoning may result from exposure to substances as:

• silicones (e.g. waterproofing, adhesives, release agents, special oils

and greases, certain medical products, commercial cleaning agents)

• tetraethyl lead (e.g. leaded petrol, particularly aviation petrol ‘Avgas’)

• sulfur compounds (sulfur dioxide, hydrogen sulfide)

• halogenated compounds (R134a, HFO, etc.)

• organo-phosphorus compounds (e.g. herbicides, insectic ides, and

phosphate esters in fireproof hydraulic fluids)

Oldham recommends regular testing of fixed gas detection installations (read

0).

Destruction of equipment

European Union only. This symbol indicates that, in conformity with

directive DEEE (2002/96/CE) and in accordance with local regulations,

this product must not be discarded with household waste.

It must be disposed of in a collection area that is designated for this

purpose, for example at a site that is officially designated for recycling of

electrical and electronic equipment (EEE) or a point of exchange for

authorized products in the event of the acquisition of a new product of the

same type.

The OLCT80 transmitter contains a lithium ion battery intended to supply

power to certain parts of the electronic circuit. The battery will be removed

prior to the destruction of the transmitter and deposited in a collection

center for used batteries.

Page 7

1 – Overwiew 3

Symbols used

Icon

Signification

This symbol indicates:

useful additional information.

This symbol indicates:

This equipment must be connected to ground.

This symbol denotes:

Protective earth terminal. A cable of the adequate diameter

must be connected to ground and to the terminal having this

symbol

This symbol denotes:

Attention! In the present mode of use, failure to adhere to

the instructions preceded by this symbol can result in a

risk of electric shock and/or death.

This symbol indicates:

You must refer to the instructions.

Page 8

1 – Overwiew 4

Page 9

2 – Description 5

| Description

Overview

OLC 20 gas detectors are catalytic type detectors intended for the detection of

combustible gases. They are flameproof certified (OLC 20d).

OLCT 20 gas detectors are 4-20 mA transmitters and are intended for the

measurement of combustible and toxic gases and oxygen. They are either

flameproof certified (OLCT 20d) or intrinsically safe certified (OLCT 20i).

OLC 20s and OLCT 20s are available in ¾ NPT or M25 screw fittings and are

designed to be attached on a junction box or any compatible generic

transmitters.

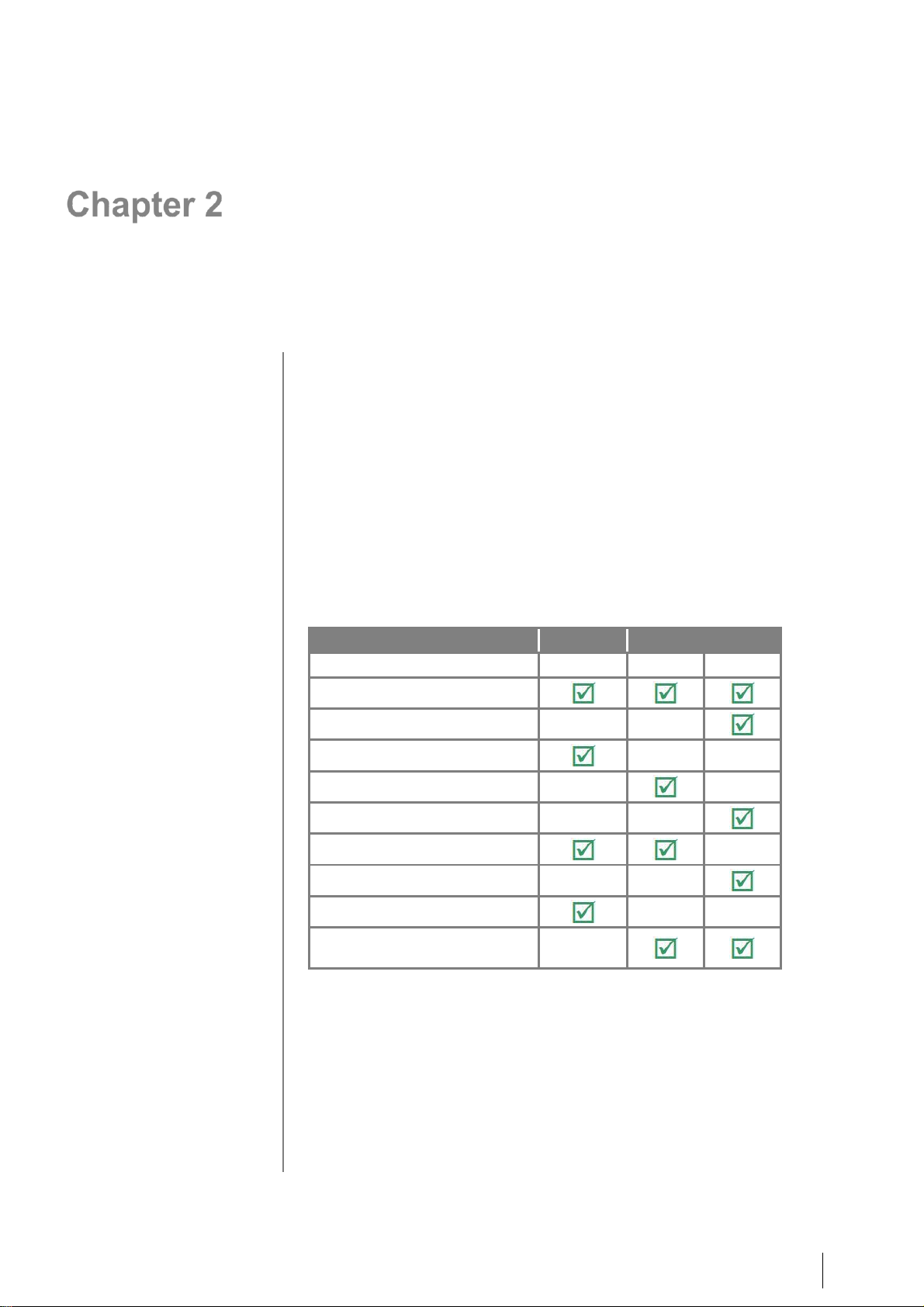

Main characteristics of the various versions

OLC 20

OLCT 20

LEL

LEL

TOX/O2

Flameproof design

Intrinsic safety design

3-wire cable / Wheatstone bridge

3-wire cable / 4-20 mA output

2-wire cable / 4-20 mA output

Catalytic sensor

Electrochemical sensor

Replacement catalytic sensor

Replacement pre-calibrated

sensor

Page 10

2 – Description 6

Mechanical installation of the various versions

Please ensure you read the paragraph: Special Specifications for use in

Potentially Explosive Atmospheres in Accordance with European Directive

ATEX 2014/34/EU.

See Appendix 1 for general installation instructions.

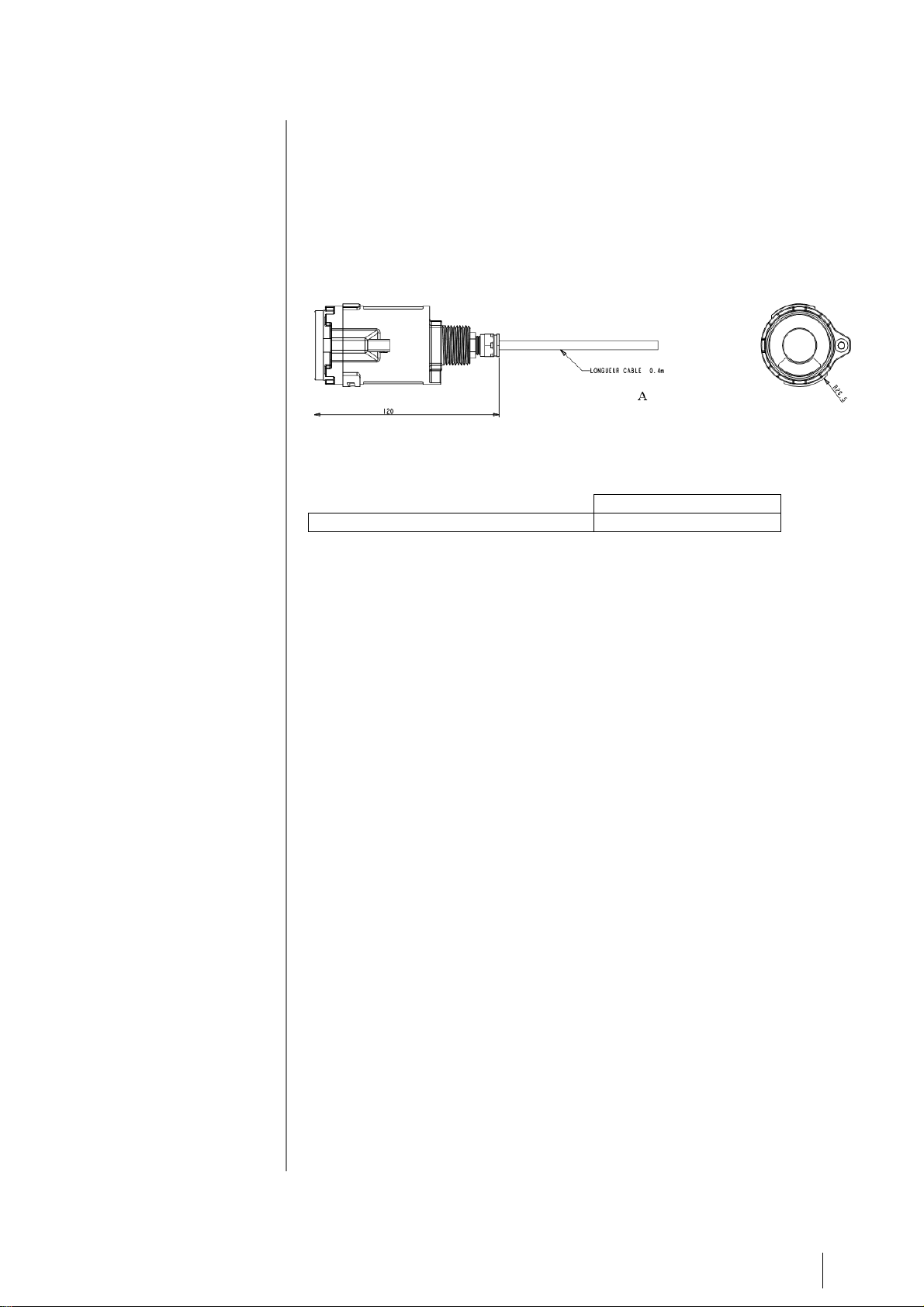

Figure 1 : Dimensions

A Dimensions OLC/OLCT 20

Cable length 0.2 m

Page 11

5 – Maintenance 7

| Wiring Arrangements

Please ensure you read the paragraph: Special Specifications for use in

Explosive Atmospheres in Accordance with European Directive ATEX

2014/34/EU.

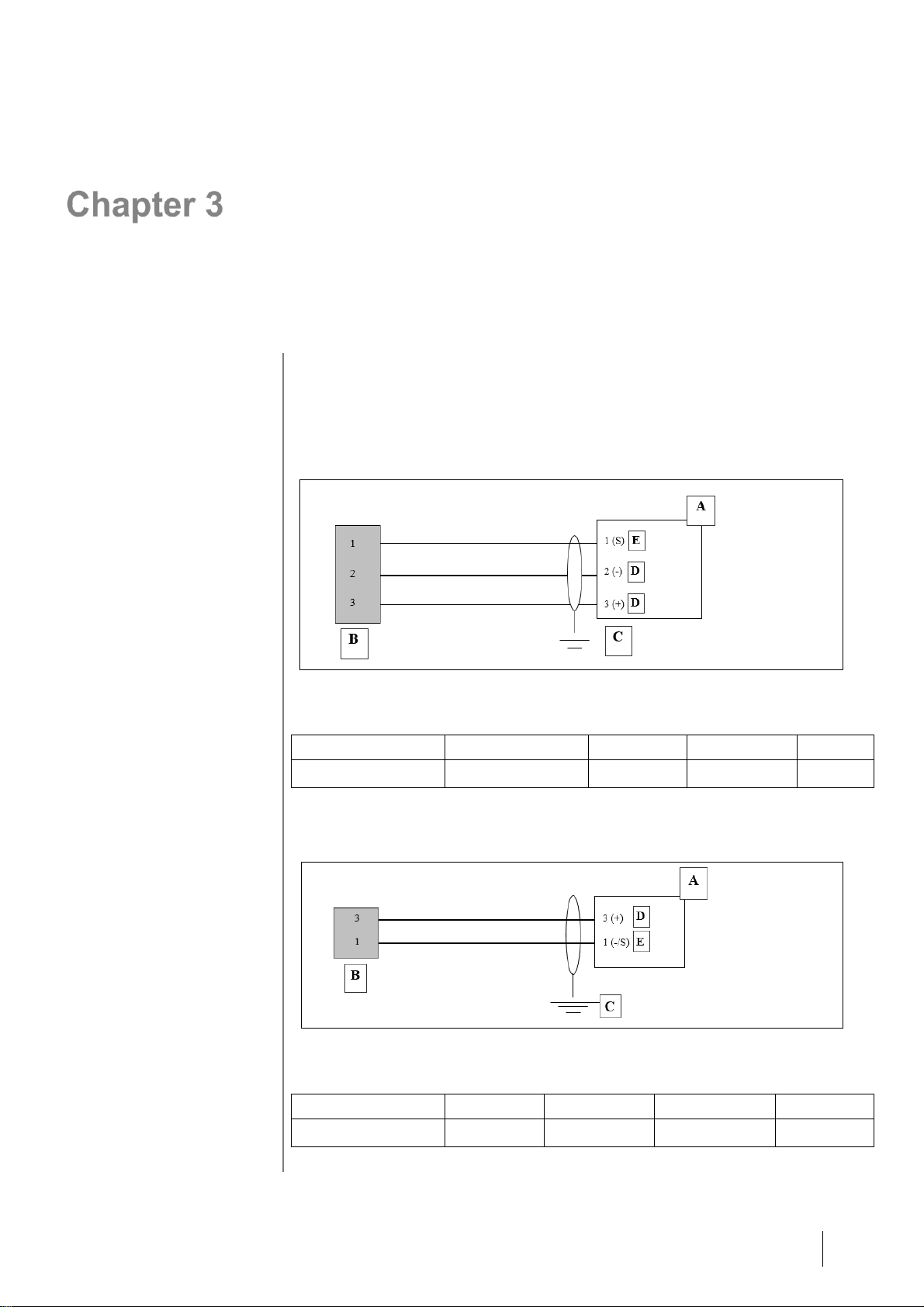

3-wire version (OLC 20d, OLCT 20d)

Figure 2

A

B

C D E

OLDHAM controller

OLC or OLCT 20

Grounding

Power supply

Signal (I)

2-wire version (OLCT 20d)

Figure 3

A

B C D

E

OLDHAM controller

OLCT 20

Grounding

Power supply

Signal (I)

Page 12

5 – Maintenance 8

2-wire Intrinsic Safety version (OLCT 20i)

Figure 4

A

B

C

OLDHAM controller

OLCT 20

Zener Barrier

Page 13

5 – Maintenance 9

| Installation

It is recommended that you read the relevant guides for installing,

operating and maintaining flammable gas and oxygen detectors

(EN 60079-29-2) and toxic detectors (EN 45544-4).

Regulations and operating conditions

■ Installation must comply with current edition of EN 60079-14 for systems

installed in explosive atmospheres and eventually with any local or national

additional requirements that may apply in the country of installation.

■ In general, the ambient temperature, the power supply voltage and power

mentioned in this document pertain to safety precautions against explosion.

These temperatures are not the detector's operating temperatures.

■ OLC20d and OLCT20d are authorized for use in zones 1, 2, 21 and 22 for

ambient temperatures ranging between -20°C to +70°C (except OLC20d HT.

See Chapter 10).

■ OLCT20i are authorized for use in zones 0, 1, 2, 20, 21 and 22 for ambient

temperatures ranging between -20°C to +70°C.

■ The detection sensor must always be in contact with the ambient air.

Therefore:

- Do not cover the detection module.

- Do not apply paint on the detection module.

- Keep dust from building up.

Equipment required

■ Complete detector.

■ Connection cable.

■ Tools for mounting the device.

■ Mounting materials.

Positioning the detector

The detector should be positioned at ground level, on the ceiling, at the height

of the respiratory tract or near air extraction ducts, depending on the application

or the density of the gas to be detected. Heavy gases should be detected at

ground level, while light gases should be detected at ceiling height.

Page 14

5 – Maintenance

10

Mounting the detector

The detector must be installed with the detection sensor pointing downwards.

For combustible gas detectors, tilting the device more than 45° past vertical can

lead to imprecise readings.

Despite its high degree of protection (IP66), it may be necessary to protect the

detector against adverse weather conditions (rain, dust, direct sunlight, etc.) and

from direct spraying with cleaning or maintenance products (causing soiling of

the detection sensor).

The detector must also be positioned so as to allow access to the measuring

sensor so that it can be replaced easily.

Factors to be considered in determining optimal detector positioning:

potential sources of gas and vapour emissions

chemical and physical data on gases and vapours which may be present

liquids with low volatility (place the detectors as near as possible to the leak)

type and concentration of gas leaks (high-pressure jet, slow leak, etc.)

air movements:

- indoors: natural and mechanical ventilation

- outdoors: wind speed and direction

effect of temperature

installation so as to avoid mechanical damage or deterioration caused by

water in summer

positioning to allow easy maintenance, if possible

avoiding direct sunlight on the readout area as this would lead to

maintenance problems

Page 15

5 – Maintenance

11

| Maintenance

The operations explained in this section must be performed by

authorized, qualified personnel because they could affect detection

reliability. Inspection and maintenance must be carried out in

accordance with the current editions of EN60079-17 and eventually

with any local or national additional requirements that may apply in

the country of installation.

It is prohibited to open the transmitter when energized

Periodic inspections ensure that the equipment and system is functioning

properly and providing reliable detection services. The section describes the

preventative maintenance procedures required and how often they are to be

performed. Inspection and maintenance must be carried out in accordance with

the current editions of EN60079-17 and eventually with any local or national

additional requirements that may apply in the country of installation.

Maintenance frequency

Gas detectors are safety devices. Oldham recommends regular testing of fixed

gas detection installations. This type of test involves injecting a standard gas of

sufficient concentration into the detector to trigger pre-set alarms. This test does

not, in any event, replace a full calibration of the detector.

Frequency of gas testing depends on the industrial application in which the

detector is used. Inspection should occur frequently during the months following

installation start-up; later it may be spaced out if no significant problem is

observed. If a detector does not react upon contact with gas, it must be

calibrated. Calibration frequency will depend on the results of these tests

(moisture, temperature, dust, etc.); however, the device should be calibrated at

least once per year.

The site manager is responsible for implementing the safety procedures at the

site. Oldham is not responsible for implementing safety procedures.

Page 16

5 – Maintenance

12

Detector OLC 20

Calibration

Replacing a sensor on an OLC 20

When?

- When the sensor is damaged or cannot be calibrated

- On a preventive basis

How?

- Turn off the relevant measuring channel

- Remove the sensor to be replaced

- Replace it with a new sensor

- Turn on the channel and check that it operates correctly

Transmitters OLCT 20

OLCT 20 gas transmitters are equipped with a pre-calibrated sensor and do not

require any adjustment on installation.

However, as gas detectors are safety equipment, it is recommended to bump

test the complete transmitter after a sensor replacement.

Calibration

After removing the sensor from the transmitter, perform the calibration by using

the calibrating bench provided for that purpose (see CALIBRO’s user manual).

Page 17

5 – Maintenance

13

Procedure

On the controller

On the detector

Set the measuring channel to the

calibration position (alarm relays

inhibited)

Set the measuring channel back

to the "normal" position and

make sure that it is working

properly.

Rotate the

sensor module

and extract it

1

2

Once calibrated put the sensor back in

place or use a replacement sensor and

reinstall the whole assembly.

Loosen the

locking

screw

Page 18

5 – Maintenance

14

Calibration specifications

Calibration shall be performed outside classified areas and by

using suitable equipment that is described during the training

course provided by OLDHAM or by a person authorized by

OLDHAM.

Replacing a sensor on OLCT 20

When?

- When the sensor is damaged or cannot be calibrated.

- On a preventive basis.

How?

- Turn off the relevant measuring channel.

- Remove the sensor to be replaced.

- Replace it with a new, precalibrated unit.

- Turn the channel on and check that it operates correctly.

Page 19

6 – Spare Parts

15

| Spare Parts

All replacement parts must be Oldham-manufactured parts.

The use of non-Oldham parts could jeopardize the

instrument's safety.

Flameproof approved replacement sensors

Part number

Description

6 313 757

OLC 20d sensor cell, 0-100% LEL, VQ1 type

6 313 758

OLC 20d sensor cell, 0-100% LEL, 4F type

6 313 995

OLC20d sensor cell, 0--100% LEL, butadiene/acetylene, VQ1 type

6 313 759

OLC20d sensor cell, 0-100% vol. CH4

6 314 204

OLC 20d sensor cell, 0-100% vol. H2

6 313 988

OLC 20d sensor cell, 0-100% vol. SF6

6 313 689

OLC 20d HT sensor cell, 0-100% LEL, VQ1 type

6 313 685

OLCT 20d sensor cell, 0-100% LEL, VQ1 type

6 313 974

OLCT 20d poison control sensor cell, 0-100% LEL, 4F type

6 313 872

OLCT 20d sensor cell, 0-100% LEL, butadiene/acetylene, VQ1 type

6 313 687

OLCT 20d sensor cell, 0-100% vol. CH4

6 313 986

OLCT 20d sensor cell, 0-100% vol. SF6

6 313 203

OLCT 20d sensor cell, 0-100% vol. H2

6 314 100

Infrared sensor cell, 0-5% vol. CO2, for OLCT 20 XP IR

6 314 101

Infrared sensor cell, 0-10% vol. CO2, for OLCT 20 XP IR

6 314 146

Infrared sensor cell, 0-100% vol. CO2, for OLCT 20 XP IR

6 313 710

OLCT 20d O2 sensor cell, 0-30% vol.

6 313 707

OLCT 20d NH3 sensor cell, 0-100 ppm

6 313 708

OLCT 20d NH3 sensor cell, 0-1000 ppm

6 313 894

OLCT 20d NH3 sensor cell, 0-5000 ppm

6 313 690

OLCT 20d CO sensor cell, 0-100 ppm

6 313 691

OLCT 20d CO sensor cell, 0-300 ppm

6 313 692

OLCT 20d CO sensor cell, 0-1000 ppm

6 313 693

OLCT 20d CO (H2 null) sensor cell, 0-1000 ppm

6 313 695

OLCT 20d H2S sensor cell, 0-30 ppm

6 313 965

OLCT 20d H2S sensor cell, 0-30 ppm, no HC interference

6 313 696

OLCT 20d H2S sensor cell, 0-100 ppm

6 313 697

OLCT 20d H2S sensor cell, 0-1000 ppm

6 313 698

OLCT 20d sensor cell, 0-100 ppm NO

6 313 699

OLCT 20d sensor cell, 0-300 ppm NO

6 313 700

OLCT 20d sensor cell, 0-1000 ppm NO

6 313 706

OLCT 20d sensor cell, 0-2000 ppm H2

6 313 772

OLCT 20d sensor cell, methylene/methylene chloride

Page 20

6 – Spare Parts

16

Part number

Description

6 313 773

OLCT 20d sensor cell, R12

6 313 774

OLCT 20d sensor cell, R134a

6 313 775

OLCT 20d sensor cell, MOS

Intrinsically-safe approved replacement sensors

Part number

Description

6 313 748

OLCT 20i O2 sensor cell, 0 - 30% vol.

6 313 728

OLCT 20i NH3 sensor cell, 0-100 ppm

6 313 729

OLCT 20i NH3 sensor cell, 0-1000 ppm

6 313 895

OLCT 20i NH3 sensor cell, 0-5000 ppm

6 313 694

OLCT 20i CO (H2 null) sensor cell, 0-1000 ppm

6 313 711

OLCT 20i CO sensor cell, 0-100 ppm

6 313 712

OLCT 20i CO sensor cell, 0-300 ppm

6 313 713

OLCT 20i CO sensor cell, 0-1000 ppm

6 313 716

OLCT 20i H2S sensor cell, 0-30 ppm

6 313 717

OLCT 20i H2S sensor cell, 0-100 ppm

6 313 718

OLCT 20i H2S sensor cell, 0-1000 ppm

6 313 719

OLCT 20i NO sensor cell, 0-100 ppm

6 313 720

OLCT 20i NO sensor cell, 0-300 ppm

6 313 721

OLCT 20i NO sensor cell, 0-1000 ppm

6 313 722

OLCT 20i NO2 sensor cell, 0-10 ppm

6 313 723

OLCT 20i NO2 sensor cell, 0-30 ppm

6 313 727

OLCT 20i H2 sensor cell, 0-2000 ppm

6 313 730

OLCT 20i HCl sensor cell, 0-30 ppm

6 313 731

OLCT 20i HCl sensor cell, 0-100 ppm

6 313 724

OLCT 20i SO2 sensor cell, 0-10 ppm

6 313 725

OLCT 20i SO2 sensor cell, 0-30 ppm

6 313 726

OLCT 20i SO2 sensor cell, 0-100 ppm

6 313 734

OLCT 20i Cl2 sensor cell, 0-10 ppm

6 313 746

OLCT 20i ETO sensor cell, 0-50 ppm

6 313 732

OLCT 20i HCN sensor cell, 0-10 ppm

6 313 733

OLCT 20i HCN sensor cell, 0-30 ppm

6 313 736

OLCT 20i COCl2 sensor cell, 0-1 ppm

6 313 740

OLCT 20i CIO2 sensor cell, 0-3 ppm

6 313 735

OLCT 20i O3 sensor cell, 0-1 ppm

6 313 737

OLCT 20i PH3 sensor cell, 0-1 ppm

6 313 739

OLCT 20i HF sensor cell, 0-10 ppm

6 313 738

OLCT 20i AsH3 sensor cell, 0-1 ppm

6 313 747

OLCT 20i SiH4 sensor cell, 0-50 ppm

Page 21

7 – Accessories

17

| Accessories

Accessory

Use

Illustration

Code

Tool kit

Tool kit for maintenance.

6147869

Gas injection

pipe

Inject the calibration gas onto

the measurement sensor.

Impact on reading:

measurement similar to

measurement in diffusion mode.

Impact on response time: none.

6331141

Plastic

material. Risk of

electrostatic

charges. Wipe

with a damp cloth

Gas flow head

Used to take bypass readings.

Impact on reading: none if

calibration is performed under

the same conditions (pipe, flow

rate).

Impact on response time: none.

6327910

Plastic

material. Risk of

electrostatic

charges. Wipe

with a damp cloth

Splash guard

Protects the detector from

liquids.

Impact on reading: none.

Impact on response time:

response time in diffusion mode

may increase for certain gases;

contact us for more information.

6329004

Plastic

material. Risk of

electrostatic

charges. Wipe

with a damp cloth

Splash guard in

Stainless Steel

Protects the detector from

liquids.

Impact on reading: none.

Impact on response time:

response time in diffusion mode

may increase for certain gases;

contact us for more information.

6129010

Splash guard

(high risk)

Protects the detector from

liquids.

Impact on reading: none.

Impact on response time:

response time may increase for

certain gases; contact us for

more information.

6329014

Plastic

material. Risk of

electrostatic

charges. Wipe

with a damp cloth

Remote gas

injection head

Used to detect ambient gases

while a calibration gas injection

pipe is being used. Only for

combustible gases,

Impact on reading: none.

Impact on response time:

negligible.

6327911

Plastic

material. Risk of

electrostatic

charges. Wipe

with a damp cloth

Removable

PTFE protection

filter

Protects the gas inlet from

liquids and dust.

Impact on reading: none, but

this part cannot be used for the

detection of O3, HCL, HF and

Cl2.

Impact on response time:

response time may increase for

certain gases; contact us for

more information.

6335975

Plastic

material. Risk of

electrostatic

charges. Wipe

with a damp cloth

Page 22

7 – Accessories

18

Page 23

8 – Technical Specifications

19

| Technical Specifications

Common

Ingress Protection IP66

Weight 800 g

Dimensions 60 X 120 mm

Source mode current 4-20 mA

Max. current 25 mA

Fault current <1 mA

OLC 20d

Power supply: voltage on detector terminals = 2.8 V max

Power consumption: 3-wire version = 400 mA max

Measurement signal: Wheatstone bridge

Line length (shielded cable): 3-wire version = 1 km with 3x1.5 mm2 (32 ohms

in loop mode)

Output signal mV bridge output, 3 wires

OLCT 20d

Power supply: voltage on detector terminals = 15 Vdc to 30 Vdc

Power consumption: 3-wire version = 100 mA

2-wire version = 25 mA

Load resistance: maximum resistance = 250 ohms

Line length (shielded cable): 3-wire version = 1 km as 3x 1.5 mm2 (32 ohms in

loop mode)

2-wire version = 4 km as 3x 1.5 mm2 (32 ohms in

loop mode)

OLCT 20i

Zener barrier: 28 Vdc max - 300 ohms

Supply voltage for barrier: 19 Vdc to 26 Vdc

Voltage on detector terminals: 10 Vdc to 26 Vdc

Power consumption: 25 mA max

Load resistance: 47 ohms

Line length (shielded cable): 1 km as 3x 1.5 mm2 (32 ohms in loop mode)

Page 24

8 – Technical Specifications

20

Sensors

Gas type

Measure-

ment range

(ppm)

Explosion

-proof

sensor

Intrinsically

-safe

sensor

Temp.

range (°C)

% RH

Accuracy (ppm)

Average

service life

(months)

Resp. time

T50/T90 (s)

Storage

conditions

and time

Combustible

gases

Catalytic

0-100% LEL

-20 to +55

0-95

+/-1% LEL

(from 0-70% LEL)

40

6/15 (CH4)

(b)

AsH

3

Arsine

1.00

-20 to +40

20 - 90

+/- 0.05

18

30/120

(a)

Cl

2

Chlorine

10.0

-20 to +40

10 - 90

+/- 0.4

24

10/60

(a)

ClO

2

Chlorine

dioxide

3.00

-20 to +40

10 - 90

+/- 0.3

24

20/120

(a)

CO

Carbon

monoxide

100

300

1000

-20 to +50

15 - 90

+/- 3

(0-100 range)

40

15/40

(a)

CO

2

Carbon

dioxide

0-5% vol.

-20 to +55

0 - 95

+/- 3%

48

11/30

(a)

COCl

2

Phosgene

1.00

-20 to +40

15 - 90

+/- 0.05

12

60/180

(c)

ETO

Ethylene

oxide

30.0

-20 to +50

15 - 90

+/- 1.0

36

50/240

(a)

H

2

Hydrogen

2000

-20 to +50

15 - 90

+/- 5%

24

30/50

(a)

H

2

S

Hydrogen

sulfide

30.0

100

1000

-20 to +50

15 - 90

+/- 1.5

(0-30 range)

36

15/30

(a)

HCl

Hydrogen

chloride

30.0

100

-20 to +40

15-95

+/- 0.4

(0-30 range)

24

30/150

(a)

HCN

Hydrogen

cyanide

30.0

-20 to +40

15-95

+/- 0.3

(0-10 range)

18

30/120

(c)

HF

Hydrogen

fluoride

10.0

-10 to +30

20 - 80

+/- 5%

12

40/90

(c)

NH

3

Ammonia

100

1000

5000

-20 to +40

15 - 90

+/- 5

+/- 20

+/- 150 or 10%

24

25/70

20/60

60/180

(a)

NO

Nitric oxide

100

300

1000

-20 to +50

15 - 90

+/- 2

(0-100 range)

36

10/30

(a)

NO

2

Nitrogen

dioxide

30.0

-20 to +50

15-90

+/-0.8

24

30/60

(a)

O

2

Oxygen

0-30% vol.

-20 to +50

15 - 90

0.4% vol.

(from 15-22% O2)

28

6/15

(a)

O

3

Ozone

1.00

0 to +40

10 - 90

+/- 0.03 (from 0-

0.2 ppm) +/- 0.05

(from 0.2-1 ppm)

18

40/120

(c)

PH

3

Phosphine

1.00

-20 to +40

20 - 90

+/- 0.05

18

30/120

(a)

SiH

4

Silane

50.0

-20 to +40

20 - 95

+/- 1.0

18

25/120

(a)

SO

2

Sulfur

dioxide

10.0

30.0

100

-20 to +50

15 - 90

+/- 0.7

(0-10 range)

36

15/45

(a)

CH

3

Cl

Chloromethane

500

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

CH2Cl2

Dichloromethane

500

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R12

1% vol.

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R22 2000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R123

2000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

FX56 2000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R134a

2000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R11

1% vol.

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R23

1% vol.

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R143a

2000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R404a

2000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R507

2000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Page 25

8 – Technical Specifications

21

Gas type

Measure-

ment range

(ppm)

Explosion

-proof

sensor

Intrinsically

-safe

sensor

Temp.

range (°C)

% RH

Accuracy (ppm)

Average

service life

(months)

Resp. time

T50/T90 (s)

Storage

conditions

and time

Freon R410a

1000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R32 1000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R407c

1000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Freon R408a

1000

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/90

(d)

Ethanol 500

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/60

(d)

Toluene 500

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/60

(d)

Isopropanol

500

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/60

(d)

2-butanone

(MEK)

500

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/60

(d)

Xylene 500

-20 to +55

20 - 95

+/- 15% (from 2070% PE)

40

25/60

(d)

a) +4°C to +20°C

20% to 60% RH

1 bar ± 10%

6 months maximum

b) -25°C to +60°C

20% to 60% RH

1 bar ± 10%

6 months maximum

(c) +4°C to +20°C

20% to 60% RH

1 bar ± 10%

3 months maximum

(d) -20°C to +50°C

20% to 60% RH

1 bar ± 10%

6 months maximum

Cross gas factors for combustible gases

It is recommended that the detector is calibrated using the gas to be measured.

Users wishing to calibrate the detector using a gas other that detected and

factory-programmed should refer to the following table, and use the

recommended gas and corresponding coefficient.

Poison resistant catalytic sensor, type 4F

Gas

Methane

Pentane

Hydrogen

Acetone

1.80

0.90

Acetylene

1.40

0.70 Ammonia

1.00

0.50 Benzene

2.10

1.05 n-Butane

1.80

0.90

Ethane

1.40

0.70

Ethanol

1.60

0.80 Ethylene

1.40

0.70

n-Hexane

2.85

1.40

Hydrogen

1.00

Isopropanol

1.80

0.90

JP-4

3.00

1.50

JP-5

3.10

1.55 JP-8

3.20

1.60 Methane

1.00

Methanol

1.35

0.65

n-Pentane

2.00

1.00

Propane

1.60

0.80 Styrene

2.40

1.20

Toluene

2.50

1.25

Xylene

2.40

1.20

Page 26

8 – Technical Specifications

22

Poison resistant catalytic sensor, type VQ1

Gas

Molecular

formula

LEL

(% v/v)

UEL

(% v/v)

CH4

coef.

H2

coef.

C4H10

coef.

C5H12

coef.

Ethyl acetate

C4H8O

2

2.10

11.50

1.65 0.90

0.80

Acetone

C3H6O

2.15

13.00

1.65 0.90

0.80

Acetylene

C2H

2

2.30

100

2.35

1.90

1.25

1.15

Acrylic acid

C3H4O

2

2.40

8.00

5.00 2.65

2.40

Butyl acrylate

C7H12O

2

1.20

8.00

3.50 1.85

1.70

Ethyl acrylate

C5H8O

2

1.70

13.00

3.05 1.65

1.50

Acrylonitrile

C3H3N

2.80

28.00

1.45

1.20

0.80

0.70

Ammonia

NH

3

15.00

30.20

0.90

0.75

0.50

0.45

Benzene

C6H

6

1.20

8.00

4.00 2.15

1.90

1,3-butadiene

C4H

6

1.40

16.30

2.55 1.35

1.25

Butane

C4H

10

1.50

8.50

1.90 1.00

0.90

Butanol (butyl alcohol

)

C4H10O

1.4

11.3

1.95 1.05

0.95

2-butanone (MEK)

C4H8O

1.80

11.50

3.90 2.10

1.90

Cyclohexane

C6H

12

1.20

8.30

2.00 1.10

1.00

Dimethylether

C2H6O

3.00

27.00

1.80 0.95

0.90

Dodecane

C12H

26

0.60

~6.0

4.00 2.15

1.90

Ethane

C2H

6

3.00

15.50

1.50 0.80

0.75

Ethanol

C2H6O

3.30

19.00

2.15

1.75

1.15

1.05

Ether (diethylether)

(C2H5)2O

1.70

36.00

1.90 1.00

0.90

Ethylene

C2H

4

2.70

34.00

1.65

1.35

0.90

0.80

G.P.L.2

Prop+But

1.65

~9.0

1.9 1.00

0.90

Diesel

mixture

0.60

~6.0

3.20 1.70

1.55

Natural gas

CH

4

5.00

15.00

1.05 0.60

0.50

Heptane 4

C7H

16

1.10

6.70%

2.20 1.20

1.05

Hexane 4

C6H

14

1.20

7.40

2.10 1.15

1.00

Hydrogen

H

2

4.00

75.60

1.00

Isobutane

C4H

10

1.50

8.40

1.50 0.80

0.75

Isobutylene

C4H

8

1.60

10.00

2.20 1.20

1.05

Isopropanol

C3H8O

2.15

13.50

1.60 0.85

0.80

Kerosene (JP-4)

C10-C

16

0.70

5.00

5.00 2.65

2.40

Methyl methacrylate

C5H8O

2

2.10

12.50

2.25 1.20

1.10

Methane

CH

4

5.00

15.00

1.00

Methanol (methyl

alcohol )

CH3OH

5.50

44.00

1.40

1.15

0.75

0.70

Naphtha

mixture

0.90

5.90%

3.50 1.85

1.70

Nonane

C9H

20

0.70

5.60

4.40 2.35

2.10

Octane

C8H

18

1.00

6.00

2.70 1.45

1.30

Ethylene oxide

(epoxyethane)

C2H4O

2.60

100

2.10

1.70

1.15

1.00

Propylene oxide

(epoxypropane)

C3H6O

1.90

37.00

2.35

1.90

1.25

1.15

Pentane

C5H

12

1.40

8.00

2.10 1.15

1.00

Propane

C3H

8

2.00

9.5

1.55 0.85

0.75

Propylene

C3H

6

2.00

11.70

1.65 0.90

0.80

Page 27

8 – Technical Specifications

23

Gas

Molecular

formula

LEL

(% v/v)

UEL

(% v/v)

CH4

coef.

H2

coef.

C4H10

coef.

C5H12

coef.

Styrene (vinyl

benzene)

C8H

8

1.1

8.00

6.30 3.35

3.00

Premium unleaded

gasoline (95)

-

1.10

~6.0

1.80 0.95

0.90

Toluene

C7H

8

1.20 7 4.00 2.15

1.90

Turpentine oil

-

0.8

6.0

3.50 1.85

1.70

Triethylamine

C6H15N

1.20 8 2.05 1.10

1.00

White spirit

mixture

1.10

6.50

3.50 1.85

1.70

Xylene

C8H

10

1.00

7.60

4.00 2.15

1.90

Items in gray: recommended gas for calibrating the detector.

Example

Calibration of an “acetone” detector using a calibration gas with 1% butane

Value to be displayed:

1% (injected butane) x 100 x 0.90 (butane/acetone coefficient) = 60% LEL

1.5% (butane LEL)

Note:

■ LELs vary according to the source.

■ Coefficients are accurate to ± 15%.

Page 28

8 – Technical Specifications

24

Page 29

9 – EU Declaration of Conformity

25

| EU Declaration of Conformity

Page 30

9 – EU Declaration of Conformity

26

Page 31

10 – Special instructions for use in explosive atmospheres

and fonctional safety

27

| Special instructions for use in

explosive atmospheres and

fonctional safety

General comments

OLCT 20 gas detectors comply with the requirements of ATEX 2014/34/UE

European Directive relating to explosive Dust and Gas atmospheres.

The information given in the following sections should be respected and taken

into account by the manager of the site where the equipment is installed. With

respect to requirements for improving the safety and health protection of

workers potentially at risk from explosive atmospheres, please refer to ATEX

1999/92/CE European Directive.

Warnings

Do not open when energized. After de-energizing, delay 2 minutes before

opening. Read instructions notice (cable glands).

Requirements for use in dust explosive atmospheres

For the equipment installed in dust explosive atmosphere, user shall ensure a

sufficient cleaning to prevent dust accumulation on the device. The maximum

permissible thickness of a dust layer must be less than 5 mm.

Cable entries

Cable glands and other wiring accessories (plugs, adaptors, etc.) shall be “db”

certified for use in gas explosive atmospheres and “tb” for use in dust explosive

atmospheres. They must be at least IP66 and of M20x1.5 6g or M25x1.5 6g

types in accordance with ISO965-1 and ISO965-3 standards. Minimum depth of

engagement must be 5 threads and installation must be done in accordance

with current version of EN 60079-14 and eventually with any local or national

additional requirements that may apply in the country of installation.

The cables should be suitable for use at a temperature equal to or greater than

80°C.

Page 32

10 – Special instructions for use in explosive atmospheres and

fonctional safety

28

Threaded joints

Threaded joints have different values than those specified in EN60079-1

standard. Oldham does not allow the repair of the threaded joints and shall not

be held responsible for any damage to the equipment or for any physical injury

or death resulting from any product modification.

The threaded joints on the OLCT 20 may be lubricated to ensure protection

against explosions. Only non-hardening lubricants or non-corrosive agents

without volatile solvents may be used. Warning: silicone-based lubricants are

strictly prohibited since they contaminate some of the gas sensing elements

used in the OLCT 20.

Limitations of use

Gas detection cells have certain limitations that shall be known and understood

by the user.

Overange and exposition to specific components

■ A bump test and/or a calibration is recommended each time the detector has

been exposed to high gas concentration and moreover if the detector went

to overange condition.

■ Vapors from silicone or sulfur compounds can affect the catalytic sensor and

thereby distort the measurements. If the sensors have been exposed to

these types of compounds, an inspection or calibration must be performed.

■ High concentration of organic solvents (e.g. alcohols, aromatic solvents,

etc.) or exposure to gas concentration above the measuring range can

damage electrochemical sensors. If sensors have been exposed to such

condition, a bump test or calibration must be then performed.

■ In the event of high levels of Carbon Dioxide (CO2 > 1% vol.),

electrochemical Oxygen (O2) sensors can slightly overestimate the actual

concentration of oxygen by 0.1 to 0.5% volume.

Operation under low oxygen levels

■ If an electrochemical detector sensor is used in an atmosphere comprising

less than 1% oxygen for over one hour, the measurement may be an

underestimate.

■ If a thermocatalytic detector sensor is used in an atmosphere comprising

less than 10% oxygen, the measurement may be an underestimate.

■ If a semiconductor detector sensor is used in an atmosphere comprising less

than 18% oxygen, the measurement may be an underestimate.

Installation and calibration

■ The detector will be installed with the sensor cell pointing downwards

■ The detector should be calibrated with the gas to be measured. With respect

to combustible gases only, and in the event it is impossible to calibrate with

the targeted gas, see tables on pages 21 and further for recommended

calibration gas and cross gas interference.

Page 33

10 – Special instructions for use in explosive atmospheres and

fonctional safety

29

Transfer curve for OLCT20 gas detectors

The curve below gives the transmitter output current as a function of gas

concentration. In the event that the user connects the transmitter to a nonOldham central controller, the user must ensure that the transfer curve is

compatible with the equipment's input characteristics to correctly interpret the

data coming in from the transmitter. Similarly, the central controller must

provide sufficient voltage to compensate for any voltage drop caused by the

cable.

Marking

Safety relevant parameters:

OLC 20d and OLC 20d HT

• Maximum supply voltage: 2,8 Vdc

• Maximum supply current: 400 mA

• Maximum power: 0,8 W

OLCT 20d

• Maximum input voltage: 30 Vdc

• Maximum input current: 100 mA

OLCT 20i

OLC 20d detector

OLDHAM SAS

62027, ARRAS France

OLC20d

CE0080

INERIS 01ATEX0004X

II 2 G D

Ex db IIC T6 Gb

Ex tb IIIC T85°C Db

T.Amb : -20°C to 70°C

% range

46

Page 34

10 – Special instructions for use in explosive atmospheres and

fonctional safety

30

WARNING: Do not open when energized. Read user manual (cable entry).

OLC 20d HT detector

OLDHAM SAS

62027, ARRAS France

OLC20d HT

CE0080

INERIS 01ATEX0004X

II 2 G D

Ex db IIC T* Gb

Ex tb IIIC T* Db

T.Amb : -20°C to T* °C

(*) T4 for T

amb

up to +110°C, T3 for T

amb

up to +180°C, T2 for T

amb

up to 200°C

WARNING: Do not open when energized. Read user manual (cable glands).

OLCT 20d detector

OLDHAM SAS

62027, ARRAS France

OLCT20d

CE0080

INERIS 01ATEX0004X

II 2 G D

Ex db IIC T6 Gb

Ex tb IIIC T85°C Db

T.Amb : -20°C to 70°C

WARNING: Do not open when energized. Read user manual (cable entry).

OLCT 20i detector

OLDHAM SAS

62027, ARRAS France

OLCT20i

CE0080

INERIS 01ATEX0004X

II 1 G D

Ex ia IIC T4 Ga

Ex ia IIIC T135°C Da

T.Amb : -20°C to 70°C

WARNING: Read user manual (cable entry).

Page 35

10 – Special instructions for use in explosive atmospheres and

fonctional safety

31

OLCT 20i detector (for mine)

OLDHAM SAS

62027, ARRAS France

OLCT20i

CE0080

INERIS 01ATEX0004X

I M1

Ex ia I Ma

T.Amb : -20°C to 70°C

WARNING: Read user manual (cable entry).

Page 36

contact info : gasandflamedetection@mmm.com

The Fixed Gas Detection Experts

EUROPEAN PLANT AND OFFICES

Z.I. Est – rue Orfila CS 20417 – 62027 Arras Cedex FRANCE

Tél: +33 (0)3 21 60 80 80 – Fax: +33 (0)3 21 60 80 00

Website: https:/gasdetection.3m.com

AMERICAS

Tel: +1-713-559-9280

Fax: +1-281-292-2860

ASIA PACIFIC

Tel: +86-21-3127-6373

Fax: +86-21-3127-6365

EUROPE

Tel: +33-321-608-080

Fax: +33-321-608-000

Loading...

Loading...