Okidata OKIPAGE 10e Service Manual

Thank You for purchasing this

Click Here for more Factory Service

Manuals for other Computer and

Printer / Copier Manufacturers

from PCTECHINFO!

Front Cover

Service Guide OKIPAGE 10e

Chapter 0 Introduction

Oki Data

Service Guide

OKIPAGE 10e

To propel your company into the future, you need technology that fits the way you work. You need the OKIPAGE® 10ex,

the best-featured desktop printer in its class. This digital LED printer combines professional performance with

excep-tional value, for years of high-quality documents and low ongoing operating costs.

Adobe Acrobat printable reference copy

of the OKIDATA Service Training Manual.

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the pictures

rendered at 300 dpi, which is ideal for printing, but does not display well on most displays.

05/13/98

Table of Contents Page

Service Guide OKIPAGE 10e

0 Introduction

Introduction 1

1 Specifications

1.1 System Configuration 2

1.2 Printer Configuration 3

1.3 Optional Configuration 4

1.4 Specification 5

1.5 Safety Standards 6

....1.5.1 Certification Label 7

....1.5.2 Warning Label 8

....1.5.3 Warning/Caution Marking 9

2 Operation

Operation Description 10

2.1 Main Control Board 11

2.2 Power Supply/Sensor Board 12

2.3 Electrophotographic Process 13

....2.3.1 Electrophotographic Process Mechanism 14

....2.3.2 Electrophotographic Process 15

....2.3.3 Process Operation Descriptions 16

2.4 Paper Jam Detection 18

2.5 Cover Open 19

2.6 Toner Low Detection 20

3 Disassembly

3.1 Precautions for Parts Replacement 21

3.2 Parts Layout - [Lower base unit] 22

........[Upper cover unit] 23

........[Base unit] 24

3.3 How to Change Parts 25

....3.3.1 Upper Cover Assy 26

....3.3.2 IC Card Cover 27

....3.3.3 LED Head 28

....3.3.4 Operator Panel Assy 29

....3.3.5 Lower Base Unit 30

....3.3.6 Pulse Motor Main/Drum 31

....3.3.7 Pulse Motor (Registration) 32

....3.3.8 Face Up Stacker Assy 33

....3.3.9 Eject Roller Assy 34

....3.3.10 Motor Assy 35

....3.3.11 Hopping Roller Shaft Assy 36

....3.3.12 Stacker Cover Assy 37

....3.3.13 Registration Roller 38

....3.3.14 Transfer Roller Assy 39

....3.3.15 Fusing Unit 40

....3.3.16 Back-up Roller 41

....3.3.17 Sensor Plate (Inlet) 42

....3.3.18 Sensor Plate (Outlet) 43

....3.3.19 Manual Feed Guide Assy 44

....3.3.20 Sensor Plate (Paper Supply) 45

....3.3.21 Main Control M5G-PCB 46

....3.3.22 Transformer 47

Table of Contents Page

....3.3.23 Power Supply/Sensor Board and Contact Assy 48

....3.3.24 Cassette Guide L Assy 49

....3.3.25 Cassette Guide R 50

....3.3.26 Spacer Bearing (L/R) 51

4 Adjustments

4. Adjustment 52

....4.1 Adjustment Types & Functions 53

........4.1.1 Status Monitor 54

........4.1.2 Engine Maintenance Utility 55

....4.2 Adjustment When Replacing a Part 58

........4.2.1 Setting of LED Head Drive Time 59

........4.2.2 Uploading/Downloading EEPROM data 60

5 Maintenance

5.1 Periodical Replacement Parts 61

5.2 Cleaning 62

....5.2.1 Cleaning of LED Lens Array 63

....5.2.2 Cleaning Page Function 64

6 Troubleshooting

6.1 Troubleshooting Tips 65

6.2 Points to Check before Correcting Image Problems 66

6.3 Tips for Correcting Image Problems 67

6.4 Preparation for Troubleshooting 68

6.5 Troubleshooting Flow 69

....6.5.1 LCD Status Monitor Message List 70

....6.5.2 Status Message Troubleshooting 71

........(1) The printer does not work normally after the power is

turned on.

........(2) [JAM error] 73

............2-1 Paper input jam 74

............2-2 Paper feed jam 75

............3-3 Paper exit jam 76

........(3) Paper size error 77

........(4) Fusing unit error 78

........(5) SSIO error 79

........(6) Fan error (ERROR 70) 80

....6.5.3 Image Troubleshooting 81

........(1) Images are light or blurred entirely 82

........(2) Dark background density 83

........(3) Blank paper is output 84

........(4) Black vertical belts or stripes 85

........(5) Cyclical defect 86

........(6) Prints voids 87

........(7) Poor fusing 88

........(8) Vertical belts or streaks 89

........Figure 6-4 90

........Figure 6-5 91

7 Wiring Diagram

7.1 Interconnect Signal Diagram 92

7.2 PCB Layout and Connector Signal List 93

7.3 Resistance Check 94

8 Parts List

72

Table of Contents Page

Lower Base Unit 96

Upper Cover Unit 97

Base Unit 98

A Loop Test (RS-232C Interface)

Loop Test (RS-232C Interface) 100

B Centronics Parallel

Centronics Parallel Interface 99

C Maintenance Utility GUI Manual

1. Maintennace Utility GUI Manual 101

....1.0 Main Menu Dialog 101

....1.1 Printer Status Group 101

....1.2 Engine Menu Setting Group 101

....1.3 Engine Counter Reset Group 101

2. Explanation of Buttons 101

....2.1 Test Print Buttons 101

Product Accessory 1: RS-232C Serial Interface (Option)

RS-232C Serial Interface (Option) 106

Product Accessory 2: Multi-Purpose Feeder Maintenance

1. PREFACE 107

....1.1 Functions 108

....1.2 External View and Component Names 109

2. MECHANISM DESCRIPTION - General Mechanism 110

....2.2 Hopper Mechanism 111

3. PARTS REPLACEMENT 112

....3.1 Precautions Concerning Parts Replacement 113

....3.2 Parts Layout 114

....3.3 Parts Replacement Methods 115

........3.3.1 Link 116

........3.3.2 Separator 117

........3.3.3 OLEV-11 PCB 118

........3.3.4 Pulse Motor 119

........3.3.5 Planet Gear 120

........3.3.6 Roller-A and B 121

4. TROUBLESHOOTING - Precautions Prior to the

Troubleshooting

....4.1 TROUBLESHOOTING - Precautions Prior to the

Troubleshooting

....4.2 Preparations for the Troubleshooting 123

....4.3 Troubleshooting Method 124

........4.3.1 LCD Status Message List 125

5. CONNECTION DIAGRAM 126

....5.1 Interconnection Diagram 126

....5.2 PCB Layout 127

6. PARTS LIST 128

Product Accessory 3: High Capacity 2nd Paper Feeder

High Capacity Second Paper Feeder Maintenance 129

1. OUTLINE 130

....1.1 Functions 130

....1.2 External View and Component Names 131

2. MECHANISM DESCRIPTION 132

....2.1 General Mechanism 132

122

122

Table of Contents Page

....2.2 Hopper Mechanism 133

3. PARTS REPLACEMENT 134

....3.1 Precautions Concerning Parts Replacement 135

....3.2 Parts Layout 136

....3.3 Parts Replacement Methods 137

........3.3.1 Stepping Motor (Hopping) 138

........3.3.2 TQSB-2 PCB 139

........3.3.3 Hopping Roller Shaft Assembly and One-way Clutch

140

Gear

4. TROUBLESHOOTING 141

....4.1 Precautions Prior to the Troubleshooting 141

....4.2 Preparations for the Troubleshooting 142

....4.3 Troubleshooting Method 143

........4.3.1 LCD Status Message List 144

5. CONNECTION DIAGRAM 145

....5.1 Interconnection Diagram 146

....5.2 PCB Layout 147

6. PARTS LIST 148

....6.1 High Capacity Second Paper Feeder 148

....6.3 CABINET & CASSETTE ASSEMBLY 150

....6.4 MECHANICAL ASSEMBLY 151

....6.5 2nd Tray Parts List 152

Page: 1

Service Guide OKIPAGE 10e

Chapter 0 Introduction

Introduction

This Service Handbook describes the field maintenance methods for OKIPAGE 10e Digital LED Printer. This manual is

written for use by the maintenance personnel. Please note that you should refer to the Printer Handbook and Printer

Setup for the handling and operating methods of the equipment.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OKIPAGE 10e

Chapter 1 Specifications

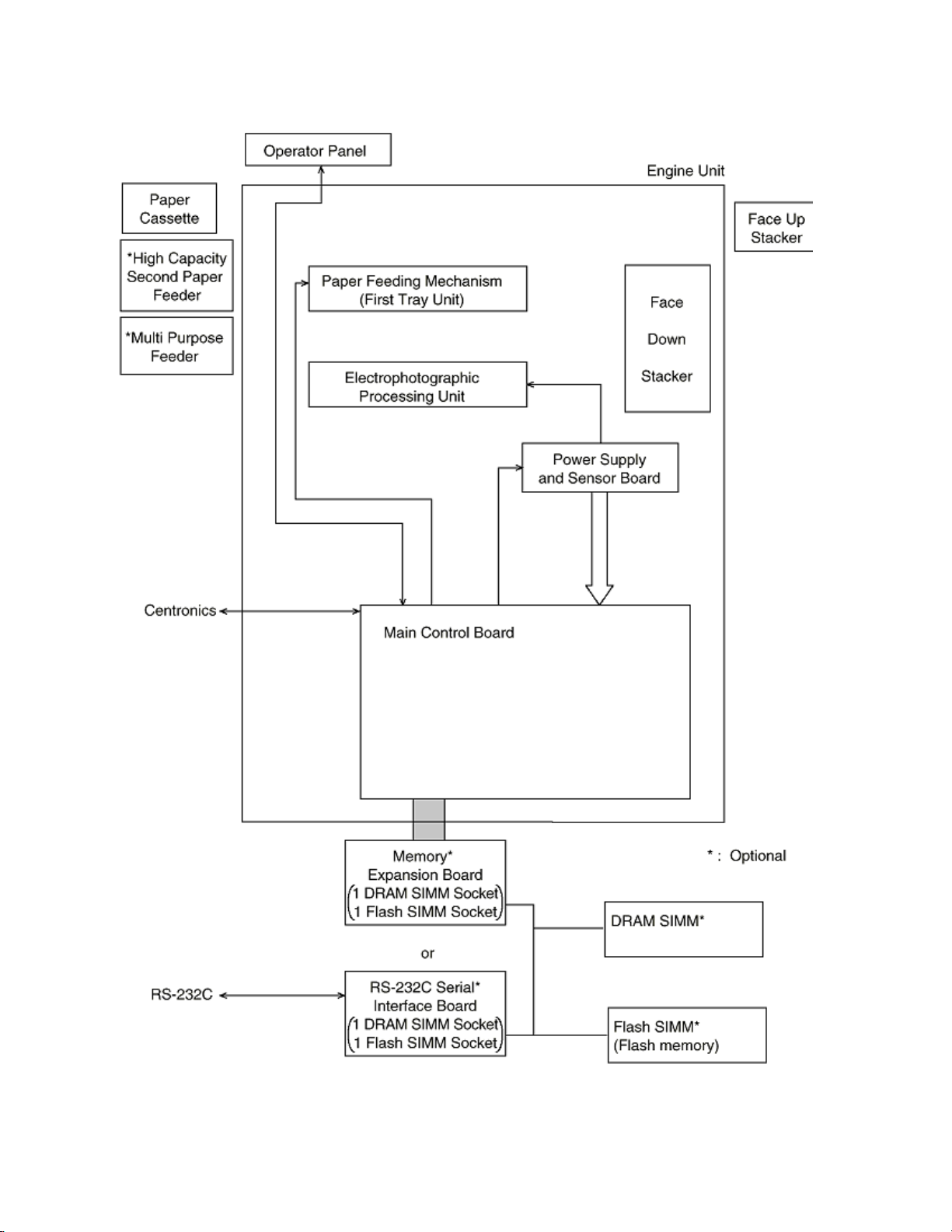

1.1 System Configuration

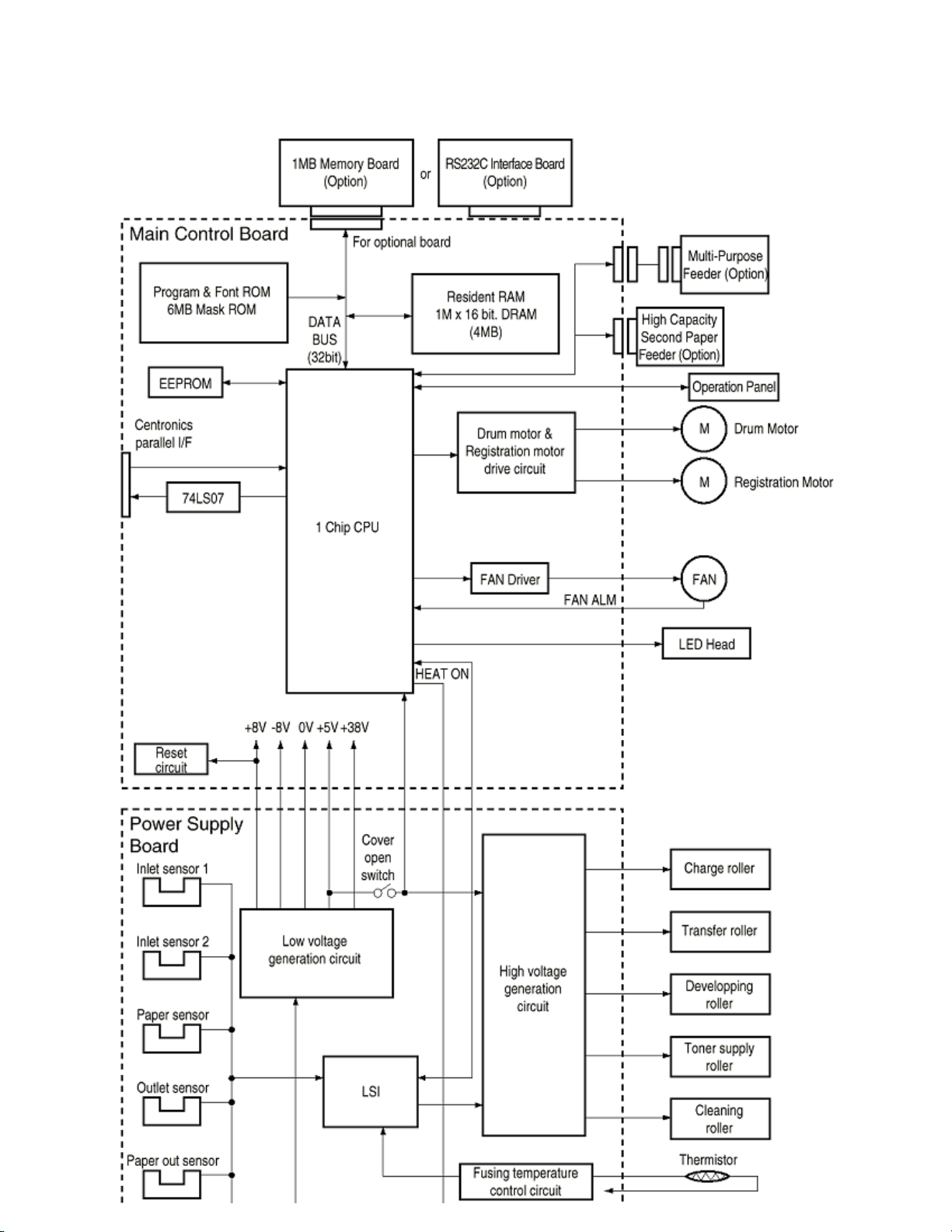

OKIPAGE 10e consists of control and engine blocks in the standard configuration, as shown in Figure 1-1.

In addition, the options marked with asterisk (*) are available.

Page: 2

Figure 1-1

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OKIPAGE 10e

Chapter 1 Specifications

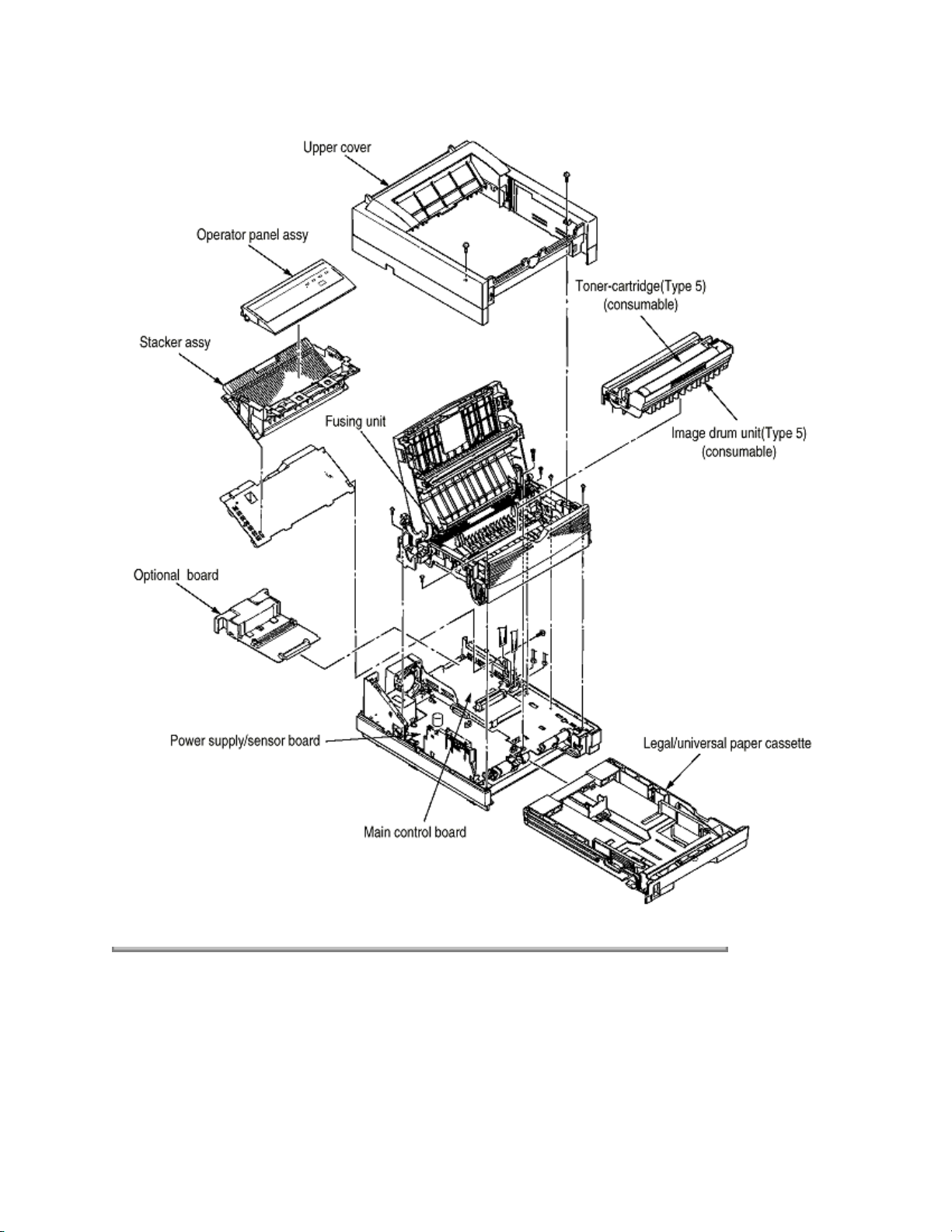

1.2 Printer Configuration

The printer unit consists of the following hardware components:

Electrophotographic Processorl

Paper Feederl

Controllerl

Operator Panell

Power Supply Unitl

The printer unit configuration is shown in Figure 1-2.

Page: 3

Figure 1-2

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 4

Service Guide OKIPAGE 10e

Chapter 1 Specifications

1.3 Optional Configuration

The options shown below are available for use with OKIPAGE 10e. These are available separately from the printer unit.

(1) High Capacity Second Paper Feeder

(2) Multi-Purpose Feeder

(3) 1 MB Memory Expansion Board

(4) RS-232C Serial Interface Board

(5) DRAM SIMM Memory

DRAM SIMM memory is available with

memory of 2, 8, 8, 16 or 32 MB. The access

time of SIMM memories are 60ns, 70ns,

80ns, and 100ns.

(6) Flash SIMM

Flash SIMM is available with memory of 4 MB

and 8 MB.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OKIPAGE 10e

1.4 Specification

(1) Type: Desktop

(2) Outside dimensions Height: 7.9" (200 mm)

Width 13.0" (330 mm)

Depth 15.6" (395mm)

(3) Weight 22 lbs. (10 kg)

Page: 5

Chapter 1 Specifications

(4) Development method

Exposure method

(5) Paper used <Type>

Dry electrophotography LED stationary head

Standard paperl

- Xerox 4200 (20 lbs)

Application paper (manual face-up feed)l

- Label

- Envelope

- OHP paper (Transparency)

<Size>

Standardl

Letter

Legal * [*Without Mutli-Purpose Feeder (Option)]

Legal-13*

Executive

-COM-10** [**manual feed and Multi-Purpose Feeder (Option)

only]

Monarch**

DL**

C5**

A4

A5

B5 (JIS)

A6

Applicable sizesl

- Width: 3.87" x 8.5" (116 to 216 mm)

- Length: 5.83" to 14" (148 to 355.6 mm)

<Thickness>

- Automatic feed: 16 to 28 lbs (60 to 135 g/m2)

- Manual feed: Label, OHP paper (transparency), Envelope (24 to

28 lbs.)

(6) Printing speed: Continuous print: 10 pages per minute with Letter size paper.

[Except Second Paper Feeder (8.8 PPM), Multi-Purpose Feeder

(8.3 PPM)]

Warm-up time: 60 seconds typical at room temperature [68o F (20o

C), AC 120/230 V].

First print: 12 seconds typical for the Letter size paper after

warm-up

(7) Paper feeding method Automatic paper feed or manual paper feed

(8) Paper delivery

Face down/face up

method

(9) Resolution 300 x 300 dots/inch (true)

300 x 1200 dots/inch (graphics)

(10) Power input 120 VAC + 5.5%, -15%

230 VAC +/- 10%

(11) Power consumption Peak: Approx. 460W

Typical operation: Approx. 215W

Idle: Approx. 61W

Power save mode: Approx. 18W

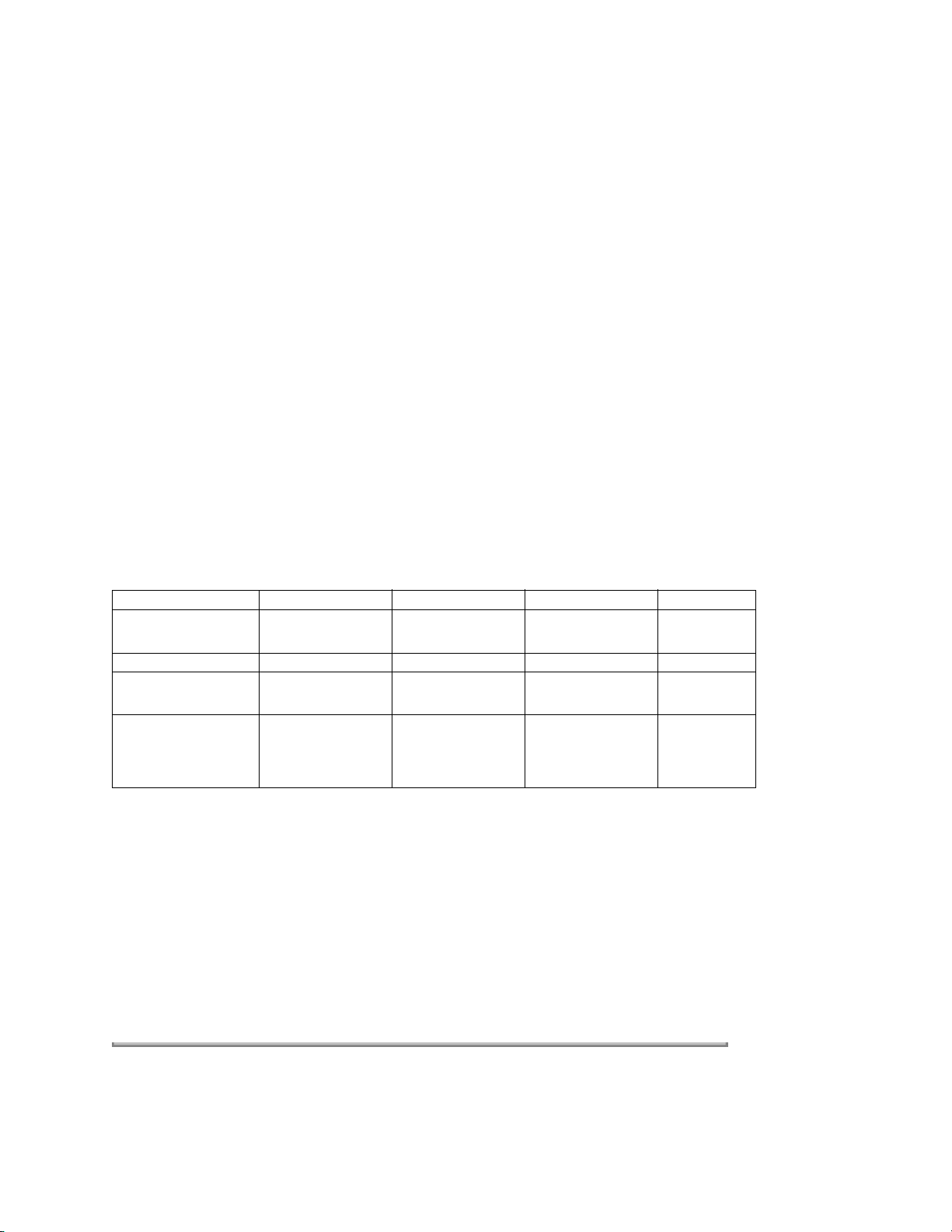

(12) Temperature and

humidity

In operation Power off mode During Storage Unit

Temperature 50-90

(10-32)

32-110

(0-43)

14-110

(-10-43)

Humidity 20-80 10-90 10-90 %RH

Maximum wet bulb

temperature

Minimum difference

between wet and

77

(25)

35.6

(2)

80.4

(26.8)

35.6

(2)

-----

-----

dry bulb

o

F

o

C

o

F

o

C

o

F

o

C

temperatures

1. Storage conditions specified above apply to printers in packed condition.

2. Temperature and humidity must be in the range where no condensation occurs.

(13) Noise During operation: 50 dB (A) or less

Standby: 38 dB (A) or less

Quite mode: Back ground level

(14) Consumables Toner cartridge kit - 2,000 (5% duty) ---- 45g cartridge kit

Image drum cartridge - 20,000 (at continuous printing); 14,000 (3

page/job) without Power Save

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 6

Service Guide OKIPAGE 10e

Chapter 1 Specifications

1.5 Safety Standards

1.5.1 Certification Label

1.5.2 Warning Label

1.5.3 Warning/Caution Marking

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OKIPAGE 10e

Chapter 1 Specifications

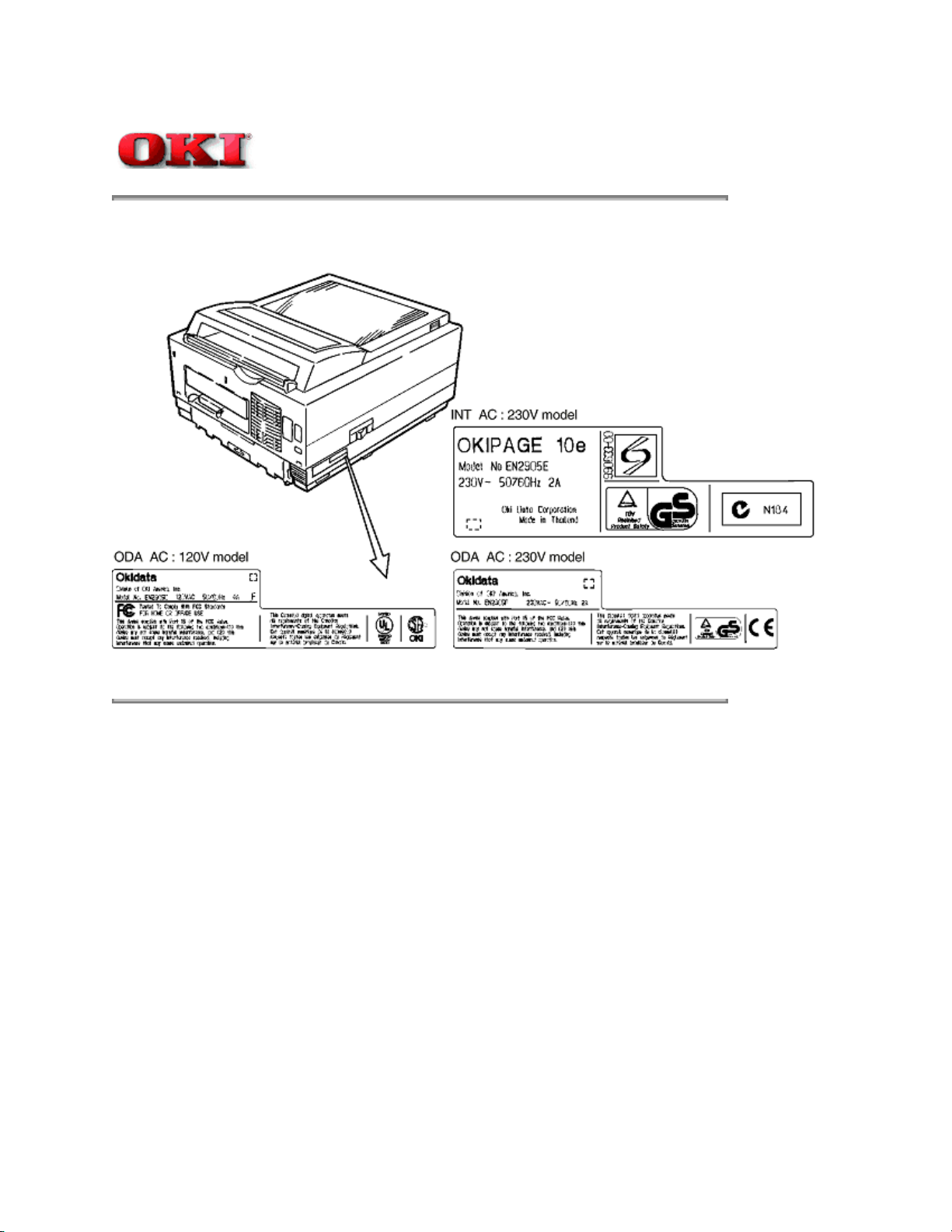

1.5.1 Certification Label

The safety certification label is affixed to the printer in the position described below.

Page: 7

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OKIPAGE 10e

Chapter 1 Specifications

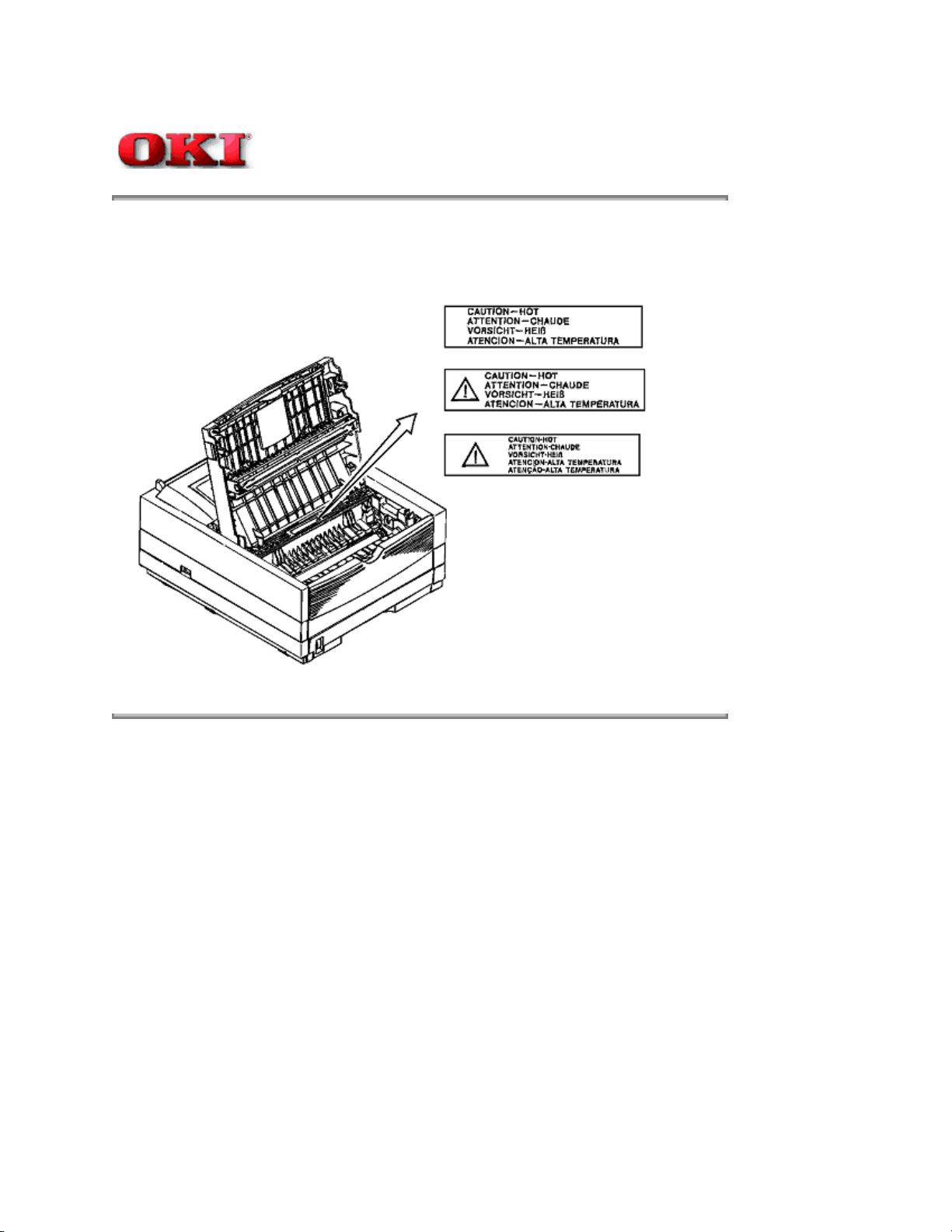

1.5.2 Warning Label

The warning labels are affixed to the sections which may cause bodily injury.

Follow the instructions on warning labels during maintenance.

Page: 8

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OKIPAGE 10e

Chapter 1 Specifications

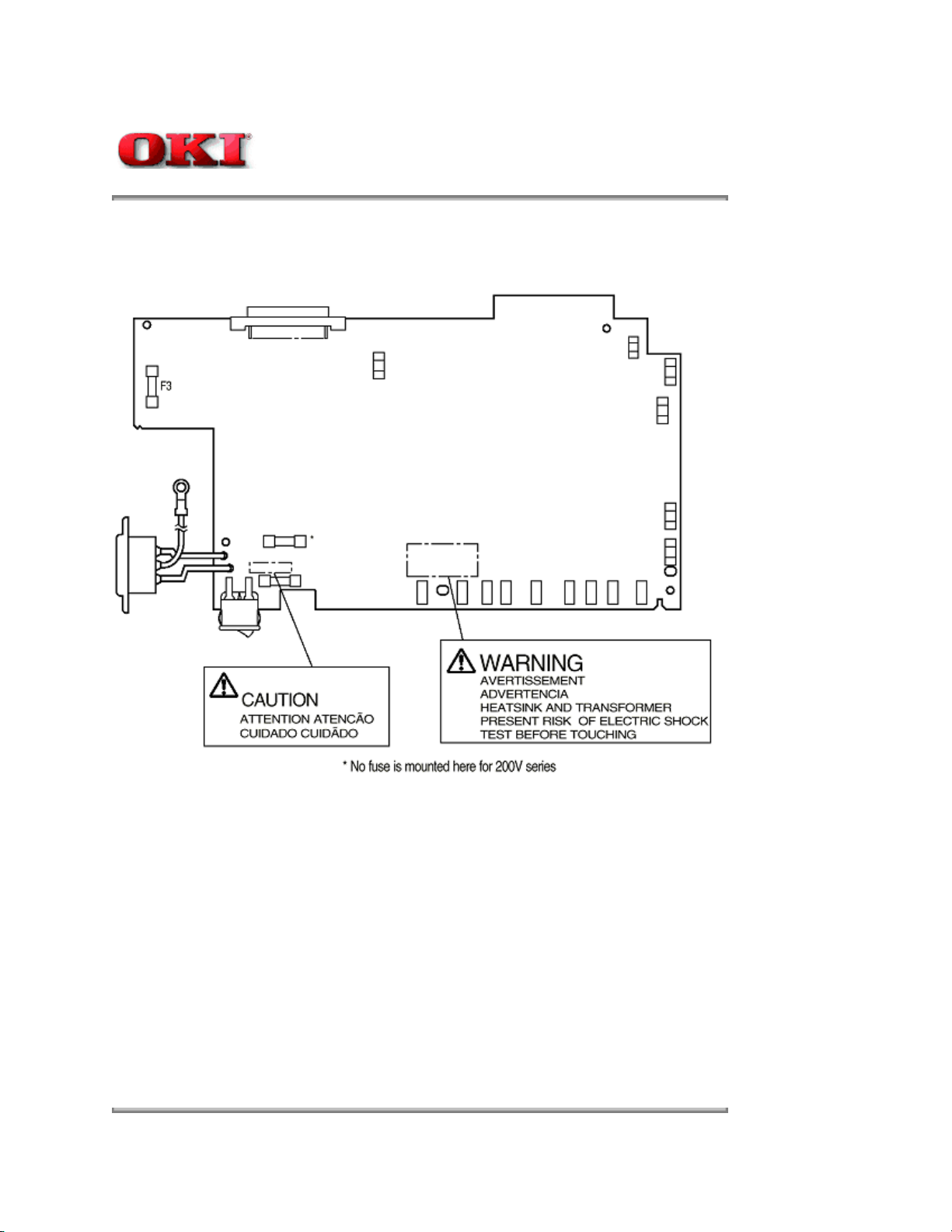

1.5.3 Warning/Caution Marking

The following warning and caution markings are made on the power supply/sensor board.

Page: 9

ENGLISH - Heatsink and transformer core present risk of electric shock. Test before touching.

FRENCH - Le dissipateur thermique et le noyau du transformateur présentent des risques de choc électrique. Testez

avant de manipuler.

SPANISH - Las disipadores de color el núcel del transformador pueden producir un choque eléctrico. Compruebe antes

de tocar.

PORTUGUESE - O dissipador de calor e o núcleo do fransiormador apresentam risco de choque elétrico. Teste antes de

focar.

ENGLISH - Circuits maybe live after fuses open.

FRENCH - Il se peut que les circuits soient sous tension une fois que les fusibles ont éfé rerirés.

SPANISH - Las circuitos pueden estar activos una vez que se hayan abierio los fusibles.

PORTUGUESE - Os circuitos podem estar energizados após os fusiveis se queimarem.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 10

Service Guide OKIPAGE 10e

Chapter 2 Operation

Operation Description

OKIPAGE 10e consists of a main control board, a power supply/sensor board, an operator panel, an electrophotographic

process mechanism, and revision for illumination of LED head.

The main control board receives data via the host I/F, it then decodes, edits and stores the data in memory. After

completing the editing of a single page of data, it references the font memory and generates bit image data, which is

transferred to the LED head in one dot line units.

Through the electrophotographic process mechanism, the data is printed on the paper.

The operator panel is used for operations and status display.

OKIPAGE 10e block diagram is shown in Figure 2-1.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 11

Service Guide OKIPAGE 10e

Chapter 2 Operation

2.1 Main Control Board

The main control board consists of a single chip CPU, two program/font ROMs, four DRAMs, an EEPROM, a host

interface circuit, and a mechanism driving circuit.

(1) Single chip CPU

The single chip CPU is a custom CPU (32-bit internal bus, 32-bit external bus, 28.24-MHz clock, with input frequency

from a 7.06-MHz clock) which incorporates the RISC CPU and its peripheral devices, and has the following functions:

Built-in Device Function

Chip select controller

Control of ROM, DRAM and I/O device.

Bus controller

DRAM controller

DMA controller Transfer of image data from DRAM to video output port.

Parallel interface controller Control of Centronics parallel interface.

Serial interface controller Control of RS-232C serial interface.

Video output port

Controls LED head.

LED STB output port

Timer Generation of various control timing

Monitoring of paper running and paper size.

I/O Port Input and output of sensor and motor signals.

(2) Program and Font ROMs

The Program and Font ROMs store the equipment program and various types of fonts. Mask ROM is used as Program

and Font ROMs. The mounting locations of these Program and Font ROMs vary depending on the type of the ROMs.

(3) DRAM

The DRAM is a 4MB resident memory on the main control board that stores edited data, image data, DLL data and

macro data.

(4) EEPROM

4Kbit Electrically Erasable PROM (EEPROM), is loaded with the following kinds of data:

Menu datal

Various counter data (page counter, drum counter)l

Adjusting parameters (LED head drive time, print start position, paper feed length)l

(5) Parallel Interface

Parallel data is received from a host system via parallel interface which conforms to the IEEE 1284 specification.

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 12

Service Guide OKIPAGE 10e

Chapter 2 Operation

2.2 Power Supply/Sensor Board

The power supply/sensor board consists of an AC filter circuit, a low voltage power supply circuit, a high voltage power

supply circuit, heater drive circuit, and photosensors.

(1) Low Voltage Power Supply Circuit

This circuit generates the following voltages.

Output voltage Application

+5 V Logic circuit supply voltage.

+38 V Motor and fan drive voltage and source voltage for high-voltage supply.

+ 8 V RS-232C line voltage.

- 8 V RS-232C line voltage and PS board supply voltage.

(2) High Voltage Power Supply Circuit

This circuit generates the following voltages required for electrophotographic process from +5 V, according to the control

sequence from the main control board. When cover open state is detected, +5 V supply is interrupted automatically to

stop the supply of all high-voltage outputs.

Output Voltage Application

CH -1.3 KV Voltage to be applied to charge roller.

DB -265 V/+300 V Voltage to be applied to a developing roller.

SB -500 V/ 0 V Voltage to be applied to a sponge roller.

CB +400 V/+3.5 KV Voltage to be applied to a cleaning roller.

TR +500 V to +3.5 KV/-1100 V Voltage to be applied to a transfer roller. (Variable)

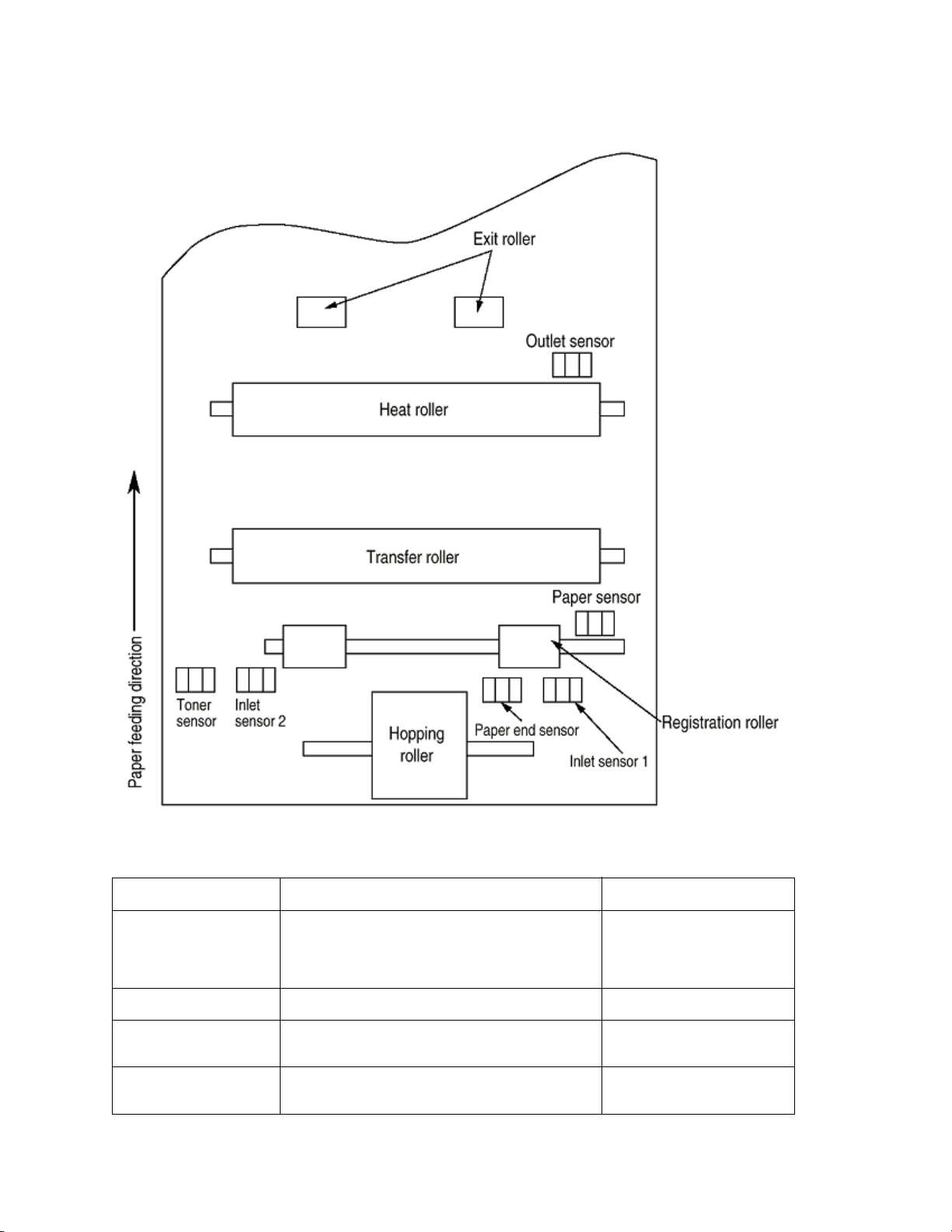

(3) Photosensor

The photosensor mounted on this power supply/sensor board monitors the status of paper being fed through the printer

during printing.

The sensor layout diagram is shown in Figure 2-2 below.

Figure 2-2

Sensor Function Sensing State

Inlet sensor 1 Detects the leading part of the paper and gives the

monitor timing for switching from hopping operation

to feeding operation. Monitors paper feeding

situation and paper size based on the paper arrival

time and running time.

Inlet sensor 2 Detects the paper width. ON: A4 or larger.

Paper sensor Detects the leading portion of the paper. Monitors

paper feeding situation.

Output sensor Monitors paper feeding and size according to the

time of arrival to and leaving past the sensor.

ON: Paper exists.

OFF: No paper exists.

OFF: Smaller than A4.

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

Toner sensor Detects the lack of toner. - - - - -

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 13

Service Guide OKIPAGE 10e

Chapter 2 Operation

2.3 Electrophotographic Process

2.3.1 Electrophotographic Process Mechanism

2.3.2 Electrophotographic Process

2.3.3 Process Operation Descriptions

Copyright 1998, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business Partner Exchange

(BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide OKIPAGE 10e

Chapter 2 Operation

2.3.1 Electrophotographic Process Mechanism

This mechanism actuates the printing of image data supplied by the main control board on the paper by

electrophotographic process.

The layout of the electrophotographic process mechanism is shown in Figure 2-3.

Page: 14

Loading...

Loading...