Page 1

USER MANUAL

OLC/OLCT 20

Part Number: NPO20GB

Revision: D.0

Gas Detector

The Fixed Gas Detection Experts

Page 2

2

GAS DETECTION

We are delighted that you have chosen an OLDHAM instrument and would like to thank you for your

choice.

We have taken all the necessary measures to ensure that your instrument provides total satisfaction.

Now it is important to read this document carefully.

EEXXTTEENNTT OOFF RREESSPPOONNSSIIBBIILLIITTYY

* OLDHAM declines its responsibility towards any person for material damage, physical injury or death resulting

wholly or partly from inappropriate use, installation or storage of its equipment resulting from failure to observe

instructions and warnings and/or standards and regulations in force.

* OLDHAM neither supports nor authorises any company, physical or moral person to assume responsibility on

behalf of OLDHAM, even if it is involved in the sale of OLDHAM products.

* OLDHAM cannot be held responsible for direct or indirect damage or be required to pay direct or indirect

compensation resulting from the sale or use of any of its products IF THESE PRODUCTS HAVE NOT BEEN

DEFINED AND CHOSEN BY OLDHAM FOR THEIR SPECIFIC USE.

CCLLAAUUSSEESS CCOONNCCEERRNNIINNGG PPRROOPPEERRTTYY

* Drawings, plans, specifications and information included in this document contain confidential information that is

the property of OLDHAM.

* None of this information may be reproduced, copied, divulged or translated, by physical, electronic or any other

means, nor used as the basis for the manufacture or sale of OLDHAM equipment or for any other reasons without

prior consent from OLDHAM.

WWAARRNNIINNGGSS

* This document is not contractually binding. In the interests of its customers, OLDHAM reserves to modify the

technical specifications of its equipment without notice, in order to improve its performance.

* READ THIS MANUAL CAREFULLY BEFORE FIRST USE OF THE EQUIPMENT: this manual must be

read by any person who is or will be responsible for using, maintaining or repairing this equipment.

* This equipment will only provide the announced performance levels if it is used, maintained and repaired

according to OLDHAM directives, by OLDHAM personnel or by personnel approved by OLDHAM.

GGUUAARRAANNTTEEEE

2 years guarantee in normal conditions of use on parts and technical labour, return in our workshops, excluding

consumables (sensors, filters, etc.)

Page 3

3

CONTENTS

1 Description ................................................................................................... 5

1.1 General .......................................................................................................................... 5

1.2 Main characteristics of the various versions ................................................................. 5

1.3 Mechanical installation of the various versions ............................................................ 6

2 Wiring arrangements .................................................................................. 7

2.1 3-Wire version (OLC 20d, OLCT 20d) ........................................................................ 7

2.2 2-wire versions (OLCT 20d) ......................................................................................... 7

2.3 2-wire Intrinsic Safety versions (OLCT 20i) ................................................................ 8

3 Maintenance ................................................................................................. 9

3.1 Detector OLC 20 ........................................................................................................... 9

3.1.1 Calibration ............................................................................................................... 9

3.1.2 Replacing a sensor on an OLC 20 ......................................................................... 10

3.2 Transmitters OLCT 20 ................................................................................................ 10

3.2.1 Calibration ............................................................................................................. 10

3.2.2 Calibration specifications ...................................................................................... 12

3.3 Replacing a sensor on OLCT 20 ................................................................................. 12

3.4 Disposal of OLC(T) 20 ............................................................................................... 12

4 Spare Parts ................................................................................................. 13

4.1 OLC 20 flameproof gas detector ................................................................................ 13

4.2 OLCT 20 flameproof gas detector .............................................................................. 13

4.3 OLCT 20 Intrinsic Safety detector .............................................................................. 14

5 Accessories ................................................................................................. 15

6 Technical characteristics of OLC 20 ....................................................... 17

7 Technical characteristics of OLCT 20..................................................... 17

8 Specific Instructions for use in Explosive Atmospheres according to

European Directive ATEX 94/9/EC ........................................................ 19

8.1 Specifications for mechanical and electrical installation in Classified Areas. ........... 19

8.1.1 Flameproof detectors (d) ....................................................................................... 19

8.1.2 Intrinsic safety detectors (i) OLCT 20 i ................................................................ 19

Page 4

4

8.2 Metrological specifications for explosive gas and oxygen measurement detectors ... 20

8.2.1 Technical Specifications and Special Instructions for explosive gas detectors .... 21

8.2.2 Technical Specifications and Special Instructions for Oxygen detectors ............. 25

8.3 Markings ..................................................................................................................... 26

8.3.1 Flameproof certified version: OLC 20d and OLCT 20 d ...................................... 26

8.3.2 Intrinsic safety version: OLCT 20 i ...................................................................... 26

9 Recommendations ..................................................................................... 27

10 EU Declaration of Conformity ................................................................. 29

Page 5

5

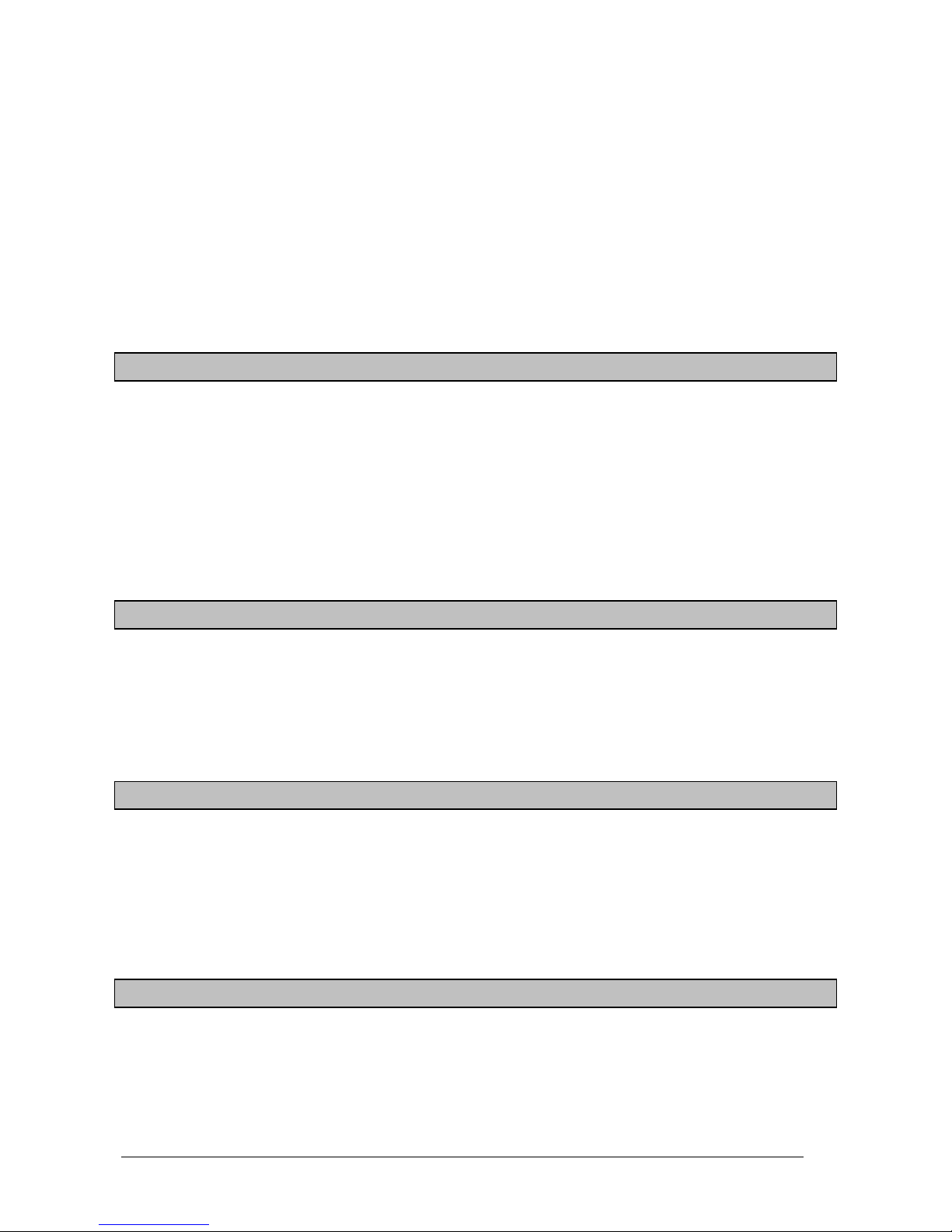

1 Description

1.1 General

OLC 20 gas detectors are catalytic type detectors intended for the detection of combustible

gases. They are flameproof certified (OLC 20d).

OLCT 20 gas detectors are 4-20 mA transmitters and are intended for the measurement of

combustible and toxic gases and oxygen. They are either flameproof certified (OLCT 20d)

or intrinsically safe certified (OLCT 20i).

OLC 20s and OLCT 20s are available in ¾ NPT or M25 screw fittings and are designed to

be attached on a junction box or any compatible generic transmitters.

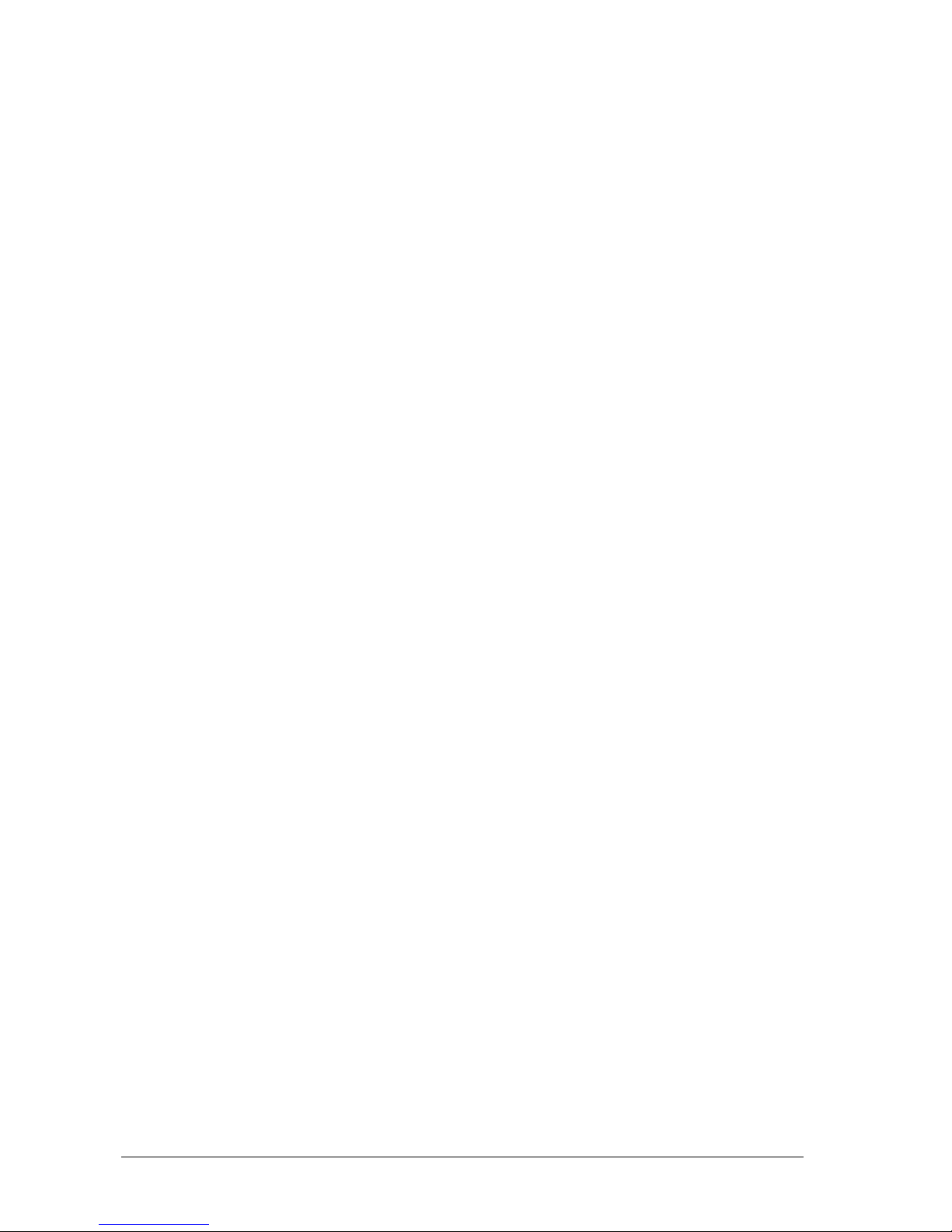

1.2 Main characteristics of the various versions

OLC 20

OLCT 20

LEL

LEL

TOX/O2

Flameproof design

X X X

Intrinsic safety design

X

3-wire cable / Wheatstone bridge

X

3-wire cable / 4-20 mA output

X

2-wire cable / 4-20 mA output

X

Catalytic sensor

X X

Electrochemical sensor

X

Replaceable sensor

X

Replaceable and pre-calibrated sensor

X X

Page 6

6

1.3 Mechanical installation of the various versions

Please ensure you read the paragraph: Special Specifications for use in Potentially Explosive

Atmospheres in Accordance with European Directive ATEX 94/9/EC

See Appendix 1 for general installation instructions.

Figure 1 : Dimensions

A Dimensions OLC/OLCT 20

Cable length 0.2 m

A

Page 7

7

C

3

1

3 (+)

1 (-/S)

E

C

B

A

D

1

2

3

1 (S)

2 (-)

3 (+)

B

E D D

A

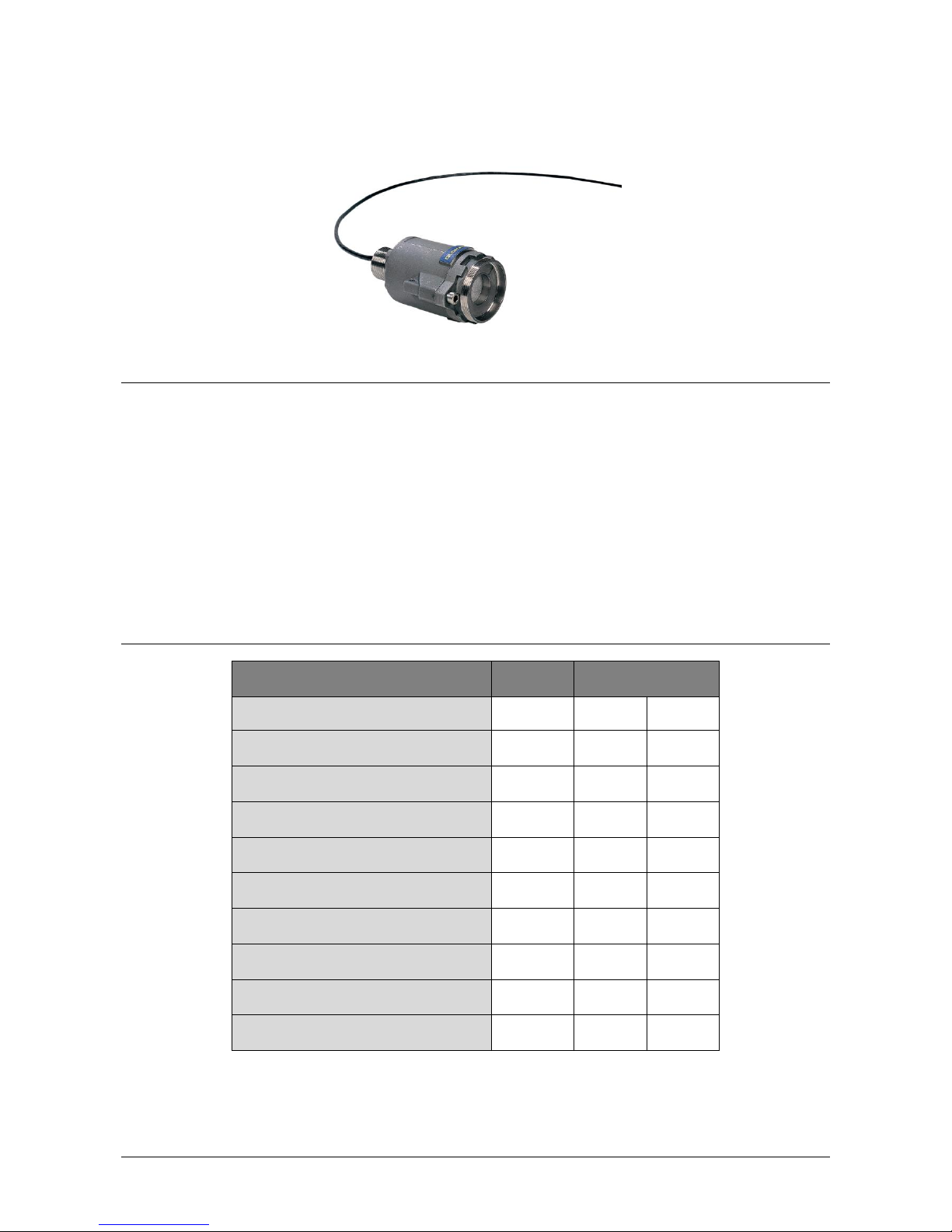

2 Wiring arrangements

Please ensure you read the paragraph: Special Specifications for use in Potentially Explosive

Atmospheres in Accordance with European Directive ATEX 94/9/EC

2.1 3-Wire version (OLC 20d, OLCT 20d)

Figure 2

A

B C D

E

OLDHAM controller

OLC or OLCT 20

Grounding

Power supply

Signal (I)

2.2 2-wire versions (OLCT 20d)

Figure 3

A

B C D

E

OLDHAM controller

OLC 20 or OLCT 20

Grounding

Power supply

Power supply

Signal

Page 8

8

Hazardous area

Safe area

C

B

A

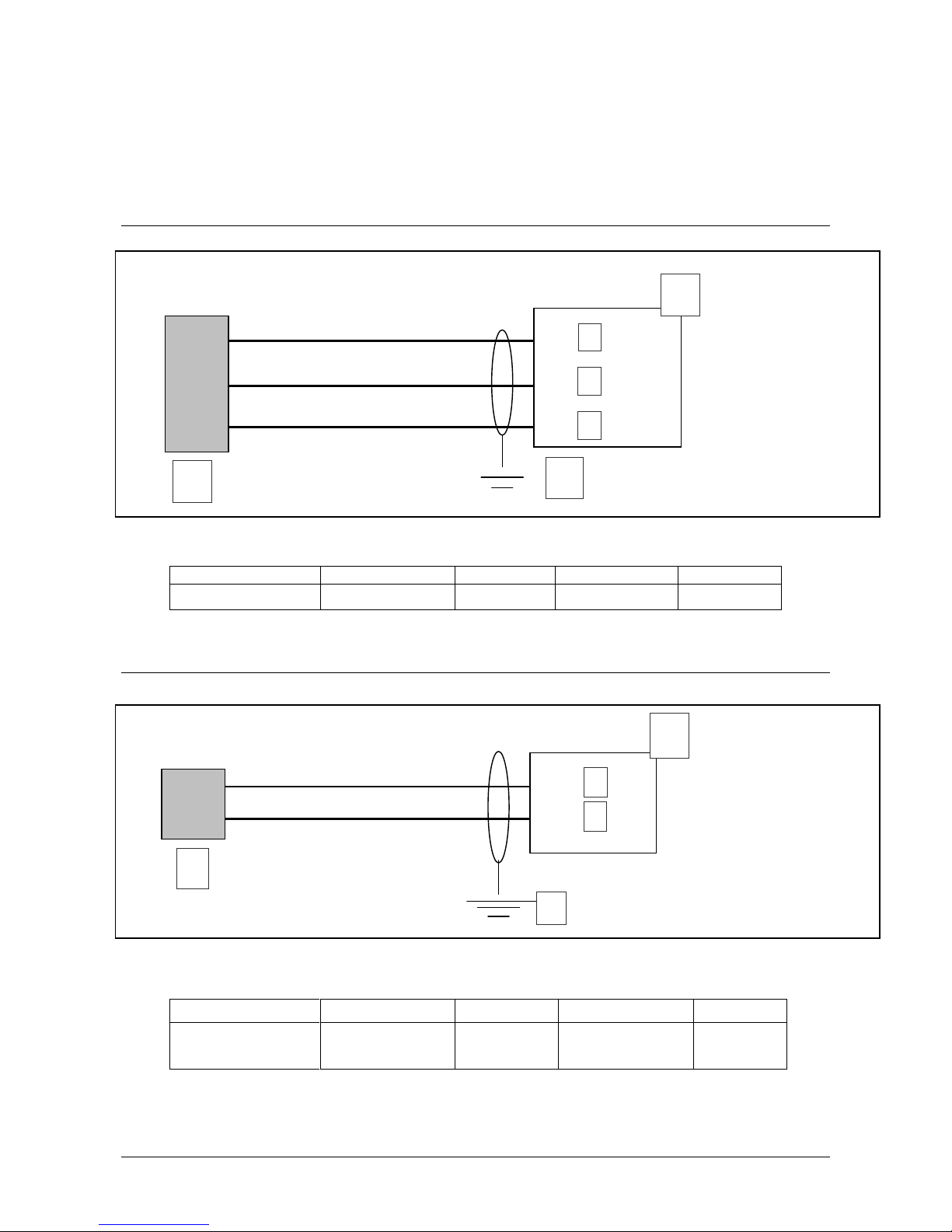

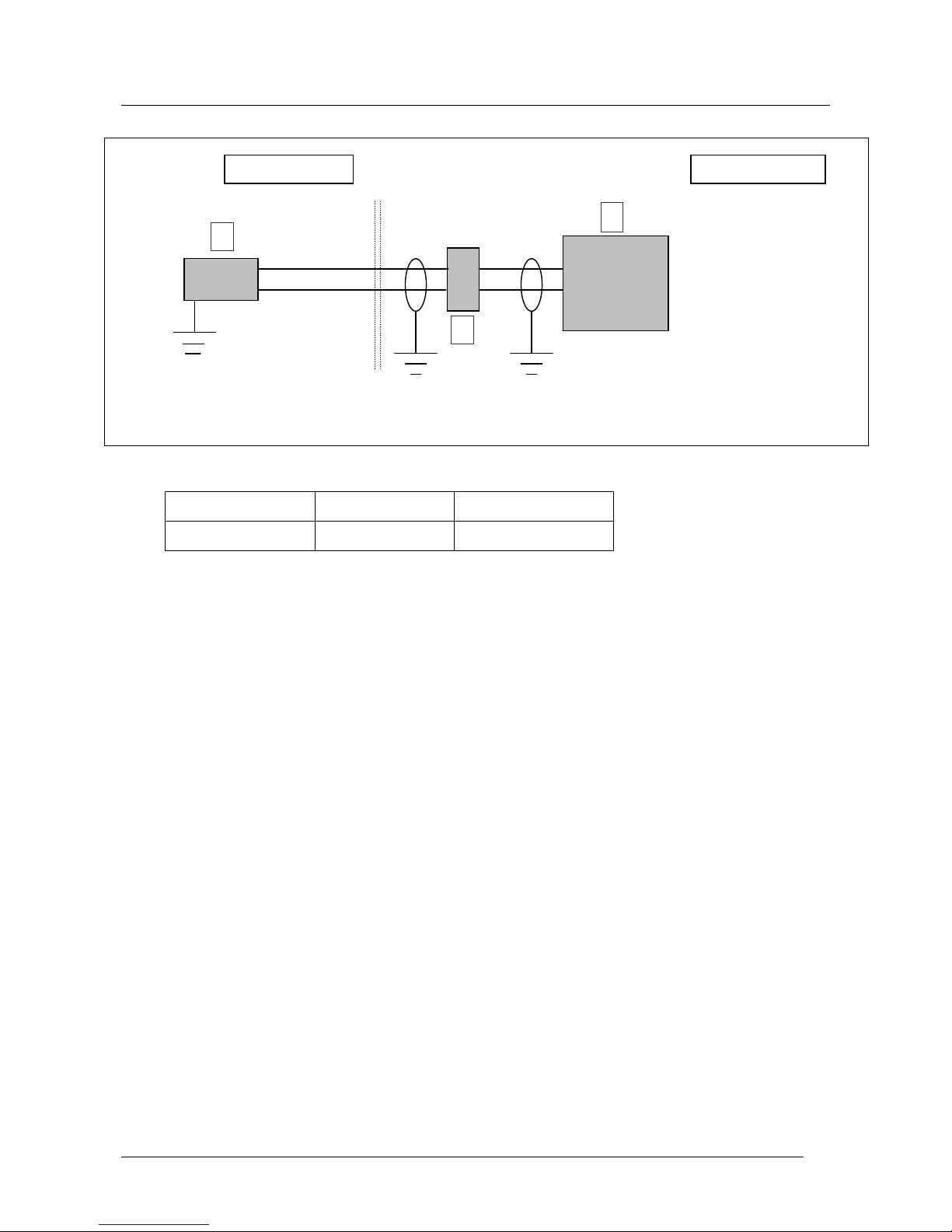

2.3 2-wire Intrinsic Safety versions (OLCT 20i)

Figure 4

A B C

OLDHAM controller

OLC 20 or OLCT 20

ZENER Barrier

Page 9

9

3 Maintenance

The operations and adjustments described in this chapter must be performed

by authorized personnel only as they can affect the appliance's reliability in

detection.

It is prohibited to open the transmitter when energized

3.1 Detector OLC 20

Gas detection instruments are potential life-saving devices. Recognizing this fact, OLDHAM Corporation

recommends that a functional “bump” test be performed on every fixed gas-monitoring instruments as part of

a regular maintenance program. A functional test is defined as a brief exposure of the detector to a

concentration of gas(es) in excess of the lowest alarm set-point for each sensor for the purpose of verifying

sensor and alarm operation and is not intended to be a measure of the accuracy of the instrument.

OLDHAM further recommends that a full instrument calibration be performed using a certified

concentration(s) of calibration gas(es) quarterly, every 3 months.* Calibrations may be necessary more or

less frequently based, for example, on application, field conditions, exposure to gas, sensor technology, and

environmental conditions. The frequency of calibration is best determined by company policy or local

regulatory agencies.

If an instrument fails to operate properly during any functional “bump” test, a full instrument calibration

should be performed successfully prior to use.

These recommendations are based on safe work procedures, industry best practises, and regulatory standards

to ensure worker safety. OLDHAM is not responsible for setting safety practices and policies.

* For new installations it may be prudent to carry out bump tests frequently at first (perhaps weekly),

increasing the time intervals (to, perhaps, monthly or more) as confidence grows with experience in the

installation concerned, on the basis of the maintenance record.

3.1.1 Calibration

On the controller

On the detector

Set the measuring channel to the calibration

position (alarm relays inhibited)

Proceed the zero and span

Set the measuring channel back to the

"normal" position and make sure that it is

working properly.

Apply the calibration cup and perform the

calibration in accordance with the procedure

defined during the training course provided

by OLDHAM or by an OLDHAM’s

authorized person

Page 10

10

3.1.2 Replacing a sensor on an OLC 20

When?

- When the sensor is damaged or cannot be calibrated

- On a preventive basis

How?

- Turn off the relevant measuring channel

- Remove the sensor to be replaced

- Replace it with a new sensor

- Turn on the channel back and check that it operates correctly

(see the following page for more information)

3.2 Transmitters OLCT 20

OLCT 20 gas transmitters are equipped with a pre-calibrated sensor and do not require any

adjustment on installation.

However, as gas detectors are safety equipment, it is recommended to bump test the complete

transmitter after a sensor replacement.

3.2.1 Calibration

After removing the sensor from the transmitter, perform the calibration by using the calibrating

bench provided for that purpose (see CALIBRO’s user manual).

Page 11

11

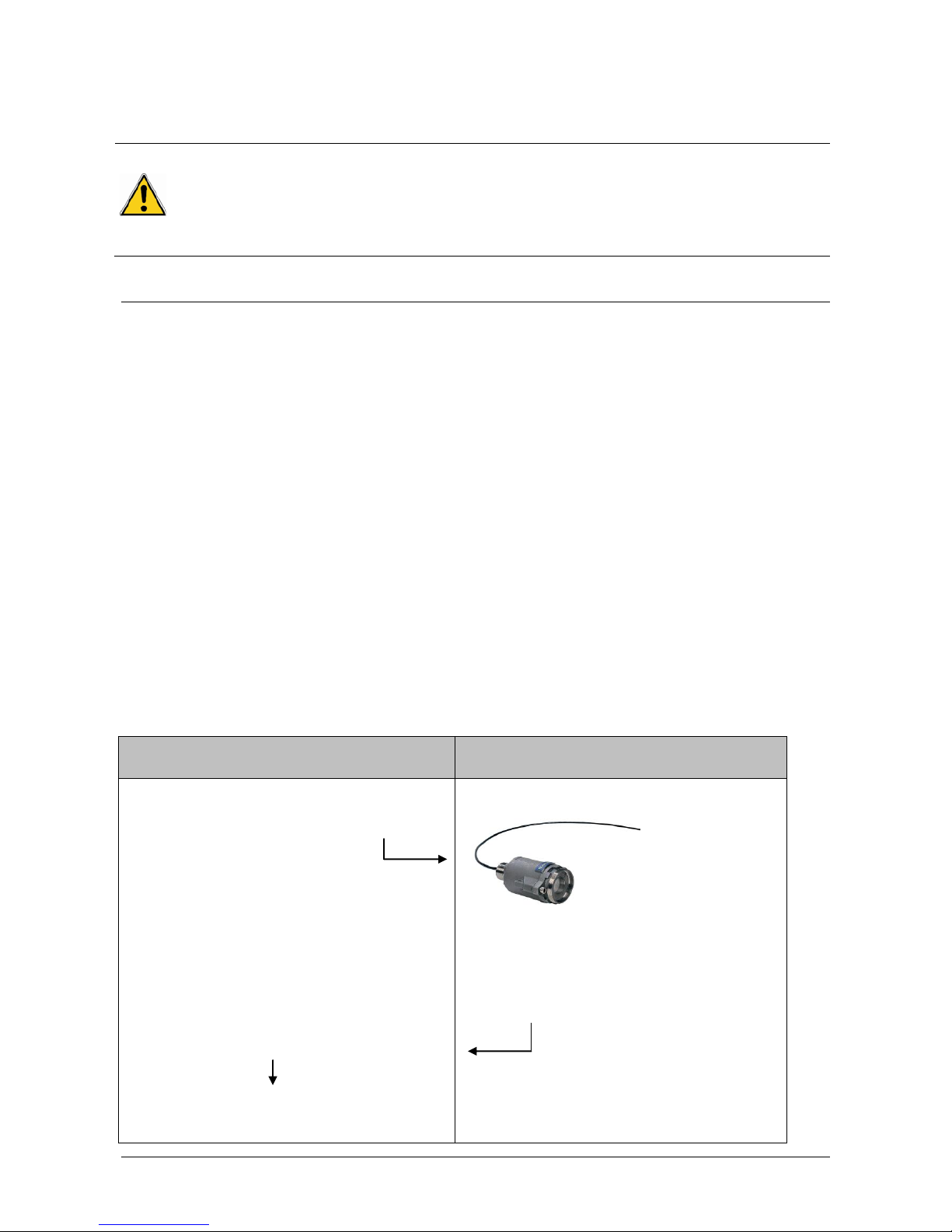

Procedure

On the controller

On the detector

Set the measuring channel to the calibration

position (alarm relays inhibited)

Set the measuring channel back to the

"normal" position and make sure that it is

working properly.

Rotate the sensor

module then

extract it

1

2

Once calibrated put the sensor back in place or

use a replacement sensor and reinstall the whole

assembly.

Loosen the

locking screw

Page 12

12

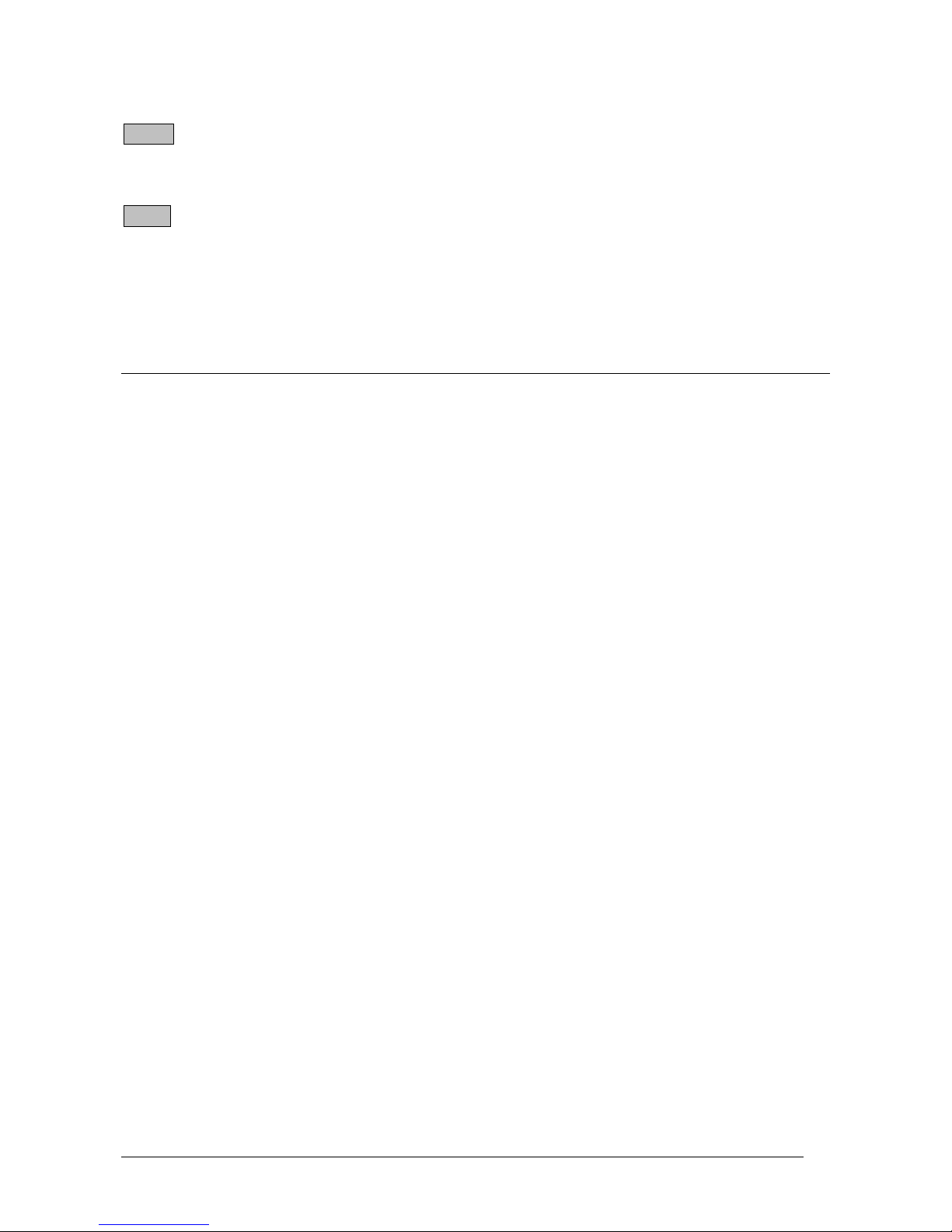

3.2.2 Calibration specifications

Calibration shall be performed outside classified areas and by using suitable

equipment that is described during the training course provided by OLDHAM

or by a person authorized by OLDHAM.

OLCT 20 sensor module

(LEL/TOX/O2)

3.3 Replacing a sensor on OLCT 20

When?

- When the sensor is damaged or cannot be calibrated.

- On a preventive basis.

How?

- Switch off the relevant measuring channel.

- Remove the sensor to be replaced.

- Replace it with a new, precalibrated unit.

- Switch the channel back on and check that it operates correctly.

3.4 Disposal of OLC(T) 20

Concerning the conservation, of the protection and the improvement of the

quality of the environment, as well as for the protection of the health of the

persons and the careful and rational use of natural resources, OLCT 20 has to be

the object of a selective collection for the electronic equipments and cannot be

scrapped with the normal domestic waste. The user thus has the obligation to

separate the OLCT 20 of the other waste so as to guarantee that it is recycled in a

sure way at the environmental level. For more details of the existing sites of

collection, contact the local administration or the distributor of this product.

- Adjustment of 0 in

clean air, using

potentiometer (item 1).

- Adjustment of

sensitivity (with

standard gas), using the

potentiometer (item 2).

item 1

item 2

Page 13

13

4 Spare Parts

Use only genuine spares, otherwise the reliability of the equipment could be adversely

affected

4.1 OLC 20 flameproof gas detector

Flameproof replacement sensors

Part number

Replacement sensor (VQ1 – standard)

6313757

Replacement sensor (AP – poison resistant)

6313758

Catharometric sensor

6313759

4.2 OLCT 20 flameproof gas detector

Flameproof replacement sensors

Part number

OLCT 20, 0-100% LEL (VQ1)

OLCT 20, 0-100% LEL (AP)

OLCT 20, 0-100% vol. (catharometer)

OLCT 20 CO, 0 – 100 ppm

OLCT 20 CO, 0 – 300 ppm

OLCT 20 CO, 0 - 1000 ppm

OLCT 20 H2S, 0 – 30 ppm

OLCT 20 H2S, 0 – 100 ppm

OLCT 20 H2S, 0 - 1000 ppm

OLCT 20 NO, 0 – 100 ppm

OLCT 20 NO, 0 – 300 ppm

OLCT 20 NO, 0 - 1000 ppm

OLCT 20 H2, 0 - 2000 ppm

OLCT 20 NH3, 0 – 100 ppm

OLCT 20 NH3, 0 - 1000 ppm

OLCT 20 O2, 0 - 0–30% vol.

6313685

6313974

6313687

6313690

6313691

6313692

6313695

6313696

6313697

6313698

6313699

6313700

6313706

6313707

6313708

6313710

Page 14

14

4.3 OLCT 20 Intrinsic Safety detector

INTRINSIC SAFETY SENSORS (SI)

Part number

OLCT 20 CO, 0 – 100 ppm

OLCT 20 CO, 0 – 300 ppm

OLCT 20 CO, 0 - 1000 ppm

OLCT 20 H2S, 0 – 30 ppm

OLCT 20 H2S, 0 – 100 ppm

OLCT 20 H2S, 0 - 1000 ppm

OLCT 20 NO, 0 – 100 ppm

OLCT 20 NO, 0 – 300 ppm

OLCT 20 NO, 0 - 1000 ppm

OLCT 20 NO2, 0 – 10 ppm

OLCT 20 NO2, 0 – 30 ppm

OLCT 20 SO2, 0 – 10 ppm

OLCT 20 SO2, 0 – 30 ppm

OLCT 20 SO2, 0 - 100 ppm

OLCT 20 H2, 0 – 2000 ppm

OLCT 20 NH3, 0 – 100 ppm

OLCT 20 NH3, 0 - 1000 ppm

OLCT 20 HCl, 0 – 30 ppm

OLCT 20 HCl, 0 - 100 ppm

OLCT 20 HCN, 0 – 30 ppm

OLCT 20 HCN, 0 - 100 ppm

OLCT 20 Cl2, 0 – 10 ppm

OLCT 20 O3, 0 – 1 ppm

OLCT 20 COCl2, 0 – 1 ppm

OLCT 20 PH3, 0 – 1 ppm

OLCT 20 AsH3, 0 – 1 ppm

OLCT 20 HF, 0 – 10 ppm

OLCT 20 ClO2, 0 – 3 ppm

OLCT 20 ETO, 0 – 30 ppm

OLCT 20 SiH4, 0 – 50 ppm

OLCT 20 O2, 0 – 30% vol.

6313711

6313712

6313713

6313716

6313717

6313718

6313719

6313720

6313721

6313722

6313723

6313724

6313725

6313726

6313727

6313728

6313729

6313730

6313731

6313732

6313733

6313734

6313735

6313736

6313737

6313738

6313739

6313740

6313746

6313747

6313748

Page 15

15

5 Accessories

TOOL KIT

6147869

CALIBRATION CUP

6331141

BY-PASS ADAPTOR

for combustible gases, CO, H2S, O2

6327910

PLASH GUARD

6329004

PROTECTIVE FILTER, PTFE

6335975

ACTIVE CARBON FILTER

6335976

REMOTE CALIBRATION CUP

(for combustible gases only)

6327911

Page 16

16

Page 17

17

6 Technical characteristics of OLC 20

Power supply: voltage on detector terminals = 2.8 V max

Power consumption: 3-wire version = 400 mA max

Measurement signal: Wheatstone bridge

Line length (shielded cable): 3-wire version = 1 km as 3x 1.5 mm2

(32 ohms in loop mode)

Output signal mV bridge output, 3 wires

Ingress Protection IP66

Weight 800 g

Dimensions 60 X 120 mm

7 Technical characteristics of OLCT 20

A) Explosion-proof version

Power supply: voltage on detector terminals = 15 V to 30 V

Power consumption: 3-wire version = 100 mA

2-wire version = 25 mA

Load resistance: maximum resistance = 250 ohms

Line length (shielded cable): 3-wire version = 1 km as 3x 1.5 mm2 (32 ohms in

loop mode)

2-wire version = 4 km as 3x 1.5 mm2 (32 ohms in

loop mode)

B) Intrinsic safety version

Characteristics of ZENER barrier: 28 V - 300 ohms

Supply voltage for barrier: 19 V to 26 V

Voltage on detector terminals: 10 V to 26 V

Power consumption: 25 mA max

Load resistance: 47 ohms

Line length (shielded cable): 1 km as 3x 1.5 mm2 (32 ohms in loop mode)

Output signal

Source mode current 4-20 mA

Max. current 25 mA

Fault current <1 mA

Miscellaneous

Ingress Protection IP66

Weight 800 g

Dimensions 60 X 120 mm

Page 18

18

Page 19

19

8 Specific Instructions for use in Explosive Atmospheres

according to European Directive ATEX 94/9/EC

The OLC/OLCT 20 gas detectors comply with the requirements of European Directive ATEX

94/9/EC relating to explosive Dust and Gas atmospheres.

As a result of their metrological performance, as tested by the Approval Agency INERIS, the

OLC/OLCT 20 gas detectors designed to measure explosive gasses and oxygen are classified as

safety devices and may therefore contribute to limiting the risk of explosion.

The information contained in the following paragraphs should be respected and taken into

account by the manager of the site where the equipment is installed. Please refer to the provisions of

European Directive ATEX 1999/92/EC on improving health and safety conditions for workers

exposed to potentially explosive atmospheres.

8.1 Specifications for mechanical and electrical installation in Classified Areas.

Installation will comply with all applicable standards, and particularly with EN 60079-14 and

EN 60079-17.

8.1.1 Flameproof detectors (d)

- These detectors are intended for use in surface industries II, Category 2, zones 1 and 2

(Gas) and zones 21 and 22 (Dust) in ambient temperature from -20°C to +70°C.

- Cables will be mechanically protected.

- The transmitter casing will be earthed using the external or internal terminal, which

should be corrosion-protected. Users should clean detectors regularly in order to prevent

any external accumulation of dust.

- Mechanically, detectors will be installed such that the detection sensor points downwards.

Any variance of over 45° from the vertical will result in measurement errors.

- Where connections are located in a classified zone, they will be enclosed in approved

envelopes.

- The width of the threaded joint of cable gland is superior to the value specified in the table

of EN 60079-1 standard.

8.1.2 Intrinsic safety detectors (i) OLCT 20 i

- These detectors are intended for use in surface industries II, Category 1, zones 0, 1 and 2

(Gas) and zones 20, 21 and 22 (Dust). They are also intended for use in coal mines,

Category M1. The ambient operating temperature range is –20°C to +70°C.

- Users should clean detectors regularly in order to prevent any external accumulation of

dust.

- The person responsible for IS installation (the “System Designer”) must draw up a system

document demonstrating that every aspect of the Power Cable Detector system complies

with intrinsic safety.

- They must be powered by an intrinsic safety source: 28V - 300 ohms

- Where connections are located in a classified zone, they will be enclosed in approved

envelopes.

- The safety parameters applying to the OLCT 20i detectors are :

Ui (V)

Ii (mA)

Pi (mW)

Ci (nF)

Li (H)

28

94

658

40

15μH

Page 20

20

8.2 Metrological specifications for explosive gas and oxygen measurement

detectors

In case of exposure above the measuring range, it is mandatory to bump test

the instrument with gas and/or to perform a calibration.

In the event of a change of position, it is necessary to re-calibrate the detector.

The OLC/OLCT 20 transmitter sensors intended to measure explosive gasses and oxygen are

classified as safety devices and may therefore contribute to limiting the risk of explosion.

Detectors comply with the following European standards:

Explosive gas detectors:

- OLC 20 explosive gas detectors comply with European standards EN 50054 and EN

50057 for Methane (calibration gas), Propane and Hydrogen (gasses following response

curves) where they are used with the following OLDHAM controllers SV 4B, MX 15,

MX 32, MX 42A, MX 43, MX 48 and MX 52.

- OLCT 20 explosive gas detectors comply with European standards EN 50054 and EN

50057 for Methane (calibration gas), Propane and Hydrogen (gasses following response

curves), where they are used with SV 4B, MX 15, MX 32, MX 42A, MX 43, MX 48, MX

52 and MX 62 OLDHAM controllers, or where they are connected to measurement

devices with 4-20 mA inputs in accordance with paragraph 1.5 of Appendix II of the

ATEX 94/9/EC Directive and are compatible with their characteristics (cf. transfer curve).

Oxygen detectors:

- OLCT 20 oxygen detectors comply with European Standard EN 50104 where they are

used with MX 15, MX 32, MX 42A, MX 43, MX 48, MX 52 and MX 62 OLDHAM

controllers, or where they are connected to measurement devices with 4-20 mA inputs in

accordance with paragraph 1.5 of Appendix II of the ATEX 94/9/EC Directive and are

compatible with their characteristics (cf. transfer curve).

Page 21

21

8.2.1 Technical Specifications and Special Instructions for explosive gas detectors

8.2.1.1 Transfer curves for OLCT 20 detectors

The following curve shows transmitter output current values as a function of gas

concentration. Where the user connects the transmitter to a device other than a device manufactured

by OLDHAM, he must check that the transfer curve is fully compatible with its input characteristics

to ensure that the information generated by the transmitter is correctly interpreted. Equally, the

device must supply a suitable power supply voltage, allowing for cable voltage losses.

Please note: Detectors can generate ambiguous measurements at high gas concentrations, i.e. the

current output for a > 20% concentration of gas by volume is the same as for a concentration of < 5%

by volume (bell curve). It is therefore essential that the measuring device memorises the fact that the

value has exceeded the scale and that resetting is manual rather than automatic, and follows the safety

regulations specific to the site.

0 %

100 % 120%

20.0 mA

4.0 mA

1 mA

Concentration

in % LEL

Output Current in

mA

Fault

23.2 mA

Fault

Page 22

22

8.2.1.2 Metrological data

Type

VQ1

Maximum concentration

100% LEL

Principle

Catalytic

Estimated service life

> 36 months

Storage

Away from air -10°C < T < 35°C

10% < RH < 60%. Maximum 6 months

Continuous temperature range

-20°C to +55°C

Humidity range

0% RH to 95% RH

Pressure range

1 bar ± 10%

Linearity variance (methane scale)

Between 0% and 70% LEL: 1% LEL

Between 70% and 100% LEL: 7% LEL

Measurement reproducibility

± 2% of the value measured, or ± 1 LEL

(or ± 0.05% CH4)

Long-term drift

in normal

operating

conditions

Zero point:

Sensitivity:

Methane

Propane/Butane

< 5% methane LEL per year

Typical drift values

< 20% of the value measured per year

< 10% of the value measured per year

Effect of humidity (10% to 90% RH) at

40°C

± 5% of relative sensitivity

Maximum recommended interval between

calibrations (normal operating conditions)

6 months

Calibration concentration

30– 80% LEL

Response time

(may vary ± 10%

between sensors)

gas and

concentration

injected

Methane

(50% LEL)

Hydrogen

(50% LEL)

Pentane

(52% LEL)

Styrene

(45% LEL)

t25

4 sec

3 sec

8 sec

12 sec

t50

8 sec

6 sec

12 sec

40 sec

t90

15 sec

10 sec

27 sec

60 sec

Page 23

23

8.2.1.3 Special precautions for explosive gas detectors

Sensors are sensitive to certain poisons, which can reduce their sensitivity: emission of

silicone-containing vapours at concentrations > 10 ppm and chlorinated or sulphurous

products at concentrations > 100 ppm.

A lack of oxygen (< 15% O2) or over-oxygenation (> 23% O2) may cause under-measurement

(in the former case) or over-measurement (in the latter case).

Sensors must be located head downwards at installation or during maintenance work.

8.2.1.4 Response to other explosive gasses

It is recommended that the detector is calibrated using the gas to be measured. Users wishing to

calibrate the detector using a gas other that detected and factory-programmed should refer to the

following table, and use the recommended gas and corresponding coefficient.

Table 1 : Calibration Coefficients

Gas

Chemical

Formula

LEL

(%)

LSE

(%)

Flash

point

(°C)

Vapor

density

Coefficient

-

Calibration gas

CH4 (methane)

Coefficient

Calibration gas

H2 (Hydrogen)

Coefficient

- Calibration gas

C4H10 (Butane)

Coefficient

- Calibration gas

C5H12

(Pentane)

Ethyl acetate

C4H8O2

2,10

11,50

-4

3,0

1,65

1,35

0,90

0,80

Acetone

C3H6O

2,15

13,00

-18

2,1

1,65

1,35

0,90

0,80

Acetylene

C2H2

1,50

100

-18

0,9

2,35

1,90

1,25

1,15

Acrylic acid

C3H4O2

2,40

8,00

54

2,5

5,00

4,00

2,65

2,40

Butyl acrylate

C7H12O2

1,20

8,00

37

4,4

3,50

2,80

1,85

1,70

Ethyl acrylate

C5H8O2

1,70

13,00

-2

3,5

3,05

2,45

1,65

1,50

Acrylonitrile

C3H3N

2,80

28,00

-1

1,8

1,45

1,20

0,80

0,70

Ammoniac

NH3

15,00

30,20

< -100

0,6

0,90

0,75

0,50

0,45

Benzene

C6H6

1,20

8,00

-11

2,7

4,00

3,20

2,15

1,90

1.3Butadiene

C4H6

1,40

16,30

-85

1,9

2,55

2,05

1,35

1,25

Butane

C4H10

1,50

8,50

-60

2,0

1,90

1,55

1,00

0,90

Butanol

(Butyl Alcool)

C4H10O

1,4

11,3

29

2,6

1,95

1,60

1,05

0,95

2 - Butanone

(MEK)

C4H8O

1,80

11,50

-4

2,5

3,90

3,15

2,10

1,90

Cyclohexane

C6H12

1,20

8,30

-17

2,9

2,00

1,60

1,10

1,00

Dimethylether

C2H6O

3,00

27,00

-41

1,6

1,80

1,45

0,95

0,90

Dodecane

C12H26

0,60

~6,0

74

5,9

4,00

3,20

2,15

1,90

Ethane

C2H6

3,00

15,50

135

1,0

1,50

1,20

0,80

0,75

Ethanol

C2H6O

3,30

19,00

13

1,6

2,15

1,75

1,15

1,05

Ether

(Diethylether)

(C2H5)2O

1,70

36,00

-45

2,6

1,90

1,55

1,00

0,90

Ethylene

C2H4

2,70

34,00

- 135

1,0

1,65

1,35

0,90

0,80

LPG

Prop+But

1,65

~9,0

< -50

1,9

1,90

1,55

1,00

0,90

Diesel

Melange

0,60

~6,0

55

> 4

3,20

2,60

1,70

1,55

Natural Gas

CH4

5,00

15,00

-188

0,6

1,05

Heptane

C7H16

1,10

6,70

-4

3,5

2,20

1,80

1,20

1,05

Page 24

24

Gas

Chemical

Formula

LEL

(%)

LSE

(%)

Flash

point

(°C)

Vapor

density

Coefficient

-

Calibration gas

CH4 (methane)

Coefficient

Calibration gas

H2 (Hydrogen)

Coefficient

- Calibration gas

C4H10 (Butane)

Coefficient

- Calibration gas

C5H12

(Pentane)

Hexane

C6H14

1,20

7,40

-23

3,0

2,10

1,70

1,15

1,00

Hydrogen

H2

4,00

75,60 - 0,069 1,00

Isobutane

C4H10

1,50

8,40

-83

2,0

1,50

1,20

0,80

0,75

Isobutene

C4H8

1,60

10,00

<-10

1,9

2,20

1,80

1,20

1,05

Isopropanol

C3H8O

2,15

13,50

11,7

2,1

1,60

1,30

0,85

0,80

Kerosene

(JP4)

C10 -

C16

0,70

5,00

> 50

> 4

5,00

4,00

2,65

2,40

Methyl

Methacrylate

C5H8O2

2,10

12,50 2 3,5

2,25

1,80

1,20

1,10

Methane

CH4

5,00

15,00

-188

0,55

1,00

Methanol

CH3OH

5,50

44,00

11

1,1

1,40

1,15

0,75

0,70

Naphta

melange

(Mixture)

0,90

5,90

> 44

> 4

3,50

2,80

1,85

1,70

Nonane

C9H20

0,70

5,60

31

4,4

4,40

3,55

2,35

2,10

Octane

C8H18

1,00

6,00

12

3,9

2,70

2,20

1,45

1,30

Ethylene

Oxyde

C2H4O

2,60

100

-20

1,5

2,10

1,70

1,15

1,00

Propylene

oxide

C3H6O

1,90

37,00

70

2,0

2,35

1,90

1,25

1,15

Pentane

C5H12

1,40

8,00

-49

2,5 1,00

Propane

C3H8

2,00

9,5

-104

1,6

1,55

1,25

0,85

0,75

Propylene

C3H6

2,00

11,70

-107,8

1,5

1,65

1,35

0,90

0,80

Styrene

C8H8

1,1

8,00

31

3,6

6,30

5,05

3,35

3,00

Gasoline lead

free

/

1,10

~6,0

21

3 à 4

1,80

1,45

0,95

0,90

Toluene

C7H8

1,20 7 5

3,1

4,00

3,20

2,15

1,90

Turpentine

Oil

-

0,8

6,0

35

4,7

3,50

2,80

1,85

1,70

Triethyl

amine

C6H15N

1,20 8 -15

3,5

2,05

1,65

1,10

1,00

White Spirit

melange

(Mixture)

1,10

6,50

>30

> 4

3,50

2,80

1,85

1,70

Xylene

C8H10

1,00

7,60

25

3,7

4,00

3,20

2,15

1,90

Sensors with a grey background: gases recommended for calibrating the detector (VQ1)

Example (second row of table): calibration of an Acetone detector using 1% butane (by volume) as

the calibrating gas.

Value to be displayed:

1% (butane injected) x 100 x 0.90 (Butane/Acetone coefficient) = 60% LEL

1.5% (butane LEL)

N.B.:

- LELs vary depending on the source. Those values shown here are taken from European

Standard EN 50054

- Coefficients are accurate to 15%

Page 25

25

8.2.2 Technical Specifications and Special Instructions for Oxygen detectors

8.2.2.1 Transfer curves for OLCT 20 detectors

The following curve shows the transmitter output current value as a function of gas

concentration. Where the user connects the transmitter to a device other than a device manufactured

by OLDHAM, he must check that the transfer curve is fully compatible with its input characteristics

to ensure that the information generated by the transmitter is correctly interpreted. Equally, the

device must supply a suitable power supply voltage, allowing for cable voltage losses.

8.2.2.2 Metrological data

Maximum concentration

30% O2

Type and number

CT5020 CELL

Principle

2-electrode electrochemical

(Measurement of oxygen

concentration by volume)

Estimated service life

30 months

Storage

4°C < T < 12°C

10% < RH < 60%

Temperature range

-20°C to +45°C

Humidity range

20% RH to 95% RH

Pressure range

1 bar ± 10%

Accuracy at 20°C

15 to 21% O2 ± 0.5% vol O2

1 to 14% O2 ± 0.6% vol O2

Repeatability

< 2% of signal

T90 response time

< 15 seconds

Effect of temperature (0 to 40°C)

< 0.5% vol O2

Effect of humidity (10% to 90% RH)

The measurement is lower as a

result of the air being diluted by

water vapour

Sensitivity drift over time

< 2% per month

Zero stabilisation time following

power-up

30 to 60 minutes

0 %

30.0 % 36.0%

20.0 mA

4.0 mA

1 mA

% O2 concentration

by volume

Output Current in mA

Fault

23.2 mA

Fault

Page 26

26

8.2.2.3 Characteristics and Special precautions for oxygen detectors

When the transmitter is powered up or the measurement sensor is replaced, it takes between

30 and 60 minutes for the measurement to stabilise at 20.9% v/v in pure ambient air.

The use of an oxygen-rich atmosphere (> 25%) can compromise safety.

8.3 Markings

8.3.1 Flameproof certified version: OLC 20d and OLCT 20 d

OLDHAM

F – 62027 Arras

0080

OLC 20d or OLCT 20d

II 2GD

Ex d IIC T6 Gb

Ex tb IIIC T85°C Db IP66

Tamb : -20°C to 70°C

INERIS 01ATEX0004X

Read instruction manual

WARNING: Do not open when energized

Serial number, year of manufacture

8.3.2 Intrinsic safety version: OLCT 20 i

OLDHAM

F – 62027 Arras

0080

OLCT 20i

II 1 GD

Ex ia IIC T4 Ga

Ex ia IIIC T135°C Da IP66

I M1 Ex ia I Ma

Tamb : -20°C to 70°C

INERIS 01ATEX0004X

Read instruction manual

WARNING: Do not open when energized

Serial number, year of manufacture

Page 27

27

9 Recommendations

The measuring sensor shall be positioned facing downwards. The physical location of the

TRANSMITTER depends on the type of gas to be detected:

at the high point if the gas is lighter than air,

at the low point if the gas is heavier than air,

near outlet vents in the case of mechanical ventilation,

or, more generally, in locations where the gas is likely to accumulate.

Despite its high degree of protection (IP66), it may be necessary to protect the TRANSMITTER

against adverse weather conditions (rain, dust, direct sunlight, etc.) and from direct spraying with

cleaning or maintenance products (causing soiling of the detection sensor).

The TRANSMITTER must also be positioned so as to allow access to the measuring sensor so that

it can be replaced.

Detectors must be positioned so as to optimize the detection of accumulations of gas emitted in the

air.

Factors to be considered in determining optimal detector positioning:

potential sources of gas and vapour emissions

chemical and physical data on gases and vapours which may be present

liquids with low volatility detectors as near as possible to the leak risk area

type and concentration of gas leaks (high-pressure jet, slow leak, etc.)

air movements

- indoors: natural and mechanical ventilation

- outdoors: wind speed and direction

effect of temperature

installation so as to avoid mechanical damage or deterioration caused by water in summer

positioning to allow easy maintenance, if possible

avoiding direct sunlight on the readout area as this would lead to maintenance problems

Page 28

28

Page 29

29

10 EU Declaration of Conformity

Page 30

30

Page 31

31

Page 32

Thank you for reading this data sheet.

For pricing or for further information, please contact us at our UK Office, using the details

below.

UK Office

Keison Products,

P.O. Box 2124, Chelmsford, Essex, CM1 3UP, England.

Tel: +44 (0)330 088 0560

Fax: +44 (0)1245 808399

Email: sales@keison.co.uk

Please note - Product designs and specifications are subject to change without notice. The user is responsible for determining the

suitability of this product.

Loading...

Loading...