Page 1

MICROLINE® 520/521

User's Guide

Page 2

Every effort has been made to ensure that the information

in this document is complete, accurate and up-to-date.

OKIDATA assumes no responsibility for the results of

errors beyond its control. OKIDATA also cannot guarantee

that changes in software and equipment made by other

manufacturers, and referred to in this handbook, will not

affect the applicability of the information in this handbook.

Mention of software products manufactured by other

companies does not necessarily constitute endorsement by

OKIDATA.

© 1993, 1995, 1996, 1997, 1998, 2001 by OKIDATA

Revised edition, September, 2001

Year 2000 Compliance

All products currently sold by Okidata are Year 2000

Compliant. Each product contains information technology

that accurately processes date and time data between the

years 1999 and 2000. These products, when used in combination with products purchased from other manufacturers,

whose products properly exchange date and time information, will accurately process the date and time. All future

products are committed to meeting the same Year 2000

compliance.

ENERGY STAR

Written and produced by the OKIDATA Training &

Publications Department. Please address any comments

on this publication

• by mail to:

Training & Publications Department

Okidata, Div. of Oki America, Inc.

2000 Bishops Gate Blvd.

Mount Laurel, NJ 08054-4620

• or by e-mail to: pubs@okidata.com

We welcome you to visit our web site:

http://www.okidata.com

As an ENERGY STAR® Partner, Okidata

has determined that this product meets

the E

NERGY STAR guidelines for energy

efficiency.

OKIDAT A, OKILINK and MICROLINE are re gistered trademarks

of Oki Electric Industry Company, Ltd. OKIDAT A and

MICROLINE: marques déposées de Oki Electric Industry

Company, Ltd. OKIDATA: marca registrada, Oki Electric

Industry Company, Ltd. Epson is a registered trademark of Epson

America, Inc. IBM is a registered trademark of International

Business Machines Corporation. Microsoft is either a registered

trademark or a trademark of Microsoft Corporation in the United

States and/or other countries.

Page 3

Important Safety Instructions

Your OKI printer has been carefully designed to give

you years of safe, reliable performance. As with all

electrical equipment, there are a few basic precautions

you should take to avoid hurting yourself or damaging

the printer:

• Read the setup and operating instructions in this

manual carefully. Be sure to save it for future

reference.

• Read and follow all warning and instruction labels on

the printer itself.

• Unplug the printer before you clean it. Use only a

damp cloth; do not use liquid or aerosol cleaners.

• Place your printer on a firm, solid surface. If you put

in on something unsteady, it might fall and be

damaged; if you place it on a soft surface, such as a

rug, sofa, or bed, the vents may be blocked, causing

it to overheat.

• To protect your printer from overheating, make sure

no openings on the printer are blocked. Do not put

the printer on or near a heat source, such as a radiator

or heat register. If you put the printer in any kind of

enclosure, make sure it is well ventilated.

• The printhead can get quite hot when it has been

printing for a length of time. Do not touch the

printhead until it has had a chance to cool off.

• Do not use your printer near water, or spill liquid of

any kind into it.

• Be certain that your power source matches the rating

listed on the back of the printer. If you are not sure,

check with your dealer or with your local power

company.

• Your printer has a grounded, 3-prong plug as a safety

feature, and it will only fit into a grounded outlet. If

you can not plug it in, chances are that you have an

older, non-grounded outlet; have an electrician

replace it with a grounded outlet. Do not use an

adapter to defeat the grounding.

• The printer must be installed near a power outlet

which remains easily accessible.

• To avoid damaging the power cord, do not put

anything on it or place it where it will be walked on.

If the cord becomes damaged or frayed, replace it

immediately.

E-i

Page 4

• If you’re using an extension cord or power strip with

the printer, make sure that the total of the amperes

required by all the equipment on the extension is less

than the exten-sion’s rating. Generally, the total

ratings of all equipment plugged into any one power

line should not exceed 15 amps. Don’t exceed this

unless you know that the power line your equipment

is plugged into has a rating above 15 amps.

• Aside from the routine maintenance described in this

handbook, don’t try to service the printer yourself;

opening the cover may expose you to shocks or other

hazards. Don’t make any adjustments other than

those outlined in the manual — you might cause

damage requiring extensive repair work. the

Warranty, Regulatory, and Safety Information booklet

supplied with your printer explains how to get your

printer serviced by qualified Okidata technicians.

• If anything happens that indicates that your printer is

not working properly or has been damaged, unplug it

imme-diately and follow the procedures in the

Warranty, Regulatory, and Safety Information booklet

supplied with your printer for having your printer

serviced.

Some of the things to look for:

- The power cord or plug is frayed or damaged.

- Liquid has been spilled into the housing, or the

printer has been exposed to water.

- The printer has been dropped or its cabinet has

been damaged.

- The printer doesn’t function normally when

you’re following the operating instructions.

E-ii

Page 5

Contents

Section 1: Getting Started ...................................................... 1

Unpack.....................................................................................1

Remove The Protective Film...................................................1

Remove The Shipping Retainers ............................................ 2

Install/Replace the Ribbon

Cartridge ............................................................................. 3

Connect to Power and Computer ............................................5

Power Up..................................................................................6

Load Paper ...............................................................................6

Loading Rear-Feed Paper ...................................................7

Loading Single-Sheet Paper .............................................1 0

Set the T op of F orm...........................................................12

Run the Self Tests ..................................................................13

Selecting an Emulation .........................................................1 3

Changing Emulations ....................................................... 13

Selecting a Printer Driver..................................................14

Printer Drivers ........................................................................14

Okidata Drivers .................................................................14

Section 2: Maintaining Your Printer .................................... 15

Replacing the Ribbon Cartridge ........................................... 1 5

Clearing Paper Jams...............................................................15

Clearing Rear Feed Jams...................................................15

Clearing Single Sheet Feed Jams......................................16

Cleaning the Housing ............................................................ 1 7

Section 3: Using Your Printer ...............................................19

Control Panel Indicator Lights..............................................19

Control Panel Buttons: Print Mode....................................... 2 0

Control Panel Buttons: Menu Mode..................................... 2 1

Print Mode ............................................................................. 2 2

Selecting Print Quality .....................................................2 2

Selecting Character Pitch ................................................. 2 3

Menu Mode ........................................................................... 2 4

Entering The Menu Mode ................................................24

Exiting The Menu Mode .................................................. 24

Resetting The Menu .........................................................24

Printing Out the Menu ...................................................... 2 4

Sample Default Menu Printout .........................................25

Summary of Menu Settings ..............................................26

Explanation of Menu Items ..............................................29

Using the Printer's Features ...................................................32

Tear Feature.......................................................................32

Forms Tear-of f Feature ......................................................32

Paper Park Feature ............................................................33

Section 4: Problem Solving ..................................................35

Section 5: Specifications .......................................................39

Section 6: Parts & Accessories .............................................43

Before Y ou Order ...................................................................43

How to Order..........................................................................43

Replacement Parts .................................................................43

Manuals .................................................................................44

Accessories ............................................................................ 44

E-iii

Page 6

Section 7: Commands ........................................................... 45

Epson FX Commands ............................................................45

IBM Proprinter III Commands ...............................................47

Okidata MICROLINE Standard Commands..........................49

FCC/IC/CE Statements ........................................................... 51

Index ......................................................................................53

Material Safety Data Sheet ................................................... 57

E-iv

Page 7

Conventions Used in This Guide

The following conventions are used in this guide:

• Notes containing general information are preceded

by the Note icon.

For example:

4

Interface cable and paper are sold separately.

• Statements containing precautions against actions

which could cause printing problems or damage to

the printer are set in italics, preceded by the Caution

icon.

For example:

Leave the ribbon shield on the cartridge!

!

• Statements containing precautions against actions

which could cause personal injury are set in bold

italics, preceded by the Warning icon.

For example:

Make sure the outlet is grounded. Do not use

an adapter to defeat the grounding.

E-v

Page 8

ection 1: Getting Started

S

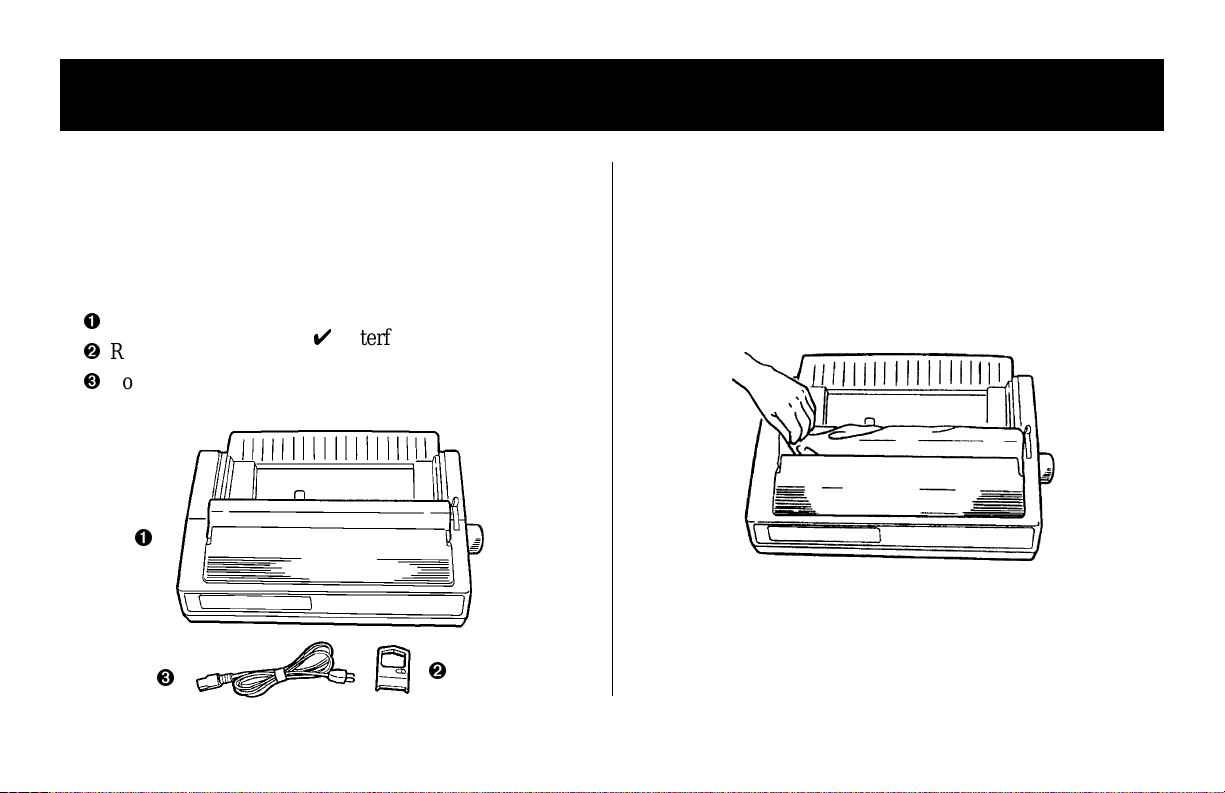

Unpack

Choose a sturdy table, desk or printer stand to place your

printer on when you remove it from the carton. Be sure

to save all packing materials in case you need to ship the

printer again. Check the box for these contents:

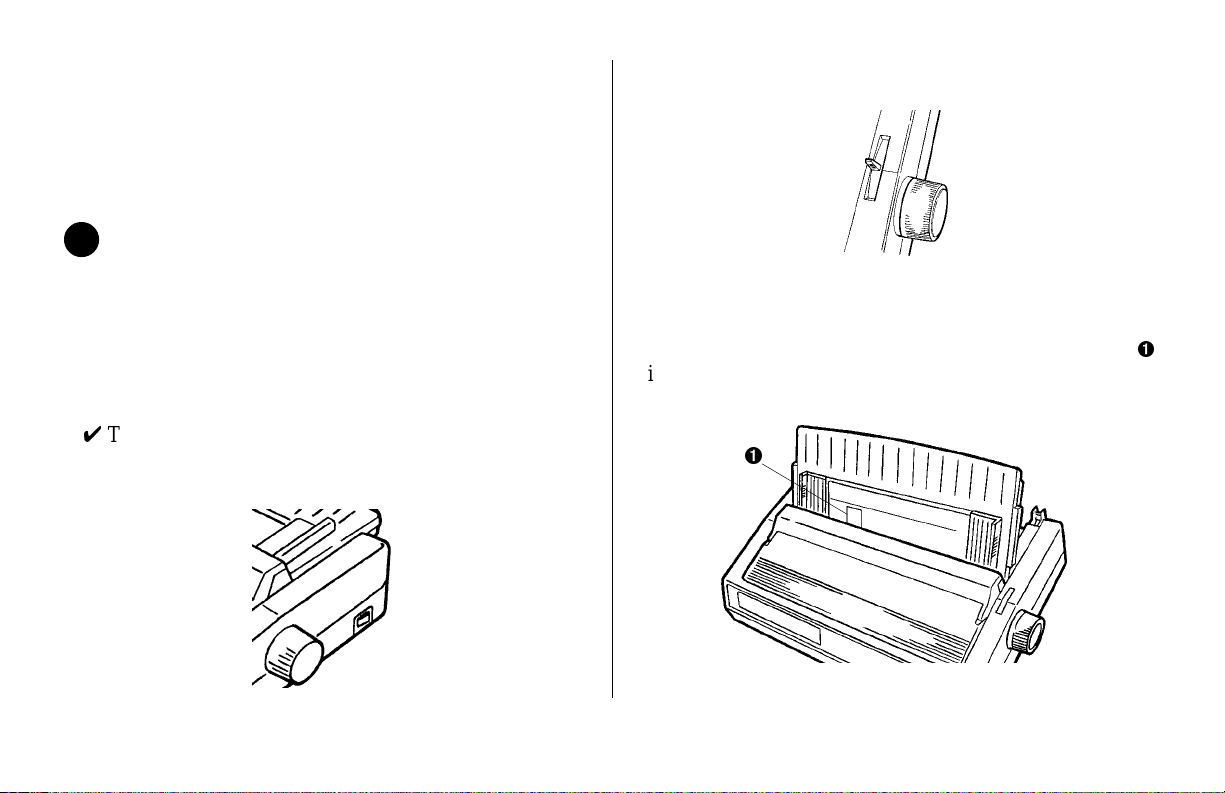

Ê

Printer

Ë

Ribbon cartridge

Ì

Power cord

Ê

Ì

4

Interface cable and paper

are sold separately.

Ë

If any of these items is missing or damaged, see your

dealer immediately for a replacement.

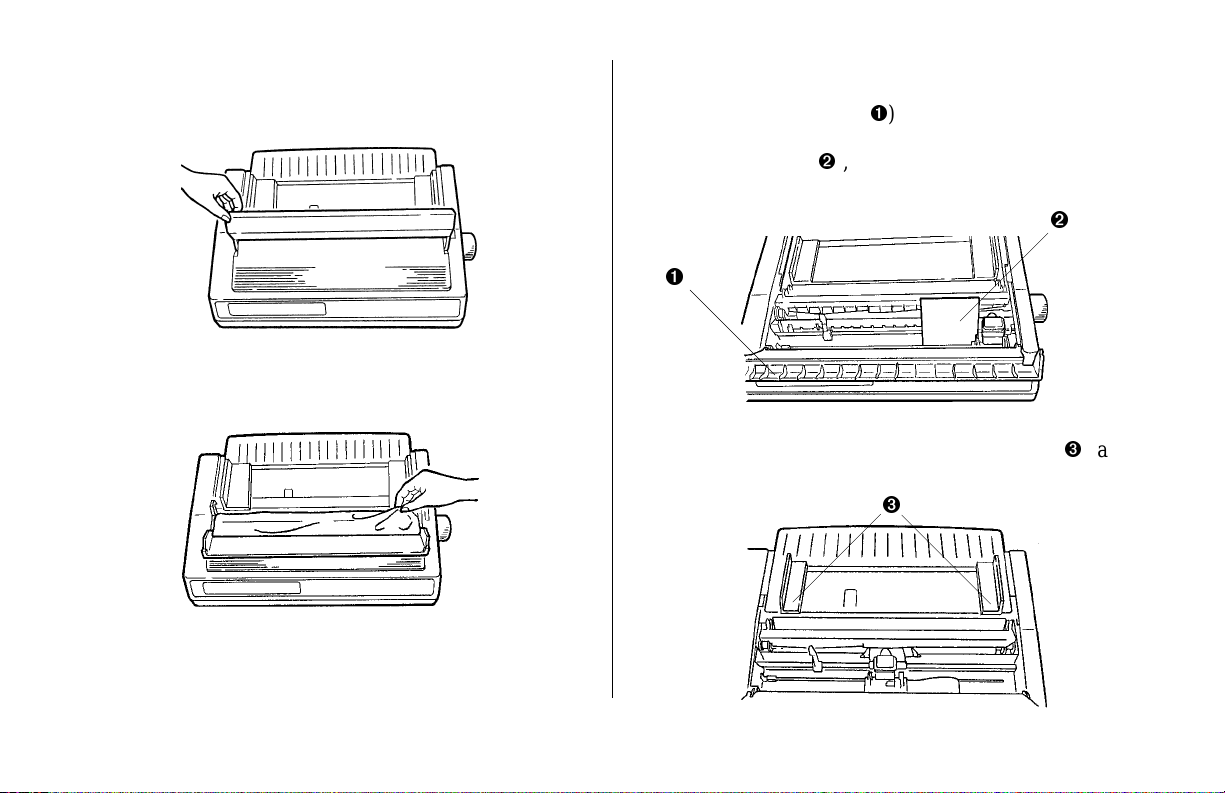

Remove The Protective Film

1. Peel the clear protective film from the carriage cover.

English-1

Page 9

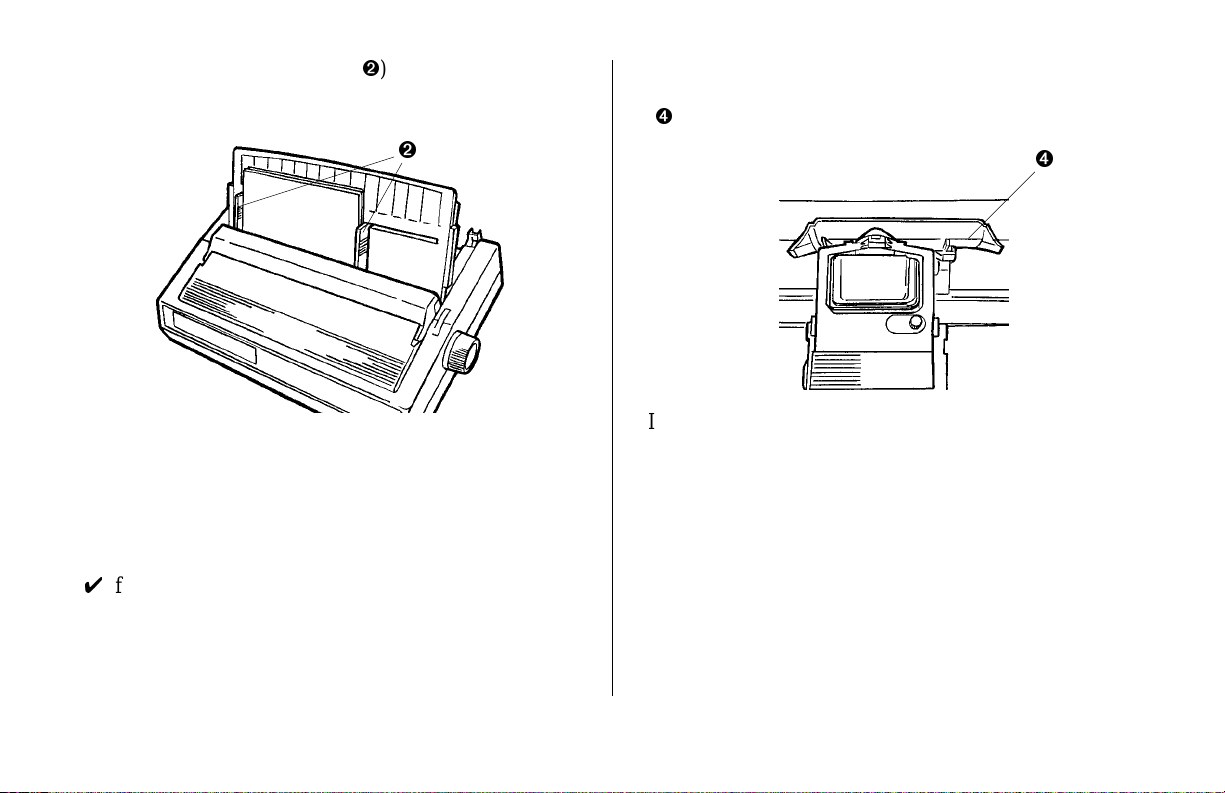

2. Lift up on the ridged area at either end of the carriage

cover.

3. Peel the clear protective film from the access cover.

Remove The Shipping Retainers

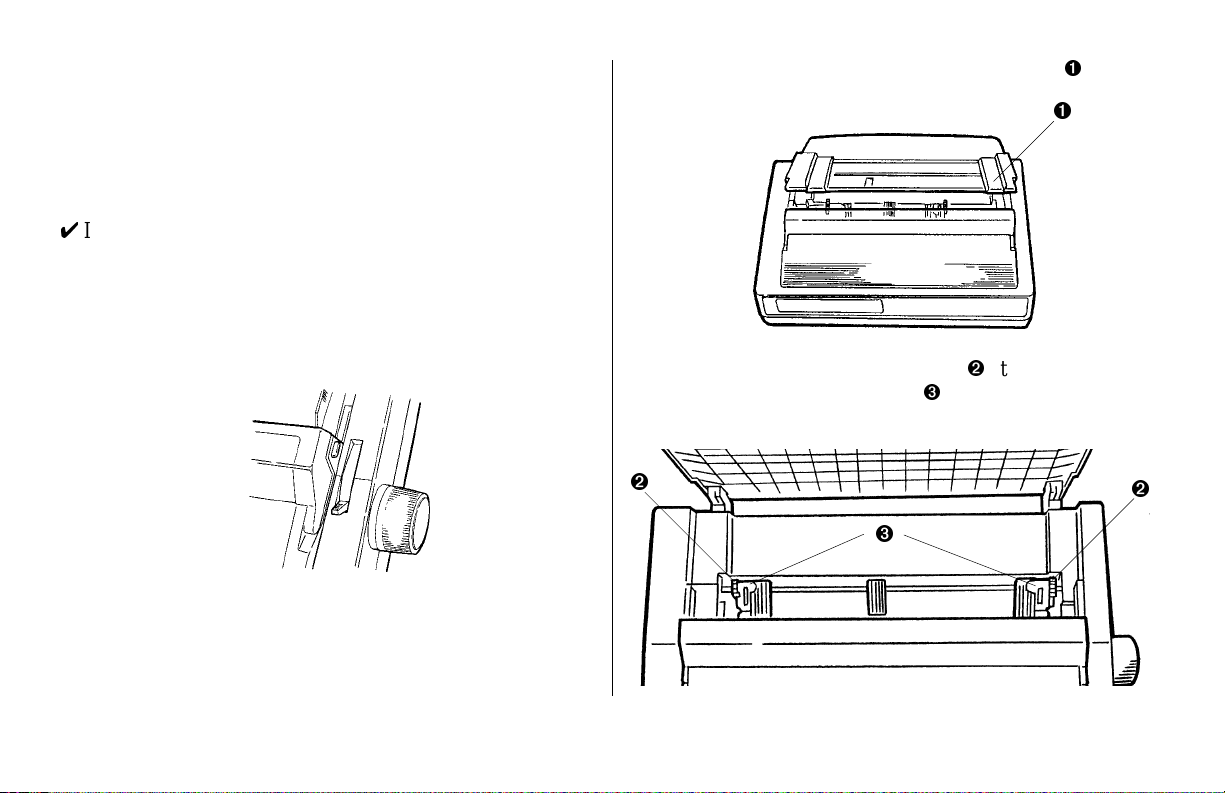

1. Open the access cover (Ê) by grasping the tabs at

either end and lifting, then remove the printhead

shipping retainer (Ë), leaving the cover open for

installation of the ribbon.

Ë

Ê

2. Grasp the front edge of the paper separator (Ì) and

pull it up.

Ì

4. Press the carriage cover back into place.

E-2 Section 1

Page 10

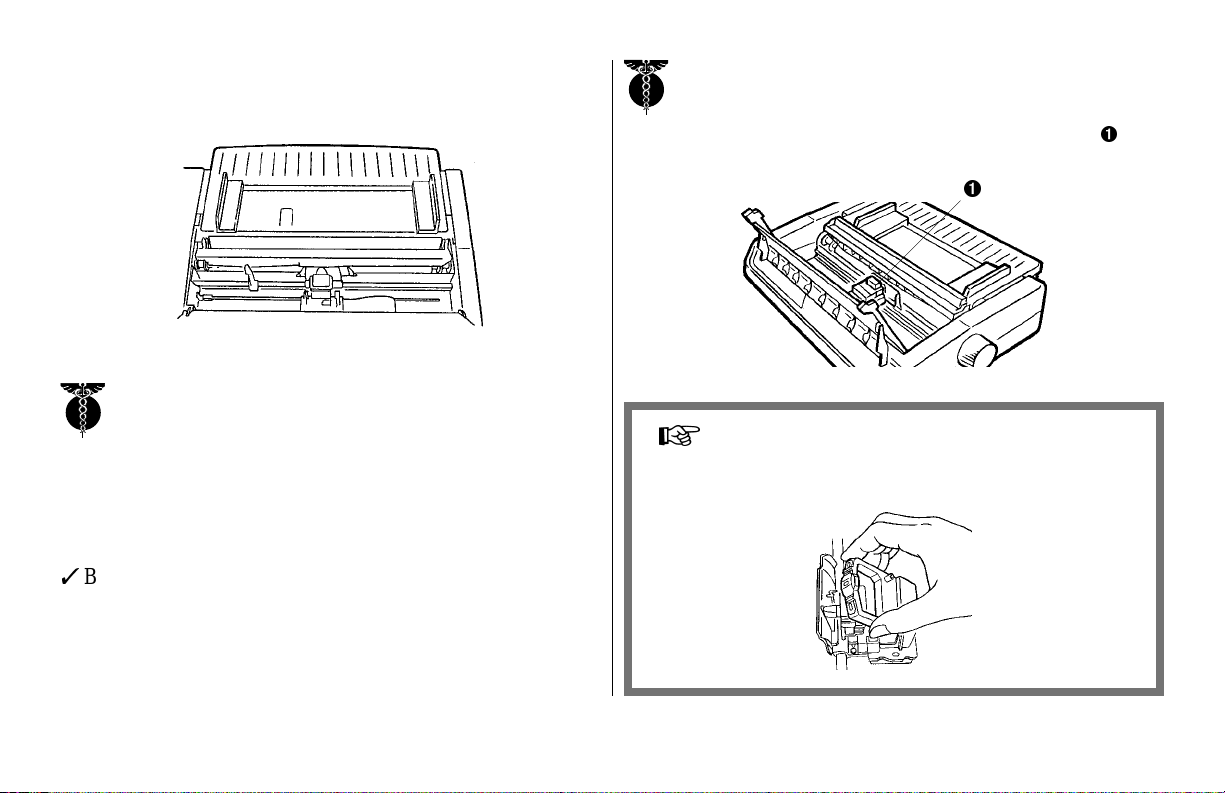

4. Remove the styrofoam shipping retainer, then lower

the paper separator and press it into place.

It is recommended that the printer be switched off

prior to opening or removing the access cover.

Install/Replace the Ribbon

Cartridge

3

Be sure to use only ribbons specifically designated for

MICROLINE 520/521 printers. For the best results, use

genuine Okidata ribbons, Part No. 52107001.

Caution! If you are replacing the ribbon, the

printhead may be

1. With the access cover open, slide the printhead (Ê) to

the center of the platen.

If you’re replacing the ribbon, lift up the

+

cartridge at the end nearest the platen, then

remove and discard it.

HOTHOT

HOT!

HOTHOT

Ê

Getting Started E-3

Page 11

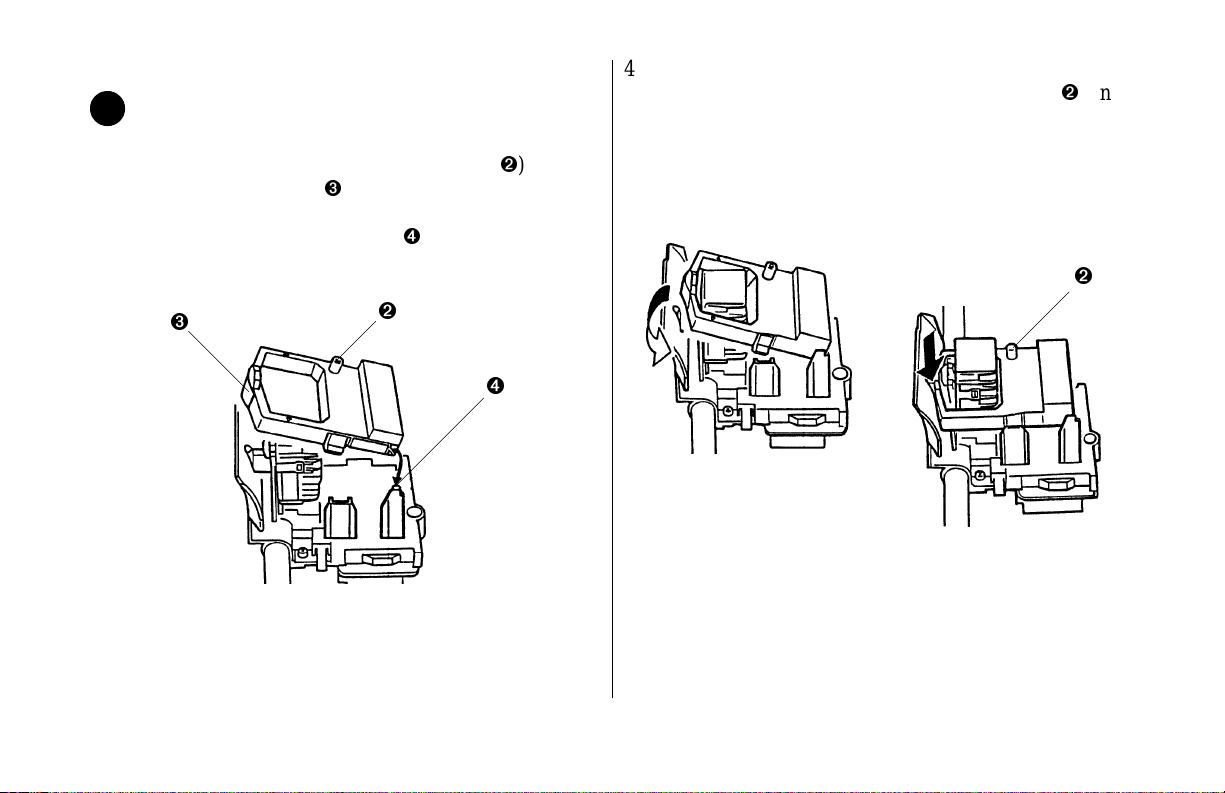

2. Remove the new ribbon cartridge from its packaging.

!

Leave the ribbon shield on the cartridge!

3. Holding the ribbon cartridge with the knob (Ë) facing

up and the ribbon shield (Ì) facing the platen, fit the

grooves on either side at the back end of the cartridge

over the pins on the ribbon plate (Í).

4. Lower the front of the cartridge over the printhead

until it snaps into place, then turn the knob (Ë) in the

direction of the arrow (clockwise) to take up the

ribbon slack.

Ë

Ì

E-4 Section 1

Ë

Í

Page 12

Connect to Power and Computer

3

You must supply the cable for connecting your printer

to your computer. A shielded cable is required in order

to ensure compliance of this equipment with FCC

regulations.

3

These instructions are for the standard parallel inter-

face. If you have the optional serial interface, see the

instructions included with it.

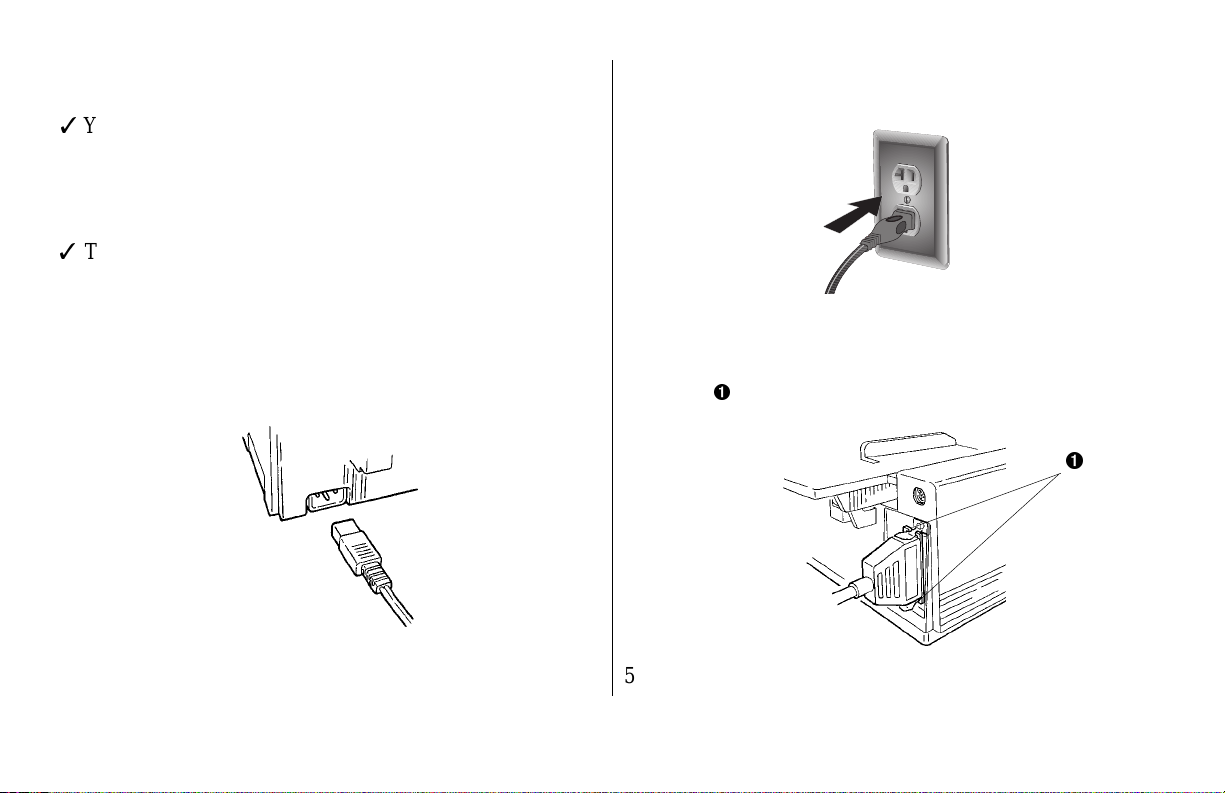

3. Plug the other end into a 120-volt, grounded outlet.

1. Make sure both the printer and the computer are off.

2. Plug the power cord into the back of the printer.

4. Plug the interface cable into the parallel port on the

back of the printer, and secure it in place with the wire

loops (Ê).

Ê

5. Turn the computer back on.

Getting Started E-5

Page 13

Power Up

Load Paper

Turn the printer on:

• The printhead will cross back and forth along the

platen, and the pins will gently fire to determine the

printhead gap setting.

• The POWER light will come on.

• The ALARM light will also come on, but don’t be

concerned: it’s just telling you that there is no paper

loaded.

Your printer has provision for

• Single sheets (top feed)

• Continuous-forms (rear feed)

You can also install options:

• Cut Sheet Feeder (top feed) — holds 100 sheets

• Push and/or Pull Tractors for bottom feed of continuous forms, including

– labels

– heavy card stock

– multi-part forms

4

See the instructions provided with the options for

information on installing them and on loading

paper with the option installed.

Your printer’s innovative, “smart” printhead automatically detects and adjusts to the thickness of the paper

you’re using, so you don’t have to fuss with setting the

printhead gap when you change the type of paper or

print path you’re using.

See Appendix A for more details on the types and sizes

of print media you can use with your printer.

E-6 Section 1

Page 14

Loading Rear-Feed Paper

The rear-feed path is recommended for printing reports,

etc., on single-thickness, continuous fan-fold paper. For

graphics or charts, it’s best to use the single-sheet paper

path.

4

If you have any paper in the paper path, be sure to

remove it from the path before installing rear-feed

paper!

1. Move the paper lever to the position marked “REAR”.

2. Grasp the front edge of the paper separator (Ê) and

pull it up to access the tractors.

Ê

3. Pull up on the tractor lock levers (Ë) to release them,

then open the tractor covers (Ì).

Ë

Ë

Ì

Getting Started E-7

Page 15

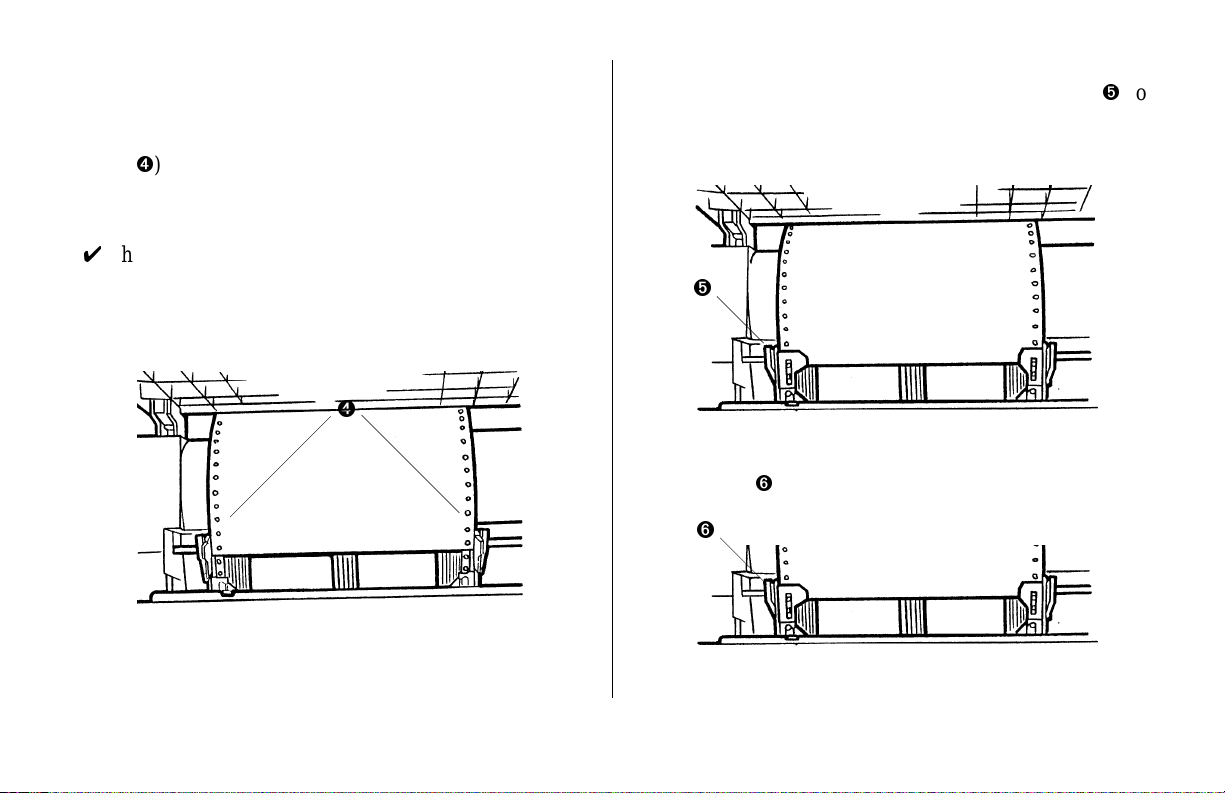

4. Position the right-hand tractor for the width of the

paper you’re loading, then pull the paper through the

opening between the printer and the rear cover, and

place the first two holes on each side over the tractor

pins (Í). Please note that an equal number of paper

holes must be engaged on either tractor in order to

ensure proper paper feed.

4

The movement of the left tractor is limited to ensure

that the paper will always contact the paper sensor

when loaded.

Í

5. Close the tractor covers and adjust the left tractor to

position the edge of the paper: reference marks (Î) on

the printer indicate the left edge position for the two

most common paper sizes.

Î

6. Lock the left tractor in place by pushing back on the

lock lever (Ï).

Ï

E-8 Section 1

Page 16

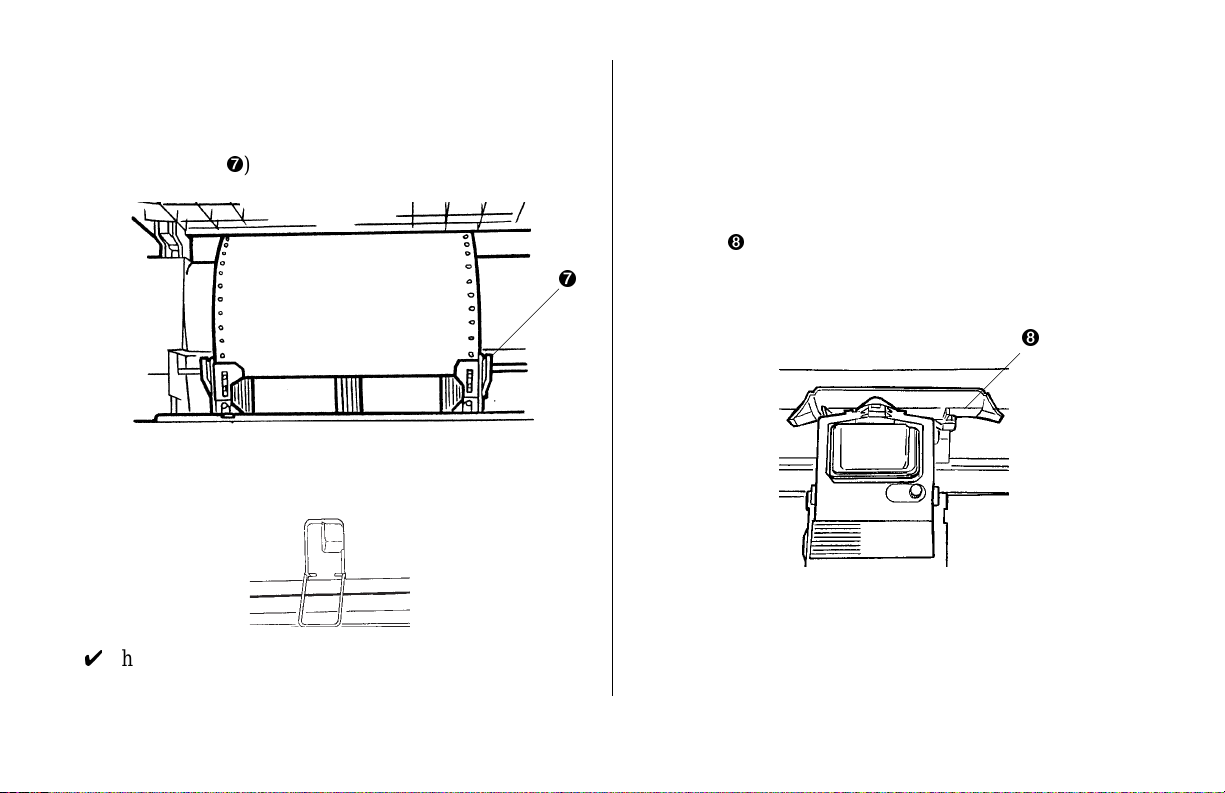

7. Adjust the right tractor so that the paper holes are

centered on the pins (careful—if paper is stretched too

tight or left too loose, it can jam and cause problems),

then lock the right tractor in place by pushing back on

the lock lever (Ð).

Ð

8. Close the paper separator and flip the wire feed guide

over onto the pull-up roller assembly.

9. Push the FF/LOAD button. The paper will automatically feed into the printer and the ALARM light will go

out. The printhead moves back and forth, gently firing

the pins to sense the paper thickness and set the

printhead gap.

10. Check the baseline for the Top of Form (TOF),

indicated by the red line on the clear plastic paper

shield (Ñ). If it’s OK, press the SEL button and

you’re ready to start printing. If it needs adjustment,

set the Top of Form.

Ñ

4

The wire feed guide keeps paper from curling back

into the printer.

Getting Started E-9

Page 17

Loading Single-Sheet Paper

The single-sheet path is best for letterhead stationery,

memos, and envelopes and is recommended for printing

graphs and charts because it provides the most accurate

control of the paper.

If you have any continuous-form paper in the

!

paper path, you must press the PARK button on the

front panel to remove it from the path before loading single sheets.

1. Make sure the printer is turned ON and deselected

(SEL light off—press SEL button to deselect if necessary).

4

The ALARM light will remain on until paper is

loaded.

2. Move the paper lever to the position marked “TOP”.

3. Grasp the back of the paper separator and unsnap it

from the housing, then swing it up into the single-sheet

feed position, making sure that the wire feed guide (Ê)

is nestled in the separator.

Ê

E-10 Section 1

Page 18

4. Adjust the paper feed guides (Ë) for the width of the

paper and drop a sheet of paper into the separator.

5 . Check the baseline for the Top of Form (TOF), indi-

cated by the red line on the clear plastic paper shield

(Í).

Ë

The paper will automatically feed into the printer, and

the printhead will move back and forth, gently firing

the pins to sense the paper thickness and set the

printhead gap.

4

If the paper doesn’t feed in properly, the “15” light

on the control panel will begin flashing. To correct

this, press the SHIFT and RESET buttons simultaneously, then reload the sheet.

Í

If it’s OK, press the SEL button and you’re ready to

start printing. If it needs adjustment, set the Top of

Form following the instructions on the next page.

Getting Started E-11

Page 19

Set the Top of Form

The red line (Ê) on the

clear plastic paper

shield shows the

baseline of the current

printing position to help

you place the top of

form.

To set the Top of Form:

ÊË

SEL

SEL

MENU

EXIT

SHIFT

Micro Feed

Down

GROUP

Í

LF

Ì

FF/LOAD

Micro Feed

Up

TEAR PARK QUIET

SET

TOF

PRINTITEM

Ê

When you’re done setting the TOF, press the SEL button

(Ê) to reselect the printer.

Temporarily Changing the Print Start Position

To place the print start position lower for one page only:

1 . Press SEL to deselect the printer.

2 . Keep pressing the LF button until the red line on the

paper shield reaches the new position.

Resetting Top of Form to Default

To reset the Top of Form to the factory default, turn off

the printer, then hold down the QUIET and PARK

buttons while turning the printer back on.

1 . Make sure the printer is deselected (SEL light off—if

necessary, press SEL (Ê) button to deselect printer).

2. Hold down the SHIFT button (Ë) and press:

• FF/LOAD button (Ì) to move the paper up in micro

increments (TOF lower on page), or

• LF button (Í) to move the paper down in micro

increments (TOF higher on page).

E-12 Section 1

SEL

SEL

MENU

EXIT

SHIFT

LF

Micro Feed

Down

GROUP

FF/LOAD

Micro Feed

TEAR PARK QUIET

Up

SET

TOF

PRINTITEM

Top of Form interacts with the Forms Tear-Off setting.

For more information, see Continuous Forms: Setting

Forms Tear-Off and Top of Form.

Page 20

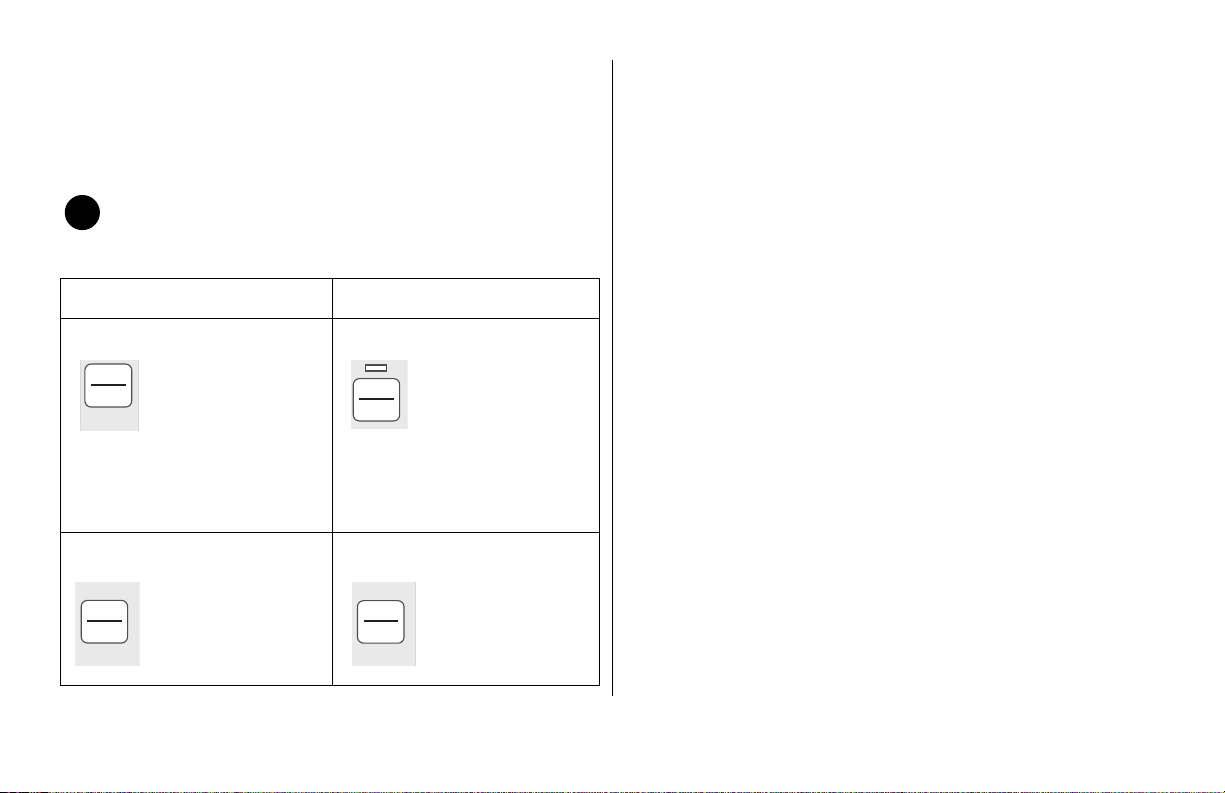

Run the Self Tests

Selecting an Emulation

After you've installed ribbon and paper, you are ready to

run the self tests. Do this any time you want to make sure

the printer is functioning properly.

For wide carriage Model 521, be sure you have

!

wide paper loaded!

Font Sample Test Rolling ASCII Test

To run the test: To run the test:

LF

Micro Feed

Down

GROUP

To stop the test before it To stop the test:

SEL

SEL

MENU

EXIT

Turn the printer Turn the printer

off, then press off, then press

and hold the LF and hold the

QUIET

TOF

key while QUIET key while

turning the turning the

printer back on. printer back on.

finishes:

Press SEL. Press SEL.

SEL

SEL

MENU

EXIT

Your printer has three emulations:

• IBM Proprinter III (factory default)

• Epson FX

• Okidata Microline Standard

Changing Emulations

Your printer is set at the factory for the IBM Proprinter III

emulation. To change the emulation:

1. Enter the Menu mode by holding the SHIFT button

while pressing the SEL button. The following line will

print:

Printer Control Emulation Mode IBM PPR

2 . Press the SET button until the emulation you wish to

select prints.

3. Exit the Menu and save your setting by holding the

SHIFT button while pressing the SEL button.

Getting Started E-13

Page 21

Selecting a Printer Driver

The drivers in the table below are listed by decreasing

compatibility with your printer: use one as close to the

top of the list as possible. If your software does not have

a printer driver from near the top of the list, call the

manufacturer to see if they have added any drivers to

those supplied when you purchased your software.

4

See your software documentation for instructions on

how to install a printer driver.

Printer Drivers

IBM Proprinter III EmulationIBM Proprinter III Emulation

IBM Proprinter III Emulation

IBM Proprinter III EmulationIBM Proprinter III Emulation

Okidata ML 520/1 IBM

IBM Proprinter III

IBM Proprinter II

IBM Proprinter

IBM Graphics Printer

Epson FX EmulationEpson FX Emulation

Epson FX Emulation

Epson FX EmulationEpson FX Emulation

Okidata ML 520/1 Epson

Epson FX850/1050

Epson FX86/286

Epson FX

Epson EX800/1000

Okidata Microline Standard EmulationOkidata Microline Standard Emulation

Okidata Microline Standard Emulation

Okidata Microline Standard EmulationOkidata Microline Standard Emulation

Okidata Microline 520/521

Okidata Microline 320/321

Okidata Microline 292/293

Okidata Microline 192/193

Okidata Microline 182/183

Okidata Drivers

Okidata drivers are available for a variety of operating

systems.

You can obtain the drivers by downloading them from

the web site at

ä

http://www.okidata.com

E-14 Section 1

Page 22

ection 2: Maintaining Your Printer

S

Replacing the Ribbon Cartridge

To replace the ribbon cartridge, see “Install/Replace the

Ribbon Cartridge” in Section 1. For the best results, use

genuine Okidata ribbons, Part No. 52107001.

Clearing Paper Jams

Always turn the printer off before you turn the

!

platen knob!

Clearing Rear Feed Jams

To clear a rear-feed paper jam:

1. Turn off printer then turn the platen knob to back the

paper out of the printer.

2. Remove any ripped pieces of paper.

3. Reload the paper, turn the printer back on and press

the FF/LOAD button.

Correcting for Continuing Rear-Feed Jams

If the paper keeps jamming, you probably have bits of

paper stuck in the paper path.

1 . Turn off the printer.

2. Use the platen knob to back the paper out.

3. Open the access cover and lift off the pull-up roller

assembly.

English-15

Page 23

4. Lift the paper separator, open the tractors and remove

the paper.

5. Fold some continuous-feed paper over three times to

make a page four sheets thick and load it on the

tractors. Use the platen knob to draw the sheet around

the platen: this brings any jammed bits of paper out.

6. Back the sheet out.

7. Replace the roller assembly.

8. Reload regular paper.

9. Close the access cover.

10 . Turn the printer on.

11 . Press the FF/LOAD button.

Clearing Single Sheet Feed Jams

1. Turn the printer off.

2. Rotate the platen knob to back the jammed paper out

of the carriage.

3. If necessary, open the access cover and lift off the

pull-up roller assembly to provide access to remove

any ripped pieces from around the carriage.

E-16 Section 2

Page 24

Cleaning the Housing

You should clean the printer every six months (or after

about 300 hours of operation).

1 . Turn the printer OFF.

2. Remove the paper from the path.

3. Open the access cover and remove the pull-up roller

assembly.

4. Use a clean, dry cloth to dust the area around the

carriage shaft and platen. Be sure to remove any loose

particles of paper.

5. Reinstall the pull-up roller assembly.

6. Close the access cover.

Never use solvents or strong detergents on the

!

cabinet — they could damage the housing.

Maintaining Your Printer E-17

Page 25

Page 26

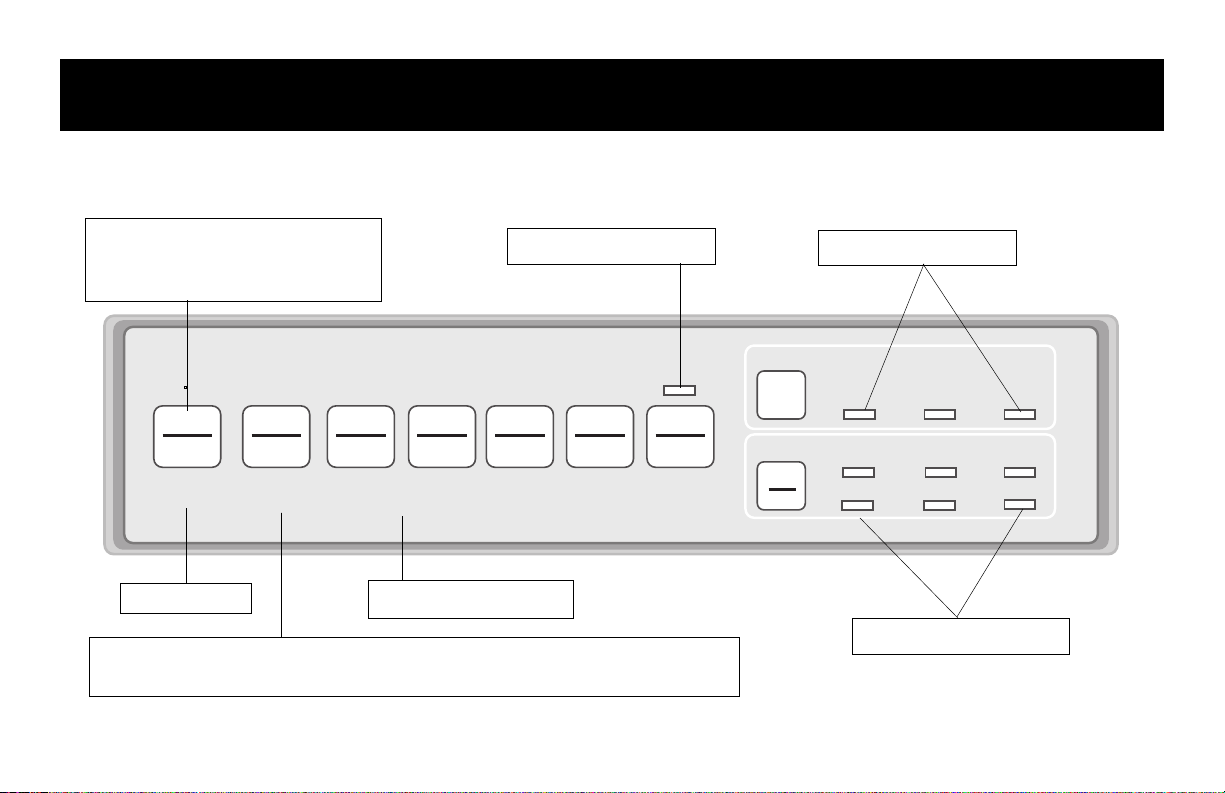

ection 3: Using Your Printer

S

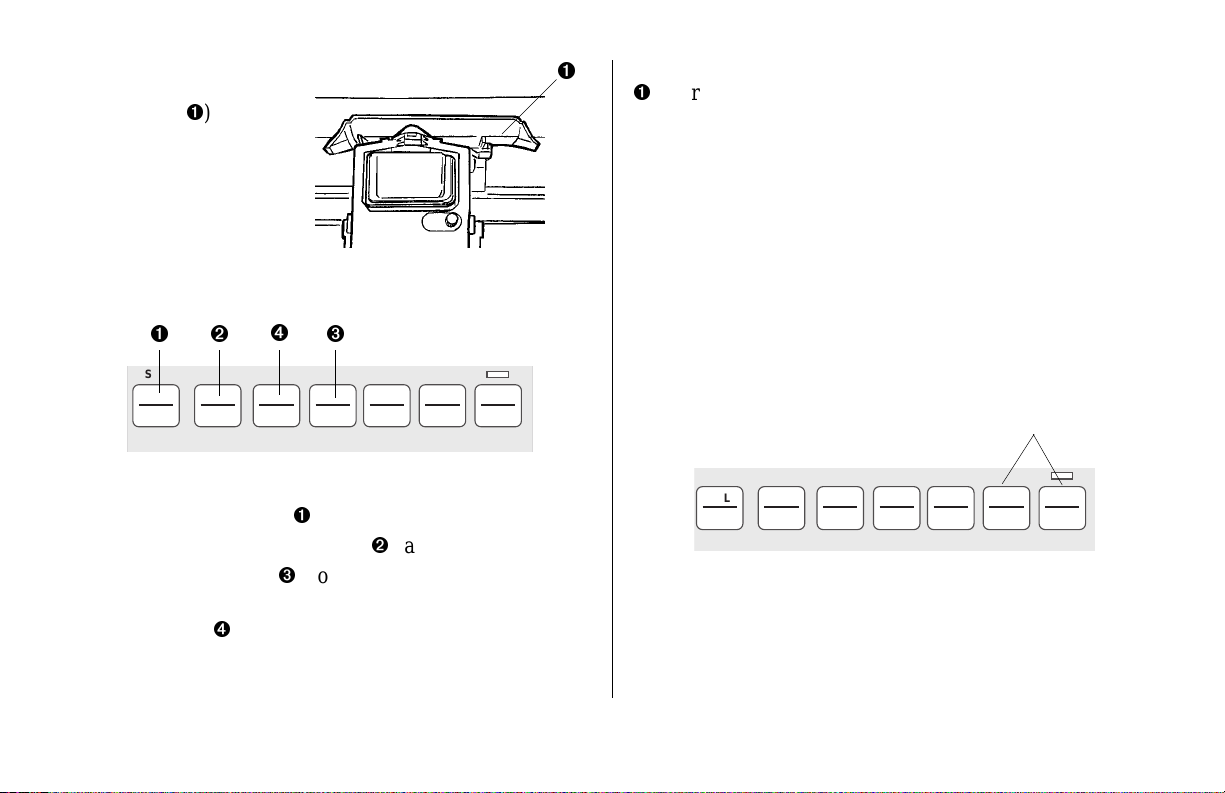

Control Panel Indicator Lights

Glows = printer selected, ready to receive data

Flashes = printer in Print Suppress mode

Not lit = printer deselected (can't receive data)

SEL

SEL

MENU

EXIT

POWER

Glows = printer on

Glows = error condition exists, such as out of paper or paper jam, or paper lever is set to wrong position.

Blinks = unrecoverable error condition. Turn printer off, then on; if light still flashes, contact service dealer.

SHIFT

ALARM MENU

LF

Micro Feed

Down

GROUP

FF/LOAD

Micro Feed

Up

Glows = printer in Menu mode

Glows = printer in QUIET state

TEAR PARK QUIET

TOF

SET

PRINTITEM

Indicate Print Quality selected

PRINT QUALITY

HSD

CHARACTER PITCH

RESET

10

17

Indicate Character Pitch selected

UTILITY

12

20

NLQ

15

PROP

English-19

Page 27

Control Panel Buttons: Print Mode

Press to select (SEL glows)/deselect printer.

Press to reset paper alarm (ALARM glows).

Press to end printer tests.

Press with SHIFT to enter Menu mode.

SEL

SEL

MENU

EXIT

POWER

SHIFT

ALARM MENU

Press to move paper up a line.

Hold for repetitive line feeds.

Hold on power up to start Font test.

LF

Micro Feed

Down

GROUP

FF/LOAD

Micro Feed

Up

Moves continuous-form paper up for

tear-off or back down for printing.

TEAR PARK QUIET

TOF

SET

PRINTITEM

Press to turn Quite mode On (light glows) and Off.

Printer deselected and no paper loaded: press with

SHIFT button to reset TOF to default

Hold on power up to start Rolling ASCII Test.

Press to set print quality, indicated

by lights (HSD, UTILIT Y, NLQ).

PRINT QUALITY

HSD

CHARACTER PITCH

RESET

10

17

UTILITY

12

20

NLQ

15

PROP

Used with other buttons to set TOF.

Press with SEL to enter Menu mode.

E-20 Section 3

Retracts continuous-form paper from path.

Press to load/eject single sheet, or to move continuous-form paper to print position.

Printer deselected: press with SHIFT to move TOF down.

Press to set character pitch, indicated

by lights (10, 12, 15, 17, 20, PROP).

Page 28

Control Panel Buttons: Menu Mode

Press to reset paper out alarm.

Press with SHIFT button to exit Menu mode.

Press and hold with LF button on power up to reset Menu to factory defaults.

Press to advance to next Group in Menu.

Press with SHIFT button to go back to previous Group in Menu.

SEL

SEL

MENU

EXIT

POWER

LF

SHIFT

ALARM MENU

Micro Feed

Down

GROUP

FF/LOAD

Micro Feed

Up

Press to advance to next setting for the Item.

TEAR PARK QUIET

TOF

SET

PRINTITEM

PRINT QUALITY

HSD

CHARACTER PITCH

RESET

10

17

UTILITY

12

20

Press and hold with SHIFT

button to print out listing of

all Menu settings, regardless

of emulation or options

engaged.

NLQ

15

PROP

Press with SEL button to exit Menu mode.

Press to advance to next Item within a Group.

Press with SHIFT button to go back to previous Item in the Group.

Press to print list of current Menu settings.

Press with SHIFT button to print out current Group Menu settings.

Using Your Printer E-21

Page 29

Print Mode

The seven buttons to the left on your control panel are

multi-function buttons. In the print mode, they are used

to manipulate the paper (see the illustration on the first

page of this chapter).

The PRINT QUALITY and CHARACTER PITCH buttons

on the right side of the control panel are used to select

the quality and size of the printing.

4

The print quality and character pitch set by means of

the front panel can be overridden by commands sent

by the commercial software package from which

you’re printing a document. If you run into this problem, see page 38 for information on how to correct it.

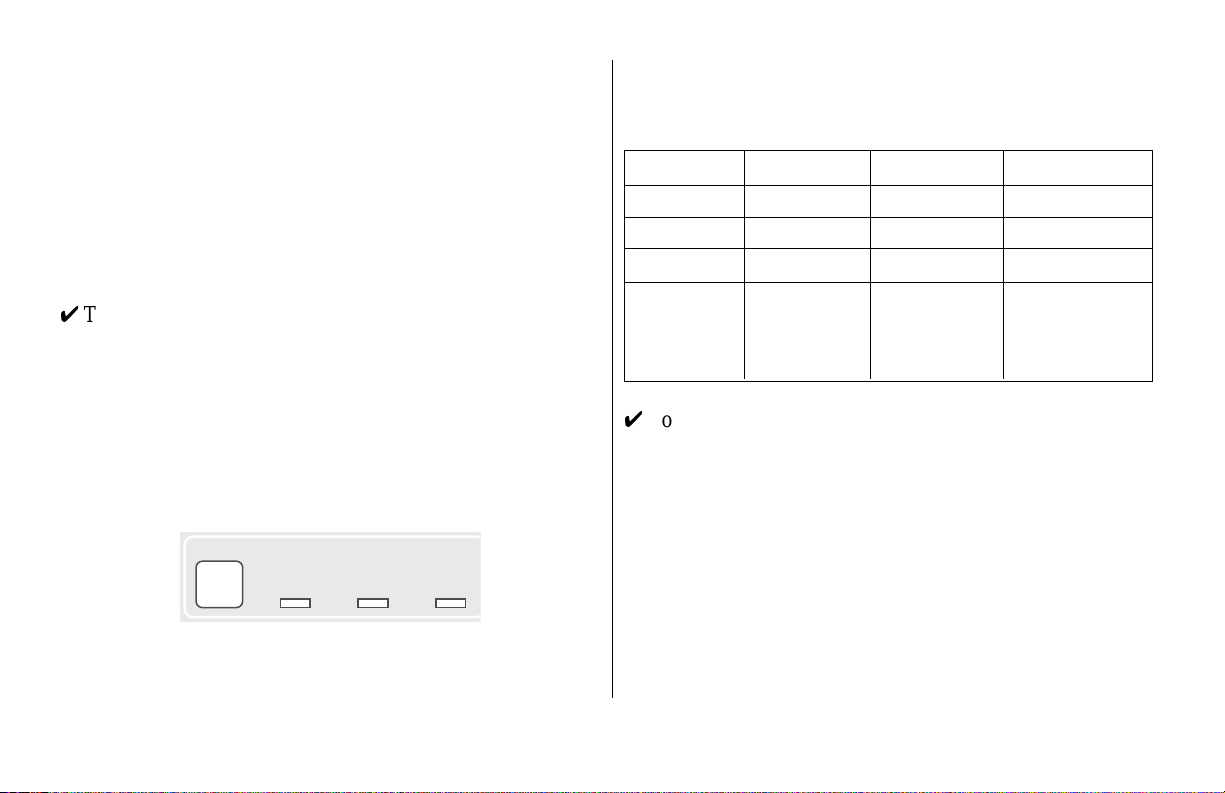

Selecting Print Quality

PRINT QUALITY

Press the PRINT QUALITY button successively until the

light underneath the print quality you wish to engage is

lit:

Print Quality HSD UTILITY NLQ

Typeface Gothic Gothic Courier or Gothic

Print Speed Fastest Fast Slowest

Quality Lowest Medium Highest

Used for Data reports Rough drafts, Correspondence,

4

Your printer also prints bar codes accessible through

on continuous internal memos documents requirforms paper ing a polished

appearance

printer commands. The Microline Reference Manual

provides complete lists of all the commands, along

with information on their use.You may view this

document by accessing it on the CD provided with

your printer.

E-22 Section 3

HSD

UTILITY

NLQ

Page 30

Selecting Character Pitch

4

If the SI command is received from your software, the

character pitch selected on the control panel will be

overridden by the SI command.

CHARACTER PITCH

RESET

Character pitch determines the width of the individual

characters and is measured in characters per inch (cpi).

Press the CHARACTER PITCH button successively to

page through the possible selections.

Epson and IBM emulations — 10 cpi, 12 cpi, 15 cpi,

17 cpi, 20 cpi, or Proportional. The lights indicate

which pitch is selected.

Okidata Microline Standard emulation — 10, 12, 15,

17, or 20 cpi, either non-proportional or proportional:

proportional is selected when both the light under the

desired cpi and the light under PROP are lit.

To reset the character pitch to the factory default (10 cpi),

make sure the printer is deselected (SEL light out), then

hold the SHIFT button while pressing CHARACTER

PITCH button.

10

17

12

20

15

PROP

Available Fonts

Typeface Spacing

NLQ Courier 10 cpi*, 12 cpi, 15 cpi, 17 cpi, 20 cpi,

Proportional

NLQ Letter Gothic 10 cpi*, 12 cpi, 15 cpi, 17 cpi, 20 cpi,

Proportional

Utility (Gothic) 10 cpi*, 12 cpi, 15 cpi, 17 cpi, 20 cpi,

Proportional

High Speed Draft 10 cpi*, 12 cpi, 15 cpi, 17 cpi, 20 cpi

(Gothic)

Bar Code** Code 39, UPC A, UPC E, EAN 8, EAN 13,

Interleaved 2 of 5, Code 128, Postnet

* cpi = characters per inch

** Bar codes are available only through appropriate software

packages or through programming.

Using Your Printer E-23

Page 31

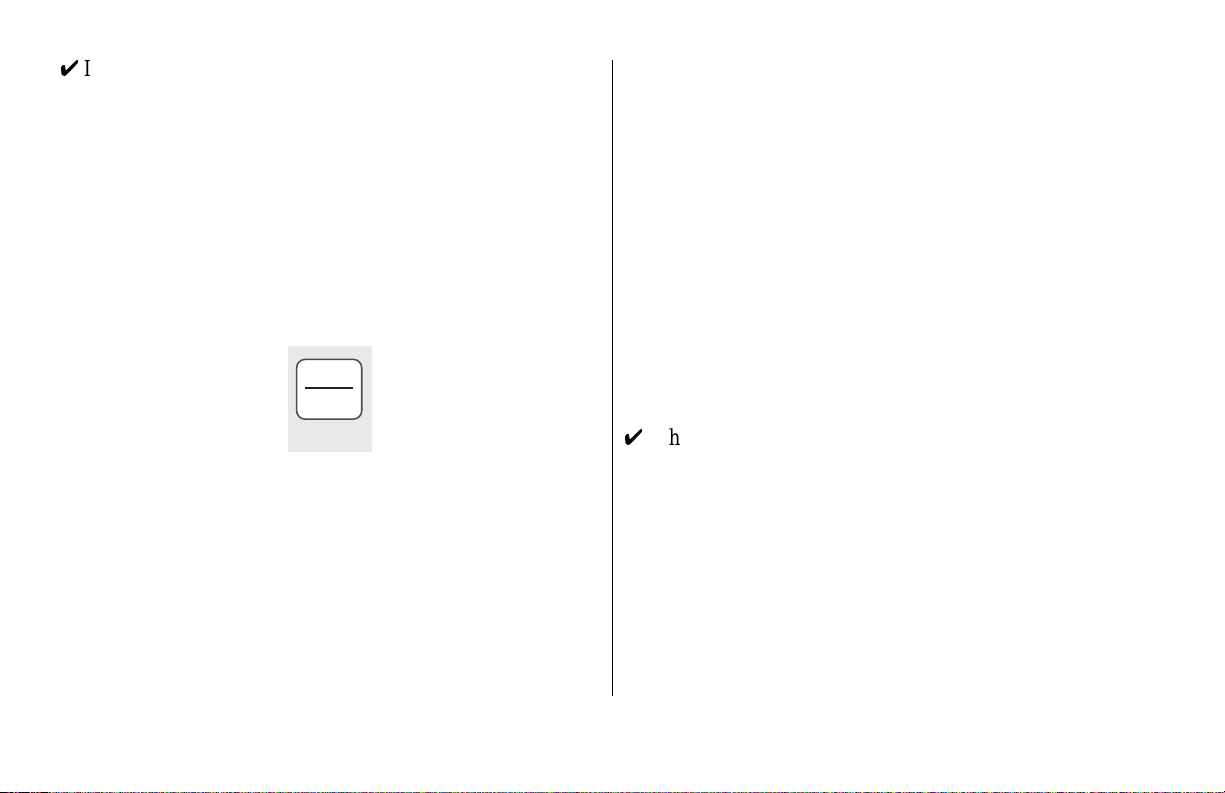

Menu Mode

When your printer is in the Menu Mode, you can use the

front panel controls to change the defaults for the printer

parameters, including emulation, page length, line

spacing, typeface, pitch, etc. The changes you make in

the Menu Mode will automatically be saved in your

printer’s memory when you exit the Menu Mode and will

be retained even if you turn the printer off.

If you are in the Menu Mode and turn the printer

!

off without first exiting, any changes you have

made in the menu will be lost.

Exiting The Menu Mode

To exit the Menu Mode, hold the SHIFT button and press

the SEL button. The MENU light will go out and the SEL

light will come on.

Resetting The Menu

To reset the Menu to the factory defaults, turn the printer

off, then hold the SEL and LF buttons while turning it

back on.

Printing Out the Menu

Entering The Menu Mode

To place your printer in the Menu Mode hold the SHIFT

button while pressing the SEL button. The MENU light

will come on and, if the printer was selected, the SEL

light will go out.

E-24 Section 3

To print out the menu settings engaged, enter the Menu

Mode, then press the PRINT button.

Page 32

Sample Default Menu Printout

Printer Control Emulation Mode IBM PPR

Font Print Mode Utility

Font Pitch 10 cpi

Font Proportional Spacing No

Font Style Normal

Font Size Single

Symbol Sets Character Set Set I

Symbol Sets Language Set American

Symbol Sets Zero Character Slashed

Symbol Sets Code Page USA

Rear Feed Line Spacing 6 LPI

Rear Feed Form Tear-Off Off

Rear Feed Skip Over Perforation No

Rear Feed Page Length 11”

Rear Feed Gap Control Auto Gap

Bottom Feed Line Spacing 6 LPI

Bottom Feed Form Tear-Off Off

Bottom Feed Skip Over Perforation No

Bottom Feed Page Length 11”

Bottom Feed Gap Control Auto Gap

Top Feed Line Spacing 6 LPI

Top Feed Bottom Margin Valid

Top Feed Page Length 11”

Top Feed Gap Control Auto Gap

Top Feed Wait Time 1 sec

Set-Up Graphics Uni-directional

Set-Up Receive Buffer Size 64K

Set-Up Paper Out Override No

Set-Up Print Registration 0

|||||||||||||||||||||||||||||||||||||—(FWD)— |||||||||||||||||||||||||||||||||||||

|||||||||||||||||||||||||||||||||||||—(REV)— |||||||||||||||||||||||||||||||||||||

Set-Up Operator Panel Function Full Operation

Set-Up Reset Inhibit No

Set-Up Print Suppress Effective Yes

Set-Up Auto LF No

Set-Up Time Out Print Valid

Set-Up Auto Select No

Set-Up Printhead Gap Adjust 0

Parallel I/F I-Prime Buffer Print

Parallel I/F Pin 18 +5v

Using Your Printer E-25

Page 33

Summary of Menu Settings

The table below details all possible entries in the printer Menu. The defaults are in bold italics. Explanations for each

item (in alphabetical sequence) follow the table.

Group Item Settings

Printer Control Emulation Mode IBM PPR, Epson FX, ML

Font Print Mode Utility, NLQ Courier, NLQ Gothic, HSD

Pitch 10 cpi, 12 cpi, 15 cpi, 17.1 cpi, 20 cpi

Proportional spacing No, Ye s

Style Normal, Italics

Size Single, Double

Symbol Sets Character Set Set I, Set II

Language Set American, French, German, British, Danish I, Swedish, Italian, Spanish I, Japanese, Norwegian,

Danish II, Spanish II, Latin American, French Canadian, Dutch, Publisher

Zero Character Slashed, Unslashed

Code Page USA, Canada French, Multilingual, Portugal, Norway

Rear Feed Line Spacing 6 LPI, 8 LPI

Form Tear-Of f Off, 500ms, 1 sec, 2 sec

Skip Over Perforation No, Yes

E-26 Section 3

Page 34

Group Item Settings

Rear Feed (cont.) Page Width* 13.6”, 8”

Page Length 11”, 11-2/3“, 12”, 14”, 17”, 3”, 3.5”, 4”, 5.5”, 6”, 7”, 8”, 8.5”

Gap Control Auto Gap, Semi Auto Gap, 1, 2, 3, 4, 5, 6, 7, 8, 9

Bottom Feed ∗∗ Line Spacing 6 LPI, 8 LPI

Form Tear-Of f Off, 500ms, 1 sec, 2 sec

Skip Over Perforation No, Yes

Page Width* 13.6”, 8”

Page Length 11”, 11-2/3“, 12”, 14”, 17”, 3”, 3.5”, 4”, 5.5”, 6”, 7”, 8”, 8.5”

Gap Control Auto Gap, Semi Auto Gap, 1, 2, 3, 4, 5, 6, 7, 8, 9

Top Feed Line Spacing 6 LPI, 8 LPI

Bottom Margin Valid, In valid

Page Width* 13.6”, 8”

Page Length 11”, 11-2/3“, 12”, 14”, 17”, 3”, 3.5”, 4”, 5.5”, 6”, 7”, 8”, 8.5”

Gap Control Auto Gap, Semi Auto Gap, 1, 2, 3, 4, 5, 6, 7, 8, 9

Wait T ime 500 ms, 1 sec, 2 sec

∗ Model 521 only

** Applicable only when optional Bottom-Feed Push Tractor is installed.

Using Your Printer E-27

Page 35

Group Item Settings

Set-Up Graphics Uni-directional, Bi-directional

7 or 8 Bit Graphics‡ 8, 7

Receive Buffer Size 64K, 1 Line, 32K

Paper Out Override No, Yes

Print Registration 0, 0.05 mm Left, 0.10 mm Left, 0.15 mm Left, 0.20 mm Left, 0.25 mm Left, 0.25 mm Right,

Operator Panel Function Full Operation , Limited Operation

Reset Inhibit No, Ye s

Print Suppress Effective Yes, No

Auto LF No, Ye s

Auto CR† No, Yes

Print DEL Code‡ No, Yes

SI Select Pitch (10 cpi)† 17.1 CPI, 15 CPI

SI Select Pitch (12 cpi)† 20 CPI, 12 CPI

Time Out Print V alid, In valid

Auto Select No, Yes

Printhead Gap Adjust 0, -1, +1

0.20 mm Right, 0.15 mm Right, 0.10 mm Right, 0.05 mm Right

† Appears only when IBM Proprinter emulation is selected.

‡ Appears only when MICROLINE Standard emulation is selected.

E-28 Section 3

Page 36

Group Item Settings

Parallel I/F I-Prime Buffer Print, Buffer Clear, Invalid

Pin 18 +5V, Open

Auto Feed XT♥ Invalid, Valid

♥ Appears only when Epson LQ emulation is selected.

Explanation of Menu Items

These explanations are in alphabetical sequence. Line

Spacing, Form Tear-Off, Skip Over Perforation, Page

Length, and Gap Control appear several times in the

menu.

7 or 8 Bit Graphics. Choose graphics your system uses:

7 or 8 (factory default) dots in each column printed.

Auto CR (IBM). If you wish to have the printer automatically add a carriage return when a Line Feed is

received at the end of the line, change the setting to Yes.

Auto LF. If your printout is consistently double spaced,

select No (factory default); if it overprints, choose Yes.

Auto Feed XT (Epson). If your system uses pin 14 of the

parallel interface to control automatic line feed, change

the setting to Valid.

Auto Select. With the factory default (No) engaged, the

printer will remain deselected after you load in paper so

that you can set the Top of Form. If you always use the

same Top of Form setting, change this setting to Yes.

Bottom Margin. Change the setting to Invalid if you

want printer to ignore the bottom margin setting. Cau-

tion!! This can cause loss of data and damage the

printhead.

Character Set. Choose IBM Set I (factory default) or

IBM Set II.

Code Page. Choose USA (factory default), Canada

French, Multilingual, Portugal, or Norway.

Emulation Mode. Choose IBM PPR (default) for IBM

Proprinter III, Epson FX, or ML for Okidata Microline

Standard.

Using Your Printer E-29

Page 37

Form Tear-Off. Choose 500ms, 1 sec, or 2 sec to turn

this feature on and select a time interval for the printer to

wait before advancing the paper.

Gap Control. Determines how the printhead gap is set.

Auto Gap automatically determines paper thickness on

first page: for single sheets, it also rechecks each page

while printing. Semi Auto Gap is similar; but it does not

recheck single sheets while printing. You can also choose

a fixed headgap setting of 1 (narrowest) to 9 (widest).

Graphics. Change to bi-directional graphics for faster

printing: optimize by the Print Registration setting in the

Menu.

I-Prime. Sets what the printer does when it receives the IPrime signal from software. Buffer Print (factory default):

prints out buffer contents before resetting. Buffer Clear:

dumps buffer contents immediately. Invalid: ignores IPrime signal.

Language Set. Replaces certain symbols with special

characters used in the respective foreign language.

Line Spacing. Change from 6 to 8 lpi (lines per inch) to

get more lines per page.

Operator Panel Function. Change to Limited Operation to

deactivate PRINT QUALITY and CHARACTER PITCH

buttons when several people are using the printer and you

don’t want these settings changed from the control panel.

4

This feature also prevents normal access to the

Menu. To access the Menu, turn the printer off, then

hold down the SEL key while turning the printer on.

Page Length. Selects the length of the paper you’re using.

Page Width (Model 521 only). Choose 8” for letter-size

paper.

Paper Out Override. Senses when less than one inch of

paper remains and stops printing. Choose Yes to override

the detector. Caution!! This can cause loss of data and

damage the printhead.

Pin 18. Sets the signal on pin 18 to +5V (factory default)

or Open.

Pitch. Choose character width measured in characters per

inch (cpi).

Print DEL Code (MICROLINE Standard). Change to

Yes if you wish to print the DEL code (decimal 127) as a

solid box.

Print Mode. Choose NLQ Courier or NLQ Gothic font for

letter quality printing, utility (factory default) for faster draft

printing, or HSD for fastest printing (lowest quality).

E-30 Section 3

Page 38

Print Registration. Change the setting as required to

obtain the best registration for bi-directional printing.

Print Suppress Effective. If you system uses the DC1

and DC3 codes for something other than the print suppress mode, change the setting to No.

Printhead Gap Adjust. Fine tunes the automatic setting

of the printhead gap. If your printer is consistently

printing too light, change the setting to -1; if it’s too dark,

change the setting to +1.

Proportional Spacing. Change the setting to Yes to

engage proportional spacing of characters.

Receive Buffer Size. 64K (factory default), 1 Line, or

32K. Selects amount of memory devoted to holding

received data. 1 Line will tie up your computer while

printing, but if you abort the print job, the printer will

stop printing much sooner.

Reset Inhibit. Selecting Yes prevents your software from

resetting your printer’s settings.

SI Select Pitch, 10 CPI (IBM only). Sets the pitch

(17.1—the factory default— or 15 characters per inch) to

be engaged when the printer control panel is set for 10

cpi and the SI command is received.

SI Select Pitch, 12 CPI (IBM only). Sets the pitch (20—

the factory default— or 12 characters per inch) to be

engaged when the printer control panel is set for 12 cpi

and the SI command is received.

Size. Change to Double for double width and height

printing.

Skip Over Perforation. Change to Yes if you want the

printer to go to the next page when it comes within 1” of

the bottom. Keep it set to No if your software has its own

page formatting controls.

Style. Change to Italics if you want the printed characters

to be slanted.

Time Out Print. If your software spends a long time

processing between portions of data it feeds to the

printer, change the setting to Invalid to keep your printer

from inadvertently dumping the received data while it’s

waiting for more.

Wait Time. Sets the amount of time—500 ms, 1 sec

(factory default), or 2 sec—the printer will wait for more

data before moving to the form tear-off position.

Zero Character. If you don’t wish the printer to use a

slash to distinguish the number 0 from the capital letter

O, change the setting to Unslashed.

Using Your Printer E-31

Page 39

Using the Printer's Features

Tear Feature

When you’re using continuous forms with either the

built-in rear-feed tractor or the optional bottom-feed push

tractor, you can use this feature to advance the forms up

to the tear position so you can easily tear off a printed

sheet without wasting paper or readjusting the printer. To

do this, simply press the TEAR button on the front panel.

TEAR

SET

The tear feature can NOT be used when the op-

!

tional pull tractor is installed!

Forms Tear-off Feature

Never engage Forms Tear-off when printing on

!

labels!

The Forms Tear-off feature automatically moves the

paper up to the tear position after the selected interval.

When the printer receives data, it will move down to the

initial printing position.

This feature is normally turned off. To activate it:

ÊËÌÍ

SEL

LF

Down

FF/LOAD

Micro Feed

SEL

MENU

EXIT

POWER

Micro Feed

SHIFT

ALARM MENU

GROUP

1. Hold the SHIFT button (Ê) and press the SEL button

(Ë) to enter the Menu mode.

2. Press the GROUP button (Ì) until the line

Rear Feed Form Tear-Off Off

prints.

3. Press the SET button (Í) until the time interval you

wish to select prints .

4. Hold the SHIFT button (Ê) and press the SEL button

(Ë) to exit the Menu mode and save the setting.

4

Some programs pause occasionally while sending

data. If the pause lasts more than the selected interval,

the paper will advance to the tear-off position until

more data is received. This extra paper movement can

cause uneven print registration in graphics. If you

have this problem, use the menu to deactivate Forms

Tear-Off.

TEAR PARK QUIET

Up

SET

TOF

PRINTITEM

E-32 Section 3

Page 40

4

If you have problems setting the Top of Form high

enough on the page when using Forms Tear Off, see

“Problem Solving.”

2. Swing the wire guide up into the paper separator, and

swing the separator upright.

3. Move the paper lever to “TOP.”

4. Load single sheet paper.

Paper Park Feature

If you have continuous-form paper loaded and you wish

to switch to another paper path, first tear off the printed

pages, then press the PARK button. The continuous-form

paper will immediately retract from the paper path.

PARK

PRINT

Switching Paper Paths

To switch to single-sheet feed:

1. Tear off any printed pages, then press PARK.

To switch to continuous-form feed:

1. Press FF/LOAD to remove single sheet from paper

path if needed.

2. Lower the paper separator and swing the wire guide

out.

3. Move the paper lever to “REAR” or “BOT,” as appropriate.

4. Press FF/LOAD.

4

When you switch paths, the printhead travels and

gently fires pins to sense paper thickness and set the

gap.

Using Your Printer E-33

Page 41

Page 42

ection 4: Problem Solving

S

Problem: Nothing happens when I turn on the printer.

Solution: The printer may not be plugged in. Check the

power cord connection to the outlet and to your printer. If

you’re using a power strip, make sure it’s turned on.

Check to be sure that the fuse hasn’t blown or that the

circuit breaker hasn’t tripped.

Problem: The printer doesn’t print when the computer

sends data.

Solutions: (1) The printer may be deselected. If the SEL

light is out, press the SEL button to select the printer.

(2) The printer cable may not be securely connected.

Check the cable to be sure that it is properly connected to

both the PC and the printer.

(3) If you have installed the serial I/F board, it may not

be firmly seated. Check to be sure that the board is firmly

seated in the printer.

Problem: I’m getting strange symbols, incorrect fonts,

etc., when I try to print a document.

Solution: The printer driver you have engaged does not

agree with the emulation selected for your printer.

To check the emulation selected, first make sure paper is

loaded, then press the SEL and SHIFT buttons simultaneously to enter the MENU on your printer. Next, press

the GROUP button: this will print the emulation selected.

If the emulation is not the one you want to use, press the

SET button to change it to the one you want before

exiting the MENU (to exit, press SEL and SHIFT buttons).

If the emulation is correct, check your software documentation on how to select a printer driver, then check to

be sure that you have selected one of the drivers listed

for that emulation in Section 1. The closer the driver is to

the top of the list, the more compatible it will be with

your printer. If your software doesn’t have any of the

indicated drivers available, check with the software

manufacturer to see if they have added any additional

drivers since you purchased your software.

If you have embedded any printer commands in your

software, check to be sure that you entered them correctly.

English-35

Page 43

Problem: I’ve installed a brand new ribbon and the

printing is smeared and streaked.

Solution: The plastic ribbon shield is either loose or

missing. The shield must be left on the ribbon when you

are installing the cartridge. To remedy this situation,

(caution—printhead may be HOT!) move the printhead

to the center of the platen and lift off the ribbon cartridge. If the ribbon shield is loose, secure it in place

properly. If it’s missing, locate it and reinstall it.

Problem: I see printing on the right side of the page

which is lighter or darker than the rest of the print.

Solution: Although the printer automatically sets the

head gap, it may sometimes need minor adjustment. To

do this:

1. Hold SHIFT button and press SEL button to enter

Menu mode.

2. Press GROUP button until Setup group prints.

3. Press ITEM button until Printhead Gap appears.

4. Press SET button to change setting. The default setting

is 0. If the printing is sometimes lighter, change the

setting to -1; if it’s sometimes darker, change it to +1.

5. Hold SHIFT button and press SEL button to save

setting and exit Menu mode.

Problem: The Alarm light is on and the Character Pitch

15 light is flashing.

Solution: This indicates a paper loading error. To stop the

flashing light, press the SEL button. Before trying to load

paper again, check to be sure that the paper lever is in

the correct position (BOT, TOP, REAR) for the path

you’re using.

If the paper lever is in the correct position and you’re

using rear feed, lift up the paper separator and check to

be sure that the paper is properly on the tractors and has

not jammed up somehow.

If the paper lever is in the correct position and you’re

using the optional bottom-feed push tractor, check the

bottom tractor unit to be sure that the paper is properly

on the tractors and has not jammed up before entering

the printer.

Once the paper is correctly loaded, press and release the

SEL button, then hold the SHIFT button and press the

RESET (Character Pitch) button.

E-36 Section 4

Page 44

Problem: The first line is printing too far down on the

page and I can’t get it any higher using the SHIFT and

LF/Micro Feed Down buttons.

Solution: The setting for the Top of Form (TOF) will be

restricted if you have the Forms Tear-Off feature engaged when you set the TOF. To correct for this, you

must reset the TOF with the Forms Tear-Off disengaged,

as follows:

1. Hold SHIFT button and press SEL button to enter Menu

mode.

2. Use GROUP and ITEM buttons to reach Rear Feed

Form Tear-Off entry and/or Bottom Feed Form Tear-Off

entry, depending on paper path(s) you’re using.

3. Use SET button to change Form Tear-Off setting to Off.

4. Hold SHIFT button and press SEL button to exit Menu

mode.

5. Press SEL button to deselect printer.

6. Hold SHIFT button while pressing LF/Micro Shift Down

button to set TOF at desired position.

7. Hold SHIFT button and press SEL button to enter Menu

mode.

8. Use GROUP and ITEM buttons to reach Rear Feed

Form Tear-Off entry and/or Bottom Feed Form Tear-Off.

9. Use SET button to change Form Tear-Off to desired

setting (500ms, 1 sec or 2 sec).

10. Hold SHIFT button and press SEL button to exit Menu

mode.

Problem: I need to load paper, but the Alarm light is

not on and I can’t load paper.

Solution: If the Alarm light is off, the printer thinks it

has paper loaded. To correct this problem, press and

release the SEL button, then hold the SHIFT button and

press the RESET (Character Pitch) button. The Alarm

light will come on and you’ll be able to load paper.

Problem: My word processor files don’t print the way I

have the MENU and front panel set.

Solution: Before sending a file to the printer, many

word processors send either an “initialization string” or

an I-Prime signal to the printer.

The initialization string contains codes that reset the

printer to a default set of features: otherwise the printer

might accidentally print using features set for a previous

job. These codes override panel or MENU settings. To

set your printer to ignore the reset code, enter the printer

MENU (hold SHIFT button while pressing SEL/MENU

button) and change the Reset Inhibit item (in the Set-Up

group) to Yes. Please note that while this will stop the

reset code from resetting your printer, other codes in the

Problem Solving E-37

Page 45

initialization string may still override the printer MENU

and/or front panel settings.

The I-Prime signal is sent over the parallel interface (pin

31) and will automatically override any settings you have

made using the front panel buttons. To eliminate this

problem, enter the program MENU (hold SHIFT button

while pressing SEL/MENU button) and change the IPrime item (in the Parallel I/F group) to Invalid.

Problem: The Print Quality and Character Pitch buttons

on the front panel won’t work.

Solution: The Operator Panel Function item on the

printer MENU can be used to disable these buttons. If the

printer is part of a customized system or if it is used by a

number of people, the system manager may have used

this option to make sure the printer is always set properly.

Problem: Static electricity causes the paper to stick.

Solution: In cold, dry weather, static charges can build

up on continuous-form paper. This can make the paper

cling to the paper separator. If you have this problem

during high-volume printing jobs, try moving the single

sheet paper guides on the separator together so that the

paper rests on the guides rather than on the separator

itself.

E-38 Section 4

Page 46

ection 5: Specifications

S

Print Method: Impact dot matrix

Printhead: 9 pins, 0.34 mm diameter, automatically

adjusting to paper thickness, with thermal

protection

Print Speed

Mode Characters per second at 10 Cpi

High Speed Draft (HSD) 427 cps

Utility 320 cps

Near Letter Quality (NLQ) 80 cps

Characters per Line (CPL)

Setting ML520 ML521

10 cpi 80 cpl 136 cpl

12 cpi 96 cpl 163 cpl

15 cpi 120 cpl 204 cpl

17.1 cpi 137 cpl 233 cpl

20 cpi 160 cpl 272 cpl

Emulations: Epson FX, IBM Proprinter, and

Okidata Microline Standard

co-resident

Interface: Standard: Centronics parallel

Optional: RS-232C serial

Graphics Resolution

Emulation Resolution

Epson/IBM Single Density: 144 ´ 240 dpi

Double Density: 120 ´ 144 dpi

Quadruple Density: 72 ´ 120 dpi

Okidata Single Density: 144 ´ 288 dpi

MICROLINE Double Density: 144 ´ 144 dpi

Standard Quadruple Density: 72 ´ 72 dpi

Resident Fonts

Print Quality Available F onts

Near Letter Quality Courier, Gothic

Utility Gothic

High Speed Draft Gothic

English-39

Page 47

Bar Codes: Code 39, UPC A, UPC E, EAN 8, EAN 13,

Interleaved 2 of 5, Code 128 (A, B, C),

Postnet

Receive Buffer Size: 64K

Reliability

Parameter Rel iability

Mean Time Between 6000 hours at 25% duty

Failures (MTBF) cycle and 35% page density

Mean Time to Repair 15 minutes

(MTTR)

Printhead life 200 million characters average

in 10 cpi utility mode at 25%

duty and 35% page density

Ribbon Life (on 4 million characters

average, 10 cpi utility)

Paper Width: Minimum: 3”

Maximum: Model 520, 10”

Model 521, 16”

Paper Weight: 12 to 24 lb.

Paper Thickness: Rear feed: 0.014” (0.36 mm)

Bottom feed: 0.017” (0.44 mm)

Paper Specifications

Paper Type Fee d Weight Width Range*

Cut sheets Top only 14 to 24 lb. NM: 7.2 to 8.5”

WM: 7.2 to 14.3”

Single-part Rear, Bottom 12 to 24 lb. NM: 3 to 10”

continuous forms WM: 3 to 16”

Carbonless, Rear, Bottom 9 to 11 lb. NM: 3 to 10”

continuous forms WM: 3 to 16”

(orig. + 5 copies)

Interleaf, Rear, Bottom 10 to 12-lb. NM: 3 to 10”

continuous forms paper, 9-lb. WM: 3 to 16”

(orig + 5 copies) carbon

Labels Bottom only N.A. NM: 3 to 10”

WM: 3 to 16”

Envelopes, Top only 24 lb. max 6.5 to 9.5”

single feed

Envelopes, Bottom only 24 lb. max 6.5 to 9.5”

continuous feed,

non-overlap type

Card stock Bottom only 120 lb. max. N.A.

Transparencies Top only — 8.5 to 11”

* NM = Model 520; WM = Model 521

E-40 Section 5

Page 48

Dimensions (W ´ D ´ H)

Model 520: 17 ´ 15 ´ 6½ inches

(431 ´ 380 ´166 mm)

Model 521: 23 ´ 15 ´ 6½ inches

(585 ´ 380 ´ 166 mm)

Weight

Model 520: 17lb. 10oz. (8 kg)

Model 521: 23lb. 2oz. (10.5 kg)

Environmental Requirements

Parameter Range

Operating Temperature 41 to 104°F (5 to 40°C)

Storage Temperature 14 to 122°F (-10 to +50°C)

Operating Humidity 20 to 80% RH

Storage Humidity 5 to 95% RH

Electrical requirements: 120 volts ac (+5.5%, ±15%),

60 Hz (±2%)

Also available for 230 volts

ac (+6%, -10%) or 240

(+10%) volts ac, 50/60 Hz

(±2%)

Specifications subject to change without notice.

Specifications E-41

Page 49

Page 50

ection 6: Parts & Accessories

S

Before You Order

Before you order, make sure you know your printer model

number (on the front of the unit) and have the correct part

number and description of the item. For your convenience,

the most commonly used items are listed below.

How to Order

• Consult the dealer where you purchased your printer.

• Consult an Okidata Authorized Sales or Service Dealer.

(To locate an Authorized Okidata Sales or Service

Dealer, visit http:\\www.o,idata,com.)

• In the United States, purchase directly from Okidata:

- Via the internet at http://www.mylokidata.com

- Order toll-free by phone at 1-800-OKI-DATA

(1-800-654-3282), using VISA, MasterCard, or

American Express.

• In Canada, call 888-309-4570.

Replacement Parts

Replacement Part Order No.

AC Cord Ê...............................56609701

Access Cover

Model 520 .......................53067101

Model 521 .......................53067201

Platen Knob Ì.........................53562601

Printhead Í..............................50099501

Pull-up Roller Assembly

ML520 .............................53341501

ML521 .............................53341601

Ribbon Ï.................................52107001

Ë

Î

Ë

Ì

Ê

Í

Î

Ï

English-43

Page 51

Manuals

Manual Order No.

Maintenance Manual ............................................. 59258401

Accessories

Accessory Order No.

Model 520

Cut Sheet Feeder Ê.............................................70022501

Dual-Bin Cut Sheet Feeder .................................70022601

Pull Tractor, Top-Mount Ë.................................70023001

Push Tractor, Bottom-Feed Ì.............................70022901

Roll Paper Stand Í.............................................70023301

Model 521

Cut Sheet Feeder Ê.............................................70022701

Dual-Bin Cut Sheet Feeder .................................70022801

Pull Tractor, Top-Mount Ë.................................70023201

Push Tractor, Bottom-Feed Ì.............................70023101

Ë

Ê

Ì

Both Models

Serial Interface Î................................................70012801

E-44 Section 6

Í

Î

Page 52

ection 7: Commands

S

This section contains a listing of the more commonly

used commands. The Microline Reference Manual

provides complete lists of all the commands, along with

information on their use.You may view this document by

accessing it on the CD provided with your printer.

Epson FX Commands

Epson Command ASCII Decimal

Backspace BS 8

Carriage Return, Execute CR 13

Character Pitch

Select 10 cpi ESC P 27 80

Select 12 cpi ESC M 27 77

Select 15 cpi ESC g 27 103

Select 20 cpi ESC SI 27 15, or 15

Cancel 20 cpi DC2 18

Epson Command ASCII Decimal

Delete DEL 12 7

Double Height On ESC w 1 27 119 49

Double Height Off ESC w 0 27 119 48

Double Width On ESC W 1 27 87 49

Double Width Of f ESC W 0 27 87 48

Double Width, One Line Only

On ESC SO 27 14

Off DC4 20

Emphasized Print On ESC E 27 69

Emphasized Print Off ESC F 27 70

Enhanced Print On ESC G 27 71

Enhanced Print Off ESC H 27 72

Epson Set 1, Select ESC t 0 27 116 48

Epson Set 2, Select ESC t 1 27 116 49

Italic Printing On ESC 4 27 52

Italic Printing Off ESC 5 27 53

Form Feed FF 12

English-45

Page 53

Epson Command ASCII Decimal

Form Length

n Inches (n = 1 to 22) ESC C NUL n 27 67 0 n

n Lines (n = 1 to 255) ESC C n 27 67 n

Horizontal Tab HT 9

Justification

Left ESC a 0 27 97 48

Center ESC a 1 27 97 49

Right ESC a 2 27 97 50

Full ESC a 3 27 97 51

Line Feed, Execute

w/ Carriage Return LF 10

n/216" (n = 0 to 255) ESC J n 27 74 n

n/144" (n = 0 to 127) ESC % 5 n 27 37 53 n

Reverse, n/216"

(n = 0 to 255) ESC j n 27 106 n

Line Spacing, Set

n/144" (n = 0 to 127) ESC % 9 n 27 37 57 n

n/216" (n = 0 to 255) ESC 3 n 27 51 n

n/72" (n = 0-85 or 128-213) ESC A n 27 65 n

1/6" ESC 2 27 50

1/8" ESC 0 27 48

7/72" ESC 1 27 49

Epson Command ASCII Decimal

Paper Out Sensor Off ESC 8 27 56

Paper Out Sensor On ESC 9 27 57

Print Quality/Font

Select HSD Print Mode ESC ( 0 27 40 48

Select NLQ ESC x 1 27 120 49

Select UTL ESC x 0 27 120 48

Print Speed

Half-Speed On ESC s 1 27 115 49

Half-Speed Off ESC s 0 27 115 48

Print Suppress Mode On DC3 19

Print Suppress Mode Off DC1 17

Proportional Spacing On ESC p 1 27 112 49

Proportional Spacing Off ESC p 0 27 112 48

Reset Printer

Clear Buffer & Initialize ESC @ 27 64

Clear Print Buffer C A N 24

Skip Over Perforation, Cancel ESC O 27 79

Software I-Prime ESC } NUL 27 125 0

Subscript On ESC S 1 27 83 49

Superscript On ESC S 0 27 83 48

Subscript/Superscript Off ESC T 27 84

E-46 Section7

Page 54

Epson Command ASCII Decimal

Underline On ESC - 1 27 45 49

Underline Off ESC - 0 27 45 48

Uni-Directional Printing

One Line Only ESC < 27 60

On ESC U 1 27 85 49

Of f ESC U 0 27 85 48

V ertical Tab, Execute VT 11

IBM Proprinter III Commands

IBM Command ASCII Decimal

Backspace BS 8

Carriage Return CR 13

Character Pitch

Select 10 cpi DC2 18

Select 12 cpi ESC : 27 58

Select 15 cpi ESC g 27 103

Select 20 cpi ESC SI 27 15

Select Compressed Pitch SI 15

IBM Command ASCII Decimal

Character Sets

IBM Set I ESC 7 27 55

IBM Set II ESC 6 27 54

Double Width On ESC W 1 27 87 49

Double Width Of f ESC W 0 27 87 48

Double Width, One Line Only

On SO 27 14

Off DC4 20

Emphasized Printing On ESC E 27 69

Emphasized Printing Off ESC F 27 70

Enhanced Printing On ESC G 27 71

Enhanced Printing Off ESC H 27 72

Form Feed FF 12

Form Length, n inches

(n = 1 to 22) ESC C NUL n 27 67 0 n

Form Length, n lines

(n = 1 to 255) ESC C n 27 67 n

Horizontal Tab, Execute HT 9

Italics On ESC % G 27 37 71

Italics Off ESC % H 27 37 72

Commands E-47

Page 55

IBM Command ASCII Decimal

Line Feed, Execute

w/ Carriage Return LF 10

n/144" (n = 1 to 127) ESC % 5 n 27 37 53 n

n/216" (n = 0 to 255) ESC J n 27 74 n

Auto Line Feed On ESC 5 1 27 53 49

Auto Line Feed Off ESC 5 0 27 53 48

Line Spacing

Set Spacing to 1/8" ESC 0 27 48

Set Spacing to 7/72" ESC 1 27 49

Set Spacing to n/72"

(n = 0 to 255) ESC A n 27 65 n

Store Spacing Set

by ESC A n ESC 2 27 50

Set Spacing to n/144"

(n = 1 to 127) ESC % 9 n 27 37 57 n

Set Spacing to n/216"

(n = 0 to 255) ESC 3 n 27 51 n

Overscore On ESC _ 1 27 95 49

Overscore Off ESC _ 0 27 95 48

Paper Out Sensor Off ESC 8 27 56

Paper Out Sensor On ESC 9 27 57

Print Quality, Select HSD ESC # 0 27 35 48

IBM Command ASCII Decimal

Print Suppress On, ML520 ESC Q STX 27 81 3

Print Suppress On, ML521 ESC Q SYN 27 81 22

Print Suppress Off DC1 17

Proportional Spacing On ESC p 1 27 112 49

Proportional Spacing Off ESC p 0 27 112 48

Reset: Clear Print Buffer CA N 24

Software I-Prime ESC } NUL 27 125 0

Stop Printing ESC j 27 106

Subscript On ESC S 0 27 83 48

Superscript On ESC S 1 27 83 49

Subscript/Superscript Off ESC T 27 84

T op of F orm, Set at Current

Position ESC 4 27 5 2

Underline Printing On ESC - 1 27 45 49

Underline Printing Off ESC - 0 27 45 48

Uni-Directional Print On ESC U 1 27 85 49

Uni-Directional Print Off ESC U 0 27 85 48

V ertical Tab, Execute VT 11

E-48 Section7

Page 56

Okidata MICROLINE Standard

Commands

Okidata Command ASCII Decimal

Backspace BS 8

Carriage Return CR 13

Character Pitch

Select 10 cpi RS 30

Select 12 cpi FS 28

Select 15 cpi ESC g 27 103

Select 17.1 cpi GS 2 9

Select 20 cpi ESC # 3 27 35 51

Character Sets

Standard ESC ! 0 27 33 48

Line Graphics ESC ! 2 27 33 50

Double Height On ESC US 1 27 31 49

Double Height Off ESC US 0 27 31 48

Double Width Printing US 31

Emphasized Printing On ESC T 27 84

Emphasized Printing Off ESC I 27 73

Enhanced Printing On ESC H 27 72

Enhanced Printing Off ESC I 27 73

Okidata Command ASCII Decimal

Form Feed FF 12

Horizontal Tab, Execute HT 9

Initialize Printer ESC CAN 27 24

Italic On ESC ! / 27 33 47

Italic Off ESC ! * 27 33 42

Line Feed Commands

w/ Carriage Return LF 10

w/o Carriage Return ESC DC2 27 18

n/144" (n = 0 to 127) ESC % 5 n 27 37 53 n

Reverse ESC LF 27 10

Line Spacing

Set Spacing to 1/6" ESC 6 27 54

Set Spacing to 1/8" ESC 8 27 56

Set Spacing, in n/144"

(n = 0 to 127) ESC % 9 n 27 37 57 n

Skip Over Perforation, in

1/3" increments (n = 1 to 9) ESC G nn 27 71 nn

Skip Over Perforation

Default ESC % S 0 27 37 83 48

Paper Out Sensor Off ESC E 1 27 69 49

Paper Out Sensor On ESC E 0 27 69 48

Commands E-49

Page 57

Okidata Command ASCII Decimal

Print Quality

Select HSD ESC # 0 27 35 48

Select NLQ Courier ESC 1 27 49

Select NLQ Gothic ESC 3 27 51

Select Utility ESC 0 27 48

Print Speed, Set to Full ESC > 27 62

Print Speed, Set to Half ESC < 27 60

Print Suppress On DC3 19

Print Suppress Off DC1 17

Proportional Spacing

On ESC Y 27 89

Of f ESC Z 27 90

Reset: Clear Print Buffer CA N 24

Software I-Prime ESC } 0 27 125 48

Subscript Printing On ESC L 27 76

Subscript Printing Off ESC M 27 77

Superscript Printing On ESC J 27 74

Superscript Printing Off ESC K 27 75

T op of Form, Set at

Current Position ESC 5 27 53

Okidata Command ASCII Decimal

Underline Printing On ESC C 27 67

Underline Printing Off ESC D 27 68

Uni-Directional Print On ESC - 27 45

Uni-Directional Print Off ESC = 27 61

V ertical Tab, Execute VT 11

E-50 Section7

Page 58

CC/IC/CE Statements

F

Federal Communications Commission (FCC)

Radio Frequency Interference (RFI)

Statement for 120V Models

WARNING: This equipment has been tested and found

to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio

communications. However, there is no guaranteed that

interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio

or television reception, which can be determined by

turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver

• Plug unit into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/television

technician for help.

4

It is the responsibility of the user to obtain the required

shielded cable in order to ensure compliance of this

equipment with FCC regulations.

Changes or modifications not expressly approved by

Okidata may void your authority to operate this device.

Industry Canada (IC) Radio Frequency

Interference (RFI) Statement

for 120V Models

This Okidata apparatus complies with the Class B limits

for radio interference as specified in the Industry Canada

Radio Interference Regulations.

English-51

Page 59

FCC RFI Statement for 230/240V Models

IC RFI Statement for 230/240V Models

WARNING: This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses

and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions,

may cause harmful interference to radio communications. Operation of the equipment in a residential area is

likely to cause harmful interference, in which case the

user will be required to correct the interference at their

own expense.

4

It is the responsibility of the user to obtain the required

shielded cable in order to ensure compliance of this

equipment with FCC regulations.

Changes or modifications not expressly approved by

Okidata may void your authority to operate this device.

This Okidata apparatus complies with the Class A limits

for radio interference as specified in Industry Canada

Radio Interference Regulations.

European Union Council of the European

Communities Statement of Electromagnetic

Conformance for 230/240V Models

This product complies with the requirements of the

Council Directive 89/336/EEC on the approximation of

the laws of the member states relating to electromagnetic

compatibility.

European Union Council of the European

Communities Statement of Safety

Conformance for 230/240V Models

This product is in conformity with Directive 73/23/EEC

on the harmonization of the laws of member states

relating to electrical equipment designed for use within

certain voltage limits.

E-52 FCC/IC/CE Statements

Page 60

ndex

I

7 or 8 bit graphics,

menu item......................28, 29

A

Accessories ...........................44

ALARM light .......................19

Auto

CR menu item ............28, 29

feet XT menu item ...........29

gap .......................................

LF menu item.............28, 29

select menu item ........28, 29

B

Backspace