Page 1

Installation and

Operating Manual

MX 32

2 CHANNEL

CONTROLLER

Reference: NPM32GB

Revision: B.1

The Fixed Gas Detection Experts

Page 2

ii

MX 32

Instruction Manual

Copyright 2013 by Oldham

All rights reserved. Reproduction in any form, in whole or in part, without the

express written consent of Oldham is strictly prohibited.

The information contained within this manual is true and correct to the best of

our knowledge.

Due to ongoing research and development, the specifications of this product

may be changed at any time without notice.

Oldham

Rue Orfila

Z.I. Est – CS 20417

F – 62027 ARRAS Cedex

Phone: +33 (0)3 21 60 80 80

Fax: +33 (0)3 21 60 80 00

Page 3

iii

MX 32

Instruction Manual

Table of Contents

Chapter 1 │General Information ................................................... 1

The User’s Guide ......................................................................................... 1

Symbols used .............................................................................................. 1

Safety Warnings .......................................................................................... 2

Important Information .................................................................................. 2

Limitation of liability ..................................................................................... 2

Chapter 2 │General Introduction .................................................. 3

Subject ........................................................................................................ 3

View: Front internal ...................................................................................... 3

View: Front .................................................................................................. 4

LCD Information .......................................................................................... 5

View: Internal ............................................................................................... 5

Chapter 3 │ Installation and wiring .............................................. 7

Mounting the controller ................................................................................ 7

Wiring .......................................................................................................... 8

Chapter 4 │Operating instructions ............................................. 13

Displays ..................................................................................................... 13

Navigating the menus ................................................................ ................ 16

PRG Menu (Programming) ........................................................................ 18

INI Menu (Initialization) .............................................................................. 23

Cal Menu (Calibration) ............................................................................... 25

Cod Menu (Access code) .......................................................................... 30

Buz Menu (Buzzer) .................................................................................... 31

Chapter 5 │Cleaning, servicing and maintenance ..................... 33

Cleaning .................................................................................................... 33

Maintenance and servicing ........................................................................ 33

Fuse replacement ................................ ...................................................... 34

Page 4

iv

MX 32

Instruction Manual

Parts .......................................................................................................... 34

Chapter 6 │Technical specifications .......................................... 35

Chapter 7 │Technical specifications .......................................... 37

Chapter 8 │ Particular Specifications ......................................... 39

Specifications for mechanical

and electrical installations in Explosive Zones. .......................................... 39

Metrological specifications ......................................................................... 39

Connecting detectors other than

Oldham detectors to the MX 32 controller ................................................. 40

Markings: ................................................................................................... 41

Page 5

1 – General Information

1

Chapter 1 │General Information

The User’s Guide

Please read the following notice carefully before installation and start-up,

paying particular attention to the end-user safety instructions. This user’s

guide should be distributed to every individual involved in the start-up, use,

maintenance or repair of the system. The information contained in this

manual, the data and technical drawings are correct as of the date of

publication. Should questions arise, please contact Oldham for additional

information.

This manual is designed to provide users with simple and precise information.

Oldham shall not be held responsible or liable for any misinterpretation that

may result from the reading of this manual. Although every effort is made to

ensure accuracy, this manual may contain unintentional technical

inaccuracies.

On behalf of its clients, Oldham reserves the right to modify the technical

characteristics of its equipment, without notice, to improve product

performance. This user manual and its contents are the inalienable property of

Oldham.

Symbols used

Icon

Meaning

This symbol indicates useful additional information.

This symbol indicates:

This equipment must be grounded.

This symbol indicates:

Safety grounding terminal. A cable of adequate diameter must

ground any terminal with this signal.

This symbol indicates:

Caution: In the current operating mode, failure to adhere to

the instructions preceding this symbol can result in a risk of

electric shock or death.

This symbol indicates:

Please refer to the instructions.

Double isolation.

Page 6

2

MX 32

Instruction Manual

European Union (and EEA) only. This icon indicates that in

accordance with Directive DEEE (2002/96/EC) and with the

regulations of your country, this product may not be disposed with

household waste.

Dispose of this product at a collection site intended for electrical

waste, for example an official EEE (Electrical and Electronic

Equipment) collection site with a recycling or take-back program

for authorized products available to consumers whose purchases

replace old EEE products with new equivalents.

Failure to comply with regulations for the disposal of this type of

waste can be harmful to the environment and to public health, as

EEE products typically contain potentially hazardous substances.

Your complete cooperation in the disposal of this product will help

to ensure a more efficient use of natural resources.

Safety Warnings

Icons have been placed on the central controller to call attention to general

use safety precautions. These labels are an integral component of the central

controller. Replace any label that has peeled off or become illegible. The

meanings of these labels are explained below.

Installation and electrical connections must be performed by a

qualified professional, according to the manufacturer’s specif ications

and to the standards of authorities in the field.

Failure to observe these rules may result in serious injury.

Exactness, particularly regarding electricity and assembly

(couplings, network connections) is imperative.

Important Information

The modification of any component or the use of any third party components

will automatically void any and all guarantees.

The central controller is intended to be used for precise applications of a

technical nature. Exceeding the indicated values is strictly prohibited.

Limitation of liability

Neither Oldham nor any other affiliated organization shall be held liable under

any circumstances for any damage whatsoever including, without limitations,

damages for loss of production, interruption of production, loss of information,

controller failure, personal injury, loss of time, money, or materials, or for any

indirect or consecutive consequence of loss occurring during the use of the

product or the inability to use the product, even in the event that Oldham had

been informed of such damages.

Page 7

2 – General Introduction

3

Chapter 2 │General Introduction

Subject

The MX 32 controller is intended for light units that do not require an electrical

cabinet.

The MX 32 measurement and alarm controller can measure 1 or 2 channels

independently. Each channel is linked to one or more sensors installed in the

locations being monitored. The measurement from the sensor is displayed on

the MX 32 controller and compared to the alarm thresholds. In the event that

the measurement exceeds the threshold, the controller activates the relays

which can be used to control external components.

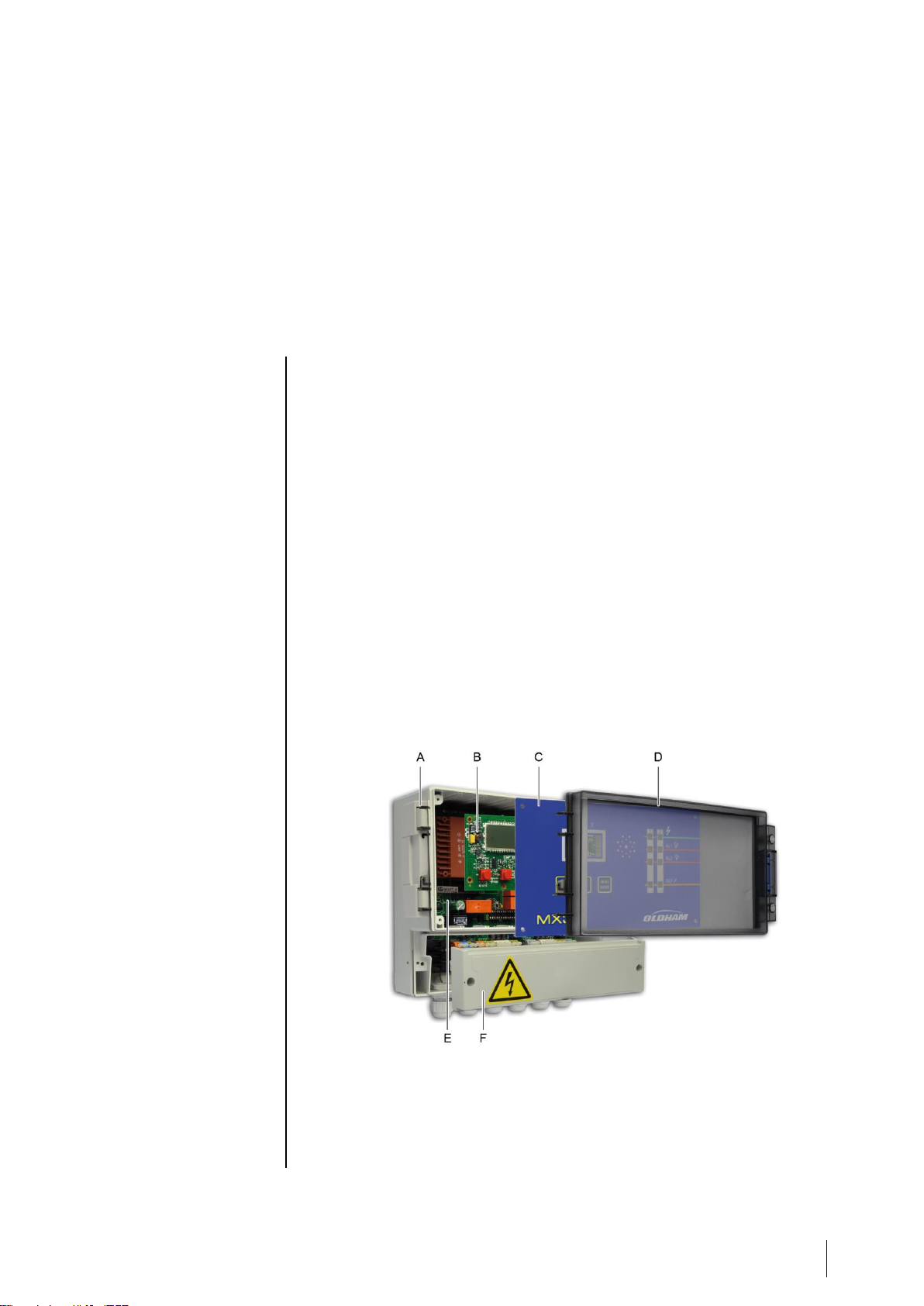

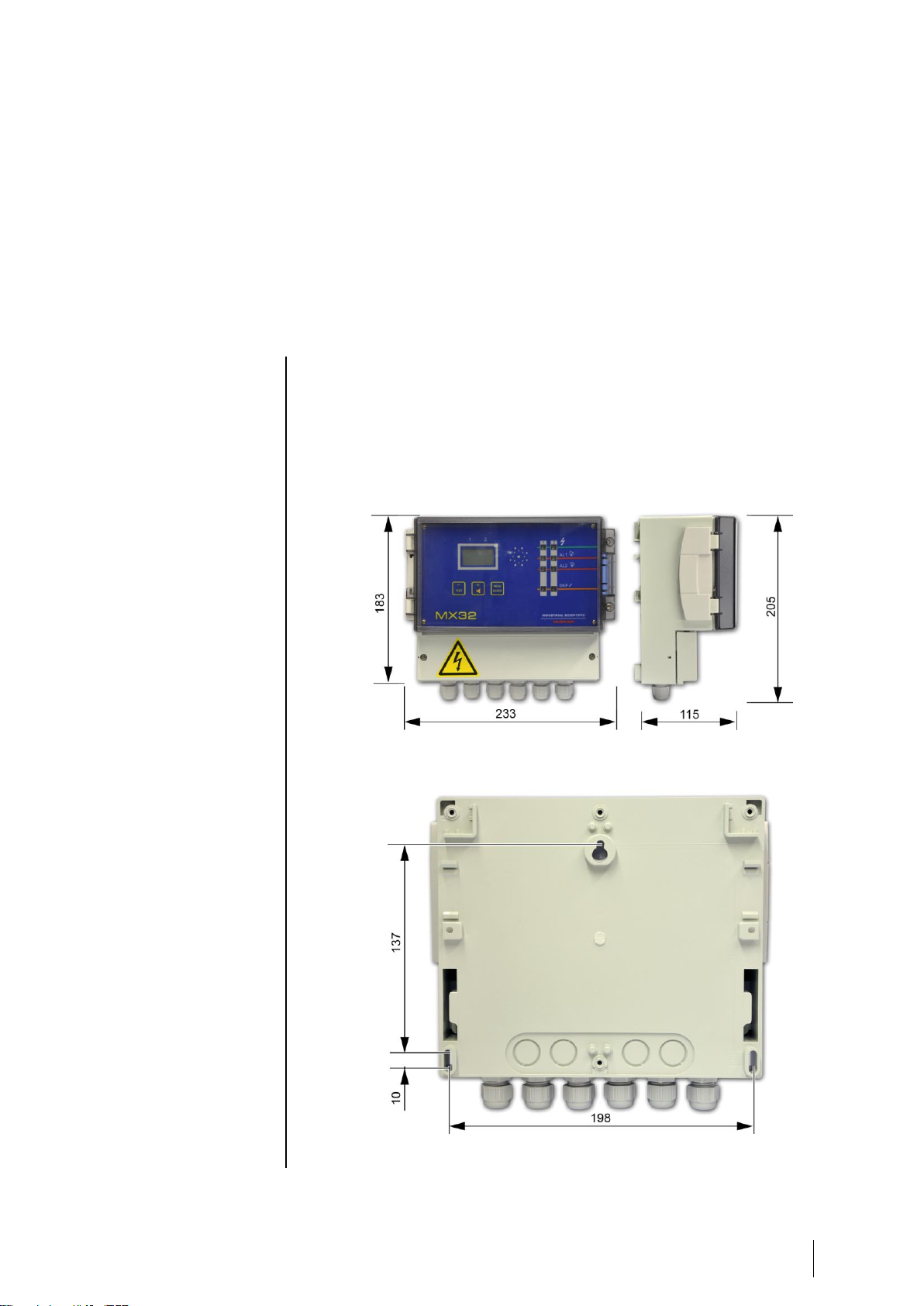

View: Front internal

The MX 32 controller is composed of the following components:

■ A wall-mounted enclosure (ref. A) equipped with a terminal cover (ref. F), a

faceplate (ref. C) and a transparent hinged cover (ref. D) ;

■ a power supply board (analog) (ref. E) ;

■ a display card (microprocessor) (ref. B).

Figure 1: Overall view of the MX 32 controller components.

Page 8

4

MX 32

Instruction Manual

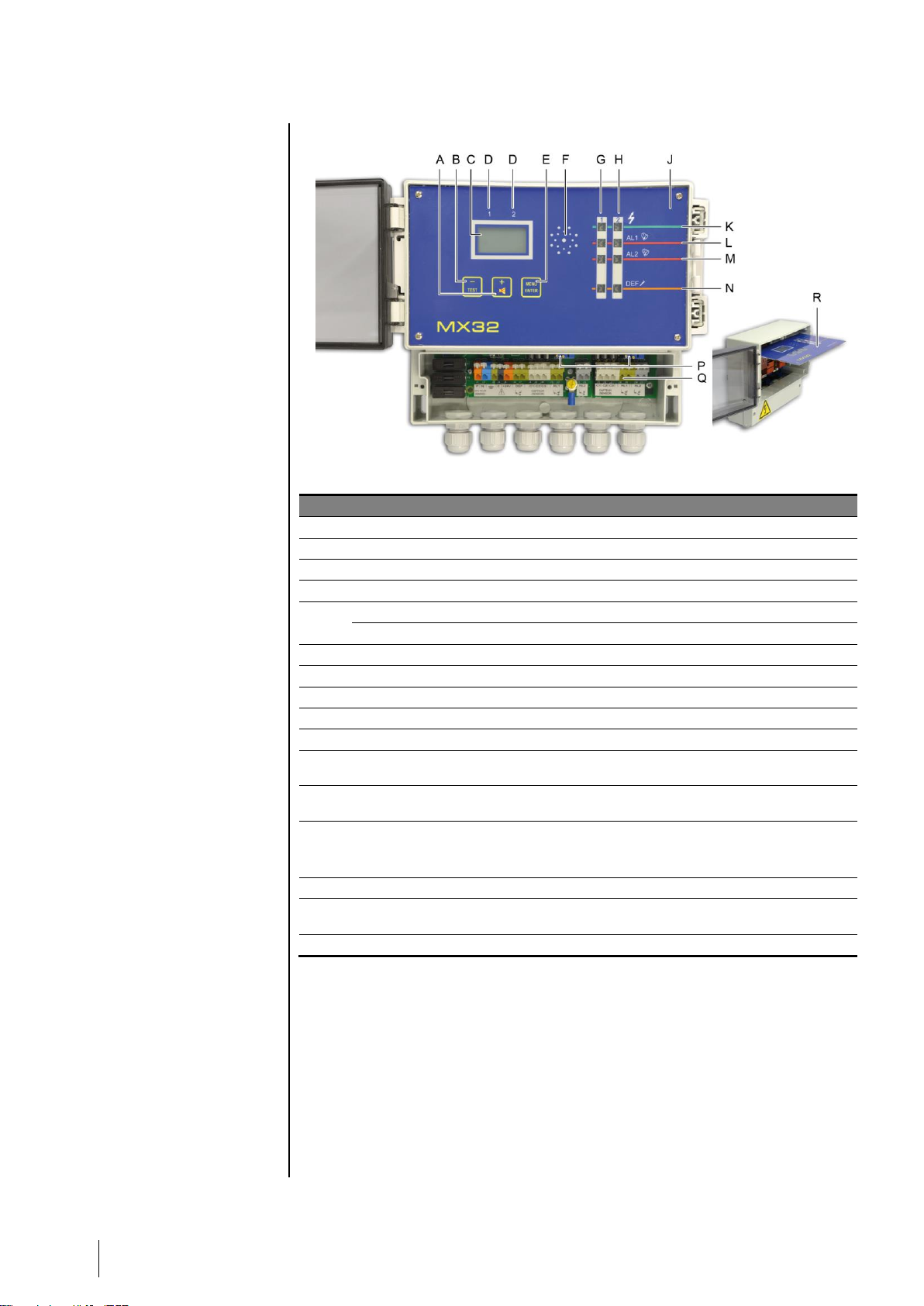

View: Front

Figure 2: Full view of the MX 32 controller.

Ref.

Function

A.

Button to increase the value displayed or flip to the next menu/option.

B.

Button to decrease the value displayed or flip to the previous menu/option.

C.

LCD screen displaying measurements, menus and options.

D.

Labels, for the LCD screen, indicating the display for Channel 1 or Channel 2.

E.

Menu access button. See page 16.

Button to confirm the value displayed.

F.

Buzzer activated in the case of fault or alarm if authorization is granted. See page 31.

G.

LEDs for Channel 1.

H.

LEDs for Channel 2.

J.

Removable faceplate; also see ref. R.

K.

LED lights up when the channel is active.

L.

Alarm threshold for level 1. LED lights up when the alarm threshold is exceeded or

when programming the alarm threshold for the channel.

M.

Alarm threshold for level 2. LED lights up when the alarm threshold is exceeded or

when programming the alarm threshold for the channel.

N.

Fault LED

■ Lights up when there is a fault in the channel.

■ Blinks during programming of the channel.

P.

Access to the zero and sensitivity settings (Figure 4, ref. O to R).

Q.

Connection terminals (sector, 24VDC, sensors, dry alarm contacts); front view with

protective cover removed.

R .

Removable faceplate in maintenance position.

Page 9

2 – General Introduction

5

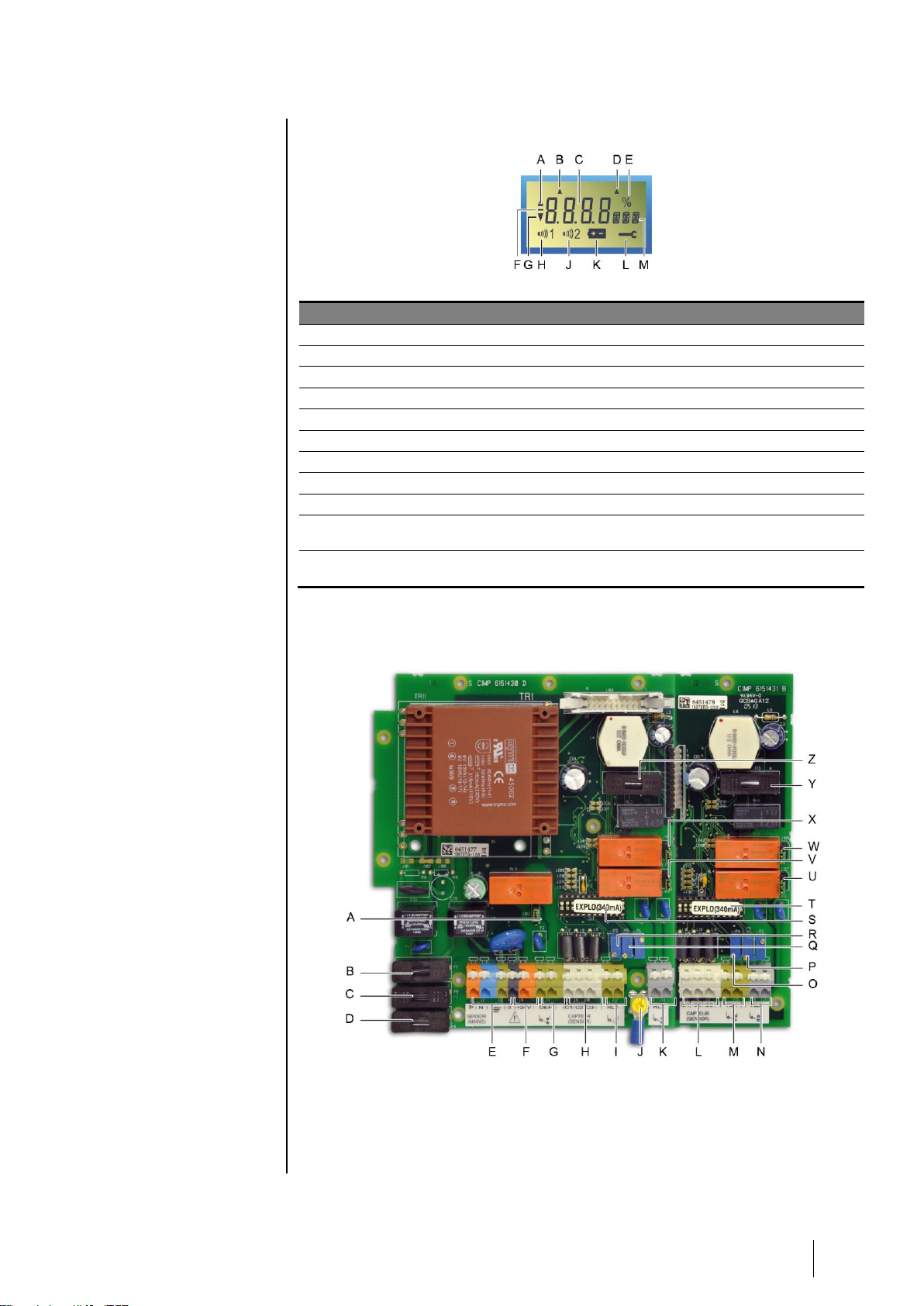

LCD Information

Figure 3: LCD Information.

Ref.

Function

See page

A.

Indicator for alarm threshold rising.

13

B.

Indicator that Channel 1 is selected. See Figure 2, ref. D.

14

C.

Digital indicator (measurement value, alarm threshold value, etc.)

13

D.

Indicator that Channel 2 is selected. See Figure 2, ref. D.

14

E.

Percent symbol.

18

F.

Negative sign.

G.

Indicator for alarm threshold falling.

18

H.

Symbol indicating level 1 alarm threshold (AL1) activated.

18

J

Symbol indicating level 2 alarm threshold (AL2) activated.

18

K.

Time delay after calibration (blocking the relays): the yellow LED blinks

and the icon is displayed.

18

L.

A Maintenance key icon is displayed while the programming and

calibration menu is being used.

18

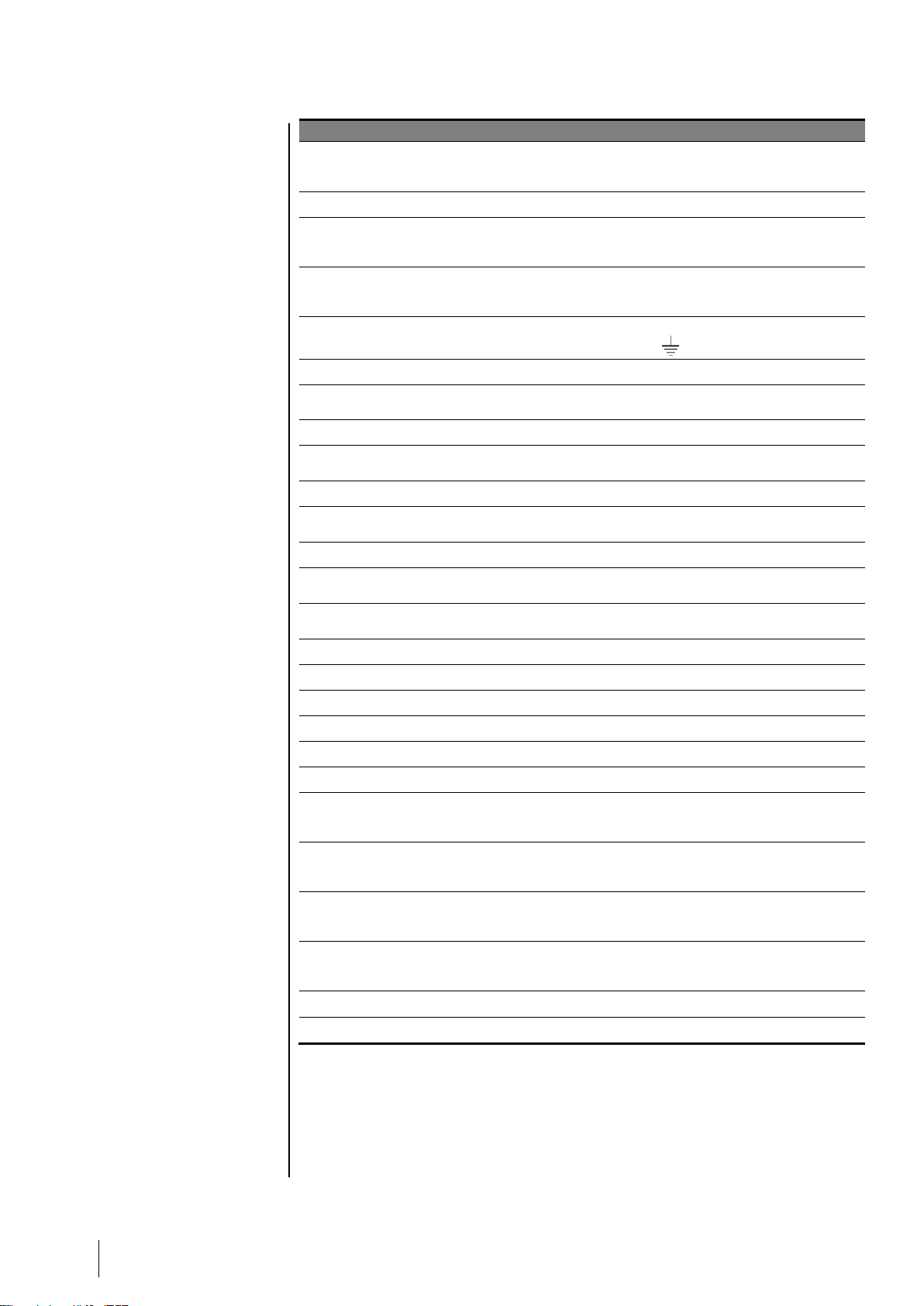

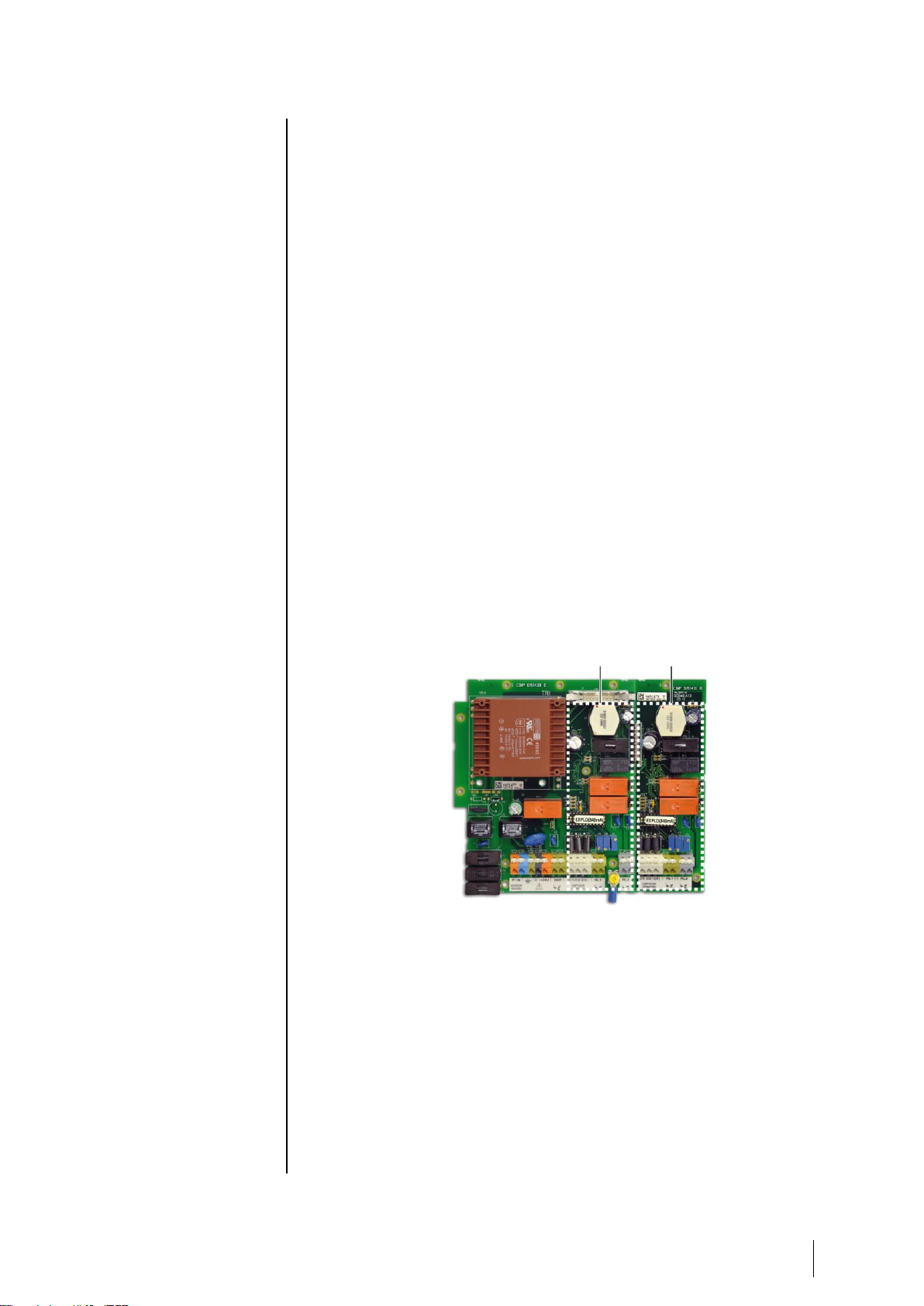

View: Internal

Figure 4: Internal view.

Page 10

6

MX 32

Instruction Manual

Ref.

Function

See page

A.

Configuration jumper (J03) for Fault* relay settings.

■ Up position: Fault relay contact closed in alarm mode.

■ Down position: Fault relay contact open in alarm mode.

10

B.

F7 Fuse (5x20, 250 V AC - 2 A T) with 24V DC power supply.

8

C.

F9 Fuse:

■ 5x20, 250 V AC - 160 mA T with 230 VAC power supply.

■ 5x20, 250 V AC - 315 mA T with 115 VAC power supply.

8

D.

F8 Fuse:

■ 5x20, 250 V AC - 160 mA T with 230 VAC power supply.

■ 5x20, 250 V AC - 315 mA T with 115 VAC power supply.

8

E.

Sector power supply terminal (230 V AC or 110 V AC upon request) with

the following identifications: P (phase), N (neutral) and (ground).

8

F.

Power terminal block 24 V DC (0, + 24V).

8

G.

Fault relay terminal block. Contacts RCT, 250 V AC – 2 A. Contact

status not in alarm mode as defined by J03 (ref. A).

10

H.

Terminal block connection for channel #1 sensor.

9

I.

Relay terminal block RL 1 - Channel 1. Contacts RCT, 250 V AC – 2 A.

Contact status not in alarm mode as defined by J10 (ref. X).

10

J.

Secondary ground connection.

8

K.

Relay terminal block RL 2 - Channel 1. Contacts RCT, 250 V AC – 2 A.

Contact status not in alarm mode as defined by J05 (ref. V).

10

L.

Terminal block connection for channel #2 sensor.

9

M.

Relay terminal block RL 1 - Channel 2. Contacts RCT, 250 V AC – 2 A.

Contact status not in alarm mode as defined by J08 (ref. W).

10

N.

Relay terminal block RL 2 - Channel 2. Contacts RCT, 250 V AC – 2 A.

Contact status not in alarm mode as defined by J07 (ref. U).

10

O.

Zero settings (P4) for channel #2.

26

P.

Sensitivity settings (P6) for channel #2.

27

Q.

Sensitivity settings (P5) for channel #1.

26

R.

Zero settings (P3) for channel #1.

27

S.

Programming circuit (Explo 340 mA or 4-20 mA) for channel #1.

-

T.

Programming circuit (Explo 340 mA or 4-20 mA) for channel #2.

-

U.

Configuration jumper (J07) for Alarm 2*, channel #2 relay.

■ Up position: relay contact closed in alarm mode.

■ Down position: relay contact open in alarm mode.

-

V.

Configuration jumper (J05) for Alarm 2*, channel #1 relay.

■ Up position: relay contact closed in alarm mode.

■ Down position: relay contact open in alarm mode.

-

W.

Configuration jumper (J08) for Alarm 1*, channel #2 relay.

■ Up position: relay contact closed in alarm mode.

■ Down position: relay contact open in alarm mode.

-

X.

Configuration jumper (J10) for Alarm 1*, channel #1 relay.

■ Up position: relay contact closed in alarm mode.

■ Down position: relay contact open in alarm mode.

Y.

F13 Fuse (5x20, 250 V AC – 630 mA T).

-

Z.

F11 Fuse (5x20, 250 V AC – 630 mA T).

-

*alarm relays are configured as energized at the factory. This means that they are supplied with

power when not in alarm.

Page 11

3 – Installation and wiring

7

Chapter 3 │ Installation and wiring

Mounting the controller

The MX 32 controller can be installed in any location except for explosive

atmospheres. Ideally, the controller should be located in an area under

surveillance (security office, control room, equipment room, etc.).

The central controller cover opens at a 90° angle to the left. Make sure to

leave adequate space to completely open the cover once the central controller

is mounted.

Figure 5: Dimensions of the controller

The dimensions for the wall-mounting of the enclosure are indicated on the back.

Figure 6: drilling dimensions for mounting the controller with three M4 screws.

Page 12

8

MX 32

Instruction Manual

Wiring

Before installing the controller, cut off the power supply.

Also refer to the Particular Specifications chapter on page 39.

The controller is intended for use in installation areas that meet Class II

overvoltage requirements and Degree 2 pollution requirements.

The electrical connection must be:

■ Performed by a specialist and conform to current regulations in force ;

■ Compliant with NF C 15-100.

Verify the current and the grid power supply (the grid power supply must

correspond to the supply indicated on the controller front plate). The operating

voltage is configured at the factory.

The MX 32 does not have an on/off switch.

Certain power supplies can cause serious or fatal injury. All

installation and wiring should be performed before turning on the

power supply.

Incorrect installation can lead to measurement errors or system

failure, all instructions in this manual must be followed carefully to

guarantee proper system operation.

Ground Connection Protection

The controller must be connected to a functional ground connection.

The ground terminal (yellow) (Figure 4, ref. J) is indicated with the following

symbol: .

The cable used must have a minimum diameter of 1.5 mm² and a maximum

diameter of 2.5 mm².

Refer to the wiring examples beginning on page 11.

Power

The MX 32 must be protected upstream by a differential bipolar circuit

breaker. The response curve must be type D.

Power supply

115 V AC

230 V AC

Differential bipolar circuit

breaker caliber

2 x 2 A

2 x 1 A

The cable used must have a minimum diameter of 1.5 mm² and a maximum

diameter of 2.5 mm².

There are two options for transformers suggested for use as a power supply

for the MX 32.

■ Bobbin transformer (standard default).

■ Toric Transformer (for connecting special sensors such as flame sensors,

etc.).

Page 13

3 – Installation and wiring

9

Power supply 230 V AC

The sector power supply must be wired to the two terminals marked P

(orange) and N (blue) (Figure 4, ref. E) on the 12 point terminal block for the

power supply card; also see the wiring example on page 11. Protection is

provided by fuses F8 and F9 (160 mA/250 VAC) (Figure 4, ref. C and ref. D).

Power supply 115 V AC

Protection is provided by fuses F9 and F8 (315mA/250 VAC) (Figure 4, ref. C

and ref. D).

Power supply 24 V DC

Must be connected to the terminals marked 0 (grey) and +24V (orange) on the

12 point terminal block for the power supply card (Figure 4, ref. F) as

indicated by the wiring example on page 11. Protection is provided by fuse F7

(2A/250 VAC) (Figure 4, ref. B).

Measurement Channels

The MX 32 controller can be equipped with one or two adjustable and dual

measurement channels (see Figure 7). Three options are suggested at

purchase:

■ MX 32 with 2 measurement channels (dual);

■ MX 32 with 1 measurement channel (dual);

■ 1 extension card (to add on to a 1-channel controller).

The MX 32 controller will automatically recognize the number of measurement

channels installed (display).

Figure 7: the 2 measurement channels for the controller.

Sensors

The sensors must be connected to points C1, C2 and C3 on the 12 point

connector for each channel card, as indicated on the wiring example on page

10.

Wheatstone bridge 3 active wire explosive gas detectors

■ C1: mid-point (signal).

■ C2: detector filament.

■ C3: compensator filament.

Channel 1 Channel 2

Page 14

10

MX 32

Instruction Manual

4/20 mA 2 active wire sensors/transmitters

■ C1: signal (return to ground).

■ C2: not connected

■ C3: positive power supply (+24 Volts).

4/20 mA 3 active wire sensors/transmitters

■ C1: signal (return to ground).

■ C2: power supply (0 Volts).

■ C3: positive power supply +24 Volts.

Note

For each family of sensors, on the measurement channel circuits:

■ Programming will be carried out by Oldham (programming circuit pads).

■ A programming circuit (Explo 340 mA or 4-20 mA) will be inserted on the

mounting by the manufacturer (Figure 4, ref. S and T).

Alarm relays

The MX 32 controller uses two alarm relays per measurement channel which

correspond to two instant pre-programmed alarm thresholds 1 and 2.The

relays are energized (de-energized available on request) and voltage-free.

■ The relay corresponding to alarm 1 is connected to the RL1 (green)

terminals on the 12 point connector for each channel card.

■ The relay corresponding to alarm 2 is connected to the RL2 (grey)

terminals on the 12 point connector for each channel card.

The relay contacts can be used "normally open" (NO) or "normally closed"

(NC) by flipping the corresponding switch (Figure 4, ref. U or V for AL1 alarms

and references W and X for AL2 alarms).

Refer to the wiring examples beginning on page 11.

Relay fault

The MX 32 controller uses one "Fault" alarm per measurement channel (visual

and auditory) but a single shared "Fault" rela y for both c hannels . The fault

relay is energized and voltage-free. The shared fault relay can be connected

to the points marked DEF (fault) on the 12 point terminal block for the power

supply card.

The relay contact can be used "normally open" (NO) or "normally closed" (NC)

by flipping the corresponding switch (Figure 4, ref. L).

Refer to the wiring examples beginning on page 11.

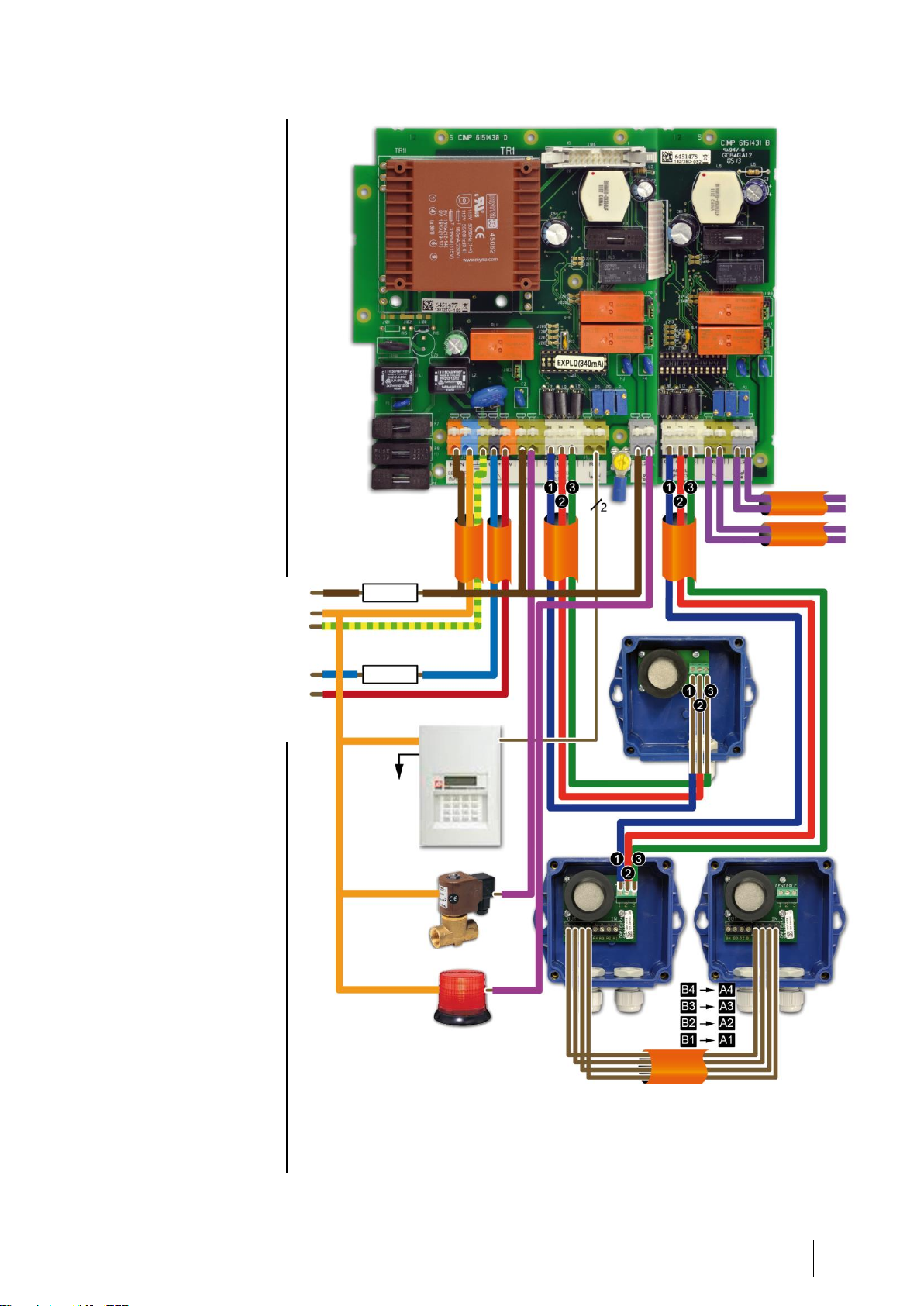

Wiring examples

The following pages contain two examples of wiring.

Page 15

3 – Installation and wiring

11

Figure 8: MX 32 controller with 1 explosive sensor on Channel 1 and dual explosive

sensors on Channel 2.

Grounding sector

0V DC

+24 V DC

Telephonic

transmitter

To the

telephone line

Gas valve, closed when

power is cut off*

Shared fault indicator

Fuse or

circuit breaker

Fuse

Contact alarm

Channel 2.

Contact alarm

Channel 1.

The AL1 and AL2 relays can be programmed as

energized or de-energized (factory settings).

The fault relays are energized.

The contact relays are available on the NO or

NC terminals according to the position of the

switch next to each relay.

*Capacity to cut the power to relays 120 VA-

30W resistive; use a relay with external power

source if necessary.

Page 16

12

MX 32

Instruction Manual

Figure 9: MX 32 controller with 1 explosive sensor on Channel 1 and 2 parking CO sensors

on Channel 2 (maximum of 5 loop-connected sensors).

Grounding sector

0V DC

+24 V DC

Telephonic

transmitter

To the

telephone line

Gas valve, closed

when power is cut off*

Shared fault indicator

Fuse or

circuit breaker

Fuse

Contact alarm

Channel 2.

Contact alarm

Channel 1.

The AL1 and AL2 relays can be programmed as

energized or de-energized (factory settings).

The fault relays are energized.

The contact relays are available on the NO or

NC terminals according to the position of the

switch next to each relay.

*Capacity to cut the power to relays 120 VA-

30W resistive; use a relay with external power

source if necessary.

Page 17

4 – Operating instructions

13

Chapter 4 │Operating instructions

Displays

Indications for start-up

Action or result

Illustration

■ Current version of the software and buzzer test.

■ Access code for menus currently programmed.

■ Display of current AL1 threshold for channel #1.

Simultaneously, the AL1 and Fault-channel 1

indicators light up.

■ Display of current AL2 threshold for channel #1.

Simultaneously, the AL2 and Fault-channel 1

indicators light up.

■ Display of current AL1 threshold for channel #2.

Simultaneously, the AL1 and Fault-channel 2

indicators light up.

■ Display of current AL2 threshold for channel #2.

Simultaneously, the AL2 and Fault-channel 2

indicators light up.

■ Time delay (in minutes) for (1) stabilization time

for the measurement channels.

During this time the two yellow DEF (fault)

indicators are lit up.

(1) Time is factory set.

Page 18

14

MX 32

Instruction Manual

■ Cyclic display of the measurement channels.

Note: The display alternates between the

measurements of each of the activated channels

(the unit and gas being detected is displayed).

Temporary display of a measurement channel

Action or result

Illustration

■ Select the channel to be displayed:

- Press (-) to display Channel 1.

- OR press (+) to display Channel 2.

■ Display of the measurement for the channel

selected.

... or.

■ One minute later, if the (-) or (+) buttons

are not pressed, the display will return to cyclic

display of the two measurement channels (if in

use).

Page 19

4 – Operating instructions

15

Cyclic display of the 2 measurement channels

Action or result

Illustration

■ Press (-) AND (+) together.

■ The alternating display (cyclic) of the 2

measurement channels is now activated.

No display of measurements after manual display

Action or result

Illustration

■ Display is presented as shown in the illustration

seen opposite (cyclic display).

■ Press (-) AND (+) together.

■ The measurements disappear and are replaced

by dashes. The MX 32 controller continues to

monitor the sensor(s) but the display is hidden.

No display of measurements after cyclic display

Action or result

Illustration

■ Alternate (cyclic) display of the 2 measurement

channels.

■ Press (-) AND (+) together.

Page 20

16

MX 32

Instruction Manual

■ The measurements disappear and are replaced

by dashes. The MX 32 controller continues to

monitor the sensor(s) but the display is hidden.

Navigating the menus

Reminder: for security reasons, only trained personnel (with access

codes) are authorized to use the menus listed below.

To quit a menu at any stage, press the (-) and (+) buttons

together.

Viewing the menus

Action or result

Illustration

■ Press the button (MENU/ENTER).

■ Request for access code.

Note: the first number is blinking.

If there is a response within one minute, the unit

will return to normal mode.

■ Enter the first digit of the code.

Press (-): to decrease the number.

Press (+): to increase the number.

Press (ENTER): to confirm the number.

■ Proceed to the next stage for each of the other 3

numbers in the code.

■ Final display of the access code.

■ Confirm the code by pressing (MENU/ENTER).

■ The menu flashing PRG (Programming) is

displayed.

See page 18 for instructions on using this menu.

■ Press (+) to display the CAL menu

(Calibration).

See page 23 for instructions on using this menu.

Page 21

4 – Operating instructions

17

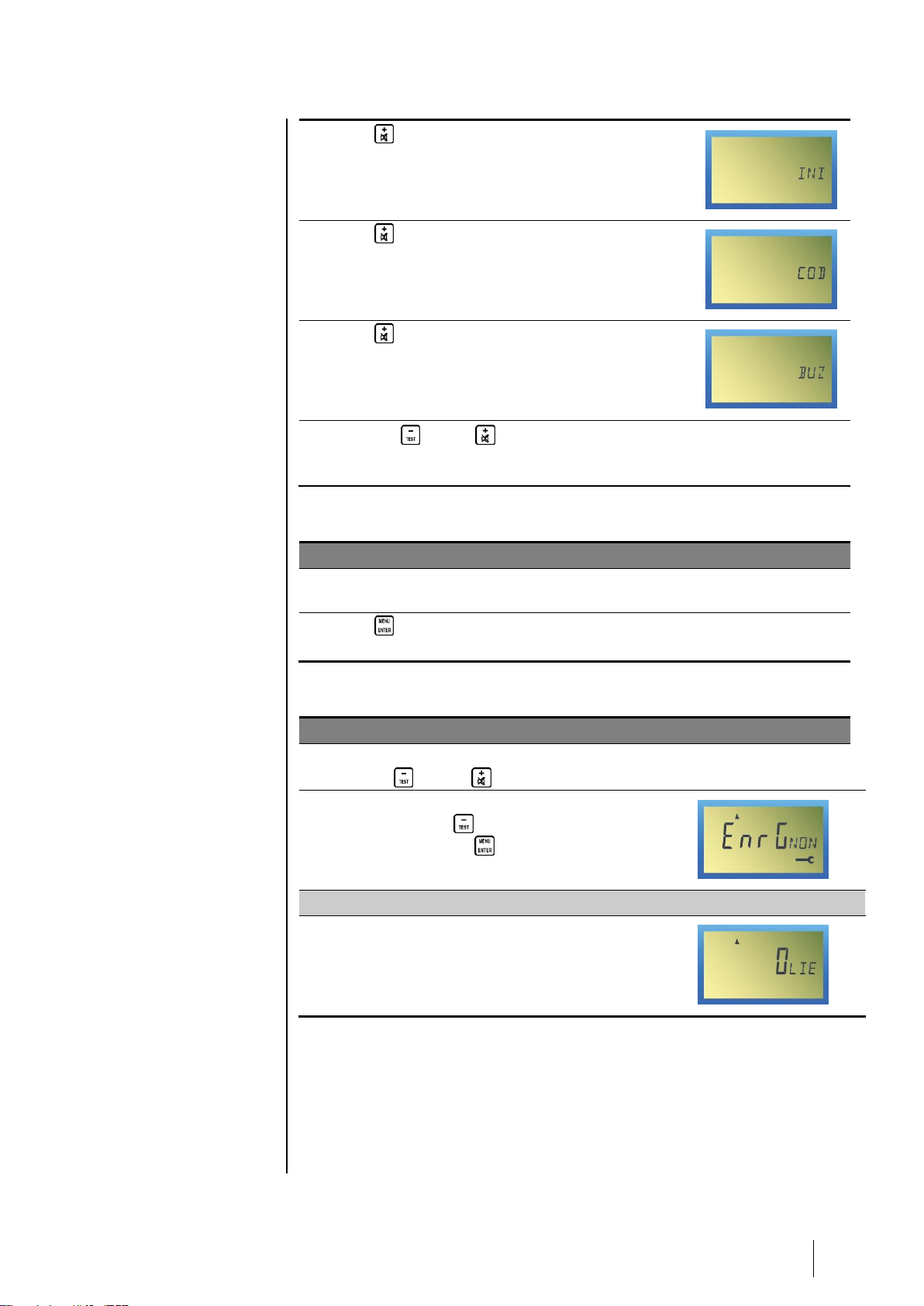

■ Press (+) to display the INI menu

(Initialization/Start-up).

See page 25 for instructions on using this menu.

■ Press (+) to display the COD menu (Access

Code).

See page 30 for instructions on using this menu.

■ Press (+) to display the BUZ menu (Buzzer).

See page 31 for instructions on using this menu.

■ Press the (-) and (+) buttons at the same

time to quit the list of menus without activating

them.

Menu Confirmation

Action or result

Illustration

■ Display the desired menu by following the

instructions described in the above paragraph.

■ Press (MENU/ENTER) to confirm the menu to be

used.

Exiting a menu (escape)

Action or result

Illustration

■ While using a menu it is possible to exit by

pressing (-) AND (+) together.

■ The screen will display Recording. If

necessary, press (-) to select No.

■ Confirm by pressing (MENU/ENTER).

Return to normal measurement display

■ The screen will display the current

measurement.

Page 22

18

MX 32

Instruction Manual

PRG Menu (Programming)

To quit a menu at any stage, press the (-) and (+) buttons

together.

This menu allows the user to program measurement channel configurations

such as:

Action or result

Illustration

■ The PRG indicator blinks.

Selecting the channel to be programmed

■ Confirm by pressing (MENU/ENTER).

The Channel 1 icon blinks indicating

Channel 1 has been selected.

■ To select Channel 2, press (+).

The Channel 2 icon blinks indicating

Channel 2 has been selected.

■ Confirm the channel to be programmed by

pressing (MENU/ENTER).

- ON blinks.

- The icon is displayed.

- The yellow fault indicator (Figure 2, ref.

N) for the corresponding channel blinks.

The alarm relays for the channel are

blocked.

Start-up or stopping the channel

■ Activating or deactivating the channel:

- (-) deactivates the channel (channel

stopped).

- (+) activates the channel (channel in

operation).

■ Confirm by pressing (MENU/ENTER).

Page 23

4 – Operating instructions

19

Selecting the gas to be detected

■ Press (-) to display a list of the gases

programmed. Then use to display the

other gases again.

■ Confirm by pressing (MENU/ENTER).

Selecting the unit of measurement

■ Press (-) or (+) to display a list of the

units programmed (%, LIE, PPM, PPB, UEG,

C, BAR, MG, ----).

■ Confirm by pressing (MENU/ENTER).

Selecting the measurement scale

■ The screen will display (for example):

■ Press (+) to modify the first digit of the

measurement scale.

■ Confirm by pressing (MENU/ENTER).

■ Use the same method for the other digits.

■ Confirm by pressing (MENU/ENTER).

Defining the AL1 alarm threshold

■ The alarm threshold indicator lights up

(Figure 2, ref. F) and the screen will display

(for example):

- : increasing alarm.

- : AL1 alarm.

- 40: current value for the alarm threshold.

- MAN: see next step.

■ Press (-) or (+) to define the first digit

of the AL1 alarm threshold. Confirm by

pressing (MENU/ENTER). Use the same

method for the rest of the digits for the

threshold.

Defining the direction (increasing/decreasing) for AL1 alarm

■ In this example, the display indicates

(increasing alarm).

- : increasing alarm (icon blinks).

- : AL1 alarm.

- 40: current value for the alarm threshold.

- MAN: see next step.

■ To proceed directly to the next step, press

(MENU/ENTER).

■ Press (-) or (+) to define the AL1

alarm direction.

Page 24

20

MX 32

Instruction Manual

- : increasing alarm.

- : decreasing alarm.

■ Confirm by pressing (MENU/ENTER).

Defining alarm acknowledgment (manual/automatic)

■ To proceed directly to the next step, press

(MENU/ENTER).

■ Press (-) or (+) to define the AL1

alarm acknowledgment.

- MAN : (-). Alarm clearing

(acknowledgment) by pressing the

(+) button once the measurement is

below the programmed alarm

threshold.

- AUT : (+). Automatic alarm clearing

(acknowledgment) once the

measurement is below the programmed

alarm threshold.

■ Confirm by pressing (MENU/ENTER).

Defining the time delay for triggering alarm relays

■ Press (-) or (+) to define the 4 digits

for the time delay (in minutes, seconds)

once the AL1 alarm relay is engaged.

Confirm the 4 digits by pressing

(MENU/ENTER)

Example: the value 10.20 indicates a delay

of 10 minutes and 20 seconds.

Defining the AL2 alarm threshold

■ Follow the same instructions for the AL2

alarm threshold. Comply with the above

paragraphs Defining the AL1 alarm

threshold to Defining the time delay for

triggering alarm relays.

Defining the time delay at start-up

■ Press (-) or (+) to define each of

the 4 digits for the time delay (in minutes,

seconds). Confirm the 4 digits by

pressing (MENU/ENTER)

Example: the value 10.20 indicates a time

delay at start-up of 10 minutes and 20

seconds.

Alarm threshold

exceeded

LED alarm

and buzzer

Delay

Alarm relay

switching

Page 25

4 – Operating instructions

21

Defining the type of sensor

■ To proceed directly to the next step,

press (MENU/ENTER).

■ Press (-) or (+) to define the type of

sensor connected.

- BRIDGE: sensor (Wheatstone bridge

output).

- EHP: explosive sensor 4-20 mA.

- FIRE: fire detector (ionic, optic, etc.).

- O2: oxygen detector 4-20 mA.

- OTH: another type of sensor (flame,

etc.).

- MAN: see next step.

■ Confirm by pressing (MENU/ENTER).

Defining the calibration mode for the

sensor

■ To proceed directly to the next step,

press (MENU/ENTER).

■ The MAN indicator blinks.

■ Press (-) or (+) to define the

operating mode for the yellow sensor LED:

- MAN: no visualization (blinking yellow

LED) by the MX 32 controller, of the

sensor being calibrated (sensor

maintenance mode).

- OTH: visualization (blinking yellow

LED) on the controller when the sensor

is being calibrated.

■ Confirm by pressing (MENU/ENTER).

Defining the time delay after calibration

mode

(displaying a time)

■ Press (-) or (+) to define the time

delay (in minutes). Confirm the 4 digits by

pressing (MENU/ENTER)

Saving programming

■ Press:

- (+) to select Yes. The programming

completed will be used.

- (-) to select No. The changes will be

abandoned and the old programm ing

will be saved.

■ Confirm by pressing (MENU/ENTER).

Page 26

22

MX 32

Instruction Manual

Return to measurement display

■ Indicating the current measurement.

If necessary, repeat the same procedure for the other channel.

Page 27

4 – Operating instructions

23

INI Menu (Initialization)

To quit a menu at any stage, press the (-) and (+) buttons

together.

This menu is used to automatically initialize the measurement curve managed

by the microprocessor with the sensor connected to the appropriate channel.

It is used in the following situations:

■ By Oldham when shipping new material.

■ At the initial installation.

■ When changing a sensor or a detector.

Action or result

Illustration

■ The INI indicator blinks.

Selecting the channel to initialize

■ Press (ENTER) to confirm.

The Channel 1 icon blinks indicating Channel 1

has been selected.

■ To select Channel 2, press (+).

The Channel 2 icon blinks indicating Channel 2

has been selected.

■ Confirm the channel to initialize by pressing

(ENTER).

- ON blinks.

- The icon is displayed.

- The yellow indicator of the corresponding

channel blinks (the channel relays are

blocked).

Confirming initialization

■ Press:

- (+) to select Yes. The initialization will

launch.

- (-) to select No. The initialization will be

abandoned.

■ Confirm by pressing (MENU/ENTER).

Page 28

24

MX 32

Instruction Manual

Return to normal measurement display

■ The screen will display the current

measurement.

Important: once the settings are

completed, perform a new

calibration for this measurement

channel; see the following

paragraph.

Page 29

4 – Operating instructions

25

Cal Menu (Calibration)

To quit a menu at any stage, press the (-) and (+) buttons

together.

Caution: the settings operations in this paragraph are reserved for

authorized, trained personnel because they may compromise

detection reliability.

The user must refer to the gas detector manual for calibration of

detectors.

The only way to verify the accuracy of the detection function of the sensor(s)

linked to the MX 32 controller is through calibration using a test gas.

Gas detectors are safety devices. Accordingly, Oldham recommends regular

testing of fixed gas detection installations. This type of test consists of

injecting a standard gas of sufficient concentration into the sensor to set off

the pre-adjusted alarms. This test does not, in any event, replace a full

calibration of the sensor.

Oldham also recommends completely calibrating detectors with a known and

certified concentration of gas every 3 or 4 months.

Frequency of gas testing depends on the industrial application in which the

sensors are used. Inspection should occur frequently during the months

following installation start up, later it may be spaced out if no significant

problem is observed. Time intervals between tests should not exceed 3

months.

If a detector does not react upon contact with gas, it must be calibrated.

Calibration frequency should be adapted based on test results. However, it

should not be greater than one year.

Oldham recommends using a test gas to calibrate detectors.

The site manager is responsible for implementing the safety procedures on

his site. Oldham is not responsible for implementing safety procedures.

Reminder: for security reasons, only trained personnel should be

authorized to use the following menus.

The Calibration menu will allow the user to perform zero control and settings

in a clean environment and the sensitivity of the test gas.

Calibration can be performed:

■ After initialization; see the following page.

■ For preventative maintenance (minimum and regular service); see

page 28.

Page 30

26

MX 32

Instruction Manual

After initialization

Action or result

Illustration

■ The CAL indicator blinks.

Selecting the channel to calibrate

■ Press (ENTER) to confirm.

The Channel 1 icon blinks indicating Channel 1

has been selected.

■ To select Channel 2, press (+).

The Channel 2 icon blinks indicating Channel 2

has been selected.

Zero settings

■ Confirm the channel to calibrate by pressing

(ENTER).

- Display of the current value.

X0 = zero settings.

- The icon is displayed.

- The yellow indicator of the corresponding

channel blinks (the channel relays are

blocked).

■ Make sure that the air is clean, if not, using a test

kit, inject air at the level of the detector at a flow

rate of 60 l/h, then wait for stabilization of the

signal.

If the display is not zero, adjust the zero

measurement by moving the zero potentiometer

corresponding to the appropriate channel (Figure

4, ref. R for Channel 1 or ref. O for Channel 2).

■ Confirm the zero by pressing (ENTER).

Page 31

4 – Operating instructions

27

Sensitivity settings

■ Inject the calibration gas (60 l/h) at sensor level

and wait for signal stabilization.

■ Confirm the entry in the sensitivity settings by

pressing (ENTER).

- Display of the current value.

XF = setting the.

- The icon is displayed.

- The yellow indicator of the corresponding

channel blinks (the channel relays are

blocked).

If necessary (display other than the value of the

calibration gas), adjust the sensitivity by moving

the sensitivity potentiometer corresponding to the

appropriate channel (Figure 4, ref. Q for Channel

1 or ref. P for Channel 2).

■ Confirm the sensitivity by pressing (ENTER).

Caution: never confirm without having injected

gas and completed the settings, at the risk of false

triggering.

Saving calibration

■ Press:

- (+) to select Yes. The completed

calibration will be saved.

- (-) to select No. The changes will be

abandoned and the old calibration will be

saved.

■ Confirm by pressing (MENU/ENTER).

Return to measurement display

■ The screen will display the current

measurement.

Page 32

28

MX 32

Instruction Manual

Preventative maintenance

Action or result

Illustration

■ The CAL indicator blinks.

Selecting the channel to calibrate

■ Press (ENTER) to confirm.

The Channel 1 icon blinks indicating Channel 1

has been selected.

■ To select Channel 2, press (+).

The Channel 2 icon blinks indicating Channel 2

has been selected.

Zero settings

■ Confirm the channel to calibrate by pressing

(ENTER).

- Display of the current value (±0).

X0 = zero settings.

- The icon is displayed.

- The yellow indicator of the corresponding

channel blinks (the channel relays are

blocked).

■ Make sure that the air is clean, if not, using a test

kit, inject air at the level of the detector at a flow

rate of 60 l/h, then wait for stabilization of the

signal.

If the display is a value other than zero, adjust the

zero measurement using the (+) or (-)

buttons.

Sensitivity settings

■ Inject the calibration gas (60 l/h) at sensor level

and wait for signal stabilization.

■ Confirm the entry in the sensitivity settings by

pressing (ENTER).

- Display of the current value (±0).

XF = sensitivity settings (blinking icon).

- The icon is displayed.

- The yellow indicator of the corresponding

channel blinks (the channel relays are

blocked).

If necessary (displayed value other than the value

of the calibration gas), adjust the sensitivity by

using the (+) or (-) buttons.

Page 33

4 – Operating instructions

29

■ Confirm the sensitivity by pressing (ENTER).

Caution: never confirm without having injected

gas and completed the settings, at the risk of false

triggering.

Saving calibration

■ Press:

- (+) to select Yes. The completed

calibration will be saved.

- (-) to select No. The changes will be

abandoned and the old calibration will be

saved.

■ Confirm by pressing (MENU/ENTER).

Return to measurement display

■ The screen will display the current

measurement.

Page 34

30

MX 32

Instruction Manual

Cod Menu (Access code)

To quit a menu at any stage, press the (-) and (+) buttons

together.

Action or result

Illustration

■ The COD indicator blinks.

■ Press (ENTER) to confirm.

Defining the code

■ The current code is displayed.

■ The first digit blinks. Enter the first digit of the new

code using the (+) or (-) buttons.

■ Confirm the first digit by pressing (ENTER).

■ Proceed to the next stage for each of the other 3

digits in the code.

Saving the new code

■ Press:

- (+) to select Yes. The new code will be

saved.

- (-) to select No. The changes will be

abandoned and the old code will be saved.

■ Confirm by pressing (MENU/ENTER).

Return to measurement display

■ The screen will display the current

measurement.

Page 35

4 – Operating instructions

31

Buz Menu (Buzzer)

Action or result

Illustration

■ The BUZ indicator blinks.

■ Press (ENTER) to confirm.

Defining the buzzer action

■ The ON or OFF icon blinks, depending on the

current buzzer configuration.

■ Select On or Off:

- On: the buzzer will be activated in the case of

alarm or a fault. Press (+).

OFF: the buzzer will not be activated in the

case of alarm or a fault. Press (-).

■ Press (ENTER) to confirm.

Saving the new buzzer settings

■ Press:

- (+) to select Yes. The new buzzer

settings will be saved.

- (-) to select No. The old buzzer settings

will be saved.

■ Confirm by pressing (MENU/ENTER).

Return to measurement display

■ The screen will display the current

measurement.

Page 36

32

MX 32

Instruction Manual

Page 37

5 – Cleaning, servicing and maintenance

33

Chapter 5 │Cleaning, servicing and

maintenance

Cleaning

Do not use alcohol- or ammonia-based liquids to clean the central controller. If

necessary, clean the exterior of the enclosure with a damp cloth.

Maintenance and servicing

The controller does not require special servicing.

Adjustments

Caution: the settings operations in this paragraph are reserved for

authorized, trained personnel because they may compromise

detection reliability.

If it is necessary to re-adjust the sensors, this operation must only be

completed by a qualified personnel. First, the front cover must be opened

(Figure 2, ref. P) on the controller. Refer to the Viewing the menus paragraph

on page 16.

Zero adjustment

Use the following settings:

■ Channel 1: P3 (Figure 4, ref. R).

■ Channel 2: P4 (Figure 4, ref. O).

Sensitivity adjustments

Use the following settings:

■ Channel 1: P5 (Figure 4, ref. Q).

■ Channel 2: P6 (Figure 4, ref. R).

Page 38

34

MX 32

Instruction Manual

Calibration

Gas detectors are safety devices. Accordingly, OLDHAM recommends regular

testing of fixed gas detection installations. This type of test consists of

injecting a standard gas of sufficient concentration into the sensor to set off

the pre-adjusted alarms. This test does not, in any event, replace a full

calibration of the sensor.

Frequency of gas testing depends on the industrial application in which the

sensors are used. Inspection should occur frequently during the months

following installation start up, later it may be spaced out if no significant

problem is observed.

If a detector does not react upon contact with gas, it must be

calibrated. Calibration frequency should be adapted based

on test results. However, it should not be greater than one

year.

Safety Procedures

The site manager is responsible for implementing the safety procedures on

his site. Oldham is not responsible for implementing safety procedures.

■ Refer to the Menu Initialization paragraphs (page 23).

■ Do not forget to complete a system start-up after changing the sensor by

using the "INI" menu (Menu Initialization (INI) paragraph, on page 23).

Fuse replacement

Replacement of the fuses should only be performed by a qualified

professional. The fuses in use must conform to CEI 127 regulations (timedelayed, low breaking capacity, 250 V AC power source). Please see the

following paragraph.

Parts

Description

Reference

Fuse F7 (2 A T, 250 V AC) – Versions 115 or 230 V AC.

6 154 624

Fuse F8 (315 mA T, 250 V AC) – Version 115 V AC.

6 154 722

Fuse F8 (160 mA T, 250 V AC) – Version 230 V AC.

6 154 723

Fuse F9 (315 mA T, 250 V AC) – Version 115 V AC.

6 154 722

Fuse F9 (160 mA T, 250 V AC) – Version 230 V AC.

6 154 723

Fuse F11 (630 mA T, 250 V AC).

6 154 627

Fuse F13 (630 mA T, 250 V AC).

6 154 627

Programming strip 340 mA

6 353 442

Programming strip 4-20 mA

6 353 443

Dual channel analog card

6 451 476

Single channel analog card

6 451 477

Channel extension card

6 451 478

Micro card (display)

6 451 475

Page 39

6 – Declaration of Conformity

35

Chapter 6 │Technical specifications

Page 40

36

MX 32

Instruction Manual

Page 41

7 - Technical specifications

37

Chapter 7 │Technical specifications

Case

Enclosure:

wall-mount.

Dimensions:

240 x 205 x 120 mm.

Material:

ABS plastic

Cable input/outputs:

6 x PG9 type cable glands.

Protection:

IP65.

Power supply

Power supply:

■ 115 or 230 VAC.

■ 21 V to 30 V DC.

Power consumption:

30 VA.

Connections

Type:

spring terminal.

Cable diameter:

2.5 mm² maximum.

Measurement Channels

Number:

1 or 2.

Type:

■ Wheatstone bridge type explosive sensor.

■ 4/20 mA to 2 or 3 fils.

Measurement:

simultaneous channel measurement.

Measurement Ranges

Type :

programmable independently for each channel.

Number of measurement

points:

continuous programming from 0 to 9999.

Display

Position:

on the front.

Type:

■ liquid-crystal display (LCD).

■ 4 digits of 7 segments each, 3 characters of 14

segments each, fixed or drop-down icons for

each channel.

■ 4 light-emitting diodes (LEDs) per channel (on,

AL1, AL2, fault).

Unit description:

definable for each channel.

Gas description:

definable for each channel.

Keypad:

buttons for menu access, indicators and acknowledgment.

Page 42

38

MX 32

Instruction Manual

Alarms

Type:

■ 2 independent thresholds per channel defined

by the user.

■ manual or automatic clearing for increasing or

decreasing values as programmed.

■ visualization with red indicator.

■ output relays (alarms 1 and 2).

Relay:

■ 2 independent alarm relays per channel

energized or de-energized, programmable by

the manufacturer.

■ 1 relay with energized disturbance.

■ open or closed contact configurable for all the

relays using a switch.

Breaking capacity:

2A - 250 VAC, 2A - 30 VDC.

LED:

4 electroluminescent diodes.

Integrated audible alarm:

■ buzzer.

■ alarm sound level:

- to 50 cm: 72 to 74 dB.

- to 100 cm: 66 to 68 dB.

Sensors

■ 1 OLC 10 combustible gas detector or 2 OLC

10 TWIN detectors for the detection of

methane, butane, propane in boiler rooms and

LPG, CNG or H2 in parking lots.

■ 1 OLCT 10 combustible gas detector for the

detection of methane, butane, propane in boiler

rooms and LPG, CNG or H2 in parking lots.

■ 1 to 5 detectors, also OLCT 10 for the detection

of CO, NO and NO2.

Cable length (1.5 mm² diameter).

■ Wheatstone bridge: 300 m max. per channel

■ 4 / 20 m A: 2000 m m ax. per channel.

Operating conditions

Ambient temperature:

-10 to +55°C

Storage temperature:

-10 to +45°C

Humidity:

5 to 95 % non condensing

Certifications

ATEX Directive 94/9/EC:

category (3) G for metrology in the detection of

explosive gases EN 61779-1 and 4 in Zone 2.

Low Voltage Directive:

in compliance with EN 61010-1:10.

Electromagnetic

Compatibility (EMC)

Directive:

in compliance with EN 50270:06.

Page 43

8 – Particular specifications

39

Chapter 8 │ Particular Specifications

Particular Specifications for use in Explosive Atmospheres in Accordance with

the European ATEX 94/9/CE Directive.

The MX 32 detection controller intended for the measurement of explosive

gases, conforms to European ATEX Directive 94/9/CE pertaining to explosive

atmospheres.

Due to their metrological performances as tested by INERIS (French National

Institute for Industrial Environment and Risks), the MX 32 paired with Oldham

CEX 300 and TBGW-EX detectors as well as those in the OLC/OLCT series:

20, 40, 50, 60, 100 and OLCT IR is c lassified as a safety device. The

controller can also reduce the risk of explosion by sending data to outside

units.

Information in following paragraphs must be taken into account and followed

by the person responsible for the equipment installation site. Refer to the

provisions of European ATEX Directive 1999/92/EC, concerning the

improvement of safety protection and the health of workers exposed to the

risks of explosive atmospheres.

Specifications for mechanical and electrical

installations in Explosive Zones.

All installations must be in compliance with currently enforced standards,

notably standards EN 60079-14, EN 60079-17, and EN 50281-1-2.

The MX 32 controller must not be subject to intense mechanical vibration and

must be installed in a safe area away from explosive atmospheres.

It is very important to refer to the user and start-up manuals for the gas

detectors being used.

For intrinsically safe installations, the person responsible for the IS

installation, called “the system designer,” must establish a system document

demonstrating that the entire Sensor/Cable/Power Supply system is

Intrinsically Safe. See the EN 50039 standard for group II and the EN 50394-1

standard for group I to prepare this document.

Metrological specifications

The controller conforms with the following European standards.

With Explosive Gas Detectors

■ European standards EN 50054 and EN 50057 for methane (calibration

gas), propane and hydrogen gases (gas following response curves), when

Page 44

40

MX 32

Instruction Manual

the controller is used with CEX 300 gas detectors and those in the

OLC/OLCT series including 20, 40, 50, 60, 100 and OLCT IR. Where the

controller is used with other types of detectors delivering a current of 4/20

mA, they must conform to ATEX Directive 94/9/EC, Annex II, paragraph

1.5 and be compatible with the characteris tics des cribed therein (r ef er to

the controller transfer curve in Figure 10).

■ European standard EN 50271.

Oxygen gas detectors

■ European standard EN 50104 when the controller is used with OLCT 20,

40, 50, 60 and TBGW-EX gas detectors. Where the controller is used with

other types of detectors delivering a current of 4/20 mA, they must conform

to ATEX Directive 94/9/EC, Annex II, paragraph 1.5 and be compatible

with the characteristics described therein (refer to the controller transfer

curve in Figure 11).

■ European standard EN 50271.

Connecting detectors other than Oldham

detectors to the MX 32 controller

Any user wishing to use detectors other than Oldham detectors must ensure

that they are compatible with the controller, in order for the unit to be

considered a safety device.

Configuration transfer curve 0 to 100 % LEL

The following curve demonstrates the controller response in terms of values

measured and treatment of faults, as a function of the value of the input

current delivered by the detector. In the case that the user connects a nonOldham brand detector to the MX 32 controller, the user must ensure that the

transfer curve is compatible with the input characteristics for the controller, so

that the information delivered by the detector will be properly interpreted. In

addition, the controller must provide sufficient supply voltage, taking into

account voltage drops in the cables.

Figure 10: Configuration transfer curve 0 to 100 % LEL

LEL Display in %

ABOVE

100% LEL

0% LEL

-15% LEL

Fault

Fault

Signal delivered by

the detector in mA

Page 45

8 – Particular specifications

41

Caution: when the measurement is above or equal to 100 % LEL,

the measurement controller records that the scale has been

exceeded; the channel switches to alarm and fault mode. The user is

responsible for manually rearming these settings, following the

safety regulations applicable at their site. Rearming can be

accomplished by restarting the controller or through a maintenance

operation.

Configuration transfer curve 0 to 30.0 % oxygen

The following curve demonstrates the controller response in terms of values

measured and treatment of faults, as a function of the value of the input

current delivered by the detector. In the case that the user connects a nonOldham brand detector to the MX 32 controller, the user must ensure that the

transfer curve is compatible with the input characteristics for the controller, so

that the information delivered by the detector will be properly interpreted. In

addition, the controller must provide sufficient supply voltage, taking into

account voltage drops in the cables.

Figure 11: Configuration transfer curve 0 to 30 % oxygen

Power supply and resistance characteristics

■ Maximum current available between terminals 2 and 3: 250 mA

under 19 V.

■ Maximum voltage without load between terminals 2 and 3: 30 V.

■ Resistance (outside of the intrinsic safety barrier) between terminals

1 and 2: 47 ohm.

Markings:

OLDHAM Arras

0080

II (1) (2) G

INERIS 04ATEX0064

Display in %

oxygen volume

Fault

Fault

Signal delivered by

the detector

Page 46

42

MX 32

Instruction Manual

Page 47

Page 48

44

The Fixed Gas Detection Experts

EUROPEAN PLANT AND OFFICES

Z.I. Est – rue Orfila CS 20417 – 62027 ARRAS Cedex FRANCE

Phone: +33 (0)3 21 60 80 80 – Fax: +33 (0)3 21 60 80 00

Web site: http://www.oldhamgas.com

AMERICAS

Phone: +1-713-559-9280

Fax: +1-281-292-2860

americas@oldhamgas.com

ASIA PACIFIC

Phone: +86-21-3127-6373

Fax: +86-21-3127-6365

sales@oldhamgas.com

EUROPE

Phone: +33-321-608-080

Fax: +33-321-608-000

info@oldhamgas.com

Loading...

Loading...