Page 1

Microline 520/521

Service Handbook

P/N 59257803

Page 2

Microline 520/521

Service Handbook

Page 3

This document may not be reproduced without the written permission of the Okidata Technical Training

Group. Every effort has been made to ensure the accuracy of the information contained in this training

course. Okidata is not responsible for errors beyond its control.

© 1994 by Okidata All rights reserved.

First Edition February, 1993 P/N 59257801

Second Edition September, 1993 P/N 59257802

Third Edition December, 1994 P/N 59257803

Written and produced by the Okidata Technical Training Group

Please address any comments on this publication to:

Technical Train ing Group

Okidata

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Fax Number: (609) 235-2600, ext. 7034

Okilink Login Name : Technica l Trai nin g

OKIDATA is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de Oki

Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

MICROLINE is a registered trademark of Oki Electric Industry Company, Ltd.; marque depose de Oki

Electric Industry Company, Ltd.

OkiSmart Paper Handling is a trademark of Oki Electric Industry Company, Inc.

PLUG ’n PRINT is a registered trademark of Oki America, Inc.; marque deposee de Oki America, Inc.

Bitstream is a registered trademark of Bitstream Incorporated.

Epson is a registered trademark of Seiko Epson Corporation.

IBM is a registered trademark of International Business Machine Corporation.

MS-DOS is a registered trademark of Microsoft Corporation.

PC is a registered trademark of International Business Machine Corporation.

Proprinter is a registered trademark of International Business Machine Corporation.

Windows is a trademark of Microsoft Corporation

Page 4

Table of Contents

COURSE ADMINISTRATION:

OVERVIEW.................................................................................................................................i-1

RECOMMENDATIONS. ............................................................................................................. i-2

INFORMATION UPDATES........................................................................................................ i-3

NOTICES......................................................................................................................................i-3

WHERE TO SEND TESTING MATERIALS.............................................................................i-4

MISSING ITEMS OR MISSING PAGES....................................................................................i-5

COURSE PATH ...........................................................................................................................i-6

SERVICE TRAINING............................................................................... .............................. .....i-7

SERVICE AUTHORIZATION..................................................................................................i-11

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ...........i-11

Answer Sheet: Microlin e 520/52 1.......... ...... ... ...... ...... ... ...... ...... ... ...... ...... ... ...... ...... ... ..i-13

Course Critique: Microline 520/521..............................................................................i-14

Certification Test: Microline 520/521............................................................................i-16

SECTION ONE: SPECIFICATIONS

1.1 OVERVIEW....................................................................................................................1-1

1.1.01 General Information..........................................................................................1-1

1.2 PHYSICAL SPECIFICATIONS.....................................................................................1-2

1.2.01 Dimensions .......................................................................................................1-2

1.2.02 Printer Weight...................................................................................................1-2

1.3 POWER REQUIREMENTS...................... ... ... ...... ... ... ...... ... ... ...... ... ... ...... ... ... ...... ... ... .... 1- 3

1.3.01 Input Powe r......................... ..................... ..................... ............ ..................... ...1-3

1.3.02 Power Consumption..........................................................................................1-3

1.3.03 Power Frequency ..............................................................................................1-3

1.4 ENVIRONMENTAL CONDITIONS.............................................................................. 1-4

1.4.01 Acoustic Rating.................................................................................................1-4

1.4.01 Altitude .............................................................................................................1-4

1.4.03 Ambie nt Temp erature and Re la tive Humid it y (RH).... ... ............ .....................1-4

i

Page 5

1.5 AGENCY APPROVALS................................................................................................. 1-5

1.5.01 Listings..............................................................................................................1-5

1.6 OPERATIONAL SPECIFICATIONS.............................................................................1-6

1.6.01 Charact er Mat r i x Siz es.......................... ..................... ..................... ..................1-6

Table of Print Speed and Character Matrix......... ............ ............ ............ ............ ......1-6

1.6.02 Characters Per Line...........................................................................................1-6

Microline 520.............................................................................................................1-6

Microline 521.............................................................................................................1-6

1.6.03 Character Pitches..............................................................................................1-6

1.6.04 Character Sets...................................................................................................1-7

1.6.05 Emulations........................................................................................................1-7

1.6.06 Fonts..................................................................................................................1-8

Near Letter Quality ....................................................................................................1-8

Utility.........................................................................................................................1-8

High Speed Draft.......................................................................................................1-8

Bar Code....................................................................................................................1-8

1.6.07 Front Panel Switches.........................................................................................1-8

1.6.08 Graphics Resolution............................................. ......... ...... ......... ...... ......... ......1 -8

1.6.09 Interface ....................................... ......... ...... ......... ...... ......... ...... ......... ...... .........1 -8

Standa rd... ............ ....................................... .............................. .................................1-8

Optional......................................................................................................................1-8

1.6.10 Line Feed Increments........................................................................................1-9

Fixed ..........................................................................................................................1-9

Variable......................................................................................................................1-9

1.6.11 Line Feed Ti me............................ ..................... ..................... ..................... ......1-9

1.6.12 Menu Mode .......................................................................................................1-9

1.6.13 Paper Feed Methods........................................................................................1-10

Standard ...................................................................................................................1-10

Optional....................................................................................................................1-10

1.6.14 Paper Feed Paths.............................................................................................1-10

1.6.15 Paper Loading.................................................................................................1-10

1.6.16 Paper Out Detection........................................................................................1-10

1.6.17 Paper Tear Capabilities...................................................................................1-10

1.6.18 Print Method...................................................................................................1-11

Printhead Type.........................................................................................................1-11

General Info rma ti o n............... ............ ............ ............ ............ ............ ............ ....1-11

Overheat Protection ...........................................................................................1-11

Printhead Gap Information.......................................................................................1-12

1.6.19 Print Modes.....................................................................................................1-14

ii

Page 6

1.6.20 Print Speed......................................................................................................1-14

Table of Print Speed and Character Matrix.................. ............ ............ ............ .......1-14

1.7 PAPER SPECIFICATIONS .......................................................................................... 1-15

1.7.01 Types...............................................................................................................1-15

Card Stock................................................................................................................1-15

Continuous Form.....................................................................................................1-15

Cut Sheet..................................................................................................................1-16

Envelopes.................................................................................................................1-16

Labels.......................................................................................................................1-17

Transparency............................................................................................................1-17

1.7.02 Length.............................................................................................................1-18

1.7.03 Number of Copies...........................................................................................1-18

1.7.04 Thickness ........................................................................................................1-18

1.7.05 Weight.............................................................................................................1-19

1.7.06 Width...............................................................................................................1-19

Paper ........................................................................................................................1-19

Printing Area............................................................................................................1-19

1.8 MEMORY SPECIFICATIONS.....................................................................................1-20

1.8.01 EEPROM........................................................................................................1-20

1.8.02 EPROM...........................................................................................................1-20

1.8.03 RAM ...............................................................................................................1-20

1.9 CONSUMABLES.......................................................................................................... 1-21

1.9.01 Ribbon.............................................................................................................1-21

1.10 OPTIONS.......................................................................................................................1-22

1.10.01 Cut Sheet Feeders ...........................................................................................1-22

Single Bin.................................................................................................................1-22

Dual Bin...................................................................................................................1-22

1.10.02 Pull Tract or Kit ........................ ............ ..................... ............ ..................... ....1-23

1.10.04 Bottom Push Tractor Kit ............. ... ... ............ ............ ... ............ ............ ..........1-23

1.10.05 Serial Interface................................................................................................1-23

1.10.06 Roll Paper St an d............................. ..................... ..................... ..................... .1-24

1.10.08 OKISmart Typer Utility.. ................................................................................ 1-24

1.10.09 OKISmart Panel Utility................................................................................... 1-24

1.11 RELIABILITY............................................................................................................... 1-25

1.11.01 Mean Time Before Failure (MTBF) ...............................................................1-25

1.11.02 Mean Time To Repair (MTTR)......................................................................1-25

1.11.03 Printer Life......................................................................................................1-25

1.11.04 Printhead Life..................................................................................................1-25

1.11.05 Ribbon Life ....................................................................................................1-25

iii

Page 7

1.11.06 Warranty (Limited)...................... ... ...... ...... ... ...... ...... ... ...... ...... ... ...... ...... ... ....1-25

1.11.07 Service.. ............ ....................................... .............................. ..........................1-25

SECTION TWO: PRINCIP LES OF OPERAT IO N

2.1 ELECTRICAL OPERATION.. ........................................................................................2-1

2.1.01 Main Cont rol Board.................................... ..................... ..................... ............2-2

Block Diagram...........................................................................................................2-3

Program ROM............................................................................................................2-4

RAM ..........................................................................................................................2-4

LSI..............................................................................................................................2-5

Electrically Erasable Programmable Read Only Memory (EEPROM).....................2-5

2.1.02 Initialization......................................................................................................2-6

2.1.03 Parallel Interface Control..................................................................................2-7

2.1.04 Print Control......................................................................................................2-8

LSI/Printhead Interface..............................................................................................2-8

Gap Adjust Control....................................................................................................2-9

Print Compensation Control....................................................................................... 2-9

2.1.05 Space and Line Feed (SP/LF) Motor Control........................ ...... ... ...... ...... ... .2-10

Line Feed Motor Control.........................................................................................2-10

Space Motor Control ................................................................................................2-11

Encoder Disk............................................................................................................2-11

2.1.06 Operation Panel...............................................................................................2-12

2.1.07 Alarm Circuit..................................................................................................2-14

Driver Circuit Alarm Processing..............................................................................2-14

Low Motor Drive Voltage Alarm............................................................................2-14

Head Drive Time.. ............ ..................... ..................... ..................... ..................... ....2-15

Print Speed...............................................................................................................2-15

Head Overheat Alarm Processing........................... ............ ............ ............ ............ .2-15

2.1.08 Power Supply Circuit......................................................................................2-16

Table of Out put Vo l ta ge s............. ... ..................... ..................... ..................... ..........2-16

2.2 MECHANICAL OPERATION.....................................................................................2-17

2.2.01 Printhead Mechanism......................................................................................2-17

Printhead Gap Information.......................................................................................2-18

Interconnect Diagram: Control Board to Printhead................................................2-20

Line Feed Motor Resistance ..............................................................................2-21

Space Motor Resistance.....................................................................................2-21

Printhead Operation.................................................................................................2-22

Printhead Temperature.............................................................................................2-22

2.2.02 Spacing Mechanism........................................................................................2-24

Spacing Operation.................. ..................... ..................... ..................... ...................2-24

iv

Page 8

2.2.03 Head Gap Mechanism.....................................................................................2-26

Head Gap Setting Operation....................................................................................2-26

2.2.04 Ribbon Drive Mechanism...............................................................................2-29

Ribbon Drive Operation...........................................................................................2-29

2.2.05 Line Feed Me chanism..................... ..................... ..................... ..................... .2-30

Change Lev er (Pap er Path Sele ction Lever )........... ............ ............ ............ ............ .2-30

Paper Clam p Me chanism....... ... ............ ..................... ..................... ..................... ....2-30

Cut Sheet/Continuous Sheet Switching Mechanism................................................2-31

Top Feed (for cut sheet paper)........................................................................... 2-31

Rear/Bot t om Feed (for co nt i nuo us feed pap er)............. ............ ............ ... ..........2-31

Cut Sheet Paper Feed Operation..............................................................................2-32

Continuous Paper Feed (Rear Tractor Mechanism).................................................2-32

Continuous Paper Feed (Pull Tractor Mechanism) .................................................2-32

Continuous Paper Feed (Bottom Tractor Feed Mechanism) ..................................2-33

Continuous Paper Feed (Push/Pull Tractor Mechanism).........................................2-33

2.2.06 Paper Detection Mechanism ..........................................................................2-34

Top Feed Paper Detection........................................................................................2-34

Rear Feed Dete ct io n...... ... ... ..................... ..................... ..................... ..................... .2-34

Bottom Feed Det ection............. ... ... ..................... ..................... ..................... ..........2-34

2.2.07 Support Protector Mechanism.........................................................................2-35

2.2.08 Automatic Paper Load....................................................................................2-36

Cut Sheet Paper........................................................................................................2-36

Continuous Feed Paper............................................................................................2-37

2.2.09 Paper Park ......................................................................................................2-38

Paper Park Operat i on................ ............ ............ ............ ............ ............ ............ .......2-38

SECTION THREE: MAINTENANCE

3.1 OVERVIEW....................................................................................................................3-1

3.1.01 General Information..........................................................................................3-1

3.1.02 Maint en an ce To ol s.................... ..................... ............ ..................... ............ ......3-1

3.1.03 Mainten an ce Precautions.......... ............ ..................... ..................... ............ ......3-2

3.2 DISASSEMBLY/ASSEMBLY PROCEDUR ES............................................................ 3-3

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ......3-3

3.2.01 Preliminary Items..............................................................................................3-4

3.2.02 Printhead Assembly..........................................................................................3-6

3.2.03 Ribbon Protector...............................................................................................3-8

3.2.04 Gear Case Assembly............................. ...... ......... ...... ......... ...... ......... ...... .......3-10

3.2.05 Pull-up Roller Assembly.................................................................................3-12

3.2.06 Upper Cover, Access C over, and Sheet Guide Assem bli es........................ ... .3-14

3.2.07 C ontrol Board (FJIM)................................... ......... ......... ...... ......... ......... ...... .. 3-16

v

Page 9

3.2.08 Power Supply Assembly.................................................................................3-18

3.2.09 Operator Panel PCB (LEOP) ..........................................................................3-20

3.2.10 PC Connect o r.......... ... ..................... ..................... ..................... ..................... .3-22

3.2.11 Space Motor and Roller Guide Assembl ie s.............................. ...... ... ...... ...... .3-24

3.2.12 Carriage Cable ................................................................................................3-26

3.2.13 Space Rack................. ..................... ..................... ..................... ..................... .3-28

3.2.14 Roller/Holder Backup Assembly....................................................................3-30

3.2.15 Guide Rail and Adjust Cam............................................................................3-32

3.2.16 Left Ground Plate............................................................................................3-34

3.2.17 Right Ground Plate .........................................................................................3-36

3.2.18 Rear and Cut She et Paper Feed Sensor Levers................ ............ ............ .......3-38

3.2.19 Platen Assembly............ ...... ... ...... ...... ... ...... ...... ... ...... ...... ... ...... ...... ... ...... ...... .3-40

3.2.20 Paper Chute Assembly....................................................................................3-42

3.2.21 Line Feed Motor Assembly ........................... ...... ...... ... ...... ...... ... ...... ...... ... ....3-44

3.2.22 Reset Spring....................................................................................................3-46

3.2.23 Idle Gear and Change Lever................. ...... ... ... ... ...... ... ... ... ...... ... ... ... ...... ... ... .3-48

3.2.24 Pressure Spring...............................................................................................3-50

3.2.25 Carriage Shaft.................................................................................................3-52

3.2.26 Leaf Spring......................................................................................................3-54

3.2.27 Bottom Paper Sensor Lev er s................. ..................... ..................... ............ ....3-56

3.2.28 Front Pressure Roller Assembly .....................................................................3-58

3.2.29 Tractor Assembly............................................................................................3-60

3.2.30 Main Frame.....................................................................................................3-62

3.3 PRINTER ADJUSTMENTS .........................................................................................3-65

3.3.01 General Information........................................................................................3-65

3.3.02 Printhead Gap Adjustment..............................................................................3-66

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ....3-66

Procedu r e............. ... ... ............ ..................... ..................... ..................... ...................3-68

Setup Phase............. ... ............ ..................... ..................... ............ ..................... .3-68

Printhead Gap Modification Phase ....................................................................3-68

Parallel Adjustment Phase .................................................................................3-68

Verification Phase..............................................................................................3-68

3.3.03 Key Combinations ..........................................................................................3-70

3.3.04 Menu Operation..............................................................................................3-71

General Info rma ti o n............... ............ ............ ............ ............ ............ ............ ..........3-71

Menu Mode............. ............ ..................... ..................... ............ ..................... ..........3-71

Printing the Menu ....................................................................................................3-72

Sample Me nu....... ... ............ ..................... ..................... ..................... ..................... .3-73

Reset Menu to Facto ry Defaults .......................... ............ ............ ............ ............ ....3-75

vi

Page 10

Limited Operation....................................................................................................3-76

General Info rma ti o n............... ............ ............ ............ ............ ............ ............ ....3-76

Procedu r e............. ... ............ ..................... .............................. ..................... .......3-77

Menu Setti n gs............ ... ............ ............ ..................... ..................... ..................... ....3-78

Menu Setti n gs............ ... ............ ............ ..................... ..................... ..................... ....3-78

3.3.05 Top of Form................................................... ......... ...... ......... ...... ......... ...... ....3-82

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ....3-82

Setting Top of Form.................................................................................................3-82

Reset the Top of Form to Factory Default...............................................................3-82

3.3.06 Paper Park.......................................................................................................3-83

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ....3-83

Procedure: Continuous Feed to Single Sheet..........................................................3-83

Procedu re: Single Sheet to Con ti n uou s Feed........................ ..................... ............ .3-83

3.3.07 Tear Feature....................................................................................................3-84

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ....3-84

3.3.08 Forms Tear Off ...............................................................................................3-85

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ....3-85

Vertical Line Spacing Problems ..............................................................................3-86

Setting......................................................................................................................3-87

Using........................................................................................................................3-87

Checking Top of Form with Form Tear Off Activated............................................3-87

3.3.09 Resets..............................................................................................................3-88

Reset Menu to Facto ry Defaults .......................... ............ ............ ............ ............ ....3-88

Reset the Top of Form to Factory Default...............................................................3-88

3.4 CLEANING...................................................................................................................3-89

3.4.01 General Information........................................................................................3-89

3.4.02 Cleani n g Sch ed ul e........ ... ... ... ..................... ..................... ............ ...................3-89

3.4.03 Cleani n g To ol s........... ............ ..................... ............ ..................... ............ .......3-89

3.4.04 Areas to be Cleaned..................... ... ...... ...... ... ...... ...... ... ...... ...... ... ...... ...... ... ....3-89

3.5 LUBRICATION ............................................................................................................ 3-90

3.5.01 General Information........................................................................................3-90

3.5.02 Lubrica tion Sched ul e.......... ... ... ... ..................... ..................... ............ .............3-90

3.5.03 Lubrica tion Type s............... ... ... ..................... ..................... ............ ................3-90

3.5.04 Lubrica tion Amoun t s............. ..................... ..................... ............ ...................3-90

3.5.05 Lubrica tion Table.......... ... ... ..................... ............ ..................... ............ ..........3-91

3.5.06 Areas Not Lubricated...................... ...... ... ...... ...... ... ...... ...... ... ...... ...... ... ...... ....3-91

3.6 SHIPPING INSTRUCTIONS........................................................................................ 3-92

3.6.01 Return for Service...........................................................................................3-92

3.6.02 All Other Returns............................................................................................3-93

vii

Page 11

SECTION FOUR: FAILURE ANALYS IS

4.1 OVERVIEW....................................................................................................................4-1

4.1.01 Introdu ction............. ....................................... ....................................... ............4-1

4.1.02 Printer Serial Number Identification.................................................................4-3

4.1.03 Firmware Revision Identifica tio n................................................... ......... ...... ...4-3

Header....................................... .............................. ....................................... ............4-3

4.2 REPORTING PROBLEMS............................................................................................. 4-4

4.2.01 General Information..........................................................................................4-4

4.2.02 Problem Li sts.......... ............ ............ ..................... ..................... ............ ............4-4

4.2.03 Reporting Methods............................................................................................4-5

Okili nk II........................................................... .........................................................4-5

Course Crit iq u e....... ... ... ..................... ..................... ..................... ..................... .........4-5

Fax Number ...............................................................................................................4-5

Mailing Address.........................................................................................................4-5

Information Provided.................................................................................................4-5

4.3 TROUBLESHOOTING UPDATES................................................................................ 4-6

4.3.01 General Information..........................................................................................4-6

4.3.02 Okilin k II........................................................... ................................................4-6

4.3.03 Faxable Facts ....................................................................................................4-6

4.3.04 Technical Service Bulletins ..............................................................................4-6

4.4 TROUBLESHOOTING TIPS.......................................................................................... 4-7

4.4.01 Preliminary Checks...........................................................................................4-7

4.4.02 Problem Ca te go ri es.................................. ..................... ..................... ...............4-8

ALARM Lamp Blinks (Fatal Errors)......................................................................... 4-8

Operational Errors......................................................................................................4-8

ALARM Lamp Lights (Paper End/Jam Conditions)................................................. 4-8

4.4.03 START HERE Flowchart .................................................................................4-9

4.4.04 Tips for Preventi n g Imag e Prob l ems................... ............ ............ ............ .......4-10

4.4.05 Common Problems..........................................................................................4-11

4.5 ABNORMAL OUTPUT................................................................................................ 4-14

4.5.01 Output Samples...............................................................................................4-14

Light Pri n t on the Ent i re Pa ge......... ..................... ..................... ..................... ....4-15

Uneven Print Density.........................................................................................4-15

Smeared Print.....................................................................................................4-15

Inconsistent Line Feed.......................................................................................4-15

Drifti n g Ma rgi n....... ... ... ..................... ..................... ..................... ..................... .4-15

Left Margin Dri fti n g Prob l em......... ... ... ............ ............ ............ ............ ............ .4-17

viii

Page 12

4.6 FAULT ALARMS......................................................................................................... 4-18

4.6.01 General Information........................................................................................4-18

4.6.02 ALARM/LED Display Troubleshooting Table Index .................................... 4-19

4.6.03 ALARM/LED Display Troubleshooting Tables............................................. 4-20

4.7 REPAIR ANALYSIS PROCEDURES (RAPs)............................................................. 4-22

4.7.01 Using the RAPs...............................................................................................4-22

4.7.02 RAP Index.................. ...... ... ... ... ...... ... ... ... ...... ... ... ... ...... ... ... ... ...... ... ... ... ...... ... .4-23

RAP 01 No Power Suppl ie d to Pri nter........ ... ... ............ ............ ............ ... ............ ....4-24

RAP 02 No Spacing Operation................................................................................4-26

RAP 03 Printhead Homing Error.............................................................................4-28

RAP 04 Paper Jam During Paper Loading ..............................................................4-30

RAP 05 Printhe ad Pins Not Firing........... ... ............ ............ ............ ............ ... ..........4-31

RAP 06 Poor Print Quality.......................................................................................4-32

RAP 07 Ribbo n Fee d Prob l em........ ............ ..................... ............ ..................... .......4-33

RAP 08 Line Fee d Prob le m............... ... ... ..................... ..................... ............ ..........4-34

RAP 09 Operat io n Panel Malfunc ti o n............................. ............ ..................... .......4-37

RAP 10 Parallel Interface Problem..........................................................................4-38

RAP 11 Serial Interface Problem.............................................................................4-40

4.8 PRINTER TESTS......................................... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 4- 43

4.8.01 General Information........................................................................................4-43

4.8.02 Rolling ASCII Test ............................... ...... ......... ...... ......... ...... ......... ...... .......4-44

General Info rma ti o n............... ... ............ ............ ............ ............ ............ ... ............ ....4-44

Procedu r e............. ... ... ............ ..................... ..................... ..................... ...................4-44

Sample... ..................... ..................... ..................... ..................... ..................... ..........4-45

4.8.03 Font Test .........................................................................................................4-46

General Info rma ti o n............... ............ ............ ............ ............ ............ ............ ..........4-46

Procedu r e............. ... ............ ..................... .............................. ..................... .............4-46

Sample............ ..................... ..................... ..................... .............................. .............4-47

4.8.04 Serial Interface Loopback Test.......................................................................4-48

Loopbac k Co n ne ct or Co nfiguratio n ................................ ............ ..................... .......4-49

Serial Cable Information..........................................................................................4-50

Serial Interface Signal Requirements.......................................................................4-50

Commonly Used Serial Cable Configurations.........................................................4-51

IBM 25-Pin Cable Co nfiguratio n....... ..................... ............ ..................... ..........4-51

IBM 9-Pin Cable Configuration.........................................................................4-51

ix

Page 13

4.8.05 Hexadeci mal Dump Mod e.............. ............ ..................... ..................... ..........4-52

General Info rma ti o n............... ............ ............ ............ ............ ............ ............ ..........4-52

Exampl e............... ..................... .............................. ..................... ..................... .......4-52

Procedu r e............. ... ............ ..................... .............................. ..................... .............4-52

Sample............ ..................... ..................... ..................... .............................. .............4-53

4.9 RESISTANCE CHECKS.............................. ... ... .............................. ... .......................... 4-54

4.9.01 General Description........................................................................................4-54

Layout Dia gra m......... ... ... ............ ..................... ............ ..................... ..................... .4-55

4.9.02 Printhe ad............................. ............ ..................... ..................... ............ ..........4-56

Interconnect Diagram: Control Board to Printhead................................................4-56

4.9.03 Line Feed Mot or Resistance................................ ............ ..................... ..........4-57

4.9.04 Space Motor Resistance............ ... ............ ............ ..................... ............ ..........4-57

APPENDIX A: BOARD DIAGRAMS

A.1 OVERVIEW................................................................................................................... A-1

A.1.01 General Information.........................................................................................A-1

A.2 INDEX TO CHARTS..................................................................................................... A-2

A.2.01 Main Controller Board (FJIM).........................................................................A-4

A.2.02 Operator Panel Board (LEOP)......................................................................... A-6

A.2.03 Power Supply Assembly.................................................................................. A-8

A.2.04 Space Mot or Bo ard....... ... ... ..................... ..................... ..................... ............A-10

A.2.05 RS232-C Serial Interface Board - Option (LXHI)........................................ A-12

APPENDIX B: ILLUSTRATED PARTS LISTING

B.1 OVERVIEW ....................................................................................................................B-1

B.1.01 General Information..........................................................................................B-1

Format........................................................................................................................B-2

Current Part Numbers ................................................................................................B-3

B.1.02 Definition of Terms...........................................................................................B-4

Assemblies.................................................................................................................B-4

Blank . .........................................................................................................................B-4

Consumable................................................................................................................B-4

Document...................................................................................................................B-4

Drivers........................................................................................................................B-4

Firmware. ...................................................................................................................B-4

Option........................................................................................................................B-4

Option RSPL....................................................................... ............... ............... .........B-4

RSPL........... .............................. ....................................... ....................................... ... B-4

Technica l Service Bulletins ..................... ..................... ............ ..................... ............B - 5

x

Page 14

520..............................................................................................................................B-5

521..............................................................................................................................B-5

Both............................................................................................................................B-5

B.1.03 Parts Ordering Information...............................................................................B-6

Service Cent er Re feren ce Guide....................... ... ............ ............ ............ ............ ... ...B - 6

Placing a Parts Order .............................................. ......... ...... ......... ...... ......... ...... ......B-7

B.2 CHARTS..........................................................................................................................B-8

B.2.01 Printer............. ..................... ....................................... .............................. .......B-10

B.2.02 Upper Cover Assembly......................... ............ ............ ............ ............ ..........B-1 2

B.2.03 Printer General Assembly...............................................................................B-14

B.2.04 Printer Unit......................................................................................................B-16

B.2.05 Printer Unit......................................................................................................B-18

B.2.06 Printer Unit......................................................................................................B-20

B.2.07 Carriage Assembly..........................................................................................B-22

B.2.08 Options............................................................................................................B-24

B.2.09 Option Parts ....................................................................................................B-26

B.2.10 Consumables...................................................................................................B-28

B.2.11 Packing Materials............................................................................................B-30

B.2.12 Documentation................................................................................................B-32

B.2.13 Service Training Kit Revision List.................................................................B-34

xi

Page 15

This page was intentionally l eft blan k.

xii

Page 16

COURSE ADMINI STRATION

Page 17

Page 18

OVERVIEW

Okidata develo ped this cou rse in ord er to prov i de the informa ti o n necessa ry to in sta ll and

maintain the Microline 520 and Microl i ne 521 pri nters. Upon successful compl et ion of this

training course , yo u will be able to do the foll owing.

Install and operate the produc t

Locate the major assemblies of the product

Identify fault indications

Perform corrective and prev entiv e mainten ance

The Service Handbook is the primary reference manual for this course. You cannot, however,

successfully complete this course by referring only to this manual. Take the time to familiarize

yourself with all of the docume nt ati on in the trai ni ng kit . This additio nal info rma tio n wil l

greatly simpl ify working with the prod uct.

Okidata’s Techni cal Trai nin g Program is design ed to buil d a knowled g eabl e and efficie nt

service and sup port group for Okida ta prod u ct s.

One step in becoming an Authorized Okidata Service Center is obtaining a training kit for the

appropri ate pro duct . Thi s acqui sit i on allo ws the Deale rshi p to have referen ce materials

available during service jobs. Having, and using, these reference materials will minimize the

time and money spent on repairs.

Technician s com plet e Ce rti fi cat ion Test s as part of Oki dat a’s Aut hor i zati on process. Testin g

familiarizes th e tech nici an wit h the pro duc t and refere nce mat eri al s.

This training course provides assembly level repair informat ion to the field technician. N o

attempt is made to provide basic training in being a technician. This kit strives to train a

technician to service the product. Okid at a views servi ce techn ic ians as re pre sen ta tiv es of

Okidata. Through this course, Okidata seeks to provide the means and the motivation that will

make good service a reality.

Remember

Compone nt lev el servic in g is prov id ed only at Okida t a Servi ce Rep a ir Dep ot s !

Microline 520/521 Service Handbook i - 1 Course Administration

P/N 59257803

Page 19

RECOMMENDATIONS

Prerequisites

Before begi nni ng this co urse , yo u shou ld know th e fol l owi n g conc ep ts.

Have an understanding of basic electronics

Be familiar with electrostatic principles

Be familiar with dot matrix technology and protocol

Be familiar wit h the proper procedures for handlin g circui t board s, Re ad Only

Memory (ROM), and Random Access Memory (RAM)

Be able to use basic tools

Be able to use a digital multimeter (DMM)

Equipment

The followi ng equi p men t is recom men ded for the succe ssful com plet i on of th is tra ini ng course.

Microline 520 or Microline 521 (optional)

Tools (optional - refer to Module Three of the Service Handbook)

Personal Computer (for Okilink II connection)

Modem (for Okilink II connection)

Communicatio ns Soft ware (for Okili nk II connecti on)

Telephone (for Faxable Facts connection)

Facsimile Machin e (for Faxab le Facts connec ti on)

Video Cassette Player (for viewing videotape)

Video Monitor (for viewing videotape)

Documentation

You should hav e acc ess to the foll owing documenta ti o n whi le com pl et i ng th is co urse .

Okidata Servic e Cent er Refe rence Guide

Service Handbo ok

Printer Handbook

Service Video tap e

Course Administration i - 2 Microline 520/521 Service Handbook

P/N 59257803

Page 20

INFORMATION UPDATE S

Every effort has been made to ensure the accuracy of the information contained in this training

course. Okidata is not respo nsi b le for errors beyo nd it s contro l .

Technical updates are made available to authorized Service Centers through the Technical

Service Bulleti ns (TSBs / Oki data ’s Mont hly Techni ca l Mail). The TSBs are dist ri but ed via

Okidata’s Bulle tin Board, Okil ink II.

Addition s and correc tio ns to th e train ing mate ria ls are av aila bl e in the Trai ni ng Sect i on of

Okilink II. Please sign on and check this section before beginning this course.

For informati on on using Okili nk II, pl ease refer to the Servic e Cent er Refe ren ce Gui d e.

NOTICES

Pay attention to all not ices th at appear th ro ugh out this trai n ing course. They are for your safet y !

Here are the definitions of the notices.

NOTE:

This notice refers to sup p le men ta l inf o rmat i on.

CAUTION:

Deviation from the li st ed proc ed ure s may resul t in dama ge to the pro d uct.

WARNING:

Deviation from the listed pro cedur es ma y result in personal injury.

Microline 520/521 Service Handbook i - 3 Course Administration

P/N 59257803

Page 21

WHERE TO SEND TESTING MATE RIAL S

Refer to the Okidata Servi ce Ce nter Re feren ce Guid e for whe re to send the test mate ria ls.

The Okidata Service Center Reference Guide is sent to your dealership along with the Okidata

Service Contra ct mate ria ls. It is availab le fro m Oki dat a Deal er Service. It is also available

through Okilink II.

Course Administration i - 4 Microline 520/521 Service Handbook

P/N 59257803

Page 22

MISSING ITEMS OR MISSING PAGE S

Missing Items

When you receive the training kit, you MUST verify that the kit contains the items listed on the

Read Me First sheet.

If any items are missin g, pl ease con ta ct Okidat a Logistics at the app ro pri at e nu mb er li st ed below.

Facsimile 1-609-424-7 423

Voice 1-800-72 7-8654

You must prov id e the fol l owi n g info rmation.

• Okidata Auth ori zati on Num ber (Deale r Number)

• Okidata Customer Number

• Order Acknowledgment Number (on the invoice)

• Part Number of kit

Missing Pages

If you find that pages are missi ng from any item in this ki t, please co ntac t Oki dat a Techn ical

Training.

Please FAX your request or use Okilink II.

Fax Number: (609) 235-2600, ext. 7034

Okilink Login Name : Technica l Trai nin g

You must prov id e the fol l owi n g info rmation.

• Okidata Auth ori zati on Num ber (Deale r Number)

• Part Number of docu me nt wit h missin g pages

• Name of document with missing pages

• Page numbers of mi ssin g pages

If it is the Service Han dbo ok, be sure to speci fy the secti on (i, 1, 2, 3, 4, a, or b).

• Your facsimi l e numb er (wit h area code )

Microline 520/521 Service Handbook i - 5 Course Administration

P/N 59257803

Page 23

COURSE PATH

This Course Admini stra tio n direc ts you throu gh the trai nin g packag e. Each section covers a

different part of th e train i ng. Tasks wit h in each sect ion dire ct you to the porti on s of the trai nin g

materials th at cover th e sub j ect you are stu d yin g.

When you have co mp le ted one section, move on to the next. Yo u must achieve a score of 80%

or greater on your Certi fi cation Test to successfu l ly com pl ete th is cou rse.

You must return your co mp le te d Certi fi cat i on Test Answer Sh eet an d Course Cr i tiq ue to

Okidata within 30 days after the kit is receive d by your Deal ersh i p. If multi ple tech nici an s are

training at your De alership, only one techni cian must com plet e the te sti n g duri ng th e 30 days.

DO NOT STAPLE THE ANSWER SHEET TO THE COURSE CRITIQUE!

Be sure to make a copy of the Answer Sheet for your record s.

Your Answer Sheet will be corrected wit hin two days after it is received by Okidat a. If you

achieve a score of 80% or higher, you will receive a Certificate of Training. The Dealership you

work for will become an Aut hori zed Servi ce Cente r fo r the prod u cts cov ered in this trai n in g

packag e.

Service Auth ori za tio n is appro v ed once Oki data proc esses the Answe r Sheet . The Certi fi cat e of

Training will be mail ed to you afte r the Answer Shee t is correct ed .

You and your Dealership are responsible for returnin g the Answer Sheet and Course Crit i que

within 30 days after receiving the training kit. Okidata strongly urges you to keep track of the

date you return your Answer Sheet and Course Critique. Certification and Authorization are

processed within two days after Okidata receives the testing materials. A certificate for

successful completion of the training program will be sent to you within 21 days. If

authorization is not updat ed withi n two days or a certi fi cat e rece iv ed wit hi n 21 days, con ta ct

Okidata Dealer Serv ic e.

Proceed through each section and perform the assigned tasks.

Learn from the Course and Good Luck!

Course Administration i - 6 Microline 520/521 Service Handbook

P/N 59257803

Page 24

SERVICE TRAINI NG

Requirements

You will need the following items.

Service Center Re feren ce Guide

Service Handbo ok

User’s Documentation

Service Video tap e

Video Cassette Play er and Moni tor

Service Train in g is div ide d int o the fol l owing six section s.

General Descriptio n

Installation

Principles of Operation

Failure Analysis

Appendices

Maintenance

Disassembly/Assembly

Adjustments and Service Checks

Cleaning

Lubrication

Shipping Instructions

Microline 520/521 Service Handbook i - 7 Course Administration

P/N 59257803

Page 25

General Description

This section describe s the featu res and spe ci fic atio ns of the prin t ers.

Assigned Tasks

Read Section 1 of the Service Handbook.

Read Appendix A in the Printer Handbook.

Installation

In this section, you will install the unit. You will also perform various tests.

Assigned Tasks

Review the Printer Handbook

Read the Introdu ct ion ; Chap t ers 1, 2, 3, 4, and 5; and Appen di ces B, C, D, E, and F

in the Printer Handbook.

If a product is availab le , perform th e tests li st ed below. Refer to Sect ion 4 of the

Service Handbook.

Rolling ASCII

Font Test

Principles of Operation

This section describe s the func ti on of the maj or asse mbli es from an elect ric al and mech anic al

perspecti ve .

Assigned Tasks

Read Section 2 of the Service Handbook.

Course Administration i - 8 Microline 520/521 Service Handbook

P/N 59257803

Page 26

Failure Analysis

This section covers the methods used to identify and correct problems with the unit.

Assigned Tasks

Read Section 4 of the Service Handbook.

Read Chapter 6 of the Printer Handbook.

Study the Board Diagrams in Appendix A of the Service Handbook.

Check Okilink II for addit ion al troub le shoo tin g info rmat i on. Refer to the Servi ce

Center Reference Guide for information on accessing Okilink II.

Appendices A and B

Appendices A and B contain charts, illustrations, and an illustrated parts list to support you in

servicing the product.

Appendix A

Appendix A contains inform atio n about the print ed circ uit boards (PCBs). This

appendix includes reference charts which present data regarding function,

firmware, fuses, jumpers, sensors, switches, and test points. An illustration of

each board is also included.

Appendix B

Assigned Tasks

Look through Appendix A and Appendix B in the Service Handbook.

Appendix B is an illu stra ted pa rts list in g of the produ ct . This list ing is

cross-referenced to Sectio n 3 of the Service Handb ook.

Microline 520/521 Service Handbook i - 9 Course Administration

P/N 59257803

Page 27

Maintenance

Disassembly / Assembly

Assigned Tasks

Read Section 3.2 of the Service Handbook.

View th e videotape.

CAUTION:

Okidata does not reco mmen d perfo rming the disassembl y / assembl y pro cedu res on a

product whi ch is opera ti n g norma ll y. Therefo re, you are no t requi red to perf orm the

disassembly / assembly procedures to complete this training.

Adjustments and Service Checks

This section explain s the adjust me nts perfo rmed after parts replaceme nt. Hardware repl ace men t

may require adjustments to firmware set ti ngs. This section also explai ns vi ewi ng and reset t ing

counters.

Assigned Tasks

Read Section 3.3 of the Service Handbook.

Perform the procedures li st ed in Secti on 3.3 of the Servi ce Hand book.

Cleaning

Assigned Tasks

Read Section 3.4 of the Service Handbook.

Lubrication

Assigned Tasks

Read Section 3.5 of the Service Handbook.

Shipping Instructions

Assigned Tasks

Read Section 3.6 of the Service Handbook.

Course Administra ti on i - 10 Microline 520/ 521 Servi ce Handboo k

P/N 59257803

Page 28

SERVICE AUTHORIZATION

General Information

Read throug h the instructions for co mp le ti n g the te sti n g proce ss before you begin.

This section contain s the Answer Shee t, Certification Test, and Course Cri ti q ue for this service

training pa ckag e. These are the only copie s of t hese it ems yo u wi ll re cei v e.

DO NOT WRITE ON THESE ITEMS!

PHOTOCOPY EACH ITEM!

Use the photocopies to comp lete the test ing process. Photo co py the Cert ific at ion Test, Answer

Sheet, and Cou rse Cri ti que as required for e ach techn i cian being train ed .

The informati on provi ded on the Answer Sheet and Course Crit i que is use d to update your

Dealership’s Okid at a Servic e Warran ty Profile and to process your Certi fic ate of Trai ni ng. The

critique information is used to respond to your questions regarding this training package.

MAKE YOUR RESPONSES COMPLETE AND LEGIBLE!

Feel free to reference the trai nin g materi al as you answer the test questi o ns.

Every attempt has been made to test your knowledge of the product and your ability to use the

reference materi als in this kit. No attempt has been made to write "tri ck quest ion s".

If you have a question abou t a specific test question or answe r, pl ease brin g it to the att en t ion of

Okidata Techni cal Trai ni ng. Refer to the Service Cent er Refe ren ce Gui de for in form at ion on

contacting Okidata Technical Training.

In order to improv e the qualit y of future tra in i ng courses, Okidat a wel comes you r eval uat ion of

this training prog ram . Please comp le te the course c rit iqu e for thi s trai nin g course .

Before returning your completed testing materials, photocopy your completed Answer Sheet for

your records.

DO NOT ATTACH ANYTHING TO THE ANSWER SHEET!

Microline 520/521 Servi ce Han dbo ok i - 11 Course Administra ti on

P/N 59257803

Page 29

Certificati on Tes t

Requirements

You must achiev e a score of 80% or greater on your Ce rti fi cat i on Test to suc cessfu l ly com plet e

this course.

You will need the following items.

Service Handbo ok

User’s Documentation

#2 Lead Penci l

Assigned Tasks

Read through all instructions BEFORE comp le ting the testi n g pro cess.

Photocopy the Certi fic at ion Test and Answe r Sheet pro vid ed in thi s kit. Use the

photocopies to complete the testing process.

Complete the top secti on of the Answe r Sheet. Make your resp onses le gib le .

Answer the Certification Test Questions by filling in th e appro pri at e blo ck on the

Answer Sheet. Use a Number 2 pencil and compl et ely fil l in the selected block.

DO NOT ATTACH ANYTHING TO THE ANSWER SHEET!

Make a copy of the complete d Answe r Sheet for your reco rds.

Course Critique

Requirements

You will need the following items.

Your photocop y of the Cou rse Cri ti q ue

Assigned Tasks

Complete the Course Cri ti q ue.

Return the Answer She et and Course Cri t iq ue to Okidat a Deal er Serv ic e.

DO NOT ATTACH ANYTHING TO THE ANSWER SHEET!

DATE ITEMS RETURNED TO OKIDATA: __________________________

Course Administra ti on i - 12 Microline 520/ 521 Servi ce Handboo k

P/N 59257803

Page 30

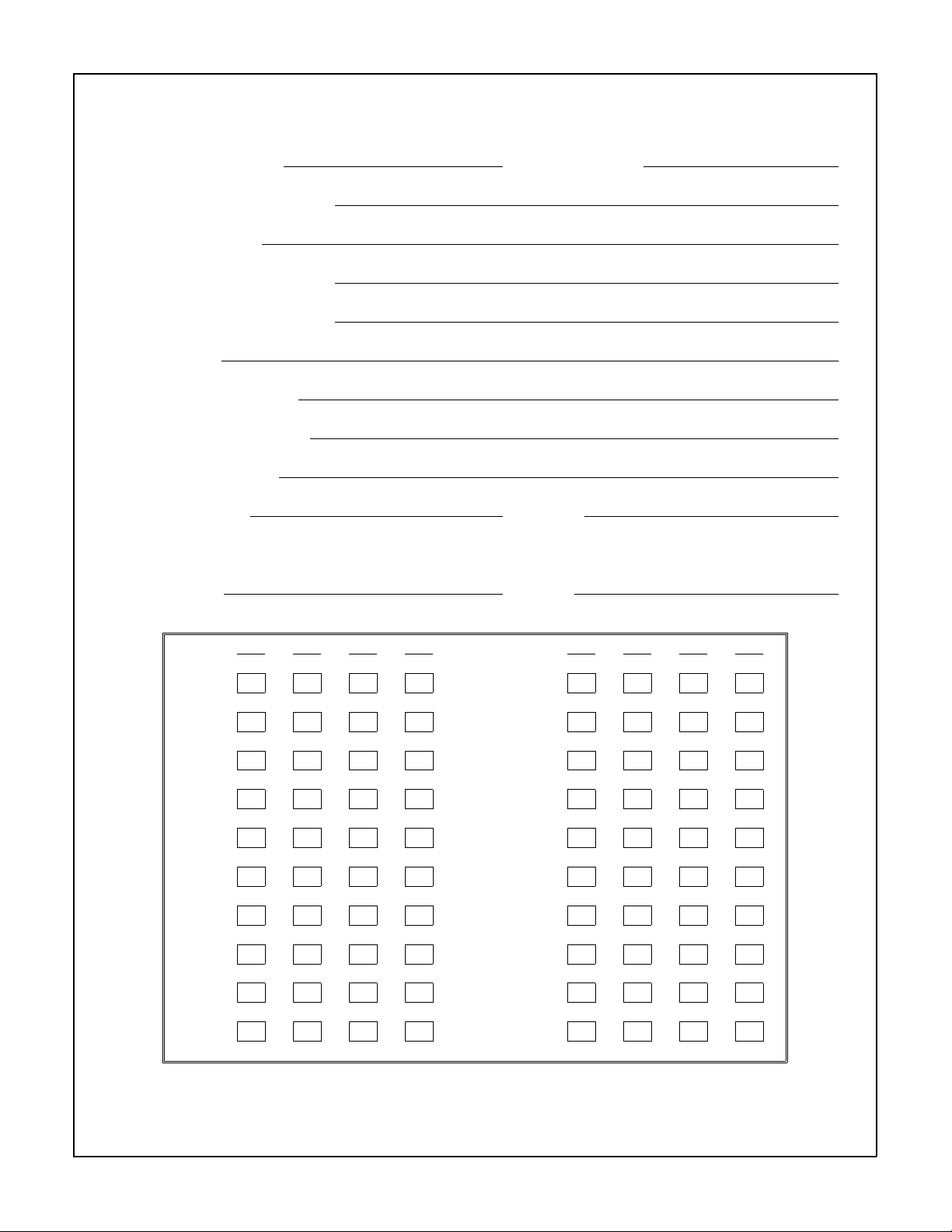

Answer Sheet: Microline 520/521

Section 1

Dealer Code:

Today’s Date:

Technician’s Name:

Company:

Company’s Address:

City:

State/Province:

Zip/Po sta l Co d e:

Country:

Phone #: Fax #:

If your Dealership uses Okil ink II, please pro vid e your Deal ersh i p’s Lo gin Name.

First:

Last:

Section 2

ABCD ABCD

1. 11.

2. 12.

3. 13.

4. 14.

5. 15.

6. 16.

7. 17.

8. 18.

9. 19.

10. 20.

Microline 520/521 Servi ce Han dbo ok i - 13 Course Administra ti on

P/N 59257803

Page 31

Course Critique: Microline 520/521

Deal er Code:

Today’s Date:

Technician’s Name:

Company:

Company’s Address:

City:

State/Province:

Zip/Posta l Code:

Country:

Phone #: Fax #:

1. Have you completed other Oki da ta Self-St ud y Servi ce Trai nin g packag es?

Yes

2. Please rate this course.

Excellent

Above Averag e Poor

Average

3. Does your Dealership use Okilink II?

Yes

If yes, please provid e your Deal ersh i p’s Lo gi n Name.

First Name:

Last Name:

No

Below Average

No

Course Administra ti o n i - 14 Microline 520/5 21 Servi ce Handbo ok

P/N 59257803

Page 32

4. Comments

Microline 520/521 Servi ce Han dbo ok i - 15 Course Administra ti on

P/N 59257803

Page 33

Certification Test: Microline 520/521

1. After install ing the space mot or, Okid at a reco mm en ds th at you check the printhead gap.

A. True

B. False

Correct Answer: A

Pages 3-2 and 3-26, Servi ce Handbook, Rev 01 and 02

Pages 3-2, 3-2 4, and 3-66, Servi ce Handbook, Rev 03

2. Refer to RAP 01. You have pressed the AC power switch to ON, but the unit does not

power ON. The next step is to

A. replace the fuse.

B. check if the AC ca ble is connected properly.

C. replace the space motor assemb l y.

D. remove the printhead.

Correct Answer: B

Page 4-10, Service Handbook, Rev 01 and 02

Page 4-24, Service Handbook, Rev 03

3. The + 40 vdc needed for the printhead and space motor drive can be verified at

__________ on the main control (FJIM) board.

A. CN1 Pins 8 and 9

B. CN3 Pins 1 and 2

C. CN7 Pins 29 and 31

D. CN6 Pins 1 and 2

Correct Answer: C

Page A-4, Service Handbook, Rev 01 and 02

Page A-4, Service Han dbo ok, Re v 03

Course Administra ti o n i - 16 Microline 520/5 21 Servi ce Handbo ok

P/N 59257803

Page 34

4. According to Appen dix A of the Servic e Handb oo k, on e funct io n of the main cont rol

board is to regulate the AC voltages from the power suppl y (transfo rme r).

A. True

B. False

Correct Answer: A

Page A-4, Service Handbook, Rev 01 and 02

Page A-4, Service Han dbo ok, Re v 03

5. You are using RAP 11 to trou bleshoot a printer. The uni t cann ot recei v e seria l

communicat ion from the host. You have verified that the cable has the prop er

configuration of pins. No ALARM LEDs are blinking. Your next step should be to

A. replace the transfo rmer.

B. replace the RS 232-C serial board.

C. check your serial interface parameters.

D. replace the main control board (FJIM).

Correct Answer: C

Page 4-26, Service Handbook, Rev 01 and 02

Page 4-40, Service Handbook, Rev 03

Microline 520/521 Servi ce Han dbo ok i - 17 Course Administra ti on

P/N 59257803

Page 35

6. The printer is processing a head overhe at alarm . When the printhead temp erature exceeds

110 degrees Celsius, the printer switches to unidirectional print. When the printhead

temperatu re excee ds 11 8 deg rees Celsius, the printer wil l

A. need a new space motor.

B. continue unidirectional print.

C. alternate between unidirectional print and bidirectional print.

D. stop printing.

Correct Answer: D

Pages 2-21, 2-28, and 4-31, Service Handbook, Rev 01 and 02

Pages 1-11, 2-15, 2-32, and 4-21, Service Handbook, Rev 03

7. Before you begin troubleshooti ng an ALARM / LED display, you should always

A. replace the power supply.

B. check that all of the connectors of the prin ter are makin g goo d contac t.

C. replace the main control board.

D. replace the operator panel.

Correct Answer: B

Page 4-30, Service Handb ook , Rev 01 and 02

Page 4-20, Service Handbook, Rev 03

Course Administra ti on i - 18 Microline 520/ 521 Servi ce Handboo k

P/N 59257803

Page 36

8. According to the Printer Handb ook or Sectio n Three of thi s Servi ce Han dbo ok, whi ch of

the following settings is NOT a default menu setti n g of the serial interfa ce

configuration?

A. Parity - Even

B. Serial Data - 8 bits

C. Protocol - Ready/Busy

D. Baud Rate - 9600 bps

Correct Answer: A

Page 90, Printer Manual User’s Docum enta tio n, Rev 01 and 02

Page 3-81, Service Handbook, Rev 03

9. The ALARM lamp is flashing. The PROP and 10 cpi lamps are lit. Which alarm is th e

printer experiencing?

A. Printhead Data Transfer Ala rm

B. Printhead Type Alarm

C. Paper End Alarm

D. Space Motor Ala r m

Correct Answer: B

Page 4-29 and 4-30, Service Handbook, Rev 01 and 02

Pages 4-19 and 4-20 , Serv ice Hand b ook , Rev 03

Microline 520/521 Servi ce Han dbo ok i - 19 Course Administration

P/N 59257803

Page 37

10. You insta ll a new control board in the printer. What are the indic at ion s of an inco rrect l y

posit ione d cut sheet / continuous s ensor lever?

A. The unit will not power-ON.

B. All lamps on the operator panel light.

C. The ALARM lamp lights and F1 on the control board blows.

D. The ALARM lamp lights and the unit will NOT auto mat ical ly load paper.

Correct Answer: D

Pages i-7 and i-8, Service Handbook, Rev 01 and 02 OLD QUESTION

Page 3-16, Service Handbook, Rev 03 NEW QUESTION

11. What is the recomm en ded amb ien t temp erat u re and rela tiv e humi dit y (RH) for the pri nte r

whil e operating?

A. 41°F to 104°F, 20% to 80% (RH)

B. 41°F to 104°F, 10% to 70% (RH)

C. 41°F to 104°F, 20% to 50% (RH)

D. 41°F to 104°F, 20% to 90% (RH)

Correct Answer: A

Page 1-2, Servic e Handb ook , Rev 01 and 02

Page 1-4, Servic e Handb ook , Rev 03

12. The Microli ne 520 and Micro l ine 521 prin ters all o w you to prin t up to eight differe nt bar

codes.

A. True

B. False

Correct Answer: A

Pages 84, Print er Man ual and 1-8, Servi ce Han dbo ok , Rev 01 and 02

Page 1-7 and 1-8, Service Handbook, Rev 03

Course Administra ti on i - 20 Microline 520/ 521 Servi ce Handboo k

P/N 59257803

Page 38

13. The Micro lin e 520 and Microline 521 print ers come wit h ____ ___ ___ ___ Kbyte of

resident RAM.

A. 32

B. 64

C. 128

D. 256

Correct Answer: C

Page 1-4, Servic e Handb ook , Rev 01 and 02

Page 1-20, Service Handbook, Rev 03

14. Refer to RAP 02. The carriage is jammed. The ribbon is not jammed. What do you do

next?

A. Install a new space motor.

B. Power OFF the printer, then power ON.

C. Remove the space motor assem bly and insp ec t the te et h on the spac e rack and

space motor gear.

D. Replace fuse F1 on the main controller board.

Correct Answer: C

Page 4-12, Service Handbook, Rev 01 and 02

Page 4-26, Service Handbook, Rev 03

15. You must replace the line feed motor. The disassembly procedure also tells you to

remove the li n e fe ed idle ge a r.

A. True

B. False

Correct Answer: B

Page 3-54, Service Handbook, Rev 01 and 02

Page 3-46, Service Handbook, Rev 03

Microline 520/521 Servi ce Han dbo ok i - 21 Course Administra ti on

P/N 59257803

Page 39

16. Three items factor into printhead gap information.

1. Printhead Gap Adjustment (performed by a service technician)

2. Printhead Gap Adjust (set in the prin t er menu, under the Set -up Grou p)

3. Gap Control (set in the printer menu, under each [Paper Feed] Group)

A. True

B. False

Correct Answer: A

Page C-1, Service Handbook, Rev 01 and 02 OLD QUESTION

Pages 1-12 and 2-18, Service Handbook, Rev 03 NEW QUESTION

17. Which of th e follo wi ng areas of the pri nte r shou l d NOT be lubricated?

1. Tractor pins

2. Pressure roller (Rubber Face)

3. Platen assembly (Rubber Face)

4. Teeth of gears in the gear case assembly

A. 1

B. 1 and 2

C. 1, 2, and 3

D. 1, 2, 3, and 4

Correct Answer: D

Page 3-88 and 3-89, Service Handbook, Rev 01 and 02

Page 3-91, Service Handbook, Rev 03

Course Administra ti on i - 22 Microline 520/ 521 Servi ce Handboo k

P/N 59257803

Page 40

18. You are performing the printhea d gap adju st men t . The printh ead gap is changed by

turning th e adju sti n g screw, locat ed on the spa ce mo to r assemb l y. Turn in g the

adjusting screw coun ter-cl oc kwi se wil l increase the gap. Turnin g it clockw i se will

decrease the gap.

A. True

B. False

Correct Answer: B

Page 3-68, Service Handbook, Rev 01 and 02

Page 3-68, Service Handbook, Rev 03

19. The ALARM lam p is flashi n g. The 15 cpi LED is lit. Which of the fol lowing should be

replaced fi rst ?

A. Printhead

B. Line feed motor

C. Space motor

D. Main cont rol boa rd and / or ROM

Correct Answer: D

Page 4-30, Service Handb ook , Rev 01 and 02

Page 4-20, Service Handbook, Rev 03

Microline 520/521 Servi ce Han dbo ok i - 23 Course Administra ti on

P/N 59257803

Page 41

20. Before rese tti ng a printer men u to facto ry set ti n gs, Okidat a reco mmends that you

A. run a self test.

B. perform the hex dump test.

C. power OFF the printer, then press and hold the LINE FEED while powering

ON the printer.

D. print the menu.

Correct Answer: D

Pages 47, User’s Documentati on and 3-81, Servi ce Handbo ok, Rev 01 and 02

Page 3-75, Service Handbook, Rev 03

Course Administra ti on i - 24 Microline 520/ 521 Servi ce Handboo k

P/N 59257803

Page 42

SECTION ONE

SPECIFICATIONS

Page 43

Page 44

1.1 OVERVIEW

1.1.01 Gene ral Infor mati on

The Microline 520 and Microline 521 are letter quality, nine-pin, dot-matrix printers which

utilize OKI

SMART paper handling. Patented Okidata technology does away with the manual

head gap adjustment. The printer actually "reads and learns" the print medium being used, then

automat ical ly adju sts th e head gap to the opt im um dist an ce . This auto gap pi n g proce ss lead s to

longer printhead life.

Options incl ude the Bott om Feed Push Tract or , Cut-Sh ee t Feed er, Pull Tract or and Serial

Interface Board.