Page 1

INSTALLATION AND OPERATING

MANUAL

Réf.: NPM42GB

Page 2

GAS DETECTION

We are delighted that you have chosen an INDUSTRIAL SCIENTIFIC instrument and would like

to thank you for your choice.

We have taken all the necessary measures to ensure that your instrument provides total

satisfaction.

Now it is important to read this document carefully.

EEXXTTEENNTT OOFF RREESSPPOONNSSIIBBIILLIITTYY

* INDUSTRIAL SCIENTIFIC declines its responsibility towards any person for material damage, physical

injury or death resulting wholly or partly from inappropriate use, installation or storage of its equipment

resulting from failure to observe instructions and warnings and/or standards and regulations in force.

* INDUSTRIAL SCIENTIFIC neither supports nor authorises any company, physical or moral person to

assume responsibility on behalf of INDUSTRIAL SCIENTIFIC , even if it is involved in the sale of

INDUSTRIAL SCIENTIFIC products.

* INDUSTRIAL SCIENTIFIC cannot be held responsible for direct or indirect damage or be required to pay

direct or indirect compensation resulting from the sale or use of any of its products IF THESE

PRODUCTS HAVE NOT BEEN DEFINED AND CHOSEN BY INDUSTRIAL SCIENTIFIC FOR THEIR

SPECIFIC USE.

CCLLAAUUSSEESS CCOONNCCEERRNNIINNGG PPRROOPPEERRTTYY

* Drawings, plans, specifications and information included in this document contain confidential information

that is the property of INDUSTRIAL SCIENTIFIC

* None of this information may be reproduced, copied, divulged or translated, by physical, electronic or any

other means, nor used as the basis for the manufacture or sale of INDUSTRIAL SCIENTIFIC equipment

or for any other reasons without prior consent from INDUSTRIAL SCIENTIFIC

WWAARRNNIINNGGSS

* This document is not contractually binding. In the interests of its customers, INDUSTRIAL SCIENTIFIC

reserves to modify the technical specifications of its equipment without notice, in order to improve its

performance.

* READ THIS MANUAL CAREFULLY BEFORE FIRST USE OF THE EQUIPMENT: this manual must be

read by any person who is or will be responsible for using, maintaining or repairing this equipment.

* This equipment will only provide the announced performance levels if it is used, maintained and

repaired according to INDUSTRIAL SCIENTIFIC directives, by INDUSTRIAL SCIENTIFIC personnel

or by personnel approved by INDUSTRIAL SCIENTIFIC

GGUUAARRAANNTTEEEE

2 years guarantee in normal conditions of use on parts and technical labour, return in our workshops,

excluding consumables (sensors, filters, etc.)

3

Page 3

CONTENT

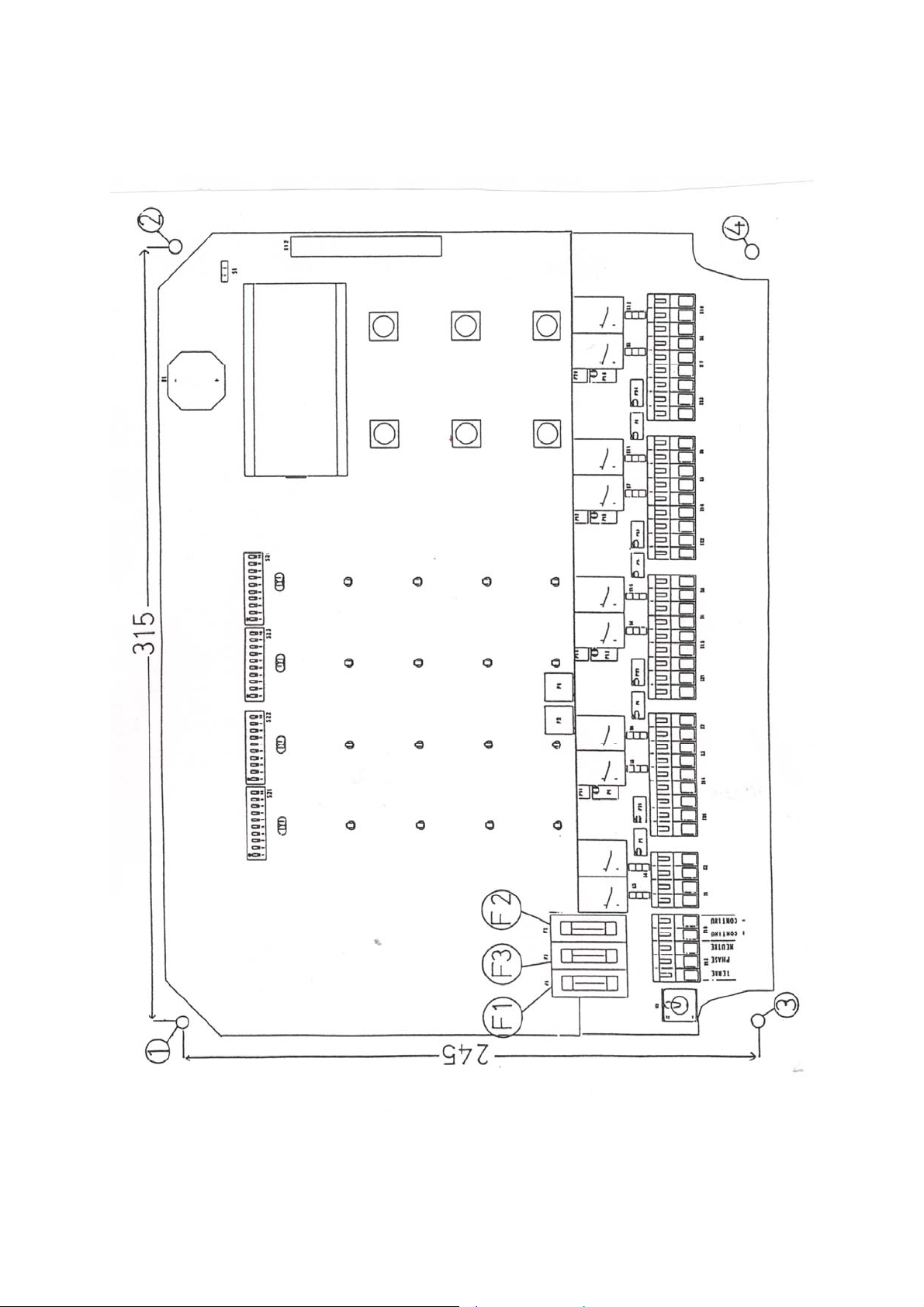

1 DESCRIPTION (fig 1) ..................................................................................................7

2. INSTALLATION AND CONNECTIONS .......................................................................9

2.1. Installation .............................................................................................................9

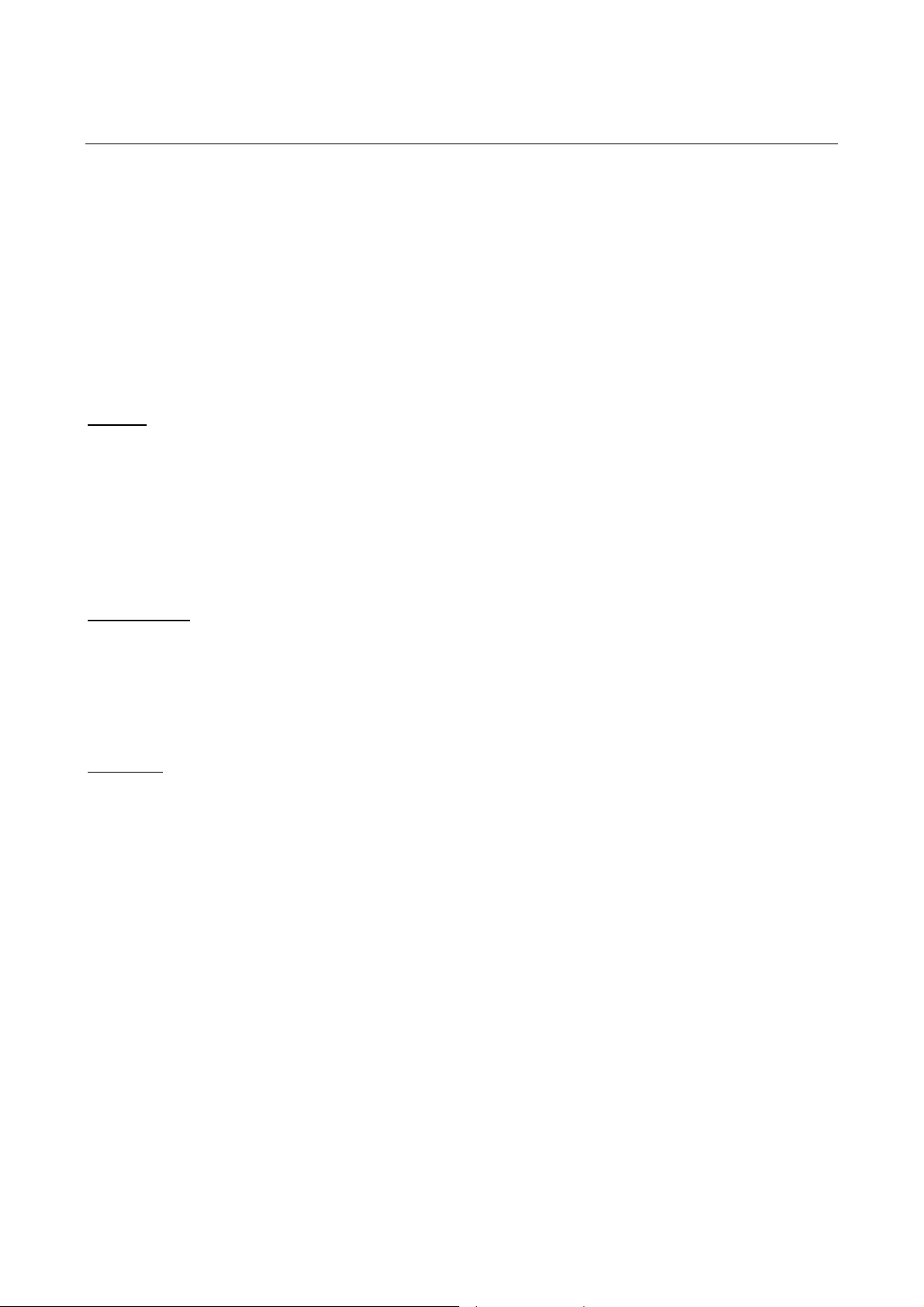

2.2. Electrical connection of the MX 42A detection unit (fig 2)......................................9

2.3. Connection of the detection unit to the detectors ..................................................9

2.3.1. Physical layout of detectors............................................................................9

2.3.2 Type and connection of detectors (fig 3)......................................................11

2.4. Connection of the detection unit to external devices ...........................................13

2.4.1. Connection to servocontrols.........................................................................13

2.4.2. 4-20 mA current output.................................................................................13

3. START-UP AND OPERATION...................................................................................15

4. CONFIGURATION OF ALARMS AND SERVOCONTROL .......................................17

4.1. Characteristics of alarm triggering.......................................................................17

4.2. Programming of parameters................................................................................20

4.3. Servocontrol ........................................................................................................23

4.3.1. Relays ..........................................................................................................23

4.3.2. 4-20 mA current output.................................................................................23

5. PERIODIC SERVICING..............................................................................................25

5.1. Adjustment of detectors from the MX 42A detection unit.....................................25

5.2. Local adjustment at the detectors........................................................................26

6. TROUBLESHOOTING...............................................................................................27

7. DETAILED TECHNICAL CHARACTERISTICS.........................................................28

7.1. Casing.................................................................................................................28

7.2. Display.................................................................................................................28

7.3. Power supply.......................................................................................................28

7.4. Measurement inputs............................................................................................29

7.5. Alarm...................................................................................................................29

7.6. Control functions..................................................................................................30

7.7. Relaying ..............................................................................................................30

7.8. Output of measurements.....................................................................................30

8. Scrapping of mx42a..................................................................................................31

9. LIST OF MX42A SPARE PARTS...............................................................................31

9.1. Spare parts..........................................................................................................31

9.2. Intrinsic barriers and accessories........................................................................ 31

10. Special Specifications for use in Potentially Explosive Atmospheres in

accordance with European Directive ATEX 94/9/EC.....................................................32

10.1. Specifications for mechanical and electrical installation in Classified Areas....32

10.2. Metrological Specifications...............................................................................32

4

Page 4

10.3. Connecting detectors other than INDUSTRIAL SCIENTIFIC detectors to the

MX42A device................................................................................................................33

10.3.1. Device transfer curves in 0% to 100% LEL configuration.........................33

10.3.2. Device transfer curves in 0% to 30.0% OXYGEN configuration ...............34

10.3.3. Power supply and load resistance characteristics ....................................34

10.4. MARKING.......................................................................................................34

5

Page 5

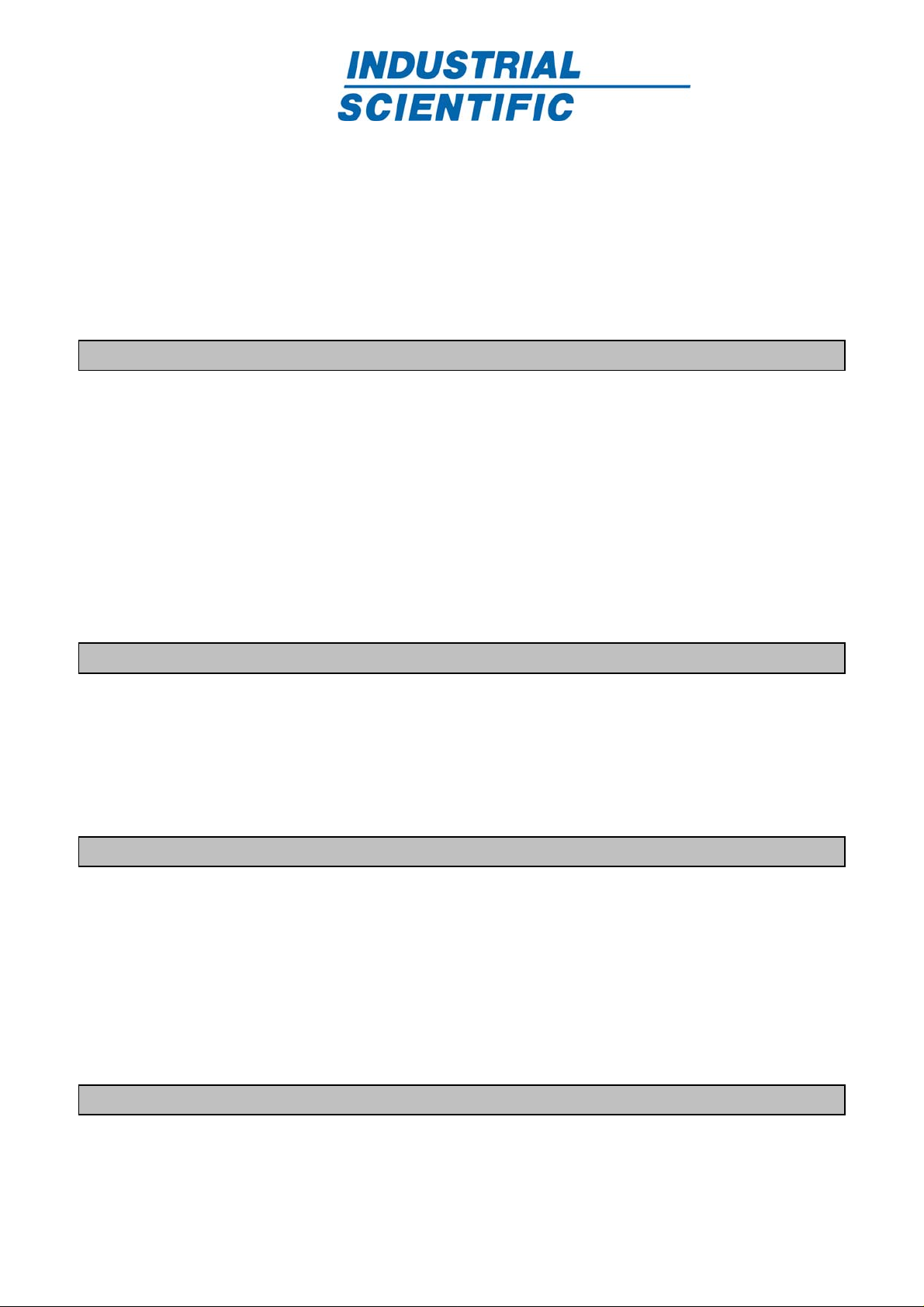

Figure 1

6

Page 6

1 DESCRIPTION (fig 1)

The MX 42A detection unit is an apparatus for the detection and measurement of various

combustible, toxic or oxygen-carrying gases.

The MX 42A detection unit has 4 independent measuring channels. Each channel is connected to a

gas detector located in places to be monitored. The measurement from the detector is displayed on

the MX 42A detection unit and compared to alarm thresholds. Should alarm thresholds be

exceeded, the MX 42A detection unit actuates relays which can be used for the control of outside

devices (horn, telephone call, exhaust fans, etc.).

Note: the detection unit also comes in a 2-measuring channel version.

Main characteristics: (cf Figure 1)

- Casing for wall mounting made of PVC (length: 340, height: 300, depth: 107) with intern

"plating".

- AC or DC power supply

- 4 measuring inputs for detectors of the explosimetric, toxic or oxygen type (or other type

on request)

- Visualization of the measurement by LCD

- Alarms per channel:

2 increasing or decreasing thresholds, manual or automatic clearance (control logic

of exhaust fans on programming)

1 increasing or decreasing threshold, automatic clearance, triggering on basis of time

or on averaging

- Relaying: a total of 10 relays distributed as follows:

2 relays per channel (NO or NC) for the first two alarm thresholds

1 relay common to the channels for the third alarm threshold (or the remote

transmission of the alarm on programming)

1 relay common to the channels for detector faults and anomalies

- 4-20 mA output per channel (< 1 mA for fault, 2 mA for maintenance)

- Resettable buzzer should alarms or an anomaly appear

7

Page 7

Figure 2

8

Page 8

2. INSTALLATION AND CONNECTIONS

Please ensure you read the paragraph: Special Specifications for use in Potentially Explosive

Atmospheres in Accordance with European Directive ATEX 94/9/EC

2.1. Installation

The detection unit can be installed in any place without an explosive atmosphere. It should be put in

a well ventilated place where it can be watched (guard house, control room, security service...).

It is attached according to Figure 2: 4 attachment points, marked 1, 2, 3 and 4, with centres of 314 x

245 mm, using 5 mm screw.

Caution: So that the cover of the detection unit can be completely opened, there must be at least

30 cm of free space above it.

Before installation, switch off the MX42A with the switch located on the inside (bottom left

corner).

2.2. Electrical connection of the MX 42A detection unit (fig 2).

Power supply: connect the power supply wires to the terminal blocks of the detection unit.

- Earth, live and neutral terminals, 220 V AC (207 V to 244 V), 50/60 Hz, protected by an

F1 630 mA time-delay fuse.

- or + DC, - DC terminals, 24 V (19 V to 32 V), DC protected by an F2 4A fuse.

On option

A sticker on the casing gives the power supply voltages.

Their location depends on three m

:

- either 115 V AC (103 V to 122 V), 50/60 Hz, protected by an F1 1.25 A time-delay fuse

- or 48 V (43 V to 60 V), protected by an F3 2 A time-delay fuse

2.3. Connection of the detection unit to the detectors

2.3.1. Physical layout of detectors

ain factors:

- Density of gas to be detected: in elevation for gases lighter than air and low down for gases

heavier than air

- Leak point: determination of the probable source of a leak

- In the flow of air in ventilated rooms.

9

Page 9

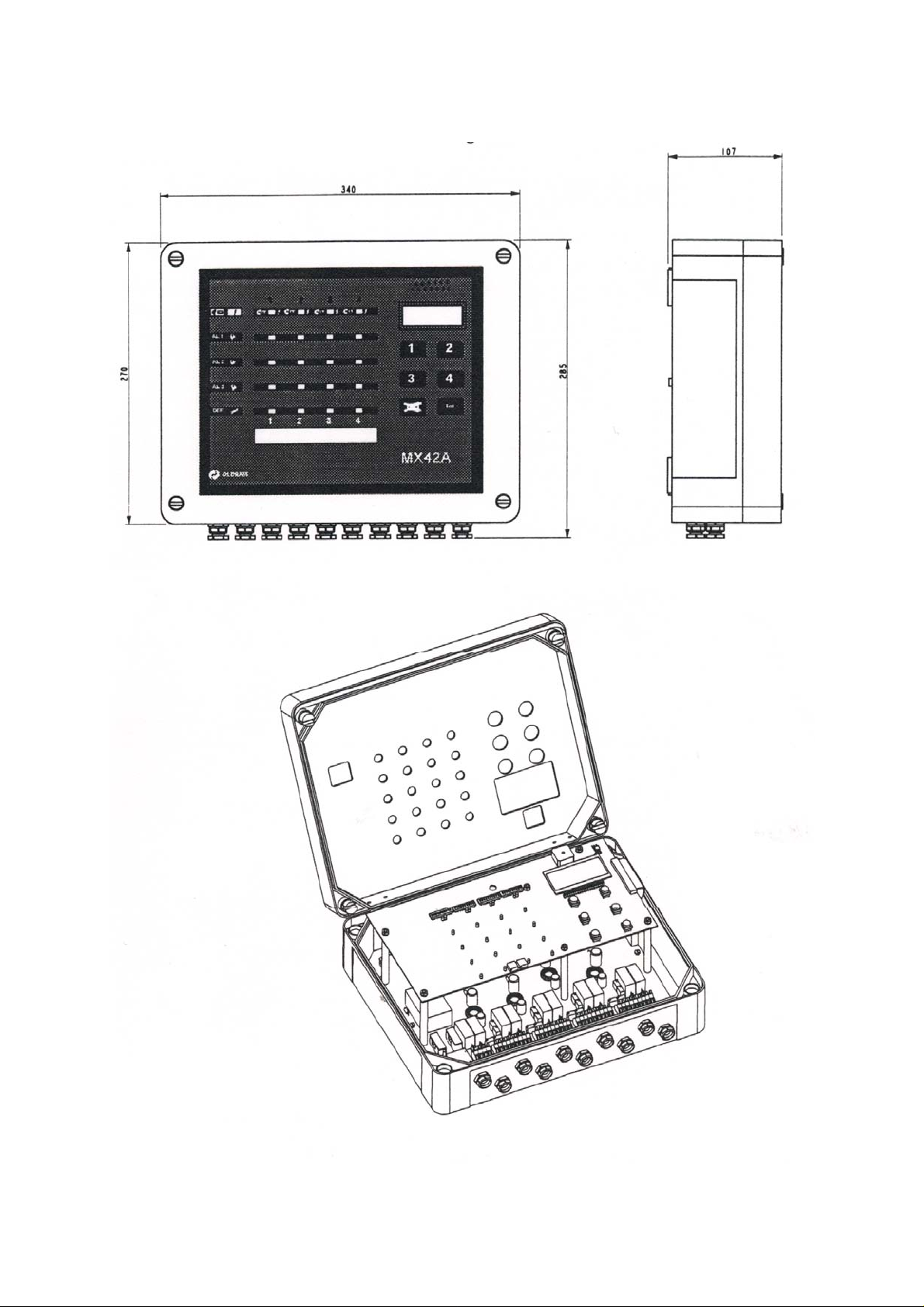

Transmitters 4.20 mA / 2 wires.

Explosimetric transmitters

(catalytic celles) with 3

wires

Figure 3

4.20 mA /3 wires for

flammable gas transmitters

4.20 mA / 2 wires /

transmitters for parking CO

detection

10

Page 10

2.3.2 Type and connection of detectors (fig 3).

3 types of detectors are to be differentiated:

- Explosimetric detectors of the BRIDGE type (no integrated electronics, 3 connecting wires

of an armoured cable).

Resistance of detection unit - detector cable: maximum 8 ohms per wire (length 500 m,

cable 3 x 1.5 mm²), or 16 ohms in a loop.

- Explosimetric detectors of the 4-20 mA type (a shielded cable with 3 wires of an armoured

cable).

Resistance of detection unit - detector cable: maximum 16 ohms per wire (length 1 km,

cable 3 x 1.5 mm²), or 32 ohms in a loop.

- Toxic gas or oxygen detectors of 4-20 mA type (a shielded cable with 2 wires).

Resistance of detection unit - detector cable: maximum 16 ohms per wire (length 1 km,

cable 3 x 1.5 mm²), or 32 ohms in loop.

It is specified that

detectors are connected by SHIELDED CABLES

using shielded cables is compulsory

the screen of shielded cables must be connected to the earth at two

extremities (detectors and control unit)

connections to the earth are considered as equipotential.

a) Parking garage application

Toxic gas detectors "Co-parking" type can be mounted in parallel in the event that it is necessary to

obtain an average gas concentration. It is absolutely essential that the detectors be located in the

same area. A max of, five detectors can be connected in parallel.

Connection of the Zener barrier

11

Page 11

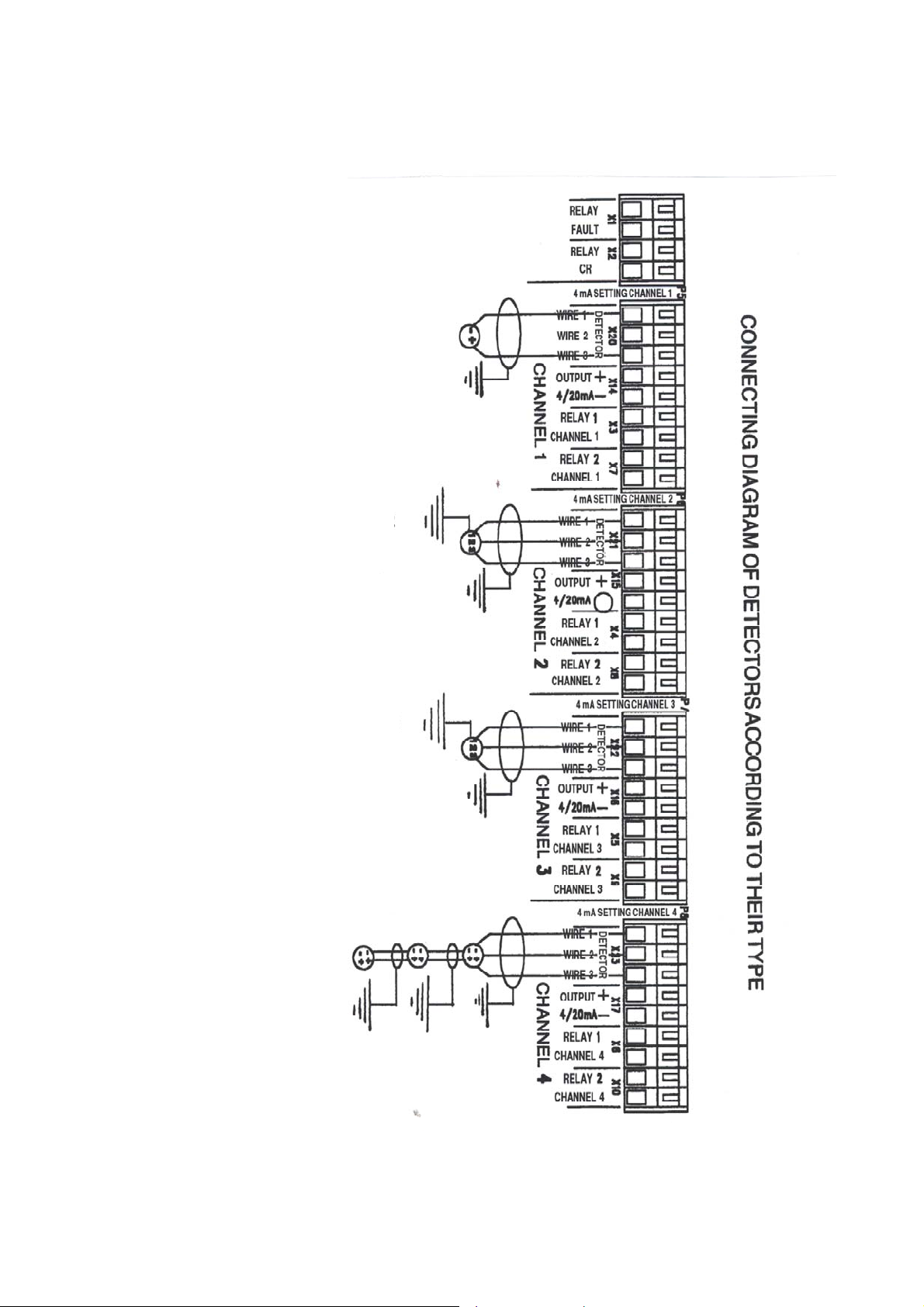

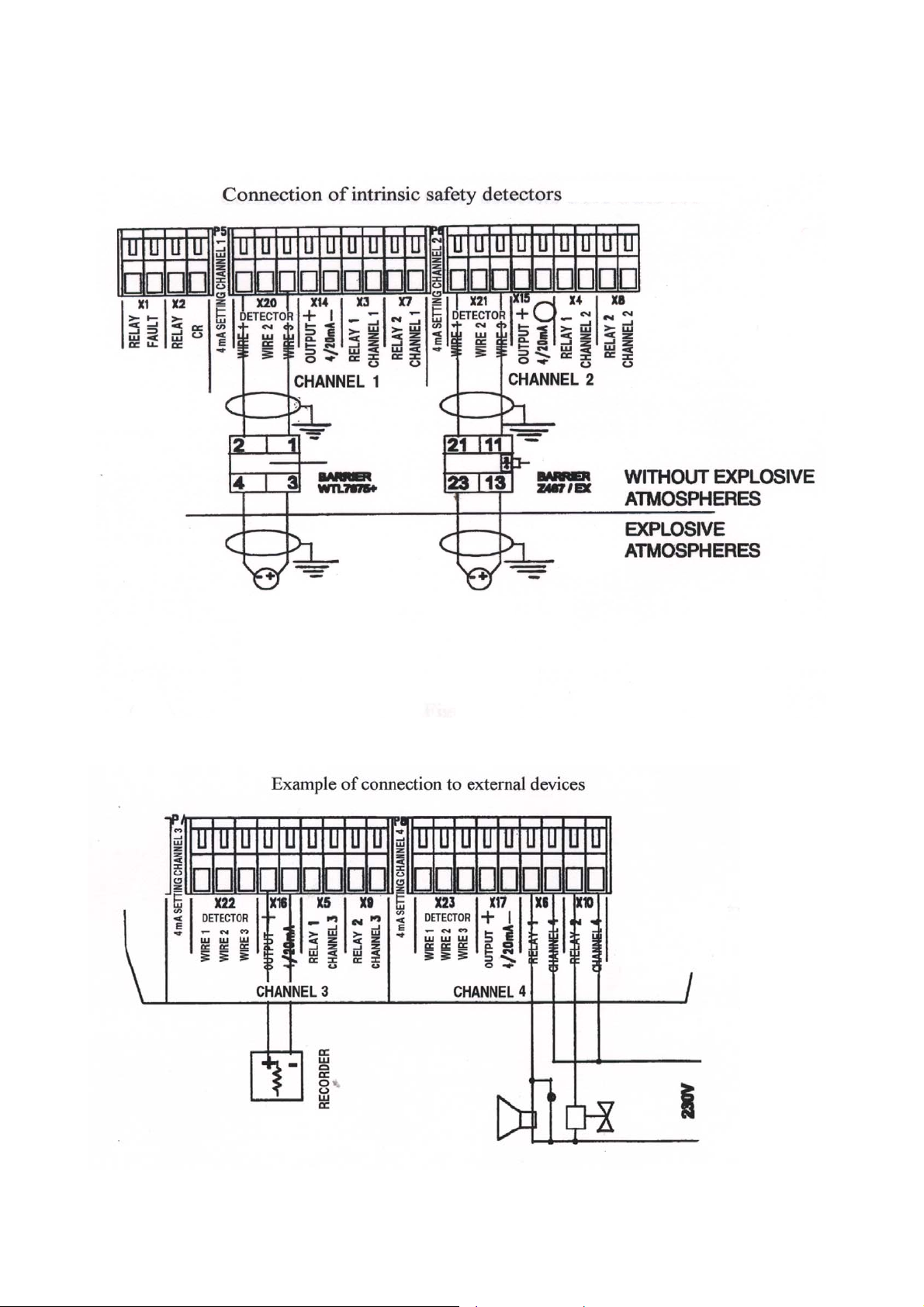

The Figure 4 describes the connection between the detector and the barrier

Figure 4

"i"

"i"

transmitters

transmitters

Figure 5

12

Page 12

b) Special case of intrinsic safety detectors

In an area classified as having an explosive atmosphere, the electrical connection between the

detection unit and the detector must be of the intrinsic safety type.

This requires the use of:

- a certified barrier

- the conformity of the connecting cable (electrical parameters stipulated in the certificate of

conformity of the detector to the legislation in force).

Figure 4 shows the connection of the detector and of the barrier according to the type of barrier

employed.

CAUTION: The conformity of the complete electrical safety system is not the responsibility of

INDUSTRIAL SCIENTIFIC.

2.4. Connection of the detection unit to external devices

2.4.1. Connection to servocontrols

The MX 42A detection unit has 10 relays which can be used to control external devices: horn,

solenoid valve, telephone call, exhaust fans,...

The relays are assigned to functions as follows:

- for each channel:

one relay, «RELAY 1», for triggering of alarm 1

one relay, «RELAY 2», for triggering of alarm 2 (or a total of 8 relays)

- for all channels:

a common relay, «CR RELAY», for triggering of alarms 3 of the channels

one relay, «FAULT RELAY», associated with faults detected on the channels

(detector malfunctions, poor electrical connections)

An example of a connection is given in Figure 5:

a light and buzzer, connected to «RELAY 1» of channel 4 will be actuated when

alarm 1 of channel 4 is present.

a solenoid valve, connected to «RELAY 2», of channel 4 will be actuated when

alarm 2 of channel 4 is present.

Note: Considering the low breaking power of the MX 42A relays (2 A with 240 V AC or

30 VDC), external relays must be interposed if the devices to be controlled have high power.

2.4.2. 4-20 mA current output

For each channel, the MX 42A detection unit has a 4-20 mA output which can be used for the copy

of measurements on a recorder or an external controller. In a loop configuration, the maximum

resistance is 600 ohms. The 4-20 mA outputs have common outer earth connections.

An example of a connection to a recorder on channel 3 is shown in Figure 5

13

Page 13

Figure 6

14

Page 14

3. START-UP AND OPERATION

Once the detection unit has been installed and connected, it is started up with the switch located on

the inside (bottom left corner).

The MX42 goes on test mode checking the proper operation of the LEDS, LCD and the buzzer.

All alarms are inhibited during test mode.

Then, the MX 42 displays channel 1 during one minute before starting scrutening all channels.

2 cases can happen:

a) Channel 1 is off (inter 8)

The display indicates « STOP », the green signal lamp « display » is steady on and the green signal

lamp « channel in operation » is off.

b) Channel 1 is in operation (inter 8)

The display indicates « INIT » and then displays the actual measurement value, and the green signal

lamp « channel in operation » blinks, the green signal lamp « display » is steady on.

During the scrutening of all channels, each channel is scanned by the MX 42 every 9 seconds, and

the reading is held during 3 seconds.

On the front of the detection unit (Figure 6), the keys 1, 2, 3 and 4 are used to display the

measurements of channels 1, 2, 3 and 4 respectively on the common LCD display window.

The «TEST» key triggers the lighting of all signal lamps and all segments of the LCD display and

the functioning of the buzzer.

The «BUZZER» key resets the alarms and clears the buzzer alarm.

For each channel, 5 signal lamps indicate the status of the channel.

a double signal lamp (Operation/Display):

- channel in operation: LED green colour, blinking or steady on (left LED).

- channel on display: LED colour green, steady on (right LED)

- display signal if channel displayed on LCD window

Alarm 1 signal: red when alarm

Alarm 2 signal: red when alarm

Alarm 3 signal: red when alarm

Fault signal:

- malfunction on line: LED colour yellow, steady on

Calibration signal:

- calibration mode: LED colour yellow, blinking

In the event of an alarm or fault, the detection unit’s buzzer is actuated until cleared by the key

«BUZZER».

Note: The buzzer can be inhibited by moving the strap on the display board (top right corner) to the

OFF position.

15

Page 15

Figure 7

16

Page 16

4. CONFIGURATION OF ALARMS AND SERVOCONTROL

Caution: Adjustments described in this section are to be performed by authorized personnel only, as

they are likely to jeopardize detection on which safety depends.

4.1. Characteristics of alarm triggering

There are three alarm thresholds associated with each channel:

- Threshold 1 controls Alarm 1 signal lamp and relay 1.

- Threshold 2 controls Alarm 2 signal lamp and relay 2.

- Threshold 3 controls Alarm 3 signal lamp and the CR relay (common relay).

Note: The CR relay is common to all channels.

For each channel, a block of micro switches are located on the display board and are used to

program the characteristics of alarm thresholds (Figure 7).

Each channel is put into service by micro switch 8 (ON-OFF).

* The alarms can be given increasing or decreasing values. Programed by micro switche 4 for

alarm 1 and 1 for alarms 2 and 3.

* The alarms can be set:

- With automatic clearance: (micro switch 3)

When a threshold is reached, the associated lamp and relay are activated. When the

threshold decreases, the signals are automatically deactivated.

- With manual clearance: (micro switch 3)

When a threshold is reached, the lamp and relay are activated.

When a threshold decreases, the signals are deactivated by the manual reset button being

pressed.

: Threshold alarm 3 has automatic clearance.

Note

a) Special case of the 3rd alarm threshold:

The 3rd alarm relay, common to the channels are energized:

- either after a period of time set by micro switches 9 and 10.

The «ALARM 3 DELAY TIME CODING» table gives the position according to the

desired lapse time required.

- or when the average value reaches the 3rd alarm threshold.

The time of averaging is set in the maintenance-adjustment Section 4.2.

Microswitch 2 is used to set alarm 3 on either delay time or averaging.

17

Page 17

Figure 8

18

Page 18

b) Special case of alarms 1 and 2 in parking garage cycle

With micro switch 5, it is possible to select the way in which relays 1 and 2 will be activated, i.e.

- according to a special control cycle, used only to start extractor fans, especialy in parking

garages.

In this case, alarm 1 is generally associated with the low speed (LS) of the extractor fan. Alarm 2 is

associated with the high speed (HS) of the fan. The control cycle in the parking garage mode is

provided to avoid destruction of the fan due to sudden change over from low speed to high speed.

The control logic is shown in Figure 8.

Figure 9

19

Page 19

4.2. Programming of parameters

The alarms are adjusted in the factory. However, these adjustments can be changed:

For the selected channel, use the following configuration (Figure 9).

Switch 8 : on

Switch 7 : maintenance

Switch 6 : adjustment

In this mode, keys 1, 2, 3 and 4 have the following functions:

Key 4 = «enter + change over to following parameter»

Key 3 = «view the value of the parameter»

Key 2 = «key +» increments the parameter

Key 1 = «key -» decrements the parameter

The following parameters are accessed successively:

AL1: alarm 1 threshold

AL2: alarm 2 threshold

AL3: alarm 3 threshold

T1 : averaging time of alarm 3 (0=<val=<1999 minutes)

PT : sets the position of the decimal point according to the detector measuring range.

SUP : overrange

EXAMPLE 1 : positioning alarm 3 at 150 for channel 2:

- On the micro switch block of channel 2, position micro switch 7 to MAINTENANCE, 6 to

ADJUSTMENT. The LCD displays AL1.

- Press the «enter» key. The LCD displays AL2.

- Press the « enter» key. The LCD displays AL3.

- Press the «view» key. The LCD displays the present value of the alarm 3 threshold.

- With the «+» and «-» keys, set the desired threshold.

- Press the «enter» key. The threshold is memorized.

- Set micro switch 7 to normal.

20

Page 20

EXAMPLE 2

: How to program the function "overrange " (SUP)

Concerning a new function "100 % LEL overrange" (software version : V9)

That function can be preprogrammed in operation or not

Procedure of programming :

Consult chapter 4.2 informations (technical manual) to use the keypad

The new list of programmable parameters will be :

AL1/AL2/AL3/TI/PT and now SupX (X=preprogrammed channel number)

The parameter "SUP" will be inhibited if "OFF" (touche 1) validated (touche 4)

The parameter "SUP" will be in operation if "ON" (touche 2) validated

If the function "SUP" is validated and if your are detecting a concentration of 100 % LEL or

more : the display will show this message "SUP" and you will be blocked

If the function "SUP" is triggered, all the alarms "gas and default" will be activated

To acknowledge this alarm "SUP" :

Either you move the switch 7 (see picture 7)

Or you move the switch 8 (see picture 7)

Or you move the switch of power supply (see picture 2)

Note:

The fault lamp blinks to signal the maintenance mode. The maintenance mode lasts for 30 minutes.

Beyond that time, the channel automatically changes over to fault. Only one channel can be

programmed at a time.

When a channel is in the maintenance mode, the 4-20 mA current output is set to 2 mA.

21

Page 21

Figure 10

22

Page 22

4.3. Servocontrol

4.3.1. Relays

With the position of straps S3 to S12 (Figure 10), the open or closed contacts of the relays can be

selected on the output of the terminal blocks.

This selection is made by simply moving the corresponding straps. As standard, the relays (except

for the fault relay) are in positive safety, which means energized without an alarm.

4.3.2. 4-20 mA current output

A 4-20 mA output is available on the terminal block for each channel. It serves to connect the MX

42A detection unit to a chart recorder or to any other data acquisition system (maximum load

resistance 600 ohms).

In the event of malfunction, the output is set to a current < 1 mA.

In the maintenance position, it is set to a current of 2 mA.

Note:

The 4-20 mA output is preset in the factory: 4 mA corresponds to a display of 0 and 20 mA

corresponds to a full-scale value. Potentiometers P5, P6, P7 and P8 (for channels 1, 2, 3 and 4

respectively) adjust the 4 mA. Potentiometers P21, P22, P23 and P24 (for channels 1, 2, 3 and 4

respectively) adjust the 20 mA.

23

Page 23

Figure 11

24

Page 24

5. PERIODIC SERVICING

Gas detection instruments are potential life-saving devices. Recognizing this fact,

Industrial Scientific Corporation recommends that a functional “bump” test be performed

on every fixed gas-monitoring instruments as part of a regular maintenance program. A

functional test is defined as a brief exposure of the detector to a concentration of gas(es)

in excess of the lowest alarm set-point for each sensor for the purpose of verifying sensor

and alarm operation and is not intended to be a measure of the accuracy of the

instrument.

Industrial scientific further recommends that a full instrument calibration be performed

using a certified concentration(s) of calibration gas(es) quarterly, every 3 months.*

Calibrations may be necessary more or less frequently based, for example, on application,

field conditions, exposure to gas, sensor technology, and environmental conditions. The

frequency of calibration is best determined by company policy or local regulatory agencies.

If an instrument fails to operate properly during any functional “bump” test, a full instrument

calibration should be performed successfully prior to use.

These recommendations are based on safe work procedures, industry best practises, and

regulatory standards to ensure worker safety. Industrial scientific is not responsible for

setting safety practices and policies.

* For new installations it may be prudent to carry out bump tests frequently at first (perhaps

weekly), increasing the time intervals (to, perhaps, monthly or more) as confidence grows

with experience in the installation concerned, on the basis of the maintenance record.

Caution: The adjustments described in this section are to be carried out by authorized personnel

only, since they are likely to jeopardize detection on which safety depends.

5.1. Adjustment of detectors from the MX 42A detection unit

Adjustm

detector to the reference gas.

For each channel, use the following configuration (Figure 7).

Switch 8 = on

Switch 7 = maintenance

Switch 6 = calibration

* Adjustment of detector zero

Use potentiometer P9 for channel 1, P12 for channel 2, P15 for channel 3 and P18 for channel 4

(Figure 11, «ZERO») to display 0000 on the channel in question. If the ambient air is not pure,

inject air from a cylinder containing synthetic air.

ent consists of calibrating the zero of the detector in pure air and the sensitivity of the

25

Page 25

* Adjustment of the sensitivity of the detector

- Inject the reference gas with the calibration tube at the recommended flow rate (30 to 60

l/h, depending upon the detector).

- When the reading has stablized, adjust display to the value of the reference gas using

potentiometer P11 for channel 1, P14 for channel 2, P17 for channel 3 and P20 for channel

4 (Figure 11, «SENS»).

Return to the configuration:

Switch 8 = on

Switch 7 = normal

Switch 6 = calibration

In the maintenance mode, the current output is set to 2 mA.

Caution: If forgotten, the channel automatically changes over to fault after 1/2 hour.

5.2. Local adjustment at the detectors

For some types of detectors, in particular the 4-20 mA detectors, the zero and sensitivity can be

adjusted directly on the detector (refer to the detector instruction manual).

Note:

We are at your disposal to supply you with calibration gas or an annual servicing contract. The

work under this contract is performed by our specialists, and this contract will guarantee perfect

operation of the installation. Between the dates of the scheduled servicing work performed by

INDUSTRIAL SCIENTIFIC, no adjustment is necessary. The maintenance department of the user

is thus not burdened by any additional work load.

26

Page 26

6. TROUBLESHOOTING

FAULT-MESSAGE CAUSES CORRECTIVE ACTION

Display off or no signal

lamp lighted

«STOP» displayed channel out of service put the channel in service

«INIT» displayed channel undergoing initialization message displayed as soon

Fault signal lamp lighted

(yellow)

Fault signal lamp lighted

and «DEF» displayed

Yellow LED lighting and

display "SUP"

Fault signal lamp

blinking

External servocontrol

controlled in opposite

direction, in relation to

the tripping of the alarm

- fuse blown

- switch on OFF

- bad detector electrical connections

- defective detector

- the type of detector does not

correspond to the factory

configuration of the channel

- channel very badly adjusted

channel in maintenance mode

for more than 30 minutes

Explosible channel overrange (>

100 % LEL) triggering

channel in maintenance position reset the channel on

bad choice of relay contact move the strap to use the

- check power supply

voltages

and change the fuses if

necessary (cf 22)

- set the switch to ON (cf

III)

(cf 41)

as a channel is put into

service (cf III)

- check the connections

- change the detector

- change the type of detector

(Caution: The channel could

have been damaged)

- adjust the channel (cf V)

reset the channel on

«NORMAL» (cf Figure 7)

Remove switches 7 or 8 (for

concerned channel)

«NORMAL» (cf Figure 7)

common NO contact or the

common NC contact (cf

431)

27

Page 27

7. DETAILED TECHNICAL CHARACTERISTICS

7.1. Casing

Casing : PVC (polyvinyl chloride), completely shielded inside

Operating temperature : -10°C to +40°C

Storage temperature : -20°C to +55°C

Relative humidity : 0 to 95%, non condensing

Tightness : IP54

Dimensions : 340 x 300 x 107 mm (length x height x depth)

Weight : 4.75 kg

Positioning : wall-mounted

Guarantee : 1 year

Function : wall-mounted monitoring unit for gas detection

Capacity : 4 channels (2 on option)

Measurement : continuous

Connection : 1 to 5 gas detectors per channel (depending on type)

Manufacturer : INDUSTRIAL SCIENTIFIC

7.2. Display

Display : Digital LCD

Measuring scale : 0 to 100 0 to 300 0 to 1000 0 to 2000

Signal lamps : 24 DELs, see details in Section «ALARM»

7.3. Power supply

Electrical supply accessible in casing

* 103 V to 122 V AC, 50/60 Hz (option)

* 207 V to 244 V AC, 50/60 Hz

* 19 V to 32 V DC

* 43 to 60 V DC (option)

Fuses:

0.63 A, time-delayed, for 230 V and 110 V

4 A for 24 V

2 A, time-delayed, for 48 V

Power consumption: 85 VA or 67 W

On/off switch inside casing

Earth terminal: yes

Cable outlet through 10 metallic cable glands, connected to the earth.

Maximum shielded cable diameter: 10 mm

28

Page 28

7.4. Measurement inputs

Line resistances (loop) in ohms between detector and detection unit

* Explosimetric detector of the BRIDGE type, 3 wires: 16 ohms (500 m long, cable 3 x 1.5mm²)

* Explosimetric detector of 4-20 mA type, 3 wires or 2 wires: 32 ohms (1 km long, cable 3 x

1.5mm²)

7.5. Alarm

Visual alarms provided: for each channel

* fault signal lamp:

- channel in service: green color

- channel off or malfunction of microprocessor: off

- disturbance on line: steady yellow color

- calibration/adjustment mode: blinking yellow color

* alarm 1 signal lamp: red color when alarm

* alarm 2 signal lamp: red color when alarm

* alarm 3 signal lamp: red color when alarm

Alarms 1 and 2

- activation after 5 seconds

- by increasing or decreasing value

- manual or automatic clearance

Alarm 3

- activation after elapsed delay time or on basis of average value

- automatic clearance

- by increasing or decreasing value

Disturbance

- complete check of short circuit or cut out of at least one wire (with just one detector)

- display per channel with yellow signal lamp

Buzzer

Triggered if:

- microprocessor malfunction

- anomaly of connecting cable or detector

- alarm threshold level exceeded

- maintenance time longer than 30 minutes

29

Page 29

7.6. Control functions

Accessible after removal of front panel

For each channel:

- A set of 10 microswitches

Microswitch no. 8: on/off

Microswitch no. 7: maintenance/normal

Microswitch no. 6: programming/normal

Microswitch no. 5: normal/parking garage (alarm 1 and 2)

Microswitch no. 4: increase/decrease (alarm 1)

Microswitch no. 3: manual/auto (alarm 1 and 2)

Microswitch no. 2: time delay/average (alarm 3)

Microswitch no. 1: increase/decrease (alarm 2 and 3)

Microswitch no. 9: time delay coding (alarm 3)

Microswitch no. 10: time delay coding (alarm 3)

- Potentiometers for the adjustment of zero and sensitivity of detector

- Programming by keys of alarms thresholds, averaging time (alarm 2)

7.7. Relaying

Relay contacts

* 2 relays per channel for alarm 1 and alarm 2 (positive safety)

* 1 common relay for alarm 3 (or on option for remote transmission of alarm) (positive safety)

* 1 common relay for malfunction (negative safety)

* for each relay, choice of common closed contact or common open contact (by positioning of

straps S3 to S12)

* characteristics of contact: 2A-250 V AC or 30 VDC

7.8. Output of measurements

4-20 mA current outputs per channel (common earth)

Load resistance (loop): maximum 600 ohms

In case of fault: output < 1 mA

In maintenance position: output = 2 mA

30

Page 30

8. Scrapping of mx42a

Concerning the conservation, of the protection and the improvement of

the quality of the environment, as well as for the protection of the health of

the persons and the careful and rational use of natural resources, MX42A

has to be the object of a selective collection for the electronic equipments

and cannot be scrapped with the normal domestic waste. The user thus

has the obligation to separate the MX42A of the other waste so as to

guarantee that it is recycled in a sure way at the environmental level. For

more details of the existing sites of collection, contact the local

administration or the distributor of this product.

9. LIST OF MX42A SPARE PARTS

9.1. Spare parts

DESIGNATION REFERENCE

Analog bus card 6451403

µp/display card 6451402

LCD 6133511

MX42A casing 6321280

PG 9 cable gland 6143442

MX42A sticked front panel

5 x 20 : 630 mA fuse 6154627

5 x 20 : 4 A fuse 6154715

tool kit 6147840

9.2. Intrinsic barriers and accessories

MODELS OF SI

BARRIERS

Z787 / EX 6184703 rail DIN mounted

MTL787S+ 6797100 Obligatory

for 5 zener

for 12 zener

REFERENCE

model

flammeproof casing

mounted model

TYPES

for 2 zener

barriers

barriers

barriers

6122435

INDUSTRIAL SCIENTIFIC

CASING

6797192

6797547

6797101

31

Page 31

10. Special Specifications for use in Potentially Explosive

Atmospheres in accordance with European Directive ATEX

94/9/EC.

The MX42A detection device designed to measure explosive gasses and oxygen complies

with the requirements of European Directive ATEX 94/9/EC on potentially explosive atmospheres.

As a result of its metrological performance, as tested by the research and testing

organisation INERIS, the MX42A device, is classified as a safety device when used with

INDUSTRIAL SCIENTIFIC CEX300 and OLC/OLCT 20, 40, 50 and 60 series detectors. The

device may therefore contribute to limiting the risk of explosion as a consequence of the data it

supplies to external units.

The information contained in the following paragraphs should be adopted and complied with

by the person responsible for the site on which the equipment is installed. Please refer to the

provisions of European Directive ATEX 1999/92/EC on improving health and safety conditions for

workers exposed to potentially explosive atmospheres.

10.1. Specifications for mechanical and electrical installation in Classified Areas.

Installation will comply with all applicable standards, and particularly with EN 60079-14,

EN 60079-17 and EN 50281-1-2.

The MX42A device must not be subject to intense mechanical vibration and must be

installed in a safe area away from potentially explosive atmospheres.

It is essential to refer to the user and installation manuals for the gas detectors referred to

above, particularly the paragraph entitled ‘Special Specifications for use in Potentially Explosive

Atmospheres in Accordance with European Directive ATEX 94/9/EC’

Where intrinsic safety installations are concerned, it should be borne in mind that the person

responsible for IS installation (the “System Designer”) must draw up a system document

demonstrating that every aspect of the Power Cable Detector system complies with intrinsic safety.

Please refer to EN 50039 for group II and EN 50394-1 for group I when drafting this document.

10.2. Metrological Specifications

The device complies with the following European standards:

With explosive gas detectors:

- European standards EN 50054 and EN 50057 for Methane (calibration gas), Propane and

Hydrogen (gasses following response curves) where the device is used with CEX300

and OLC/OLCT 20, 40, 50 and 60 series gas detectors. Where the device is used with

other types of sensor producing an output measurement current of 4/20 mA, these must

comply with paragraph 1.5 of Appendix II of the ATEX 94/9/EC Directive and be

compatible with their characteristics (cf. device transfer curve).

- European Standard EN 50271

32

Page 32

Oxygen detectors:

- European Standard EN 50104 where the device is used with OLCT 20, 40, 50 and 60 gas

detectors. Where the device is used with other types of sensor producing an output

measurement current of 4/20 mA, they must comply with paragraph 1.5 of Appendix II

of the ATEX 94/9/EC Directive and be compatible with their characteristics (cf. device

transfer curve).

- European Standard EN 50271

10.3. Connecting detectors other than INDUSTRIAL SCIENTIFIC detectors to the MX42A device

As previously explained, users wishing to connect detectors other than those manufactured by

INDUSTRIAL SCIENTIFIC, must ensure their compatibility with the device in order that the

resulting combination may be considered as a safety device.

10.3.1. Device transfer curves in 0% to 100% LEL configuration

The following curve shows the response of the device in terms of value measured, and fault

processing as a function of the input current value supplied by the detector. Where the user

connects a brand of detector other than INDUSTRIAL SCIENTIFIC to the MX42A device, he must

check carefully that the transfer curve is fully compatible with the device input characteristics, to

ensure that the data generated by the detector is correctly interpreted. Equally, the device must

supply a suitable power supply voltage, allowing for cable voltage losses.

Display

in % LEL

SUP

100% LEL

Fault

0% LEL

-17.5% LEL

1.3

mA

4

mA

Fault

20

mA

Signal supplied by

the detector in mA

Please note: When the value measured is >= 100% LEL, the measuring device memorises the fact

that the value has exceeded the scale and the channels switch to alarm and fault mode. Resetting

these statuses is a manual operation to be performed by the user, who must follow the safety

regulations specific to the site. The reset is checked either by turning the device on and off or by a

maintenance inspection.

33

Page 33

t

10.3.2. Device transfer curves in 0% to 30.0% OXYGEN configuration

The following curve shows the response of the device in terms of value measured, and fault

processing as a function of the input current value supplied by the detector. Where the user

connects a brand of detector other than INDUSTRIAL SCIENTIFIC to the MX42A device, he must

check carefully that the transfer curve is fully compatible with the device input characteristics, to

ensure that the data generated by the detector is correctly interpreted. Equally, the device must

supply a suitable power supply voltage, allowing for cable voltage losses.

Display in %

O2 by

Fault

39.4%

30.0%

0.0

-5.0%

Faul

Signal supplied

1.3

4

mA

mA

10.3.3. Power supply and load resistance characteristics

Maximum current available between terminals 2 and 3: 250 mA at 19 V.

Maximum no-load voltage between terminals 2 and 3: 30 V

Load resistance (outside the IS barrier) between terminals 1 and 2: 47 ohms

N.B.: This data applies only where detectors other than INDUSTRIAL SCIENTIFIC are used.

Where different types are mixed, please contact INDUSTRIAL SCIENTIFIC to establish the

feasibility of the combination.

10.4. MARKING

INDUSTRIAL SCIENTIFIC

0080

20

mA

25.

mA

by

II 2 (G)

INERIS 04ATEX0064

34

Page 34

35

Page 35

36

Loading...

Loading...