Oki MICROLINE 390, MICROLINE 391 Elite Maintenance Manual

OK1

MICROLlI\

JE

3901391

Elite

MA

NTENANCE

MANUAL

PREFACE

This maintenance manual describes field maintenance of the Microline

390/391

Elite printer and

options for maintenance personnel.

For performance specifications and operating procedures, refer to the “User’s Manual”.

TABLE OF CONTENTS

1.

CONFIGURATION _. _. __________________ _.

_.__. ._. .____. _. __.. ._._

I-I

1.1

Standard

Printer

Configuration

_.

_.

_.

I-I

1.2

Options

. . . . . . . . . . . . . . . . . .._____.___________________.__...______._

1-2

1.3

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..__.._._._

1-4

1.3.1

Printspecifications .

.._.________..._..____.__._........________________

1-4

1.3.2

Paperspecifications_. _.

_____

__ _.

_.

1-5

1.3.3 Physical specifications_. _. _.

__

l-6

1.3.4

Power requirements

l-6

1.3.5

Environmental conditions

_.

_.

_.

1-7

1.3.6 Noise

_._........_......_.__...__.___......_......________.......____.__._

1-7

1.3.7

Agency

approvals

__ _. _. _. _.

__

l-7

2.

INSTALLATION PROCEDURE

_. _. _. _. _, _. _.

__

_.

2-1

2.1

Unpacking

_________..________.___.__..________...._._..___._..._____..___

2-l

2.1.1

Unpacking the packing box

2-l

2.1.2

Unpackingtheprinterunit

___.___..______________...._..______..__..__..__

2-2

2.1.3

Unpackingtheaccessories

.___.____.__._____________...____._._..__._..__._

2-3

2.2

Installation ____________.______._....______._.____.__________________...__ 2-4

2.2.1

Precautionforinstallation

___......_.___________.........____________._.__

2-4

2.2.2

Removing the shipping retainer

2-6

2.2.3

lnstallingtheaccessories

_.______.___......_.____.____________.______.__.__ 2-7

2.2.4

Connectingcables

_____.____.._.._____.._.____.....___....________..______

2-8

2.2.5

Installingpaper

.____.__.____________._...._...._..___..____...___________

2-9

2.2.6

Poweringon

_____._._..,..___.._._......_.____..__.__._..__._...___.__..

2-10

2.2.7

Rolling ASCII test pattern

2-11

3.

THEORY OF OPERATION

__

__.

_. _. _. _.

_.

3-1

3.1

Electrical Operation_. _. _.

_.

3-I

3.1.1 General

_________________.___.________._....._..............._____.......

3-1

3.1.2

Microprocessor and its peripherals circuits

3-1

3.1.3

Initialization _, _. _. _. . _.

.

3-5

3.1.4 Interfacecontrol

_____________.__.._._......._............................

3-5

3.1.5 Printhead drive circuit

3-6

3.1.6 Spacing drive circuit

.._

3-7

3.1.7

Line feed circuit

..........................................................

3-9

3.1.8 Alarmcircuits

............................................................

3-9

3.1.9

Paper end detection circuit

...............................................

3-10

3.1.10

Powersupply

...........................................................

3-11

3.2

Mechanical Operation

...................................................

3-12

3.2.1

The printhead mechanism and its operation

...............................

3-12

3.2.2 Spacing

................................................................

3-14

3.2.3

Head gap adjusting

......................................................

3-16

3.2.4

Ribbon drive

............................................................

3-18

3.2.5 Paperfeed

..............................................................

3-20

3.2.6

Paper end detection

.....................................................

3-27

3.2.7

Semi-automatic sheet feeder

(SASF)

.......................................

3-28

3.2.8

Reversing continuoussheets

..............................................

3-31

4.

ASSEMBLY/DISASSEMBLY

...................................................

4-l

4.1

Precautions for Parts Replacement

4-l

4.2

MaintenanceTools

.......................................................

4-2

4.3

Disassembly/Reassemblyof Procedure

......................................

4-3

4.3.1 Separatorassembly

.......................................................

4-4

4.3.2 Printhead

................................................................

4-5

4.3.3

Uppercoverassembly

.....................................................

4-6

4.3.4 Controlboard

............................................................

4-8

4.3.5

Operator board

.........................................................

4-10

4.3.6

Bailarm

.............................................................

4-12

4.3.7

Connection board

(SRBS)

.................................................

4-12

4.3.8 ICcardpanel

............................................................

4-14

4.3.9 Bailarmbar

.............................................................

4-15

4.3.10 Transformer

............................................................

4-16

4.3.11

Filterassembly

..........................................................

4-17

4.3.12 Power supply board

.....................................................

4-18

4.3.13 Connectorcord

.........................................................

4-19

4.3.14 Ribbon drive gear assembly

..............................................

4-20

4.3.15

Space motorassembly

...................................................

4-22

ii

4.3.16 Carriageframe__ _. _. _. _. _. _. _.

_.

4-24

4.3.17 Spacerack

.._.._.._____.______..._________.._......._____..__.._.__..__

4-25

4.3.18 Guiderail

________.._....__.__.____.________..._.._..__.___.___________..

4-26

4.3.19

Head cable__ _. _. _. _. _. _.

_.

4-28

4.3.20

Platen assembly

4-28

4.3.21

Ribbon protector_. _. _. _. _.

_.

4-30

4.3.22 LFmotor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1. 4-31

4.3.23LF motor interconnect module

4-32

4.3.24 Idlergear

____..__..__._.______..________________________________.___._._

4-33

4.3.25

Releaselever

. . .

..______.___._.___.._.._._....._._____._._.....__________

4-34

4.3.26

Pressure

roller assembly

_. _. _. _. _. _. _. . _. _.

4-34

4.3.27

Tractor assembly_. _. _.

_.

4-36

4.3.28

Sensorlever .._,___..____.....,_______________.________.__._...____._,...

4-38

4.3.29

Paper end lever

4-39

4.3.30 Leafspring ______._________________.._,...._._______.__.__.__.__.._____.

4-40

5.

ADJUSTMENT

__ _. _, _. _. _. _. _. .

_.

5-1

5.1

Gap Between The Platen And Printhead

5-l

6. CLEANING AND LUBRICATION

_.

6-1

6.1

Cleaning

________..___._.....__....__.___________________....._...,......

6-l

6.2

Lubrication

_.._______.._..__._________________...................__..__..

6-1

7.

TROUBLESHOOTING AND REPAIR _. _. _.

_.

7-1

7.1

Items to Check Before Repair

7-l

7.2

Method of Troubleshooting

_.

7-l

7.3

LampDisplay ..__________._......._________._........____.__.______.____

7-2

APPENDIXA PCBLAYOUT

____.._______.,.._______________...._._______.._____........

A-l

APPENDIXB

SIGNALLIST

_____.__._________.._.___________________....__._____________

B-1

APPENDIXC

CIRCUITDIAGRAM

._______...._.__.___________.....___._.________........

C-l

APPENDIXD

SPAREPARTSLIST __________.__________.________._.______________.____....

D-l

APPENDIX E RS-232C (for

ML390/391/320/321

Elite) SERIAL INTERFACE BOARD

E-l

1.

GENERAL

_______..__._______._...___.______._._._._______.._..________...

E-l

2.

OPERATION DESCRIPTION

_.

_. _. _.

___

E-2

2.1

ElementDescription

. . . ..___________..__._________.__._._.________._.___.. E-2

iii

2.2

2.2.1

2.2.2

2.3

2.3.1

2.3.2

3.

3.1

3.2

3.3

3.3.1

4.

Circuit Description

E-2

Operation at

poweron

E-4

fS232Cinterface

_.__.________________..______________________.....______

E-4

Communication Procedure Flowchart

_.

_. _. _. _. _.

_.

E-5

Mode@

__________..________________________.___.,,,..._..___..__________

E-5

Mode@

..__._._.._______._...._____________._

E-6

TROUBLESHOOTING FLOWCHART

_.

_. _. _. _.

_.

E-7

Before Repairing a Fault

_.

E-7

Troubleshooting

_....______________...___.._____________._.._____________

E-7

LocalTest ______..__._______.___.._.___________........__.______,..._....

E-11

Circuit test mode

E-l 1

CIRCUITSYMBOLSAND CIRCUIT DIAGRAMS

E-13

iv

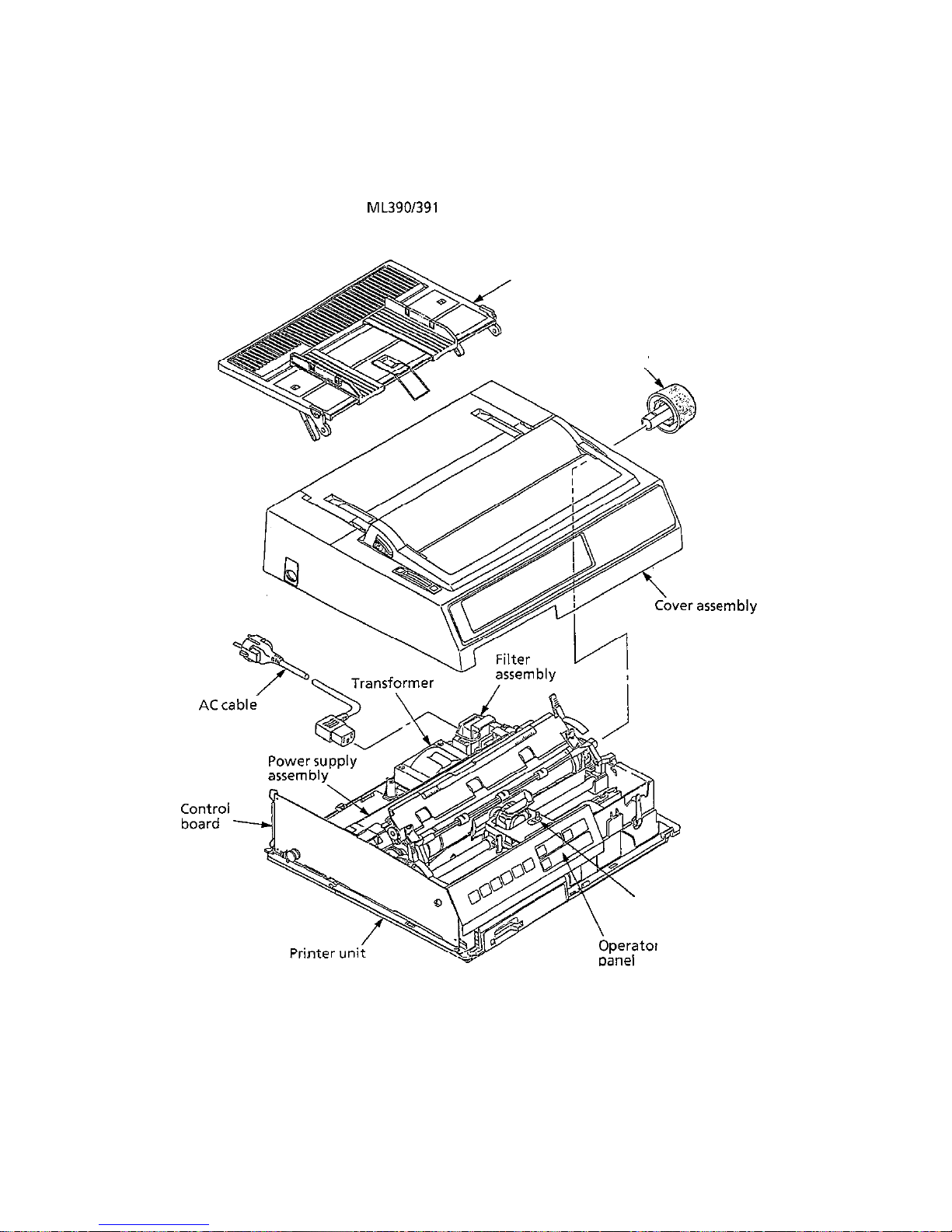

1. CONFIGURATION

1. CONFIGURATION

1.1 Standard Printer Configuration

The standard configuration of the

ML390/391

Elite is as follows

py-

Platen knob

Paperseparator

\

Ribbon

cassette

perat

smbly

Figure l-l Printer configuration

l-l

1.2 Options

(1)

Tractorfeed unit with acoustic cover

(2)

Cut-sheet feeder unit with access

cover

(3)

Super-speed RS-232C serial interface board

(4)

Font memory card

l-3

1.3 Specifications

1.3.1 Print specifications

(1)

(2)

(3)

(4)

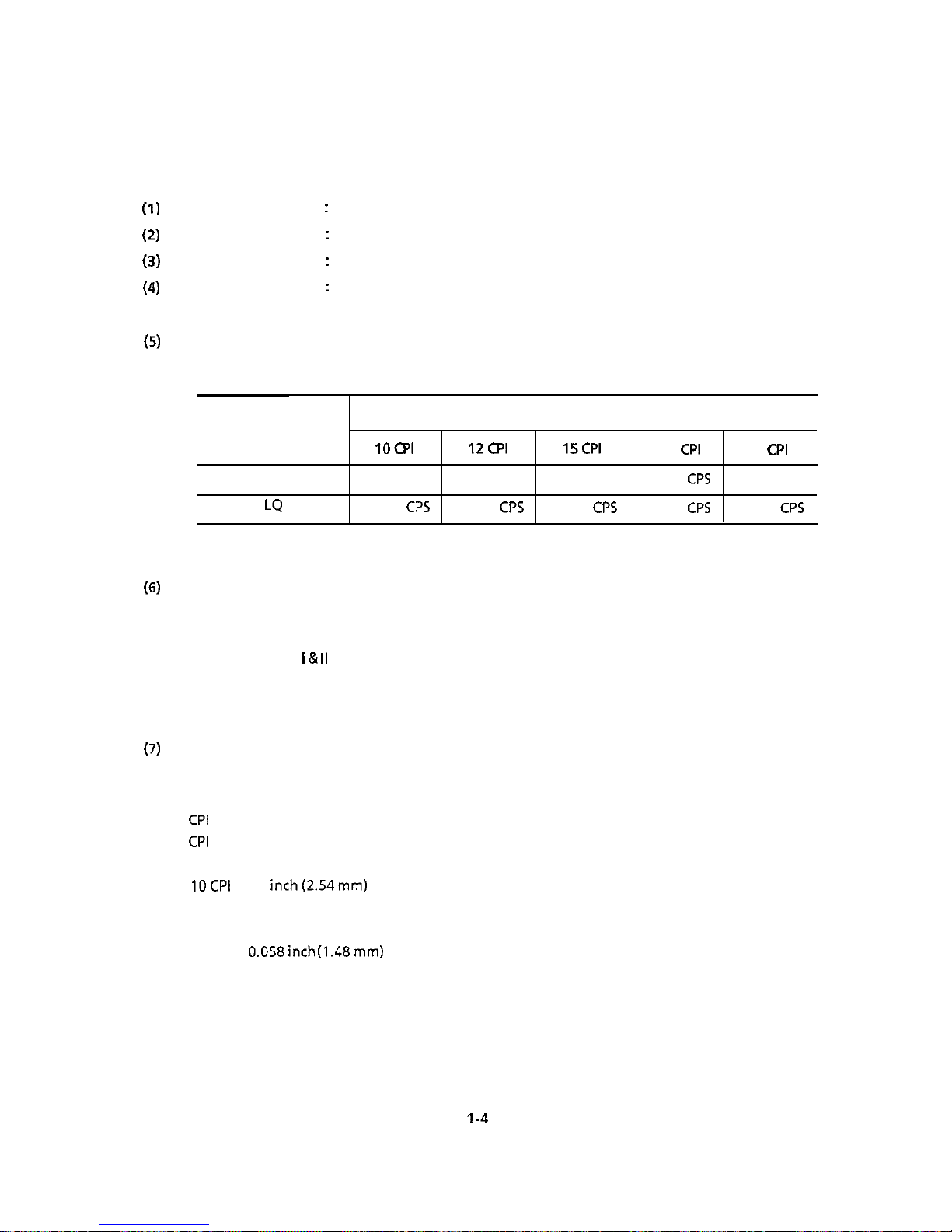

(5)

(6)

(7)

Print method

:

Number of dot wires

:

Dot wire diameter

:

Print direction

:

Impact dot matrix

24

0.0079 inch (0.2 mm)

Bidirectional, short-line-seeking printing

Unidirectional printing specifiable

Print speed

Print mode

Utility

LQ

Character pitch

IOCPI

12CPI 15CPI

17.1

CPI

20

CPI

225.0 CPS

270.0 CPS 168.6 CPS

192.9

CPS

225.0 CPS

75.0

CPS

90.0

CPS

112.5

CPS

128.6

CPS

150.0

CPS

Character sets

Standard ASCII

EPSON Character Set

IBM Character Set I &

II

IBM Proprinter Compatible Character Set

Foreign Character Substitution

Line Graphics

Character pitches

The following character pitches are selectable through the operator panel* or with control

codes:

5

CPI

0.2 inch (5.08 mm)

6

CPI

0.167 inch (4.23 mm)

8.5 CPI 0.117 inch (2.96 mm)

* 1OCPI 0.1

inch(2.54mm)

* 12 CPI

0.083 inch (2.12 mm)

* 15 CPI

0.067 inch (1.69 mm)

* 17.1 CPI

0.058inch (1.48mm)

* 20 CPI

0.05 inch (1.27 mm)

1-4

1.3.2 Paper specifications

(1)

(2)

(3)

(4)

Cut-sheet paper

The standard size :

8-l/2

inches (wide) x 11 inches (long) for the U.S.

A4 size

:

210 mm

(wide) x

297 mm (long) for Europe

Weight

: 12 to 24 lb (45 to 90

g/mz)

Multiple-part paper cannot be used.

Sprocket paper

The tractor feed unit can handle sprocket paper of the following widths:

ML390 Elite: 3 to 10 inches (76.2 to 254 mm)

ML391 Elite: 3 to 16 inches (76.2 to 406.4 mm)

One-part paper

Ream weight: 12 to 24 lb (45 to 90 g/m*)

Multiple-part paper: 0.014 inch (0.356 mm) or lesstotal thickness

Number of sheets Ream

weig~ht

Number of sheets

Carbon-lined paper

Pressure-sensitive paper

interleaf paper

(paper)

(carbon)

9toll

lb

(35 to 40 g/m*)

IOtolZlb

(38 to 45

g/m2)

9lh

(35

glm2)

upto

including original

Upt04

including original

Multiple-part paper should be fastened by spot-pasting or crimping on both sides, and should

be free of wrinkles.

Cut envelope

Weight

:

Thickness

:

Size

24

Ibs

(90

glm2)

or less

0.016 inch (0.41 mm) or less

6-112x3-518

inches

8-718x3-718

inches

9-l/2

x4-118 inches

Multiple-part envelope

Weight

:

24

Ibs

(90

glmz)

or less

Thickness

:

0.014 inch (0.36 mm) or less

Width

:

3 to 10 inches (76.2 to 254 mm)

Medium feed :Bottom paper feed only

I-5

(5) Card

Weight

:

100

Ibs

(162.8

g/m2)

or less

Thickness

:

0.008 inch (0.20 mm) or

less

Size

:

5 x 8 inches (when cut apart)

Medium feed :Bottom paper feed only

(6) Label

Thickness

:

0.011 inch (0.28 mm) or less

Size

:

ML390 Elite-8.5x3.25

inches(216x83

mm) or less

ML391 Elite- 15x3.25 inches(381 x 83 mm) or

less

(7)

OHP sheet (transparencies)

Thickness

:

0.004 inch (0.10 mm) or less

Size

:

8.5 x 11 inches (216 x 280 mm) or less

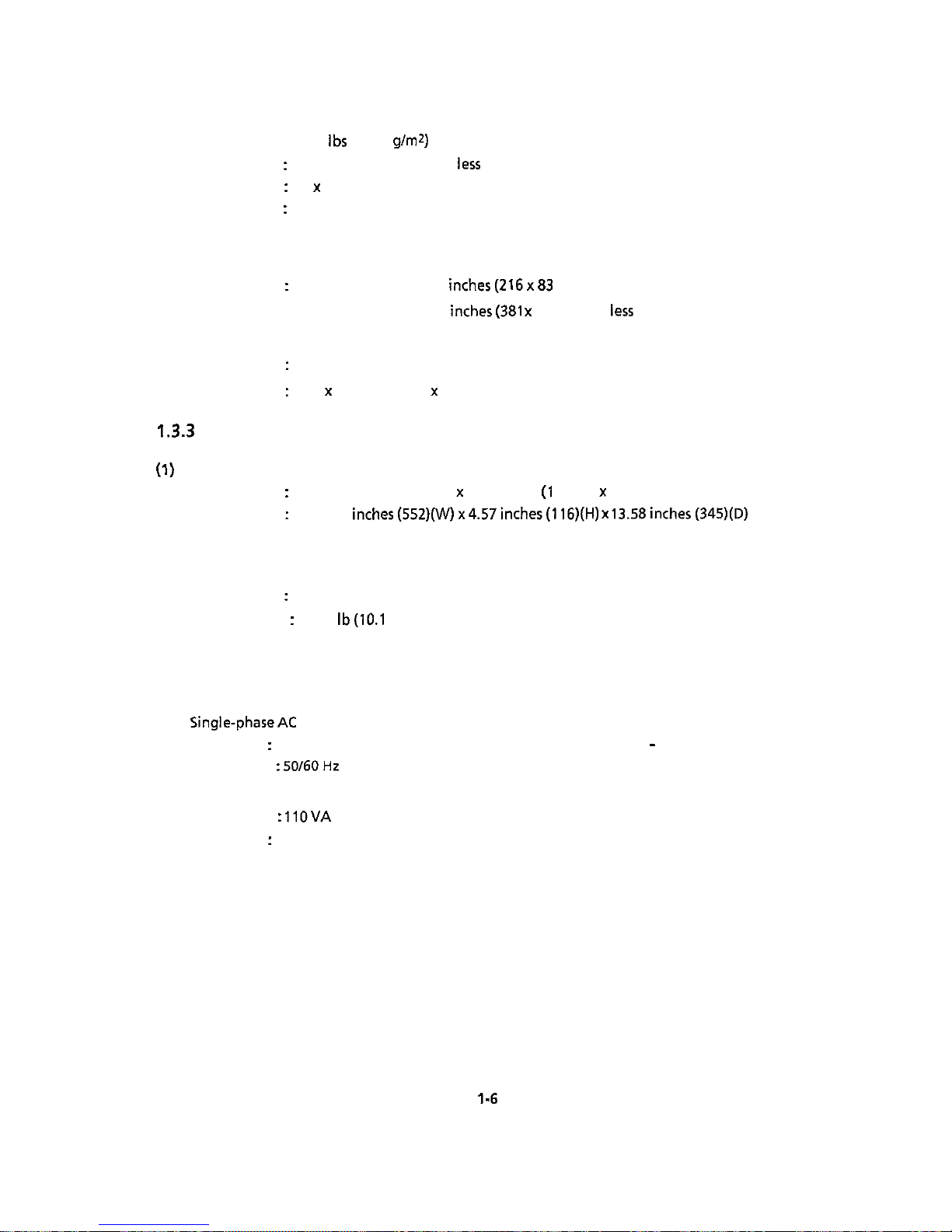

1.3.3

Physical specifications

(1)

Outside dimensions

ML390 Elite

:

15.67 inches (398)(W) x 4.57 inches (I 16)(H) x 13.58 inches (345)(D)

ML391 Elite :21.73

inches(552)(W)x4.57inches(l16)(H)

x 13.58inches(345)(D)

These dimensions do not include the platen knob, acoustic cover and paper separator,

(2) Weight

ML390 Elite :18.5 lb (8.4 kg)

ML391 Elite : 22.3 lb(10.1 kg)

1.3.4 Power requirements

(1) input power

Single-phaseAC

Voltage

:

One of the following as specified: 2201240 VAC + 10% - 10%

Frequency : 50/60Hz + 2%

(2) Power consumption

Operating :

IlOVA

Idle

:

40VA

l-6

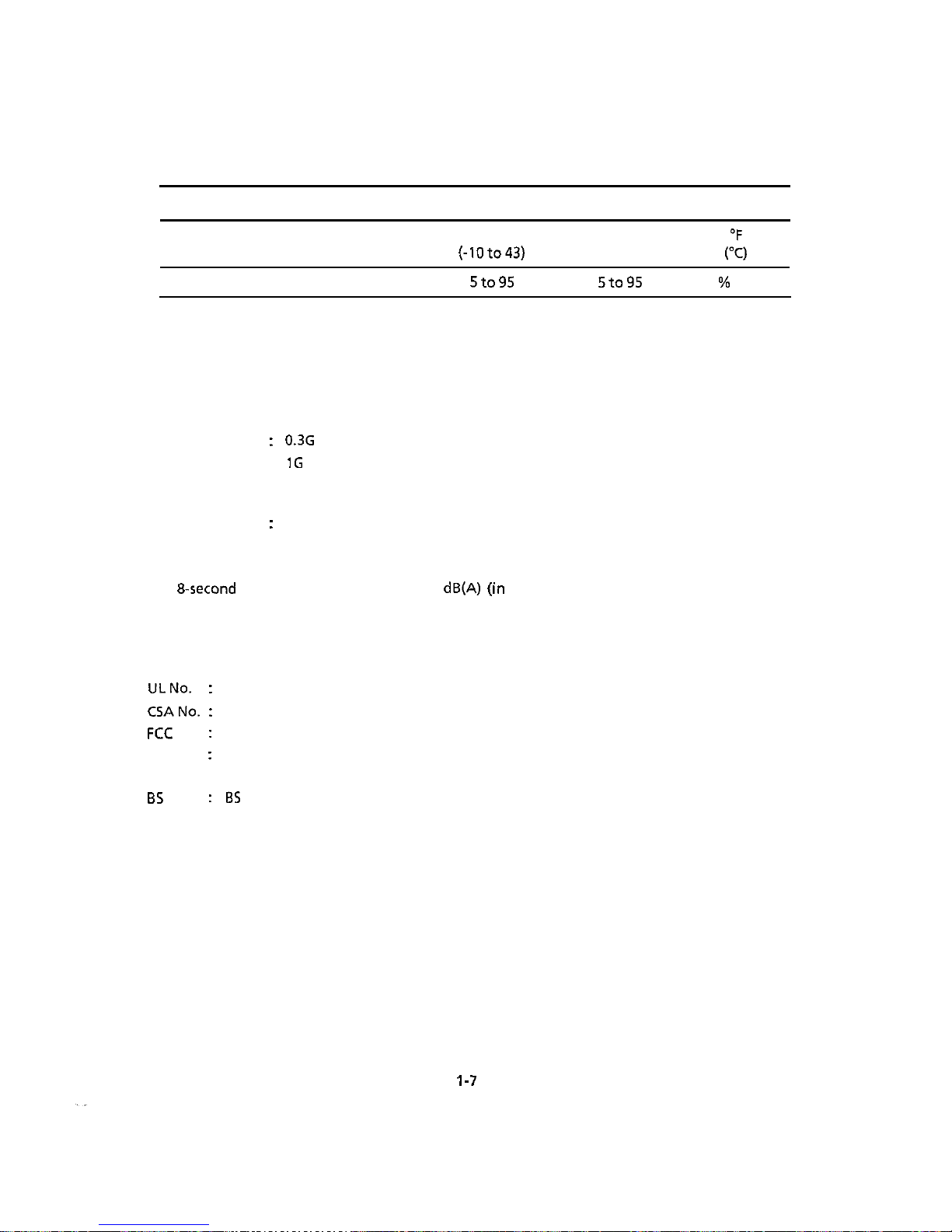

1.3.5 Environmental conditions

(1)

Ambient temperature and relative humidity

Operating Non-operating

Storage

Unit

Temperature

Relative Humidity

41to104

14to

109.4

-40to158

(5 to 40)

(-lOto43)

(-40 to 70)

20 to 90

5to95 5to95

%

RH

The printer must be packed during storage

Avoid condensation at all times.

(2) Vibration

Operating

:

0.3G

(5 to 150 Hz) or less (except the unit is resonant frequency)

Non-operating :1G (5 to 150 Hz) or less (except the unit is resonant frequency)

(3)

Impact (Drop test)

Packing

:

30” (One corner and three edges and all six sides)

1.3.6 Noise

The

8-second

average noise is less than 57

dB(A)(’In

all mode), 52 dB(A) (in quiet mode) when

measured under the above conditions with the printer fitted with the acoustic cover.

1.3.7 Agency approvals

ULNo.

:

CSANo. :

FCC

:

VDE

:

B5

:

The printer is listed in UL STANDARD No. 478.

CSA certification to CSA STANDARD C22.2 No. 220

FCC certified per Part 15, SUBJECT J, CLASS B.

VDE 0806.

VDE 0871 Class B.

ES

5850

I-7

2. INSTALLATION PROCEDURE

2. INSTALLATION PROCEDURE

2.1 Unpacking

2.1.1

Unpacking the packing box

(1) Unpackthepackingbox.

(2) Takeouttheprinterunit.

(3) Takeouttheaccessories.

Packing box

2-1

.

,’

2.1.2

Unpacking the printer unit

(1)

Removethe printer unit from the polyethylene bag.

Polyethylene bag

Printer unit

2-2

2.1.3

Unpacking the accessories

(1)

Remove the AC cable, fuses, paper separator, platen knob, ground screw, and ribbon cassette

from the polyethylene bag.

Paperseparator

Polyethylene bag

Ribbon cassette

Platen kno6

2-3

2.2 Installation (Refer to the User’s Manual for Details.)

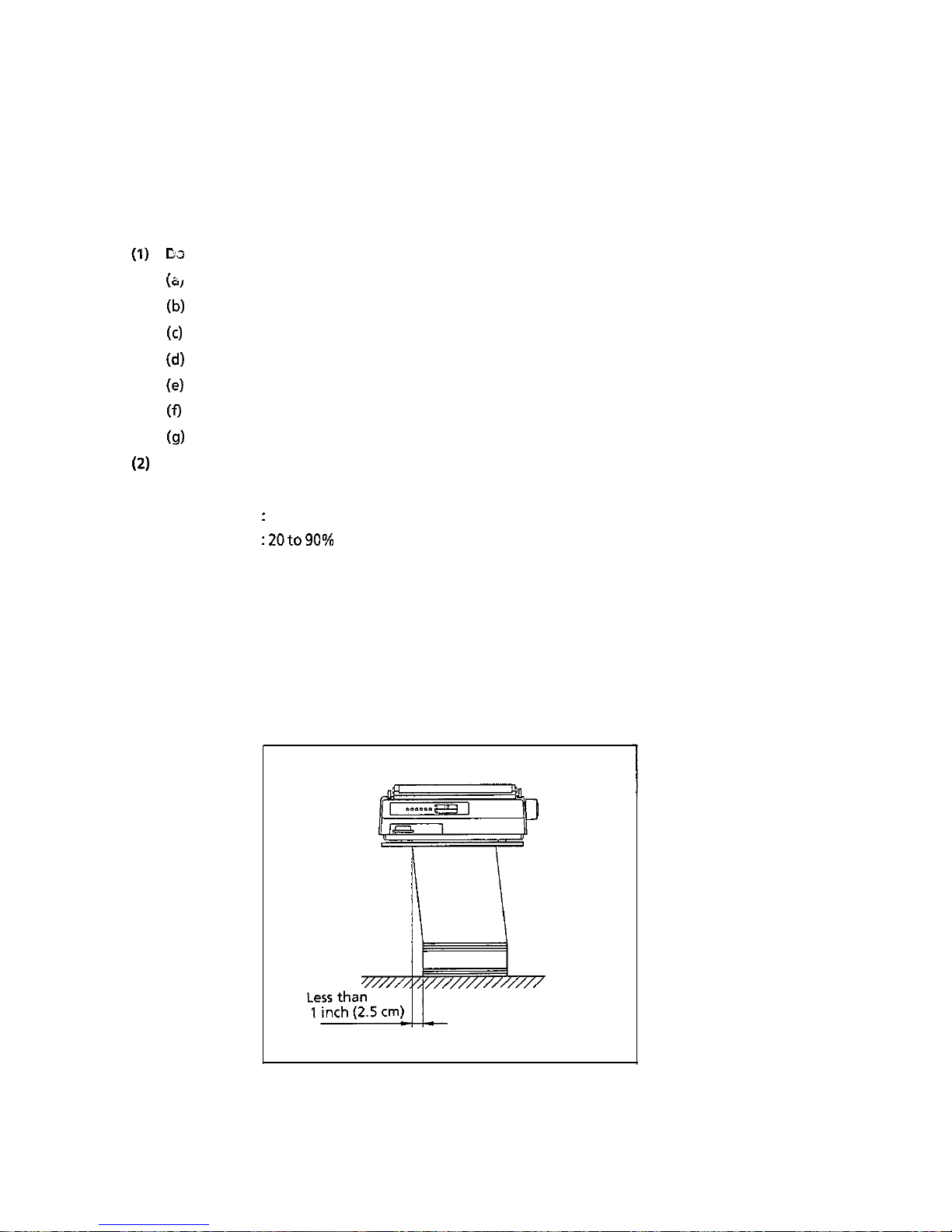

2.2.1 Precaution for installation

Pay attention to the following when installing the printer:

(1)

(2)

(3)

(4)

Do

not install the printer in the following places:

CL/

W

w

Cd)

(4

(0

(cd

Any place exposed to direct sunlight.

Any place with great fluctuations in temperature.

Any place exposed to outdoor wind.

A dusty place

Near a door

Near an air-conditioner.

Any place with heavy vibrations.

DO

not smoke in the area where the printer is installed.

Adjust the temperature and humidity of the installation site as follows:

Temperature

:

41 to 104°F (5 to 40°C)

Humidity

: 20to90%

RH

Place the printer and continuous

form

in the following procedure:

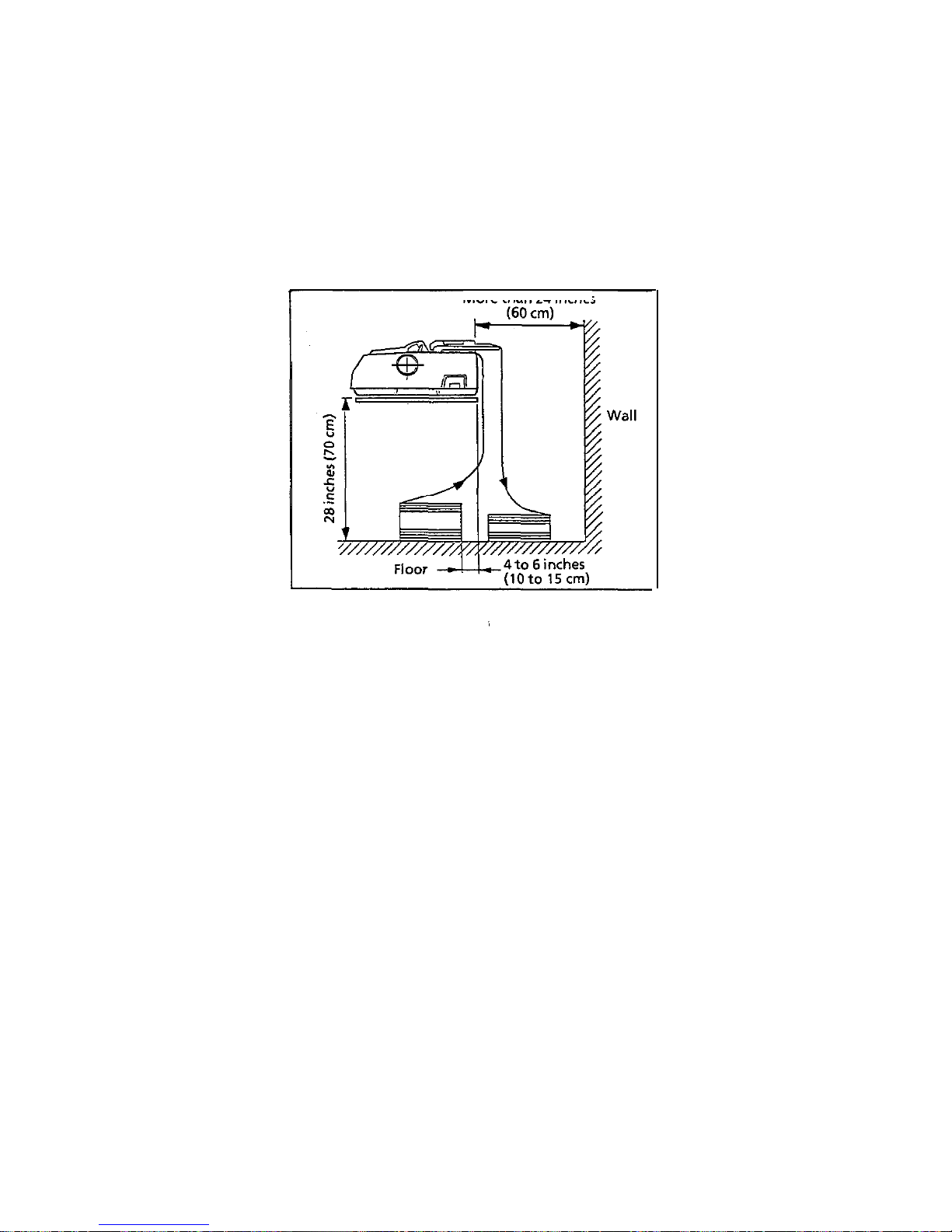

1) The height of the desk for the printer is 28 inches (70 cm) standard.

(Install the printer on a level and flat desk or stand so that its four rubber feet fit flatly on

the surface.)

2) Paper positioning

Place forms in parallel with the paper feed path.

The positioning tolerance of the left and right direction should be less than 1 inch (2.5 cm).

2-4

3) Printer rear space requirement

Match the rear part of the printer with the edge of a desk.

Leave a space of more than 24 inches (60 cm) at the rear of the printer to allow sufficient

space for paper.

4) To prevent incoming and outgoing forms from interfering with each other, place the forms

within 4to 6 inches (10 to 15 cm) from the edge of a desk.

Paper

jamming

may occur if forms interfere with each other.

More than 24

inches

2-5

2.2.2 Removing the shipping retainer

Remove the shipping retainer which secures the printhead from movement during shipping by

opening the access cover.

Shipping retainer

R

2-6

2.2.3 Installing the accessories

(1)

Install the sheet separator.

(2)

Install the platen knob.

(3)

Install the ribbon cassette.

,

Sheet separator

knob

Ribbon cassette

2.2.4 Connecting cables

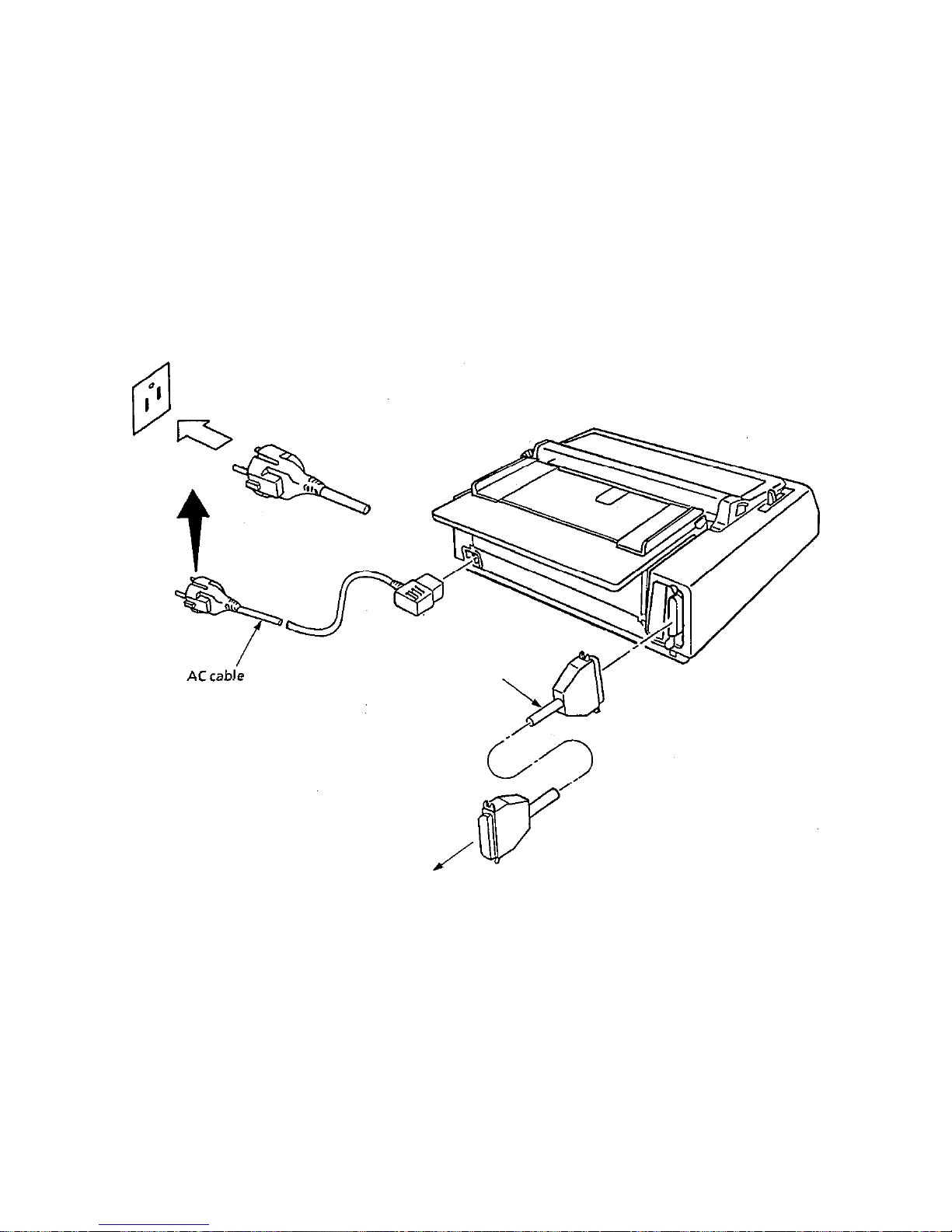

(1)

Connect the interface cable,

(2)

Connect the AC cable.

Make sure that the AC power switch on the right side of the printer is set to OFF side (the side

marked with 0).

Interface cable

To the host computer

2-8

2.2.5

installing paper

Install

continbous

form~paper to test the unit. (Refer to User’s Manual for Details).

2-9

2.2.6 Powering on

(1)

Push the AC “POWER” switch on the right side of the printerto “ON” (the side marked with I)

(2)

Confirm that the “POWER” lamp goes on and the printhead returns to its home position.

2-10

2.2.7 Rolling ASCII test pattern

(1)

Confirm

thatthe

“POWER” switch is OFF and while pressing the

“TOF/QUIET”

switch, press the

“POWER” switch to “ON”.

(2)

The rolling ASCII pattern as shown below will be printed.

(3)

To finish the test, press the “MODE” switch.

(4)

The

“SEL”

lamp will go on, indicating that the printer unit is ready to receive printing data

from the host computer.

2.11

3. THEORY OF OPERATION

3. THEORY OF OPERATION

3.1 Electrical Operation

This

secti,on de~scribes

the electrical operation of the printer circuits.

3.1.1

General

The block diagram of the printer circuit is shown in Figure 3-1.

The control board consists of the microprocessor and its peripheral circuits, the drive circuits, paper

end sensor and interface connector.

The power to the control board is provided from the power supply board via the connector cord.

The power to the other electrical parts is distributed via the connectors in the control board.

3.1.2 Microprocessor and its peripherals circuits

(1)

Microprocessor(Q8: 8OC154)

The microprocessor is the nucleus of the control circuit. Its peripheral circuits operate under

program control by this microprocessor. The

110

ports of the microprocessor are connected to

the address bus, data bus, and control lines.

(2) Program ROM (Q12)

The program ROM contains the control program for the printer. The microprocessor operates

by execution of this control program.

(3)

RAM

(Ql

and

92); (93

and

44)

are option.

The RAM stores data such as print data which has been received.

3-1

(4) LSI (MSM6990)

(911)

The MSM6990 is an external interface and motor control

LSI.

It has the following functions:

A: External interface controller

(a) Parallel interface function

The parallel interface function mode is selected when the level of the mode selection signal

(ISEL) is high. In this mode, IFDl to

IFD8

are used as an input port; the parallel data received

through the interface connector is latched in synchronization with the strobe signal

(STB)

and is sent to the CPU in synchronization with the RD signal. In this mode, the MSM6990

also sends BUSY, ACK, PE and SELECT signals to the parallel interface connector in

synchronization with the WR signal.

(b)

Serial interface function

The (ISEL) signal goes low and the serial interface function mode is selected only when the

serial interface board is installed. In this mode,

IFDl

to IFD8 are used as an input port;

parallel data received from the serial interface board is sent to the CPU in synchronization

with the RD signal. In this mode, the MSM6990 sends SSD, RTS, and DTR signals to the serial

interface connector in synchronization with the WR signal.

(c) I/O

ports

The MSM6990

(Qll)

has a

12-bit

output port and a

lo-bit

input port. It sends control signals

in accordance with the commands from the microprocessor.

The input port is also used to read information from the operation panel switches, etc.

(d)

Address latch

The address latch latches the low-order 8 bits of the address bus (A0 to

A7).

These bits are

used as an address for read/write operations with peripheral devices. Latching of (A0 to A7)

is necessary because these 8 bits are also used as the data bus.

8: Motor controller

(a)

Spacing speed control function

This function accelerates and decelerates the spacing motor in accordance with commands

from the microprocessor and controls the spacing motor speed in each printing mode.

(b)

Dot timing generation function

This function generates the dot-on timing signal

(IPT),

synchronized with the printing speed

in accordance with output

signab

(PHASE A, 8) of the encoder disk on the spacing motor,

and sends this timing information to the microprocessor.

(5) CGROM

(Q5)

The resident character fonts are stored in the character generator.

3-2

(6) EEPROM

(Q9)

This

256-bit

serial data electrically erasable and programmable ROM stores the menu mode

data.

(7)

LSI

(MSM79H097) (46)

The MSM79H097 controls the DMA, head drive and LF microstep. The details are described

below.

(a) DMA control

Data transfers from ROM to D-RAM or between

D-RAMS

is performed by DMA transfer

eliminating the need of the CPU to perform such operations.

By setting the address of the transfer origin, the transfer destination and the number of

bytes to be transferred and starting from the CPU, data in memory can be transferred

directly.

(b)

Head drive control

Drive pulses are produced for impact timing of the head using IPT signals as triggers. IPT

signals are generated by phase A and B signals from the spacing motor.

The pulse width of this drive differs according to the number of the impact pins.

Its duration

can be preset by the CPU.

(c)

Print data transfer control

Performs the serial transfer control of print data.

Print data will be transferred automatically from the memory area stored for decoding to

the register in this LSI in synchronization with an IPT signal coming from MSM6990.

The data which is stored in the register will be transferred to the head drive unit as serial

data just before the next impact timing.

(d)

LF micro step control

Performs micro step control to enable fine feed of the LF motor.

(e)

Memory interface

This function expands the memory space for ROMs and

RAMS

which are connected to this

LSI,

and makes it possible for the memory to access 368 Kbytes.

(0 D-RAM refresh

Performs refreshing of D-RAMS using the CAS before RAS refresh method.

3-3

Loading...

Loading...