Oki MICROLINE 390 TURBO, MICROLINE 391 TURBO CUT-SHEET FEEDER User's Manual

OKI

CUT-SHEET FEEDER for

MICROLINE

320/321/390/391

User's Manual

Turbo

CUT-SHEET FEEDER for

MICROLINE 320/321/390/391 Turbo

User's Manual

CUT-SHEET FEEDER for

MICROLINE 320/321/390/391 Turbo

User's Manual

Note to Customers

Every effort has been made to ensure that the information

in

this docu-

ment

is

complete, accurate,

and

up

to date. Oki assumes

no

responsibility

for the results of errors beyond

its

control. Oki also cannot guarantee that

changes

in

software and equipment made by other manufacturers and

referred to

in

this book will not affect the applicability of the information

in

this manual.

Handling Precautions

1.

Take

the utmost care when transporting the Cut-Sheet Feeder for

installation or removal so that no damage occurs.

2.

Store

the

Cut-Sheet Feeder

in

its

carton,

on a flat,

sturdy surface, free

of hazards, for future use.

3.

Do

not tamper with the paper set lever or the feeder cable when the

printer

is

in

operation.

4.

Removal

of

unnecessary parts or opening of the side covers may cause

damage to the Cut-Sheet Feeder

unit.

5.

Turn

off the main switch prior to plugging or unplugging of the Cut-

Sheet Feeder connector.

•

by

Oki.

All

rights

reserved.

OKIDATA

and

MICROLINE - Registered trademarks of Oki Electric Industry

Company

Ltd.

Epson

is

a registered trademark

of

Seiko Epson Corporation.

IBM

and Proprinter are registered trademarks of International Business

Machines Corporation.

Declaration

of

Conformity

Manufacturer's

Manufacturer's

The product

Directive

Applied Standards

Name:

Address:

herewith

89/336/EEC/

Model

Model

complies

No.:

Name:

Oki

3-1

Gunma

GE3180B/GE3181

CSF390T-S

CSF390T-D

EN

Data

Corporation

Futaba-cho,

370-8585,

with

the requirement

50081-1

Takasaki-shi,

Narrow/CSF391

Narrow/CSF391

/1992,

Japan

of

the

EMC

B/GE3182B/GE3183B

EN

T-S

T-D

50082-1

Wide/

Wide

/1992

Note to Customers

Every effort has been made to ensure that the information

is

ment

for the results of errors beyond

changes

referred to

in

complete, accurate,

in

software and equipment made by other manufacturers and

in

this book will not affect the applicability of the information

this manual.

and

up

to date. Oki assumes

its

control. Oki also cannot guarantee that

Handling Precautions

1.

Take

the utmost care when transporting the Cut-Sheet Feeder for

installation or removal so that no damage occurs.

2.

Store

the

Cut-Sheet Feeder

of hazards, for future use.

3.

Do

not tamper with the paper set lever or the feeder cable when the

printer

4.

Removal

damage to the Cut-Sheet Feeder

5.

Turn

Sheet Feeder connector.

•

by

is

in

operation.

of

unnecessary parts or opening of the side covers may cause

off the main switch prior to plugging or unplugging of the Cut-

Oki.

All

rights

reserved.

in

its

carton,

unit.

on a flat,

sturdy surface, free

in

this docu-

no

responsibility

OKIDATA

Company

Epson

IBM

Machines Corporation.

and

MICROLINE - Registered trademarks of Oki Electric Industry

Ltd.

is

a registered trademark

and Proprinter are registered trademarks of International Business

of

Seiko Epson Corporation.

INTRODUCTION

There

are

single

and

dual

bin

versions for

both

the

narrow

and

wide Cut-Sheet

Feeders.

The

narrow

ones,

which

are

normally

used

for

the

80

column printer

ML

320

Turbo

and

ML

390

Turbo,

can

also

be

installed

on

the

136

column

printers

ML

321

Turbo

and

ML

391

Turbo

by

adjusting

the

mounting

bracket.

The

dual

bin

CSF allow

you

to

select

one

of

two feeder

slots;

so

you

have

software controlled access to two different forms.

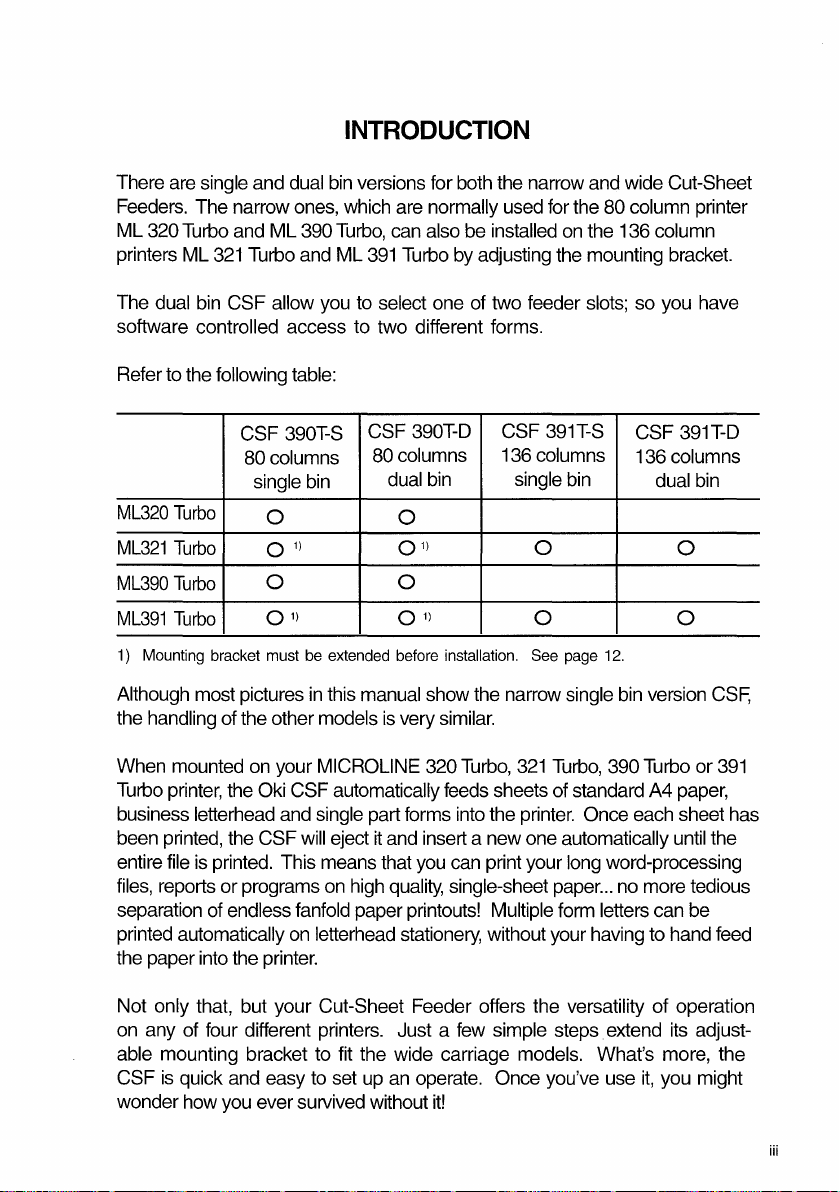

Refer

to

the

following

table:

CSF

390T-S

CSF

390T-D

CSF

391T-S

CSF

391T-D

80

columns

80columns

136

columns

136

columns

single

bin

dual

bin

single

bin

dual

bin

ML320

Turbo

ML321

Turbo

ML390

Turbo

ML391

Turbo

1)

Mounting bracket must

be

extended before installation. See page

12.

Although

most pictures

in

this

manual

show

the

narrow

single

bin

version

CSF,

the

handling

of

the other

models

is

very

similar.

When

mounted

on

your MICROLINE

320

Turbo,

321

Turbo,

390

Turbo

or

391

Turbo

printer,

the

Oki

CSF

automatically

feeds

sheets

of

standard

A4

paper,

business

letterhead

and

single

part

forms

into

the

printer.

Once

each

sheet

has

been

printed,

the

CSF

will

eject

it

and

insert

a new one automatically

until

the

entire

file

is

printed.

This

means

that

you

can

print your

long

word-processing

files,

reports

or programs

on

high

quality,

single-sheet paper

...

no

more

tedious

separation

of

endless

fanfold

paper

printouts!

Multiple

form

letters

can

be

printed

automatically

on

letterhead

stationery,

without

your

having

to

hand

feed

the paper

into

the

printer.

Not only that,

but

your Cut-Sheet Feeder offers the versatility of operation

on

any

of

four different

printers.

Just a

few

simple steps.

extend

its

adjust-

able mounting bracket

to

fit

the wide carriage models. What's

more,

the

CSF

is

quick

and

easy

to

set

up

an

operate.

Once you've

use

it,

you

might

wonder

how

you

ever

survived

without

it!

MICROLINE

CUT-SHEET

User's

FEEDER

FOR

320/321/390/391

Manual

Turbo

TABLE

INTRODUCTION ...................................................................................

GENERAL ............................................................................................

1. INSTALLATION .............................................................................. 1

Introducing the Cut-Sheet Feeder

Mounting the Cut-Sheet Feeder ..................................................... 6

Removal of the Cut-Sheet Feeder ..................................................

Adjusting the Mounting Bracket

How to modify the attachment assembly

2.

OPERATION ................................................................................ 1 5

Precautions for Setting the Paper .................................................. 15

Preparing the Loading

Loading Paper ............................................................................... 17

Removal of the Ribbon Cartridge .................................................. 20

Installation of the Ribbon Cartridge .............................................. 20

Cut-Sheet Feeder Controls .............................................................

Inserting Paper from the Loading

Setting the

Page Margins ................................................................................ 22

Printing with the Cut-Sheet Feeder ............................................... 23

3.

SPECIAL CSF OPERATING SITUATIONS ...................................... 25

Entering the Menu Select Mode .................................................... 25

Printing the Self

Clearing Paper Jams ...................................................................... 26

Refilling the Loading

(CSF 390T-S/390T-D/391

(for

(for use of a CSF 390T-S or 390T-D on ML 321/391 Turbo) ..... 14

APPENDIX

APPENDIX

A:

B:

use

of a CSF 390T-S or 390T-D on ML 321/391 Turbo) ..... 12

Top

of Form Position ...................................................

Test

..................................................................... 25

Tray

CUT-SHEET FEEDER COMMAND CHARTS ................. 27

SPECIFICATIONS ......................................................... 30

OF

Tray

CONTENTS

T-S/391

........................................................... 16

Tray

............................................................. 26

T-D)

.................................... 1

..........................................

Page

iii

iv

11

21

21

21

INTRODUCTION

There

are

single

and

dual

bin

versions for

Feeders.

ML

printers

The

320

dual

The

Turbo

ML

321

bin

narrow

and

ML

Turbo

ones,

390

and

CSF allow

which

Turbo,

ML

you

391

to

are

can

select

software controlled access to two different forms.

Refer

to

the

following

ML320

Turbo

ML321

Turbo

ML390

Turbo

ML391

Turbo

1)

Mounting bracket must

CSF

80

single

table:

390T-S

columns

bin

be

CSF

80columns

dual

extended before installation. See page

normally

also

Turbo

one

390T-D

bin

both

be

installed

by

adjusting

of

two feeder

the

used

CSF

136

single

narrow

and

for

the

on

the

the

mounting

slots;

391T-S

columns

bin

wide Cut-Sheet

80

column printer

136

column

bracket.

so

you

CSF

391T-D

136

columns

dual

bin

12.

have

Although

the

When

Turbo

business

been

entire

files,

separation

printed

the paper

Not only that,

on

most pictures

handling

mounted

printer,

letterhead

printed,

file

is

reports

of

automatically

into

any

of

four different

of

the other

on

your MICROLINE

the

Oki

and

the

CSF

printed.

This

or programs

endless

on

the

printer.

but

your Cut-Sheet Feeder offers the versatility of operation

CSF

fanfold

able mounting bracket

CSF

is

quick

and

easy

how

you

wonder

ever

in

this

models

automatically

single

will

eject

means

on

high

paper

letterhead

printers.

to

fit

to

set

survived

manual

is

very

part

forms

it

and

that

quality,

printouts!

stationery,

Just a

show

the

narrow

similar.

320

Turbo,

321

feeds

sheets

into

the

printer.

insert

a new one automatically

you

can

print your

single-sheet paper

Multiple

without

few

simple steps.

single

Turbo,

390

of

standard

Once

long

word-processing

...

form

letters

your

having

extend

bin

each

no

the wide carriage models. What's

up

an

without

operate.

it!

Once you've

use

it,

version

Turbo

A4

paper,

sheet

until

more

can

to

hand

its

more,

you

CSF,

or

391

has

the

tedious

be

feed

adjust-

the

might

GENERAL

CHAPTER 1 INSTALLATION

Introducing

the

Cut-Sheet Feeder (CSF

390T-S/390T-D/391T-S/391T-D)

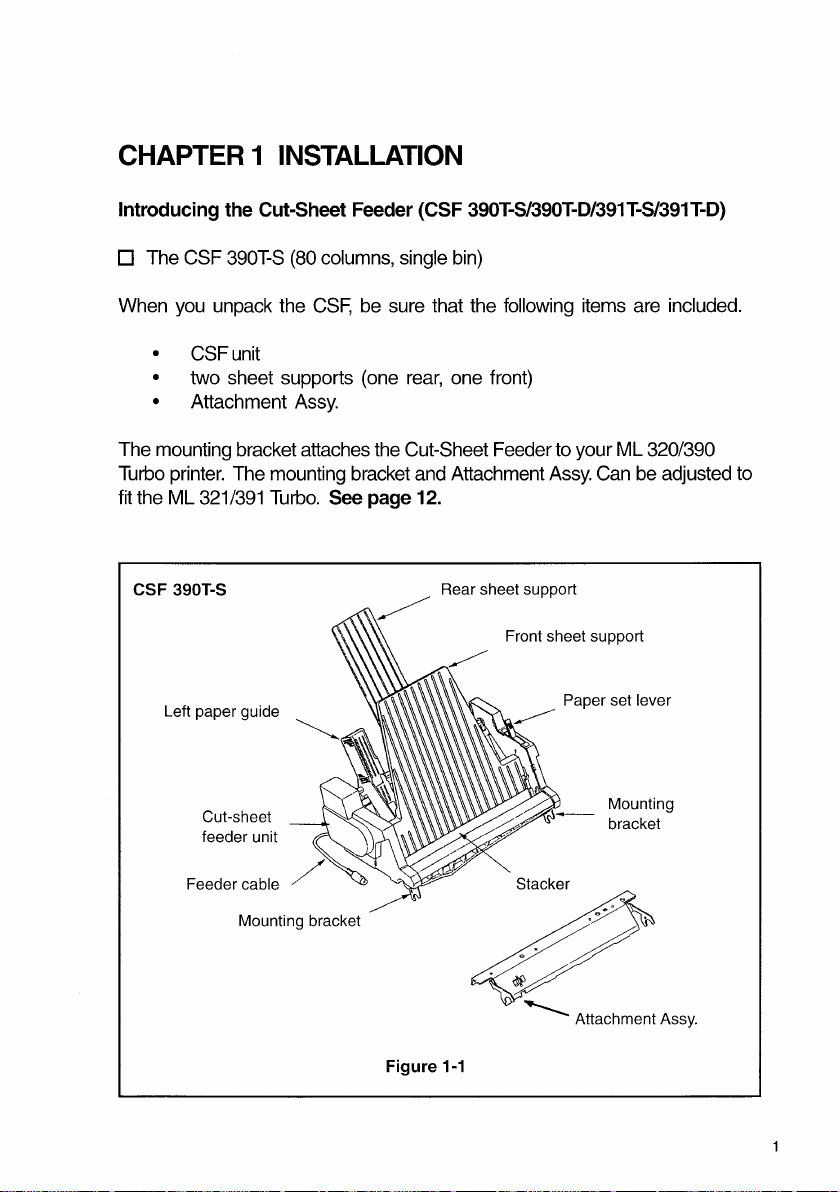

The CSF 390T-S (80 columns, single bin)

When you unpack the

CSF,

be sure that the following items are included.

• CSF unit

• two sheet supports (one rear, one front)

• Attachment Assy.

The mounting bracket attaches the Cut-Sheet Feeder to your

ML

320/390

Turbo printer. The mounting bracket and Attachment Assy. Can be adjusted to

fit the

ML

321/391 Turbo.

See

page

12.

The Cut-Sheet Feeder installed

from the printer to drive the pulse motor and feed the Cut-Sheets into

printer automatically.

The features are:

1.

Paper size

Size range:

2.

The Cut-sheet can be set manually to feed sheet by sheet (manual

override function).

3.

Paper shortage can be detected by software control.

4.

Print start position can be set anywhere within the printable area.

Narrow .................. CSF (80 columns)

Height

390T-D Rear bin .... 195-356 mm (7.7

Width

Wide ..................... CSF (136 columns)

Height

391T-D Rear bin .... 195-364 mm (7.7 to 14.3 inches)

Width

on

top of the printer

is

operated by a signal

390T-S,

.................. 182-356 mm (7.2 to 14 inches)

to

................... 182-216 mm (7.2 to 8.5 inches)

.................. 182-364 mm (7.2 to 14.3 inches)

................... 182-364 mm (7.2 to 14.3 inches)

390T-D

14 inches)

391T-S,

391T-D

CHAPTER 1 INSTALLATION

Introducing

The CSF 390T-S (80 columns, single bin)

When you unpack the

• CSF unit

• two sheet supports (one rear, one front)

• Attachment Assy.

The mounting bracket attaches the Cut-Sheet Feeder to your

Turbo printer. The mounting bracket and Attachment Assy. Can be adjusted to

fit the

the

ML

321/391 Turbo.

Cut-Sheet Feeder (CSF

CSF,

be sure that the following items are included.

See

page

12.

390T-S/390T-D/391T-S/391T-D)

ML

320/390

CUT-SHEET

_____________

1.

INSTALLATION

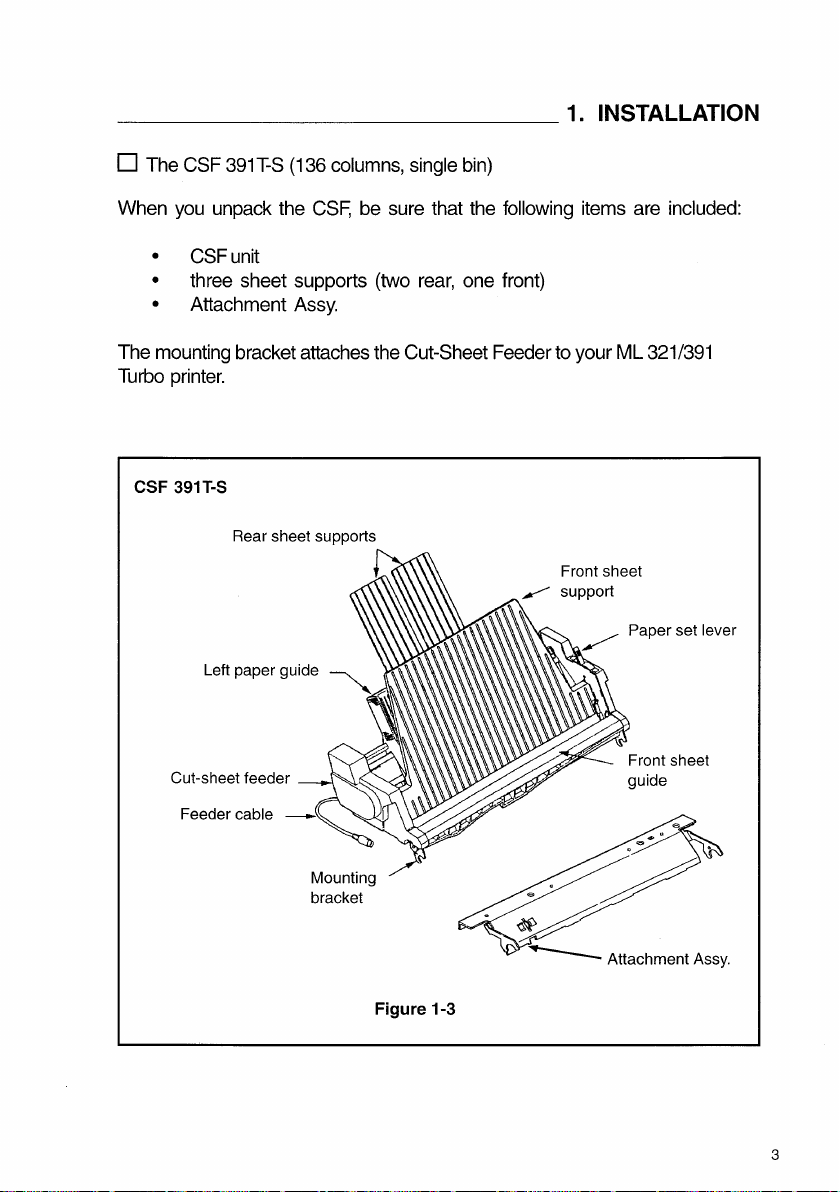

The CSF

391

T-S

(136 columns, single bin)

When you unpack the

CSF,

be sure that the following items are included:

• CSF unit

• three sheet supports (two rear, one front)

• Attachment Assy.

The mounting bracket attaches the Cut-Sheet Feeder to your

ML

321/391

Turbo printer.

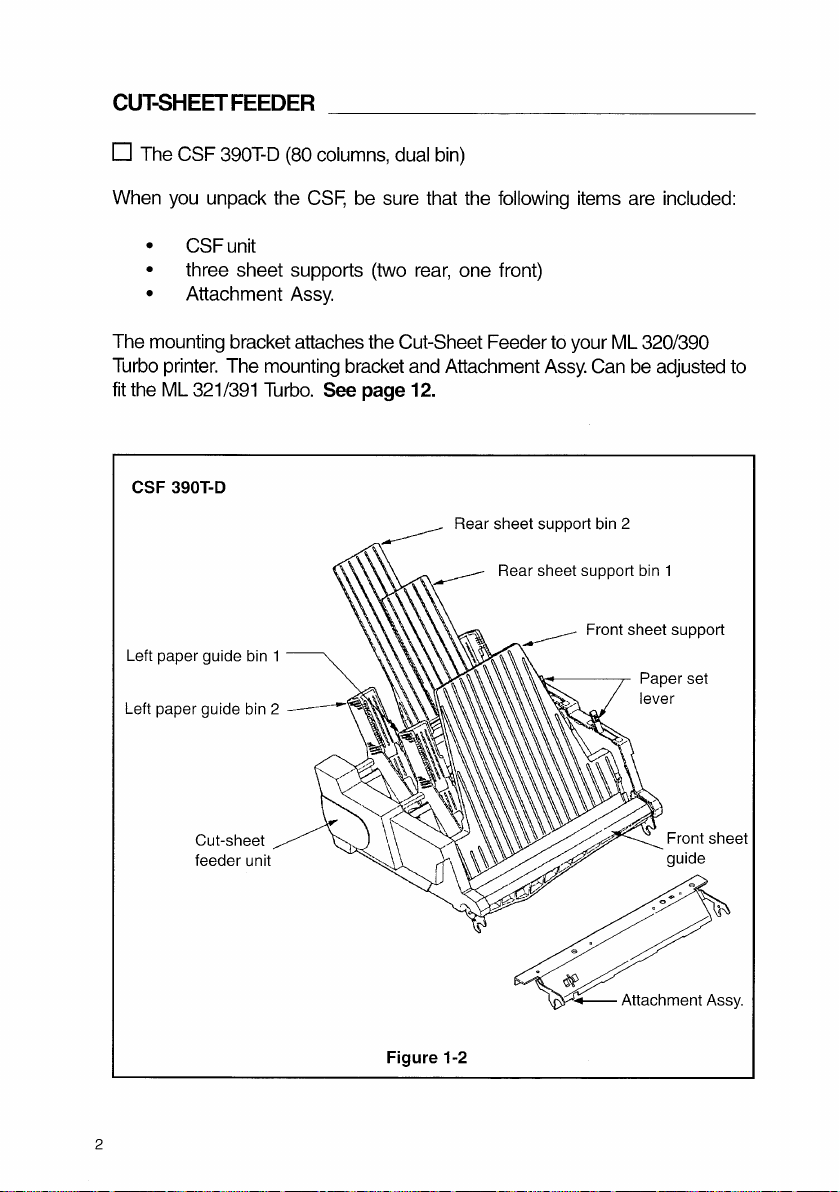

The CSF 390T-D (80 columns, dual bin)

When you unpack the

• CSFunit

• three sheet supports (two rear, one front)

• Attachment Assy.

FEEDER

CSF,

be sure that the following items are included:

The mounting bracket attaches the Cut-Sheet Feeder to your

Turbo printer. The mounting bracket and Attachment Assy. Can be adjusted to

fit the

ML

321/391 Turbo.

See

page

12.

ML

320/390

_____________

1.

INSTALLATION

The CSF

When you unpack the

• CSF unit

• three sheet supports (two rear, one front)

• Attachment Assy.

The mounting bracket attaches the Cut-Sheet Feeder to your

Turbo printer.

391

T-S

(136 columns, single bin)

CSF,

be sure that the following items are included:

ML

321/391

_____________

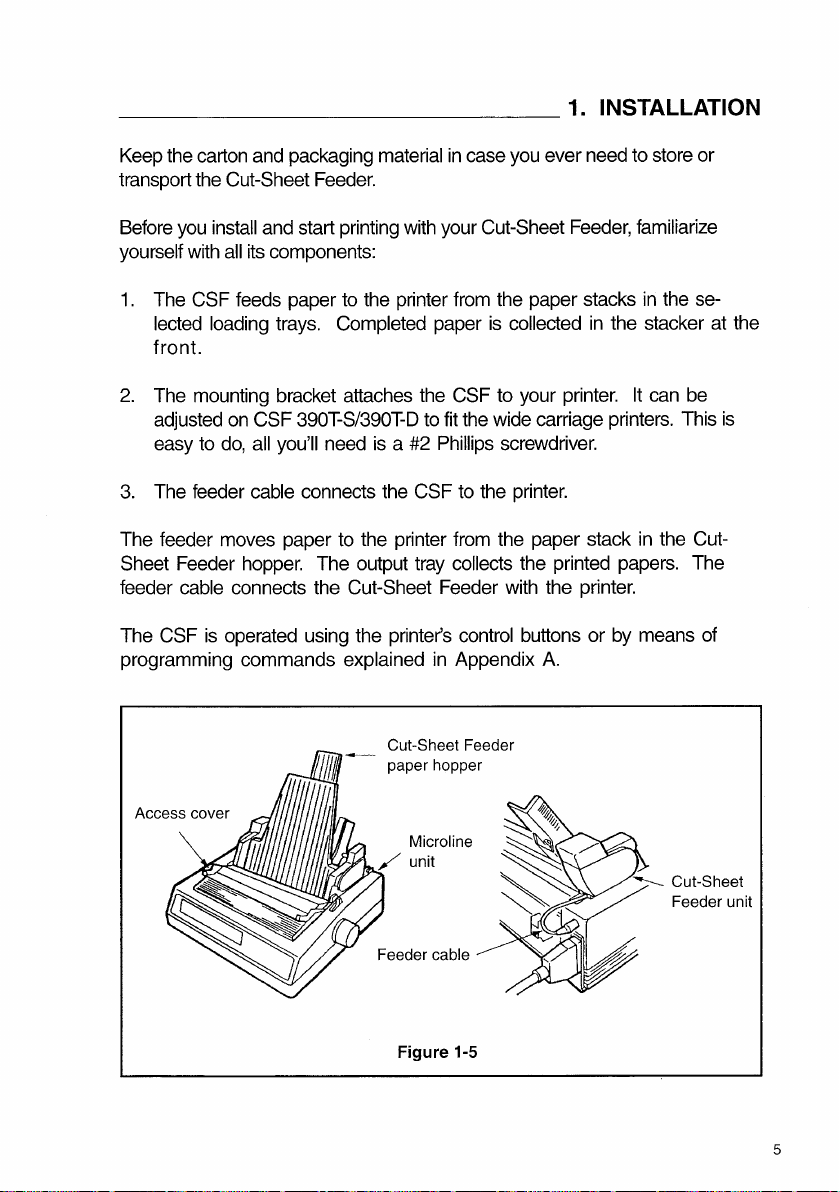

1. INSTALLATION

Keep the carton and packaging material

in

case you ever need to store or

transport the Cut-Sheet Feeder.

Before

you

install and start printing with your Cut-Sheet Feeder, familiarize

yourself with

all

its components:

1.

The CSF feeds paper to the printer from the paper stacks

in

the se-

lected loading trays. Completed paper

is

collected

in

the stacker at the

front.

2.

The mounting bracket attaches the CSF to your printer.

It

can be

adjusted

on

CSF 390T-S/390T-D to fit the wide carriage printers. This

is

easy to

do,

all you'll need

is

a #2 Phillips screwdriver.

3.

The feeder cable connects the CSF to the printer.

The feeder moves paper to the printer from the paper stack

in

the Cut-

Sheet Feeder hopper. The output tray collects the printed papers. The

feeder cable connects the Cut-Sheet Feeder with the printer.

The CSF

is

operated using the printer's control buttons or by means of

programming commands explained

in

Appendix

A.

CUT-SHEET

FEEDER

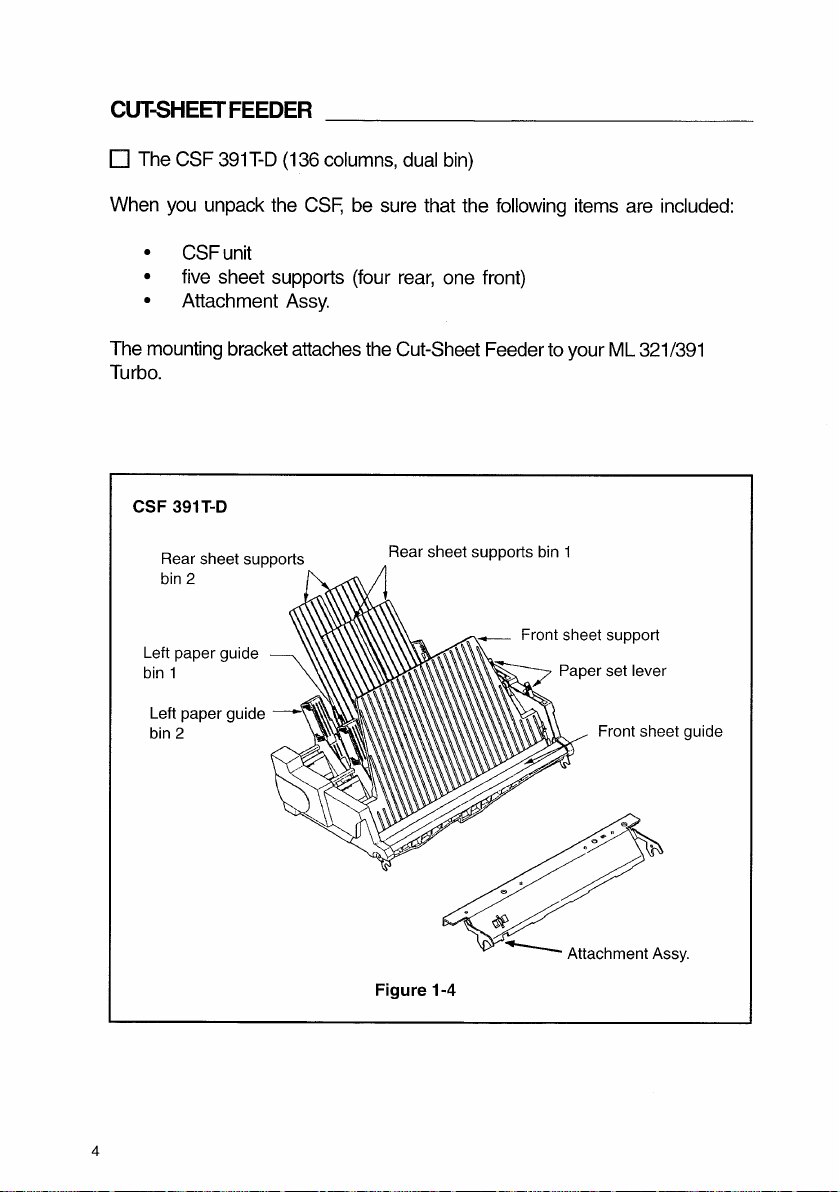

The CSF

When you unpack the

• CSF unit

• five sheet supports (four

• Attachment Assy.

The mounting bracket attaches the Cut-Sheet Feeder to your

Turbo.

391

T-D

(136 columns, dual bin)

CSF,

be sure that the following items are included:

rear,

one front)

ML

321/391

_____________

1. INSTALLATION

Keep the carton and packaging material

transport the Cut-Sheet Feeder.

Before

you

install and start printing with your Cut-Sheet Feeder, familiarize

yourself with

1.

The CSF feeds paper to the printer from the paper stacks

lected loading trays. Completed paper

front.

2.

The mounting bracket attaches the CSF to your printer.

adjusted

easy to

3.

The feeder cable connects the CSF to the printer.

The feeder moves paper to the printer from the paper stack

Sheet Feeder hopper. The output tray collects the printed papers. The

feeder cable connects the Cut-Sheet Feeder with the printer.

The CSF

programming commands explained

all

its components:

on

CSF 390T-S/390T-D to fit the wide carriage printers. This

do,

all you'll need

is

operated using the printer's control buttons or by means of

is

in

case you ever need to store or

is

collected

a #2 Phillips screwdriver.

in

Appendix

A.

in

the se-

in

the stacker at the

It

can be

in

the Cut-

is

Loading...

Loading...