Page 1

User Manual

OLC 10

OLCT 10

Analog

Gas Detector

Part Number : NPO10GB

Revision : H.0

The Fixed Gas Detection Experts

Page 2

2

Page 3

GAS DETECTION

We are delighted that you have chosen an OLDHAM instrument and would like to thank you for your

choice.

We have taken all the necessary measures to ensure that your instrument provides total satisfaction.

Now it is important to read this document carefully.

E X T E N T O F R E S P O N S I B I L I T Y

* OLDHAM declines its responsibility towards any person for material damage, physical injury or death resulting

wholly or partly from inappropriate use, installation or storage of its equipment resulting from failure to observe

instructions and warnings and/or standards and regulations in force.

* OLDHAM neither supports nor authorises any company, physical or moral person to assume responsibility on

behalf of OLDHAM, even if it is involved in the sale of OLDHAM products.

* OLDHAM cannot be held responsible for direct or indirect damage or be required to pay direct or indirect

compensation resulting from the sale or use of any of its products IF THESE PRODUCTS HAVE NOT BEEN

DEFINED AND CHOSEN BY OLDHAM FOR THEIR SPECIFIC USE.

C L A U S E S C O N C E R N I N G P R O P E R T Y

* Drawings, plans, specifications and information included in this document contain confidential information that is

the property of OLDHAM.

* None of this information may be reproduced, copied, divulged or translated, by physical, electronic or any other

means, nor used as the basis for the manufacture or sale of OLDHAM equipment or for any other reasons without

prior consent from OLDHAM.

W A R N I N G S

* This document is not contractually binding. In the interests of its customers, OLDHAM reserves to modify the

technical specifications of its equipment without notice, in order to improve its performance.

* READ THIS MANUAL CAREFULLY BEFORE FIRST USE OF THE EQUIPMENT: this manual must be

read by any person who is or will be responsible for using, maintaining or repairing this equipment.

* This equipment will only provide the announced performance levels if it is used, maintained and repaired

according to OLDHAM directives, by OLDHAM personnel or by personnel approved by OLDHAM.

G U A R A N T E E

2 years guarantee in normal conditions of use on parts and technical labour, return in our workshops, excluding

consumables (sensors, filters, etc.).

Page 4

4

Page 5

TABLE OF CONTENTS

I. PRESENTATION OF DIFFERENT VERSIONS................................................................. 7

Different versions available .......................................................................................................... 7

II. MECHANICAL INSTALLATION OF DIFFERENT VERSIONS, DIMENSIONS AND

MOUNTING ............................................................................................................................. 7

III. ELECTRICAL INSTALLATION OF DIFFERENT VERSIONS ...................................... 9

1. Connection of OLC 10, OLCT 10 EXPLO or OLCT 10 SC (Semi-Conductor) to a

controller for combustible gas detection: ............................................................................... 9

2. Connection of two OLC 10 TWIN to a controller ............................................................... 10

3. Connection of two OLCT 10 TOX (maximum 5) to a controller for detection of the same

toxic gas ............................................................................................................................... 11

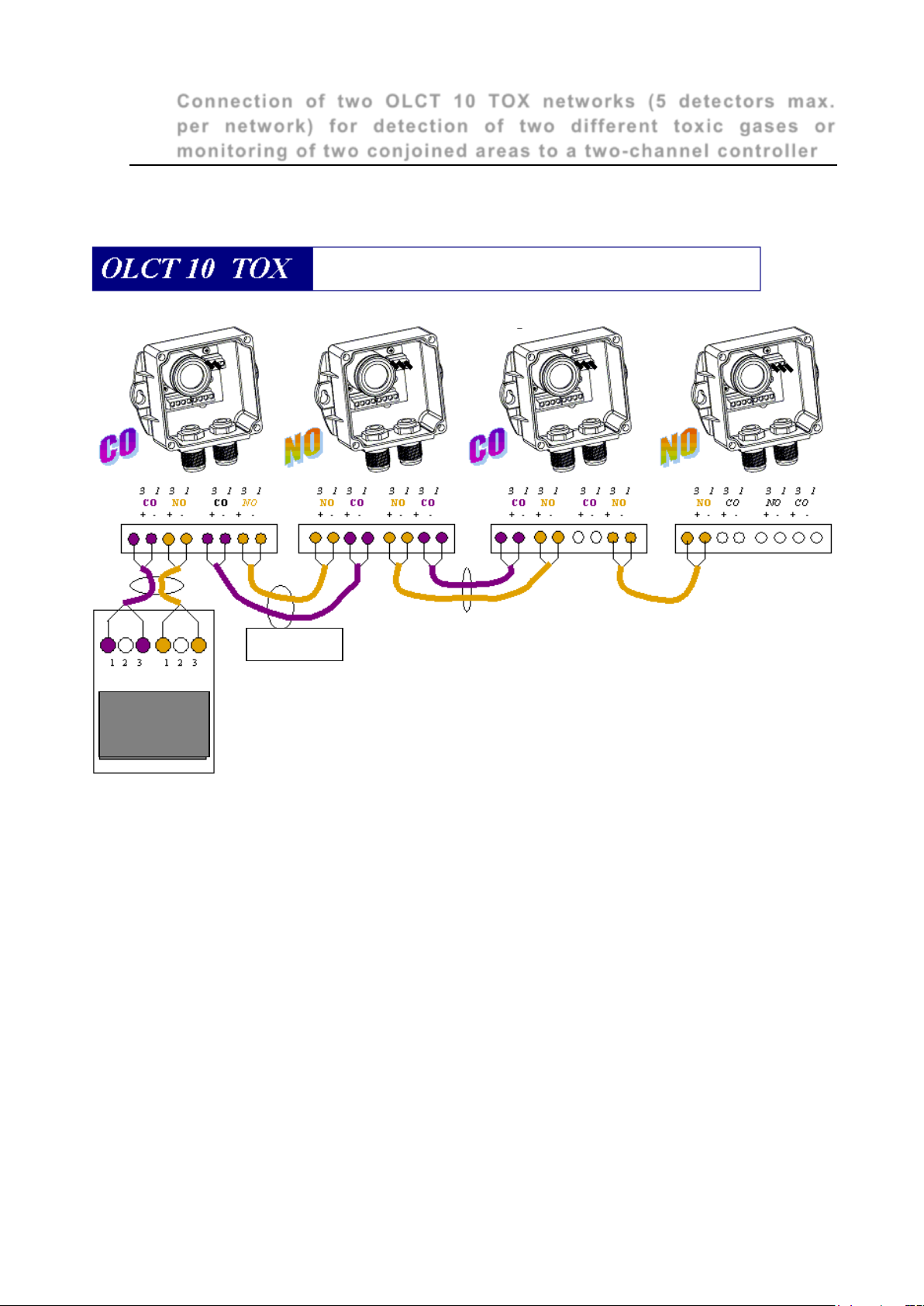

4. Connection of two OLCT 10 TOX networks (5 detectors max. per network) for detection

of two different toxic gases or monitoring of two conjoined areas to a two-channel

controller .............................................................................................................................. 12

IV. MAINTENANCE.................................................................................................................... 13

1. Periodic maintenance with an OLC 10 detector (comb. gas) .............................................. 13

2. Periodic maintenance with an OLC 10 TWIN transmitter (comb. gas) .............................. 13

3. Periodic maintenance with an OLCT 10 transmitter (comb. or toxic gas) .......................... 13

4. Periodic maintenance with several OLCT 10 transmitters for toxic gas ............................. 15

5. Sensor replacement .............................................................................................................. 15

6. Scrapping ............................................................................................................................. 15

V. TECHNICAL SPECIFICATIONS ....................................................................................... 17

1. TECHNICAL SPECIFICATIONS - OLC 10 / OLC 10 Twin ............................................ 17

2. TECHNICAL SPECIFICATIONS - OLCT 10 Explo Transmitter ..................................... 18

3. TECHNICAL SPECIFICATIONS - OLCT 10 CO Transmitter ......................................... 19

4. TECHNICAL SPECIFICATIONS - OLCT 10 SC Transmitter .......................................... 20

5. TECHNICAL SPECIFICATIONS - OLCT 10 NO Transmitter ......................................... 21

6. TECHNICAL SPECIFICATIONS - OLCT 10 NO2 Transmitter ....................................... 22

VI. DETAIL SPECIFICATIONS FOR USE IN EXPLOSIVE ATMOSPHERES IN

ACCORDANCE WITH THE ATEX 94/9/CE EUROPEAN DIRECTIVE...................... 23

1. Specifications for installation in ATEX Zone 2G ............................................................... 23

2. Metrological specifications for OLC 10 combustible gas detector ..................................... 23

2.1. Special precautions ........................................................................................................ 23

2.2. Reactions to other combustible gases ............................................................................ 23

3. MARKING .......................................................................................................................... 24

3.1. Version OLC 10 / OLC 10 Twin..................................................................................... 24

3.2. Version OLCT 10 ........................................................................................................... 24

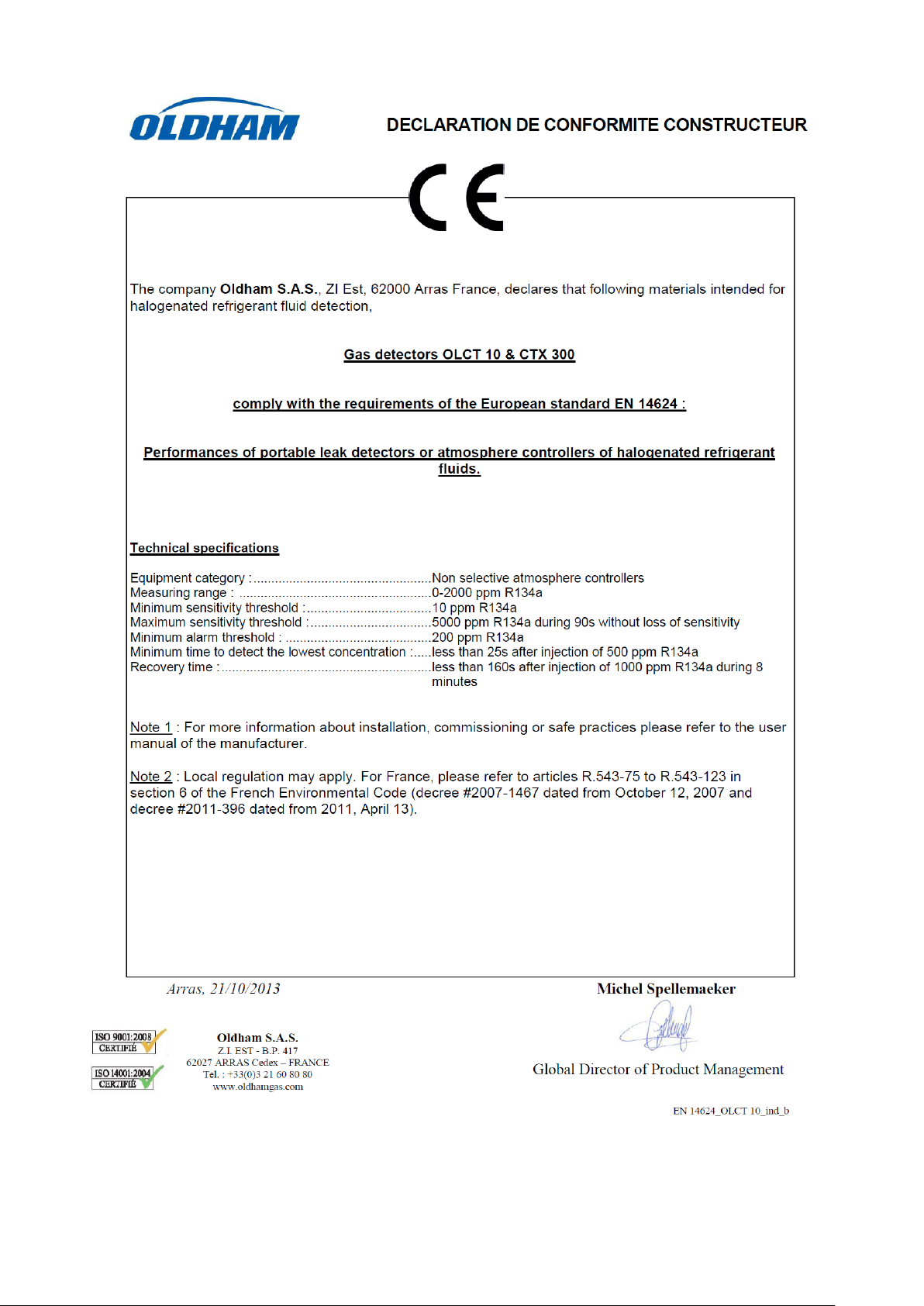

VII. DECLARATIONS OF CONFORMITY .............................................................................. 25

Page 6

6

Page 7

104 mm

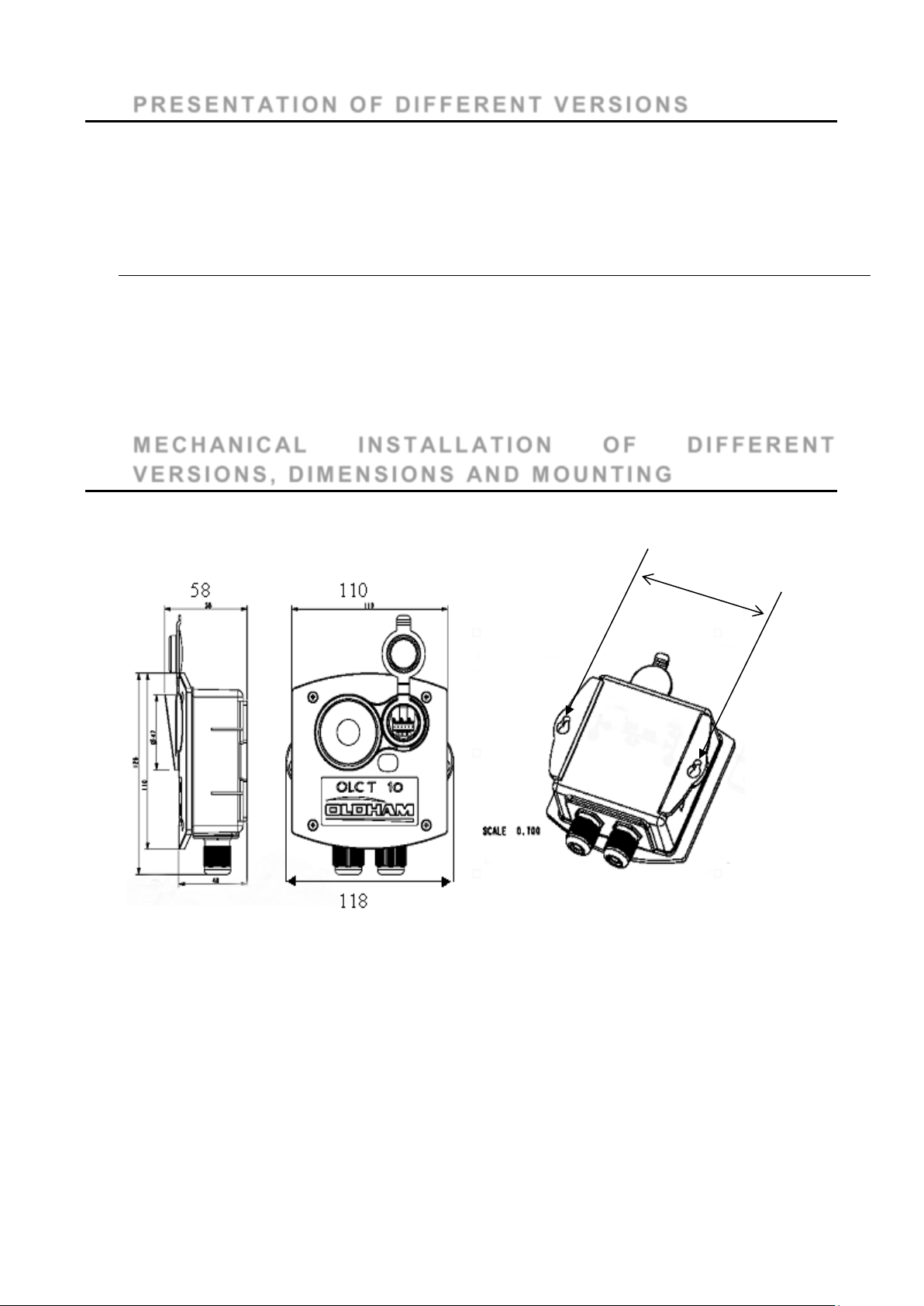

I. PRESENTATION OF DIFFERENT VERSIONS

The OLC 10, OLC 10 TWIN and OLCT 10 EXPLO combustible gas detectors are detectors fitted with catalytic

sensors and intended for use in boiler rooms and parking lots.

The OLCT 10 TOX gas detectors are 4-20mA transmitters equipped with electrochemical sensors and especially

designed to detect toxic gases in commercial and light industrial applications (parking lots, boiler room, etc).

Different versions available

- OLC 10: combustible gas

- OLC 10 TWIN: combustible gas

- OLCT 10 EXPLO: combustible gas (transmitter version, 4-20 mA output)

- OLCT 10 TOX: toxic gas (transmitter version, 4-20 mA output)

II. MECHANICAL INSTALL ATION OF DIFFERENT

VERSIONS, DIMENSIONS AND MOUNTING

The OLC/OLCT 10 gas detectors-transmitters are mounted vertically with the cable entries positioned downwards.

Drill two holes 104 mm apart on the base to mount the units.

Page 8

8

Page 9

1 2 3

1 2 3

e.g., CONTROLLER MX 15

Connect the 3 wires based on the

Connect the 3 wires based on the

1= signal*

1

OLC 10

OLCT 10

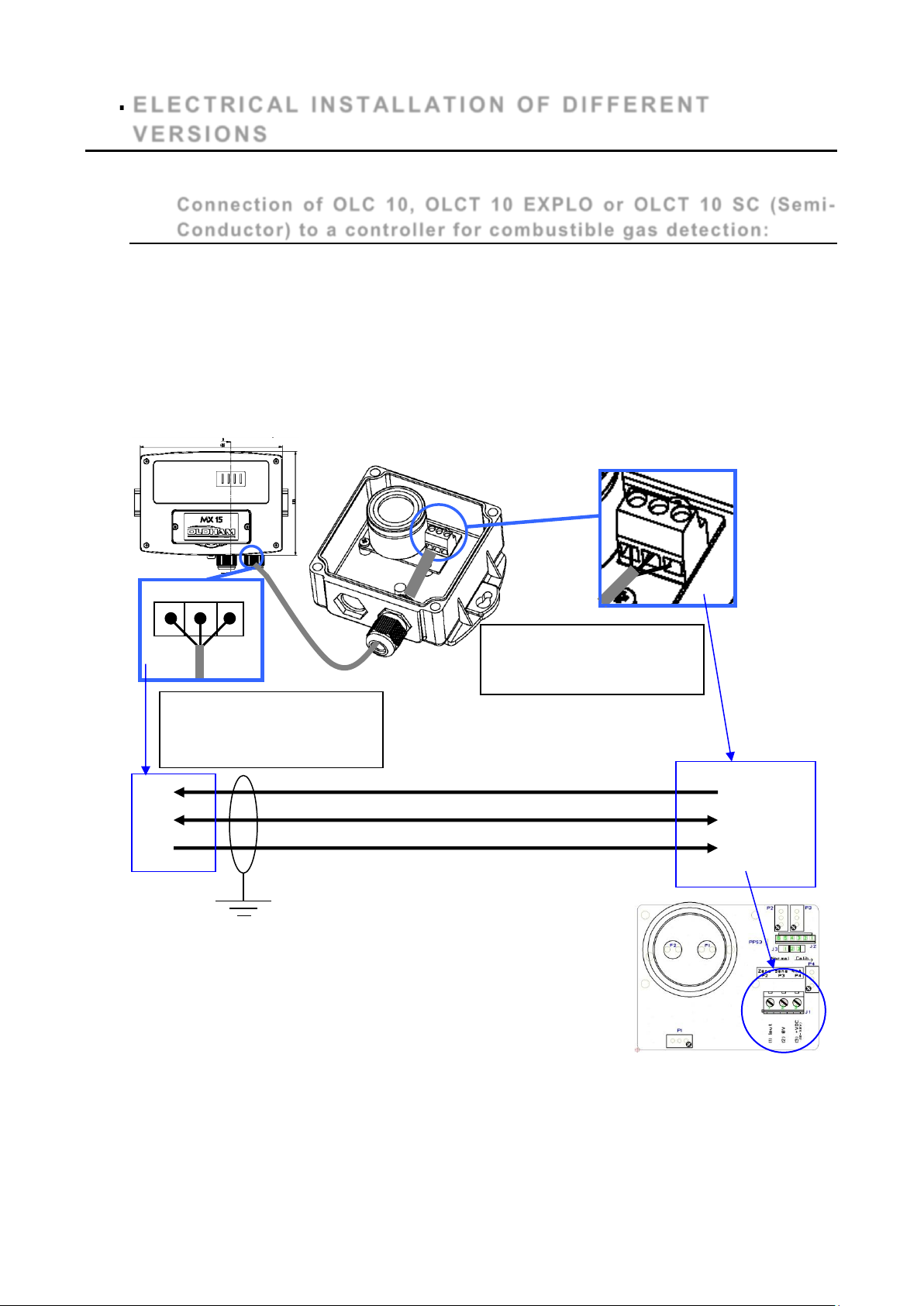

III. ELECTRICAL INSTALLATION OF DIFFERENT

VERSIONS

1. Connection of OLC 10, OLCT 10 EXPLO or OLCT 10 SC (SemiConductor) to a controller for combustible gas detection:

Notes: - The controller configuration will be different based upon the use of an OLC 10 or OLCT 10

- Cable to be used: 3 conductors, 3x1 mm² LiYCY type

corresponding numbering on the

sensor.

2

3

*analog signal 4-20 mA (I out) on OLCT 10.

corresponding numbering on the

controller.

2= -

3= +

EXPLO

Page 10

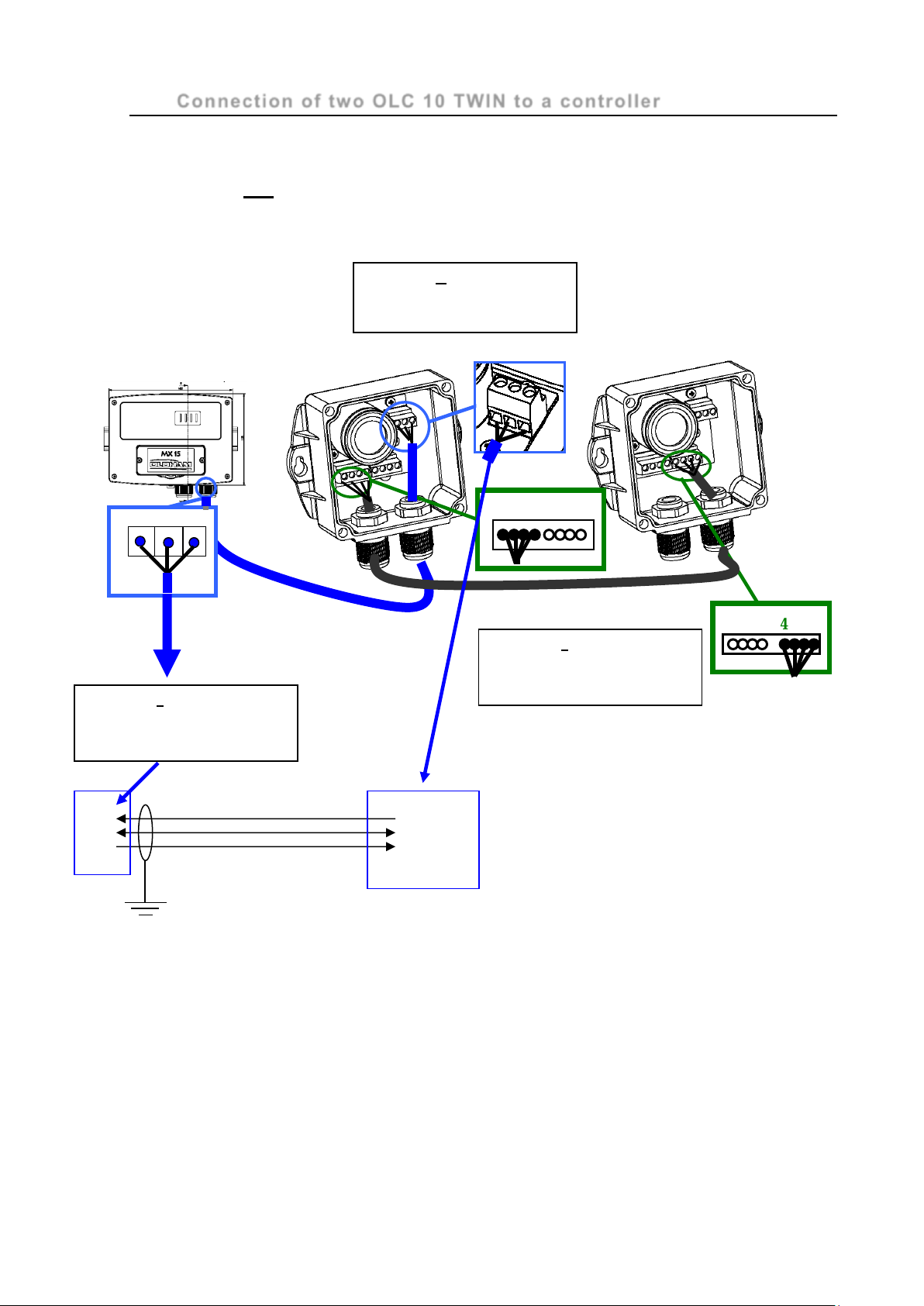

2. Connection of two OLC 10 TWIN to a controller

Connect the 3 wires based on the

Connect the 3 wires based on the

Connect the 4 wires based on the

1

3

1= signal

3= +

IN

4 3 2 1

MX 15 CONTROLLER

OUT

4 3 2 1

IN

OUT

4 3 2 1

4 3 2 1

1 2 3

Cable to be used: 3 and 4 core cable, 3x1 mm² and 4x1 mm² LiYCY type

corresponding numbering on the

controller.

corresponding numbering on the

first sensor.

corresponding numbering on the

previous and the following sensor.

2

2= -

10

Page 11

IN

1 2 3

IN OUT

CONTROLLER MX15 for example

1 3

3 1 3 1 3 1 3 1

Connect the 2 wires based on the

Connect the 2 wires based on the

Connect the 2 wires based on the

1

3 1 3 1 3

1= Iout

OLCT 10 TOX

3 1 3 1

3. Connection of two OLCT 10 TOX (maximum 5) to a controller

for detection of the same toxic ga s

Cable to be used: One pair (0.75 mm²) screened cable

corresponding numbering on the

first sensor.

corresponding numbering on the

controller.

corresponding numbering on the following

sensor.

3= +Vdc

Note: the free terminals allow the connection of another network of OLCT 10 TOX.

COMMENTS:

- the number of OLCT 10 toxic gas detectors shall be configured on the controller,

- the signal read by the controller is the average of the “n” detectors. As a result, a signal fault may not be

detected.

In the event that 2 networks are used, it is cost-effective to use a single cable (2 pairs) subject to compliance with

wiring as follows:

Page 12

4. Connection of two OLCT 10 TOX networks (5 detectors max.

Example: one zone, 2 gases

Detector 1

Detector 2

Detector 3

Detector 4

Cable with 4

wires

Channel 1

Channel 2

MX 32

per network) for detection of two different toxic ga ses or

monitoring of two conjoined areas to a two-channel controller

Cable to be used: Two pairscreened cable (0.75 mm²)

controller

Controller with 2 channels at minimum

Information for this example:

- channel 1 is a channel connected to two sensors for detection of CO

- channel 2 is a channel connected to two sensors for detection of NO

- detector 1 (CO) also acts as junction box for detector 2 (NO)

- detector 2 (NO) also acts as junction box for detector 3 (CO)

- detector 3 (CO) also acts as junction box for detector 4 (NO)

12

Page 13

IV. MAINTENANCE

Caution: The actions described in this paragraph are intended for authorized and trained individuals who are

likely to question the detection safety.

Gas detection instruments are potential life-saving devices. Recognizing this fact, OLDHAM recommends that a

functional “bump” test be performed on every fixed gas-monitoring instrument as part of a regular maintenance

program. A functional test is defined as a brief exposure of the detector to a concentration of gas(es) in excess of the

lowest alarm set-point for each sensor for the purpose of verifying sensor and alarm operation and is not intended to be

a measure of the accuracy of the instrument.

Bump test frequency depends on application, field conditions, exposure to gas, sensor technology, and environmental

conditions. For new installations it may be prudent to carry out bump tests frequently at first, increasing the time

intervals as confidence grows with experience in the installation concerned, on the basis of the maintenance record. The

maintenance test interval should not be more than 3 months.

If an instrument fails to operate properly during any functional “bump” test, a full instrument calibration should be

performed successfully prior to use. Calibration frequency will be based on bump tests results. However it cannot be

more than 12 months.

These recommendations are based on safe work procedures, industry best practises, and regulatory standards to ensure

worker safety. OLDHAM is not responsible for setting safety practices and policies.

1. Periodic maintenance with an OLC 10 detector (comb. gas)

- The “maintenance” position was selected on the controller in order to disable its relays (see manual of relevant

product)

Reminder: make sure the detector is in clean air - otherwise inject zero air on the detector (with calibration kit)

with a flow rate of 60 l/h, then wait for the stabilisation of measurement

- Perform the zero setting of the controller (see manual of relevant product)

- Now inject the calibration gas (flow rate 60l/h) into the OLC 10 sensor and wait for signal stabilisation on the

controller display

- If necessary, calibrate the sensitivity using the “S” potentiometer of the controller (see manual of relevant

product)

- Upon completion of calibration: wait for the “return to zero” on the controller display

Return to the “normal” mode of the controller (see manual of relevant product)-

2. Periodic maintenance with an OLC 10 TWIN transmitter (comb.

gas)

- The procedure is almost identical to point 1 (OLC 10), with the exception of sensitivity adjustment which is

performed on the OLC 10 TWIN detector that is less sensitive.

- To determine the least sensitive detector, inject gas on the two detectors, one after the other (wait for the signal

to read zero). The detector that gives the lowest measurement is the less sensitive.

3. Periodic maintenance with an OLCT 10 transmitter (comb. or

toxic gas)

- It is required that the kit provided by OLDHAM be used (P/N 6147872)

- Remove the end-cap that provides access to settings, located on the right side of the sensor

- Connect this kit on the male plug of the circuit, as indicated below:

Page 14

MAINTENANCE CONNECTOR WIRES:

ZERO (4mA) potentiometer SENSITIVITY (20mA) potentiometer

S Signal

+VDC

+ 4-20 mA

- 4-20 mA

Ref 2.5V

GND

V

voltmeter

CHANGER-OVER

Voltmeter

Read on the voltmeter 400mV for 4mA and 2000mV for 20mA

- +VDC/red = + power supply

- - 4-20 mA/blue = - of voltage, image of 4-20mA

- + 4-20 mA/green = + of voltage, image of 4-20mA

- S Signal /yellow = signal from 0mV to 1600mV for zero and sensitivity setting

- Ref 2.5 V/gray = zero reference for reading of signal from 0mV to 1600mV

- GND/black = electronic circuit ground.

- Toggle the changer-over (under the connector) on «CAL» position (to the right)

Caution: after 9 minutes the transmitter automatically returns to normal operation! (only version OLCT

10 explo)

Reminder: make sure the detector is in clean air - otherwise inject zero air or nitrogen on the sensor at a flow

rate of 60 l/h – and wait for the stabilisation of the measurement given by the voltmeter.

- Set the ZERO using the zero potentiometer to read 0 mV on the voltmeter

- Now inject the calibration gas (60l/h), wait for the signal stabilisation on the voltmeter

- If required, set the sensitivity using the “S” potentiometer to read 1,600mV for the full scale (corresponding to

20mA)

- Note: if you use a gas concentration lower than 100% of the scale, calculate (rule of three) and adjust to obtain

the corresponding value (from 0 to 1600 mV)

- Stop calibration gas injection (remove the calibration cup)

- Wait for the “return to zero” on the voltmeter

- Again toggle the changer-over to the normal position (to the left)

14

Page 15

PPS3

Notes regarding the OLCT 10 version for combustible gases:

- the transmitter controls an “ambiguity resolution” function: if the sensor detects a gas concentration over

100% LEL (20 mA), it will be locked on a signal of 23.2 mA acknowledgeable through power supply shut-off

or toggling of maintenance switch. The ambiguity resolution may be automatically acknowledged if the PPS3

points are short-circuited.

- Upon switching on, the output signal is set to 2mA during the 60-second stabilisation time.

4. Periodic maintenance with several OLCT 10 transmitters for

toxic gas

Use the procedure described in the previous paragraph. However:

- Start with the last transmitter in the loop in relation to the controller

- Calibrate each transmitter in the loop and end with the first

5. Sensor replacement

Sensor has to be replaced as a result of impracticable calibration or as a preventive measure.

Perform a new calibration after a sensor replacement.

6. Scrapping

Concerning the conservation, of the protection and the improvement of the quality of the

environment, as well as for the protection of the health of the persons and the careful and

rational use of natural resources, OLCT 10 has to be the object of a selective collection for

the electronic equipment and cannot be scrapped with the normal domestic waste. The user

thus has the obligation to separate the OLCT 10 of the other waste so as to guarantee that it

is recycled in a sure way at the environmental level. For more details of the existing sites

of collection, contact the local administration or the distributor of this product.

Page 16

16

Page 17

V. TECHNICAL SPECIFICATIONS

1. TECHNICAL SPECIFICATIONS - OLC 10 / OLC 10 Twin

Combustible gas detector

Detection principle: Catalytic

Range: 0-100% LEL methane, propane or butane.

Output signal: Wheatstone bridge circuit

Power supply: Current through Oldham MX controllers

Connections: OLC 10 Version:

- 3-wire terminal block, maximum distance 300 m in 1.5 mm² with

MX 15 controller

OLC 10 Twin Version (two sensors on channel input MX 15)

Dimensions: Width 118 mm, Height 157 mm, Depth 60 mm

Material: Plastic

Protection: IP65

Storage: 6 months safe from air 0°C<T<20°C +10%<RH<60%

Estimated lifetime: > 36 months

Temperature range: -10°C to + 45°C

Humidity range: 0% RH to 95% RH

Pressure range: 1 bar ± 20%

Linearity deviation: from 0 and 70% LEL: 1% LEL CH4

from 70 and 100% LEL: 7% LEL CH4

Long-term drift Zero < 10% LEL/year

under normal operating Sensitivity < 20 % of the measured value/year

conditions:

Humidity impact: ± 5 % of relative sensitivity

(10 to 90% RH) at 40°C

Response time: T50 <10 sec, T90<20 sec

Certification: Electromagnetic Compatibility EN 50270

- 1 cable gland M16: cable diameter 4 to 8 mm

- 1 3-wire terminal block to the controller

- 1 4-wire terminal block to the second sensor

- maximum total distance 300 m in 1.5 mm² with MX 15 controller

- 2 cable glands M16: cable diameter 4 to 8 mm

Explosive Atmospheres: II 3 G / Ex nA IIC T6

Page 18

2. TECHNICAL SPECIFICATIONS - OLCT 10 Explo Transmitter

Combustible gas transmitter

Detection principle: Catalytic

Range: 0-100% LEL methane, propane or butane.

Signal output: 4 – 20 mA, default 0.5 mA or 23.2 mA

Ambiguity resolution: signal sets at 23.2 mA if measurement 100% LEL

Acquit by power cycling the transmitter

Ambiguity resolution may be deleted through point of programming

Settings: Local through Zero and Sensitivity potentiometers

Position Maintenance 2 mA

6-pin connector for gas measuring and current image

Power supply: 15 to 30 V dc

Consumption: maximum 100 mA

Cable length: according to the controller

Load resistance: 300 ohms

Connection: 3-wire terminal block, 2 wires for power supply, 1 wire for signal

Dimensions: Width 118 mm, Height 157 mm, Depth 60 mm

Material: Plastic

Protection: IP65

Storage: 0°C<T<30°C

Estimated lifetime: > 36 months

Temperature range: -10 to + 4°C

Humidity range: 0% RH to 95% RH

Pressure range: 1 bar ± 20%

Linearity deviation: from 0 and 70% LEL: 1% LEL CH4

Temperature drift: < 5% LEL Methane or < 20% of indication

(-10°C + 40°C)

Long-term drift under Zero point < 10% LEL methane

normal operating conditions: Sensitivity < 20% of measured value/year

Humidity impact: ± 5% of relative sensitivity

(10 to 90% RH) at 40°C

Response time: T50 <10 sec, T90<20 sec

Certification: Electromagnetic Compatibility EN 50270

(100-ohm shunt)

1 cable gland M16: cable diameter 4 to 8 mm

from 70 and 100% LEL: 7% LEL CH4

Explosive Atmospheres: II 3 G / Ex nA IIC T4

18

Page 19

3. TECHNICAL SPECIFICATIONS - OLCT 10 CO Transmitter

Detection principle: Electrochemical sensor

Range: 0-300 ppm CO

Signal output: 4 – 20 mA

Settings: Local through Zero and Sensitivity potentiometers

Position Maintenance 2 mA

6-pin connector for gas measuring and current image

Power supply: 15 to 30 VDC

Consumption: maximum 30 mA

Cable length: according to the controller

Connection: 1 terminal block with 2 input wires, 1 terminal block with 2 output wires

If cable with a gas signal pair: 1 terminal block with 2 input wires

2 cable gland M16: cable diameter 4 to 8 mm

Dimensions: Width 118 mm, Height 157 mm, Depth 60 mm

Material: Plastic

Protection: IP65

Storage: 6 months safe from air 0°C<T<20°C +10%<RH<60%

Estimated lifetime: > 24 months

Temperature range: -10 to + 45°C

Humidity range: 15% RH to 90% RH

Pressure range: 1 bar ± 20%

Linearity deviation: 0 - 100 ppm ± 3 ppm

Temperature drift: < 5 ppm or < 5 % of the indication

(-10°C + 40°C)

Long-term drift under

normal operating conditions: Sensitivity: < 10% of measured value/year

Response time: T50 <15 sec, T90<30 sec

Certification: Electromagnetic Compatibility EN 50270

(100-ohm shunt)

with copy on 1 terminal with 2 wires

100 – 1,000 ppm ± 4% relative

Explosive Atmospheres: II 3 G / Ex nA IIC T4

Page 20

4. TECHNICAL SPECIFICATIONS - OLCT 10 SC Transmitter

Detection principle: semi-conductor sensor

Range: 0-2000 ppm R134A, R22

Signal output: 4 – 20 mA

Settings: Local through Zero and Sensitivity potentiometers

Position Maintenance 2 mA

4-pin connector for gas measuring and current image

(100-ohm shunt)

Power supply: 15 to 30 VDC

Consumption: maximum 100 mA

Cable length: according to the controller

Connection: 3-wire terminal block, 2 wires for power supply, 1 wire for signal

1 cable gland M16: cable diameter 4 to 8 mm

Dimensions: Width 118 mm, Height 157 mm, Depth 60 mm

Material: Plastic

Protection: IP65

Storage: 6 months safe from air 0°C<T<30°C

Estimated lifetime: > 24 months

Temperature range: -10 to + 60°C

Humidity range: 20% RH to 90% RH

Pressure range: 1 bar ± 10%

Linearity deviation: 0 - 10 ppm ± 0.3 ppm

10 – 30 ppm ± 5% relative

Temperature drift: < 0.4 ppm or < 20 % of the indication

(-10°C + 40°C)

Long-term drift under

normal operating conditions: Sensitivity: < 20% of measured value/year

Response time: T50< 51s (R22)

T50 <30 sec, (R134a)

Minimum sensitivity threshold 10 ppm

Maximum sensitivity threshold 5000 ppm during 90s without sensitivity loss

Recommended Alarm Threshold 200 ppm

Minimum time to detect the lowest concentration less than 25s after injection of 500 ppm R134A

Recovery time less than 160s after injection of 8 min of 1000 ppm R134A

Certification: Electromagnetic Compatibility EN 50270

In accordance with EN 14624 certification

20

Page 21

5. TECHNICAL SPECIFICATIONS - OLCT 10 NO Transmitter

Detection principle: electrochemical sensor

Range: 0-100 ppm NO

Signal output: 4 – 20 mA

Settings: local through Zero and Sensitivity potentiometers

Position Maintenance 2 mA

4-pin connector for gas measuring and current image

(100-ohm shunt)

Power supply: 15 to 30 VDC

Consumption: maximum 30 mA

Cable length: according to the controller

Connection: 1 terminal block with 2 input wires, 1 terminal with 2 output wires

If cable with other gas signal pair: 1 terminal block with 2 input wires

with copy on 1 terminal block with 2 wires

2 cable glands M16: cable diameter 4 to 8 mm

Dimensions: Width 118 mm, Height 157 mm, Depth 60 mm

Material: Plastic

Protection: IP65

Storage: 6 months safe from air 0°C<T<20°C +10%<RH<60%

Estimated lifetime: > 36 months

Temperature range: -10 to + 45°C

Humidity range: 15% RH to 90% RH

Pressure range: 1 bar ± 20%

Linearity deviation: 0 - 10 ppm ± 3 ppm

10 - 100 ppm ± 5 % relative

Temperature drift: < 10 ppm or < 10% of the indication

(-10°C + 40°C)

Long-term drift under

normal operating conditions: Sensitivity: < 20% of measured value/year

Response time: T90 < 120 sec

Certification: Electromagnetic Compatibility EN 50270

Explosive Atmospheres: II 3 G / Ex nA IIC T4

Page 22

6. TECHNICAL SPECIFICATIONS - OLCT 10 NO2 Transmitter

Detection principle: electrochemical sensor

Range: 0-30 ppm NO2

Signal output: 4 – 20 mA

Settings: local through Zero and Sensitivity potentiometers

Position Maintenance 2 mA

4-pin connector for gas measuring and current image

(100-ohm shunt)

Power supply: 15 to 30 VDC

Consumption: 30 mA max

Cable length: according to the controller

Connection: 1 terminal block with 2 input wires, 1 terminal block with 2 output wires

If cable with other gas signal pair: 1 terminal block 2 input wires

with copy on 1 terminal block with 2 wires

2 cable glands M16: cable diameter 4 to 8 mm

Dimensions: Width 118 mm, Height 157 mm, Depth 60 mm

Material: Plastic

Protection: IP65

Storage: 6 months safe from air 0°C<T<20°C +10%<RH<60%

Estimated lifetime: > 24 months

Temperature range: -10 to + 50°C

Humidity range: 15% RH to 90% RH

Pressure range: 1 bar ± 20%

Linearity deviation: 0 - 10 ppm ± 0.3 ppm

10 - 30 ppm ± 5 % relative

Temperature drift: < 0.4 ppm or < 20% of indication

(-10°C + 40°C)

Long-term drift under

normal operating conditions: Sensitivity: < 20% of measured value/year

Response time: T90 < 60 sec

Certification: Electromagnetic Compatibility EN 50270

Explosive Atmospheres: II 3 G / Ex nA IIC T4

22

Page 23

VI. DETAIL SPECIFICATIONS FOR USE IN EXPLOSIVE

ATMOSPHERES IN ACCORDANCE WITH THE ATEX

94/9/CE EUROPEAN DIRECTIVE

The OLC 10 sensor complies with the requirements of the ATEX 94/9/CE European Directive regarding

explosive atmospheres.

The site manager where the equipment is installed should take into consideration and comply with the

information in the following paragraphs. Refer to the provisions of the ATEX 1999/92/CE European

Directive regarding the enhancement of safety and health of the workers exposed to explosive atmosphere

risks.

1. Specifications for installation in ATEX Zone 2G

The installation will be performed in accordance with existing standards, in particular EN 60079-14 and EN

60079-17 standards.

The detectors are designed for surface industries Group II, Category (3) G zone 2 for minimum and maximum

ambient temperatures from –25°C to + 60°C. They should not be exposed to mechanical vibrations.

The detectors are installed vertically (wall-mounted type) with the cable output downwards. An angle of over

45° from the vertical or a horizontal position (ceiling-mounted type) will result in measurement errors and will require a

recalibration of the detector.

2. Metrological specifications for OLC 10 combustible gas

detector

The OLC 10 combustible gas detector is compliant with the European standards EN 61779-1 and -4 for

methane (calibration gas), butane, propane and hydrogen (gas following response curves), when they are used with SV

4B, MX 15, MX 32, MX 42A, MX 43, MX 48, MX 52 OLDHAM controllers.

Note: the vibration tests based on EN 61779-4 paragraph 4.13 have not been conducted because they do not apply due

to the operating conditions of this type of detector.

2.1. Special precautions

Sensors are sensitive to some poisons that may cause their desensitisation: emanation of siliconized vapours

with concentrations > 10 ppm, chlorinated species or sulphur with concentrations > 100 ppm

The lack of oxygen (< 15% O2) or over-oxygenation (> 23% O2) may cause an underestimation or

overestimation of the measurement.

2.2. Reactions to other combustible gases

It is recommended to calibrate the detector with the gas to be measured. When the user wishes to calibrate it with

another gas than that detected and factory programmed, refer to the table below, using the recommended gas and

corresponding coefficient.

Page 24

Empirical

formula

LEL

LSE

Vapour

density

Coefficient

CH4

Coefficient

H2

Coefficient

But

Butane

C4H10

1.5%

8.5 % 2 1.75

1.25

1.0

Hydrogen

H2

4.0%

75.6%

0.069

1.25

1.0

0.8

Methane

CH4

5.0%

15.0%

0.55

1.0

0.75

0.55

Propane

C3H8

2.0%

9.5

1.6

1.5

1.1

0.85

Gas recommended for the calibration.

Table 1: COEFFICIENTS FOR CALIBRATION

Example (first line in the table): calibration of a “Acetone” detector with a calibration gas of 1% butane volume

Value to be displayed: 1% (injected butane) x 100 x 0.95 (butane/acetone coefficient) = 63% LEL

1.5% (LEL butane)

Note:

- LEL varies based on sources. Those reported here are required by European standard EN 50054.

- The coefficients are accurate at 15%

3. MARKING

3.1. Version OLC 10 / OLC 10 Twin

OLDHAM Arras

OLC 10 / OLC 10 TWIN

II 3G

Ex nA IIC T6

OSA 05ATEX0116

Caution: electrostatic loads. Rub or wipe with a damp cloth only.

Serial number, year of fabrication.

3.2. Version OLCT 10

OLDHAM Arras

OLCT 10

II 3G

Ex nA IIC T4

OSA 05ATEX0116

Caution: electrostatic loads. Rub or wipe with a damp cloth only.

Serial number, year of fabrication.

24

Page 25

VII. DECLARATIONS OF CONF ORMITY

Page 26

26

Page 27

Page 28

The Fixed Gas Detection Experts

EUROPEAN PLANT AND OFFICES

Z.I. Est – rue Orfila CS 20417 – 62027 Arras Cedex FRANCE

Tél: +33 (0)3 21 60 80 80 – Fax: +33 (0)3 21 60 80 00

Website: http://www.oldhamgas.com

AMERICAS

Tel: +1-713-559-9280

Fax: +1-281-292-2860

americas@oldhamgas.com

ASIA PACIFIC

Tel: +86-21-3127-6373

Fax: +86-21-3127-6365

sales@oldhamgas.com

EUROPE

Tel: +33-321-608-080

Fax: +33-321-608-000

info@oldhamgas.com

Loading...

Loading...