Page 1

OKIPAGE 14ex

LED Page Printer

Maintenance Manual

ODA / OEL / INT

Rev.2 2001-03-19

41356901TH Rev.2 1 / 196

Page 2

Document Revision History

Rev.No. Date

No.

Corrected items

Page Description of change

Person in

1 2000-09-21 ISSUE EMP Ono

2 2001-03-19 NP39 H Ono

charge

41356901TH Rev.2 2 /

Page 3

PREFACE

This Maintenance Manual describes the field maintenance methods for LED Page Printers.

This manual is written for use by service persons. Please note that you should refer to the Printer Handbook

for the handling and operating methods of the equipment.

41356901TH Rev.2 3 /

Page 4

CONTENTS

1. CONFIGURATION.................................................................................................. 7

1.1 System Configuration ..................................................................................... 7

1.2 Printer Configuration....................................................................................... 9

1.3 Optional Configuration.................................................................................... 10

1.4 Specification ................................................................................................... 12

1.5 Safety Standards ............................................................................................ 14

1.5.1 Certification Label................................................................................................... 14

1.5.2 Warning Label ........................................................................................................ 14

1.5.3 Warning/Caution Marking....................................................................................... 15

2. OPERATION DESCRIPTION ................................................................................. 16

2.1 Main Control Board......................................................................................... 18

2.2 Power Supply/Sensor Board........................................................................... 19

2.3 Electrophotographic Process.......................................................................... 21

2.3.1 Electrophotographic Process Mechanism .............................................................. 21

2.3.2 Electrophotographic Process ................................................................................. 24

2.3.3 Process Operation Descriptions............................................................................. 27

2.3.4 Revision of LED Head Illumination......................................................................... 37

2.4 Paper Jam Detection ...................................................................................... 38

2.5 Cover Open .................................................................................................... 40

2.6 Toner Low Detection....................................................................................... 41

3. PARTS REPLACEMENT........................................................................................ 43

3.1 Precautions for Parts Replacement................................................................ 43

3.2 Parts Layout.................................................................................................... 45

3.3 How to Change Parts...................................................................................... 48

3.3.1 Upper Cover Assy .................................................................................................. 49

3.3.2 LED Head............................................................................................................... 50

3.3.3 Operator Panel Assy .............................................................................................. 51

3.3.4 Lower Base Unit ..................................................................................................... 52

3.3.5 Pulse Motor (Main/Drum) ....................................................................................... 53

3.3.6 Pulse Motor (Registration)...................................................................................... 54

3.3.7 Face Up Stacker Assy............................................................................................ 55

3.3.8 Eject Roller Assy .................................................................................................... 56

3.3.9 Motor Assy ............................................................................................................. 57

3.3.10 Hopping Roller Shaft Assy ..................................................................................... 58

3.3.11 Stacker Cover Assy................................................................................................ 59

3.3.12 Registration Roller .................................................................................................. 60

3.3.13 Roller Transfer Assy............................................................................................... 61

3.3.14 Fusing Unit ............................................................................................................. 62

3.3.15 Back-up Roller........................................................................................................ 63

3.3.16 Sensor Plate (Inlet)................................................................................................. 64

3.3.17 Sensor Plate (Outlet), Sensor Wire Assy ............................................................... 65

3.3.18 Manual Feed Guide Assy ....................................................................................... 66

3.3.19 Sensor Plate (Paper Supply).................................................................................. 67

3.3.20 M7E-PCB ............................................................................................................... 68

3.3.21 Power Supply/Sensor Board, High Voltage Unit and Contact Assy ....................... 69

3.3.22 Cassette Guide L Assy........................................................................................... 70

3.3.23 Cassette Guide R Assy .......................................................................................... 71

3.3.24 Spacer Bearing (L/R).............................................................................................. 72

41356901TH Rev.2 4 /

Page 5

4. ADJUSTMENT........................................................................................................ 73

4.1 Maintenance Modes and Functions................................................................ 73

4.1.1 User Maintenance Mode ........................................................................................ 73

4.1.2 System Maintenance Mode.................................................................................... 73

4.1.3 Engine Maintenance Mode..................................................................................... 74

4.1.4 EEPROM initialization ............................................................................................ 75

4.2 Adjustment When Replacing a Part................................................................ 76

4.2.1 Uploading/Downloading EEPROM data................................................................. 76

5. PERIODICAL MAINTENANCE .............................................................................. 77

5.1 Periodical Replacement Parts ........................................................................ 77

5.2 Cleaning.......................................................................................................... 77

5.2.1 Cleaning of LED Lens Array ................................................................................... 77

5.2.2 Cleaning Page Function ......................................................................................... 79

6. TROUBLESHOOTING PROCEDURES ................................................................. 80

6.1 Troubleshooting Tips ...................................................................................... 80

6.2 Points to Check before Correcting Image Problems....................................... 80

6.3 Tips for Correcting Image Problems............................................................... 80

6.4 Preparation for Troubleshooting ..................................................................... 81

6.5 Troubleshooting Flow ..................................................................................... 82

6.5.1 LCD Status Message/Problem List ........................................................................ 82

6.5.2 LCD Message Troubleshooting.............................................................................. 92

7. WIRING DIAGRAM................................................................................................ 112

7.1 Interconnect Signal Diagram .......................................................................... 112

7.2 PCB Layout and Connector Signal List .......................................................... 113

7.3 Resistance Check........................................................................................... 123

8. PARTS LIST ........................................................................................................... 125

APPENDIX A RS-232C SERIAL INTERFACE (OPTION) ........................................... 132

APPENDIX B CENTRONICS PARALLEL INTERFACE.............................................. 137

APPENDIX C UNIVERSAL SERIAL BUS (USB)......................................................... 143

APPENDIX D LOOP TEST (RS-232C INTERFACE) ................................................... 147

APPENDIX E DIAGNOSTICS TEST ............................................................................ 148

APPENDIX F MULTI PURPOSE FEEDER MAINTENANCE..................................... 157

1. OUTLINE ........................................................................................................ 157

1.1 Functions................................................................................................................ 157

1.2 External View and Component Names .................................................................. 157

2. MECHANISM DESCRIPTION ........................................................................ 158

2.1 General Mechanism ............................................................................................... 158

2.2 Hopper Mechanism ................................................................................................ 158

41356901TH Rev.2 5 /

Page 6

3. PARTS REPLACEMENT................................................................................ 159

3.1 Precautions Concerning Parts Replacement ......................................................... 159

3.2 Parts Layout ........................................................................................................... 161

3.3 Parts Replacement Methods .................................................................................. 162

3.3.1 Link........................................................................................................... 163

3.3.2 Separator ................................................................................................. 164

3.3.3 OLEV-11-PCB.......................................................................................... 165

3.3.4 Pulse Motor .............................................................................................. 166

3.3.5 Planet Gear .............................................................................................. 167

3.3.6 Roller-A and B.......................................................................................... 168

4. TROUBLESHOOTING.................................................................................... 169

4.1 Precautions Prior to the Troubleshooting ............................................................... 169

4.2 Preparations for the Troubleshooting ..................................................................... 169

4.3 Troubleshooting Method......................................................................................... 170

4.3.1 LCD Status Message List......................................................................... 170

5. CONNECTION DIAGRAM.............................................................................. 172

5.1 Interconnection Diagram ........................................................................................ 172

5.2 PCB Layout ............................................................................................................ 173

6. PARTS LIST ................................................................................................... 174

APPENDIX G HIGH CAPACITY SECOND PAPER FEEDER ................................... 176

1. OUTLINE ........................................................................................................ 176

1.1 Functions................................................................................................................ 176

1.2 External View and Component Names .................................................................. 176

2. MECHANISM DESCRIPTION ........................................................................ 177

2.1 General Mechanism ............................................................................................... 177

2.2 Hopper Mechanism ................................................................................................ 177

3. PARTS REPLACEMENT................................................................................ 178

3.1 Precautions Concerning Parts Replacement ......................................................... 178

3.2 Parts Layout ........................................................................................................... 180

3.3 Parts Replacement Methods .................................................................................. 181

3.3.1 Stepping Motor (Hopping) ........................................................................ 182

3.3.2 TQSB-2 PCB............................................................................................ 184

3.3.3 Hopping Roller Shaft Assy and One-way Clutch Gear............................. 184

4. TROUBLESHOOTING.................................................................................... 185

4.1 Precautions Prior to the Troubleshooting ............................................................... 185

4.2 Preparations for the Troubleshooting ..................................................................... 185

4.3 Troubleshooting Method......................................................................................... 186

4.3.1 LCD Status Message List......................................................................... 186

5. CONNECTION DIAGRAM.............................................................................. 188

5.1 Interconnection Diagram ........................................................................................ 188

5.2 PCB Layout ............................................................................................................ 189

6. PARTS LIST ................................................................................................... 190

41356901TH Rev.2 6 /

Page 7

1. CONFIGURATION

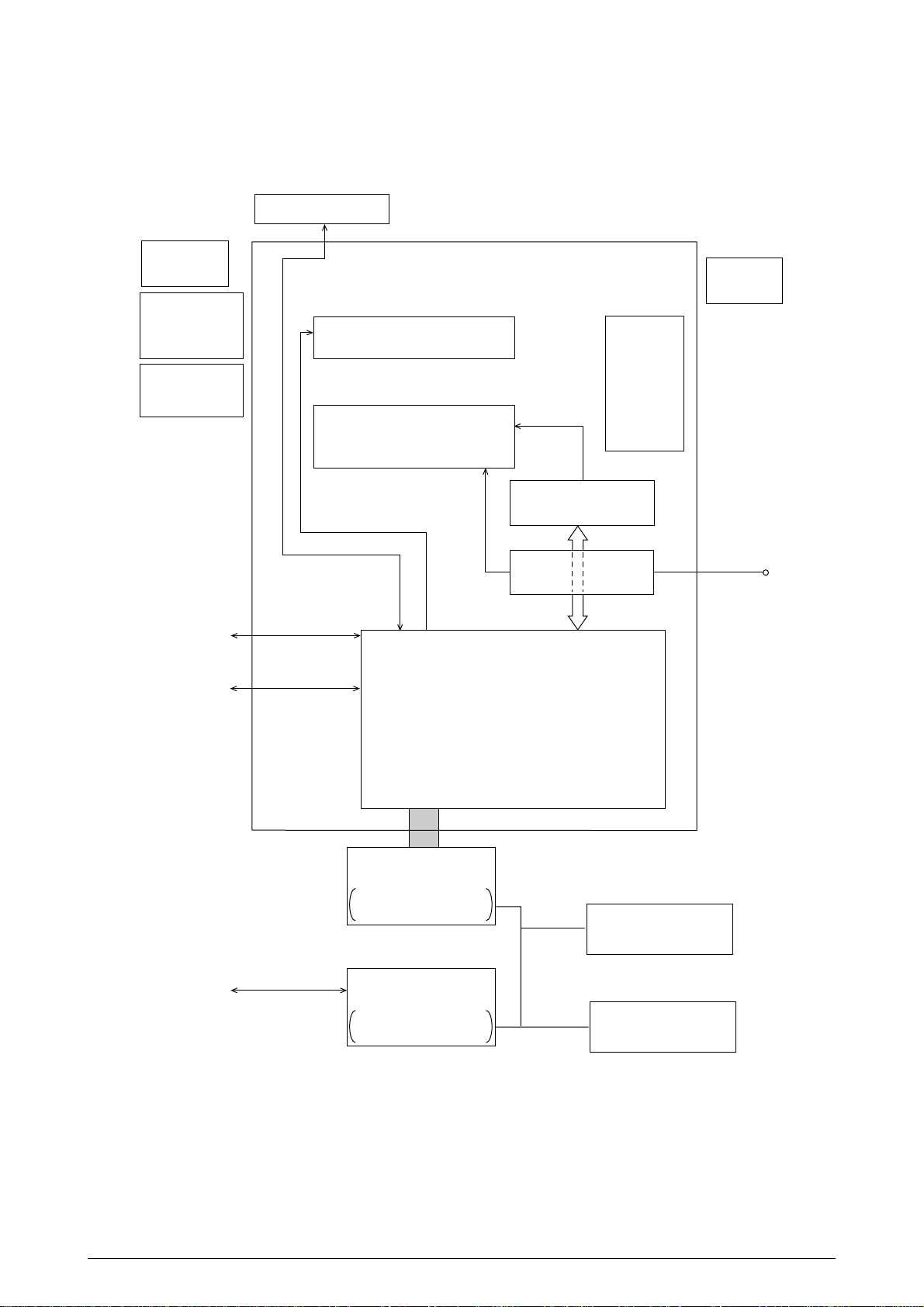

1.1 System Configuration

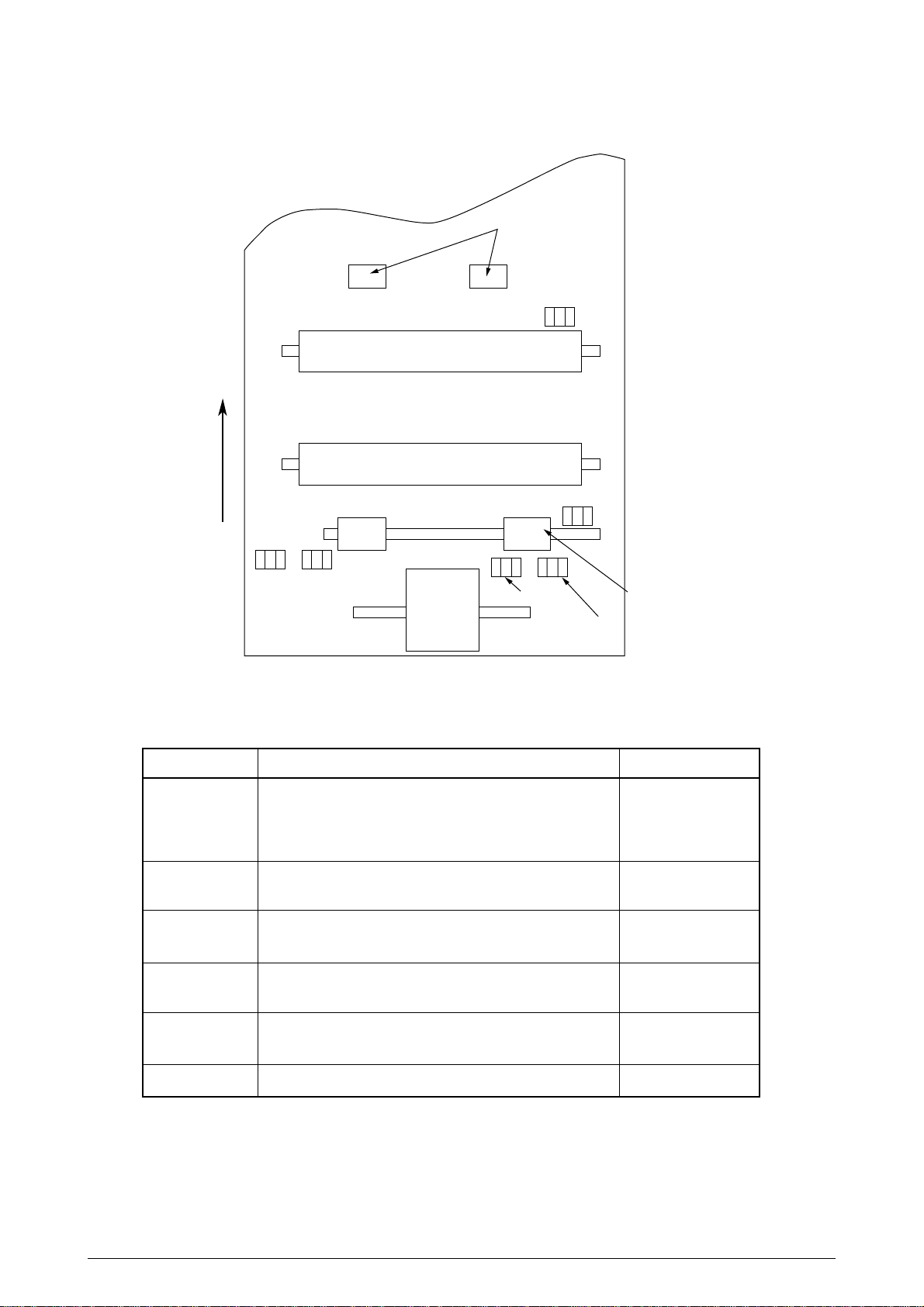

OKIPAGE 14ex consists of control and engine blocks in the standard configuration, as shown in Figure

1-1.

In addition, the options marked with asterisk(*) are available.

41356901TH Rev.2 7 /

Page 8

Paper

Cassette

*High Capacity

Second Paper

Feeder

Operator Panel

Paper Feeding Mechanism

(First Tray Unit)

Engine Unit

Face Up

Stacker

Face

*Multi Purpose

Feeder

Centronics

USB

Electrophotographic

Processing Unit

Fuser Unit

Main Control Board

Down

Stacker

High Voltage Unit

and Sensor Board

Power Supply

AC

* : Optional

RS-232C

Expansion Board

1 DRAM SIMM Socket

1 Flash SIMM Socket

or

RS-232C Serial*

Interface Board

1 DRAM SIMM Socket

1 Flash SIMM Socket

DRAM SIMM*

Flash SIMM*

(Flash memory)

Figure 1-1

41356901TH Rev.2 8 /

Page 9

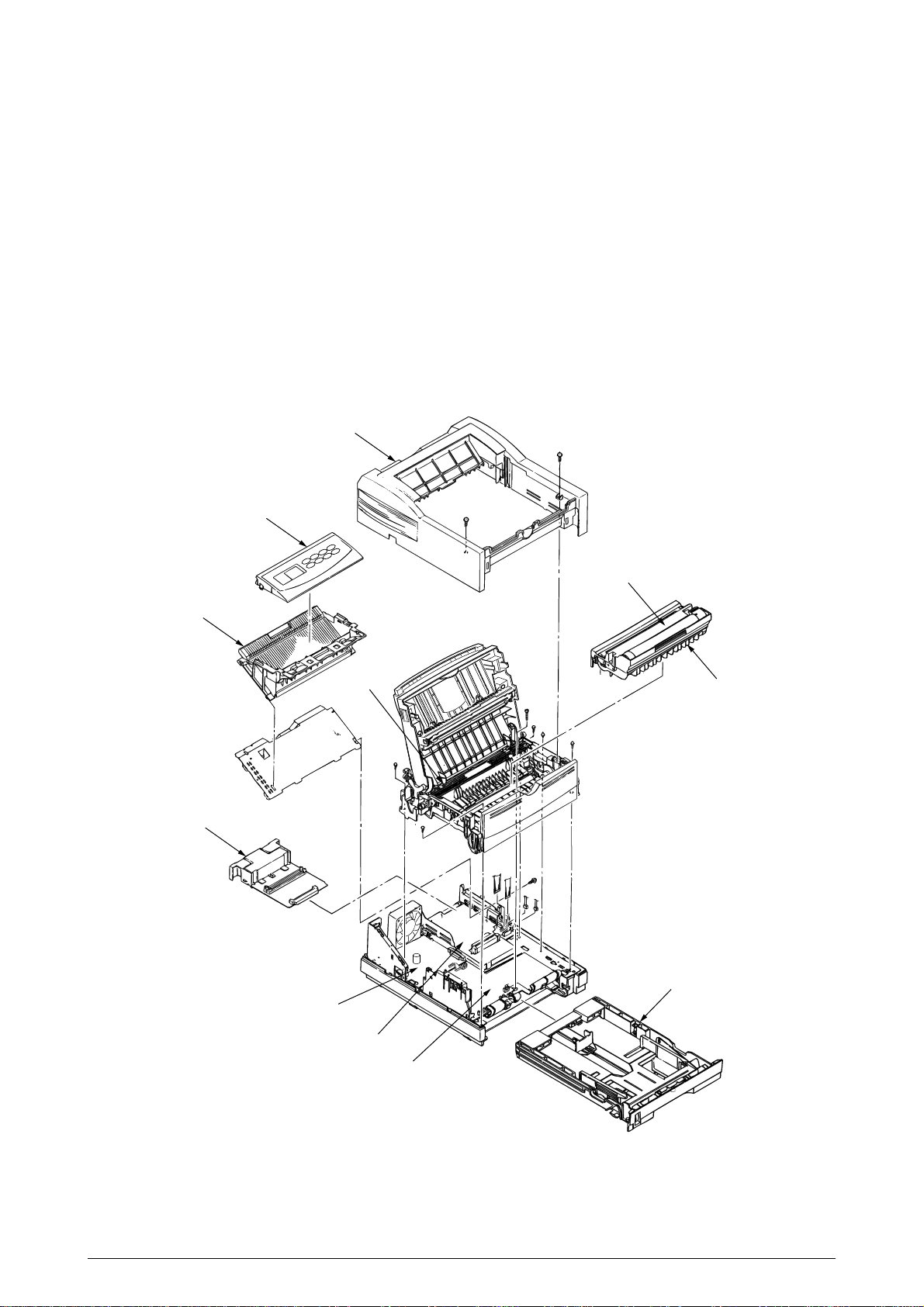

1.2 Printer Configuration

The printer unit consists of the following hardware components:

• Electrophotographic Processor

• Paper Feeder

• Controller

• Operator Panel

• Power Supply Unit

The printer unit configuration is shown in Figure 1-2.

Operator panel assy

Upper cover

Stacker assy

Optional board

Fusing unit

Toner-cartridge(Type 5)

(consumable)

Image drum unit(Type 8)

(consumable)

Legal/universal paper cassette

Power supply

Main control board

High Voltage Unit/sensor board

Figure 1-2

41356901TH Rev.2 9 /

Page 10

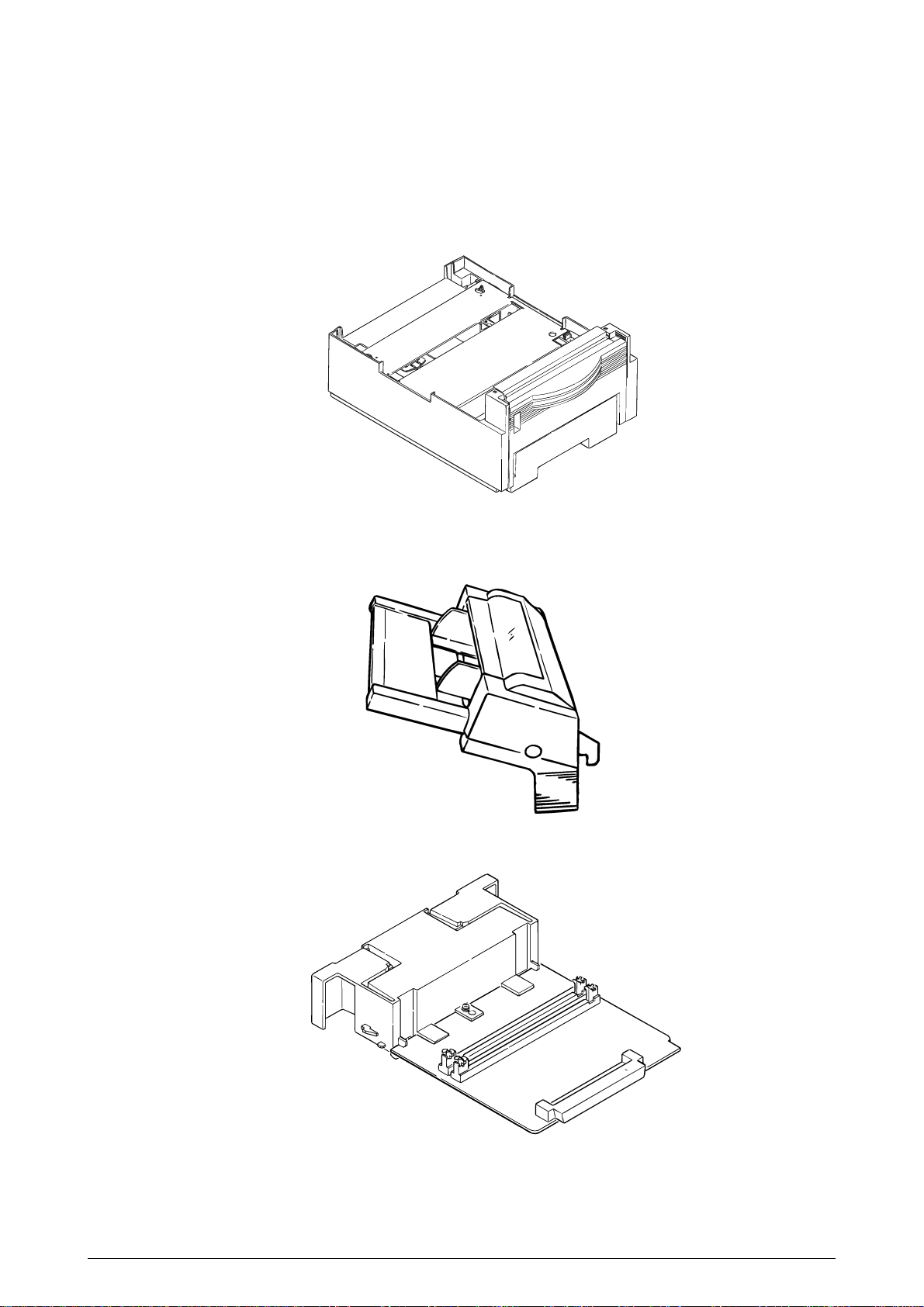

1.3 Optional Configuration

The options shown below are available for use with OKIPAGE 14ex. These are available separately from

the printer unit.

(1) High Capacity Second Paper Feeder

(2) Multi Purpose Feeder

(3) Expansion Board

41356901TH Rev.2 10 /

Page 11

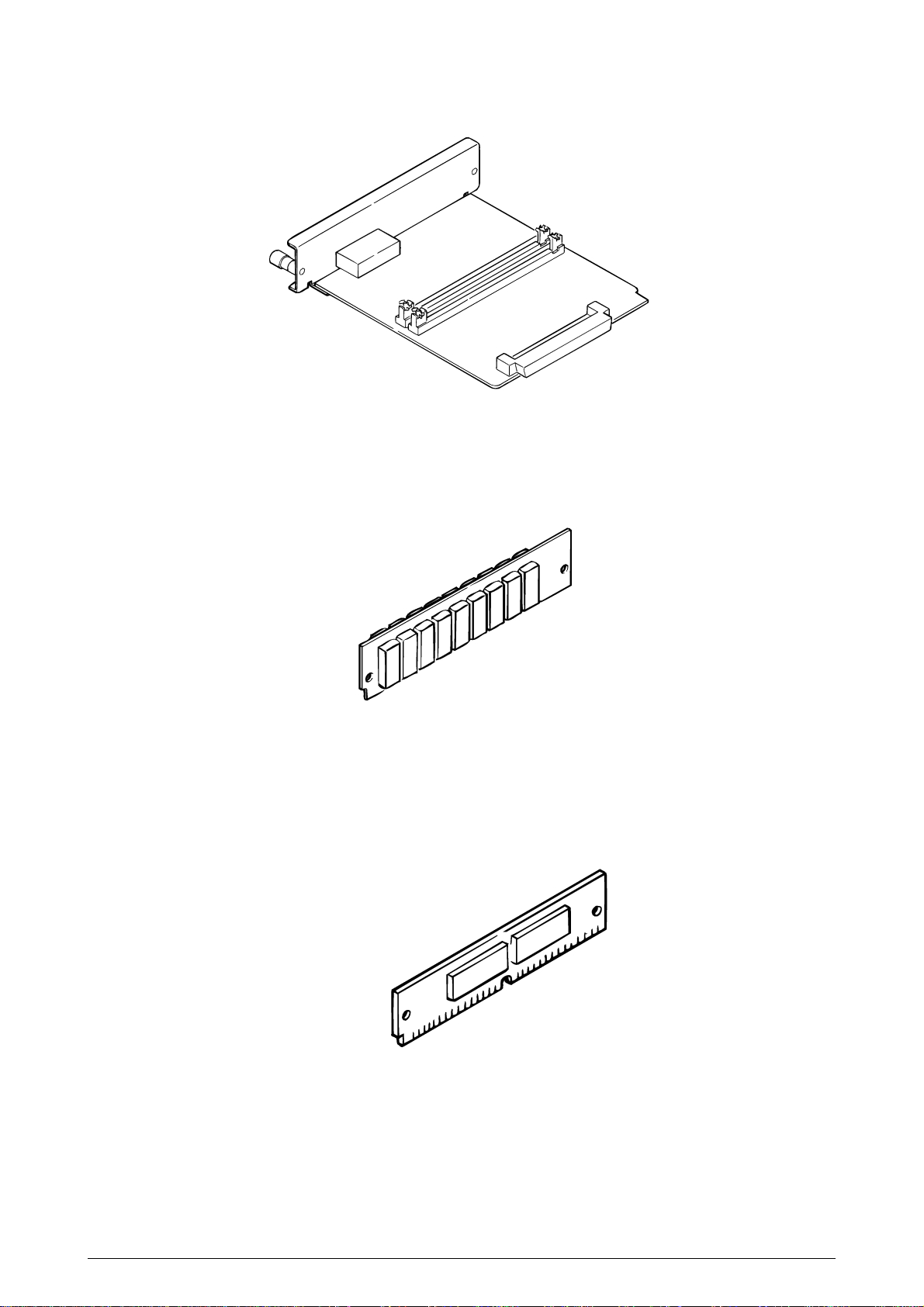

(4) RS-232C Serial Interface Board

(5) DRAM SIMM Memory

DRAM SIMM memory is available with memory of 8MB,16MB,32MB [Oki Data genuine].

The access time of SIMM memories are 60ns, 70ns, 80ns, and 100ns.

(6) Flash SIMM

Flash SIMM is available with memory of 4MB, 8MB and 16MB.

41356901TH Rev.2 11 /

Page 12

1.4 Specification

(1) Type Desktop

(2) External dimensions Height 8.5” (215 mm)

(3) Weight Approx. 9kg

(4) Developing method Dry electrophotography

Exposing method LED stationary head

(5) Paper used <Type>

Width 13.6” (345 mm)

Depth 15.6” (395 mm)

• Standard paper

– Xerox 4200 (20 lbs)

• Application paper (manual face-up feed)

– Label

– Envelope

– OHP paper (transparency)

<Size>

• Standard sizes

– Letter

– Legal* [*Without Multi Purpose Feeder (Option)]

– Legal-13*

– Executive

– COM-10** [**manual feed and Multi Purpose Feeder

(Option) only]

– Monarch**

– DL**

– C5**

– A4

– A5

– B5 (JIS)

– A6

• Applicable sizes

– Width: 3.4” to 8.5” (86 to 216 mm)

– Length: 5.5” to 14” (140 to 355.6 mm)

<Thickness>

– Automatic feed : 16 to 28 lbs (60 to 105 g/m2)

– Manual feed : Label, OHP paper (transparency)

Envelope (24 to 28lbs)

(6) Printing speed Continuous printing : 14 pages per minute with Letter size paper.

[Except, Multi purpose Feeder (11ppm)]

Warm-up time : 45 seconds typical at room temperature

[68˚F (20˚C), AC 120/230 V].

First page print time : 7.5 seconds typical for the Letter size paper

after warm-up.

(7) Paper feeding method Automatic feed or manual feed

(8) Paper delivery method Face down/face up

(9) Resolution 600 × 600 dots/inch

600 × 1200 dots/inch

(10)Power input 120 VAC + 5.5%, -15%

230 VAC ± 10%

41356901TH Rev.2 12 /

Page 13

(11)Power consumption 120VAC 230VAC

Peak : Approx. 600W Approx. 600W

Typical operation : Approx. 340W Approx. 340W

Idle : Approx. 75W Approx. 66W

Power save mode : Approx. 10W Approx. 11W

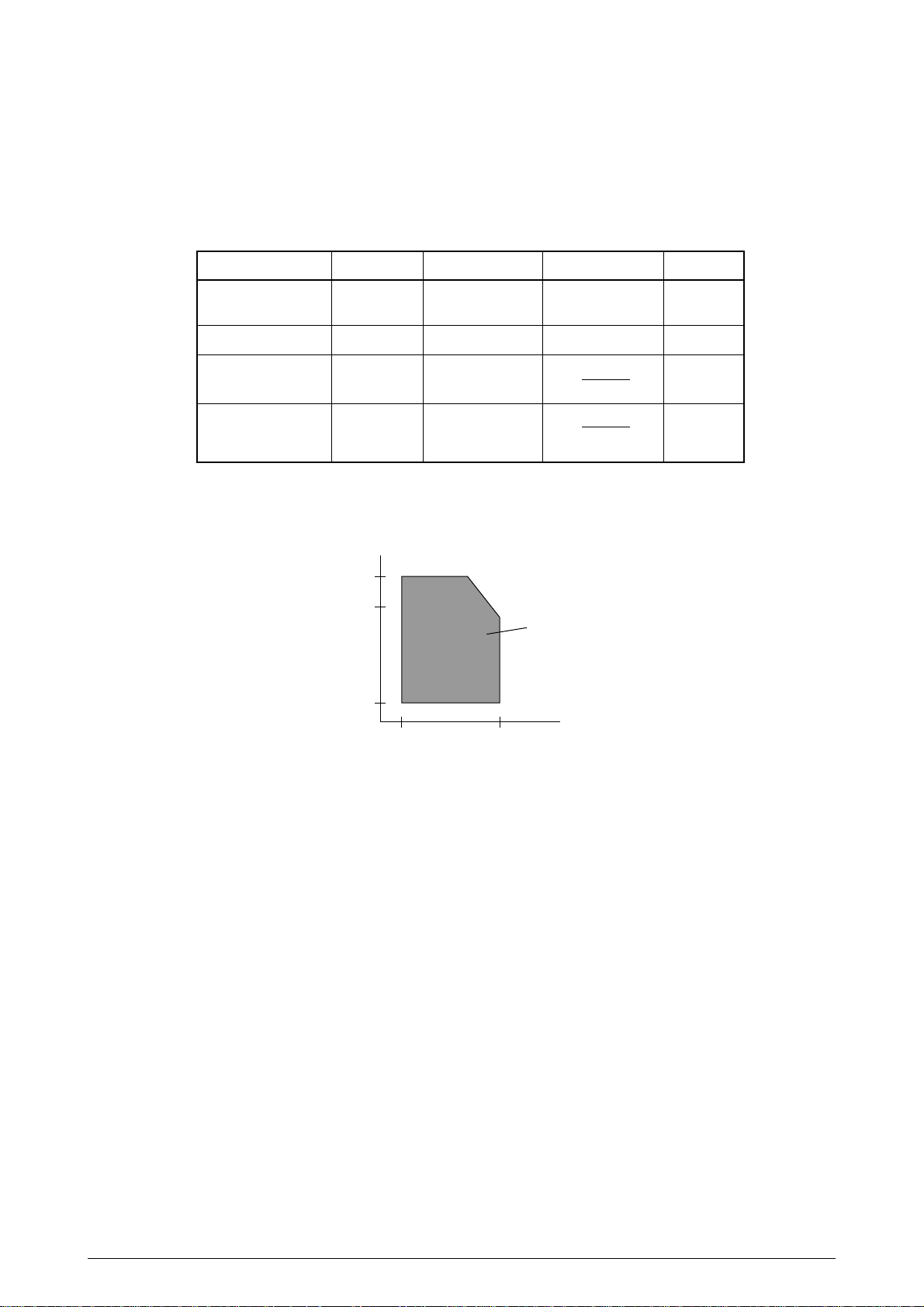

(12)Temperature and humidity

In operation Power off mode During Storage Unit

Temperature

Humidity

Maximum wet bulb

temperature

Minimum difference

between wet and dry

50-90

(10-32)

20-80

77

(25)

35.6

(2)

32-110

(0-43)

10-90

80.4

(26.8)

35.6

(2)

14-110

(–10-43)

10-90

˚F

(˚C)

%RH

˚F

(˚C)

˚F

(˚C)

bulb temperatures

1. Storage conditions specified above apply to printers in packed condition.

2. Temperature and humidity must be in the range where no condensation occurs.

Temperature

(

°

C)

32

28

Operation range

10

20 80

Humidity (%)

(13) Noise During operation: 53 dB (A) or less

Standby: 38 dB (A) or less

Quiet mode: Back ground level

(14) Consumables Toner cartridge kit ODA : 2,000 (5% duty) 4,000(optional 4K

Toner 5% duty)

OEL/INT : 2,500 (5%duty) 4,000(optional 4K

Toner 5% duty)

Image drum cartridge 20,000 (at continuouts printing)

14,000 (3 page/job) without Power Save

9,000 (1 page/job) without Power Save

8,000 (1 page/job) with Power Save

(Minimum)

41356901TH Rev.2 13 /

Page 14

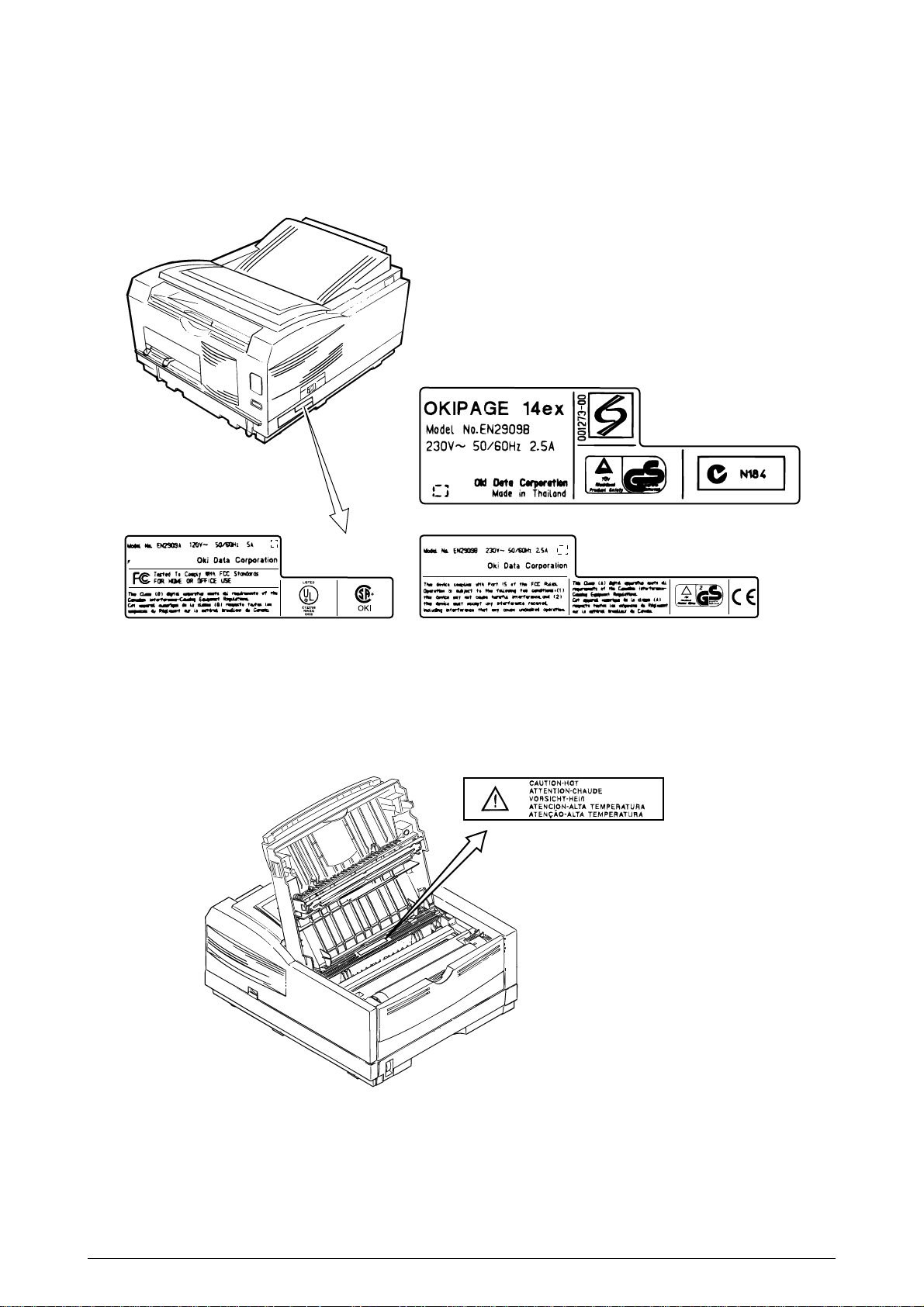

1.5 Safety Standards

1.5.1 Certification Label

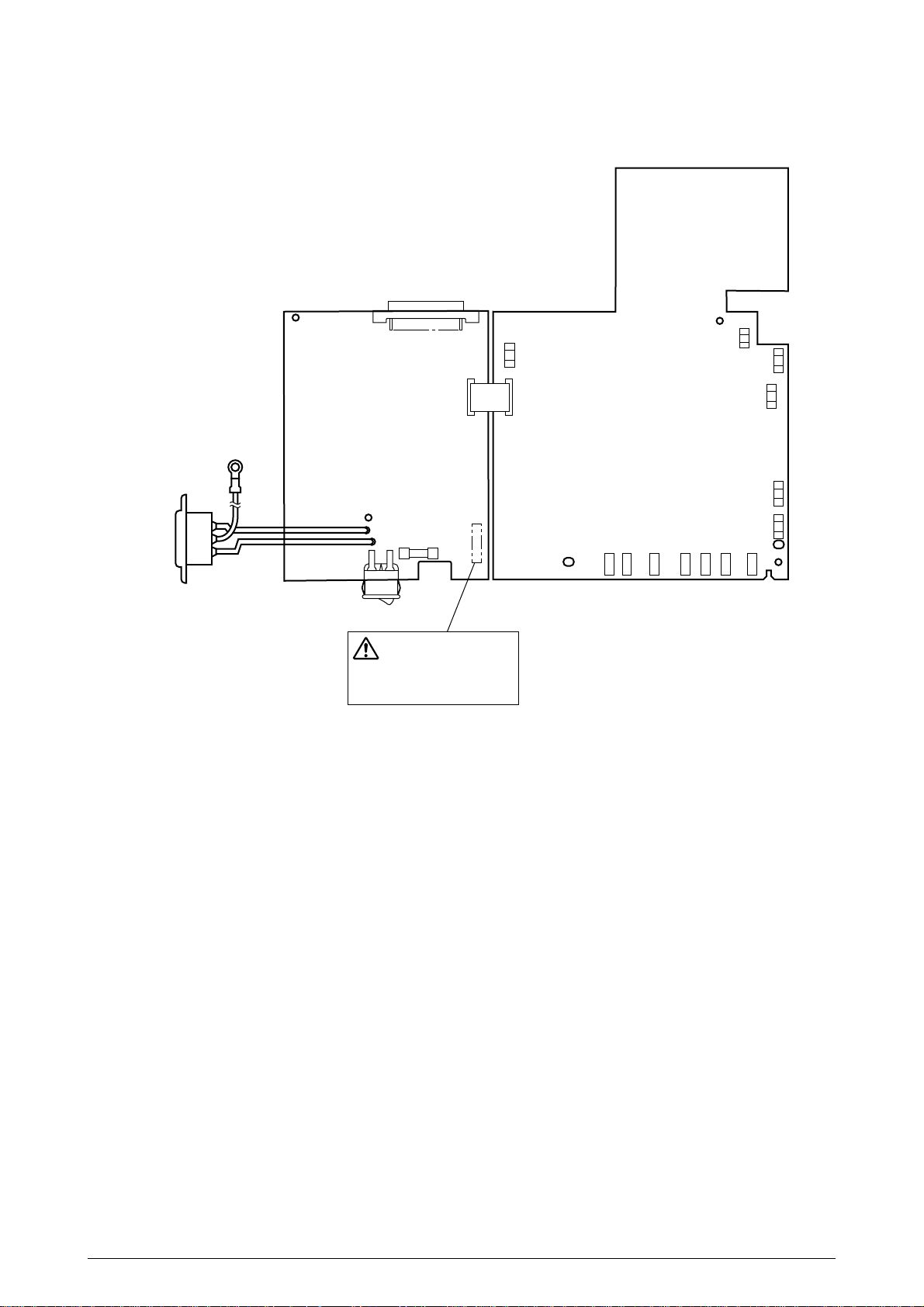

The safety certification label is affixed to the printer in the position described below.

INT AC : 230V model

ODA AC : 120V model ODA AC : 230V model

1.5.2 Warning Label

The warning labels are affixed to the sections which may cause bodily injury.

Follow the instructions on warning labels during maintenance.

41356901TH Rev.2 14 /

Page 15

1.5.3 Warning/Caution Marking

The following warning and caution markings are made on the power supply/sensor board.

ENGLISH

FRENCH

SPANISH

CAUTION

ATTENTION ATENCÃO

CUIDADO CUIDÃDO

ENGLISH

Heatsink and transformer core present risk of electric shock. Test before touching.

FRENCH

Le dissipateur thermique et le noyau du transformateur présentent des risques de choc électrique.

Testez avant de manipuler.

SPANISH

Las disipadores de color el núcel del transformador pueden producir un choque eléctrico. Compruebe

antes de tocar.

PORTUGUESE

O dissipador de calor e o núcleo do fransiormador apresentam risco de choque elétrico. Teste antes de

focar.

Circuits maybe live after fuses open.

Il se peut que les circuits soient sous tension une fois que les fusibles ont éfé rerirés.

Las circuitos pueden estar activos una vez que se hayan abierio los fusibles.

PORTUGUESE

Os circuitos podem estar energizados após os fusiveis se queimarem.

41356901TH Rev.2 15 /

Page 16

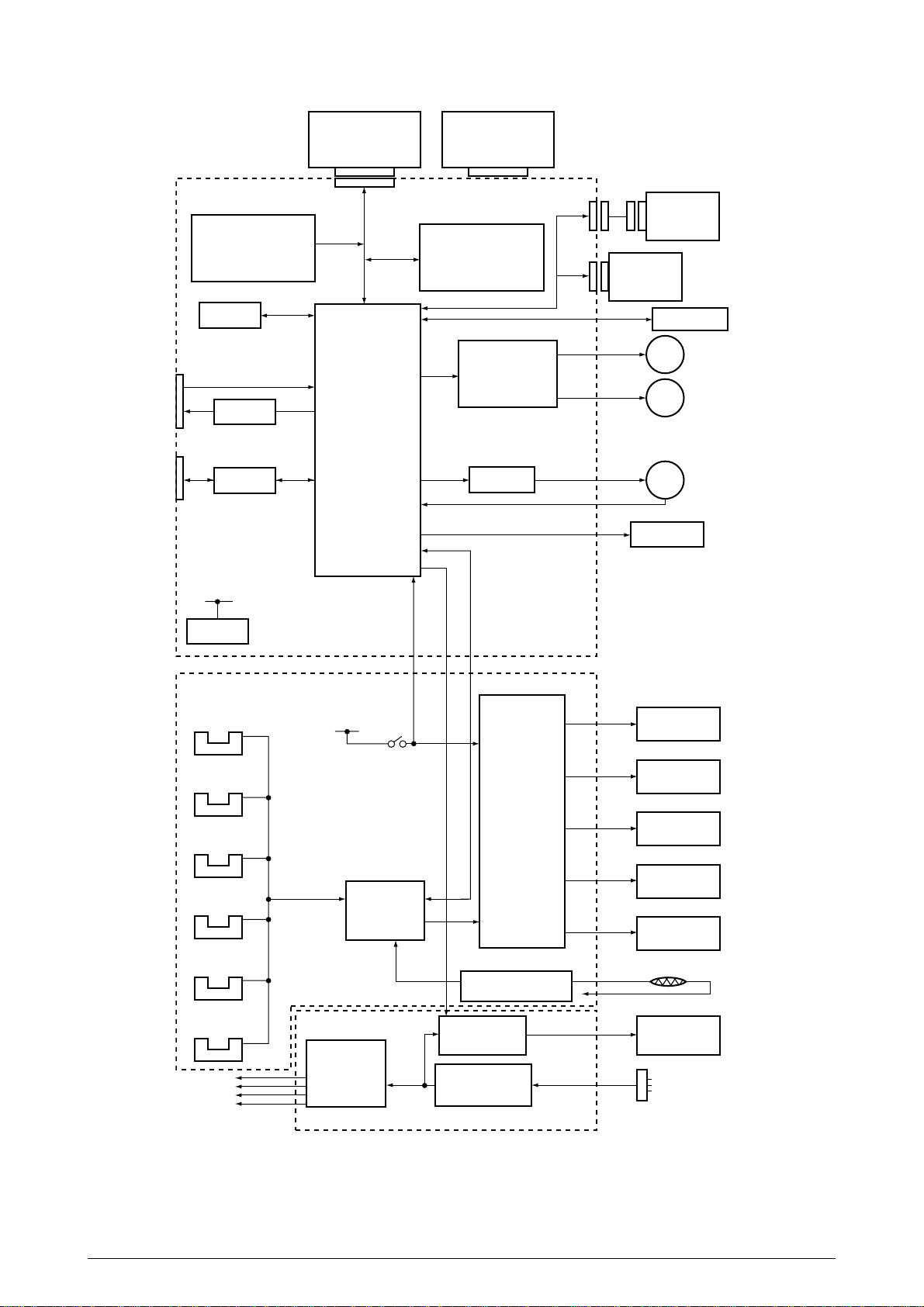

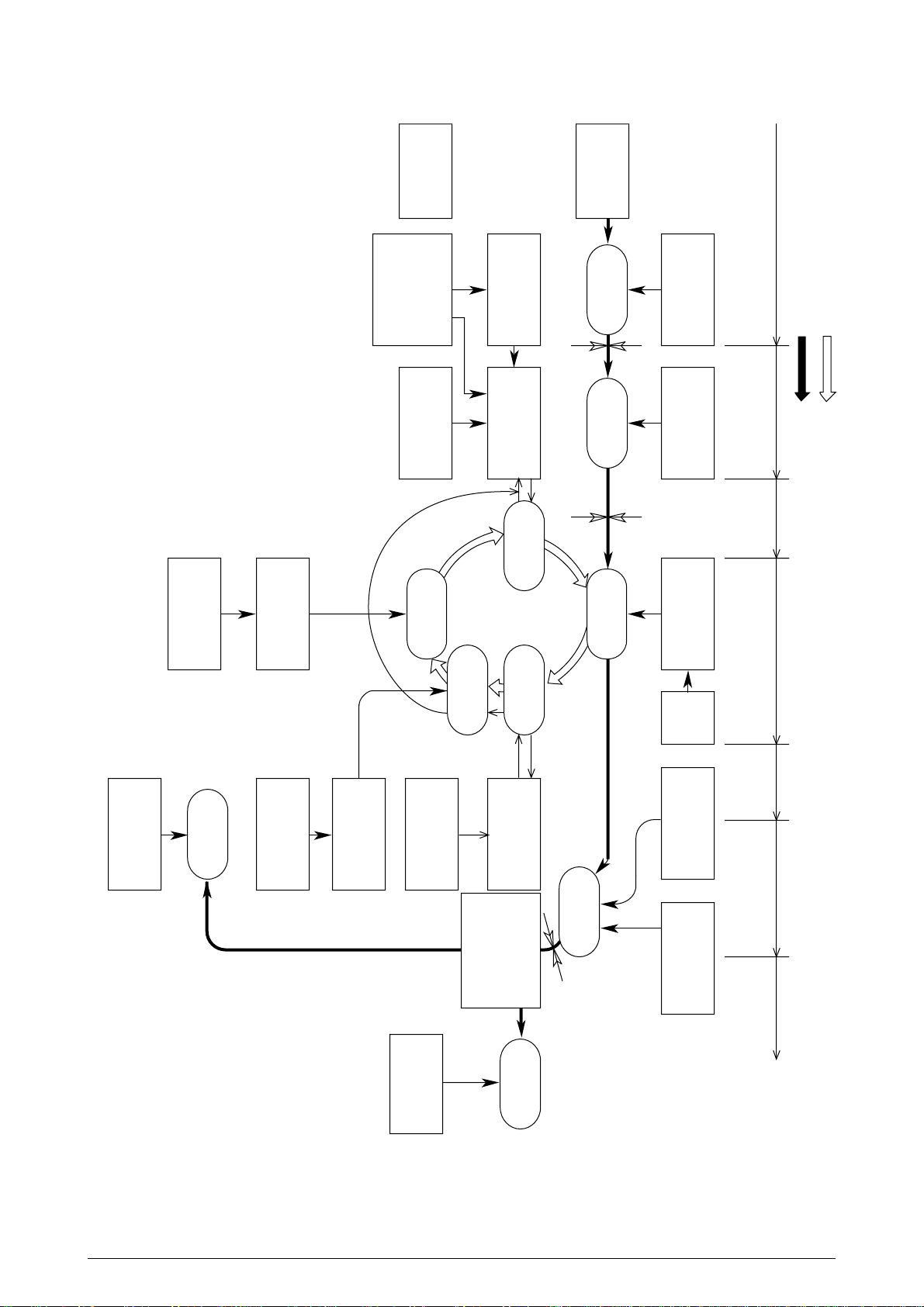

2. OPERATION DESCRIPTION

OKIPAGE 14ex consists of a main control board, a power supply/sensor board, an operator panel, an

electrophotographic process mechanism, and revision for illumination of LED head.

The main control board receives data via the host I/F, it then decodes, edits and stores the data in

memory. After completing the editing of a single page of data, it references the font memory and

generates bit image data, which is transferred to the LED head in one dot line units.

Through the electrophotographic process mechanism, the data is printed on the paper.

The operator panel is used for operations and status display.

OKIPAGE 14ex block diagram is shown in Figure 2-1.

41356901TH Rev.2 16 /

Page 17

Expansion Board

(Option)

RS232C Interface Board

or

(Option)

Main Control Board

Program & Font ROM

8MB Mask ROM

EEPROM

Centronics

parallel I/F

74LS07

USB I/F

ML60851

5V

Reset

circuit

For optional board

DATA

BUS

(32bit)

1 Chip CPU

Resident RAM

2MB x 2 DRAM

(4MB)

Registration motor

HEAT ON

Drum motor &

drive circuit

FAN Driver

Multi-Purpose

Feeder (Option)

High Capacity

Second Paper

Feeder (Option)

Operation Panel

Drum Motor

MMRegistration Motor

FAN

FAN ALM

LED Head

High Voltade

Unit

Inlet sensor 1

Inlet sensor 2

Paper sensor

Outlet sensor

Paper out sensor

Toner low sensor

3.3V

5V

12V

30V

5V

AC-DC

Converter

Cover

open

switch

LSI

Charge roller

Transfer roller

High voltage

generation

circuit

Fusing temperature

control circuit

Heater drive

circuit

Filter circuit AC IN

Developping

roller

Toner supply

roller

Cleaning

roller

Thermistor

Heater

Power Supply Unit

Figure 2-1 OKIPAGE 14ex Block Diagram

41356901TH Rev.2 17 /

Page 18

2.1 Main Control Board

The main control board consists of a single chip CPU, two program/font ROMs, four DRAMs, an

EEPROM, a host interface circuit, and a mechanism driving circuit.

(1) Single chip CPU

The single chip CPU is a custom CPU (32-bit internal bus, 32-bit external bus, 49.766-MHz clock)

which incorporates the RISC CPU and its peripheral devices, and has the following functions:

(2) Program and Font ROMs

Built-in device Function

Chip select controller

Bus controller

DRAM controller

DMA controller

Parallel interface controller

Serial interface controller

Video output port

LED STB output port

Timer

Serial I/O port

I/O port

The Program and Font ROMs store the equipment program and various types of fonts. Mask ROM

is used as Program and Font ROMs. The mounting locations of these Program and Font ROMs vary

depending on the type of the ROMs.

(3) DRAM

Control of ROM, DRAM and I/O device

Transfer of image data from DRAM to video output port

Control of Centronics parallel interface

Control of RS-232C serial interface

Control of LED head

Generation of various control timing

Monitoring of paper running and paper size

Control of operator panel, EEPROM, and options

Input and output of sensor and motor signals

The DRAM is a 4MB resident memory on the main control board that stores edited data, image data,

DLL data and macro data.

(4) EEPROM

4,096-bit Electrically Erasable PROM (EEPROM), is loaded with the following kinds of data:

• Menu data

• Various counter data (page counter, drum counter)

• Adjusting parameters (LED head drive time, print start position, paper feed length)

(5) Parallel Interface

Parallel data is received from a host system via parallel interface which conforms to the IEEE1284

specification.

(6) USB Interface

Serial data is received from a host system via USB which conforms to the USB 1.1 specification.

41356901TH Rev.2 18 /

Page 19

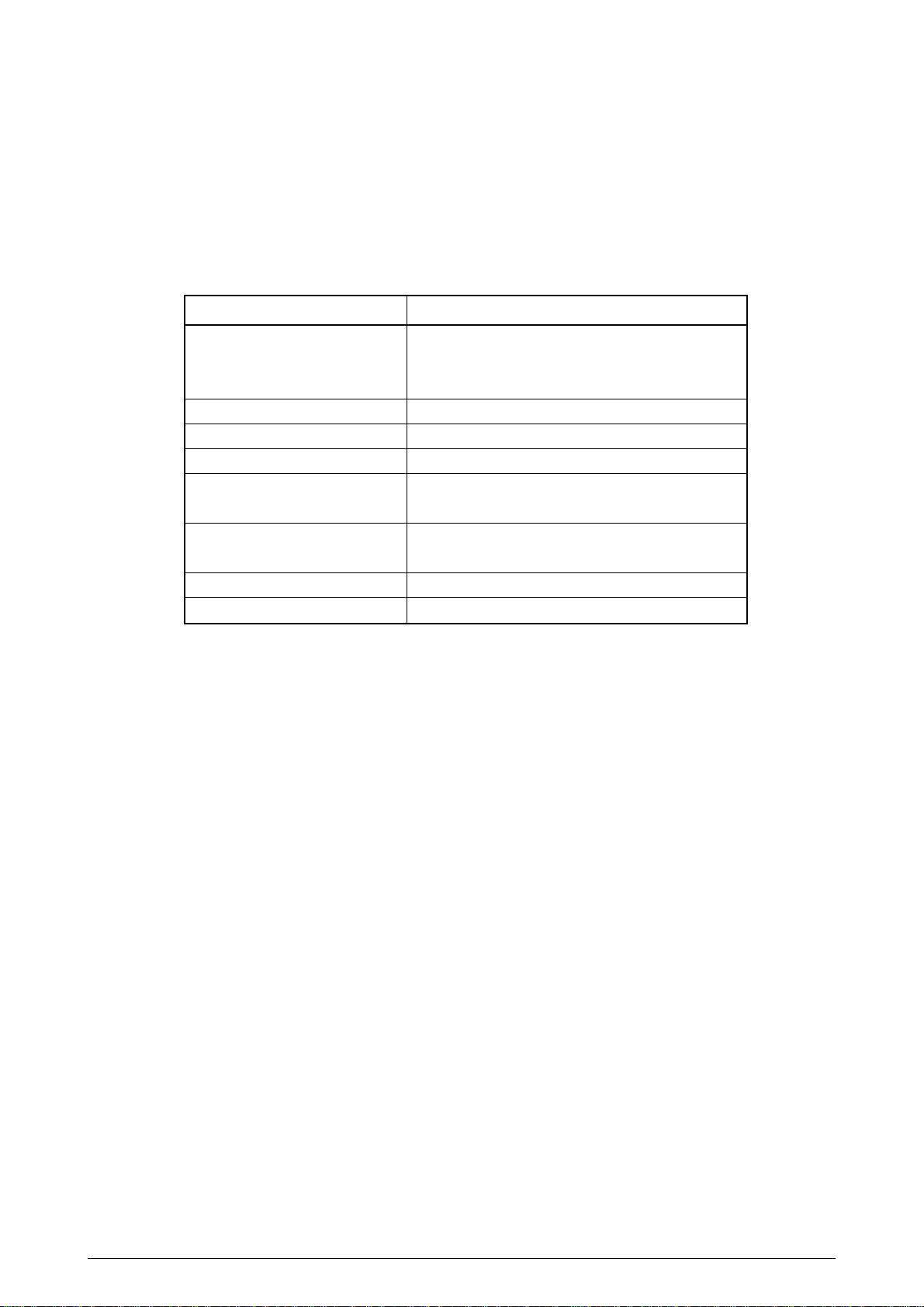

2.2 Power Supply/Sensor Board

The power supply/sensor board consists of an AC filter circuit, a low voltage power supply circuit, a high

voltage power supply circuit, heater drive circuit, and photosensors.

(1) Low Voltage Power Supply Circuit

This circuit generates the following voltages.

Output voltage Use

+5 V

+30 V

+12 V

+3.3V

(2) High Voltage Power Supply Circuit

This circuit generates the following voltages required for electrophotographic process from +5 V,

according to the control sequence from the main control board. When cover open state is detected,

+5 V supply is interrupted automatically to stop the supply of all high-voltage outputs.

Output Voltage Use Remarks

CH

DB

SB

TR

CB

(3) Photosensor

-1.3 KV

-265 V/+300 V

-500 V/ 0 V

+500 V to +4.5 KV/-1100 V

+400 V/-1350 V

Logic circuit supply voltage

Motor and fan drive voltage and source voltage for high-voltage supply

Source voltage for high-voltage supply

LED head supply voltage

Voltage applied to charging roller

Voltage applied to developing roller

Voltage applied to toner supply roller

Voltage applied to transfer roller

Voltage applied to cleaning roller

Variable

The photosensor mounted on this power supply/sensor board monitors the status of paper being

fed through the printer during printing.

41356901TH Rev.2 19 /

Page 20

The sensor layout diagram is shown in Figure 2-2.

Heat roller

Transfer roller

Exit roller

Outlet sensor

Paper sensor

Inlet

Toner

sensor 2

sensor

Paper feeding direction

Hopping

roller

Paper end sensor

Inlet sensor 1

Registration roller

Figure 2-2

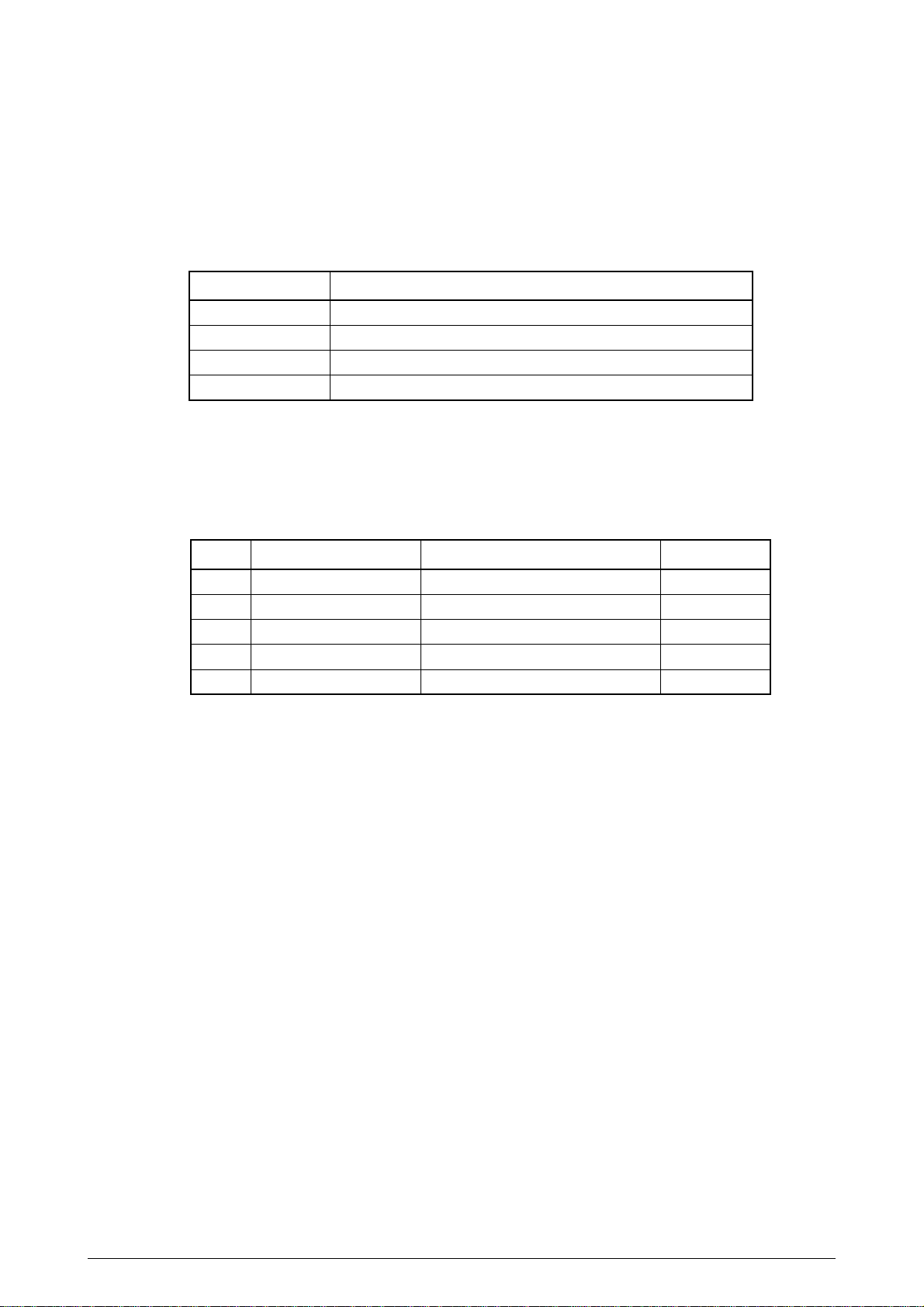

Sensor Function Sensing state

Inlet sensor 1

Detects the leading part of the paper and gives the monitor timing

for switching from hopping operation to feeding operation.

ON

: Paper exists.

OFF

: No paper exists.

Monitors paper feeding situation and paper size based on the

paper arrival time and running time.

Intel sensor 2

Paper sensor

Outlet sensor

Detects the paper width.

Detects the leading portion of the paper.

Monitors the paper feeding situation.

Monitors the paper feeding and size according to the time of

arrival to and leaving past the sensor.

ON

: A4 or larger

OFF

: Smaller than A4

ON

: Paper exists.

OFF

: No paper exists.

ON

: Paper exists.

OFF

: No paper exists.

Paper end sensor

Toner low sensor

41356901TH Rev.2 20 /

Detects the end of the paper.

Detects the lack of toner.

ON

: Paper exists.

OFF

: No paper exists.

- - - - -

Page 21

2.3 Electrophotographic Process

2.3.1 Electrophotographic Process Mechanism

This mechanism actuates the printing of image data supplied by the main control board on the paper by

electrophotographic process.

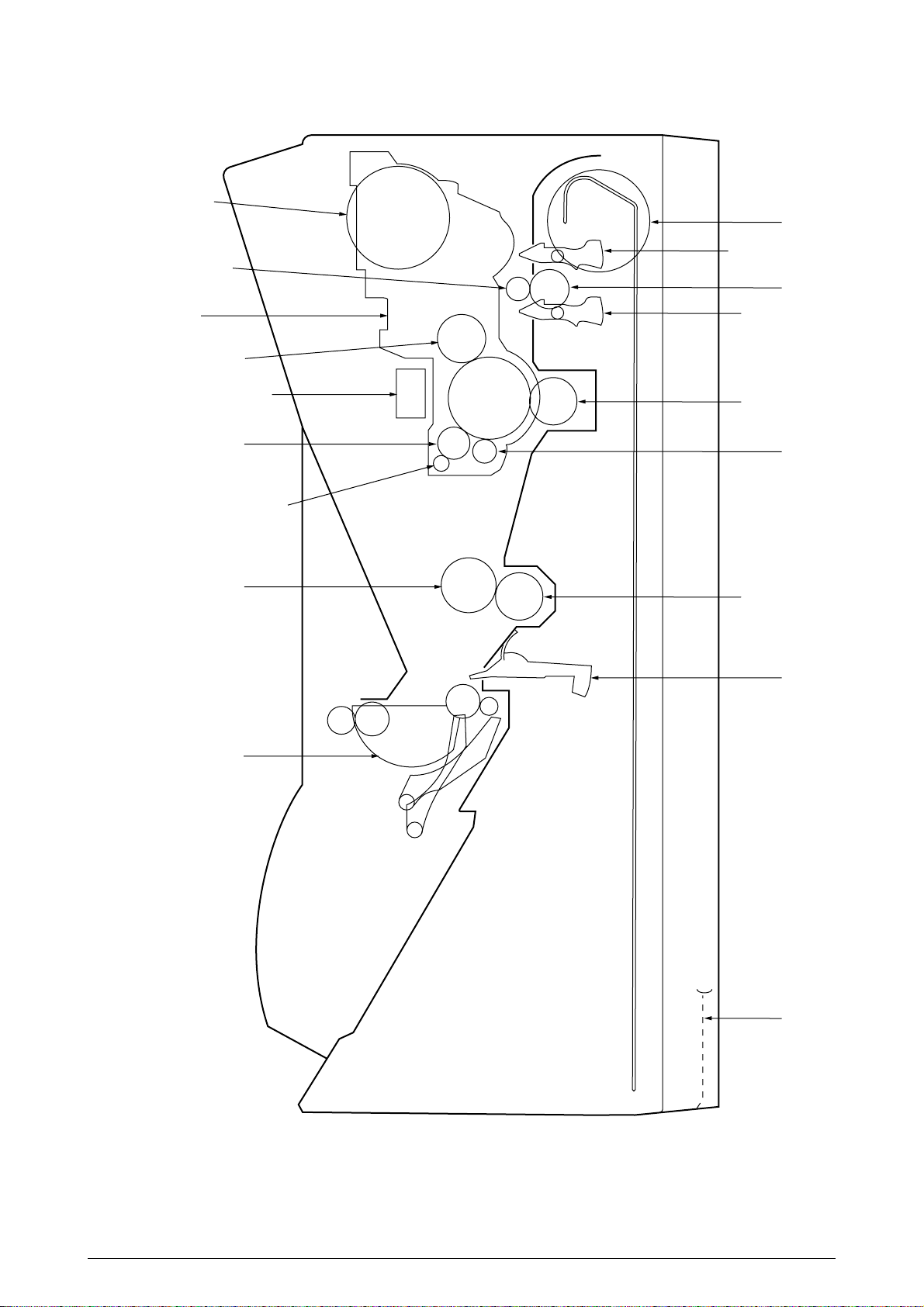

The layout of the electrophotographic process mechanism is shown in Figure 2-3.

41356901TH Rev.2 21 /

Page 22

Paper cassette Eject sensor lever

Eject roller assy Heat roller Charge roller

Developing

roller

LED head

Image drum unit

Back-up roller

Cleaning roller

Transfer roller Paper sensor

plate

Inlet

sensor

plate

Registration

roller

Hopping roller

Toner cartridge

Pressure roller

Sub-charge roller

Figure 2-3

41356901TH Rev.2 22 /

Page 23

(1) Image Drum Unit

The image drum unit consists of a sensitive drum, a charger, and a developer. The unit forms a toner

image on the sensitive drum, using a electrostatic latent image formed by the LED head.

(2) Registration Motor

The registration motor is a pulse motor of 48 steps/rotation with two-phase excitement by the signal

from the main control board. It drives the hopping and registration rollers via two one-way clutches

according to the direction of rotation.

(3) Main (Drum) Motor

The main or drum motor is a pulse motor of 48 steps/rotation with two-phase excitement by the signal

from the main control board and is the main motor of this mechanism.

(4) LED Head

Image data for each dot line from the main control board is received by the shift register and latch

register. The 4992 LED's are driven to radiate the image data on the image drum.

(5) Fuser

The fuser consists of a heater, a heat roller, a thermistor and a thermostat.

The AC voltage from the power supply/sensor board is applied to the heater controlled by the

HEATON signal from the main control board. This AC voltage heats the heater. The main control

board monitors the heat roller temperature via the thermistor, and regulates the heater roller to keep

it at a designated temperature in the menu, depending on the thickness of the paper (tray 1&2:

light=175~185°C, medium light=180~190°C, medium=185~195°C, medium heavy and

heavy=195~205°C; manual feeding and power envelope feeder: light=165~180°C, medium

light=170~185°C, medium=175~190°C, medium heavy=180~195°C, heavy=190~205°C, transparency = 170~185°C) by connecting or disconnecting the AC voltage supply to the heater.

When an abnormal rise of the heater roller temperature takes place, the thermostat of the heater

voltage supply circuit becomes active and forcibly cuts the AC voltage supply.

The temperature setting of the fuser can be changed through operator panel setting.

41356901TH Rev.2 23 /

Page 24

2.3.2 Electrophotographic Process

The electrophotographic processing is outlined below. The electrophotographic printing process is

shown in Figure 2-4.

1 Charging

The surface of the image drum is charged uniformly with a negative charge by applying the negative

voltage to the charge roller.

2 Exposure

Light emitted from the LED head irradiates the negatively charged surface of the image drum. The

surface potential of the irradiated portion of the image drum surface becomes lower, forming the

electrostatic latent image associated with the print image.

3 Developing and toner recovery

When the negatively charged toner is brought into contact with the image drum, it is attracted to the

electrostatic latent image by static electricity, making the image visible.

At the same time, the residual toner on the image drum is attracted to the developing roller by static

electricity.

4 Transfer

When paper is placed over the image drum surface, the positive charge which is opposite in polarity

to that of the toner, is applied to the reverse side of the paper by the transfer roller. The toner is

attracted by the positive charge and is transferred onto the paper. This results in the transfer of the

toner image formed on the image drum onto the paper.

5 Temporary cleaning

Residual toner which remains on the image drum without being transferred is evened out by the

cleaning roller and is temporarily attracted to the cleaning roller by static electricity.

6 Fusing

The toner image transferred onto the paper is fused to the paper by heat and pressure.

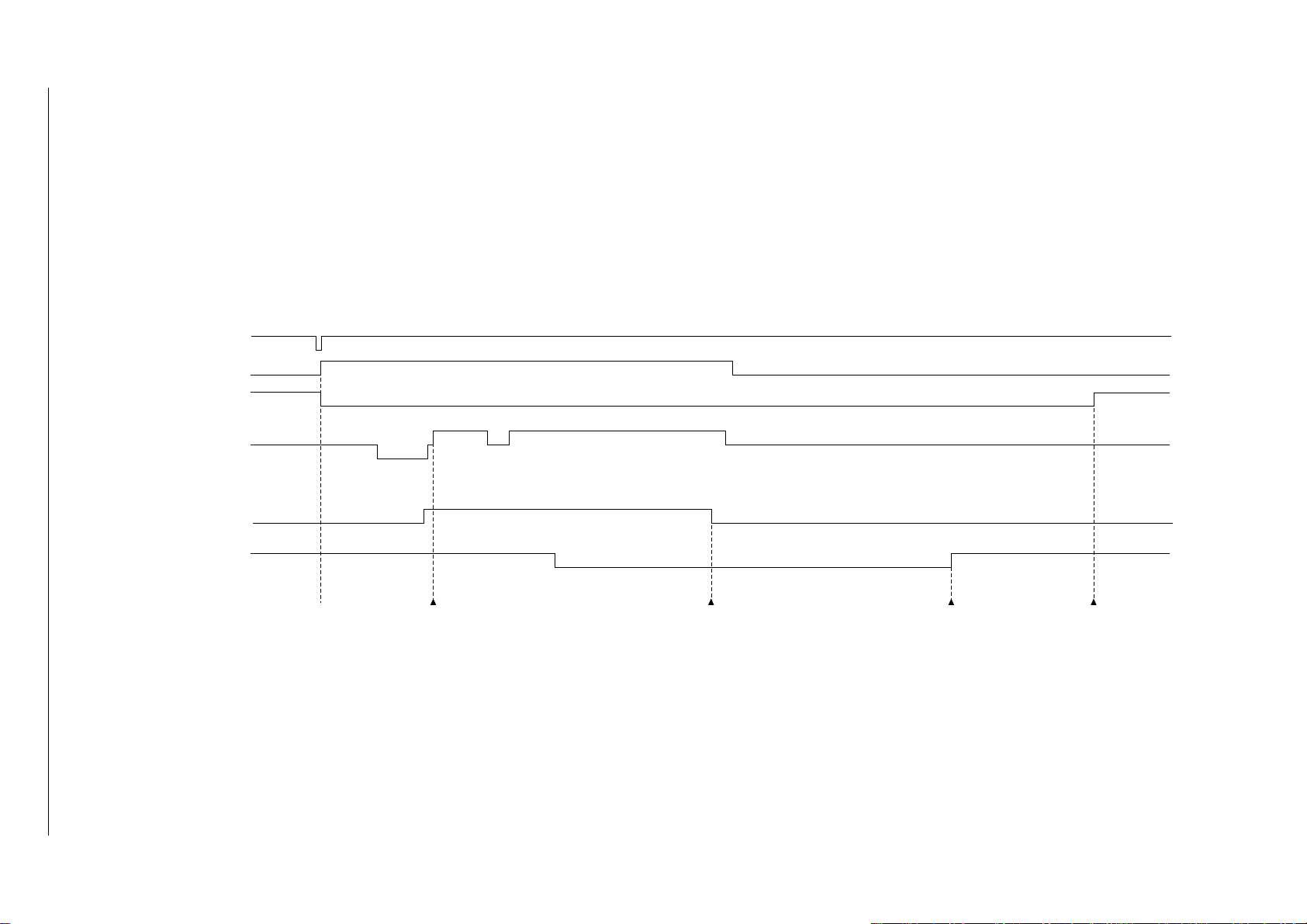

An electrophotographic process timing chart is shown in Figure 2-5.

41356901TH Rev.2 24 /

Page 25

Paper eject roller

(Face down)

Power supply

Paper eject roller

Paper eject

(Face up)

Cleaning roller

LED head

Image data

Registration roller Hopping roller

Heater roller

Power

supply

Doctor blade

Power supply

(Bias voltage)

Toner supply roller

Toner cartridge

Paper

eject

Fusing

Back-up roller Transfer roller

Charger roller

Charging

Cleaning

Paper hopping

Paper feed

Image

production

developing

Transfer

Cleaning

FusingPaper eject

Path of paper feeding

Direction of rotation of the image drum

Power supply

Outlet sensor

Inlet sensor

Developing

Developing roller

Paper sensor

Exposure

Transfer

Paper path selector

Paper

registration

Paper

supply

Paper tray

Figure 2-4

41356901TH Rev.2 25 /

Page 26

41356901TH Rev.2 26 /

PRINT-N

PRDY-N

DM-ON-N

Figure 2-5

RM-ON

INSNS

OUTSNS-N

OUT Sensor OFF

Feed stopIN Sensor OFFFeed start

Page 27

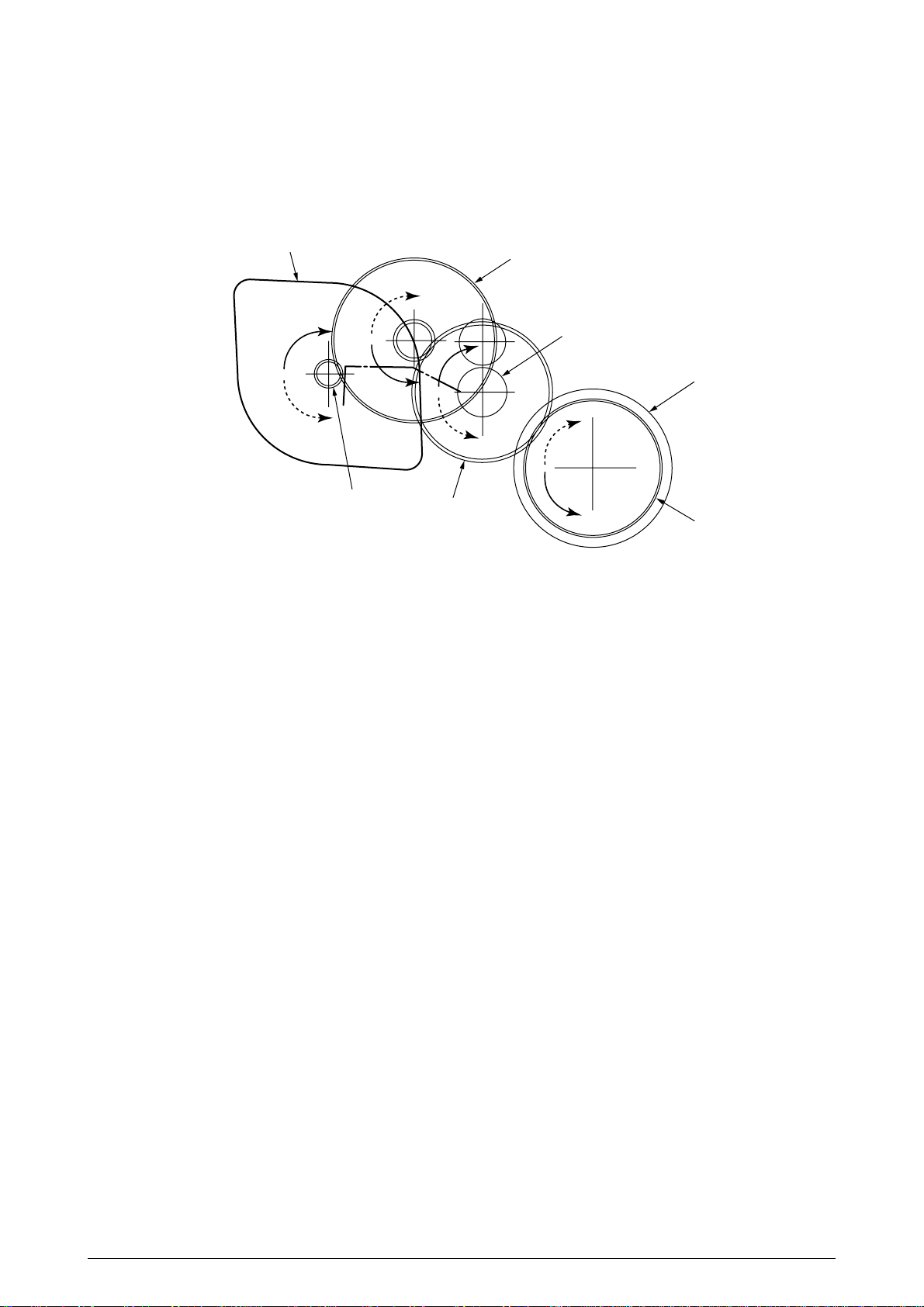

2.3.3 Process Operation Descriptions

(1) Hopping and Feeding

Hopping and feeding motions are actuated by a single registration motor in the mechanism as

shown below:

Registration motor

a

Idle gear

Registration roller

Hopping roller

b

Motor gear

Registration gear

Hopping gear

The registration motor turning in direction "a" drives the hopping roller. The registration motor

turning in direction "b" drives the registration roller. The registration and hopping gears have oneway bearing, so turning any of these gears in the reverse direction will not transmit the motion to the

corresponding roller.

41356901TH Rev.2 27 /

Page 28

(a) Hopping

1 For hopping, the registration motor turns in direction "a" (clockwise direction) and drives

the hopping roller to advance the paper until the inlet sensor turns on (in this case, the

registration gear also turns, but the registration roller is prevented from turning by the oneway bearing).

2 After inlet sensor is turned on by the paper advance, the paper is further advanced to a

predetermined distance until the paper hits the registration roller (the skew of the paper

can thus be corrected).

Paper

a

Registration roller

Hopping roller

(b) Feeding

1 When hopping is completed, the registration motor turning in direction "b" (counter-

clockwise direction) drives the registration roller to advance the paper (in this case, the

hopping gear also turns, but the hopping roller is prevented from turning by the one-way

bearing).

2 The paper is further advanced in synchronization with the print data.

Image drum

Paper

b

Transfer roller

Registration roller

Hopping roller

41356901TH Rev.2 28 /

Page 29

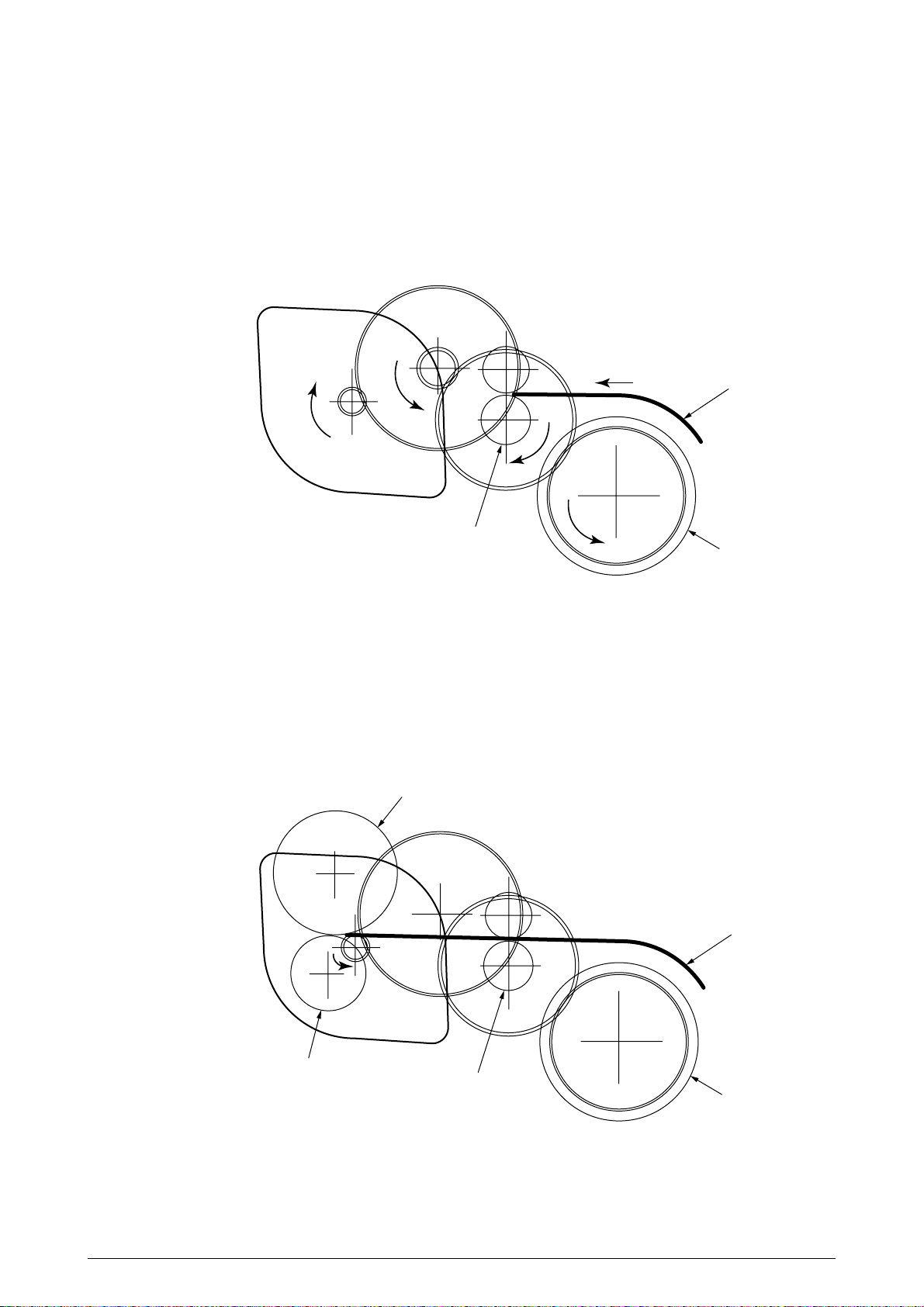

(2) Charging

Charging is actuated by the application of the DC voltage to the charge roller that is in contact with

the image drum surface.

Power

supply

(Sub-CH)

(CH)

Sub-charge roller

Charge roller

Image drum

The charge roller is composed of two layers, a conductive layer and a surface protective layer, both

having elasticity to secure good contact with the image drum. When the DC voltage applied by the

power supply exceeds the threshold value, charging begins. The applied voltage is proportional to

the charge potential, with offset of approximately –550V.

charge potential

[V]

-750

-1300-550 [V]

applied voltage

41356901TH Rev.2 29 /

Page 30

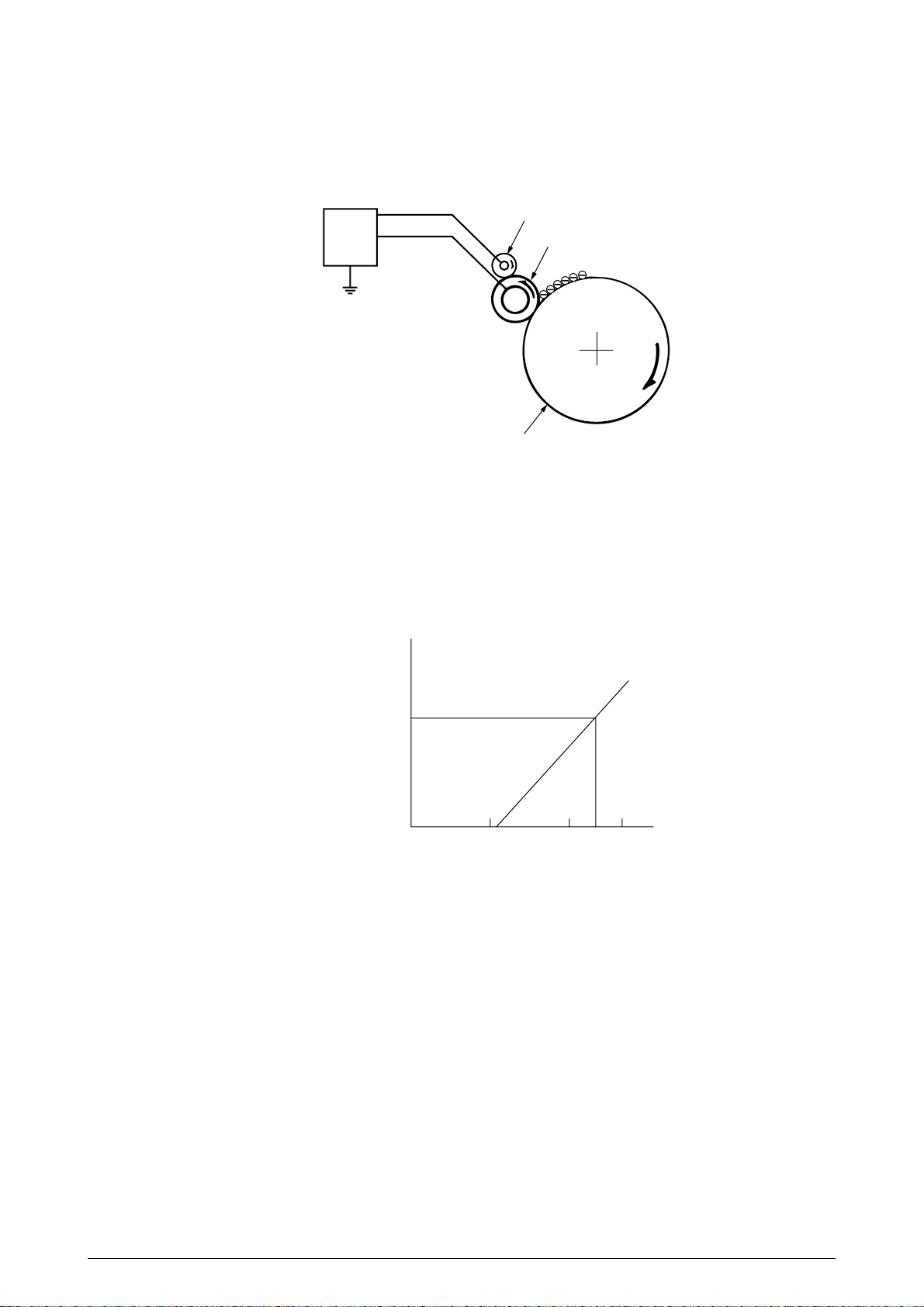

(3) Exposure

Light emitted by the LED head irradiates the image drum surface with a negative charge. The

surface potential of the irradiated portion of the image drum drops, forming an electrostatic latent

image associated with the image signal.

LED head

Charge roller

Power

supply

Paper

Image drum

LED head

Image drum

The image drum is coated with an underlayer (UL), a carrier generation layer (CGL), and carrier

transfer layer (CTL) on aluminum base. The organic photo conductor layer (OPC), comprising CTL

and CGL, is about 20 µm thick.

20

30mm

Image drum

CTL

CGL

UL

Base

µ

m

41356901TH Rev.2 30 /

Page 31

The image roller surface is charged to about –750 V by the contact charge of the charge roller.

When the light from the LED head irradiates the image drum surface, the light energy generates

positive and negative carriers in the CGL. The positive carriers are moved to the CTL by an electrical

field acting on the image drum. Likewise, the negative carriers flow into the aluminum layer (ground).

The positive carriers moved to the CTL combine with the negative charges on the image drum

surface accumulated by the contact charge of the charge roller, lowering the potential on the image

drum surface. The resultant drop in the potential of the irradiated portion of the image drum surface

forms an electrostatic latent image on it. The irradiated portion of the image drum surface is kept

to about –100 V.

(V)

–750

Image drum

surface potential

–100

0

Charged part

Light

from

LED

Part

irradiated

by

LED

Charged

part

41356901TH Rev.2 31 /

Page 32

(4) Developing

Toner is attracted to the electrostatic latent image on the image drum surface, converting it into a

visible toner image. Developing takes place through the contact between the image drum and the

developing roller.

1 As the toner supply roller rotates while rubbing on the developing roller, a friction charge is

generated between the developing roller and the toner, allowing the toner to be attracted to the

developing roller (the developing roller surface is charged positive and the toner, negative).

Doctor blade

Charge roller

Developing roller

Image drum

Toner supply roller

2 The toner attracted to the developing roller is scraped off by the doctor blade, forming a thin coat

of toner on the developing roller surface.

3 Toner is attracted to the exposed portion (low-potential part) of the image drum at the contact

of the image drum and the developing roller, making the electrostatic latent image visible.

-300V

Developing roller

+

–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–+–

+++++++++++++++++++++++

-750V -100V -750V -750V

Toner

Image drum

Exposed

part

An illustration of activities at the contact point of the image drum surface and

the developing roller (arrow marks denote the direction of the electrical field).

41356901TH Rev.2 32 /

Exposed

part

-100V

Page 33

Note:

The bias voltage required during the developing process is supplied to the toner supply roller and the

developing roller, as shown below. –500 VDC is supplied to the toner supply roller, –265 VDC to the

developing roller.

Connected and bias supplied

when the cover is closed.

Developing roller

Base

Image drum

Toner supply roller

41356901TH Rev.2 33 /

Page 34

(5) Transfer

The transfer roller is composed of conductive sponge material, and is designed to get the image

drum surface and the paper in a close contact.

Paper is placed over the image drum surface, and the positive charge, opposite in polarity to that

of the toner, is applied to the paper from the reverse side.

The application of a high positive voltage from the power supply to the transfer roller causes the

positive charge inducement on the transfer roller surface, transferring the charge to the paper as

it contacts the transfer roller. The toner with negative charge is attracted to the image drum surface,

and it is transferred to the upper side of the paper due to the positive charge on the reverse side of

the paper.

Image drum

Transfer roller

Paper

Power

supply

41356901TH Rev.2 34 /

Page 35

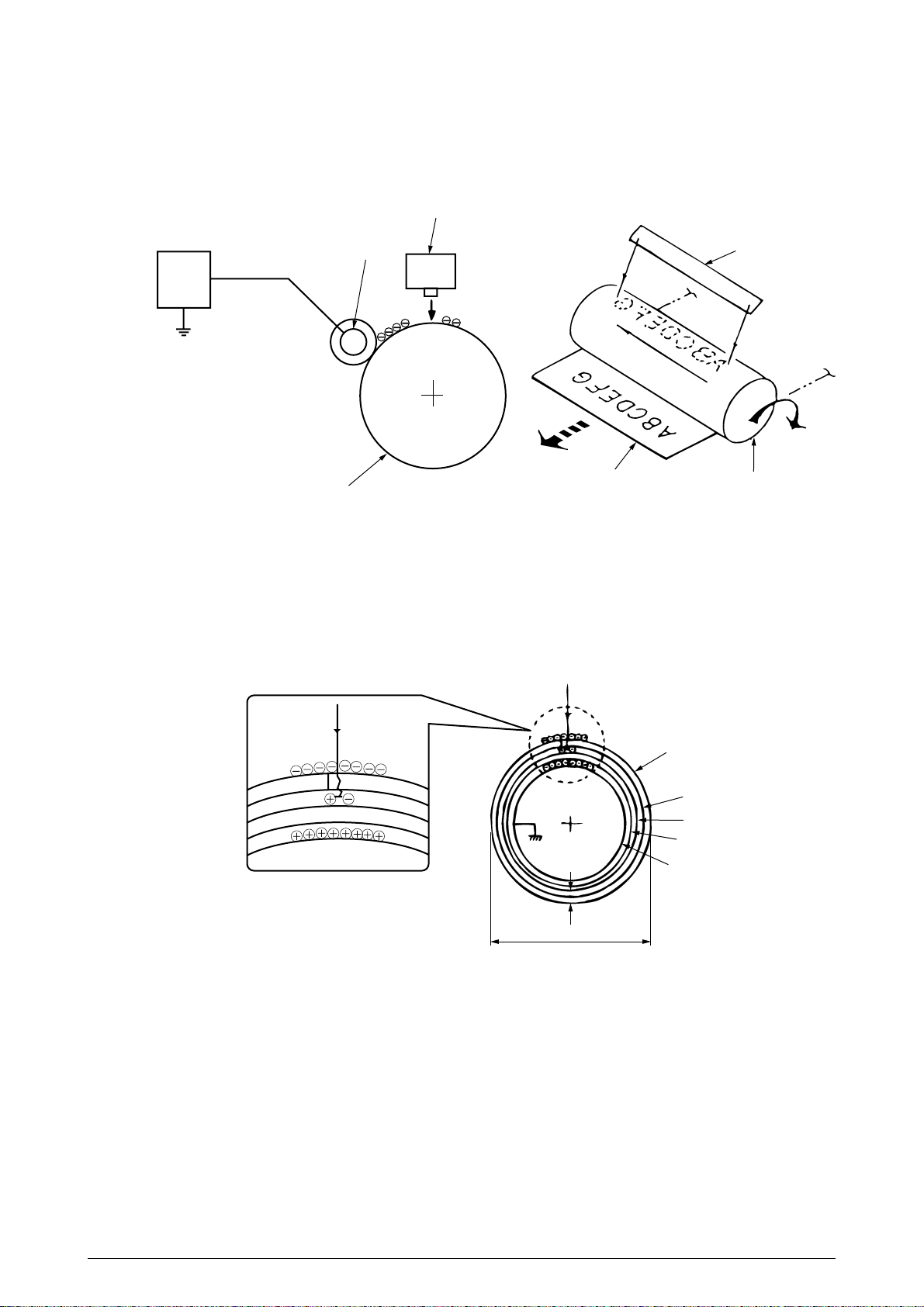

(6) Fusing

When the transfer is completed, the toner image is fused to the paper by heat and pressure as the

paper with unfused toner image passes between the heater roller and the back-up roller. The heater

roller with Teflon coating incorporates a 550W heater (Halogen lamp), which generates heat.

A thermistor which is in contact with the heater roller regulates the temperature of the heater roller

to a designated temperature in the menu, depending on the thickness of the paper (tray 1&2:

light=175~185°C, medium light=180~190°C, medium=185~195°C, medium heavy and

heavy=195~205°C/manual feeding and power envelope feeder: light=165~180°C, medium

light=170~185°C, medium=175~190°C, midium heavy=180~195°C, heavy=190~205°C, transparency = 170~185°C). A safety thermostat cuts voltage supply to the heater off by opening the

thermostat in the event of abnormal temperature rises.

The back-up roller is held under a pressure of 3.76 kg applied by the pressure spring on each side.

Separation claw

Paper

Heater

Heater roller

Thermistor

Back-up roller

Pressure Spring

41356901TH Rev.2 35 /

Page 36

(7) Cleaning

When the transfer is completed, the residual toner left on the image drum is attracted to the cleaning

roller temporarily by static electricity, and the image drum surface is cleaned.

Image drum

Cleaning roller

Power

supply

+DC

Transfer roller

(8) Cleaning of rollers

The charge, transfer and cleaning rollers are cleaned for the following cases:

• Warming up when the power is turned on.

• Warming up after the opening and closing of the cover.

• When the number of sheets accumulated reaches 14 or more.

• When the print out operation ends.

Changes in bias voltage applied to each roller move the attaching toner off the roller to the image

drum and return it to the developer.

41356901TH Rev.2 36 /

Page 37

2.3.4 Revision of LED Head Illumination

An LED correcting head, which is capable of correcting the illumination of the LED for each dot, is being

used in this printer. LED illumination correction function of 16 steps is carried out by using an EEPROM

which is installed in the LSI that maintains the LED illumination correction values, and an LED correction

drivers together as a pair.

The printing and correction data obtained from the CPU through four signal lines are sent to the LED

array.

The printing operation timing chart is shown below.

CLOCKI

LOADI

DATAI3~0

STRB1I-N

Normal Mode Printing Timing Chart

STRB2I-N

STRB3I-N

STRB4I-N

First line printing data sent Second line printing data sent

First line printing

The printing operation is carried out in normal mode. Under ordinary circumstances such as when the

power is turned on or when LOADI signal level is low, the normal mode is enabled.

The printing operation is carried out in the following sequence. First, the printing data DATAI3 through

DATAI0 are stored, sequentially shifted, in the shift registers of the LED drivers, by the printing data

synchronous clock, CLOCKI. Then the printing data stored in shift registers are latched by the high level

pulse of LOADI. The latched printing data turns the LEDs on by STRB1I-N through STRB4I-N and

actuates printing.

41356901TH Rev.2 37 /

Page 38

2.4 Paper Jam Detection

The paper jam detection function monitors the paper condition when the power is turned on and during

printing. When any of the following conditions arises, this function interrupts the printing process. If any

of the following errors is encountered, printing can be recovered by removing the jammed paper (by

opening the upper cover, removing the jammed paper and closing the upper cover).

Error Cause of error

Paper input jam

Paper feed jam

Paper exit jam

Paper size error

Main (drum) motor

• The paper is in contact with the inlet sensor when the power is turned on.

• After hopping operation is attempted three times, the leading edge of the paper does not reach

the inlet sensor.

• The paper is in contact with the paper sensor when the power is turned on.

• The leading edge of the paper does not reach the paper sensor within a predetermined feeding

distance since the paper has reached the inlet sensor.

• The trailing edge of the paper does not pass over the paper sensor within a predetermined

feeding distance after the same has passed over the inlet sensor.

• The leading edge of paper does not reach the outlet sensor within a predetermined feeding

distance after the paper has reached the paper sensor.

• The paper is in contact with the outlet sensor when the power is turned on.

• The paper does not pass over the outlet sensor within a predetermined feeding distance after

the leading edge of the paper has reached the outlet sensor.

• The paper size check for manual feeding finds that the paper size is free size.

• The size of the paper is monitored by the inlet sensor 1. The paper is not detected by the inlet

sensor 1 within predetermined feeding distance.

• The inlet sensor 2 detects that the size of the loaded paper is A4 or larger, or smaller than A4.

The detected paper size differs from the paper size set by command or menu.

• The paper size check for manual feeding finds that the paper size is free size.

Registration motor

Paper end sensor

Inlet sensor

Paper sensor

Outlet sensor

Jam Monitor

Top to top

Top to bottom

Top to bottom

Bottom to bottom

Checking for

paper form

Hopping

Monitoring

paper

input jam

Paper

feed

Paper size check

(paper width)

Monitoring

paper feed jam

Paper size check

(Paper length)

Monitoring

paper feed jam

Paper Feed Timing Chart

Paper

feed

Monitoring

paper

feed jam

Monitoring

paper exit jam

41356901TH Rev.2 38 /

Page 39

Paper Feed Check List

Type of error Monitor Standard value

Plus

Error

Minus

Paper feed error

Paper feed jam

Paper feed jam

Paper size error

Paper exit jam

Paper feed jam

Note:

Paper Length List

Hopping start

In sensor on

Write sensor on

In sensor on

Out sensor on

In sensor off

to

In sensor on

to

Write sensor on

to

Out sensor on

to

Out sensor on

to

Out sensor off

to

Write sensor Off

Depends on the paper length

Depends on the paper length

Hyphen "-" in the table represents "not checked."

Type Paper length

A4

A5

B5

LETTER

LEGAL 13

LEGAL 14

EXEC

A6

Monarch

COM-9

COM-10

DL

C5

Free

297.0

210.0

257.0

279.4

330.2

355.6

266.7

148.0

190.5

225.4

241.3

220.0

229.0

110.1~355.6

72.0

20.0

140.5

22.2

Check range

Min Max

252.0

165.0

212.0

234.4

285.2

310.6

221.7

103.0

145.5

180.4

196.3

175.0

184.0

65.0

342.0

255.0

302.0

324.4

375.2

400.6

311.7

193.0

235.5

270.4

286.3

265.0

274.0

400.6

Unit : mm

36.0

68.0

25.0

45.0

45.0

22.0

–

–

–

45.0

45.0

–

Unit : mm

41356901TH Rev.2 39 /

Page 40

2.5 Cover Open

When the stacker cover is opened, the cover open microswitch on the power supply/sensor board is

turned off to cut +5V supply to the high voltage power supply circuit. This results in the interruption of all

high-voltage outputs. At the same time, the CVOPN signal is sent to the main control board to notify that

the microswitch is off, and the main control board carries out the cover open process.

41356901TH Rev.2 40 /

Page 41

2.6 Toner Low Detection

• Device

The Toner Low Detection device consists of a stirring gear which rotates at a constant rate, a stirring

bar and a magnet on the stirring bar. The stirring bar rotation is driven by the link to the gouged portion

in the stirring gear.

Magnet Gouged

Stirring Bar Stirring Gear

• Operation

Toner Low is detected by monitoring the time interval of the encounter of the magnet set on

the sensor plate and the magnet on the stirring bar.

portion

Operation during Toner Full state

• The stirring bar rotates due to the mechanical

transmission of energy originating from the interlocking with the stirring gear.

• Even when the magnet on the stirring bar reaches

the maximum height, the stirring bar is pushed by

the stirring gear, since the other side is being

dipped in the toner.

Operation during Toner Low state

• When the stirring bar reaches the maximum height,

it falls to the minimum height due to its own weight,

since there is no resistance provided by the toner

on the other side. Because of this, the time interval

during which it is in encounter with the magnet of

the sensor plate becomes longer. By monitoring

this time interval, Toner Low state can be detected.

Stirring Gear Section

Stirring Bar

Sensor Plate

Toner Sensor

Stirring Bar

Sensor Plate

41356901TH Rev.2 41 /

Page 42

TONER FULL state

TNRSNS-N

TONER LOW state

TNRSNS-N

160 ms < t1 < 0.5 sec

t1

1.7564 sec.

t1 > 0.5 sec.

t1

1.7564 sec.

• When the Toner Low state is detected 2 times consecutively, Toner Low is established.

• When the Toner Full state is detected 2 times consecutively, Toner Low is cancelled.

• When there is no change with the toner sensor for 2 cycles (1.7564 sec. × 2) or more, then the Toner

Sensor Alarm is activated.

• The toner sensor is not monitored while the main (drum) motor is in a halt.

41356901TH Rev.2 42 /

Page 43

3. PARTS REPLACEMENT

The section explains the procedures for replacement of parts, assemblies, and units in the field. Only

the disassembly procedures are explained here. For reassembly, reverse the disassembly procedure.

3.1 Precautions for Parts Replacement

(1) Before starting to replace parts, remove the AC cord and interface cable.

(a) Remove the AC cord in the following sequence:

i) Turn off (“o”) the power switch of the printer

ii) Disconnect the AC inlet plug of the AC cord from the AC receptacle.

iii) Disconnect the AC cord and interface cable from the printer.

(b) Reconnect the printer in the following procedure.

i) Connect the AC cord and interface cable to the printer.

ii) Connect the AC inlet plug to the AC receptacle.

iii) Turn on (“l”) the power switch of the printer.

Disconnect

OFF

ON

(2) Do not disassemble the printer as long as it is operating normally.

(3) Do not remove parts which do not have to be touched; try to keep the disassembly to a minimum.

(4) Use specified service tools.

(5) When disassembling, follow the laid out sequences. Parts may be damaged if these sequences are

not followed.

(6) Since screws, collars and other small parts are likely to be lost, they should temporarily be attached

to the original positions during disassembly.

(7) When handling IC’s such as microprocessors, ROMs and RAMs, or circuit boards, do not wear

gloves that are likely to generate static electricity.

Reconnect

(8) Do not place printed circuit boards directly on the equipment or floor.

41356901TH Rev.2 43 /

Page 44

[Service Tools]

The tools required for field replacement of printed circuit boards, assemblies and units are listed in Table

3-1.

Table 3-1 Service Tools

No. Q' ty Application RemarksService Tools

1

2

3

4

5

6

7

8

No. 1-100 Philips screwdriver

No. 2-100 Philips screwdriver

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

Handy cleaner

LED Head cleaner

1

2~2.5 mm screws

1

3~5 mm screws

1

1

1

1

1

1

Cleans LED head

41356901TH Rev.2 44 /

Page 45

3.2 Parts Layout

This section explains the layout of main components of the equipment.

[Lower base unit]

Eject roller assy

Diselectrification bar

Spacer bearing L

Stacker cover assy

Back-up roller

View A

Transfer roller

Registration

roller Assy

Pulse motor

(main/drum)

Pulse motor

(registration)

Spacer bearing R

Fusing unit

Lower base unit

Stacker cover assy

LED head

View A

Manual feed guide assy

Toner cartridge (Type 5)

(consumable)

Hopping roller shaft

Hopping roller rubber

Image drum unit (Type 8)

(consumable)

Figure 3-1

41356901TH Rev.2 45 /

Page 46

[Upper cover unit]

Upper Cover

Figure 3-2

41356901TH Rev.2 46 /

Page 47

[Base unit]

Operator panel assy

Power supply/

sensor board

(Low voltage)

High voltage unit /

sensor board

Face up stacker assy

Cassette guide (L) Assy

DC fan assy

Main control board

Cassette guide (R) Assy

Paper cassette

Figure 3-3

41356901TH Rev.2 47 /

Page 48

3.3 How to Change Parts

This section explains how to change parts and assemblies listed in the disassembly diagram below.

In the parts replacement procedure, those parts marked with the part number inside ● with white letters

are RSPL parts.

Printer unit Upper cover assy

(3.3.1)

LED head

(3.3.3)

Transfer roller

(3.3.13)

1

2

Hopping roller shaft assy

(3.3.10)

Stacker cover assy

(3.3.11)

Registration roller

(3.3.12)

Power supply/sensor board,high voltage unit

and contact assy

(3.3.21)

Operator panel assy

(3.3.3)

Manual feed guide assy

(3.3.18)

Fusing unit

(3.3.14)

Back up roller

(3.3.15)

Cassette guide (L)

(3.3.22)

Cassette guide (R)

(3.3.23)

Face up stacker assy

(3.3.7)

Lower base unit

(3.3.4)

Pulse motor (main/drum)

(3.3.5)

Pulse motor (registration)

(3.3.6)

Eject roller assy

(3.3.8)

Motor assy

(3.3.9)

Sensor plate (inlet)

(3.3.16)

Sensor plate (outlet),

sensor wire Assy

(3.3.17)

Sensor plate (paper supply)

(3.3.19)

M7E-PCB

(3.3.20)

Spacer bearing (L/R)

(3.3.24)

To

To

1

2

41356901TH Rev.2 48 /

Page 49

3.3.1 Upper Cover Assy

(1) With the power switch turned off, unplug the AC power cord from the outlet.

(2) Disconnect the interface cable 1.

(3) Press the knobs 2 on left and right sides and open the stacker cover assy 3.

(4) Take out the image drum unit 4.

(5) Remove two screws 5, and open the manual feed guide assy 6. Lift the front side of the upper

cover 7 up and unlock the latches at two locations on the back side. Lift and remove the upper cover

assy 7.

Note : 1.

2.

When removing or reinstalling the upper cover, be careful not to get the motor cables

tangled or caught.

When reinstalling the screws 5, be sure to direct the screws into preexisting threads.

5

7

1

3

2

4

2

6

41356901TH Rev.2 49 /

Page 50

3.3.2 LED Head

(1) Press the knobs on left and right sides and open the stacker cover assy 1.

(2) Open the hook section on the left side of the stacker cover and remove the LED head 2.

Note:

• Be sure not to touch directly or push on the SLA part of the LED head.

• Do not remove the LED cable 3 from the connector.

• Remove connector 4 and cable 3 together as an assembly from the LED head.

SLA

(Seltoc Lens Array)

4

3

1

SLA

2

41356901TH Rev.2 50 /

Page 51

3.3.3 Operator Panel Assy

(1) Unlock two latches on the upper cover from the rear side, lift the operator panel assy 1 from the

back and remove it.

(2) Remove the Sumi card (operator panel) 2 from the connector (CN1) 3.

Note :

You can remove the operator panel assy while the upper cover installed on the unit. However,

it is much easier to remove the panel assy after removal of upper cover.

Rear view

2

Unlock two latches with a tip of

screw driver. For the purpose,

insert a driver through faceup

paper outlet as shown.

1

3

41356901TH Rev.2 51 /

Page 52

3.3.4 Lower Base Unit

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the connecting cables 2 and 3 of the pulse motors from the connectors (DM, RM) of the

M7E-PCB 1.

(5) Remove the LED head cables 4 and 5 from the connectors (HEAD1, HEAD2).

(6) Remove the connecting cable 8 of the heater from the connector (CN2).

(7) Open the manual feed guide assy, remove six screws 7, then remove the lower base unit 6.

7

7

8

7

1

5

7

6

4

2

3

41356901TH Rev.2 52 /

Page 53

3.3.5 Pulse Motor (Main/Drum)

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the lower base unit (see 3.3.4).

(3) Remove two screws 1 and remove the pulse motor (main/drum) 2 from the motor bracket 3.

View A

3

1

View A

1

2

41356901TH Rev.2 53 /

Page 54

3.3.6 Pulse Motor (Registration)

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the lower base unit (see 3.3.4).

(3) Remove two screws 1 and remove the pluse motor (registration) 2 from the motor bracket 3.

View A

3

1

View A

1

2

41356901TH Rev.2 54 /

Page 55

3.3.7 Face Up Stacker Assy

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the screw 1 and remove the Sumi card (operator panel cable) 2 off the latch section of

face up stacker Assy 4. Remove both the shield plate 3 and face up stacker together.

(4) Unlock the latches at two locations, and remove the face up stacker.

2

4

3

1

41356901TH Rev.2 55 /

Page 56

3.3.8 Eject Roller Assy

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Disengage the eject roller assy 1 from the lower base 2 by pressing the latch section of the eject

roller assy 1 in the direction of the arrow shown below, and remove the eject roller assy 1.

1

LATCH

2

41356901TH Rev.2 56 /

Page 57

3.3.9 Motor Assy

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Remove the heat sink from the pulse motor (main/drum) (see 3.3.5).

(6) Stand the lower base unit on its side as shown, and unlock two latches, then remove the motor assy

1.

1

41356901TH Rev.2 57 /

Page 58

3.3.10 Hopping Roller Shaft Assy

(1) Remove the upper cover (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Remove the motor assy (see 3.3.9).

(6) With the lower base unit 1 standing on its side, remove the one-way clutch gear 2 and the bearing

(A) 3.

(7) Remove the hopping roller shaft assy 4 (the bearing (B) 5 comes off, so be careful not to lose it).

2

3

1

4

5

41356901TH Rev.2 58 /

Page 59

3.3.11 Stacker Cover Assy

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the reset lever R 1.

(5) Detach the reset spring 2 from the lower base unit 3, turn the reset lever L 4 in the direction of

arrow A until it stops, and remove it in the direction of arrow B .

(6) Unlock two latches of the lower base unit 3, then remove the stacker cover assy 5.

Note :

When reinstalling the reset lever L 4, fit it onto the guide of the lower base unit 3, turn it in the

direction of arrow C while pressing down the shaft of back up roller, and engage the reset lever

L 4.

5

A

4

1

C

A

2

3

B

4

41356901TH Rev.2 59 /

Page 60

3.3.12 Registration Roller

(1) Remove the upper cover (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Remove the motor assy (see 3.3.9).

(6) With the lower base unit standing on its side, remove the one-way clutch gear 1 and the bearing 9.

(7) Remove the Registration Gear by unlocing latch of the Gear 4 .

(8) Remove the Registration Bearing(L) 3 .

(9) Press the registration roller Assy 2 in the direction of arrow A and lift up the left side of it, then

remove the registration roller Assy 2 .

(10)Pull out the registration roller Assy 2 in the direction of arrow B .

(11)Remove the pressure roller gear 5 by unlockin the lach of the gear 5 .

(12)Remove the bearing-Registration L 6 and besring-Registration R 7.

(13)Remove the spring 8 from the bearing 6 , 7 .

8

8

2

7

5

6

3

4

1

9

View A

View A

B

A

2

41356901TH Rev.2 60 /

Page 61

3.3.13 Roller Transfer Assy

(1) With the power switch turned off, unplug the AC cord from the outlet.

(2) Open the stacker cover.

(3) Release the roller transfer assy 1 by unlocking the latch of the main unit (never apply excessive

force when unlocking the latch).

(4) Lift the right side of the roller transfer assy 1, and shift it to the right side, then pull it out from the

main unit (at this time, the bearings 2 of the left and right sides of the roller transfer assy 1 will also

come off).

2

1

1

Unlock

1

41356901TH Rev.2 61 /

Page 62

3.3.14 Fusing Unit

(1) Remove the upper cover (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Remove the stacker cover assy (see 3.3.11).

(6) Remove four screws 1, lift and remove the fusing unit 2.

Caution: Fusing unit may be hot. Use care when handling.

Note : 1.

2.

3.

When reinstalling or removing the fusing unit, tighten or loosen the screws while holding

the fusing unit assy 2 down with your hand (it is being pushed up by back up roller).

When reinstalling the screws 1, be sure to direct the screws into preexisting thread and

avoid damaging the threads.

Do not apply excessive torque when tightening the screws 1.

1

2

1

41356901TH Rev.2 62 /

Page 63

3.3.15 Back-up Roller

(1) Remove the fusing unit assy (see 3.3.14).

(2) Lift the left side of the back-up roller 1, and pull it out to the left side (at this time, two bearing holders

(back-up) 2 and the bias springs (back-up) 3 and the two ball-bearing 4, washer B 5, washer

C 6 will also come off).

4

2

5

3

1

3

2

4

6

41356901TH Rev.2 63 /

Page 64

3.3.16 Sensor Plate (Inlet)

(1) Remove the upper cover (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Press the clamps of three sensor plates (inlet and paper) 1, and remove them by pressing them

upward from the bottom.

1

Sensor plate (paper)

1

Sensor plate (inlet)

1

Sensor plate (inlet)

41356901TH Rev.2 64 /

Page 65

3.3.17 Sensor Plate (Outlet), Sensor Wire Assy

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the eject roller assy (see 3.3.8).

(4) Remove the face up stacker assy (see 3.3.7).

(5) Remove the lower base unit (see 3.3.4).

(6) Remove the fusing unit assy (see 3.3.14).

(7) Press the clamps of the sensor plate (outlet) 1, and remove the sensor plate by pushing it up.

(8) Turn the clamps of the sensor wire assy 2 remove the sensor wire assy from the lower base unit.

1

2

1

2

41356901TH Rev.2 65 /

Page 66

3.3.18 Manual Feed Guide Assy

(1) Remove the upper cover assy (see 3.3.1).

(2) Open the manual feed guide assy 1, and release the engagement on both sides with the main unit

by carefully bending the manual feed guide assy 1.

Note :

When remounting, verify the proper the engagements as shown in the diagram.

Put the post into the groove.

Put the post into the groove.

1

41356901TH Rev.2 66 /

Page 67

3.3.19 Sensor Plate (Paper Supply)

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Press the clamps of the sensor plate (paper supply) 1 to unlock the latch, and remove it from the

base plate 2.

1

1

View A

View A

2

41356901TH Rev.2 67 /

Page 68

3.3.20 M7E-PCB

3

4

2

8

1

7

6

8

1

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the operator panel assy (see 3.3.3).

(3) Remove the face up stacker assy (see 3.3.7).

(4) Remove the lower base unit (see 3.3.4).

(5) Remove the connector (2NDTRAY) 6.

(6) Remove three screws 1.

(7) Move the M7E-PCB 2 in the direction of arrow to disconnect it from the power supply/sensor board

3.

(8) Remove the connector FAN, and disconnect the fan motor 4.

(9) Remove the M7E-PCB 2, together with the PCB guide plate (remove the fan motor 4 at the same

time).

(10)

Remove three screws 8 and remove the PCB guide plate 7 from the M7E-PCB 2.

Note :

When reinstalling the M7E-PCB 2 onto the guide plate 7, be careful not to bend the base plate

(it is desirable to place a block underneath it to prevent bending).

41356901TH Rev.2 68 /

Page 69

3.3.21 Power Supply/Sensor Board, High Voltage Unit and Contact Assy

(1) Remove the upper cover assy (see 3.3.1).

(2) Remove the lower base unit (see 3.3.4).

(3) Remove the M7E-PCB (See 3.3.20).

(4) Remove the AC inlet 1 from the base plate 2.

(5) Remove the screw 3 and remove the grounding (earth) wire 4.

(6) Remove the Ferite core 9 from the grounding wire.

(7) Remove nine screws 5, and remove the power supply/sensor board 6 and contact assy 7

together.

(8) Unlock two latches 8, and remove contact assy 7 from the power supply/sensor board 6.

(9) Remove the Insulation plate 0 from the base plate 2.

Note : 1.

2.

3.

Be careful about the sensor (paper supply) when reinstalling the lower base.

Make sure that no excessive force is applied to the power supply switch.

When installing the power supply/sensor onto the base plate, be careful not to bend the

base plate (it is desirable to place a block underneath it to prevent bending).

7

View A

5

1

5

5

5

9

5

View A

8

6

3

0

4

2

41356901TH Rev.2 69 /

Page 70

3.3.22 Cassette Guide L Assy

(1) Remove the paper cassette.

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the lower base unit (see 3.3.4).

(4) Remove the M7E-PCB (see 3.3.20).

(5) Remove the power supply/sensor board (see 3.3.21).

(6) Remove two screws 1, and remove the guide rails 2.

(7) Remove the screw 3, and remove the cassette guide L Assy 9 by shifting it in the direction of the

arrow as shown below.

(8) Remove cassette lock lever 4 and torsion spring 5.

(9) Remove cassette lock lever spring 8 then remove the sheet link (L) 6 and Pull block 7.

3

4

5

7

8

9

6

2

1

41356901TH Rev.2 70 /

Page 71

3.3.23 Cassette Guide R Assy

(1) Remove the paper cassette.

(2) Remove the upper cover assy (see 3.3.1).

(3) Remove the lower base unit (see 3.3.4).

(4) Remove the M7E-PCB (see 3.3.20).

(5) Remove two screws 1, and remove the guide rails 2.

(6)

Remove the screw 3, and remove the cassette guide R Assy 4 by shifting it in the direction of arrow.

(7) Remove the cassette lock lever 5 and torsion spring 6.

(8)

Remove the cassette lock lever spring 9, then remove the sheet link (R) 7 and link pull block 8.

(9) Remove two screws 0, and remove the square-shaped connector A.

3

8

5

6

9

7

4

A

1

2

0

1

41356901TH Rev.2 71 /

Page 72

3.3.24 Spacer Bearing (L/R)

(1) Remove the back-up roller (see 3.3.15).

(2) Remove spacer bearing (L/R) with a tip of screw driver.

Spacer bearing L Spacer bearing R

41356901TH Rev.2 72 /

Page 73

4. ADJUSTMENT

This chapter provides explanations concerning the adjustment necessary when replacing a part. The

adjustment is made by changing the parameter value set in EEPROM on the main control board. The

parameter can be set by the key operation from the operator panel. This printer has three kinds of

maintenance modes, and it is necessary to select one of the modes when replacing any parts.

4.1 Maintenance Modes and Functions

4.1.1 User Maintenance Mode

To enter into the user maintenance mode, turn the POWER switch on while holding the MENU key down.

Function

There are thirteen functions as follows:

• Menu reset(See Table 4-1) • Opepane menu disable

• Hex dump • X-adjust

• Drum counter reset • Y-adjust

• Recieve buffer • 2nd Tray

• ECP disable • Place page command

• Setting

• Jam Recovery (Print Performance for continuous)

• Power Save disable

Detailed descriptions of these functions are provided in Appendix E, DIAGNOSTICS TEST.

4.1.2 System Maintenance Mode

Note:

To enter into the system maintenance mode, turn the POWER switch on while holding the

down.

Function

There are seven functions as follows:

• Page count display • Loop test

• Page count printing enable/disable • EEPROM reset (See Table 4-1)

• Rolling ASCII continues printing • SIDM enable/ disable

Detailed descriptions of these functions are provided in Appendix E, DIAGNOSTICS TEST.

This mode is used only by maintenance personnel and it should not be released to the endusers.

• DRAM Memory Check mode

Recover

key

41356901TH Rev.2 73 /

Page 74

4.1.3 Engine Maintenance Mode

Note:

This mode is used only by maintenance personnel, and it should not be released to the end

users.

(1) To enter into the engine maintenance mode, turn the power on while holding ENTER and FORM

FEED keys down.

(2) Functions of this mode are selected by the menu.

(3) The way to exit out of this mode varies depending on the settings.

(4) There are following engine maintenance modes:

a) Head drive time setting

Sets the drive time of the LED head.

b) 600 x 1200 DPI strobetime relative value.

c) Installed LED head indentification.

d) Printing start position setting

Sets the starting position of printing.

e) Drum count total display

The total image drum rotation count of the printer, as counted by the engine section, is displayed

on the LCD.

f) Drum count display

The total image drum rotation count, as counted by the engine section, is displayed on the LCD.

g) Standard tray paper feeding quantity setting

Sets the amount of paper to be fed from the standard tray.

h) High Capacity Second Paper Feeder paper feeding quantity setting

Sets the amount of paper to be fed from High Capacity Second Paper Feeder.

i) High Capacity Second Paper Feeder downloading table selection

Selects the downloading table of High Capacity Second Paper Feeder.

j) Power Envelope Feeder paper feeding quantity setting

Sets the amount of paper to be fed from Power Envelope Feeder.

k) Power Envelope Feeder downloading table selection

Selects the downloading table of Power Envelope Feeder.

l) Engine Test

m) Engine Reset

All EEPROM areas used by the engine section are reset to factory default values.

(See Table 4-1)