Page 1

USER MANUAL

iTrans

FIXED POINT SINGLE OR DUAL

GAS MONITOR WITH DUAL

ANALOG OUTPUTS

Part Number: 77023554-1

Version: 16.0

Release Date: April 20, 2016

The Fixed Gas Detection Experts

FIXED POINT SINGLE OR DUAL GAS MONITOR WITH DUAL

ANALOG OUTPUTS

Page 2

Copyright © 2016 by Oldham S.A.S

All rights reserved. No reproduction of all or part of this document, in any form, is

permitted without the written consent of Oldham S.A.S.

is a trademark of Oldham.

ModBus® is a registered trademark of Schneider Automation Inc.

ModBus® protocol™ is a trademark of Schneider Automation Inc.

All other trademarks and registered trademarks are the property of their respective

owners.

All of the information that is provided in this document is accurate to the best of

our knowledge.

As a result of continuous research and development, the specifications of this

product may be changed without prior notice.

Oldham S.A.S

Rue Orfila

Z.I. Est – CS 20417

F–62027 ARRAS Cedex

Tel.: +33 (0)3 21 60 80 80

Fax: +33 (0) 3 21 60 80 00

ii iTrans User Manual (P/N: 77023554-1)

Page 3

Warnings and Cautionary Statements

CAUTION: Failure to perform certain procedures or note certain conditions may

impair the performance of the monitor. For maximum safety and performance,

please read and follow the procedures and conditions outlined below.

Oxygen deficient atmospheres may cause combustible gas readings that use

catalytic LEL sensors to be lower than actual concentrations.

Oxygen enriched atmospheres may cause combustible gas readings that use

catalytic LEL sensors to be higher than actual concentrations.

Calibrate the catalytic combustible gas sensor after each incident where the

combustible gas content causes the instrument to enter in the OVER-RANGE

alarm condition.

Silicone compound vapors may affect the catalytic combustible gas sensor and

cause readings of combustible gas to be lower than actual gas concentrations. If

the sensor has been used in an area where silicone vapors were present, always

calibrate the instrument before continued use to ensure accurate measurements.

Sensor openings must be kept clean. Obstruction of the sensor openings may

cause readings to be lower than actual gas concentrations.

Sudden changes in atmospheric pressure may cause temporary fluctuations in

the oxygen readings.

Alarms relays are non-latching.

When connecting 4-20 mA outputs to inductive loads, Oldham recommends

using an isolation barrier in line with the 4-20 mA signal.

Interior grounding terminal is to be used for grounding, the exterior terminal is

only to be used for bonding

iTrans Stand-Alone versions with on-board visible alarm are to be

installed in ordinary locations only; however, remote sensors can be

installed in hazardous locations (Gas dependent. Read Agency

Approvals paragraph).

(P/N: 77023554-1) iTrans User Manual iii

Page 4

CALIBRATION ALERT: Gas detection instruments are potential life-saving

devices. Recognizing this fact, calibration for the toxic and catalytic LEL sensors

should be at least at quarterly intervals, while the infrared sensor should be

calibrated on an annual basis with function test every 6 months.

Further, Oldham recommends prudent testing and/or includes calibration after a

gas alarm. All calibration service to sensors should be recorded and accessible.

CAUTION: For safety reasons, this equipment must be operated and serviced by

qualified personnel only.

iv iTrans User Manual (P/N: 77023554-1)

Page 5

iTrans Fixed Point Single/Dual Gas Monitor Table of Contents

Table of Contents

CHAPTER 1: INTRODUCTION

1.1. Overview of the Gas Monitor ............................................................................1-1

1.2. Specifications .........................................................................................................................1-1

1.3. Agency Approvals - CSA .......................................................................................................1-3

1.4. Special Instructions for Safe Use (EU) ..................................................................................1-5

CHAPTER 2: HARDWARE OVERVIEW

2.1. Main Electronics Unit (Housing) ...........................................................................................2-1

2.2. Sensor .....................................................................................................................................2-2

2.3. Display ....................................................................................................................................2-3

2.4. Inputs – Intrusive and Non-Intrusive ......................................................................................2-3

2.5. Electronics Modules ...............................................................................................................2-4

CHAPTER 3: INSTALLATION

3.1. Introduction ............................................................................................................................3-1

3.2. Installation Considerations .....................................................................................................3-1

3.3. Wall Mounting........................................................................................................................3-1

3.4. Column Mounting ..................................................................................................................3-1

CHAPTER 4: SYSTEM WIRING

4.1. Introduction ............................................................................................................................4-1

4.2. Wiring Preparation .................................................................................................................4-1

4.3. Alarm Relay Wiring (J1, J5, and J6) ......................................................................................4-2

4.4. Power and Output Wiring (J1) ...............................................................................................4-3

4.5. Sensor Wiring (J3) ..................................................................................................................4-4

4.6. Digital ModBus RTU Interface Wiring (J1) ..........................................................................4-9

4.6.1. ModBus Interface Wiring Overview..........................................................................4-9

4.6.2. Setting the ModBus Address on the ......................................................4-9

4.6.3. Setting the ModBus Address for Stand-Alone Sensors ...........................................4-10

4.7. Wiring Conclusion................................................................................................................4-12

CHAPTER 5: OPERATION

5.1. Initial Start-up .........................................................................................................................5-1

5.2. Warm-up Period .....................................................................................................................5-1

5.3. Normal Operating Mode.........................................................................................................5-2

5.4. Programming Mode Overview ...............................................................................................5-3

5.5. Programming Mode – Non-intrusive Operation .....................................................................5-4

5.5.1. Introduction ................................................................................................................5-4

5.5.2. Sensor Type ...............................................................................................................5-5

5.5.3. Zeroing .......................................................................................................................5-5

5.5.4. Calibration ..................................................................................................................5-6

5.5.5. Changing Span Gas Concentration ............................................................................5-7

5.5.6. Sensor Span Reserve ..................................................................................................5-8

5.6. Programming Mode – Push Button Operation .......................................................................5-8

5.6.1. Introduction ................................................................................................................5-8

5.6.2. Entering Programming Mode and Selecting a Channel .............................................5-9

5.6.3. Set Low Alarm .........................................................................................................5-10

(P/N: 77023554-1) iTrans User Manual v

Page 6

Table of Contents iTrans Fixed Point Single/Dual Gas Monitor

5.6.4. Set High Alarm ........................................................................................................5-10

5.6.5. 4-20 mA Analog Output Range ...............................................................................5-10

5.6.6. Set System Time – Minute .......................................................................................5-11

5.6.7. Set System Time – Hour ..........................................................................................5-11

5.6.8. Set System Time – Date ...........................................................................................5-12

5.6.9. Set System Time – Month ........................................................................................5-12

5.6.10. Set System Time – Year ..........................................................................................5-13

5.6.11. Zeroing ....................................................................................................................5-13

5.6.12. Calibration ...............................................................................................................5-14

5.6.13. Changing Span Gas Concentration ..........................................................................5-15

5.6.14. Sensor Span Reserve ................................................................................................5-16

5.6. Special Notes on Using Broadband Infrared (BBIR) Sensors ..............................................5-17

CHAPTER 6: MODBUS INTERFACE

6.1. Introduction ............................................................................................................................6-1

6.2. Sample Gas Reading via ModBus Network ...........................................................................6-1

6.3. ModBus Register List ............................................................................................6-2

6.4. ModBus Resources .................................................................................................................6-6

6.5. Termination ............................................................................................................................6-6

CHAPTER 7: MAINTENANCE

7.1. Introduction ............................................................................................................................7-1

7.2. Sensor Replacement ...............................................................................................................7-2

7.3. Zero and Calibration ...............................................................................................................7-2

CHAPTER 8: TROUBLESHOOTING

8.1. Introduction ............................................................................................................................8-1

8.2. Diagnosing Common Problems ..............................................................................................8-1

8.3. Fault Codes .............................................................................................................................8-2

8.4. Function Codes .......................................................................................................................8-3

CHAPTER 9: WARRANTY

9.1. Warranty .................................................................................................................................9-1

9.2. Limitation of Liability ............................................................................................................9-1

APPENDIX A: ACRONYMS AND ABBREVIATIONS

APPENDIX B: DECIMAL, BINARY, AND HEXADECIMAL EQUIVALENTS

APPENDIX C: ORDERING MATRIX

APPENDIX D: FACTORY DEFAULT SETTINGS

APPENDIX E: EU DECLARATION OF CONFORMITY CERTIFICATE

APPENDIX F: INDEX

vi iTrans User Manual (P/N: 77023554-1)

Page 7

iTrans Fixed Point Single/Dual Gas Monitor Introduction

INTRODUCTION

Chapter

1

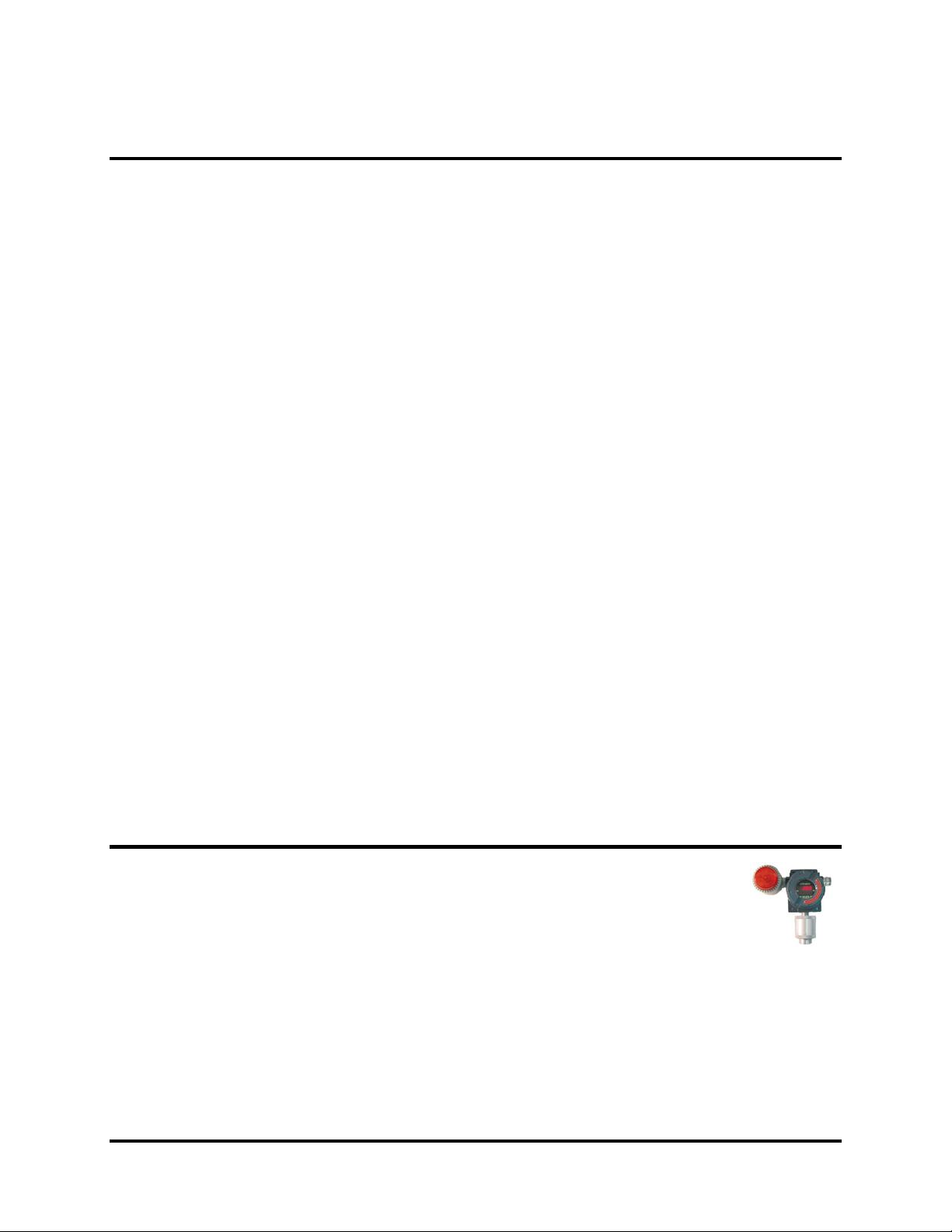

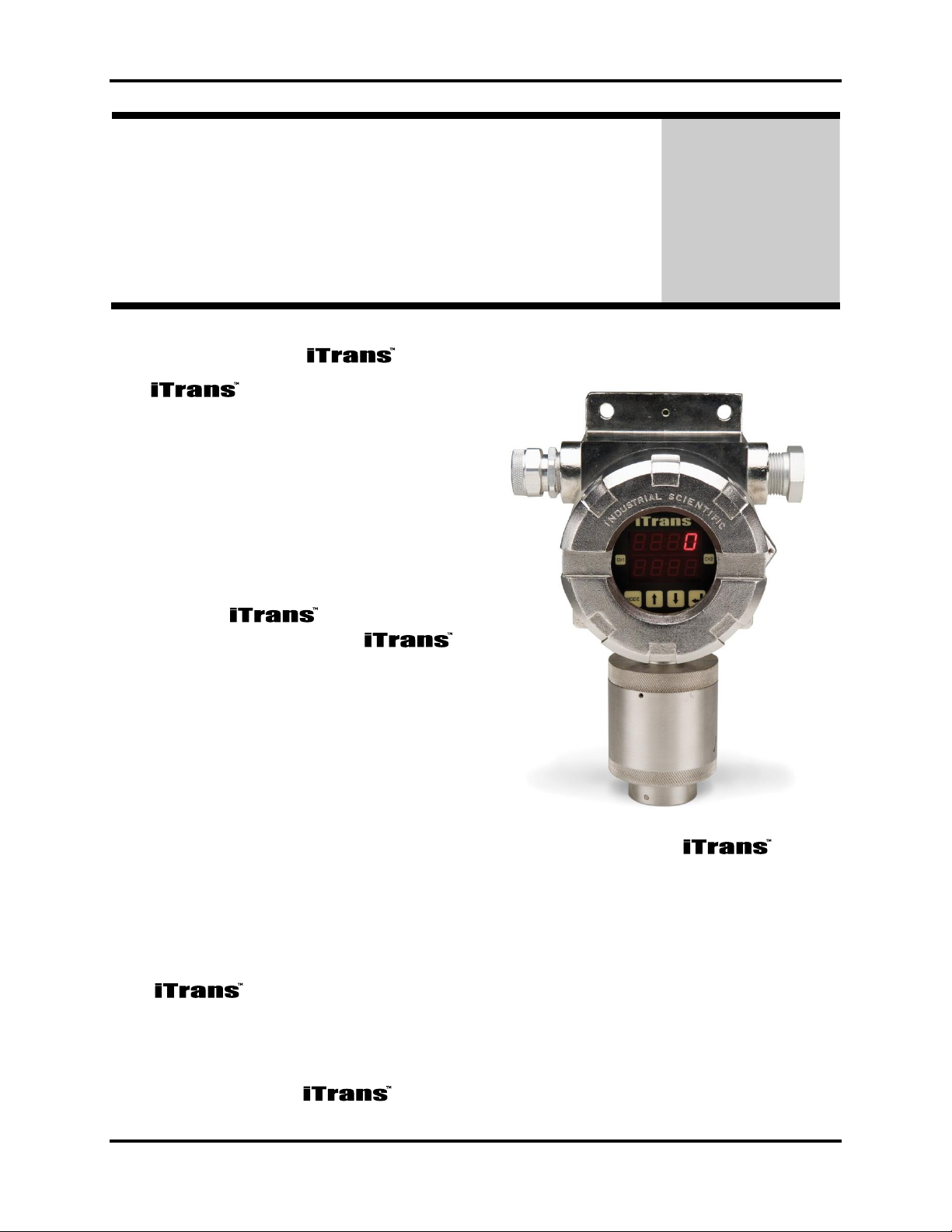

The fixed gas monitor is an

independent monitor capable of

displaying one or two gas

concentrations as well as sensor or

instrument comes standard with

independent 4-20 mA outputs for each

channel, making it ideal for interfacing

to control units. A digital ModBus

RTU interface is also available,

allowing the to interface to

digital control systems. The

is available with an optional relay

board, allowing the unit to directly

control external devices such as fans,

pumps, alarm horns, or warning lights.

Two of the relays can be programmed

for alarm activation, while the third

relay is a fault protection relay.

Figure 1-1. Typical Gas

Monitor with Single Gas Sensor

(Stainless Steel Option)

1.1. Overview of the Gas Monitor

Calibration, changing span gas concentration, and checking the instrument’s

configuration are easily accomplished using the non-intrusive magnetic wand.

The is powered with a 24 VDC (12-28 VDC) power supply and

provides a 4-20 mA control signal for each sensor.

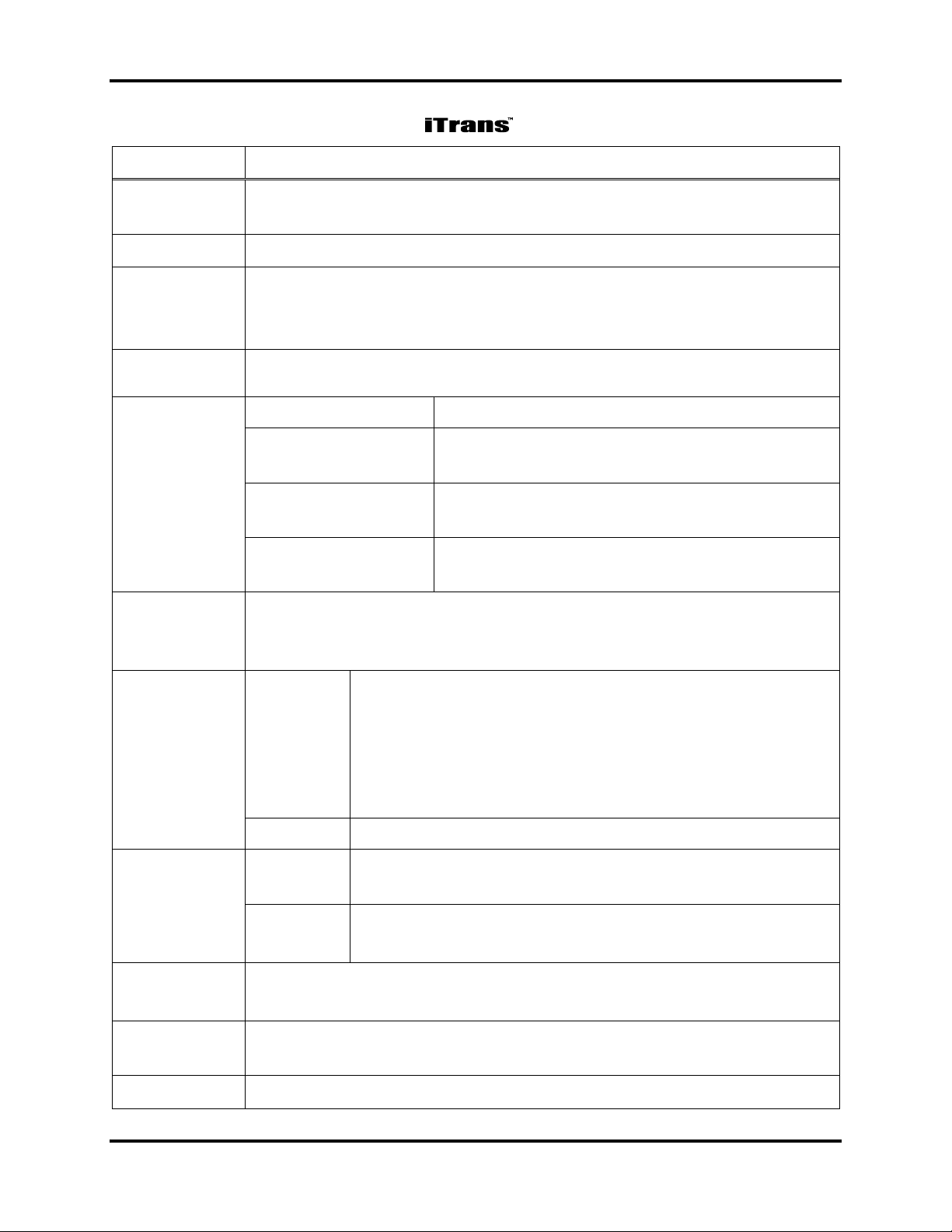

1.2. Specifications

Specifications for the gas monitor are listed in Table 1-1.

(P/N: 77023554-1) iTrans User Manual 1-1

Page 8

Introduction iTrans Fixed Point Single/Dual Gas Monitor

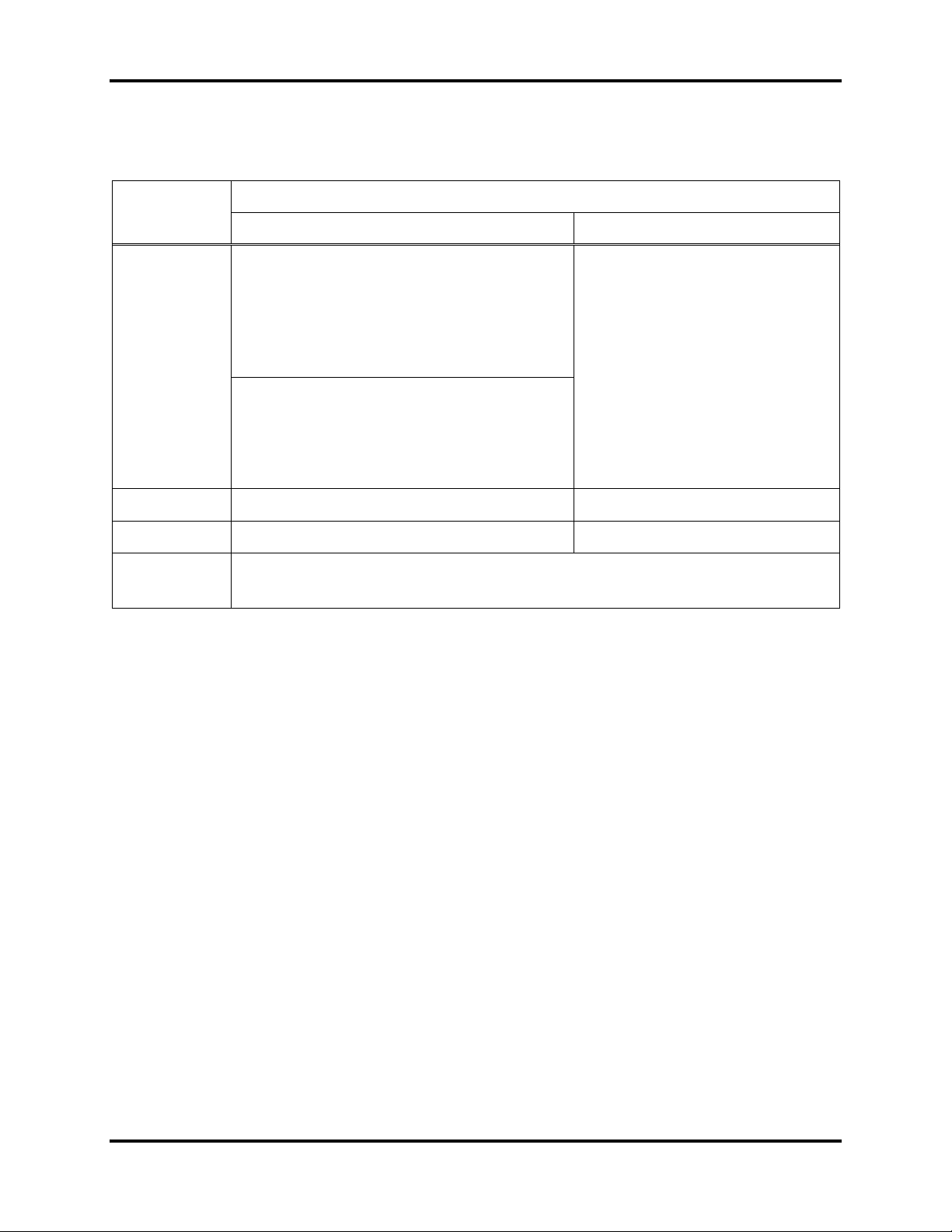

Item

Description

Enclosure

Cast aluminum, poly-bonded coating or 316 stainless steel. Both are

explosion-proof, NEMA 4X, IP66 rated.

Dimensions

5.0 6.0 5.0 inches (127 153 129 mm)

Sensors

Combustible Gases: Catalytic bead and/or Non-Dispersive Infrared

(NDIR)

Oxygen/Toxic Gases: Electrochemical diffusion

Input Voltage

12-28 VDC operating range (24 VDC typical), 350 mA (nominal)

Maximum current draw of 600 mA with 2 LEL sensors installed

Input Current

(Max)

Toxic Gas/Oxygen

150 mA @ 24 VDC (single gas)

Combustible Gases

(Catalytic)

175 mA @ 24 VDC, 0.6 A peak (single gas)

Combustible Gases

(Infrared)

150 mA @ 24 VDC, 0.6 A peak (single gas)

Combined

Catalytic/Infrared

280 mA @ 24 VDC (two gas)

Display

Dual-channel split-screen LED display (4-digit, 7-segment

arrangement per channel) provides simultaneous display of one or two

gases.

Signal

Outputs

Digital

ModBus RTU: RS485 digital communication with

ModBus RTU software protocol system at 9600 baud.

Three- or four-wire system accommodates over 200

devices in bus configuration. Address selection through

on-board 8-position DIP switch. NOTE: ModBus is not

to be used for CSA C22.2 No. 152 compliance.

Analog

4-20 mA (linear analog)

Alarm Relays

Quantity

3 alarm relays: Two user-programmable relays, SPST,

N.O.; plus one fault relay, SPST, N.C.

Contact

Capacity

5A @ 30 VDC

5A @ 30 VAC

Temperature

Range

-40º C ~ +75º C (-40º F ~ +167º F)

-20º C ~ +50º C (-4º F ~ +122º F) for BBIR only

Humidity

Range

10% - 90% RH (non-condensing), typical

Pressure

Atmospheric pressure 10%

Table 1-1. Specifications for the Monitor

1-2 iTrans User Manual (P/N: 77023554-1)

Page 9

iTrans Fixed Point Single/Dual Gas Monitor Introduction

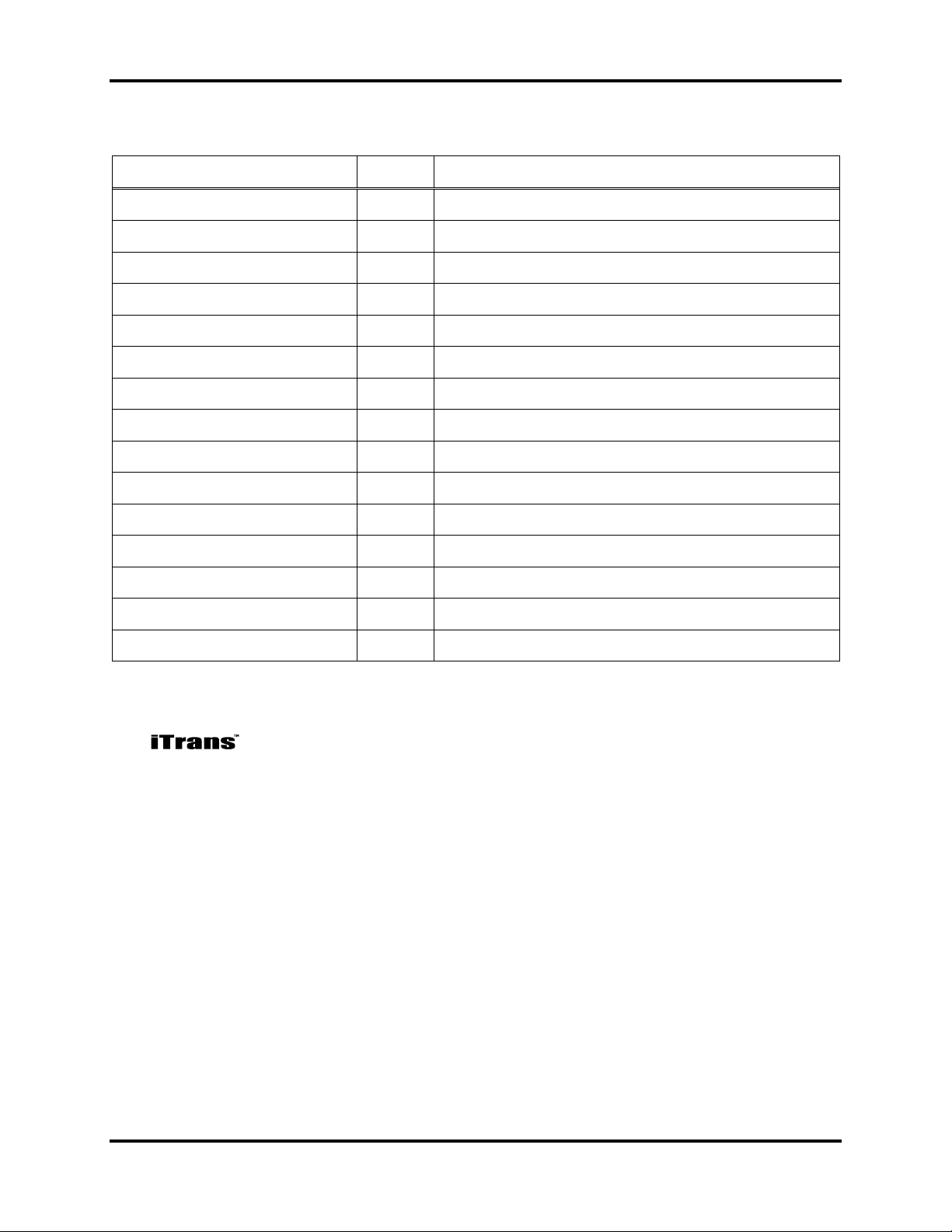

Sensor

Gas

Range/Resolution

Combustible Gases

LEL

0 -100% LEL in 1% increments

Hydrogen

H2

0 - 999 ppm in 1 ppm increments

Oxygen

O2

0 - 30.0% by vol. in 0.1% increments

Ammonia

NH3

0 - 500 ppm in 1 ppm increments

Carbon Monoxide

CO

0 - 999 ppm in 1 ppm increments

Carbon Monoxide/H2 Null

CO

0 - 999 ppm in 1 ppm increments

Hydrogen Sulfide

H2S

0 - 500 ppm in 1 ppm increments

Sulfur Dioxide

SO2

0.2 - 99.9 ppm in 0.1 ppm increments

Hydrogen Cyanide

HCN

0.2 – 30.0 ppm in 0.1 ppm increments

Hydrogen Chloride

HCl

0.2 - 30.0 ppm in 0.1 ppm increments

Phosphine

PH3

0 - 1.00 ppm in 0.01 ppm increments

Nitrogen Dioxide

NO2

0.2 - 99.9 ppm in 0.1 ppm increments

Nitric Oxide

NO

0 - 999 ppm in 1 ppm increments

Chlorine

Cl2

0.2 - 99.9 ppm in 0.1 ppm increments

Chlorine Dioxide

ClO2

0.02 - 1.00 ppm in 0.01 ppm increments

Table 1-2. Sensor Ranges

1.3. Agency Approvals

The is certified by CSA, a NRTL laboratory, to the following US and

Canadian Standards.

UL Std No. 916-Energy Management Equipment

UL Std No. 1203-Explosion-Proof and Dust-Ignition-Proof

o Electrical Equipment for Use in Hazardous (Classified) Locations

UL Std No. 1604-Division 2 Hazardous Location Electrical Equipment

ISA S12.13 Part I-2000-Performance Requirements, Combustible Gas

Detectors (catalytic sensors only)

CSA Std C22.2 No.30-M1986-Explosion-Proof Enclosures for Use in

Class I Hazardous Locations

CSA Std C22.2 No.142-M1987-Process Control Equipment

(P/N: 77023554-1) iTrans User Manual 1-3

Page 10

Introduction iTrans Fixed Point Single/Dual Gas Monitor

CSA Std C22.2 No. 152-M1984-Combustible Gas Detection Instruments

(catalytic sensors only)

CSA Std C22.2 No. 213-M1987-Non-incendive Electrical Equipment for

Use in Class I, Division 2 Hazardous Locations

Marking: Transmitter Class I, Div 1, Groups B, C, D – AEx d IIB + H2 T5

Sensor

Ambient for Model 7701-5857 Fixed IR sensor (BBIR) is -20C to +55C. Ambient for all other devices is

-40C to +75C.

(gas dependent)

(1)

Class I, Div 1, Groups B, C, D – AEx d IIB + H2 T5

(2)

Class I, Div 2, Groups A, B, C, D – AEx d IIB + H2 T5

The is certified under the IECEx scheme to:

IEC 60079-0:2007 - Electrical apparatus for potentially explosive

atmospheres–General requirements.

IEC 60079-1:2003 - Electrical apparatus for potentially explosive

atmospheres–Flameproof enclosures ‘d’.

IEC 60079-15:2005 - Electrical apparatus for explosive gas atmospheres.

Type of protection "n".

Marking: Transmitter Ex d IIB+H2 T5; IP66; Ta (-40°C to +75°C)

Sensor

(gas dependent)

(1)

Ex d IIB+H2 T5 ; IP66 ; Ta (-40°C to +75°C)

(2)

Ex nA II T5; Ta (-40°C to +75°C)

The complies with relevant provisions, per listed standards, of European

ATEX Directive 94/9/EC and EMC Directive 89/336/EEC, amended by Directives

92/31/EEC and 93/68/EEC, and is constructed with reference to published

standards of Directive 72/23/EEC, to eliminate electrical risks and fulfill 1.2.7 of

Annex II of Directive 94/9/EC.

EN 60079-0:2004 - Electrical apparatus for potentially explosive

atmospheres – General requirements.

EN 60079-1:2004 - Electrical apparatus for potentially explosive

atmospheres – Flameproof enclosures ‘d’.

EN 60079-15:2003 - Electrical apparatus for explosive gas atmospheres.

Type of protection “n”.

1-4 iTrans User Manual (P/N: 77023554-1)

Page 11

iTrans Fixed Point Single/Dual Gas Monitor Introduction

EN 50270: Electromagnetic compatibility - Electrical apparatus for the

detection and measurement of combustible gases, toxic gases or oxygen (for

Type 2 [Industrial] Apparatus).

The EC type examination certificate is KEMA 04 ATEX 2216X, with

Marking code: Transmitter Ex d IIB+H2 T5; Ta (-40°C to +75°C)

Sensor

(gas dependent)

(1)

Ex d IIB+H2 T5 ; Ta (-40°C to +75°C)

(2)

Ex nA II T5; Ta (-40°C to +75°C)

(1)

LEL, H2, O2, CO, H2S, SO2, HCN, PH3, NO2, NO, CO2

(2)

Cl2, HCl, NH3, ClO2

(P/N: 77023554-1) iTrans User Manual 1-5

Page 12

Introduction iTrans Fixed Point Single/Dual Gas Monitor

1.4. Special Instructions for Safe Use (EU)

Cable connection: The cable entry device shall be of a certified flameproof

type, suitable for the conditions of use and correctly installed.

Conduit Connection: An Ex d certified sealing device, such as, a conduit

seal with setting compound, suitable for the conditions of use, and correctly

installed, shall be provided immediately to the entrance of the housing.

Unused openings: Unused openings shall be closed with suitable Ex d

certified closing elements.

Dual Onboard: The “Y” adapter parts used to assemble dual onboard

configurations do not have Atex approval. Consult factory for dual onboard

Atex options.

1-6 iTrans User Manual (P/N: 77023554-1)

Page 13

iTrans Fixed Point Single/Dual Gas Monitor Introduction

(P/N: 77023554-1) iTrans User Manual 1-7

Page 14

Page 15

iTrans Fixed Point Single/Dual Gas Monitor Hardware Overview

HARDWARE OVERVIEW

Chapter

2

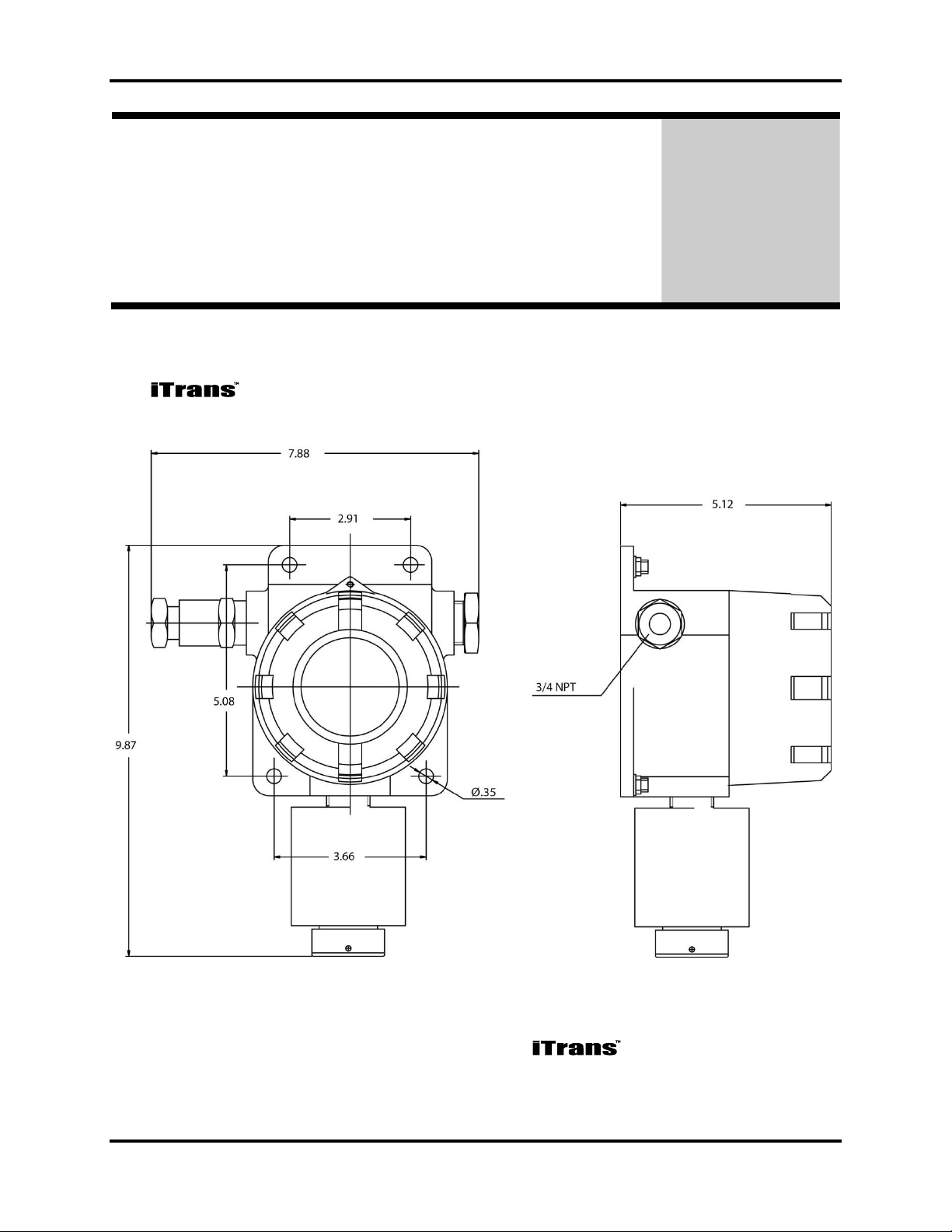

2.1. Main Electronics Unit (Housing)

The body is a cast aluminum housing that contains the electronics of the

gas monitor. Details of a single-gas housing are shown in Figure 2-1.

Figure 2-1. Details of a Single-Gas Gas Monitor

(P/N: 77023554-1) iTrans User Manual 2-1

NOTE: Dimensions are in inches.

Page 16

Hardware Overview iTrans Fixed Point Single/Dual Gas Monitor

Item

Descriptions

Catalytic and Toxics

Infrared (BBIR)

Sensor

Housing

Material

Aluminum, Anodized

Explosion-proof: Class I, Divisions 1

and 2, Groups B, C, D and Ex d IIB

+H2 T5 (ATEX and IECEx), Ex d

IICT6 Gb (China)

Stainless Steel

Explosion-proof: Class I,

Divisions 1 and 2 Groups B,

C, D, and Ex d IIB +H2 T4

(Europe), Ex d IIC T4 or IIC

T6 (China)

Aluminum, Anodized w/Gore-Tex

Membrane: Class I, Division 2, Groups

A, B, C, D and Ex nA IIC T5 (IECEx)

and Ex nA II T5 (ATEX).

Dimensions

3.0 3.0 inches (76 76 mm)

3.5 3.0 inches (89 76 mm)

Accuracy

< 3% Toxic and Oxygen

< 5% Combustibles

Protection

Class

IP 66 or NEMA4X

2.2. Sensor

Table 2-3. Sensor Specifications

2-2 iTrans User Manual (P/N: 77023554-1)

Page 17

iTrans Fixed Point Single/Dual Gas Monitor Hardware Overview

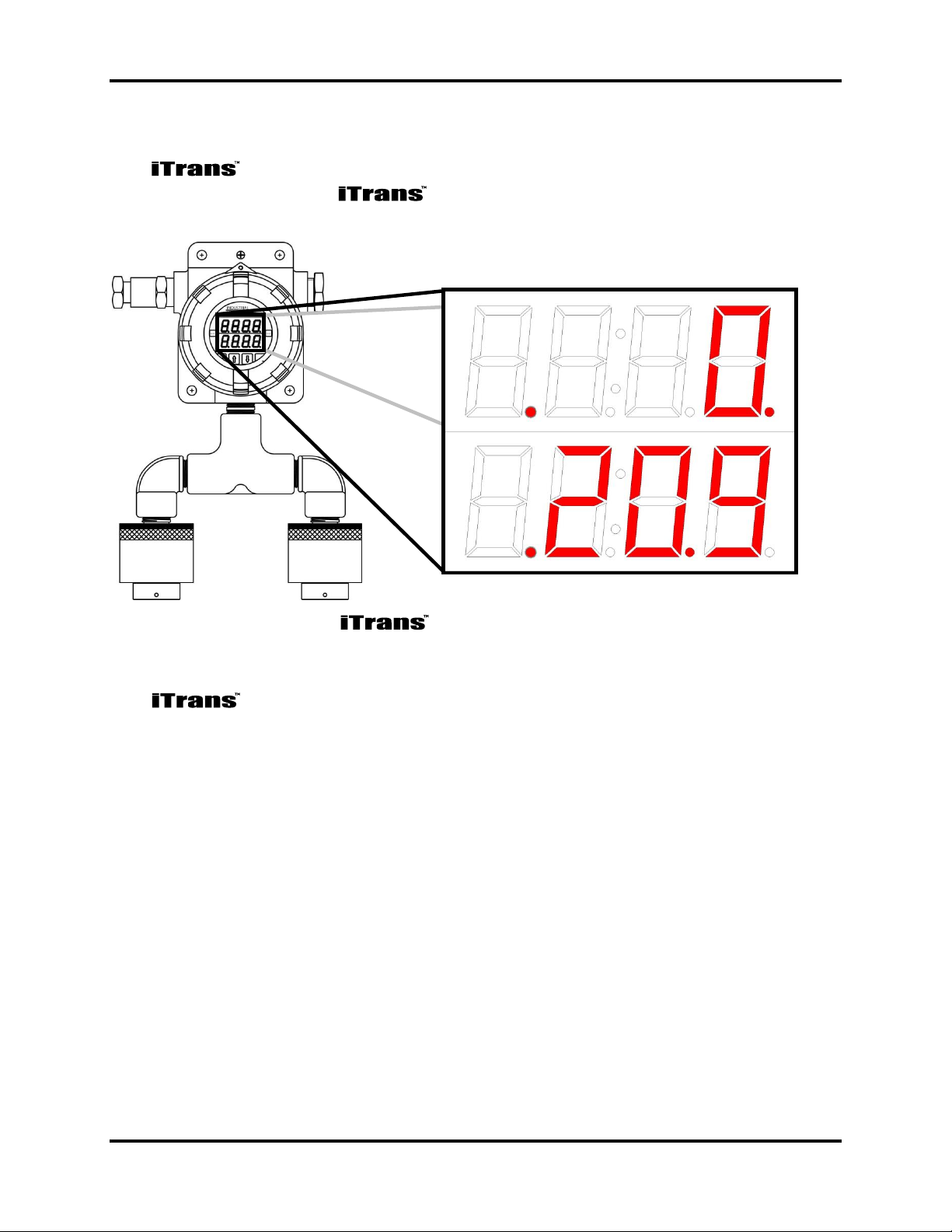

2.3. Display

The gas monitor has a 4-digit, 7-segment LED display for each of 2

channels. A dual-gas sensor and sample display are shown in

Figure 2-2.

Figure 2-2. The Display (Dual-Gas Monitor Shown)

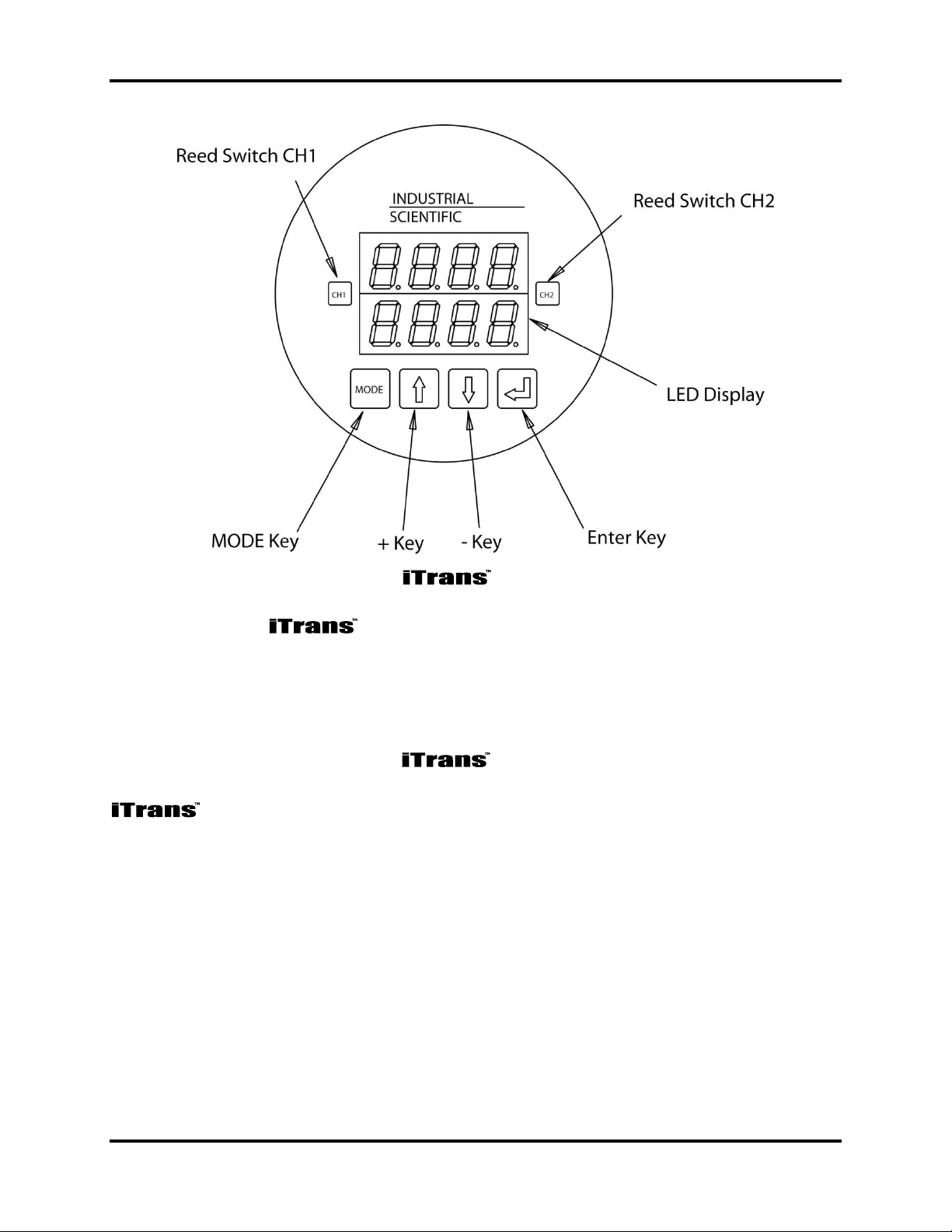

2.4. Inputs – Intrusive and Non-Intrusive

The gas monitor can be configured using intrusive and non-intrusive

means. Both methods of configuration are accomplished through physical inputs

that are visible behind the glass panel of the gas monitor.

A set of four keys are used when intrusive programming is appropriate (i.e., when

the enclosure can be removed and when the keys can be manually pressed). These

keys are the mode, increment (+), decrement (-), and enter keys. Refer to

Figure 2-3.

For applications that require non-intrusive manipulation, two magneticallyactivated reed switches are used to accomplish programming without removing the

cover. A magnetic wand is positioned over the appropriate reed switch (above the

glass face plate) without the wand physically touching the reed switches. The

locations of the reed switches are shown in Figure 2-3.

(P/N: 77023554-1) iTrans User Manual 2-3

Page 18

Hardware Overview iTrans Fixed Point Single/Dual Gas Monitor

Figure 2-3. Locations of Input Keys and Reed Switches

Programming the gas monitor in both intrusive and non-intrusive modes

is explained in detail in Chapter 5: Operation.

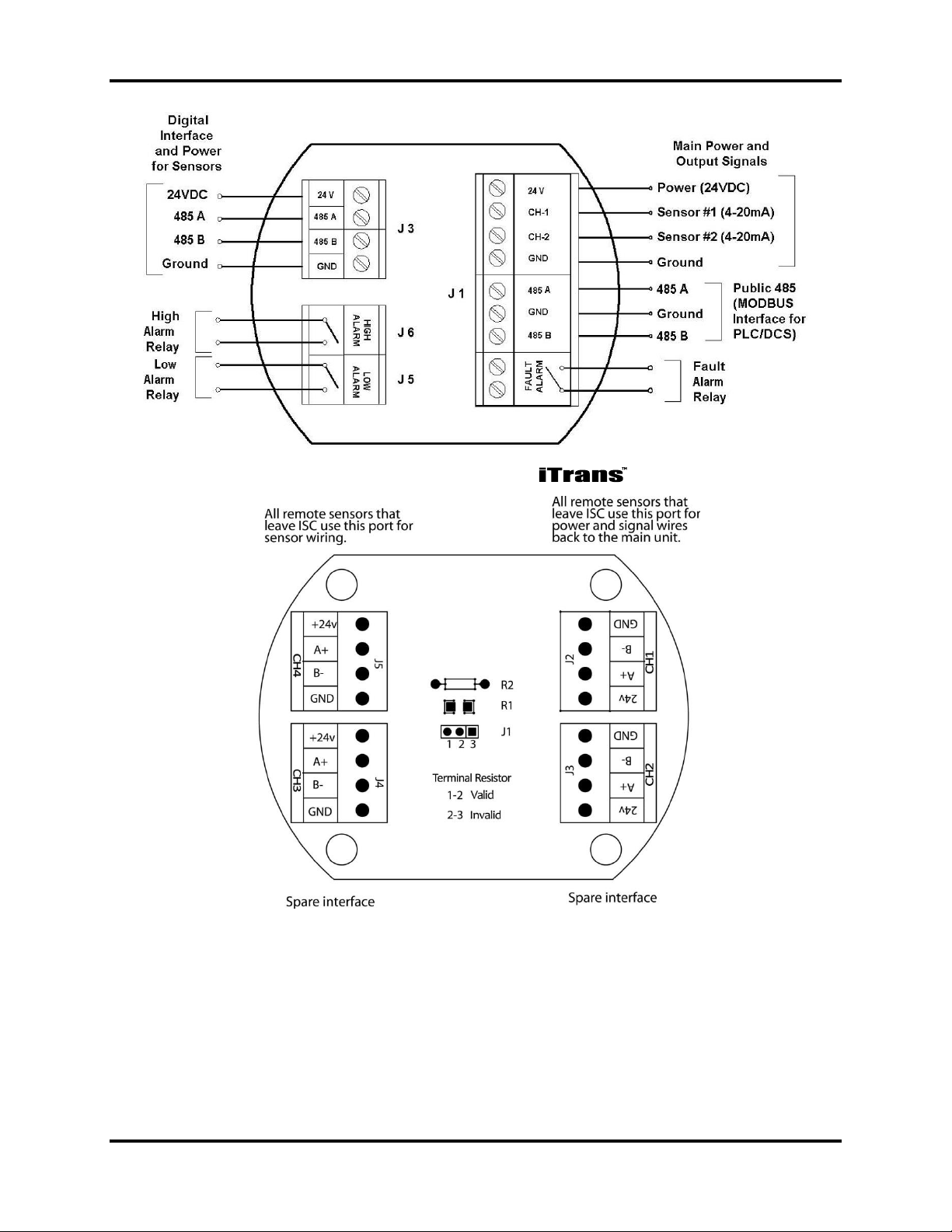

2.5. Electronics Modules

The electronics module of the gas monitor contains connectors and

jumpers for wiring and configuring the device. The electronics module for a main

unit is shown in Figure 2-4. The electronics module for a remote unit is

shown in Figure 2-5. Wiring details are explained in Chapter 4: System Wiring.

2-4 iTrans User Manual (P/N: 77023554-1)

Page 19

iTrans Fixed Point Single/Dual Gas Monitor Hardware Overview

Figure 2-4. Electronics Module for (Main Unit)

Figure 2-5. Electronics Board for Remote Sensor

(P/N: 77023554-1) iTrans User Manual 2-5

Page 20

Hardware Overview iTrans Fixed Point Single/Dual Gas Monitor

2-6 iTrans User Manual (P/N: 77023554-1)

Page 21

iTrans Fixed Point Single/Dual Gas Monitor Installation

INSTALLATION

Chapter

3

3.1. Introduction

The can be mounted in one of two ways. The unit can be wall-mounted

using the wall mounting holes in the enclosure, or it can be mounted onto a column

using U-bolts. Each of these options is discussed in this chapter. Be sure to

review the installation considerations before mounting the gas monitor.

3.2. Installation Considerations

Regardless of the installation type (wall mounting or column mounting), the

should be installed at or near the location of a possible leak or the source

of emissions. Installation height depends on the density of the gas being monitored.

Moreover, speed and direction of air flow, and relative position to potential leaking

points should also be considered.

IMPORTANT: The gas monitor must not be installed on vibrating or

heat generating sources.

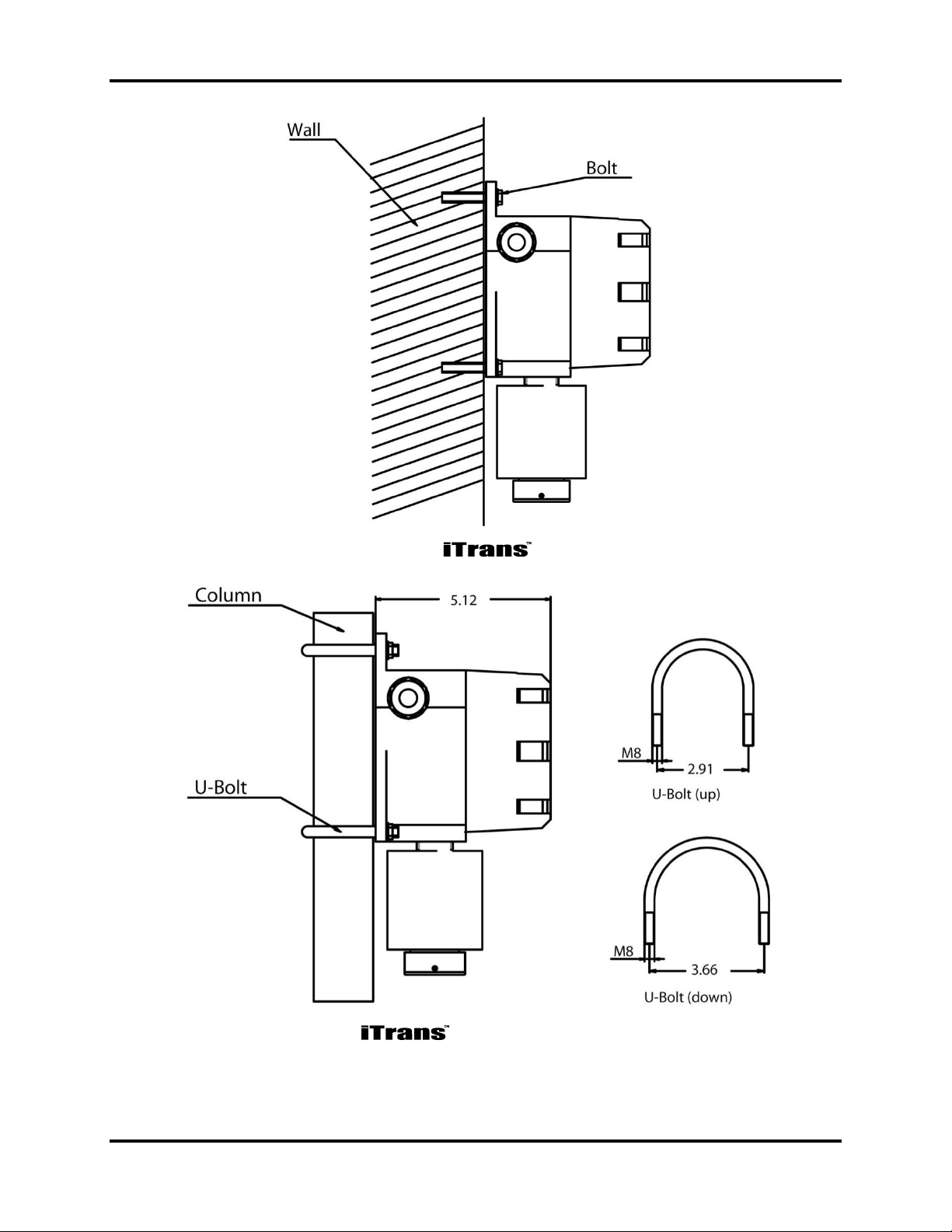

3.3. Wall Mounting

If your application is best addressed using a wall-mounted gas monitor, then use

the four 8 mm mounting holes in the enclosure to secure the to an appropriate

location on the wall. Refer to Figure 3-1.

3.4. Column Mounting

If your application is best addressed using a column-mounted gas monitor, then use

the four 8 mm mounting holes and two U-bolts to secure the to an appropriately

located segment of a target pipe or conduit. Refer to Figure 3-2.

(P/N: 77023554-1) iTrans User Manual 3-1

Page 22

Installation iTrans Fixed Point Single/Dual Gas Monitor

Figure 3-1. Mounting the Gas Monitor on a Wall

Figure 3-2. Mounting the Gas Monitor on a Column Using U-Bolts

3-2 iTrans User Manual (P/N: 77023554-1)

Page 23

iTrans Fixed Point Single/Dual Gas Monitor System Wiring

SYSTEM WIRING

Chapter

4

4.1. Introduction

This chapter outlines the steps required for wiring the gas monitor. These steps

include the following:

Wiring Preparation Sensor Wiring

Alarm Relay Wiring Power and Output Wiring

ModBus Interface Wiring.

Each of these steps is outlined in the sections that follow.

IMPORTANT: Perform all wiring in accordance with local electrical codes and

local authorities having jurisdiction.

IMPORTANT: DC signal and AC power should not be run in the same conduit.

NOTE: All field wiring colors are arbitrary (unless provided by Oldham).

4.2. Wiring Preparation

1. Collect the appropriate types and lengths of wire.

For control wire, use #18 AWG insulated, shielded cable.

For signal and power wire, use three-conductor (or four-conductor for dual

channel) #18 AWG insulated and shielded cable.

For digital ModBus signal and power, use a minimum of five-conductor

#18 AWG insulated and shielded cable.

2. Power down the unit.

3. Unthread the windowed top from the housing.

4. Gently pull out the electronics module and place it safely to the side of the unit.

5. Thread control, signal, and power wires into the transmitter housing.

(P/N: 77023554-1) iTrans User Manual 4-1

Page 24

System Wiring iTrans Fixed Point Single/Dual Gas Monitor

6. Shielding from either the controller or remote sensors should be bonded to the

enclosure screw located inside the .

IMPORTANT: Use of this product in areas where it may be subject to large

amounts of electromagnetic interference may affect the reliable operation of this

device and should be avoided.

WARNING: Supply wire with a minimum rating of 90oC must be used for

interconnection to the .

NOTE: For classified locations, a “poured” wire seal must be installed within

18 inches of the main unit for both power entry and remote sensors.

NOTE: Remove power from the before making any wiring connections.

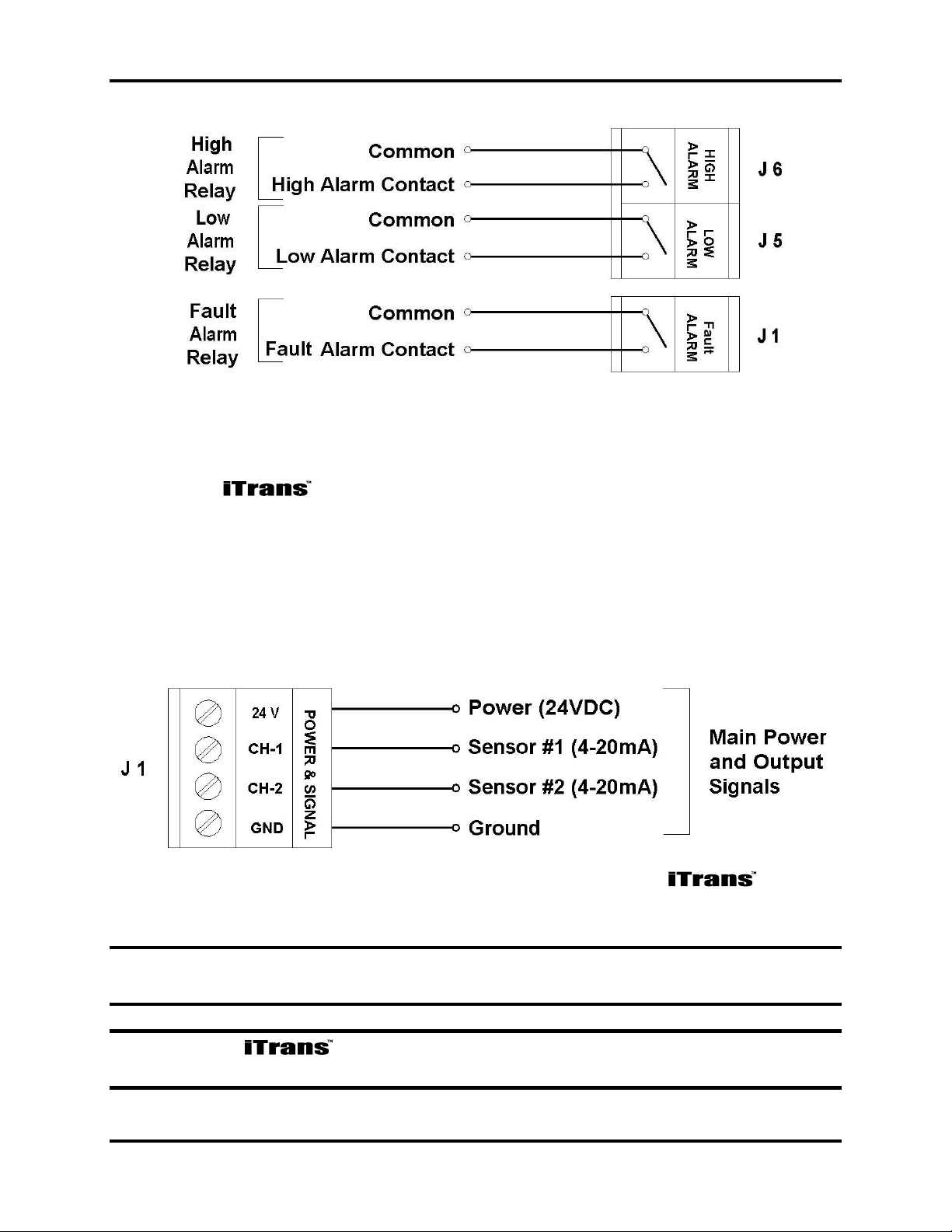

4.3. Alarm Relay Wiring (J1, J5, and J6)

To connect the control wires to the three relay terminals on the relay

board, wire the unit to the connectors shown in Figure 2-4. The low alarm relay

is activated when the low alarm threshold is met. This is a non-latching, Normally

Open (NO) contact. The high alarm relay is activated when the high alarm

threshold is met. This is a non-latching, Normally Open (NO) contact. The fault

alarm relay is activated upon power-up of the . When the fault condition

is met, the circuit opens. This is an Electronically closed (NO) contact. See Figure

4-1 for relay wiring.

NOTE: It is recommended that on-board relays should not be used to drive loads

directly. On-board relays should be used to drive a secondary, higher-power relay

which is connected to the control device (e.g., strobe, siren, exhaust fan, etc.).

4-2 iTrans User Manual (P/N: 77023554-1)

Page 25

iTrans Fixed Point Single/Dual Gas Monitor System Wiring

Figure 4-1. Alarm Relay Connectors J6, J5 and J1

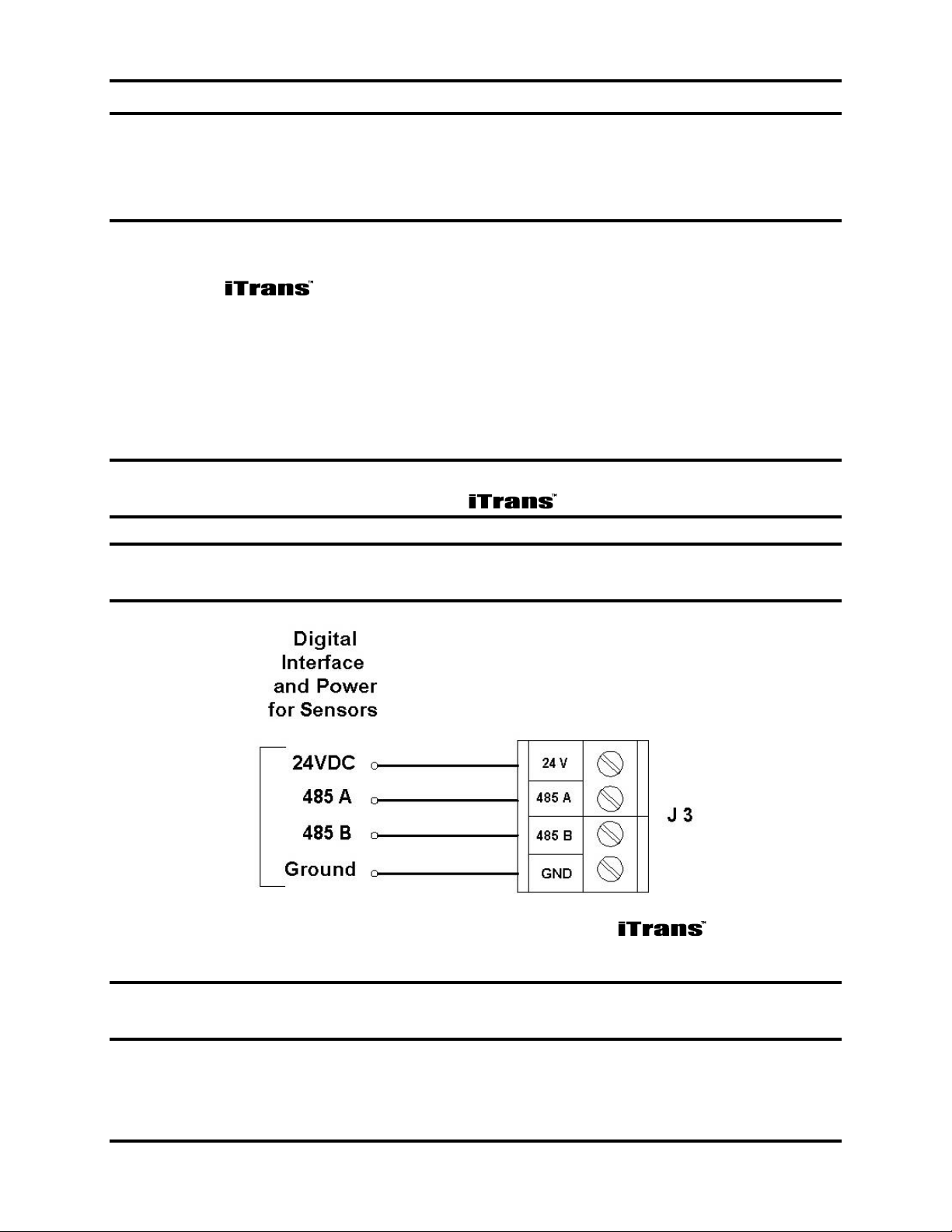

4.4. Power and Output Wiring (J1)

Connect the power and signal wires to the appropriate wiring terminals

as follows.

24 V: Connect 24 VDC (12-28 VDC) supply power

CH 1: Channel 1, 4-20 mA output signal

CH 2: Channel 2, 4-20 mA output signal

GND: DC return

Figure 4-2. Power and Signal Connector J1 on the

NOTE: Use supplied green conductor for enclosure ground. Public 485 GND is

to be used for ModBus digital ground.

NOTE: The is a 3- or 4-wire 4-20 mA device. For dual sensor

configuration you must have a second 4-20 mA signal wire pulled to the unit.

(P/N: 77023554-1) iTrans User Manual 4-3

Page 26

System Wiring iTrans Fixed Point Single/Dual Gas Monitor

NOTE: When not using 4-20 mA outputs, use the supplied resistors to connect

CH-1 and CH-2 to GND. If these resistors are not connected and the 4-20 mA

outputs are not used, a “P” will appear on the display, indicating an open loop

condition.

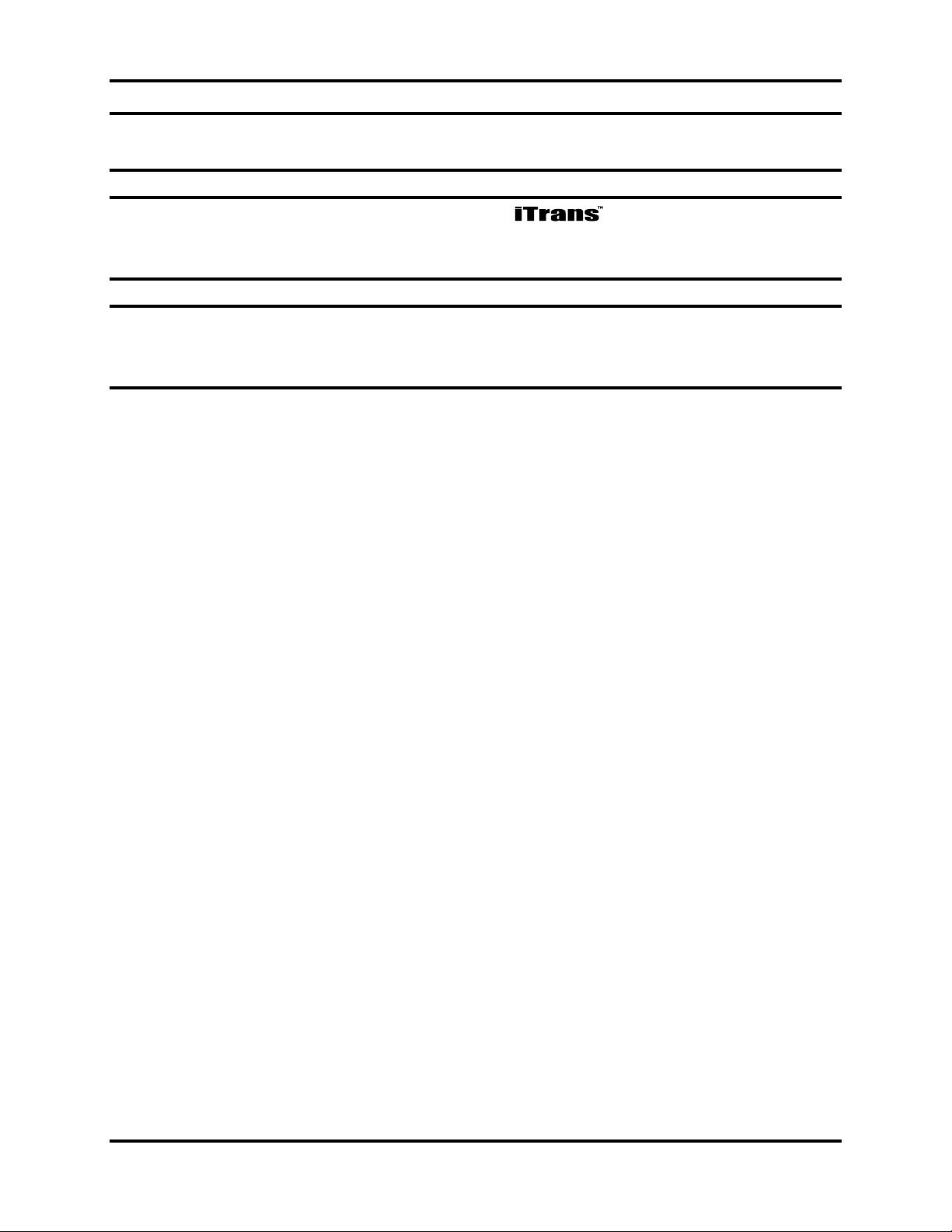

4.5. Sensor Wiring (J3)

Connect the sensor wires (for on-board, remote or stand-alone) to the

appropriate wiring terminals as follows.

24 V: Red wire from sensor head (Red wire on BBIR)

485A: Yellow wire from sensor head (White wire on BBIR)

485B: Black wire from sensor head (Green wire on BBIR)

GND: Green wire from sensor head (Black wire on BBIR)

NOTE: Shielding from either the controller or remote sensors should be bonded

to the enclosure screw located inside the .

NOTE: The 24 V terminal supplies 24 VDC to the sensor for power. This

terminal should not be connected to the output of a 24 VDC power supply.

Figure 4-3. Sensor Connector J3 on the

NOTE: For dual-sensor configurations, place both of the same colored wires in

the appropriate terminal block and firmly tighten.

4-4 iTrans User Manual (P/N: 77023554-1)

Page 27

iTrans Fixed Point Single/Dual Gas Monitor System Wiring

NOTE: Use #18 AWG shielded cable for remote sensors. Maximum distance is

200 meters (BBIR maximum distance is 300 feet with #18 AWG wire).

NOTE: When wiring remote sensors to the , “485 B” on J3 should be

connected to “B-” in the remote sensor enclosure, and “485 A” on J3 should be

connected to “A+” in the remote sensor enclosure.

NOTE: For remote or standalone sensors, there are four terminal blocks located in

the remote sensor housing. These terminal blocks are all tied together and follow

the same wiring scheme mentioned above.

(P/N: 77023554-1) iTrans User Manual 4-5

Page 28

System Wiring iTrans Fixed Point Single/Dual Gas Monitor

Figure 4-4. Wiring Diagram for a Single On-board Sensor

4-6 iTrans User Manual (P/N: 77023554-1)

Page 29

iTrans Fixed Point Single/Dual Gas Monitor System Wiring

Figure 4-5. Wiring Diagram for a Remote Sensor (Stand Alone)

NOTE: When the remote sensor is at distances of 200 meters or further, and the

sensor is not communicating, the jumper may need to be moved to terminals 1-2.

(P/N: 77023554-1) iTrans User Manual 4-7

Page 30

System Wiring iTrans Fixed Point Single/Dual Gas Monitor

NOTE: If using remote sensors and the does not recognize the sensor

upon power up (displays a sensor fault), check the placement of this jumper. If the

jumper is on terminals 1-2, move the jumper to terminals 2-3.

For digital ModBus signal and power use a minimum of 4 conductors #18 AWG

insulated and shielded cable.

Shielding from either the controller or remote sensors should be bonded to the

enclosure screw located inside the .

Figure 4-6. Wiring Diagram for Dual On-board Sensors

4-8 iTrans User Manual (P/N: 77023554-1)

Page 31

iTrans Fixed Point Single/Dual Gas Monitor System Wiring

Figure 4-7. Wiring Remote Sensors Back to

Figure 4-8. Wiring Dual Remote Sensors

(P/N: 77023554-1) iTrans User Manual 4-9

Page 32

System Wiring iTrans Fixed Point Single/Dual Gas Monitor

4.6. Digital ModBus RTU Interface Wiring (J1)

4.6.1. ModBus Interface Wiring Overview

To interface the to a digital controller, PLC, or HMI, connect the power

and ground to the appropriate terminals mentioned above. The digital signals are

wired into the RS485A and RS485B terminals on the board. See Figure 4-9.

Figure 4-9. Wiring Diagram for the ModBus Interface

4.6.2. Setting the ModBus Address on the

Located on the back of the electronics module is an 8-position DIP switch.

This switch bank is used to set the ModBus Slave Address for the

unit. The address can be set from 1 to 255. Use the DIP switches to set the

binary representation of the desired address. 1 is bit zero, and 8 is bit 7. ON

represents a 1, and OFF represents zero. Refer to Appendix B for hex-todecimal equivalents.

Figure 4-10. Switch Bank for Setting ModBus Slave Address

4-10 iTrans User Manual (P/N: 77023554-1)

Page 33

iTrans Fixed Point Single/Dual Gas Monitor System Wiring

Figure 4-11. Setting the ModBus Address (Example Address of 240 Decimal)

4.6.3. Setting the ModBus Address for Stand-Alone Sensors

NOTE: This section is only necessary if you are connecting a sensor directly to a

ModBus controller, PLC, or digital system.

For stand-alone sensor heads used in a ModBus network, the address is set in the

same manner. Once the aluminum sensor head is removed with the sensor board,

the sensor electronics module is exposed. On the back of the sensor electronics

module is a small 8-position DIP switch. The address can be set from 1 to 255 in a

similar manner as setting the ModBus address on the except pin 8 on the

sensor’s 8-position DIP switch is the least significant bit, and pin 1 is the most

significant bit.

(P/N: 77023554-1) iTrans User Manual 4-11

Page 34

System Wiring iTrans Fixed Point Single/Dual Gas Monitor

Figure 4-12. Location of Address DIP Switch on Sensor Electronics Module

Figure 4-13. Setting the ModBus Address for a Stand-Alone Sensor

4-12 iTrans User Manual (P/N: 77023554-1)

Page 35

iTrans Fixed Point Single/Dual Gas Monitor System Wiring

NOTE: If adding a second sensor to an existing module, set the ModBus address

to which represents 11110000 binary (and 240 decimal). See

Chapter 6 for more information on the ModBus interface. (Note that DIP switches

are pre-set at the factory for all dual-sensor units).

4.7. Wiring Conclusion

Once wiring is complete, place the electronics module back in the

housing by pressing the standoff banana jacks into the mating plugs. Be careful

not to pinch any of the wiring. After the module is in place, secure the windowed

top back on the housing and power up the unit.

(P/N: 77023554-1) iTrans User Manual 4-13

Page 36

Page 37

iTrans Fixed Point Single/Dual Gas Monitor Operation

OPERATION

Chapter

5

During this warm-up period, the

4-20 mA outputs are limited to 3 mA

(16 mA for oxygen). After the three

minute warm-up, the unit will enter

the Normal Operating Mode. If during

the warm-up period, the unit fails a

self test, the display will show a fault

code, and the fault relay will be

activated. Fault codes are located in

Chapter 8.

Figure 5-1. Sample Fault Code Display

5.1. Initial Start-up

Once power is applied (12-28 VDC), the is operational. The LED

display powers up, and the system enters a start-up period. During this start-up

period, the identifies the sensors that are connected and then enters a

three minute warm-up period.

NOTE: Upon initial power up, broadband infrared (BBIR) sensors do not store or

transmit the default values for Low Alarm, High Alarm, and 4-20 mA range to the

unit. These values are set to zero, and must be set following the

procedures outlined later in this manual.

5.2. Warm-up Period

(P/N: 77023554-1) iTrans User Manual 5-1

Page 38

Operation iTrans Fixed Point Single/Dual Gas Monitor

In Normal Operating Mode, the

gas monitor will display the

instantaneous readings for each sensor

wired into the unit. The top of the

display shows the gas

reading for Sensor 1. Sensor 1 should

have the internal dip switches set to 00

hex or 0F hex. The bottom row of the

display shows the gas

reading for Sensor 2. Sensor 2 should

have the internal dip switches set to F0

hex.

Figure 5-2. Sample Dual-Sensor

Display

As gas concentrations increase, the

respective channel’s readings will

respond accordingly. If low or high

alarm levels are exceeded, an alarm

indication will appear in the first digit

of the display. An “L” indicates a low

alarm while an “H” indicates a high

alarm. If a 4-20 mA fault occurs,

either a “P” indicating an open loop, or

an “U” indicating 4-20 over-range will

be present.

Figure 5-3. Sample Low and High

Alarm Displays

5.3. Normal Operating Mode

From the Normal Operating Mode, the can enter into the program mode

in one of two ways. To enter the Program Mode without opening the enclosure,

pass over the embedded reed switch located under CH1 with the magnetic wand

(see Figure 5-4). This will enter you into the non-intrusive program mode.

In this mode you can check sensor type, zero the unit, calibrate the unit, change the

span gas value, and view sensor span. With the enclosure top removed, Program

Mode can be entered using the “MODE” key. The available functions are listed in

Chapter 8: Troubleshooting.

5-2 iTrans User Manual (P/N: 77023554-1)

Page 39

iTrans Fixed Point Single/Dual Gas Monitor Operation

Figure 5-4. Locations of Reed Switches and Push Buttons

5.4. Programming Mode Overview

NOTE: Zeroing and calibrating the instrument can be accomplished one of two

ways via programming mode. Zeroing and calibrating (as well as other

programming options) can be entered either from the keypad or non-intrusively

using the magnetic wand. Refer to the sections and subsections within this chapter

for detailed information.

When in the Programming Mode, either via the magnetic wand or keypad

operation, the top line of the main display area shows a status bit and three data

bits. The bottom line of the display shows the timers (see Figure 5-5). The

decimals on the far right of each line of the display are channel indicators. The top

decimal indicates channel 1 is being programmed, and the bottom decimal

indicates channel 2.

(P/N: 77023554-1) iTrans User Manual 5-3

Page 40

Operation iTrans Fixed Point Single/Dual Gas Monitor

Figure 5-5. Components of the Display

5.5. Programming Mode – Non-intrusive Operation

5.5.1. Introduction

Non-intrusive calibration and programming is accomplished using a magnetic

wand that comes with the unit. Placing the magnetic wand over the

embedded reed switches located under the CH1 and CH2 designations (see

Figure 5-4) of the faceplate will allow you to scroll through menus and enter the

desired function. The functions available through non-intrusive operation are as

follows.

Sensor Type

Zero

Calibration

Span Gas Value

Span Reserve (in this order).

NOTE: Please see the Chapter 8 for a complete list of functions and function

codes.

5-4 iTrans User Manual (P/N: 77023554-1)

Page 41

iTrans Fixed Point Single/Dual Gas Monitor Operation

To enter non-intrusive operation

during the Normal Operating Mode,

place the magnetic wand over the CH1

designation. The will

display the sensor type for channel 1

for 5 seconds then enter in the Zero

Menu.

Figure 5-6. Sample Display Entering

Non-Intrusive Mode

Zeroing is the first option in the setup

menu. A “0 ” is displayed in the status

bit of the display to designate this

function. A 10 second timer is

displayed on the bottom line of the

LED display. To initiate zeroing, place

the magnetic wand over CH2 during

the 10-second countdown. If you do

not initiate zeroing during the 10second countdown, the will

return to the Normal Operating Mode.

To abrot zeroing at any time, place the

magnatic wand over CH1.

Figure 5-7. Sample Zeroing Display

5.5.2. Sensor Type

NOTE: If you want to operate channel 2, place the magnetic wand on CH2 first to

enter the setup menu.

Once non-intrusive mode is entered, placing the magnetic wand over CH1, will

allow scrolling through all of the functions that are available. Once the desired

function is reached, a 10-second timer will appear on the bottom row of the LED

display. During this 10-second time out, if the magnetic wand is placed over CH2,

that function is entered. Once a function is entered, a new timer will appear.

5.5.3. Zeroing

If you initiate zeroing, the status bit will start to flash. Once zeroing is complete,

the unit will return to the Normal Operating Mode.

(P/N: 77023554-1) iTrans User Manual 5-5

Page 42

Operation iTrans Fixed Point Single/Dual Gas Monitor

Calibration is the next available

option. Calibration is designated with

a “C” in the status bit. A 10 second

timer is displayed on the bottom line

of the LED display. To initiate

calibration, place the magnetic wand

over CH2 during the 10-second

countdown. If you do not initiate

calibration during the 10-second

countdown, the will return

to the Normal Operating Mode. If you

initiate calibration, the status bit will

start to flash and the will

enter the zeroing process.

Figure 5-8. Sample Calibration Display

The will automatically zero

before calibration. Zeroing is

designated with a flashing “0” in the

status bit. Once zeroing is complete,

the will automatically enter

the calibration routine. Calibration is

designated with a flashing “C” in the

status bit.

After zeroing finishes, the is

ready to calibrate. When the flashing

“C” appears on the display, apply

calibration gas. As the

responds to the gas, the current

reading will be displayed on the top

line of the LED display. To abort

calibration at any time, place the

magnetic wand over CH1.

Figure 5-9. Sample Zeroing Display

5.5.4. Calibration

NOTE: Before the will calibrate, the unit will enter the zeroing process.

Please make sure that you apply Zero Air to the instrument while it is zeroing.

5-6 iTrans User Manual (P/N: 77023554-1)

Page 43

iTrans Fixed Point Single/Dual Gas Monitor Operation

NOTE: Check and verify span setting

before starting a calibration.

NOTE: See Appendix D for a

complete list of factory default span

gases.

NOTE: Flow rate for calibration is

0.5 liter per minute (LPM) except for

NH3, ClO2, Cl2, NO2, SO2, and HCl

which require 1.0 LPM.

Figure 5-10. Apply CalGas Display

The option after calibration is Span

Gas Concentration. The span option is

designated with a flashing “S” in the

status bit with the current span value

next to it. To change the span value,

place the magnetic wand over CH2

during the 10-second countdown. If

you do not place the magnet over CH1

during the 10-second countdown, the

will return to the Normal

Operating Mode. If you initiate the

change span option, the status bit will

start to flash and the span

value can now be changed.

The current span value is displayed on

the top line of the LED display. To

increment the span value, pass the

magnetic wand over CH1. When the

desired value is reached, pass the

magnetic wand over CH2 to accept

and save changes. Passing over CH1

or letting the timer count down to zero

without saving the new value, will

take you back into the Programming

Mode.

Figure 5-11. Sample Span Gas

Concentration Display

Figure 5-12. Flashing Status Bit

5.5.5. Changing Span Gas Concentration

(P/N: 77023554-1) iTrans User Manual 5-7

Page 44

Operation iTrans Fixed Point Single/Dual Gas Monitor

The last option available is viewing

the sensor span reserve. The span

reserve option is designated with an

“r” in the status bit. The current span

reserve is displayed on the top line of

the LED display.

Figure 5-13. Sample Span Reserve

Display

In a safe environment where the

windowed top of the transmitter can be

removed, there are more programming

options available. These programming

options include all of the functions

available in the non-intrusive mode as

well as a few others. These items are

password protected. To enter the

programming options, press the

“Mode” key. The access code is

“Mode”, “Up”, “Down”, “Up”,

“Enter”.

Figure 5-14. Sample Code Entry

Display

NOTE: Span Gas Concentration for combustibles can be set from 0% to

100%LEL. For the sake of resolution, the Span Gas Concentration should be set

above 20% LEL.

5.5.6. Sensor Span Reserve

5.6. Programming Mode – Push Button Operation

5.6.1. Introduction

Once the correct password has been entered, the user will have to select a channel

for programming. But in case of wrong password or time out (10 second) the

display will revert back to Normal Operating Mode.

5-8 iTrans User Manual (P/N: 77023554-1)

Page 45

iTrans Fixed Point Single/Dual Gas Monitor Operation

On entering the correct password, the

channel selection screen will be

displayed on the LED display. Press

the “Mode” button to switch between

the available channels then press the

“” button to confirm the channel

selection.

Once a channel is selected, the gas

type for that sensor is displayed on the

top row of the LED display for 5-7

second. After that the LED display

will show the list of available

functions. Use the arrow keys to scroll

through the list of functions available.

Figure 5-15. Sample Channel Selection

Display

The low alarm setpoint is designated

with an “L” displayed in the status bit

and current low alarm value displayed

next to it. To change the low alarm

setpoint, press the “” button during

the 10-second countdown. If you do

not press “” during the 10-second

countdown, the will return

to the Normal Operating Mode. If you

initiate the low alarm option, the status

bit will start to flash and the

low alarm setpoint can be changed by

Figure 5-16. Sample Low Alarm

Setpoint Display

NOTE: If display shows “ iNet” confirm setting is “0” to ensure proper function

of onboard relay.

NOTE: Please see Chapter 8 for a complete list of functions and function codes.

5.6.2. Entering Programming Mode and Selecting a Channel

NOTE: If you have a dual-sensor unit, use the “Mode” button to switch between

the channel.

5.6.3. Set Low Alarm

(P/N: 77023554-1) iTrans User Manual 5-9

Page 46

Operation iTrans Fixed Point Single/Dual Gas Monitor

When the desired value is reached,

press the “” key to accept and save

the new value. If the value is not

saved before the time-out, the

will go back to the

Programming Mode.

5.6.5. 4-20 mA Analog Output

Range

The range of 4-20 mA analog output is

set to full range as factory default. For

full range values, see Appendix D. If

the user desires to change the output

scaling of the 4-20 mA analog signal,

they can do so.

Figure 5-17. Sample High Alarm

Setpoint Display

using the “” and “” keys. When the desired value is reached, press the “” key

to accept and save the new value. If the value is not saved before the time-out, the

will go back to the Programming Mode.

5.6.4. Set High Alarm

The high alarm setpoint is designated with an “H” displayed in the status bit and

the current high alarm value displayed next to it. To change the high alarm

setpoint, press the “” button during the 10-second countdown. If you do not

press “” during the 10-second countdown, the will return to the

Normal Operating Mode. If you initiate the high alarm option, the status bit will

start to flash and the high alarm setpoint can be changed by using the “”

and “” keys.

NOTE: Only the upper end range can be changed. The low end is always set for

4 mA.

5-10 iTrans User Manual (P/N: 77023554-1)

Page 47

iTrans Fixed Point Single/Dual Gas Monitor Operation

The 4-20 mA setpoint is designated

with a “4” displayed in status bit and

the current high end range next to it.

To change the range, press the “”

button during the 10-second

countdown. If you do not press “”

during the 10-second countdown, the

will return to the Normal

Operating Mode. If you initiate the

4-20 mA range option, the status bit

will start to flash and the

range setpoint can be changed by

using the “” and “” keys.

When the desired value is reached,

press the “” key. If the value is not

saved before the time-out, the

will go back to the

Programming Mode.

Figure 5-18. Changing the Analog

Output Upper Value

The system’s clock minute setting is

designated with a “1” in the status

bit and current value next to it. To

change the minutes, press the “”

button during the 10-second

countdown. If you do not press “”

during the 10-second countdown, the

will return to the Normal

Operating Mode. If you initiate the

minutes option, the status bit will

start to flash and the

minute can be changed by using the

“” and “” keys.

Figure 5-19. Setting System Time

(Minutes)

5.6.6. Set System Time – Minute

(P/N: 77023554-1) iTrans User Manual 5-11

Page 48

Operation iTrans Fixed Point Single/Dual Gas Monitor

The system’s clock hour setting is

designated with an “h” in the status

bit and current value next to it. To

change the hour, press the “” button

during the 10-second countdown. If

you do not press “” during the 10second countdown, the will

return to the Normal Operating Mode.

If you initiate the hours option, the

status bit will start to flash and the

hour can be changed by

using the “” and “” keys.

Figure 5-20. Setting System Time (Hour)

The system’s day of the month setting

is designated with a “d” in the status

bit and current value next to it. To

change the day, press the “” button

during the 10-second countdown. If

you do not press “” during the 10second countdown, the will

return to the Normal Operating Mode.

If you initiate the days option, the

status bit will start to flash and the

day can be changed by

using the “” and “” keys.

Figure 5-21. Setting System Date

When the desired value is reached, press the “” key. If the value is not saved

before the time-out, the will go back to the Programming Mode.

5.6.7. Set System Time – Hour

When the desired value is reached, press the “” key. If the value is not saved

before the time-out, the will go back to the Programming Mode.

5.6.8. Set System Time – Day

When the desired value is reached, press the “” key. If the value is not saved

before the time-out, the will go back to the Programming Mode.

5-12 iTrans User Manual (P/N: 77023554-1)

Page 49

iTrans Fixed Point Single/Dual Gas Monitor Operation

The system’s month setting is

designated with an “E” in the status bit

and current value next to it. To

change the month, press the “”

button during the 10-second

countdown. If you do not press “”

during the 10-second countdown, the

will return to the Normal

Operating Mode. If you initiate the

month option, the status bit will start

to flash and the month value

can be changed by using the “” and

“” keys.

Figure 5-22. Setting System Month

The system’s year setting is designated

with an “8” in the status bit and

current value next to it. To change the

year, press the “” button during the

10-second countdown. If you do not

press “” during the 10-second

countdown, the will return

to the Normal Operating Mode”. If

you initiate the year option, the status

bit will start to flash and the

year value can be changed by using

the “” and “” keys.

Figure 5-23. Setting System Year

5.6.9. Set System Time – Month

When the desired value is reached, press the “” key. If the value is not saved

before the time-out, the will go back to the Programming Mode.

5.6.10. Set System Time – Year

When the desired value is reached, press the “” key. If the value is not saved

before the time-out, the will go back to the Programming Mode.

5.6.11. Zeroing

Zeroing is an option available both through the keypad and non-intrusively. A “0 ”

is displayed in the status bit of the display to designate this function. A 10 second

timer is displayed on the bottom line of the LED display.

(P/N: 77023554-1) iTrans User Manual 5-13

Page 50

Operation iTrans Fixed Point Single/Dual Gas Monitor

To initiate zeroing, press the “” key

during the 10-second countdown. If

you do not initiate zeroing during the

10-second countdown, the

will return to the Normal Operating

Mode. If you initiate zeroing, the

status bit will start to flash. Once

zeroing is complete, the unit will

return to the Normal Operating Mode.

To abort zeroing at any time, press the

“Mode” key.

Figure 5-24. Sample Zeroing Display

The calibration option is also available

through the keypad. Calibration is

designated with a “C” in the status bit.

A 10 second timer is displayed on the

bottom line of the LED display. To

initiate calibration, press the “”key

during the 10-second countdown. If

you do not initiate calibration during

the 10-second countdown, the

will return to the Normal

Operating Mode. If you initiate

calibration, the status bit will start to

flash and the will enter the

zeroing process.

Figure 5-25. Sample Calibration

Display

5.6.12. Calibration

NOTE: Before the will calibrate, the unit will enter the zeroing process.

Please make sure that you do not apply gas to the instrument while it is zeroing.

The will automatically zero before calibration. Zeroing is designated

with a flashing “0” in the status bit. Once zeroing is complete, the will

automatically enter the calibration routine. Calibration is designated with a

flashing “C” in the status bit.

After zeroing finishes, the is ready to calibrate. When the flashing “C”

appears on the display, apply calibration gas. As the responds to the gas,

5-14 iTrans User Manual (P/N: 77023554-1)

Page 51

iTrans Fixed Point Single/Dual Gas Monitor Operation

The span option is designated with a

flashing “S” in the status bit with the

current span value next to it. To

change the span value, press the “”

key during the 10-second countdown.

If you do not press the “” during the

10-second countdown, the

will return to the Normal Operating

Mode. If you initiate the change span

option, the status bit will start to flash

and the span value can now

be changed.

Figure 5-26. Sample Span Gas

Concentration Display

The current span value is displayed on

the top line of the LED display. Use

the “” and “” keys to change the

span value. When the desired value is

reached, press the “” key to save

changes. Pressing the “Mode” key or

letting the timer count down to zero

without saving the new value, will

take you back into the Programming

Mode.

Figure 5-27. Flashing Status Bit

the current reading will be displayed on the top line of the LED display. To abort

calibration at any time, press the “Mode” key.

NOTE: Check and verify span setting before starting a calibration.

NOTE: Please refer to Appendix D for a complete list of factory default span

gases.

NOTE: Flow rate for calibration is 0.5 liter per minute (LPM) except for NH3,

ClO2, Cl2, NO2, SO2, and HCl which require 1.0 LPM.

5.6.13. Changing Span Gas Concentration

(P/N: 77023554-1) iTrans User Manual 5-15

Page 52

Operation iTrans Fixed Point Single/Dual Gas Monitor

The span reserve option is designated

with an “r” in the status bit. The

current span reserve is displayed on

the top line of the LED display.

NOTE: There are a few other options

that appear that do not have any

function associated with them. These

are reserved for future functionality.

Figure 5-28. Sample Span Reserve

Display

NOTE: If the “” key is not pressed, the new span value will not be saved.

NOTE: Span Gas Concentration for combustibles can be set from 0% to

100%LEL. For the sake of resolution, we suggest that Span Gas Concentration

should be set above 20% LEL.

5.6.14. Sensor Span Reserve

5.7. Special Notes on Using Broadband Infrared (BBIR) Sensors

The broadband infrared (BBIR) sensor currently used with the gas

monitor does not fully support or follow all of the functionality or procedures listed

within this manual. Differences between the functionality of the BBIR sensor and

the operation explained in this manual are as follows:

There is no real time clock in the BBIR sensor. When looking at the clock

settings, they will be displayed as time and date of initial test. If you set

these values, they will not increment.

Low alarm, high alarm, and 4-20 mA range are factory pre-set to 10, 20, and

100 respectively.

When calibrating the BBIR sensor, the display will not show the actual

concentration of gas applied, it will display zero. Once the calibration is

complete, the display will switch from zero to the actual concentration of gas

applied.

The Span Gas Concentration is fixed at 50% LEL and cannot be changed.

The typical zero time for the BBIR sensor is 3 minutes.

The typical calibration time for the BBIR sensor is 3 minutes.

5-16 iTrans User Manual (P/N: 77023554-1)

Page 53

iTrans Fixed Point Single/Dual Gas Monitor Operation

After a calibration, the span reserve for the BBIR sensor is not available to

the end user.

The BBIR sensor’s digital address is set at the factory for Channel 1

operation (0x0F) or Channel 2 operation (0xF0). This digital address

cannot be changed in the field.

If you have any questions concerning the functionality of the BBIR sensor and the

, please contact Oldham at 1-713-559-9280 or

americas@oldhamgas.com.

(P/N: 77023554-1) iTrans User Manual 5-17

Page 54

Operation iTrans Fixed Point Single/Dual Gas Monitor

5-18 iTrans User Manual (P/N: 77023554-1)

Page 55

iTrans Fixed Point Single/Dual Gas Monitor ModBus Interface

MODBUS INTERFACE

Chapter

6

Characteristic

Description

Hardware

2-wire mode (not 4-wire)

Baud Rate

9600

Electrical Standard

TIA/EIA-485

Transmission Mode

RTU mode (not ASCII)

Message Coding System

8-bit

Start Bits

1

Data Bits

8 (LSB sent first)

Parity Bits

0

Stop Bits

1

6.1. Introduction

When programming the ModBus ID address on the electronics module

or on the smart sensor board, use the binary reference chart on the following page.

A “1” represents “ON” on the switch bank, and position 1 of the switch bank

represents the right most binary digit (LSB).

ModBus characteristics for the are listed below.

Table 6-1. ModBus Characteristics for the Gas Monitor

Important: When commissioning master and slave units on a ModBus network, it

is critical to ensure that every device on the ModBus network must have a unique

address. Otherwise, abnormal behavior of the entire serial bus can occur.

6.2. Sample Gas Reading via ModBus Network

To get a gas reading for Channel 1, you must read register 40102. This register

holds the gas reading in ppm.

(P/N: 77023554-1) iTrans User Manual 6-1

Page 56

ModBus Interface iTrans Fixed Point Single/Dual Gas Monitor

Addr

Inst

R/W

Host

R/W

Range

Description

40101

R/W

R/W

MSB = $01 to $FF

LSB = $01 to $F7

Sensor Type

Holds the sensor instrument type code and

ModBus address. The most significant byte

(MSB) holds a value indicating the type of

instrument (see below). The least significant

byte (LSB) holds a value which is the ModBus

address of the sensor.

MSB = Instrument type code $01 to $FF

$03 = BBIR (broad band infrared)

$04 = TOX (toxic)

$05 = OXY (oxygen)

$06 = AAW (toxic)

$07 = CAT (catalytic)

LSB = MODBUS sensor address $01 to $F7

(1 to 247)

40102

W R $0000 to $FFFF

Gas Reading

Holds the gas reading in ppm or percent

depending upon the sensor in the instrument.

The range is from $0000 to $FFFF and

represents a signed decimal value range

from -32768 to +32767.

Examples:

+5 ppm = register value of 0000510 = $0005

-5 ppm = register value of 6553110 = $FFFB

Example: Gas reading of 5 ppm = register value of $0005.

Example: Gas reading of 20.9% = register value of $0209.

For Channel 2 you can access the gas reading by looking at register 40202.

For a full list of ModBus commands and registers that are accessible on the

, refer to the next section or, for the most up-to-date list, contact the

Technical Support group of Oldham at 1-713-559-9280.

6.3. ModBus Register List

ModBus register addresses are provided in Table 6-2.

Table 6-2. ModBus Registers

6-2 iTrans User Manual (P/N: 77023554-1)

Page 57

iTrans Fixed Point Single/Dual Gas Monitor ModBus Interface

Addr

Inst

R/W

Host

R/W

Range

Description

40103

R*

R*

MSB = $01 to $FF

LSB = $01 to $FF

Gas Type

Holds the decimal place holder and the gas type

code. The most significant byte (MSB) holds

the number of decimal places to be used in

calculations for this gas. This decimal locator

applies to all subsequent values of gas readings

within other registers. This can be read by the

instrument. The least significant byte (LSB)

holds a code which identifies the gas type.

This can be read by the host.

MSB = Decimal place holder $01 to $FF

LSB = Gas type code $01 to $FF

$01 CO Carbon Monoxide

$02 H2S Hydrogen Sulfide

$03 SO2 Sulfur Dioxide

$04 NO2 Nitrogen Dioxide

$05 Cl2 Chlorine

$06 ClO2 Chlorine Dioxide

$07 HCN Hydrogen Cyanide

$08 PH3 Phosphine

$09 H2 Hydrogen

$0C NO Nitric Oxide

$0D NH3 Ammonia

$0E HCl Hydrogen Chloride

$14 O2 Oxygen

$15 CH4 Methane

$16 LEL Lower Explosive Limit

(Combustible Gases)

Examples:

$0107 = 1 decimal place for gas type HCN

$0002 = 0 decimal places for gas type H2S

$0206 = 2 decimal places for ClO2

(P/N: 77023554-1) iTrans User Manual 6-3

Page 58

ModBus Interface iTrans Fixed Point Single/Dual Gas Monitor

Addr

Inst

R/W

Host

R/W

Range

Description

40105

W

R/W

$0000 to $FFFF

Instrument Mode

Holds code for current mode of instrument.

Possible working modes of instrument are listed

below.

$0001 Normal

$0002 Calibration

$0003 Warm-up

$0006 Zeroing

$0008 Fault

$0009 Reset

Examples:

Sensor in zero fault = $0008

Sensor zeroing = $0006

40106

W R $0000 to $FFFF

Status Bits

Holds 16 bits of status for various parameters in

the instrument. A bit value of “1” indicates that

the associated fault condition is present.

Bit 15 = current loop open

Bit 14 = current loop shorted

Bit 13 = power fault

Bit 12 = 5 volt fault

Bit 11 = missing sensor

Bit 10 = (not defined)

:

Bit 6 = (not defined)

Bit 5 = zero fault

Bit 4 = calibration fault

Bit 3 = over-range

Bit 2 = failed sensor

Bit 1 = high alarm

Bit 0 = low alarm

Examples:

Missing sensor = Bit 11 is set = $0800

Power fault and

failed sensor = Bits 13 and 2 set = $2004

40115

W

R

Last Alarm Date (mmdd)

Holds the month and day when the instrument

had the last alarm.

6-4 iTrans User Manual (P/N: 77023554-1)

Page 59

iTrans Fixed Point Single/Dual Gas Monitor ModBus Interface

Addr

Inst

R/W

Host

R/W

Range

Description

High byte = $01 to $0C

Low byte = $01 to $1F

Examples:

Dec 25 is represented as $0C19

June 31 is represented as $061F

40116

W

R

Last Alarm Date (00yy)

Holds the last two digits of the year when the

instrument was last in alarm. The first two

digits are assumed to be “20”.

High byte = $00, Low byte = $02 to $63

Examples:

2002 is represented by $02

2099 is represented by $63

40117

R

R/W

MSB=$01 to $0C,

LSB=$01 to $1F

RTC Month and Day

Holds the month and day to which the real time

clock (RTC) calendar should be set. The most

significant byte (MSB) represents the month

from $01 to $0C (1-12). The least significant

byte (LSB) represents the day of the month

from $01 to $1F (1-31).

Examples:

December 25 = $0C19

June 31 = $061F

40118

R

R/W

$0002 to $0063

RTC Year (00yy)

Holds the year to which the real time clock

(RTC) should be set. The most significant byte

(MSB) is always $00. The least significant byte

(LSB) represents the two-digit year (within the

21st century), from $02 (which represents 2002)

to $063 (which represents 2099).

Examples:

2002 = 02 (+ base year of 2000) = $0002

2010 = 10 (+ base year of 2000) = $000A

2099 = 99 (+ base year of 2000) = $0063

40119

R

R/W

MSB=$00 to $18,

LSB=$00 to $3C

RTC Hours and Minutes

Holds the hours and minutes to which the RTC

should be set. The most significant byte (MSB)

represents the hour from $00 to $18 (00-24).

The least significant byte (LSB) represents the

(P/N: 77023554-1) iTrans User Manual 6-5

Page 60

ModBus Interface iTrans Fixed Point Single/Dual Gas Monitor

Addr

Inst

R/W

Host

R/W

Range

Description

minutes from $00 to $3C (00 to 60). Note that

the seconds default to zero ($00) each time the

hours and minutes are set.

Examples:

13:05 = $0D05

24:00 = $1800

40124

R

R/W

$0000 to $FFFF

Low Alarm Display Setting

Holds the value of the gas reading at which the

low alarm display will activate.

40125

R

R/W

$0000 to $FFFF

High Alarm Display Setting

Holds the value of the gas reading at which the

high alarm display will activate.

40126

R

R/W

$0000 to $03E8

Cal Gas Value

Holds the value of the calibration gas to be used

on the instrument. The range is from $0000 to

$03E8 (0 to 100010).

40127

R/W R $0000 to $FFFF

Loop High Scaling

Holds a value which indicates the gas reading

represented by a 20 mA loop output signal. The

range is from $0000 to $FFFF.

440102

R R $0000 to $FFFF

WX Scaled Reading

Use with WX series controller.

NOTE: To get the ModBus reading, register 40103 must be read as well as

register 40102. Register 40103 specifies where the decimal should be placed.

6.4. ModBus Resources

ModBus is a public protocol that can be freely adopted by any developer or

manufacturer desiring to implement it. While a detailed discussion of ModBus

protocol is beyond the scope of this manual, there are a number of up-to-date

resources available on the internet for those wishing to investigate ModBus further.

The most complete resource is www.modbus.org.

6-6 iTrans User Manual (P/N: 77023554-1)

Page 61

iTrans Fixed Point Single/Dual Gas Monitor ModBus Interface

6.5. Termination

When putting devices on the ModBus network, a terminating resistor may be

required for the last device on the network (please see www.modbus.org for more

details). The has a blue jumper on the “public” jumper that can be used

to jumper in a 120-Ohm terminating resistor. By default, this jumper is not in

place. Oldham does not recommend changing the placement of any of the other

jumpers on this board.

Figure 6-1. Location of Jumpers

(P/N: 77023554-1) iTrans User Manual 6-7

Page 62

ModBus Interface iTrans Fixed Point Single/Dual Gas Monitor

6-8 iTrans User Manual (P/N: 77023554-1)

Page 63

iTrans Fixed Point Single/Dual Gas Monitor Maintenance

MAINTENANCE

Chapter

7

7.1. Introduction

Sensors have a variable life dependent on the sensor and the environment in which

they operate. Oxygen sensor life is about 2 years and toxic gas sensor life is

normally 2 years or greater. The catalytic combustible gas sensors normally

operate in excess of 3 years, while the infrared sensor carries a 5-year warranty

with an anticipated life of 7 or more years.

Sensors have baseline drift and their characteristics change with time. Thus, the

must be calibrated on a regular basis. Gas detection instruments are

potential life-saving devices. In recognition of this fact, calibration for the toxic

and catalytic LEL sensors should be at least at quarterly intervals, while the

Infrared sensor should be calibrated on an annual basis with functional tests every

6 months.

Further, Oldham recommends prudent testing and/or calibration after a gas alarm.

All calibration/service to the sensors should be recorded and accessible.

NOTE: Other than regular calibrations, the require no other routine

maintenance.

NOTE: Take special care with handling and storing sensors. They are delicate

and can be damaged by storage in environments outside the specified temperature,

pressure, and humidity limits.

NOTE: Sensors are susceptible to damage from high pressure or low pressure,

especially if the change is sudden. Also, sensors should not be operated at

pressures that are 10% above or below atmospheric pressure.

(P/N: 77023554) iTrans User Manual 7-1

Page 64

Maintenance iTrans Fixed Point Single/Dual Gas Monitor

NOTE: If sensors and the surrounding environment must be washed down at any

time, cover the opening of the sensor housing to protect it from water or excess

moisture. Remove cover when wash down is complete. An optional splashguard

is available for continuous protection.

7.2. Sensor Replacement

Sensor replacement must be done by qualified personnel. To replace the sensor,

shut down power to the unit. Un-thread the sensor-housing cap from the sensor

housing. There is a set screw that secures the cap to the housing. Once the cap is

removed, remove the old sensor and sensor board. When installing the new

sensor/sensor board make sure you line up the notch in the board with the

alignment pin. After the new sensor is in place, screw the sensor cap back on to

the housing and secure the set screw.

Once the new sensor is in place and has time to settle out, it should be zeroed and

calibrated for accuracy.

7.3. Zero and Calibration

Zeroing and calibrating the instrument can be accomplished one of two ways.

These routines can be entered either from the keypad or non-intrusively using the

magnetic wand. See Chapter 5: Operation for step-by-step procedures for zeroing

and calibrating the using the magnetic wand. Chapter 5 also contains

information on keypad zeroing and calibration.

7-2 iTrans User Manual (P/N: 77023554-1)

Page 65

iTrans Fixed Point Single/Dual Gas Monitor Troubleshooting

TROUBLESHOOTING

Chapter

8

Symptom

Problem

Solution

LED display does not

light up.

Input voltage is too low

Electronics module has

failed

Check for presence of input

voltage.

Output outside

4-20 mA range

Unit in calibration mode

Electronics module has

failed

Exit calibration mode.

Replace electronics module.

Output does not

change when gas

concentration

changes

Electronics module has

failed

Replace electronics module.

Cannot calibrate

SPAN

Sensor has failed

Electronics module has

failed

Replace sensor and

calibrate.

Replace electronics module

and calibrate.

8.1. Introduction

This chapter provides troubleshooting information for the gas monitor.

8.2. Diagnosing Common Problems

Table 8-1. Common Problems

(P/N: 77023554) iTrans User Manual 8-1

Page 66

Troubleshooting iTrans Fixed Point Single/Dual Gas Monitor

Symptom

Problem

Solution

Reading drifts by 10

counts over a short

time period (in a

stable temperature

environment)