P

REFACE

Every effort has been made to ensure that the information in this document is complete,

accurate, and up-to-date. The manufacturer assumes no responsibility for the results of

errors beyond its control. The manufacturer also cannot guarantee that changes in software

and equipment made by other manufacturers and referred to in this guide will not affect

the applicability of the information in it. Mention of software products manufactured by

other companies does not necessarily constitute endorsement by the manufacturer.

While all reasonable efforts have been made to make this document as accurate and helpful

as possible, we make no warranty of any kind, expressed or implied, as to the accuracy or

completeness of the information contained herein.

The most up-to-date drivers and manuals are available from:

http://www.okiprintingsolutions.com

07112301 iss.01; Copyright © 2010 Oki Europe Ltd. All rights reserved.

Oki is a registered trademark of Oki Electric Industry Company, Ltd.

Oki Printing Solutions is a trademark of Oki Data Corporation.

Energy Star is a trademark of the United States Environmental Protection Agency.

Microsoft, MS-DOS and Windows are registered trademarks of Microsoft Corporation.

Apple, Macintosh, Mac and Mac OS are trademarks of Apple Inc.

Other product names and brand names are registered trademarks or trademarks of their

proprietors.

As an Energy Star Program Participant, the manufacturer has determined that

this product meets the Energy Star guidelines for energy efficiency.

This product complies with the requirements of the Council Directives 2004/

108/EC (EMC), 2006/95/EC (LVD) and 2009/125/EC (ErP) as amended where

applicable on the approximation of the laws of the member states relating to

electromagnetic compatibility, low voltage and energy using products.

This product complies with EN55022 Class B. However, when fitted with the

optional network interface card, RS-232 C serial interface card or optional cutsheet feeder, compliance to EN55022 is class A. In a domestic environment

this configuration may cause radio interference, in which case the user may be

required to take adequate measures.

The following cables were used to evaluate this product to achieve EMC directive 2004/108/

EC compliance and configurations other than this may affect that compliance.

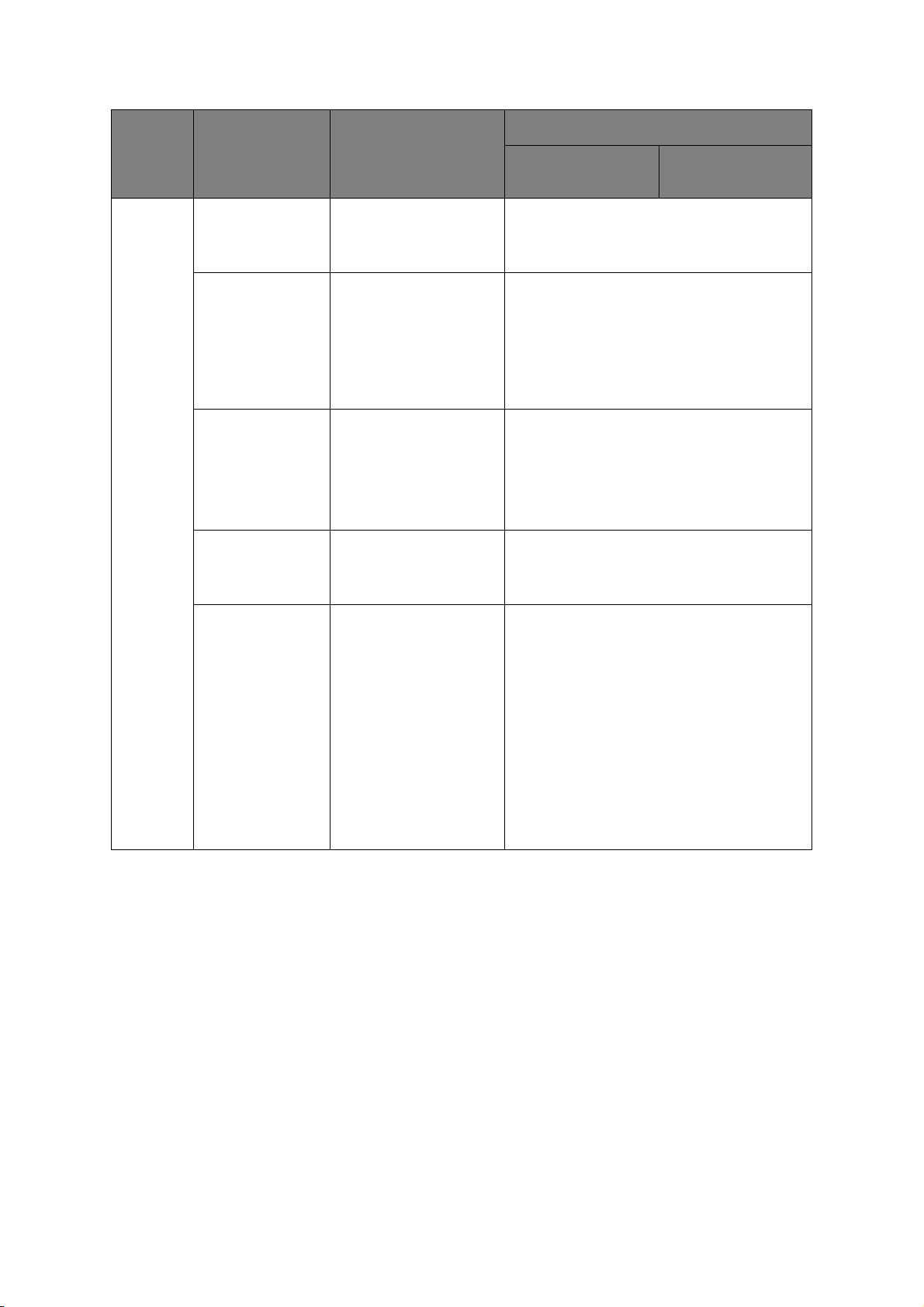

CABLE TYPE LENGTH

(METRE)

Power 1.8

USB 5.0

Serial 1.5

Parallel 5.0

CORE SHIELD

✘✘

✘ ✔

✘ ✔

✘✘

LAN 2.1

✘ ✔

Preface > 2

M

ANUFACTURER

Oki Data Corporation,

4-11-22 Shibaura, Minato-ku,

Tokyo 108-8551,

Japan

I

MPORTER TO THE

Oki Europe Limited (trading as Oki Printing Solutions)

Blays House

Wick Road

Egham

Surrey, TW20 0HJ

United Kingdom

For all sales, support and general enquiries contact your local distributor.

E

NVIRONMENTAL INFORMATION

EU/

AUTHORISED REPRESENTATIVE

Manufacturer > 3

C

ONTENTS

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Importer to the EU/authorised representative. . . . . . . . . . . . . . . . . . . . . . 3

Environmental information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Notes, cautions and warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

On-line usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Printing pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the ribbon cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ribbon cartridge handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Powering on your printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Powering off your printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Computer connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Parallel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Loading paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Printer drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Emulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Printing from the computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Oki DIPUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Controlling the printer using DIPUS . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Using your printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Components: Rear feed (continuous forms) . . . . . . . . . . . . . . . . . . . . . . .20

Components: Top feed (single sheets). . . . . . . . . . . . . . . . . . . . . . . . . . .20

Loading paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Rear feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Top feed (single sheets). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Top of form (TOF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Forms tear-off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Setting top of form (TOF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Temporarily changing the top of form . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Resetting top of form to the factory default . . . . . . . . . . . . . . . . . . . . . . .33

Forms tear-off feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Potential issues with software packages . . . . . . . . . . . . . . . . . . . . . . . .34

Changing the forms tear-off setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Manual forms tear-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Paper park . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Changing paper paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Continuous forms to single sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Single sheets to continuous forms . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Printhead gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Print quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Character pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Printer reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Changing emulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Contents > 4

Menu mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Menu mode keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Entering and exiting menu mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Resetting the menu to the factory defaults. . . . . . . . . . . . . . . . . . . . . .41

Printing the menu settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Printing all menu settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Changing the menu settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Menu settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Replacing the ribbon cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Ribbon cartridge handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Cleaning your printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Printer exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Cleaning the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Clearing paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Rear feed jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Rear feed, repeating paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Single sheet paper jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

General problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Parts and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Oki contact details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Contents > 5

N

OTES, CAUTIONS AND WARNINGS

NOTE

A note provides additional information to supplement the main text.

CAUTION!

A caution provides additional information which, if ignored, may

result in equipment malfunction or damage.

WARNING!

A warning provides additional information which, if ignored, may

result in a risk of personal injury.

For the protection of your product, and in order to ensure that you benefit from its full

functionality, this model has been designed to operate only with genuine original ribbon

cartridges. Any other ribbon cartridge may not operate at all, even if it is described as

“compatible”, and if it does work, your product's performance and print quality may be

degraded.

Use of non-genuine products may invalidate your warranty.

Specifications subject to change without notice. All trademarks acknowledged.

Notes, cautions and warnings > 6

I

NTRODUCTION

Congratulations on purchasing this printer!

This printer series is designed to provide highly reliable letter quality printing and high

resolution graphics for the desktop/office printing environment. It combines state-of-theart, 9-pin (ML5520ECO/ML5521ECO) and 24-pin (ML5590ECO/ML5591ECO), serial impact

dot matrix printing technology with advanced materials and superior construction to

provide high performance and versatility in a desktop sized unit. Careful attention to

ergonomics and application needs provides user friendly operation for operators of varying

technical capabilities.

A

BOUT THIS GUIDE

This manual is your user’s guide (check the web site, www.okiprintingsolutions.com, for the

most up-to-date version) for your printer and forms part of the overall user support listed

below:

> Installation Safety booklet: provides information as to safe use of the printer.

This is a paper document that is packaged with the printer and should be read before

setting up your printer.

> Set-up guide: to describe how to unpack, connect and turn on your printer.

This is a paper document that is packaged with the printer.

> This User’s Guide: to help you to become familiar with your printer and make the

best use of its many features. Also included are guidelines for troubleshooting and

maintenance to ensure that it performs at its best.

This is an electronic document stored on the manuals CD.

> Network Configuration Guide: to provide detailed technical information for

network administrators to configure the optional accessory network interface.

This is an electronic document stored on the CD that accompanies the network

interface card optional accessory.

> On-line Help: on-line information accessible from the printer driver and utility

software.

ON-

LINE USAGE

This guide is intended to be read on screen using an Adobe Acrobat Reader. Use the

navigation and viewing tools provided in Acrobat.

You can access specific information in two ways:

> In the list of bookmarks down the left hand side of your screen, click on the topic of

interest to jump to the required topic. (If the bookmarks are not available, use the

“Contents” on page 4.)

> In the list of bookmarks, click on Index to jump to the Index. (If the bookmarks are

not available, use the “Contents” on page 4.) Find the term of interest in the

alphabetically arranged index and click on the associated page number to jump to

the page containing the term.

Introduction > 7

P

RINTING PAGES

The whole manual, individual pages, or sections may be printed. The procedure is:

1. From the toolbar, select File, then Print (or press the Ctrl + P keys).

2. Choose which pages you wish to print:

(a) All pages, (1), for the entire manual.

(b) Current page, (2), for the page at which you are looking.

1

2

3

(c) Pages from and to, (3), for the range of pages you specify by entering their

page numbers.

3. Click on OK.

Introduction > 8

G

ETTING STARTED

L

OCATION

> Place your printer on a firm, solid surface.

> Allow enough space around the printer to easily access the platen knob and the

various paper feed paths.

> Make sure a suitable grounded power outlet is available nearby.

U

NPACKING

> If any items are missing, contact your dealer immediately.

> Keep your packing materials and carton in case you ever need to ship or transport

the printer.

> Interface cable and paper are sold separately.

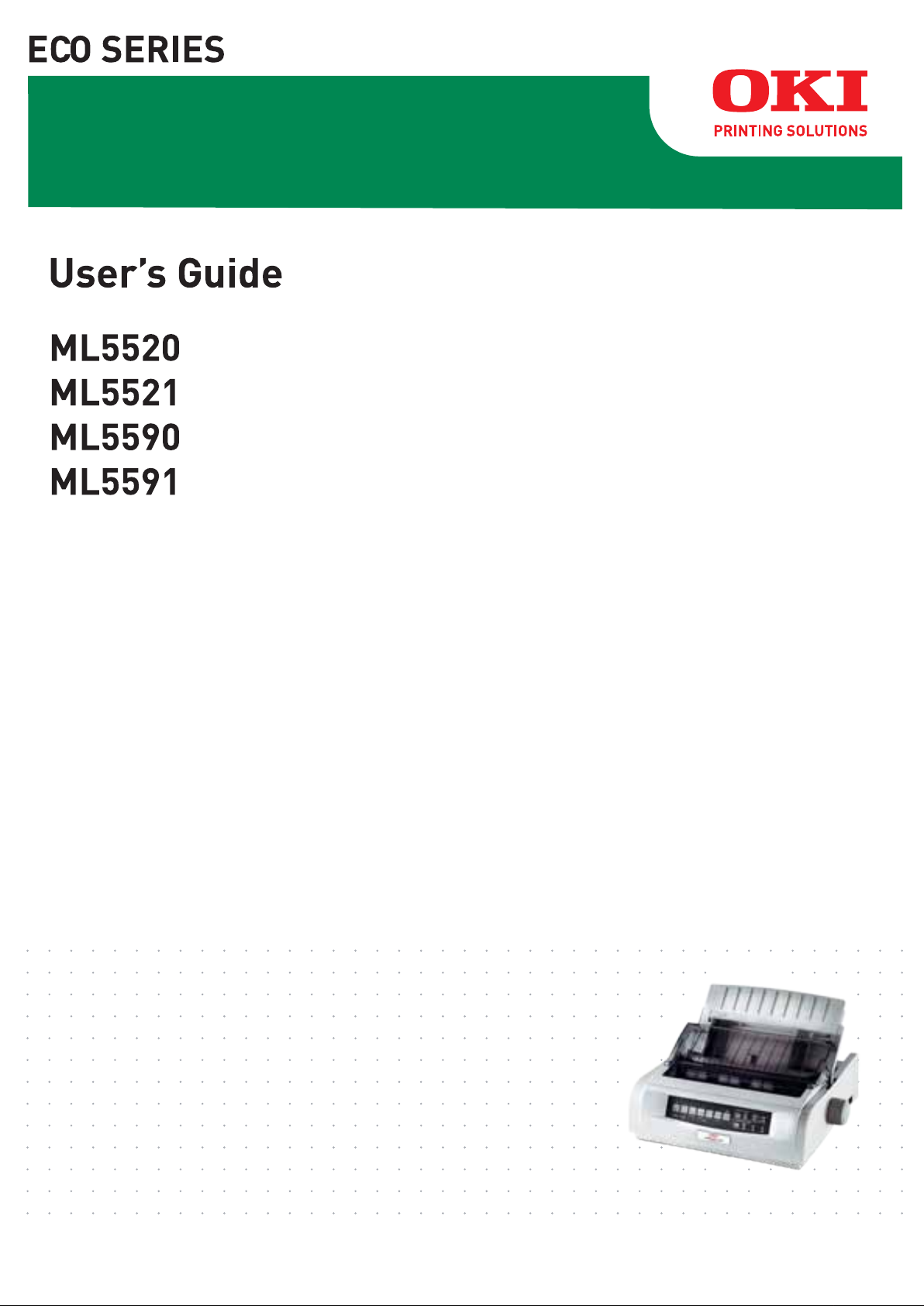

1. Printer

2. Ribbon Cartridge

3. Power Cord

1

2

3

1. Remove any packing tape, then grasp the tabs (1) at either end of the access cover

and pivot it towards the front of the printer as far as it will go.

1

2. Remove the printhead shipping restraint.

Getting started > 9

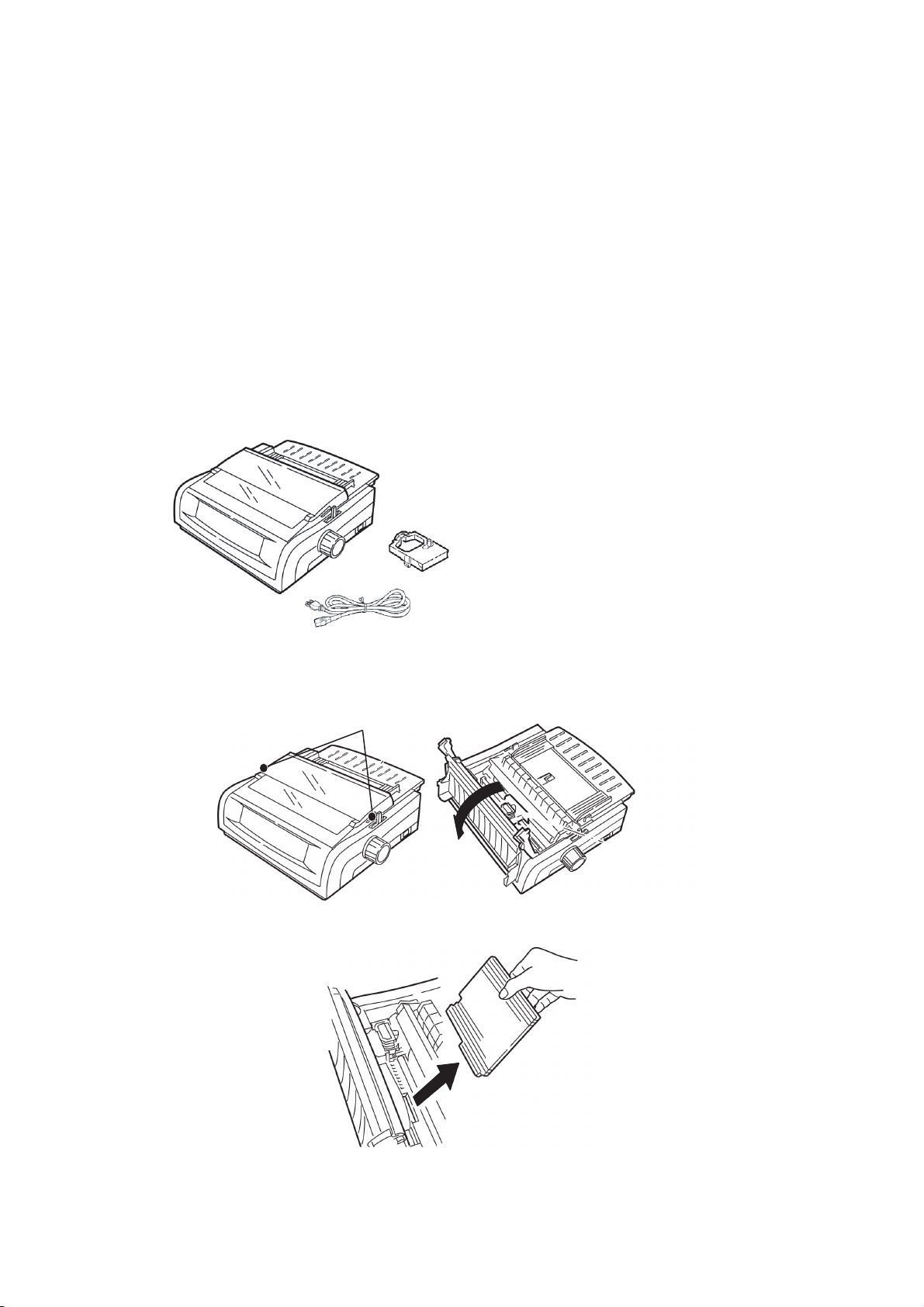

3. Remove the shipping restraint from the pull-up roller assembly (1).

1

4. Use the tabs (1) to lift and remove the sheet guide, then remove the shipping

restraint.

1

5. Reinstall the sheet guide: insert the clips on either side of the separator into the

notches marked with a triangle, then press down to secure the separator in place.

1

Getting started > 10

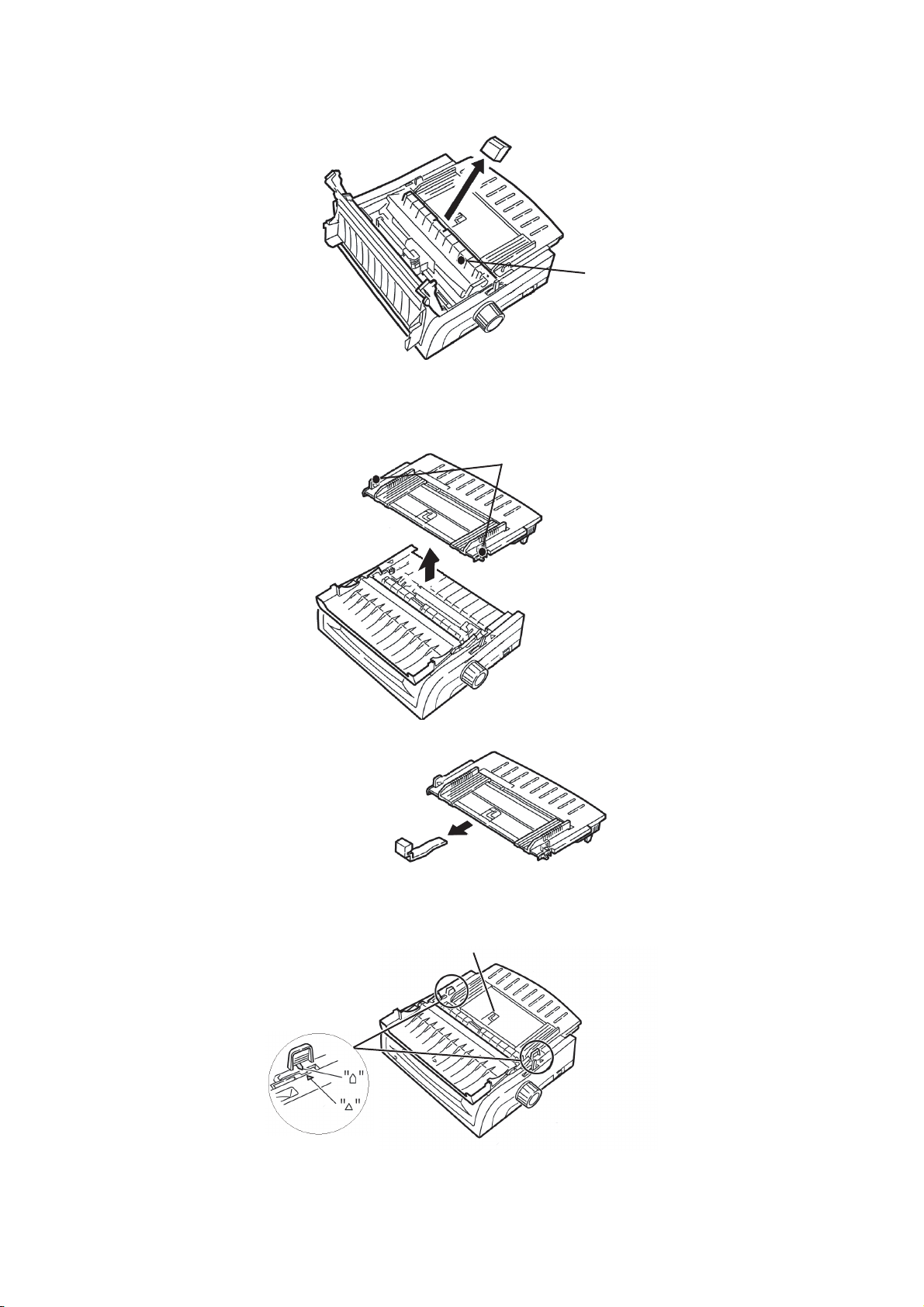

I

NSTALLING THE RIBBON CARTRIDGE

CAUTION!

Make sure you have the correct replacement ribbon for your

printer. The wrong ribbon will not print when installed in your

printer.

R

IBBON CARTRIDGE HANDLING

> Leave unused ribbon cartridges in their packages until needed.

> Careful; the ribbon ink may cause permanent stains.

> Ribbon ink on skin or clothing can usually be removed with soap and water.

Make sure the printer is turned OFF.

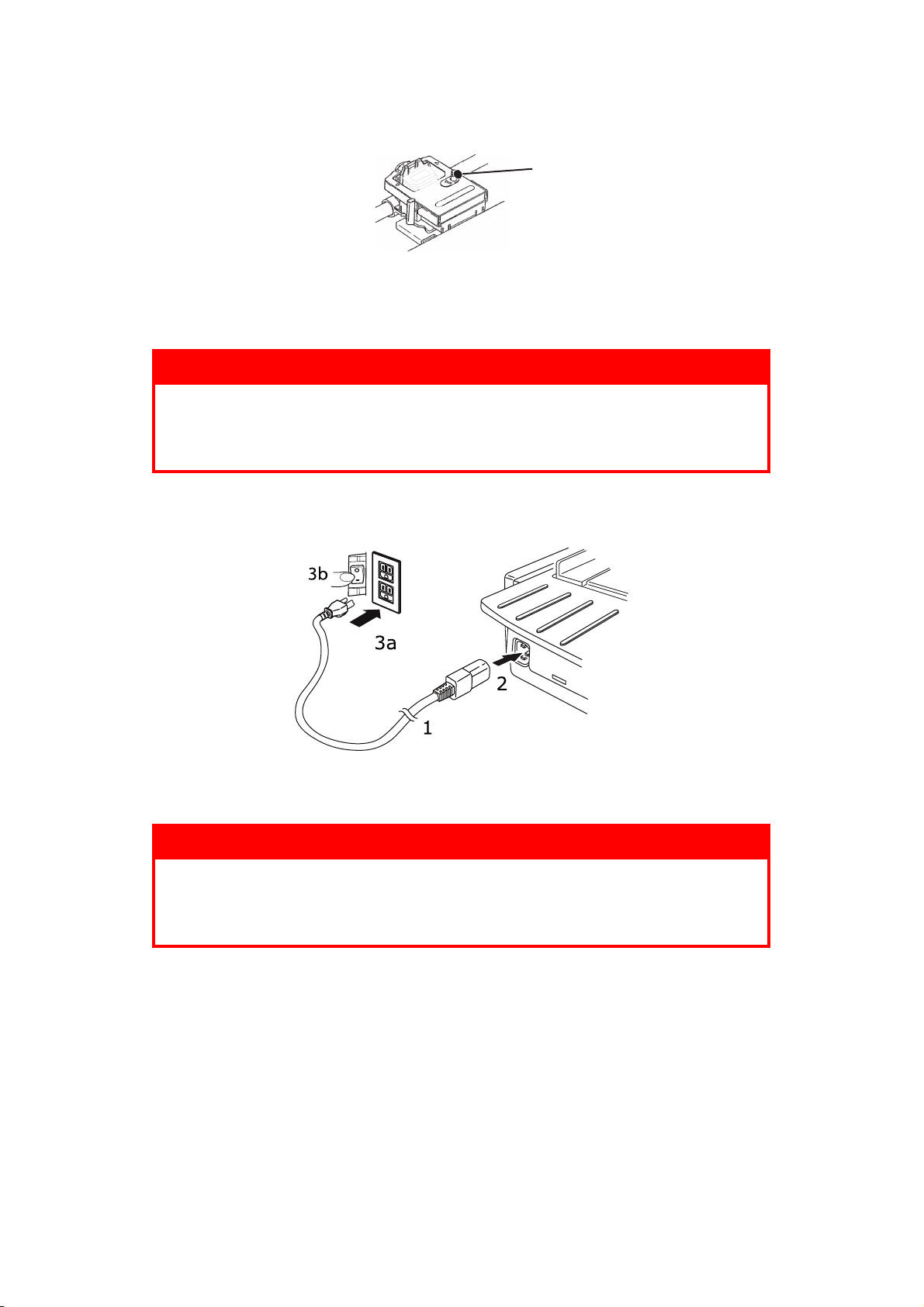

1. Open the access cover and center the printhead (1).

1

WARNING!

The printhead may be HOT.

2. Unpack the new ribbon cartridge and install it on the printhead.

1

CAUTION!

Do not remove the ribbon shield (1) from the ribbon.

Getting started > 11

3. Turn the take-up knob (1) in the direction of the moulded arrow to take up any

ribbon slack.

1

4. Close the access cover and turn the printer ON.

P

OWERING ON YOUR PRINTER

WARNING!

Operations of this equipment are not warranted when the

equipment is connected to UPS (Uninterruptible Power Supply)

and/or inverter. Doing so may result in damage of this equipment.

Do not use an UPS and/or inverter.

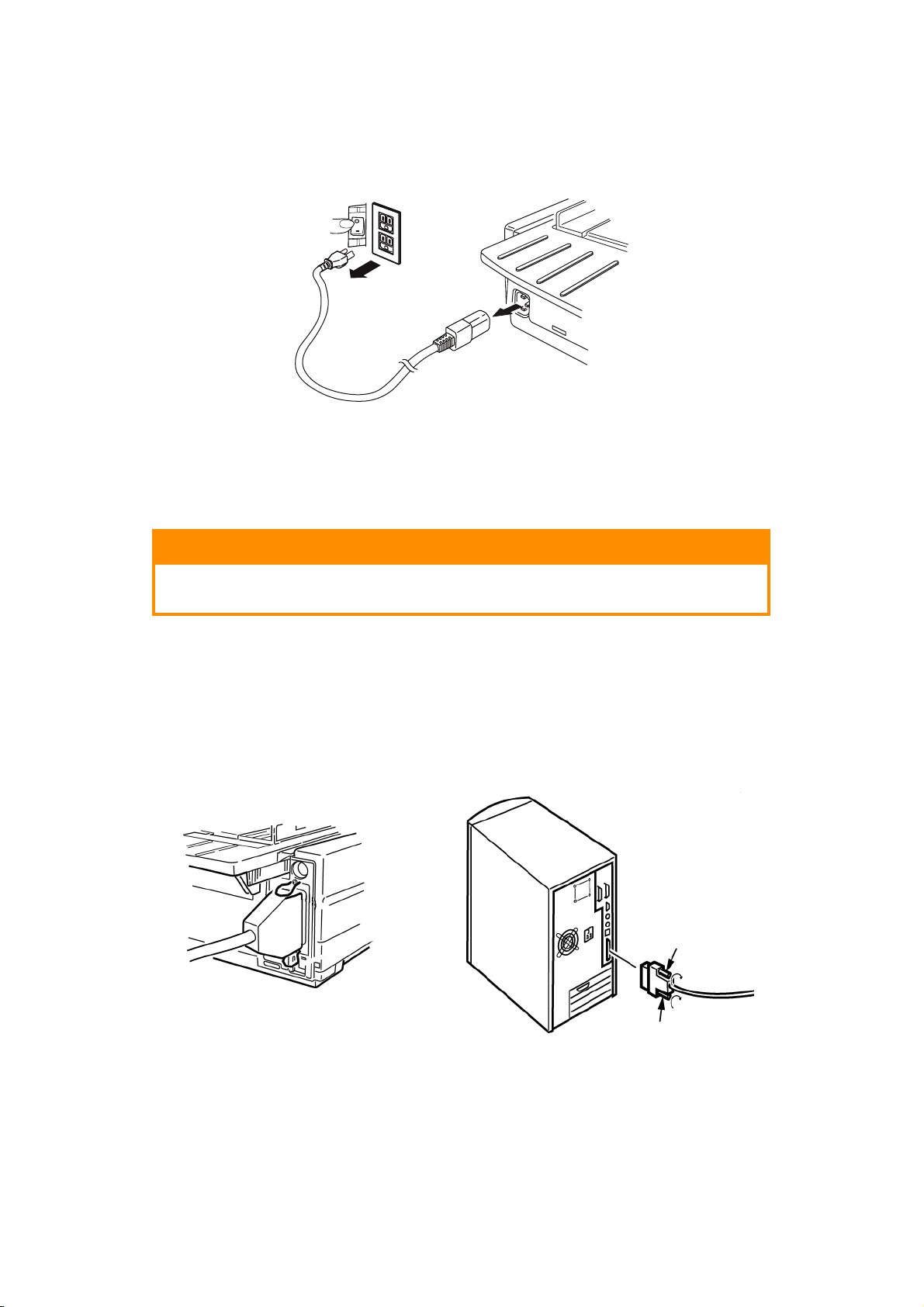

1. Ensure that your printer power switch is set to OFF.

2. Connect the power cable connector (1) to the A/C input (2) on the printer.

3. Connect the power cable to a 220/240 V A/C power outlet (3a) and switch on the

outlet power (3b).

WARNING!

Be careful when inserting a three-pronged A/C plug. Before

plugging it in, check the position of the FG terminal. Incorrect

insertion may cause damage not only to the printer main body but

also peripheral devices and electric shock, smoke and ignition.

4. Turn the printer power switch ON.

5. Check that the power indicator on the control panel illuminates.

Getting started > 12

P

OWERING OFF YOUR PRINTER

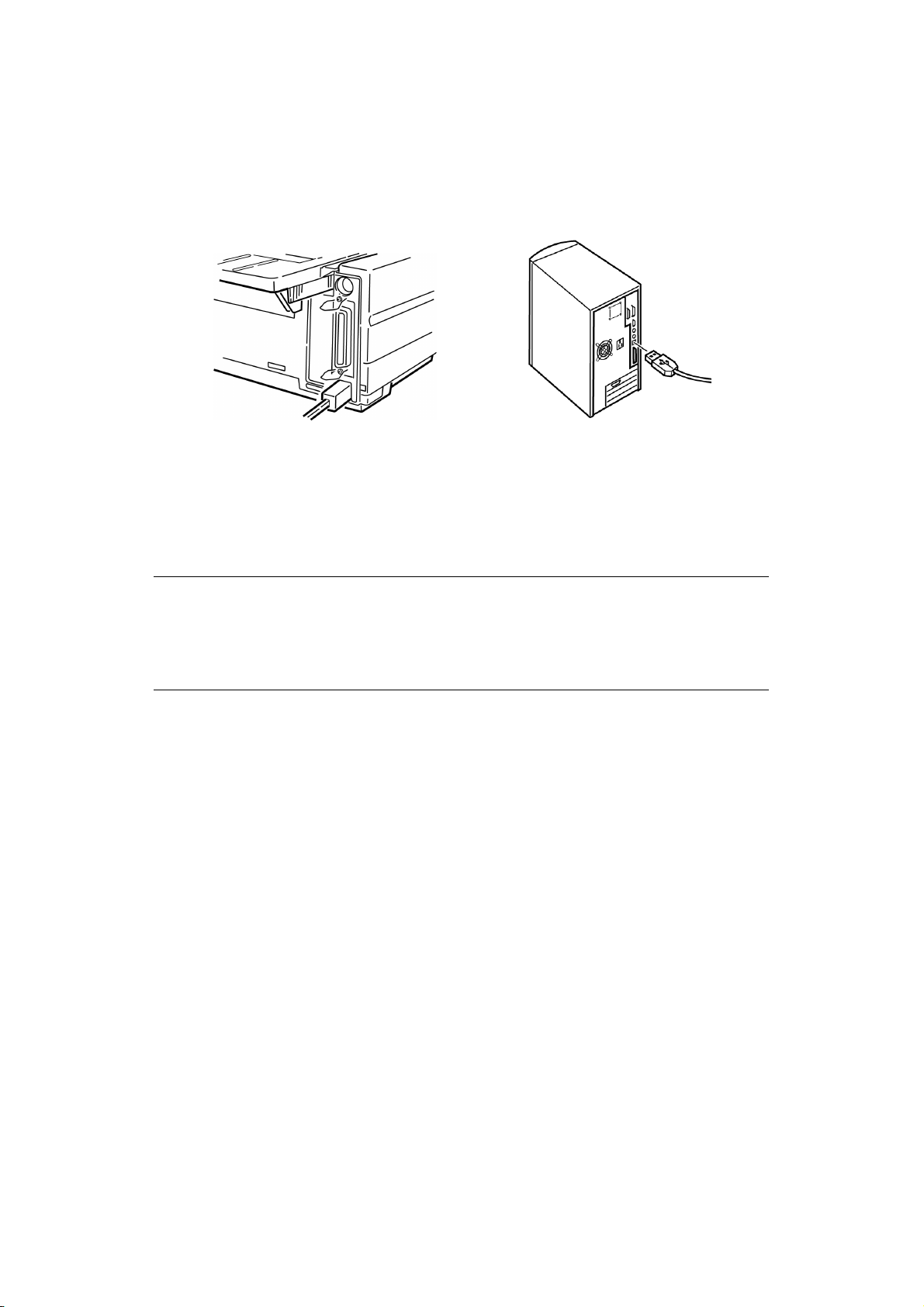

1. Turn the printer power switch to OFF.

2. Switch off the outlet power (1a) and then unplug from the power outlet (1b).

1a

1b

3

2

3. Unplug the power cable connector (2) from the printer (3).

C

OMPUTER CONNECTIONS

Your printer is equipped with two standard data interfaces.

CAUTION!

Under no circumstances attempt to use both the parallel and USB

ports simultaneously.

P

ARALLEL

> For direct connection to a PC. This port requires a bi-directional (IEEE 1284

Make sure the printer and computer are both turned OFF.

1. Attach a suitable bi-directional cable to the parallel connector on the back of the

compliant parallel cable.

printer. Then attach and secure the cable to your computer.

2. Turn the printer and computer back ON.

Getting started > 13

USB

> For connection to a PC running Windows 2000 or above. This port requires a shielded

cable 5m long confirming to USB version 2.0.

Make sure the printer and computer are both turned OFF.

1. Attach a suitable USB cable to the printer. Then attach the cable to your computer.

2. Turn the computer and printer back on.

The following interfaces are available as optional accessories and are described in their

accompanying installation documentation:

> RS-232 C Serial interface

> 100BASE-TX/10BASE-T network connection

NOTE

> Refer to the Network Configuration Guide for setting up the network

connection.

> It is not recommended that you use either the Parallel or USB port when

the RS-232 C or OL7120E3 option is installed in this printer.

Getting started > 14

L

OADING PAPER

For instructions on loading paper, see “Loading paper” on page 20.

Testing the printer

> Font Sample Test

> Rolling ASCII Test

> Hexadecimal Dump Mode

Font sample test

CAUTION!

Wide carriage model: ML5521ECO/ML5591ECO:

If you are using 8.5 inch paper to run the tests, make sure the

paper width selection in the printer menu is set to 8.5 inches.

Otherwise, printing on the platen may damage the printer. See

“Menu mode” on page 41 for more information.

The Font Sample Test prints a sample of the fonts standard to the printer.

The top of the printout shows the Printer Model, Emulation, Country Code, Interface, and

Firmware Revision Level.

Make sure paper is loaded.

1. Turn the printer OFF.

2. Press and hold the LF key while turning the printer back ON.

The printer will print a page of font samples and the test ends.

Getting started > 15

Rolling ASCII test

CAUTION!

Wide carriage Model ML5521ECO/ML5591ECO:

If you are using 8.5 inch paper to run the tests, make sure the

paper width selection in the printer menu is set to 8.5 inches.

Otherwise, printing on the platen may damage the printer. See

“Menu mode” on page 41 for more information.

The Rolling ASCII Print Test produces a continuous printout of all 96 ASCII characters in a

rolling pattern in whatever typeface is selected (ML5521ECO default = Utility; ML5591ECO

default = LQ Courier).

The top of the printout shows the Printer Model, Emulation, Country Code, and Firmware

Revision Level.

Make sure continuous forms paper is loaded.

1. Turn the printer OFF.

2. Press and hold the QUIET/TOF key while turning the printer back ON. (If the printer

comes on without starting the Rolling ASCII test print, you did not hold the QUIET/

TOF key long enough.)

The printer prints the rolling ASCII text continuously.

3. Press SEL to end the test.

Getting started > 16

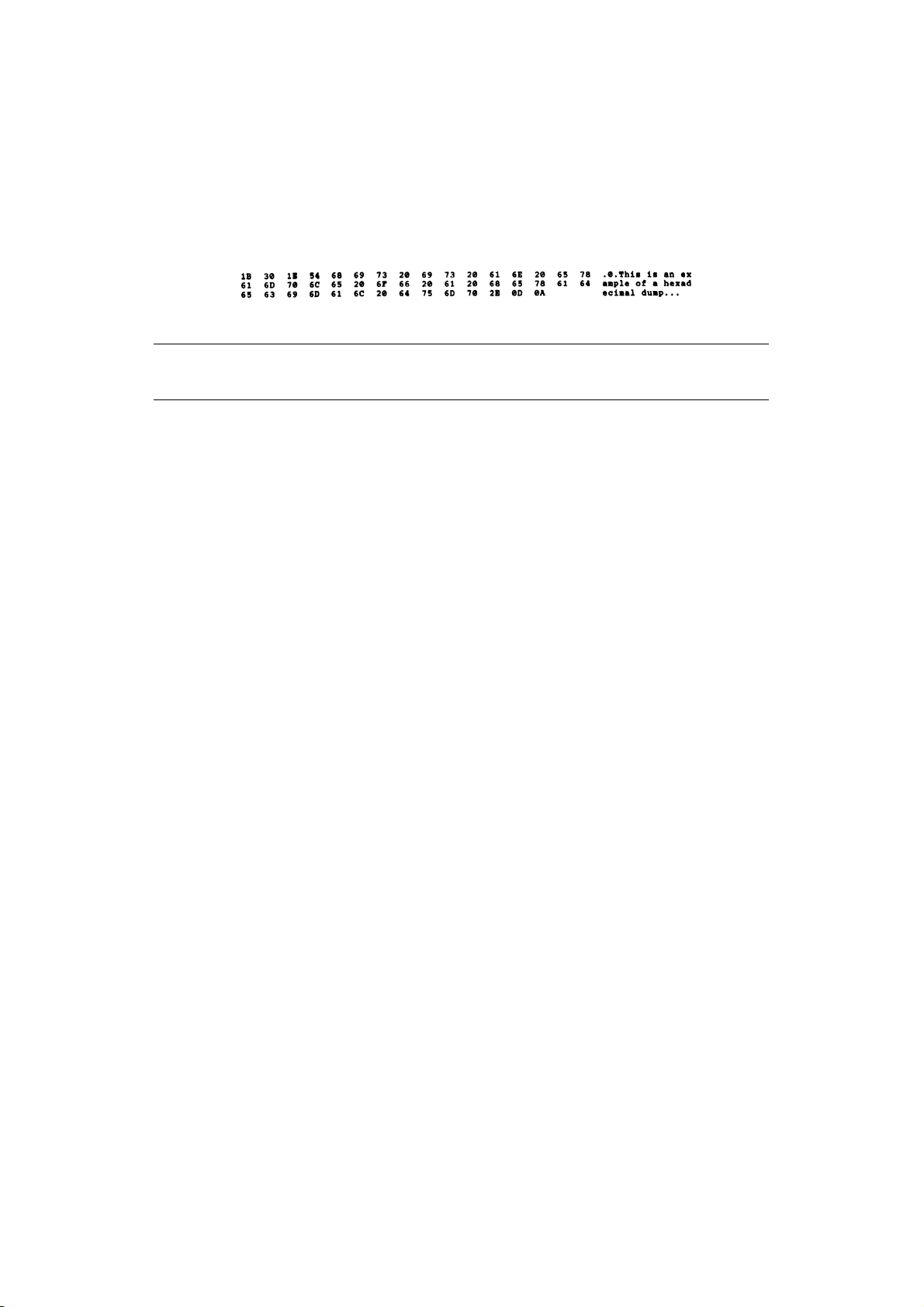

Hexadecimal dump mode

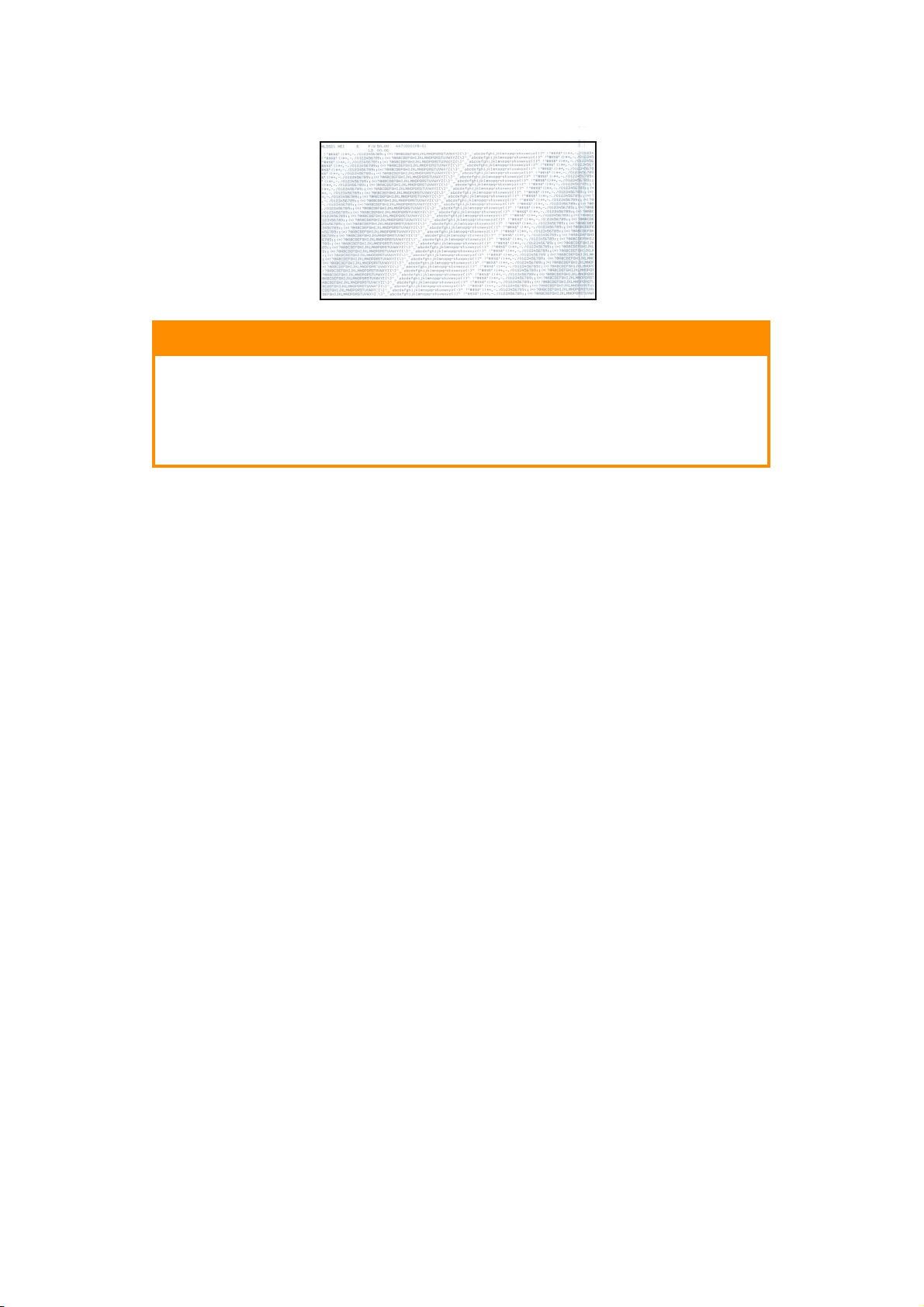

When the printer is placed in the Hexadecimal Dump Mode, all data received, including text

and printer commands, is printed in both hexadecimal and ASCII format.

For example, the following line of BASIC code

LPRINT CHR$ (27);”0”;CHR$ (30);”THIS IS AN EXAMPLE OF A HEXADECIMAL DUMP.”

would print like this:

NOTE

In the ASCII format, all non-printable characters are represented by a period.

To engage the Hexadecimal Dump Mode:

Make sure paper is loaded.

1. Turn the printer OFF.

2. Hold the SEL and FF/LOAD keys for several seconds while turning on the printer.

To exit the Hexadecimal Dump Mode:

1. Press the SEL key.

or

Turn the printer off, then on again.

Getting started > 17

P

RINTER DRIVERS

The driver for your printer is provided on the CD included with the printer. You can either

load the driver or select one of the compatible drivers listed below in your software

application.

1. Insert the CD into your CD-ROM drive.

NOTE

If the CD does not AutoPlay, click Start

CD-ROM drive, double-click Setup.exe and click OK.

2. Select your Language.

3. Click I agree to accept the terms of the Software Licence Agreement.

4. When the Menu Installer window appears, click the Install Driver button.

5. Follow the on-screen instructions.

E

MULATIONS

The factory default emulation for your printer is:

MODEL EMULATION (DEFAULT)

ML5520ECO/ML5521ECO IBM PPR

>

Run > Browse, then browse to your

ML5590ECO/ML5591ECO EPSON LQ

If you wish to change to other emulations, see “Changing emulations” on page 40.

P

RINTING FROM THE COMPUTER

When printing to your printer from, for example, a Windows application on your computer,

make your printing selections from the driver windows that appear on screen. These driver

windows have been designed to be easy to use and intuitive while supplementary on-line

help is available by clicking each window help button.

OKI DIPUS

The OKI DIPUS utility allows you remote access to the printer settings using the available

applications. You can access DIPUS from Start > All Programs > Okidata > OKI DIPUS.

C

ONTROLLING THE PRINTER USING

There are four utilities available within OKI DIPUS. Each utility provides access to the

printer settings from your computer. Using these utilities you can change the button

settings, menu settings, top of form settings and also view the current status of the printer.

Any changes made can then be uploaded to the printer and it will be saved to the printer

as new settings. These utilities are an alternative to the printer operator panel.

Button setup utility

DIPUS

Using this utility you can activate or deactivate buttons on your printer operator panel. Each

button and its function is described in a message view.

Menu setup utility

Using this utility you can view and change your printers’ Menu settings.

Printer drivers > 18

Status monitor

The Status Monitor utility allows you to view your printers’ current status for example, Online, On-line (power saving) and so on. In the event of a printer error occurring, a warning

message is also displayed.

TOF setup utility

Using this utility you can now set the first line of print (TOF) for each page. This utility

allows you to treat each print job individually.

For detailed information on each utility and the different settings contained within, refer to

the on-line help, by clicking each window Help button.

Printer drivers > 19

U

SING YOUR PRINTER

C

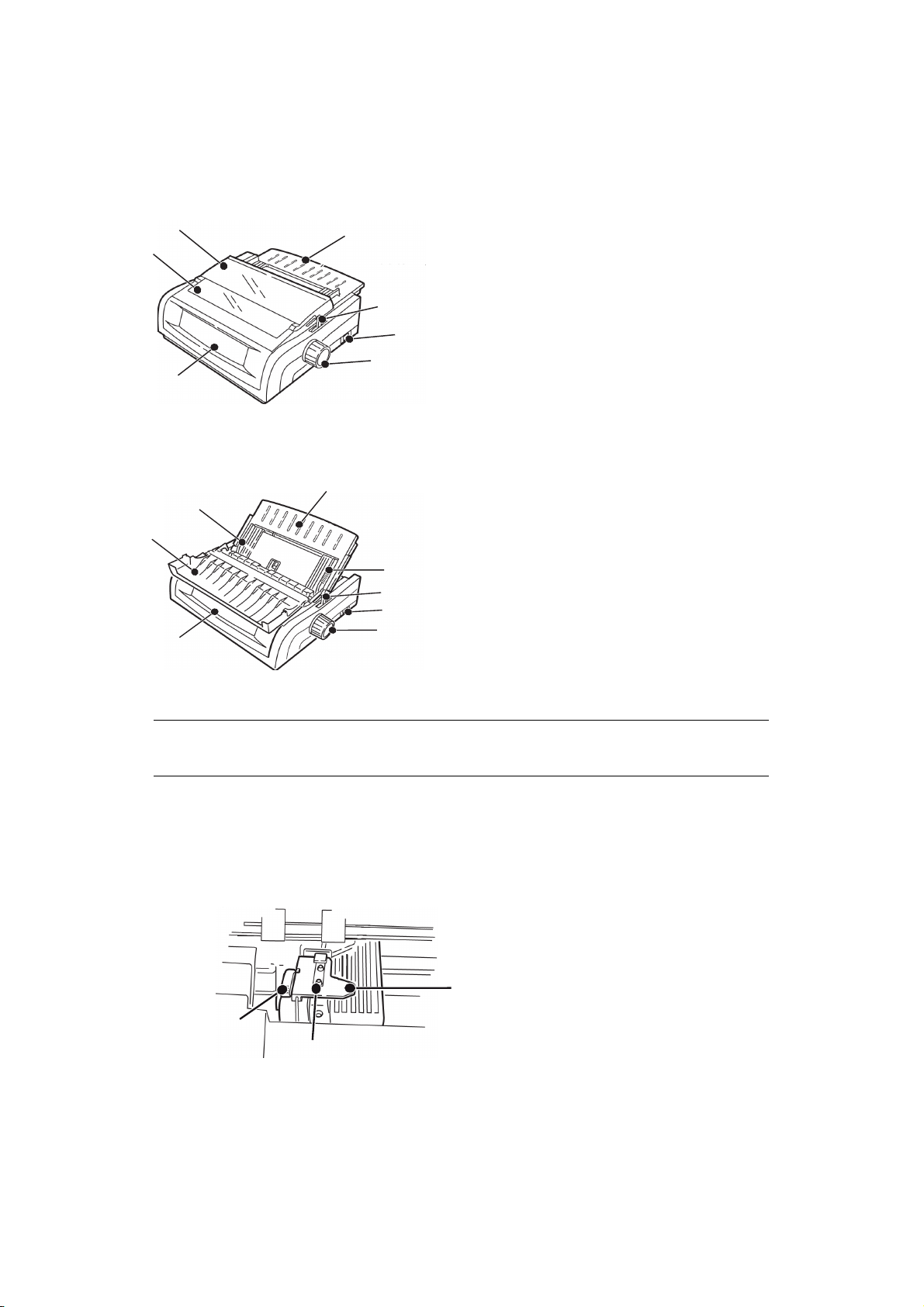

OMPONENTS

The serial number of your printer is on a label fixed to the back of the printer.

: R

EAR FEED (CONTINUOUS FORMS

)

7

6

5

C

OMPONENTS

1

7

6

: TOP

1

2

3

4

FEED (SINGLE SHEETS

2

1

3

4

5

1. Sheet Guide

2. Paper Lever

3. ON-OFF Switch

4. Platen Knob

5. Control Panel

6. Acoustic Cover

7. Access Cover

)

1. Paper Guides

2. Sheet Guide

3. Paper Lever

4. ON-OFF Switch

5. Platen Knob

6. Control Panel

7. Acoustic Cover

NOTE

For single sheet printing, the paper lever must be in the middle position.

L

OADING PAPER

R

EAR FEED

If you have any paper in the paper path, remove it before installing rear feed paper.

1. Lock Lever

2. Upper Tractor Cover

3. Pins

2

1

3

Using your printer > 20

Loading rear feed paper from the back of the printer

These instructions assume you have ready access to the back of the printer. If you do not,

go to “Loading rear feed paper from the front of the printer” on page 25.

Make sure the paper lever is forward (position marked “REAR”).

1. Open the access cover (1).

1

2. Grasp the sheet guide (1). Lift it slightly, then slide it back.

1

2

Using your printer > 21

3. Pivot the sheet guide forward and gently rest it against the roller assembly (2).

If you push the sheet guide too hard against the roller assembly, it may dislodge it.

If it does, be sure to reseat the roller assembly before continuing.

4. From the back of the printer, locate the tractors (1).

1

1

1

5. Open the lock levers (1) and move the right tractor (as viewed from the back of the

printer) to the reference mark (2) matching the width of the paper you are loading.

Then close the lock lever on the right tractor:

1

5920

15

16

5921

10

1

9.5

2

NOTE

The movement of the right tractor is limited to ensure that the paper covers

the paper sensor.

Using your printer > 22

6. Open the tractor covers.

7. Place continuous forms paper on the first two pins of either tractor.

NOTE

You must keep the number of paper holes engaged on either pin the same. If

you don’t the paper will skew and jam.

8. Close the right tractor cover.

Using your printer > 23

9. Adjust the left tractor until the holes in the paper are centered on the pins then lock

the lever and close the left tractor cover.

NOTE

If the paper is too loose, or too tight, it can cause jams.

10. Lower the sheet guide and slide it towards the front of the printer until the marks

align.

11. Place the wire guide in the sheet guide on the pull-up roller assembly.

12. Press FF/LOAD.

NOTE

The factory default setting for the Top of Form (where the printing should

begin) is 1" down from the top of the page. To change the setting, see “Top

of Form (TOF)” in the previous chapter.

Using your printer > 24

Loading rear feed paper from the front of the printer

These instructions assume you do not have ready access to the back of the printer. If you

do, go back to “Loading rear feed paper from the back of the printer” on page 21.

1. Lock Lever

2. Upper Tractor Cover

3. Pins

2

1

3

Make sure the paper lever is forward (position marked “REAR”).

1. Open the access cover (1).

1

Using your printer > 25

2. Grasp the tabs and lift off the sheet guide.

3. Pull up on the lock levers to release them.

NOTE

The movement of the left tractor (as viewed from the front of the printer) is

restricted to ensure that the paper covers the paper out sensor.

4. Move the left tractor to the position to match your paper size and push back on the

lever to lock it in place, then move the right tractor to fit the width of the paper. You

will find reference marks (1 in illustration below) on the printer for the two most

common paper sizes:

10 15

9.5

5520/5590 5521/5591

16

1

Using your printer > 26

5. Open the tractor covers and place continuous forms paper on the first two pins of

either tractor, then close the left tractor cover.

15 16

NOTE

You must keep the number of paper holes engaged on either pin the same. If

you don’t the paper will skew and jam.

6. Adjust the position of the right tractor to center the holes in the paper on the pins.

Then, close the right tractor cover and push back the lock lever. Do not stretch the

paper.

If the paper is too loose or too tight it can cause jams.

Using your printer > 27

7. Reinstall the sheet feeder.

8. Place the wire guide (1) in the sheet guide on the pull-up roller assembly.

1

Using your printer > 28

9. Press FF/LOAD.

NOTE

The factory default setting for the Top of Form (where the printing should

begin) is 1" down from the top of the page. To change the setting, see “Top

of Form (TOF)” in the previous chapter.

TOP

FEED (SINGLE SHEETS

)

If you have continuous form paper in the path, press PARK to remove it before loading

single sheets.

Make sure the printer is on and deselected (SEL light off).

1. Move the paper lever (1) to the center position (marked “TOP”).

1

2. Open the acoustic cover (1) and raise the sheet guide (2) to the single sheet

position. Pivot the wire feed guide (3) up into the sheet guide.

1

2

3

Using your printer > 29

3. Adjust the paper feed guides (1) for the width of the paper, then place a sheet of

paper in the separator. The paper will feed into the printer.

1

1

NOTE

> If the paper does not feed in, remove it. Check the paper lever position.

Make sure the ALARM light is ON: if it is flashing, hold the SHIFT key and

press the CHARACTER PITCH/RESET key. Reload the sheet of paper.

> The factory default setting for the Top of Form (where the printing should

begin) is 1" down from the top of the page. To change the setting, see

“Top of Form (TOF)” in the previous chapter.

TOP OF

Top of Form (TOF) sets the print start position. The factory default is 1" from the top.

The TOF can be changed in increments of 1/144” (ML5520ECO/ML5521ECO) and 1/180"

(ML5590ECO/ML5591ECO), for either a single print job, or all print jobs. The overall

amount of adjustment is limited to avoid paper jams.

The first line prints at the red line of the plastic paper shield (1) on the printhead.

FORM

(TOF)

1

CAUTION!

If you turn the platen knob when the printer is not at Top of Form,

the TOF will misalign. Always feed the paper to TOF before turning

the platen knob!

Using your printer > 30

NOTE

> Your software may print the first line of print above or below where TOF is

set. You may need to adjust the TOF to meet your software’s

requirements.

> The Top of Form and Forms Tear-Off settings of your printer interact. How

you set the Top of Form depends on whether Forms Tear-Off is ON (set to

500 ms, 1 sec, or 2 sec) or OFF (the factory default setting).

F

ORMS TEAR-OFF

The Forms Tear-Off feature allows a printed continuous forms page to be torn off without

wasting paper or adjusting the printer.

When printing stops, Forms Tear-Off automatically moves the paper to align the perforation

with the tear bar (located under the access cover), after a time interval which you select

through the menu.

Paper remains in the tear-off position until the printer receives more data. Then, the paper

moves back down for printing.

This feature has to be enabled.

There are two ways to determine the status of the Forms Tear-Off menu setting:

> Print the Menu.

> Use the TEAR key.

To print the Menu:

1

2

3

1. Make sure paper is loaded.

2. Hold SHIFT (2), then press SEL (1) to enter the Menu Mode.

3. Press PARK (4) to print the menu.

4. Look for the Form Tear-Off setting in the paper feed group you are using (Rear Feed,

Bottom Feed or Top Feed—Forms Tear–Off appears in the Top Feed group only if the

optional Roll Paper Stand is installed).

4

To use the TEAR key:

1. Make sure paper is loaded, and wait 2 seconds.

2. Press TEAR (3).

> If the paper moves up, Forms Tear-Off is OFF.

> If the paper moves down, Forms Tear-Off is ON.

Using your printer > 31

S

ETTING TOP OF FORM

(TOF)

CAUTION!

If you turn the platen knob when the printer is not at Top of Form,

the TOF will misalign. Always feed the paper to TOF before turning

the platen knob.

The first line prints at the red line of the plastic paper shield on the printhead.

Forms Tear-off set to OFF - default

With paper loaded and the printer ON and selected:

1

1. Press PARK (6) to park the paper.

The SEL light goes off and the red alarm light comes on.

2. Press FF/LOAD (4) to load the paper.

3. If the printer is ON line, press SEL|MENU (1) to take the printer OFF line.

The SEL light goes out.

4. Press and hold SHIFT (2), then:

> Press LF|Micro Feed Down (3) to set the TOF higher (the paper moves down).

> Press FF/LOAD|Micro Feed Up (4) to set the TOF lower (the paper moves up).

(When you begin pressing the Micro Feed key, the printhead will move to the right).

5. Press SEL|MENU(1) to place the printer back on line.

To reset the Top of Form to the factory default, see “Resetting Top of Form to the Factory

Default” later in this chapter.

2

3

4

5

76

Forms Tear-Off set to ON

With paper loaded and the printer ON and selected:

1

1. Press PARK(6) to park the paper.

The SEL light goes off and the red alarm light comes on.

2. Press FF/LOAD (4) to load the paper.

3. Wait briefly until the paper moves up to the tear position, then press and hold TEAR

(5).

The paper moves to the current TOF and the SEL light is illuminated.

2

3

Using your printer > 32

4

5

76

4. If the printer is ON line, press SEL|MENU (1) to take the printer Offline.

The SEL light goes out.

5. Press and Hold SHIFT, then:

> Press LF|Micro Feed Down (3) to set the TOF higher (the paper moves down).

> Press FF/LOAD|Micro Feed Up (4) to set the TOF lower (the paper moves up).

(When you begin pressing the Micro Feed key, the printhead will move to the right).

6. Press SEL|MENU (1) to save the setting and place the printer back on line.

To reset the Top of Form to the factory default, see “Resetting top of form to the factory

default” on page 33.

T

EMPORARILY CHANGING THE TOP OF FORM

CAUTION!

If you turn the platen knob when the printer is not at Top of Form,

the TOF will misalign. Always feed the paper to TOF before turning

the platen knob.

To move the Top of Form position lower for one page only:

1. Press SEL to deselect the printer.

2. Press LF to lower the position of the Top of Form.

R

ESETTING TOP OF FORM TO THE FACTORY DEFAULT

The factory default setting for the Top of Form (where the printing should begin) is 1" down

from the top of the page.

To reset the Top of Form to the factory default:

1. Remove paper from the paper path.

2. Turn the printer off.

3. Press and hold PARK + QUIET|TOF while turning on the printer.

4. Reload paper.

F

ORMS TEAR-OFF FEATURE

This feature is normally turned off. To use Forms Tear-Off, you must enter the menu and

change the setting to the desired time interval (see “Changing the forms tear-off setting”

on page 34).

The Forms Tear-Off feature allows a printed continuous forms page to be torn off without

wasting paper or adjusting the printer. It can be used for rear feed continuous forms,

bottom feed continuous forms (with the optional push tractor installed), or for top feed roll

paper (with optional roll paper stand installed).

When the printer is turned on, the paper feeds to the tear-off position.

When data is received, the paper automatically moves down to the print position (TOF) and

printing begins.

NOTE

You can also move the paper down to the print position manually by pressing

TEAR.

Using your printer > 33

When printing stops, Forms Tear-Off automatically moves the paper to align the perforation

with the tear bar (located under the access cover), after the time interval which you

selected through the menu.

Paper remains in the tear-off position until the printer receives more data. Then, the paper

moves back down for printing.

NOTE

> The status of the Forms Tear-Off menu setting affects how you set the

Top of Form: see “Top of Form (TOF) and Forms Tear-Off” earlier in this

chapter.

> Do not use Forms Tear-Off with labels or multipart forms!

> Forms Tear-Off cannot be used when the optional pull tractor is engaged.

P

OTENTIAL ISSUES WITH SOFTWARE PACKAGES

If Forms Tear-Off is set to ON and the software package you are using “pauses” for a long

enough interval while sending data to the printer, Forms Tear-Off may be activated. No

data is lost, but this causes uneven print registration due to the paper movement.

If this occurs, use the menu to turn off this feature, then use the TEAR key to move the

paper up to the tear position manually (see "Changing the forms tear-off setting").

C

HANGING THE FORMS TEAR-OFF SETTING

The default setting for Forms Tear-Off is OFF.

1

2

3

4

5

76

To change the Forms Tear-Off setting:

1. Press SHIFT (2) + SEL (1).

2. Press GROUP (3) repeatedly until the Rear Feed or Bottom Feed group shows in the

first column of the printed line, depending on which paper feed you are using,

3. Press ITEM (4) repeatedly until Form Tear-Off appears in the second column:

Rear Feed Form Tear-Off Off

4. Press SET (5) until the time interval you wish to select appears in the third column:

Rear Feed Form Tear-Off 1 Sec

5. Press SHIFT (2) + SEL (1) to exit Menu Mode and save the setting.

Using your printer > 34

M

ANUAL FORMS TEAR-OFF

If you don’t wish to engage the Forms Tear-Off feature, you can advance:

> rear-feed continuous forms loaded on the built-in tractor

or

> bottom-feed continuous forms loaded on the optional push tractor

up to the tear-off position manually, by pressing TEAR (5).

P

APER PARK

CAUTION!

Never park labels.

Paper park allows you to switch to single sheet printing without removing continuous feed

paper from the printer.

When you wish to print single sheets, simply press PARK (6) to retract the continuous form

paper from the paper path, then lift the sheet guide, load the sheet and send the print job.

C

HANGING PAPER PATHS

C

ONTINUOUS FORMS TO SINGLE SHEETS

1. Tear off any printed pages, then press PARK.

2. Raise the sheet guide (1) to the single sheet feed position.

1

3. Pivot the wire feed guide into the sheet guide.

Using your printer > 35

4. Move the paper lever (1) to the middle position marked “TOP.”

1

5. Adjust the paper guides (1) for the size of paper you are using, then place a sheet of

paper in the sheet guide.

1

1

S

INGLE SHEETS TO CONTINUOUS FORMS

1. Press FF/LOAD to remove the single sheet paper.

2. Lower the sheet guide into the continuous forms position.

3. Swing the wire feed guide over onto the pull-up roller.

Using your printer > 36

4. Move the paper lever to the appropriate position.

> Rear feed:

> Bottom feed:

> If necessary, load continuous form paper.

5. Press FF/LOAD.

Using your printer > 37

P

RINTHEAD GAP

1. The printhead gap is the distance between the printhead and the platen.

CAUTION!

Make sure the printer is turned OFF before you open the access

cover.

To adjust the gap, open the access cover and move the coloured lever (1) to the

recommended setting from the table.

1

NOTE

When the head gap is set to 2, 3, 4 or 5, the printer automatically slows down

for better print quality with multipart forms.

P

RINT QUALITY

ML5520ECO/ML5521ECO

1

SETTING MEDIA

1 Standard paper

2 2-part form (with carbon)

3 3-part form (with carbon)

4 4-part form (with carbon)

5 Envelopes or extra thick paper

Press PRINT QUALITY (1) to select:

High Speed Draft > Lower quality, lower speed

Utility > Medium quality, medium speed

> Gothic typeface only

> Gothic typeface only

Using your printer > 38

Near Letter Quality > Highest quality, lowest speed

Super Speed Draft > Lowest quality, highest speed

ML5590ECO/ML5591ECO

1

Press PRINT QUALITY (1) to select:

Letter Quality > Highest quality, slowest speed

High Speed Draft > Lower quality, higher speed

> Courier or Gothic

> Gothic typeface only

> Choice of 7 typefaces

> Gothic typeface only

Utility > Medium quality, medium speed

> Gothic typeface only

NOTE

Front panel settings for print quality and character pitch are normally

overridden by software commands.

To select the typeface you want, press PRINT QUALITY (1) until the appropriate front panel

lights are on.

C

HARACTER PITCH

1

Character pitch determines how many characters will print on each line. You can choose a

specific fixed width (10 to 20) for each character in characters per inch (CPI). The higher

cpi settings are often used for spreadsheets.

Proportional (PROP) sets character widths based on the character itself: e.g., the letter i is

assigned a narrower width than the letter m. This provides a more polished, typeset

appearance.

To select Proportional, press the CHARACTER PITCH key until both the cpi value and PROP lights are illuminated.

To select non-proportional, press the CHARACTER PITCH key until the light for the cpi value

you wish to use is illuminated.

Using your printer > 39

P

RINTER RESET

1

2

3

4

5

Clearing some error conditions requires that you reset (reinitialise) the printer. To do this:

1. Press and release SEL (1) to take the printer off line.

The SEL light goes out.

2. Press and hold SHIFT

NOTE

Pressing SHIFT and RESET reinitialises the printer, but does not affect any

menu settings and does not reset the printer to the factory defaults. For

information on resetting the printer to the factory defaults, see “Resetting the

menu to the factory defaults” on page 41.

C

HANGING EMULATIONS

(2), then press the RESET/CHARACTER PITCH key (5).

Make sure paper is loaded.

1. Press and hold SHIFT

(2), then press SEL (1).

2. Press LF(3).

The following line will print:

Printer Control Emulation Mode IBM PPR (ML5520ECO/ML5521ECO)

EPSON LQ (ML5590ECO/ML5591ECO)

3. Press TEAR (4) repeatedly until the emulation you wish to select prints in the

right-hand column.

4. Press and hold SHIFT (2), then press SEL (1) to save your setting and exit the Menu

Mode.

Using your printer > 40

M

ENU MODE

In Menu Mode, use the front panel keys to change the defaults for the printer parameters.

The changes made in the Menu Mode are automatically saved when you exit the Menu Mode

and are retained, even when the printer is turned off.

NOTE

Please print the current Menu Mode settings before you reset or change them.

This is the only way to have a record of the settings

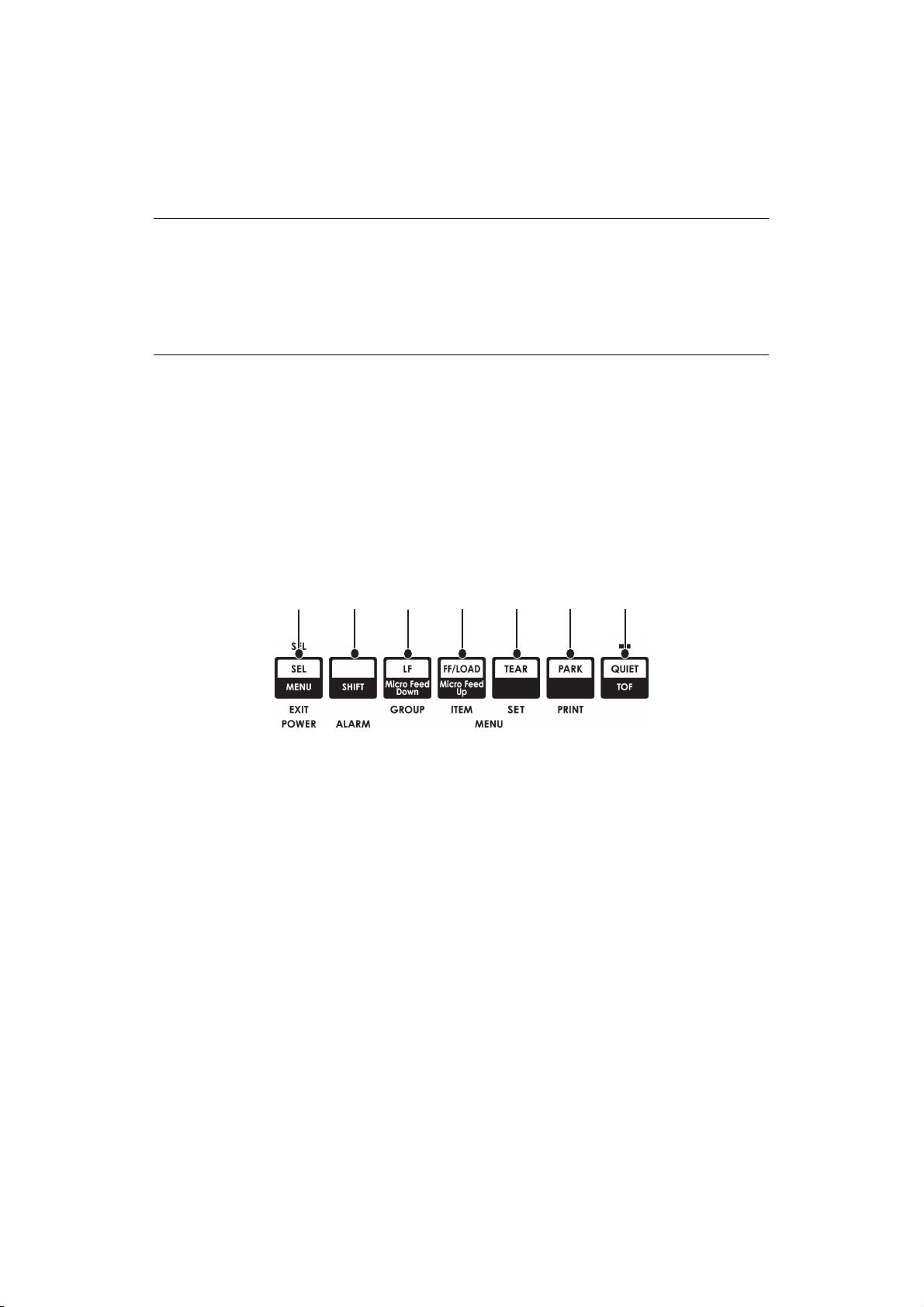

M

ENU MODE KEYS

.

1

3

2

4

5

NO. KEY/LIGHT FUNCTION

1. GROUP Prints the next Group in the Menu.

With the SHIFT key, prints the previous Group.

2. ITEM Prints the next Item in the Group.

With the SHIFT key, prints the previous Item in

the Group.

3. SET Prints the next setting for an Item.

With the SHIFT key, prints the previous setting

for an Item.

4. PRINT Prints a copy of all the Menu settings.

With the SHIFT key, prints the current settings

for the Group selected.

5. Menu Light Illuminated when the printer is in Menu mode.

E

NTERING AND EXITING MENU MODE

Hold down the SHIFT key while pressing SEL.

R

ESETTING THE MENU TO THE FACTORY DEFAULTS

1. Turn the printer OFF.

2. Press SEL and LF while turning the printer ON.

P

RINTING THE MENU SETTINGS

1. Make sure paper is loaded in the printer.

2. Press and hold SHIFT, then press SEL to enter the Menu Mode.

3. Press PRINT (PARK key).

Menu mode > 41

P

RINTING ALL MENU SETTINGS

To print out a listing of the settings for all menu items, regardless of the emulation selected

or the accessories installed:

Make sure paper is loaded in the printer.

1. Press and hold SHIFT, then press SEL to enter the Menu Mode.

2. Press and hold SHIFT, then press PRINT QUALITY.

C

HANGING THE MENU SETTINGS

1. Press and hold SHIFT, then press SEL to enter the Menu Mode.

2. Use the GROUP, ITEM and SET keys to make your changes:

3. Press GROUP until the Group you wish to change appears in the first column.

4. Press ITEM until the Item you wish to change appears in the second column.

5. Press SET until the setting you want appears in the third column.

6. Press and hold SHIFT, then press SEL to exit the Menu Mode and save your settings.

NOTE

If you turn off the printer without first exiting the Menu Mode, the changes you

have made will be lost.

Controlling access to the printer

> You can control access to the printer by changing the setting for the Operator Panel

Function in the Menu from Full Operation (the factory default) to Limited Operation.

> When Limited Operation is selected, the PRINT QUALITY and CHARACTER PITCH keys

don’t work. This prevents these settings from being changed from the control panel

when several people are using the printer.

Menu mode > 42

M

ENU SETTINGS

The table following shows the items which may appear in the menu. Settings which are

engaged at the factory (defaults) are set in bold. Some groups or entries will only appear

when a specific emulation is engaged, as noted.

GROUP ITEM FUNCTION SETS

Printer

Control

Font Print Mode Choose the quality and

Emulation Mode Selects the printer

command set

(emulation) you want to

engage.

typeface of printing.

Draft mode Applies only when the

Print Mode is set to

DRAFT. Selects the draft

mode to be used: HSD

(High Speed Draft) or

SSD (Super Speed

Draft).

Pitch Choose the character

width in characters per

inch (cpi).

ML5520ECO/

ML5521ECO

IBM PPR

EPSON FX

ML

NLQ Courier

NLQ Gothic

NLQ OCR-B

Utility

HSD

HSD

SSD

10 CPI

12 CPI

15 CPI

17.1 CPI

20 CPI

ML5590ECO/

ML5591ECO

EPSON LQ

IBM PPR

IBM AGM

LQ Courier

LQ Roman

LQ Swiss

LQ Swiss Bold

LQ Orator

LQ Gothic

LQ Prestige

LQ OCR- A

LQ OCR- B

Utility

HSD

-

Proportional

Spacing

Style Change to italics if you

Size Select the character

Select whether to use

proportional spacing or

not.

want the printed

characters to be slanted.

scale size.

Selects both double

width and double height

character or single width

and single height

characters.

Yes

No

Normal

Italics

Single

Double

Menu mode > 43

GROUP ITEM FUNCTION SETS

Symbol

Sets

Character Set Select character code

table.

Language Set Select a language

character set. Replaces

certain standard

symbols with special

characters used in

foreign languages.

ML5520ECO/

ML5521ECO

Set I

Set II (Epson and

IBM mode)

Standard (ML mode

only)

Line Graphics (ML

mode only)

Block Graphics (ML

mode only)

ASCII

French

German

British

Danish I

Swedish I

Italian

Spanish I

Japanese

Norwegian

Danish II

Spanish II

Latin American

French Canadian

Dutch

TRS80

Swedish II

Swedish III

Swedish IV

Turkish

Swiss I

Swiss II

Publisher

ML5590ECO/

ML5591ECO

Set I

Set II

ASCII

French

German

British

Danish I

Swedish I

Italian

Spanish I

Japanese

Norwegian

Danish II

Spanish II

Latin American

French Canadian

Dutch

Swedish II

Swedish III

Swedish IV

Turkish

Swiss I

Swiss II

Publisher

Zero Character Select either print font

pattern to receive a zero

character located at 30H

in ANK code.

Slashed

Unslashed

Menu mode > 44

GROUP ITEM FUNCTION SETS

Symbol

Sets cont.

ML5520ECO/

ML5521ECO

Code Page Select a code page. USA

Canada French

Multilingual

Portugal

Norway

Turkey

Greek_437

Greek_869

Greek_928

Greek_437 CYPRUS

Polska Mazovia

Serbo Croatic I

Serbo Croatic II

ECMA-94

Hungarian CWI

Windows Greek

Windows East Europe

Windows Cyrillic

East Europe Latin II 852

Cyrillic I - 855

Cyrillic II - 866

Kamenicky(MJK)

ISO Latin 2

Hebrew NC (862)

Hebrew OC

Turkey_857

Latin 5 (Windows

Turkey)

Windows Hebrew

Ukrainian

Bulgarian

ISO Latin 6 (8859/

10)

Windows Baltic

Baltic_774

KBL-Lithuanian

Cyrillic Latvia

Roman-8

Icelandic-861

Multilingual 858

ISO 8859-15

Greek_737

POL1

Macedonian

ML5590ECO/

ML5591ECO

USA

Canada French

Multilingual

Portugal

Norway

Turkey

Greek_437

Greek_869

Greek_928

Greek_437 CYPRUS

Polska Mazovia

Serbo Croatic I

Serbo Croatic II

ECMA-94

Hungarian CWI

Windows Greek

Windows East Europe

Windows Cyrillic

East Europe Latin II 852

Cyrillic I-855

Cyrillic II-866

Kamenicky (MJK)

ISO Latin 2

Hebrew NC (862)

Hebrew OC

Turkey_857

Latin 5 (Windows

Turkey)

Windows Hebrew

Ukrainian

Bulgarian

ISO Latin 6 (8859/

10)

Windows Baltic

Baltic_774

KBL-Lithuanian

Cyrillic Latvia

Roman-8

Icelandic-861

Multilingual 858

ISO 8859-15

Greek_737

Asmo 449+

Asmo 708

Arabic 864

Windows Arabic

POL1

Macedonian

Slashed Letter 0 Set whether to convert

slashed 0 located at 9BH

and 9DH in USA code

page or not.

Menu mode > 45

Yes

No

GROUP ITEM FUNCTION SETS

Rear Feed Line Spacing Select line feed pitch.

Form Tear-Off When printer is idle (0.5,

Skip Over

Perforation

Page Width

(Displayed only for

ML5521ECO and

ML5591ECO)

Change to 8 lines per

inch (lpi) to get more

lines per page.

1.0 or 2.0 sec), paper is

advanced from the

current print position to

the tear position. When

data is received, paper is

moved to its original

printing position.

Select whether to skip

over perforation or not.

(When a skip over

perforation command is

received, the received

command is given

priority.)

Change to 8” to print on

narrow paper.

ML5520ECO/

ML5521ECO

6 LPI

8 LPI

Off

0.5 sec

1.0 sec

2.0 sec

No

Yes

345.44 mm (13.6”)

203.2 mm (8”)

ML5590ECO/

ML5591ECO

Page Length Select the length of a

continuous form. This

enables the printer to

keep track of the initial

printing position (TOF)

on each page.

279.4 mm (11”)

296.3 mm (11 2/3”)

304.8 mm (12”)

355.6 mm (14”)

431.8 mm (17”)

76.2 mm (3”)

82.6 mm (3.25”)

88.9 mm (3.5”)

101.6 mm (4”)

127.0 mm (5”)

139.7 mm (5.5”)

152.4 mm (6”)

177.8 mm (7”)

203.2 mm (8”)

215.9 mm (8.5”)

Menu mode > 46

GROUP ITEM FUNCTION SETS

Bottom

Feed

ML5520ECO/

ML5521ECO

Line Spacing Select line feed pitch. 6 LPI

Form Tear-Off When printer is idle (0.5,

1.0 or 2.0 sec), paper is

advanced from the

current print position to

the tear position. When

data is received, paper is

moved to its original

printing position.

Skip Over

Perforation

Page width

(Displayed only for

ML5521ECO/

ML5591ECO)

Page Length Select the length of a

Select whether to skip

over perforation or not.

(When a skip over

perforation command is

received, the received

command is given

priority.)

Change to 8” to print on

narrow paper.

continuous form.

8 LPI

Off

0.5 sec

1.0 sec

2.0 sec

No

Yes

345.44 mm (13.6”)

203.2 mm (8”)

279.4 mm (11”)

296.3 mm (11 2/3”)

304.8 mm (12”)

355.6 mm (14”)

431.8 mm (17”)

76.2 mm (3”)

82.6 mm (3.25”)

88.9 mm (3.5”)

101.6 mm (4”)

127.0 mm (5”)

139.7 mm (5.5”)

152.4 mm (6”)

177.8 mm (7”)

203.2 mm (8”)

215.9 mm (8.5”)

ML5590ECO/

ML5591ECO

Menu mode > 47

GROUP ITEM FUNCTION SETS

ML5520ECO/

ML5521ECO

Top Feed Line Spacing Select line feed pitch. 6 LPI

Form Tear-Off

(Displayed when

IBM emulation is

selected.)

Bottom Margin Change to Invalid if you

Page width

(Displayed only for

ML5521ECO/

ML5591ECO)

Page Length Select the page length of

When printer is idle (0.5,

1.0 or 2.0 sec), paper is

advanced from the

current print position to

the tear position. When

data is received, paper is

moved to its original

printing position.

want the printer to

ignore the bottom

margin setting.

Change to 8” to print on

narrow paper.

cut sheet.

8 LPI

Off

0.5 sec

1.0 sec

2.0 sec

Valid

Invalid

345.44 mm (13.6”)

203.2 mm (8”)

279.4 mm (11”)

296.3 mm (11 2/3”)

304.8 mm (12”)

355.6 mm (14”)

420.9 mm (16.57”)

76.2 mm (3”)

82.6 mm (3.25”)

88.9 mm (3.5”)

101.6 mm (4”)

127.0 mm (5”)

139.7 mm (5.5”)

152.4 mm (6”)

177.8 mm (7”)

203.2 mm (8”)

215.9 mm (8.5”)

ML5590ECO/

ML5591ECO

Wait Time Select the waiting time

between setting paper

on the tray and feeding

it while the printer is

waiting for paper to be

fed in cut sheet manual

feed mode.

Paper Length

Control

Control the page length

of cut sheet.

0.5 sec

1.0 sec

2.0 sec

by MENU setting

by Actual Page

Length

by MENU setting

by Actual Page

Length

Menu mode > 48

GROUP ITEM FUNCTION SETS

Set-up Graphics Select the printing

7 or 8 Bits

Graphics

(Displayed only for

ML Emulation)

Receive Buffer

Size

Paper Out

Override

Print Registration Change the setting as

direction when doubleheight print data exists

in a line.

Select to change

graphics settings.

Select size of the

received buffer.

When “1 Line” is

selected, the receive

buffer size is set to 2 k

bytes.

Senses when less than

1” (25mm) of paper

remains and stops

printing. Change to YES

to override the sensor

and print closer to the

bottom of the page.

required to obtain the

best registration for bidirectional printing.

ML5520ECO/

ML5521ECO

Uni-directional

Bi-directional

7

8

1 Line

32 K

64 K

128 K

Yes

No

0.25mm Right, 0.20mm Right, 0.15mm Right,

0.10mm, Right, 0.05mm, Right, 0. 0.05mm

Left, 0.10mm Left, 0.15mm Left, 0.20mm

Left, 0.25mm Left

ML5590ECO/

ML5591ECO

-

7 or 8 Bits Data

Word

Operator Panel

Function

Reset Inhibit Changing this to Yes

Print Suppress

Effective

Select data word

lengths.

Select full or limited

operation. Change to

Limited Operation to

deactivate the PRINT

QUALITY and

CHARACTER PITCH

buttons, so that these

features can only be

controlled through your

software. This prevents

these being changed

from the control panel

when several people are

using the printer.

prevents a reset signal

from the computer from

resetting the printer to

its defaults.

If your system uses the

DC1 and DC3 codes for

something other than

the print suppress

mode, change the

setting to NO.

7

8

Full Operation

Limited Operation

No

Yes

No

Yes

-

Menu mode > 49

GROUP ITEM FUNCTION SETS

Set-up

cont.

Auto LF Select whether to

Auto CR

(Displayed only for

IBM emulation)

CSF Bin Select Appears only when the

Print DEL Code

(Displayed only for

ML Emulation)

SI Select Pitch (10

CPI) (Displayed

only for IBM

emulation)

perform auto LF

operation or not upon

receiving a CR code. If

your print out is

consistently double

spaced, select No, if it

overprints, select Yes.

Select Yes to add a

carriage return when a

Line Feed is received at

the end of a line.

optional Dual-Bin cut

Sheet Feeder is

installed. Use this to

switch to Bin 2 as the

default.

Change the setting to

Yes to print the DEL

code (decimal 27) as a

solid box.

Select how to handle an

SI command received in

10 CPI mode.

ML5520ECO/

ML5521ECO

No

Yes

No

Yes

Bin 1

Bin 2

No

Yes

17.1 CPI

15 CPI

ML5590ECO/

ML5591ECO

-

SI Select Pitch (12

CPI) (Displayed

only for IBM

emulation)

Time Out Print Select valid or invalid.If

Auto Select Determines whether or

Graphics Speed Change to High for

Select how to handle an

SI command received in

12 CPI mode.

your software spends a

long time processing

between portions of data

it feeds to the printer,

change the setting to

Invalid to keep your

printer from dumping

the received data while

it is waiting for more.

not the printer will

automatically be

selected after you load

in paper. Select No if

you want to set the Top

of Form position. If you

always want to use the

same Top of Form

position, change the

setting to YES.

faster printing when the

optimum print quality is

not an issue.

12 CPI

20 CPI

Invalid

Valid

Yes

No

High

Low

Menu mode > 50

GROUP ITEM FUNCTION SETS

Set-up

cont.

Centering Position Used to limit printhead

CSF Type To avoid paper jams,

ESC SI Pitch

(Displayed only for

IBM emulation)

Select Language

Set (Displayed

only when Epson

emulation is

selected.)

travel when printing

narrow columns. Select

Mode 1 for the narrow

carriage printer. Select

Mode 1 or Mode 2 for

the wide carriage

printer.

change the setting to

Narrow if you are using

the optional Cut-Sheet

Feeder on the wide

model (ML5521ECO and

ML5591ECO)

Sets the character pitch

used when the ESC SI

command is received.

Enable/disable the

combination of the code

page setting and the

language conversion.

Combined: Enable the

combination of the code

page and the language

conversion.

Code Page Only: Enable

the code page only and

suppress the language

conversion.

Changing the language

set replaces certain

standard symbols with

special characters used

in foreign languages.

ML5520ECO/

ML5521ECO

DEFAULT

Mode 1

Mode 2

Wide

Narrow

17.1 CPI

20 CPI

Combined

Code Page Only

ML5590ECO/

ML5591ECO

Power Saving Change to disable if you

wish to prevent the

printer from entering the

Power Save mode after

the selected interval.

Power Save Time Sets the interval the

printer waits for more

data before it goes onto

the power save mode.

Power Saving must be

set to Enable (default)

for this to be effective.

Time Out FF The printer will feed or

eject paper if no data is

received during a set

period of time.

Menu mode > 51

Enable

Disable

5 min

10 min

15 min

30 min

60 min

Invalid

200ms

500ms

1 sec

GROUP ITEM FUNCTION SETS

Parallel

I/F

Serial I/F

(Displayed

when

connected to

Serial

Interface)

I-prime Select whether to print

Auto Feed XT

(Displayed only for

EPSON emulation)

Bi-direction Set whether to return a

Parity None: Absence of parity

Serial Data 7/8

Bits

or clear buffer contents

upon initialisation by

receiving I-PRIME.

If your system uses pin

14 of the parallel

interface to control

automatic line feed,

change the setting to

Valid.

device ID or not in

accordance with

IEEE1284.

bit

Odd: Odd parity

Even: Even parity

Ignore: Do not convert

the character to ox40 in

case of parity error.

Select Serial bit. 8 bit

ML5520ECO/

ML5521ECO

Invalid

Buffer Print

Buffer Clear

Valid

Invalid

Enable

Disable

None

Odd

Even

Ignore

7 bit

ML5590ECO/

ML5591ECO

Protocol Select an I/F Busy

control method.

Diagnostic Test Select to perform input/

output diagnosis of

RS-232C interface

signals.

Busy Line Select to set the Busy

Line.

Baud Rate Select to set the Baud

Rate.

DSR Signal Select the DSR Signal. Valid

DTR Signal Select a method to

switch a DTR signal of a

serial interface.

Busy Time Select the minimum

time between BUSY to

READY.

Ready/Busy

X-On/X-OFF

Ready/Busy & X-ON/X-OFF

No

Yes

SSD-

SSD+

DTR

RTS

9,600 bps

4,800 bps

2,400 bps

1,200 bps

600 bps

300 bps

19,200 bps

Invalid

Ready on Power Up

Ready on Select

0.2 sec

1.0 sec

Menu mode > 52

GROUP ITEM FUNCTION SETS

CSF Bin 1

(Display-

ed when

Single-bin

Cut-sheet

feeder is

installed)

ML5520ECO/

ML5521ECO

Line Spacing Select line feed pitch 6 LPI

Bottom Margin Change to Invalid if you

want the printer to

ignore the bottom

margin setting.

Page Width

(Displayed only for

ML5521ECO/

ML5591ECO)

Page Length Select the length of cut

Change to 8 inch to print

on letter size paper.

sheet.

8 LPI

Valid

Invalid

203.2 mm (8”)

345.44 mm (13.6”)

279.4 mm (11”)

296.3 mm (11 2/3”)

304.8 mm (12”)

355.6 mm (14”)

420.9 mm (16.57”)

88.9 mm (3.5”)

101.6 mm (4”)

127.0 mm (5”)

139.7 mm (5.5”)

152.4 mm (6”)

177.8 mm (7”)

203.2 mm (8”)

215.9 mm (8.5”)

ML5590ECO/

ML5591ECO

CSF Bin

2(Display

-ed when

Doublebin Cutsheet

feeder is

installed)

Line Spacing Select line feed pitch. 6LPI

8LPI

Bottom Margin Change to Invalid if you

want the printer to

ignore the bottom

margin setting.

Page Length Select the length of cut

sheet.

Valid

Invalid

279.4 mm (11”)

296.3 mm (11 2/3”)

304.8 mm (12”)

355.6 mm (14”)

420.9 mm (16.57”)

88.9 mm (3.5”)

101.6 mm (4”)

127.0 mm (5”)

139.7 mm (5.5”)

152.4 mm (6”)

177.8 mm (7”)

203.2 mm (8”)

215.9 mm (8.5”)

Menu mode > 53

M

AINTENANCE

R

EPLACING THE RIBBON CARTRIDGE

Make sure you have the correct replacement ribbon for your printer. The wrong ribbon will

not print when installed in your printer. Look for the printer model number on the ribbon

package.

R

IBBON CARTRIDGE HANDLING

> Leave unused ribbon cartridges in their packages until needed.

> Careful; the ribbon ink may cause permanent stains.

> Ribbon ink on skin or clothing can usually be removed with soap and water.

Make sure the printer is turned OFF.

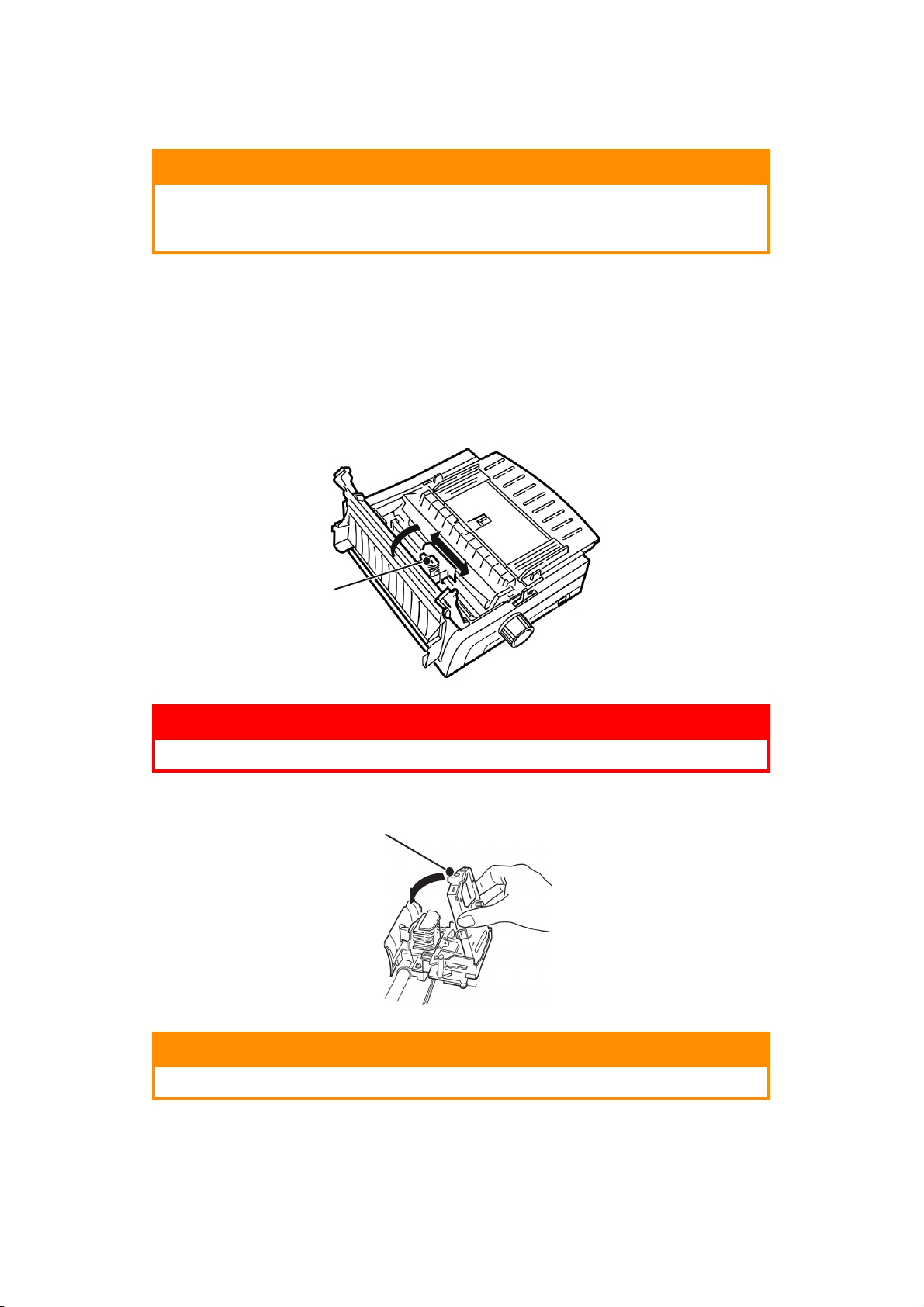

1. Open the access cover and center the printhead (1).

1

2. Swing the used ribbon cartridge up off the printhead, lift it out, and discard it.

WARNING!

The printhead may be HOT.

Maintenance > 54

3. Unpack the new ribbon cartridge and install it.

Do not remove the ribbon shield (1) from the ribbon!

1

4. Turn the take-up knob (1) in the direction of the arrow to take up any ribbon slack.

1

5. Close the access cover and turn the printer back on.

CAUTION!

> If ribbon should contact the eyes: Flush eyes with large

quantities of water for 15 minutes, keeping eyelids open with

fingers. Seek medical attention.

> If ribbon should contact the skin: Wash thoroughly with soap and

water.

Maintenance > 55

C

LEANING YOUR PRINTER

To keep your printer in good operating condition, you are advised to clean it regularly.

WARNING!

Set the printer Power Switch to OFF and disconnect the power

cable from the printer before cleaning the printer.

P

RINTER EXTERIOR

CAUTION!

Keep the access cover closed to avoid the possibility of detergent

entering the printer.

Clean the exterior of the printer as required, but at least every six months or 300 hours of

operation, whichever comes first.

> Moisten a piece of cotton cloth with diluted natural detergent and carefully wipe the

printer exterior.

C

LEANING THE HOUSING

WARNING!

> As the print head becomes hot during printing, allow it to cool

before carrying out any cleaning inside the printer.

> Do not use any flammable solvents for cleaning the printer to

avoid any risk of fire or electric shock.

You should clean the printer housing every six months (or after about 300 hours of

operation.

CAUTION!

Never use strong solvents or strong detergents on the cabinet—

they could damage the housing.

1. Turn off the printer.

2. Use the platen knob to back the paper out of the printer.

CAUTION!

Make sure the printer is turned off before you open the access

cover.

Maintenance > 56

3. Open the access cover (1) and remove the pull-up roller assembly (2).

2

1

4. Use a clean, dry cloth to dust around the carriage shaft and platen. Remove any

loose bits of paper.

CAUTION!

> When you clean the interior of the printer with a vacuum cleaner,

do not attempt to clean any parts smaller than the suction nozzle.

> Do not clean any interior working parts with suction nozzle to

avoid possible damage to the printer.

5. Reinstall the pull-up roller assembly and close the access cover.

Maintenance > 57

T

ROUBLESHOOTING

C

LEARING PAPER JAMS

R

EAR FEED JAMS

1. Turn off the printer.

2. Use the platen knob to back the paper all the way out of the printer.

CAUTION!

Make sure the printer is turned OFF before you open the access

cover.

3. Open the access cover (1) and remove the pull-up roller assembly (2). Remove any

torn paper.

2

1

4. Lift the sheet guide (1) and reload paper. Make sure you lock the tractor covers.

1

Troubleshooting > 58

5. Lower the sheet guide, then install the pull-up roller assembly and close the access

cover.

6. Turn ON the printer and press FF/LOAD.

R

EAR FEED, REPEATING PAPER JAMS

If the paper keeps jamming, you may have:

> defective paper

> misaligned paper

> bits of paper stuck in the paper path

Defective paper

Replace the defective paper with a fresh stack.

Misaligned paper

1. Turn off the printer.

2. Use the platen knob to back the paper all the way out of the printer.

3. Tear off a couple of sheets of paper, leaving a new, clean, square-cut edge.

4. Reload the paper and turn the printer back on.

Fragments of paper in the paper path

1. Turn off the printer.

2. Use the platen knob to back the paper all the way out of the printer.

CAUTION!

Make sure the printer is turned OFF before you open the access

cover.

Troubleshooting > 59

3. Open the access cover (1) and remove the pull-up roller assembly (2). Then grasp

the tabs (3) on the sheet guide (4) and lift it off the printer.

2

3

4

3

1

4. Remove any torn pieces of paper.

5. Fold some continuous form paper over three times to make a page four sheets thick.

Then, load it on the tractors and close and lock the covers.

6. Use the platen knob to draw the quadruple-thick page around the platen. This brings

out jammed pieces of paper.

7. Remove the paper pieces. Then, use the platen knob to back the paper out.

8. Load standard paper, close and lock the tractor covers.

Troubleshooting > 60

9. Install the sheet guide, then install the pull-up roller assembly and close the access

cover.

10. Turn the printer on and press FF/LOAD.

S

INGLE SHEET PAPER JAMS

1. Turn off the printer.

2. Use the platen knob to back the paper out.

3. Open the access cover (1) and remove the pull-up roller assembly (2).

2

1

4. Remove any torn pieces from around the carriage.

5. Reinstall the pull-up roller assembly and close the access cover.

Troubleshooting > 61

G

ENERAL PROBLEMS

Here are some general things to check before proceeding with detailed troubleshooting.

> Is the printer plugged in and turned ON?

> Are the connections (power and interface) secure?

> Is the product being operated under the proper ambient conditions?

> Does the paper being used meet the specifications for this product?

> Is the paper properly installed?

> Is the ribbon properly installed?

> Is an Oki ribbon being used?

> Is the printhead gap correctly set?

> Are the correct printer drivers being used for the printer?

NOTE

> Settings in your software application will normally override any settings in

your printer driver.

> Printer driver settings normally override settings from the printer menu or

printer front panel.

PROBLEM SOLUTION

My word processor files

do not print the way I

have the menu and front

panel set.

Nothing happens when I

turn ON the printer.

The printer does not

print when the computer

sends data.

Remember:

> Settings in your software application can override settings

in your printer driver.

> Your printer driver settings can override any settings from

the printer menu or printer front panel.

Before sending a file to the printer, many word processors send

either an “initialisation string” or an I-Prime signal to the printer.

The initialisation string contains codes that override the panel

and menu settings. To change your printer to ignore the reset

code, enter the Menu Mode, go to the Set-Up group and change

the setting for Reset Inhibit to YES.

The I-Prime signal will automatically override any front panel

settings you have made. To eliminate this problem, enter the

Menu Mode, go to the Parallel Interface group and change the

setting for I-Prime to Invalid.

For more information on changing menu settings, see “Changing

the menu settings” on page 42.

Check the power cord connection to the outlet and to the printer.

If you are using a power strip, make sure it is turned ON, and

that the fuse hasn’t blown or that the circuit breaker hasn’t

tripped.

1. Is the SEL light on? If not, press the SEL key.

2. Check that the interface cable is securely connected to both

the printer and the computer.

3. If you have the optional serial interface board installed, check

to be sure that it is firmly seated in the printer.

I'm getting strange

symbols, incorrect fonts,

etc., when I try to print

a document.

1. Check to be sure that the printer driver you have selected in

your software matches the printer emulation.

2. Press SHIFT and SEL keys, then press GROUP key.

This will print a line showing the emulation you have

selected.

3. If you have embedded any printer commands in your

software, check to be sure that you entered them correctly

Troubleshooting > 62

PROBLEM SOLUTION

Ink smears on the paper

when I print narrow

columns.

I've installed a new

ribbon and the printing

is smeared and

streaked.

There are dots missing

in my printouts.

The ALARM light is

flashing.

The ALARM light is ON

and the Character Pitch

10 light is flashing.

This may be caused by excessive printhead travel from the