Page 1

B410/B420/B430/MPS420b

Maintenance Manual

080409B

Oki Data CONFIDENTIAL

Page 2

Copyright © 2008 by Oki Data. All Rights Reserved

Oki Data America's, Inc. ("Oki Data"), authorizes you to view, copy, and print

documents published by Oki Data for noncommercial use within your organization only.

In consideration of this authorization, you agree and acknowledge that any copy of these

documents shall retain all copyright and proprietary rights contained herein. Each

document published by Oki Data may contain additional copyright information and

proprietary notification relating to that individual document.

Nothing contained herein shall be construed as conferring by estoppel, implication or

otherwise any license or right under any patent or trademark of Oki Data, Oki Electric

Industry Co., Ltd. ("Oki Electric"), or any third party. Except as provided above nothing

contained herein shall be construed as conferring any license or right under any Oki

Data copyright.

Oki Data has taken care to insure that the information which follows is complete,

accurate and up-to-date. However, Oki Data assumes no responsibility for errors or

omissions which may occur. All the information provided is subj ect to change from time

to time at the sole discretion of Oki Data.

All publications may include technical inaccuracies or typographical errors. We reserve

the right to make periodic changes, additions, and deletions to publications without

notice.

The most up-to-date drivers and manuals are available from the web site:

http://www.okiprintingsolutions.com

Page 3

Oki Data CONFIDENTIAL

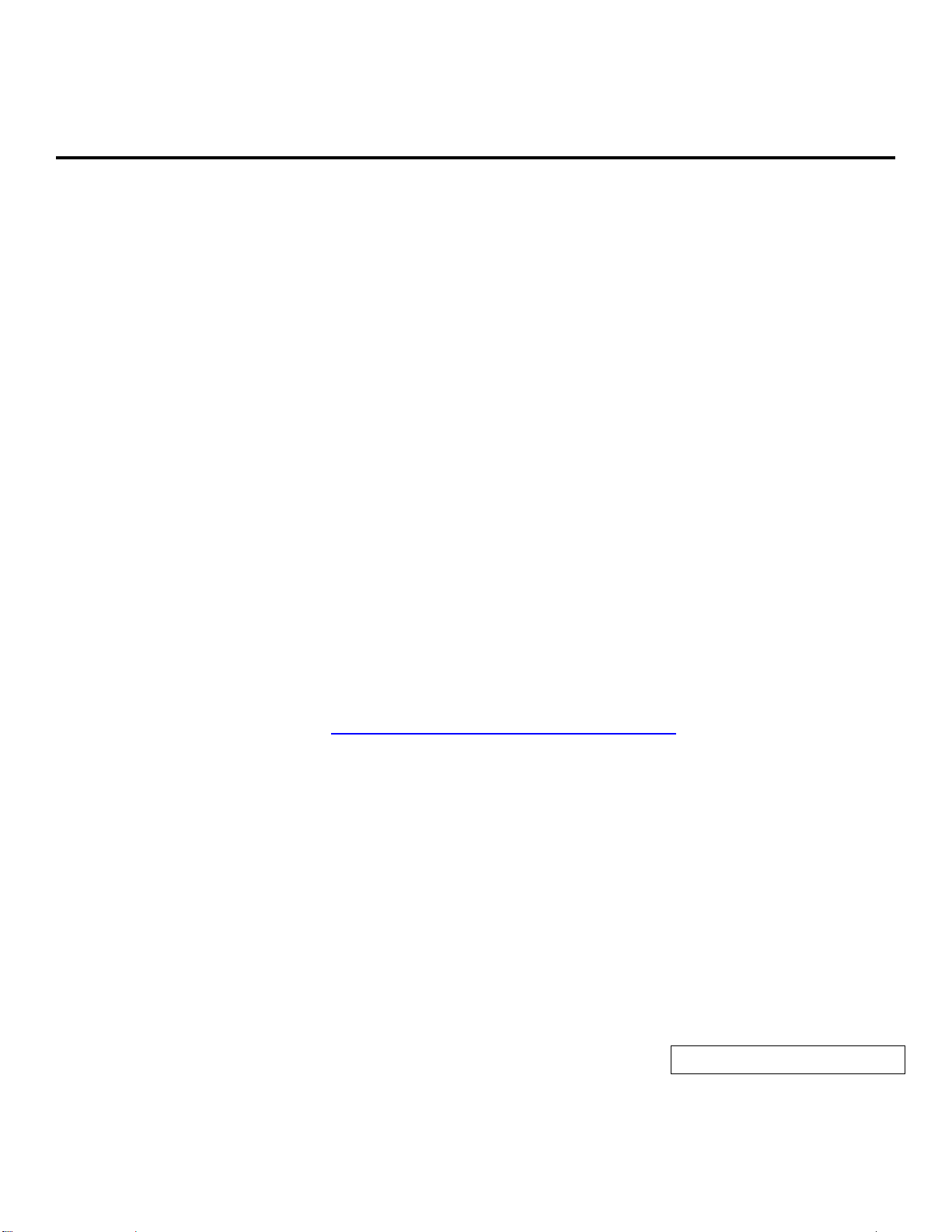

This Maintenance Manual describes the maintenance methods in the printer field for the maintenance

personnel. In addition, regarding the handling and operating method of the printer, please refer to the "User’

s Manual".

The differences between various types of printers described in this Maintenance Manual are as follows.

PREFACE

PREFACE

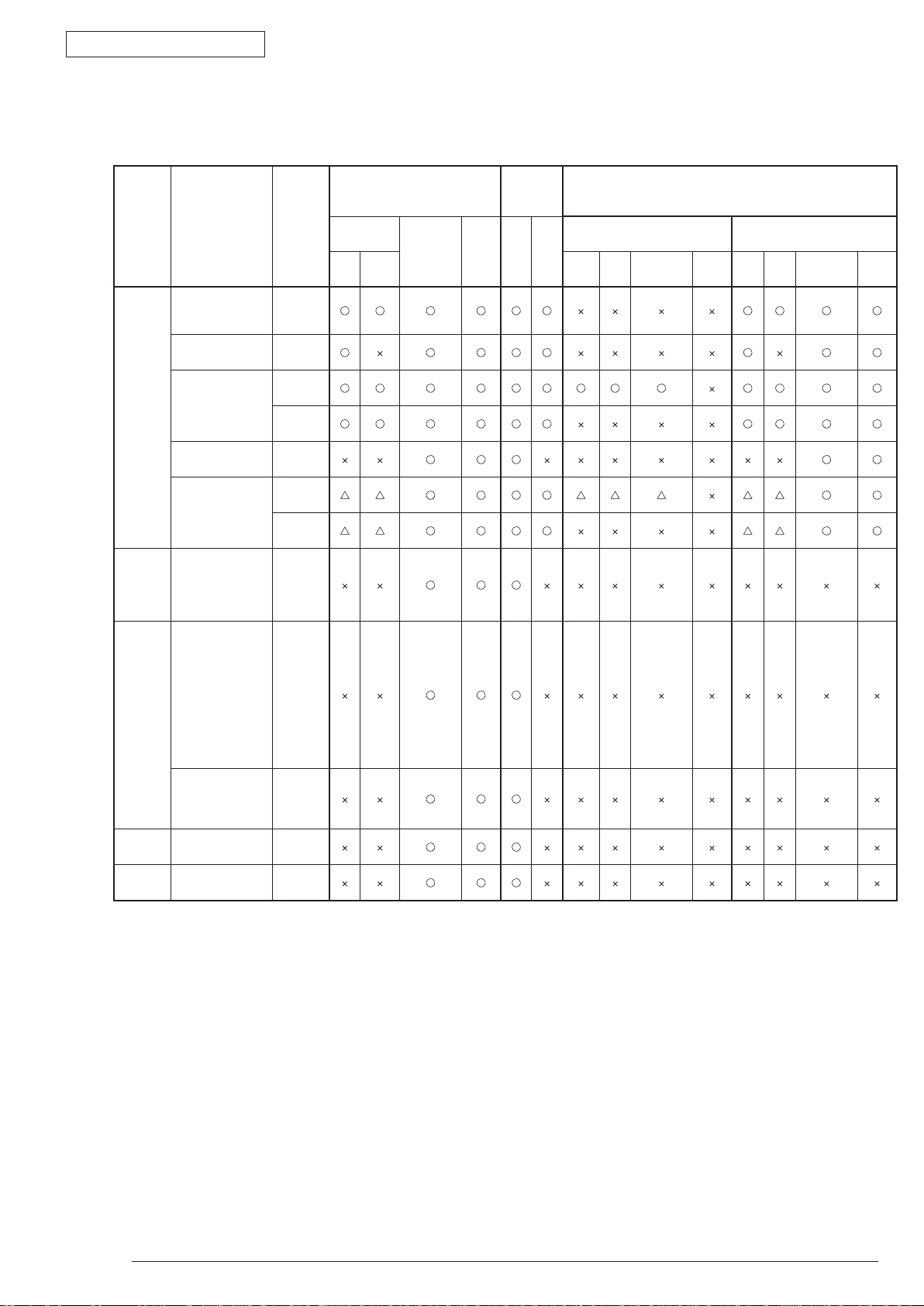

B410d B410dn B420dn B430d B430dn

Engine speed (letter/A4)

Resolution

Emulation

Max.

resolution

Standard

Option

LCD

Operation

panel

display

Switch

LED lights

Input tray (Manual/Auto)

Input tray (1st bin)

Maximum Input capacity

USB 2.0

Interface

Parallel

Ethernet

Auto Duplex

Monthly Duty

Cycle

Maximum

Toner life@ISO19752

Dimensions

(inch./mm)

Width

Depth

Height

ODA 100v

ODA 200v

Sales

Territories

OEL

AOS 1byte

AOS 2byte

Japan

China

30/28 30/28 30/28 30/28 30/28

2400 x 600

dpi

PCL6/SIDM PCL6/SIDM PCL6/SIDM

N/A N/A N/A N/A N/A N/A

16 character x 2 16 character x 2 16 character x 2 16 character x 2 16 character x 2 16 character x

1 (online/

offline)

2 2 2 2 2 2

Single sheet

manual feed

250 sheets 250 sheets 530 sheets 250 sheets 250 sheets 530 sheets

781 781 1110 830 830 1110

N/A N/A

Standard Standard Standard Standard Standard Standard

50,000 pages 50,000 pages 70,000 pages 70,000 pages 70,000 pages 70,000 pages

3,500

14.5”/369mm 14.5”/369mm 14.5”/369mm 14.5”/369mm 14.5”/369mm

15.6"/395mm 15.6"/395mm 15.6"/395mm 15.6"/395mm 15.6"/395mm

10.6"/268mm 10.6"/268mm 11.7"/297mm 10.6"/268mm 10.6"/268mm

N/A N/A N/A

TBD TBD TBD TBD TBD

2400 x 600

dpi

1 (online/

offline)

Single sheet

manual feed

3,500 (7,000

available for

JPN only)

2400 x 600

dpi

6 6 6 6

50 sheets

Multi Purpose

Feeder

3,500/7,000/

10,000

N/A

N/A

N/A

1200 x 1200

dpi

PCL6/PS3/

SIDM

50 sheets

Multi Purpose

Feeder

3,500/7,000 3,500/7,000

N/

N/A

1200 x 1200

dpi

PCL6/PS3/

SIDM

50 sheets

Multi Purpose

Feeder

dp

PCL6/PS3/

SIDM

2

50 sheets

Multi Purpose

Feeder

3,500/7,000/

10,000

Note!

• It is prohibited to reprint entire or partial of the content without prior consent.

• For the reason of printer improving and manual content revising, the content of this

maintenance manual may change without any warning in the future.

43984801TH Rev.1

/

Page 4

Oki Data CONFIDENTIAL

1. CONFIGURATION ........................................................................................................7

1.1 System Configuration ............................................................................................................................7

1.2 Printer Configuration ..............................................................................................................................8

1.3 Optional Configuration ..........................................................................................................................11

1.4 Specification .........................................................................................................................................12

1.5 Printing display .....................................................................................................................................15

1.5.1 VCCI label, Serial No. label ............................................................................................................15

1.5.2 Warning label ..................................................................................................................................15

1.5.3 Warning / Caution display ...............................................................................................................16

2. Operational explanation .............................................................................................17

2.1 Electrophotographic process mechanism ............................................................................................17

2.2 Printing process ....................................................................................................................................24

2.3 Toner entrance detection ......................................................................................................................28

Contents

Contents

3. Parts replacement ......................................................................................................30

3.1 Preparation for parts replacement ........................................................................................................30

3.2 Parts layout ...........................................................................................................................................32

3.3 Parts replacement method ...................................................................................................................37

3.3.1 LED Head .......................................................................................................................................38

3.3.2 Roller-Transfer ................................................................................................................................39

3.3.3 Cover-Side-R ..................................................................................................................................40

3.3.4 Cover-Side-L ..................................................................................................................................41

3.3.5 CU Board ........................................................................................................................................42

3.3.6 Motor-DC-Main ..............................................................................................................................43

3.3.7 OPE Cover-Assy ............................................................................................................................44

3.3.8 Ope-Board ......................................................................................................................................45

3.3.9 MPT-Assy (In case of B410dn, it is Manual-Assy) ..........................................................................46

3.3.10 Front-Guide-Assy .........................................................................................................................47

3.3.11 Roller-Assy-Feed ..........................................................................................................................48

3.3.12 Guide-Paper-Duplex .....................................................................................................................49

3.3.13 Stacker-Cover-Assy ......................................................................................................................50

3.3.14 Fuser-Assy ...................................................................................................................................51

3.3.15 Rear-Cover-Assy ..........................................................................................................................53

3.3.16 Frame-Assy-Lower .......................................................................................................................54

3.3.17 High voltage / Low voltage power board .......................................................................................56

3.3.18 Plate-Bracket-Motor ......................................................................................................................57

3.3.19 Roller-Back up ..............................................................................................................................58

3.3.20 Roller-Resist .................................................................................................................................59

3.3.21 Lever-In-Sensor ............................................................................................................................60

3.2.22 Lever-Eject-Sensor/Photo-Interrupter ...........................................................................................61

3.3.23 Lever-End/Lever-Duplex/Lever-Cassette/Gear-Assy-Clatch ........................................................62

3.3.24 Paper feeding roller (Roller-Pick-Up,Roller-Feed-NOW,Roller-Assy-MPT) ..................................64

43984801TH Rev.1

/

Page 5

Oki Data CONFIDENTIAL

4. ADJUSTMENT ...........................................................................................................66

4.1 Category and function of maintenance mode .......................................................................................66

4.4.1 User maintenance mode (Administrator Menu) .............................................................................66

4.1.2 System maintenance mode (System maintenance menu) .............................................................71

4.1.3 Engine maintenance mode .............................................................................................................76

4.1.4 Environment mode setting ..............................................................................................................84

4.1.5 EEPROM Initialization ....................................................................................................................85

4.2 Adjustment at part replacement ...........................................................................................................86

4.2.1 EEPROM data upload / download method .....................................................................................86

5. Periodic Maintenance .................................................................................................87

5.1 Periodic Replacement Parts .................................................................................................................87

5.2 Cleaning ...............................................................................................................................................87

5.2.1 Cleaning of LED lens array .............................................................................................................87

5.2.2 Cleaning Page Function .................................................................................................................89

6. Procedures for Repairing ...........................................................................................90

6.1 Troubleshooting ....................................................................................................................................90

6.2 Points to be checked before modifying printing problems. ....................................................................90

6.3 Points to be checked when the printing problems are modified ...........................................................90

6.4 Preparation for Troubleshooting ............................................................................................................90

6.5 Troubleshooting Flow ............................................................................................................................91

6.5.1 LCD Status Message/ Trouble Table ...............................................................................................91

6.5.2 LCD Message Troubleshooting.....................................................................................................103

6.5.3 Print Troubleshooting ....................................................................................................................111

Contents

7. Connection Diagram .................................................................................................119

7.1 Connection diagram ...........................................................................................................................119

7.2 Board Layout ......................................................................................................................................120

7.3 Resistance value ................................................................................................................................134

Appendix A Centronics Parallel Interface .....................................................................136

Appendix B USB Interface ...........................................................................................143

Appendix C Maintenance Manual for Second Tray unit ................................................145

1 Overview................................................................................................................................................145

1.1 Function ...........................................................................................................................................145

1.2 Exterior and Parts Name .................................................................................................................145

2. Description for Operation of Second Tray unit ......................................................................................146

3. Part Replacement .................................................................................................................................147

3.1 Precautions on replacing parts ........................................................................................................147

3.2 Arrangement of Parts ......................................................................................................................148

3.3 How to Replace Parts ......................................................................................................................149

3.3.1 Roller-Pick-Up, Roller-Feed-Now .............................................................................................150

3.3.2 Guard-Connector. Connector (9715S-08Z02-G4C) ..................................................................151

3.3.3 Roller-Feed ...............................................................................................................................152

3.3.4 Board-OT7 ................................................................................................................................153

43984801TH Rev.1

/

Page 6

Oki Data CONFIDENTIAL

3.3.5 CONN Cord-AMP8P-AMP8P ...................................................................................................154

3.3.6 Gear-Assy-Clatch .....................................................................................................................155

3.3.7 Frame-Assy-Retard, Spring-Retard ..........................................................................................157

4. Cleaning of Paper Feed Roller and Separation Roller ..........................................................................158

5. Procedure for Troubleshooting ..............................................................................................................159

5.1 Precautions for Troubleshooting ......................................................................................................159

5.2 Preparation before Troubleshooting .................................................................................................159

5.3 Troubleshooting Method ..................................................................................................................160

5.3.1 LCD Status Message List .........................................................................................................161

6. Connection Diagram .............................................................................................................................163

6.1 Connection diagram ........................................................................................................................163

6.2 Board Arrangement .........................................................................................................................163

Appendix D Network Interface .....................................................................................165

Contents

43984801TH Rev.1

/

Page 7

Oki Data CONFIDENTIAL

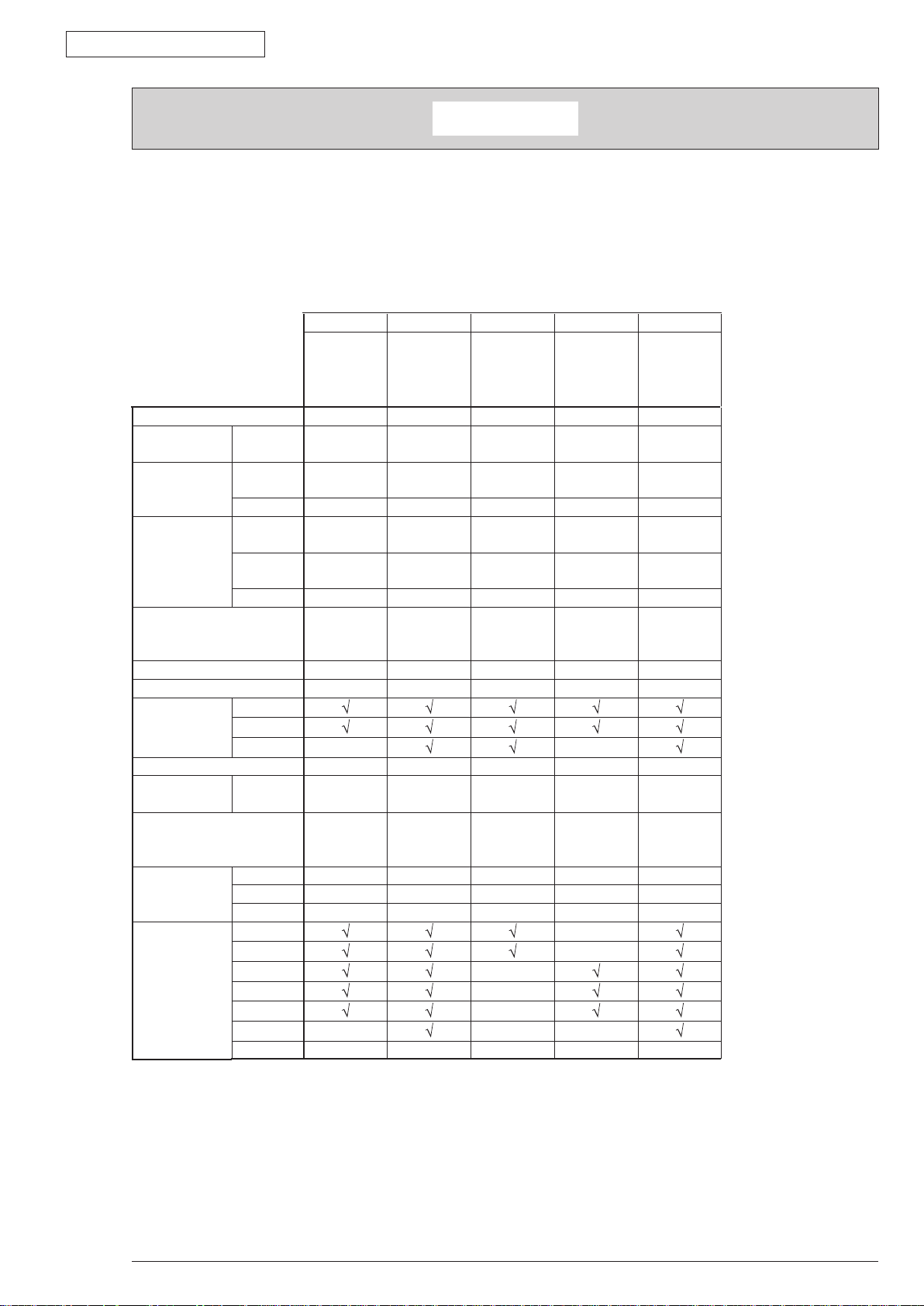

1.1 System Configuration

As the diagram 1.1 shows, for the standard configuration printer is configured by controller unit and

engine unit.

1. CONFIGURATION

1. CONFIGURATION

2nd tray unit*

Main DC Motor

LAN

(10BASE-T/100BASE-TX)

USB 2.0

Register clutch

Hopping clutch (1st)

Hopping clutch (MPT)

Solenoid for paper inverting

Main print circuit board

Paper end sensor

Cassette & Duplex detecting

Exit sensor

Rear cover open sensor

Fuser unit

Halogen lamp

Low voltage

power supply unit

FUSE

Temperature sensor

AC-SW

AC inlet

CENTRONICS

43984801TH

Rev.1

LCD:1, LED:2, SW:6

Operator panel board

LCD:1, LED:2, SW:1(B410d/B410dn)

LED head

(B420dn/B430d/B430dn)

Tag board

Toner cartridge

Tag transit board 3

Image drum cartridge

Figure1-1

Transfer roller

sensor

Toner inlet

WRT

sensor

Stacker cover open SW

High voltage power supply uint

IN

Tag transit board 1

Tag transit board 2

sensor

FAN

7 /

Page 8

Oki Data CONFIDENTIAL

A

A

A’

Paper cassette

Toner cartridge

High voltage

power board

Low voltage

power board

Image drum cartridge

A’

Stacker-Cover-Assy

Cover-Side-R

Cover-Side-L

Plate-Base-PCB

Plate-Assy-Base

Motor-Fan

Duplex

Rear-Cover-Assy

Fuser-Assy

OPE Cover-Assy

Guide-Paper-Duplex

Guide-Paper-R

Manual-Assy

Front-Guide-Assy

CU board

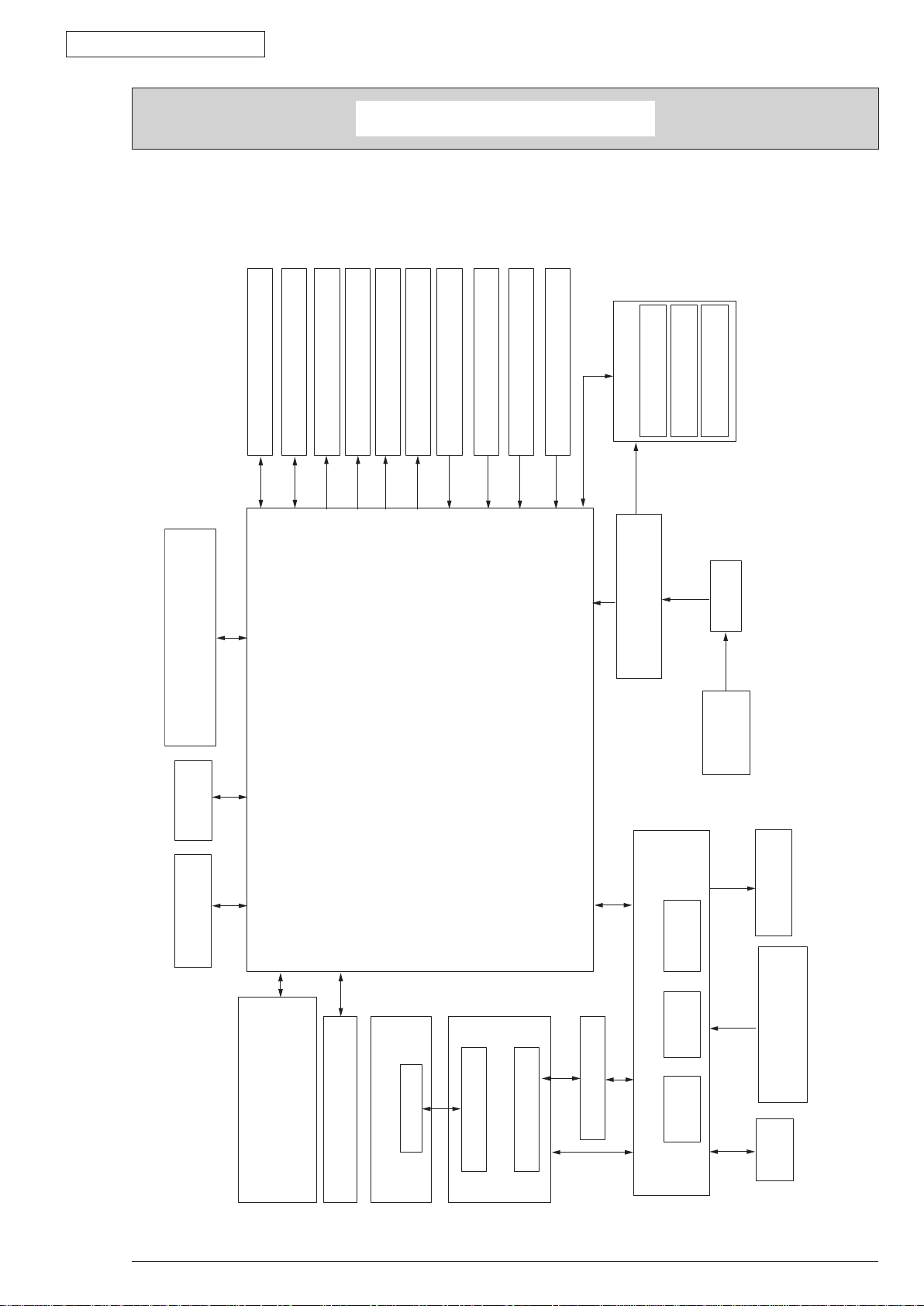

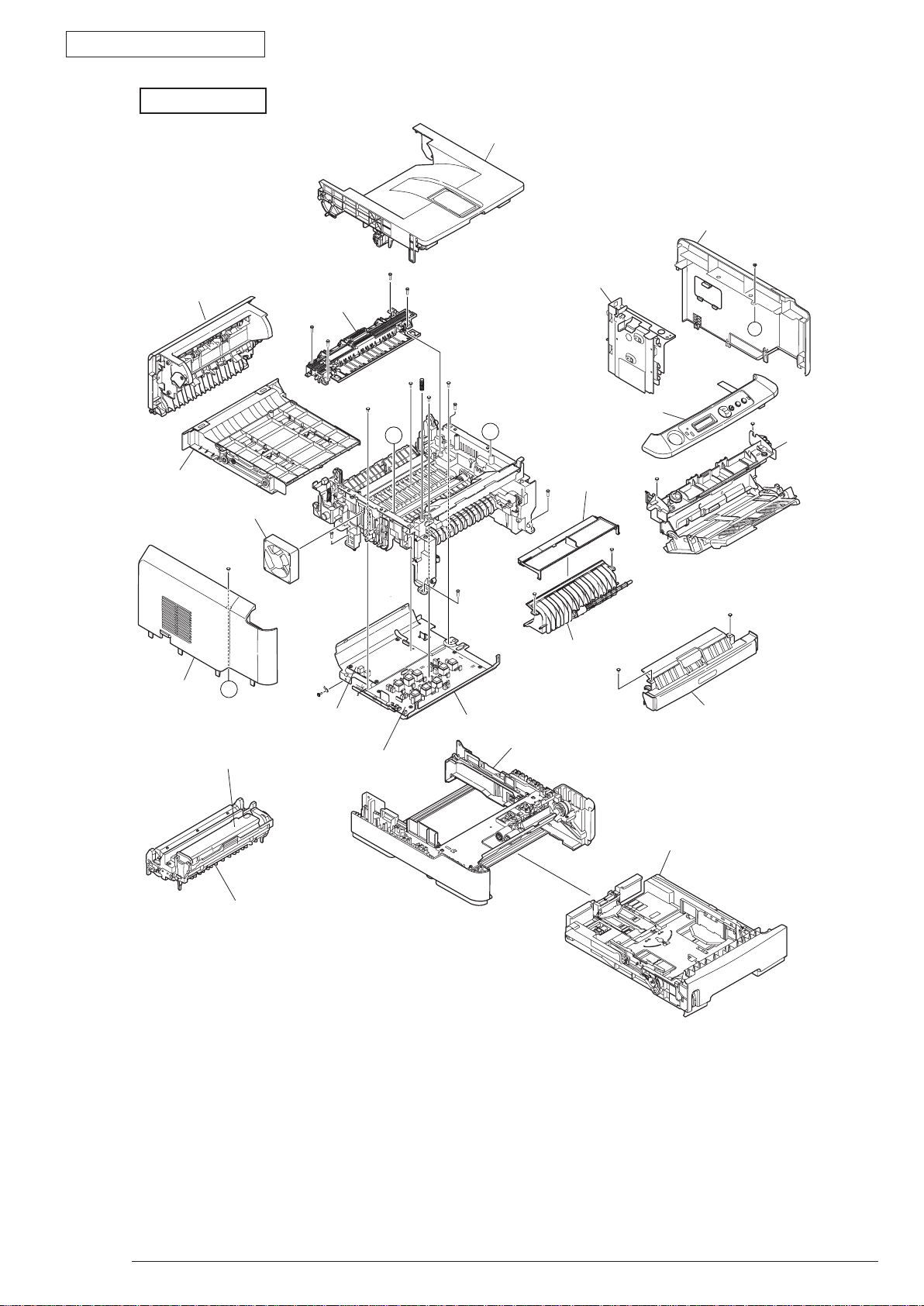

1.2 Printer Configuration

The printer main unit includes the following hardware parts.

• Electrophotographic processing part

• Paper feeding part

• Controller

• Op

erational part

• Power supply unit

•

Note!

The configuration of printer main unit is shown as diagram 1-2~1-4

B410d/B410dn

Fuser-Assy has to be replaced by Assy unit.

• It is forbidden to disassemble Fuser-Assy or reuse the disassembled Fuser-Assy.

1. CONFIGURATION

43984801TH

Rev.1

Figure1-2

8 /

Page 9

Oki Data CONFIDENTIAL

A

A

A’

A’

Stacker-Cover-Assy

Cover-Side-R

Cover-Side-L

Plate-Base-PCB

Plate-Assy-Base

Motor-Fan

Duplex

Rear-Cover-Assy

Fuser-Assy

OPE Cover-Assy

Guide-Paper-Duplex

Guide-Paper-R

MPT-Assy

Front-Guide-Assy

CU board

Paper cassette

Toner cartridge

High voltage

power board

Low voltage

power board

Image drum cartridge

B430d/B430dn

1. CONFIGURATION

43984801TH

Rev.1

Figure1-3

9 /

Page 10

Oki Data CONFIDENTIAL

B420dn

1. CONFIGURATION

Stacker-Cover-Assy

Cover-Side-R

Rear-Cover-Assy

Duplex

Cover-Side-L

Toner cartridge

Motor-Fan

A’

Fuser-Assy

Low voltage

power board

A’

High voltage

power board

A

Guide-Paper-Duplex

Plate-Base-PCB

Plate-Assy-Base

CU board

A

OPE Cover-Assy

MPT-Assy

Guide-Paper-R

Front-Guide-Assy

43984801TH

Image drum cartridge

Rev.1

Paper cassette

Figure1-4

10 /

Page 11

Oki Data CONFIDENTIAL

1.3 Optional Configuration

The options attached to the printer are as follows. These options can be ordered respectively for the

printer main unit.

(1) Second tray unit

1. CONFIGURATION

(2) Additionally installed memory (Domestic oriented printer only use 128MB.)

43984801TH

Rev.1

11 /

Page 12

Oki Data CONFIDENTIAL

1.4 Specification

(1) Type Desktop

(2) Dimension 268mm (Height) x 369mm (Width) x 395 (Depth)

:B41

297mm (Height) x 369mm (Width) x 395mm (Depth)

:B42

(3) Weight Approx. 10.6kg ( Including printer main unit & consumables.

Options, Feeding quantity of paper are excluded.)

1. CONFIGURATION

0d/B410dn/B430dn

0dn

(4) Development met

hod Dray type – Element developing method

Exposure method LED Head method

(5) Paper type, thickness, Size

Recommended paper Normal paper………….Excellent white A4

OHP Sheet…………….Sumitomo 3M CG3300

Label paper…………….Kokuyo LBP-A693

Category Size unit: mm (inch) Thickness

A4 Weig

A5

A6

B5

Letter

Normal Paper

Postcard

Envelope

Legal

Legal

Statement

Executive

h86~215.9

idt

Custom

Postcard Postcard

etu

rn Postcard

R

lope 1 (Chou #3) The envelope should be using 85g/m paper. The

Enve

lope 2 (Chou #4)

Enve

Envelope 3 (You #4)

W

Length 140~355.6

ht 55~105kg(64~120g/m2)

For double-side printing, weight55~90kg

2

(64~105g/m

Tray 1, Width 100~215.9, Length 210~355.6

Tray 2, Width 148~215.9, Length 210~355.6

flap of the envelope Chou type should not be with

fold, the flap of the envelope you should be clearly

folded.

The envelope should be using 24 lb. paper and

the flap part of it should be clearly folded.

)

Label Paper

OHP Sh

Part

ial Printing

Paper

Paper for Color

Printing

43984801TH

eet

Rev.1

Widt

Custom

Letter

Letter

h86~215.9

Length 140~355.6

ht 55~105kg(64~120g/m2)

Weig

Weight 55~105kg(64~120g/m

2

)

12 /

Page 13

Oki Data CONFIDENTIAL

(6) Paper feeding method / Ejecting method

Type Size

5

A5 *

5

B5 *

Executive *

Statement *

A4

Normal

paper

Postcard

5

*

Envelope

5

*

Label

paper

OHP A4/Letter

Letter

Legal (13 inch)

Lega (14 inch)

A6 *

Custom *3 *

Width 86~215.9mm

Length

140~355.6mm

Postcard/

Return postcard

Envelope1 (CHOU

3

Envelope2

4

Envelope3

Com-9

Com-10

DL

C5

C6

Monarch

Custom

Width 86~215.9mm

Length

140~355.6mm

A4/Letter

5

5

5

5

)

)

CHOU

(

(YOU 4

Thickness

Weight

(

Weight

55~105kg

Weight

55~105kg

Weight

55~90kg

Weight

91~105kg

Weight

55~105kg

Weight

55~90kg

Weight

91~105kg

Postcard

or less

than

weight

135kg

)

6

*

6

*

0.1~

0.5mm

0.1~

0.5mm

Kg)

:

Tray

feeding Method

Paper

cassette

Tray

1

*

Paper

Multipurpose

2

4

tray *

1

Manual

Paper

ejecting

method

Face

up

Face

down

○

× :

△

double-side print *

Tray

Tray

1

1. CONFIGURATION

It is possible to use it.

:

It is not possible to use it.

It is possible to use it by a part of size

:

Double-side print

Automatic

Multipurpose

2

4

*

tray*

2

1

Manual Tray

1

Manual

double-side print

Multipurpose

Tray

2

4

*

tray *

1

Manual

*1: Multipurpose tray can be used for B420dn/B430dn.

2

*

: Face-up paper ejecting is not available at automatic double-side printing.

3

*

: Tray 1 is as width 100~21539mm, length 210~355.6mm. Tray 2 is as width 148~215.99mm, length 210~355.6mm.

4

*

: Tray 2 (The second tray unit) is for option.

5

*

: In case to set up the paper size for A5, A6, Postcard, Envelope, if the width of B5, Executive, Statement, Normal paper is less

than 200mm, also if thick paper or thicker paper has been set up for the paper thickness, the printing speed changes to be

slowly.

6

: • Envelope CHOU should be made by the paper or basis weight of 85g/m2 and without any fold on the flap part.

*

• Envelope YOU should be made by the paper of basis weight of 85g/m2 and with clear fold on the flap part.

• Com-9, Com-10, Monarch, C5, C6, and DL should be the envelope using 24lb paper and with clear fold on the flap part.

(7) Printing speed Continuous printing : Maximum 28 piece/second (A4, At copy mode, First try)

For Envelope • Postcard, if to enhance the printing quality, the

printing speed changes to be decreased.

For the resolution degree of 600 x 2400, if to enhance the

printing quality, the printing speed changes to be decreased.

W

43984801TH

Rev.1

arm up time : Approx. 25 second (25°C, 100V)

13 /

Page 14

Oki Data CONFIDENTIAL

10

28

32

Temperature (°C)

20 80

Relative humidity (%)

Up and running

(8) Paper feeding method Automatic feeding

(9) Paper ejecting method Face down (Rear ejecting) / Face up (Front ejecting)

(10) Resolution (Max.) 2400 × 600 dots / inch (B410d/B410dn/B420dn)

1200 × 1200 dots / inch (B430d/B430dn)

(11) Input electricity AC100V ± 10V, 50/60Hz ± 1Hz(B410dn/B430dn)

(12) Electricity consumption Up and running: Maximum 800W, Average 450W (25°C)

Ready and waiting: Average 70W (25°C)

Power-saving mode: (Without option) Under 6W

(With option) Maximum 7W

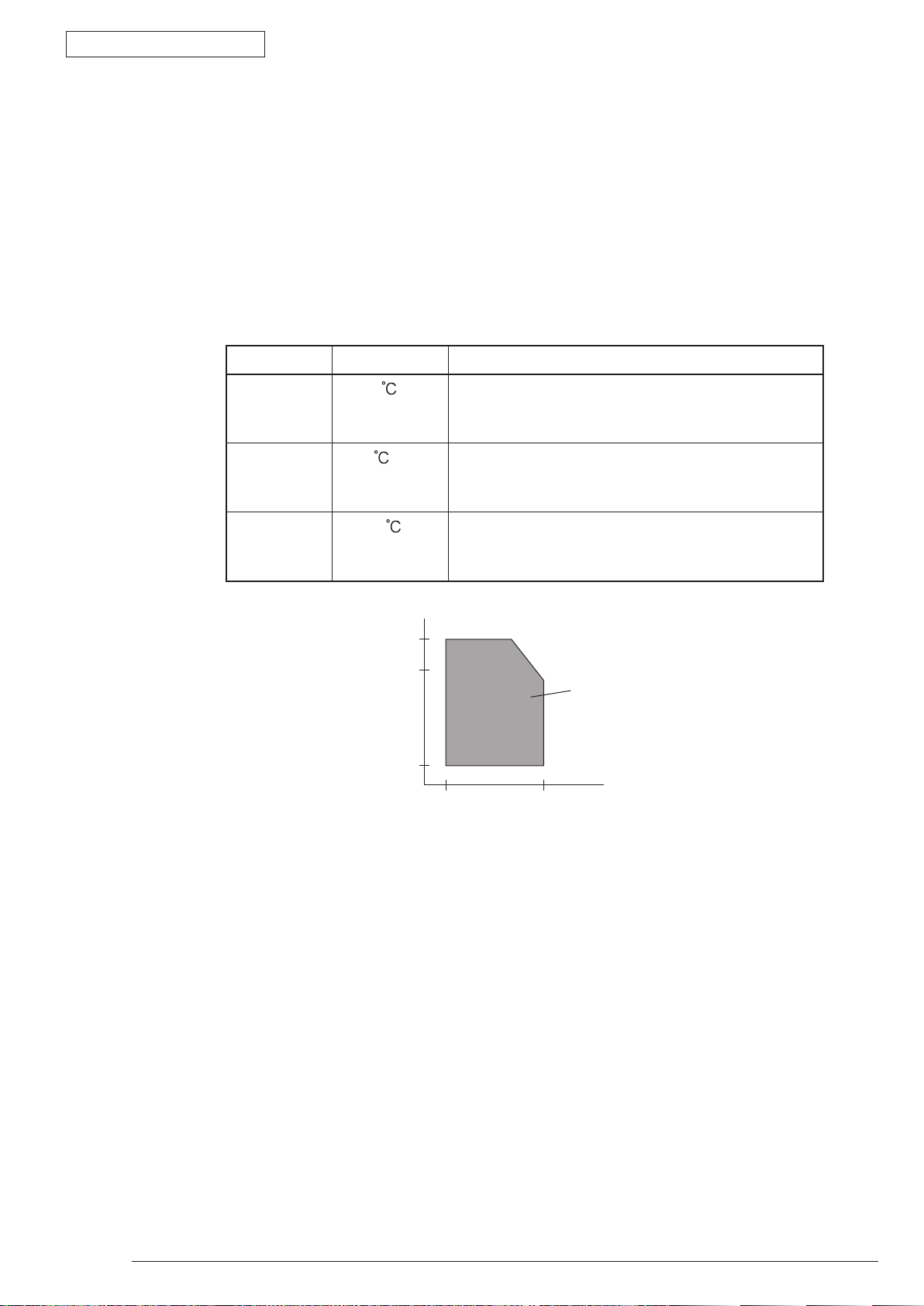

(13) Temperature and Humidity

1. CONFIGURATION

Tenperature Humidity

Up and

running

Power switch

off

Keeping

10~32

0~43

-10~43

20~80%RH (Relative Humidity) No condensation.

However, Maximum temperature of wet ball should

be 25°C.

10~90%RH (Relative Temperature) No

condensation. However, Maximum temperature of

wet ball should be 26.8°C.

10~90%RH (Relative Humidity) No condensation.

However, Maximum temperature of wet ball should

be 26.8°C.

(14) Operating noise In Printing : Rage A based on JIS Z9831, Average below 53dBA for SLOW.

Ready and waiting : Rage A based on JIS Z9831, Average below 53dBA for SLOW.

At power save : No sound (Background level)

(15) Consumables Toner cartridge : Approx. 3,500 piece /Approx. 7,000 piece/Approx. 10,000

printing paten. But, except the 1st Toner cartridge)

Imag

Cartridge : Approx. 20,000 piece (Single-side 3 pages/job) At Power save off.

Approx. 12,000 piece (Single-side 1 page/job) At Power save off.

43984801TH

Rev.1

piece(A4 ISO/IEC 19752 Continuous printing as

e drum : Approx. 25,000 piece (Continuously single-side printing of A4)

Approx. 7,000 piece (Single-side 1 page/job) At Power save on

(Minimum value)

.

14 /

Page 15

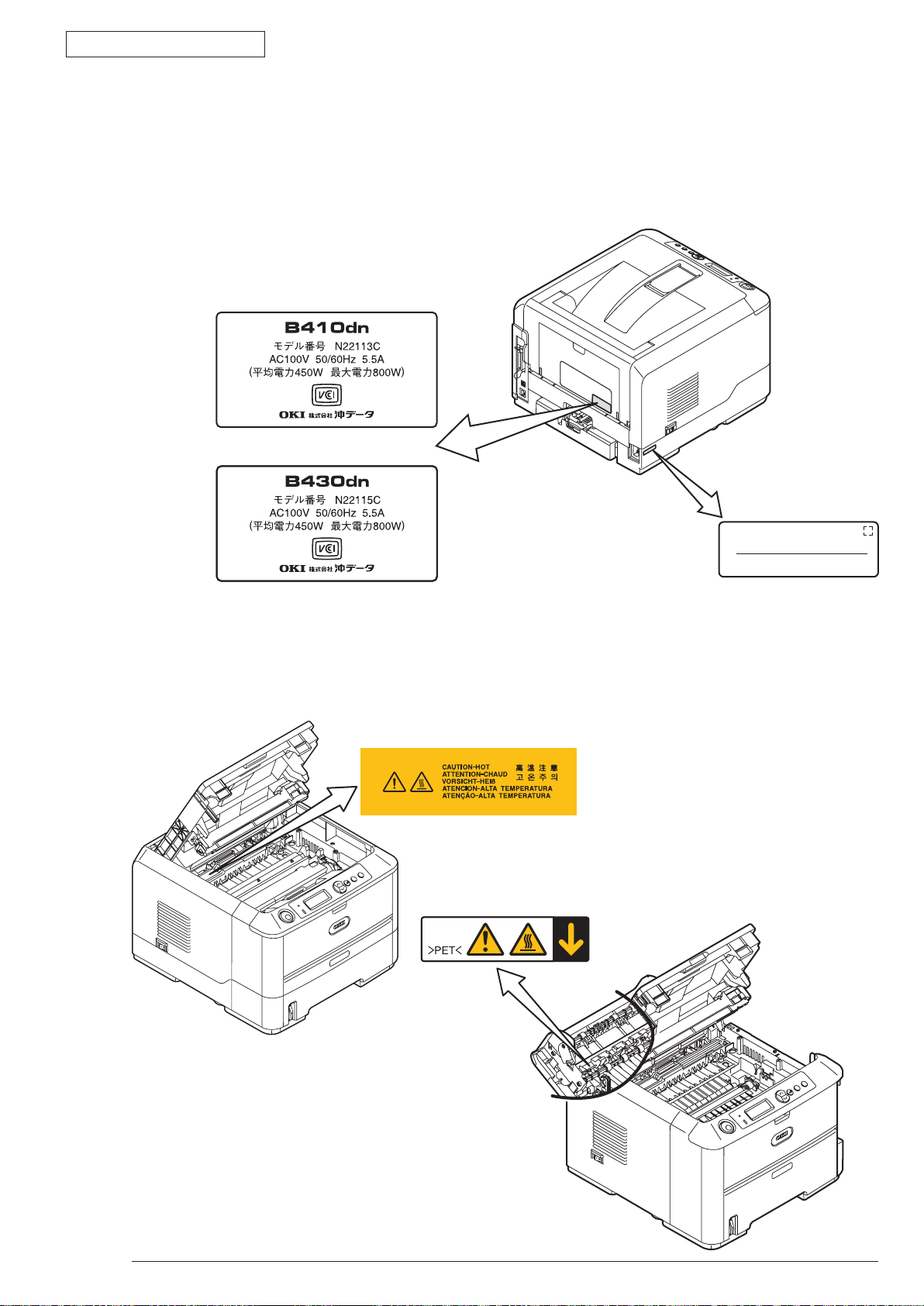

Oki Data CONFIDENTIAL

Serial No.

Made In China

B430dn

B410dn

1.5 Printing display

1.5.1 VCCI label, Serial No. label

The VCCI label and Serial No. label have been attached on the specified part of printer as shows

below.

1. CONFIGURATION

1.5.2 Warning label

Warning label has been attached on the part of printer that may cause injury to the operator.

Maintenance must be performed following the indication of the warning label.

43984801TH

Rev.1

15 /

Page 16

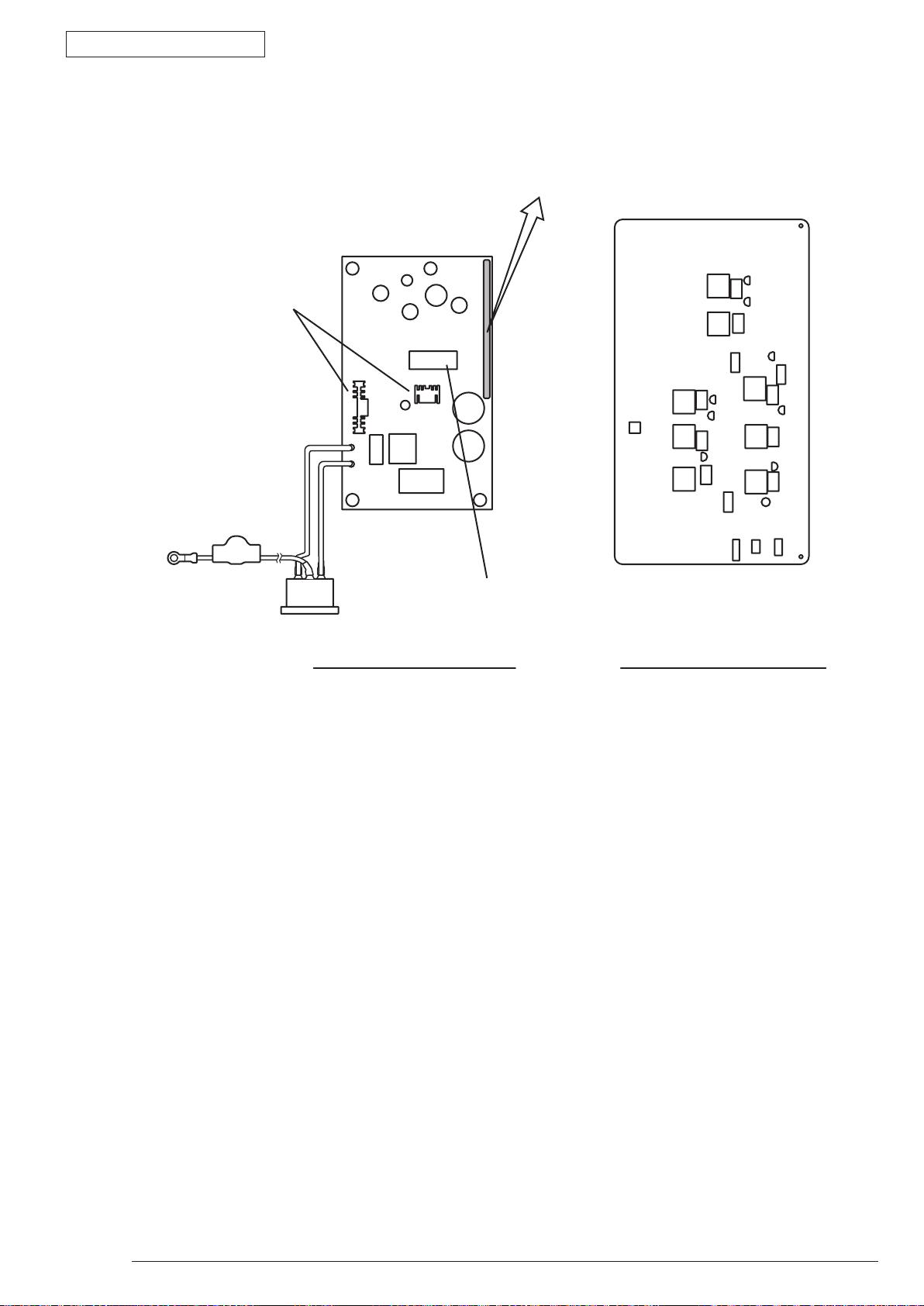

Oki Data CONFIDENTIAL

Low voltage power board

Warning / Caution content record

Heat sink

Transformer

High voltage power board

1.5.3 Warning / Caution display

The following warning / caution are displayed on the electrical power / sensor board.

1. CONFIGURATION

Note!

•

•

There is a risk of electric shock in the middle of the heat sink and transformer. Be sure to check

before touch it.

It may happen that the electricity has still left on the electrical circuit even after the fuse opened.

43984801TH

Rev.1

16 /

Page 17

Oki Data CONFIDENTIAL

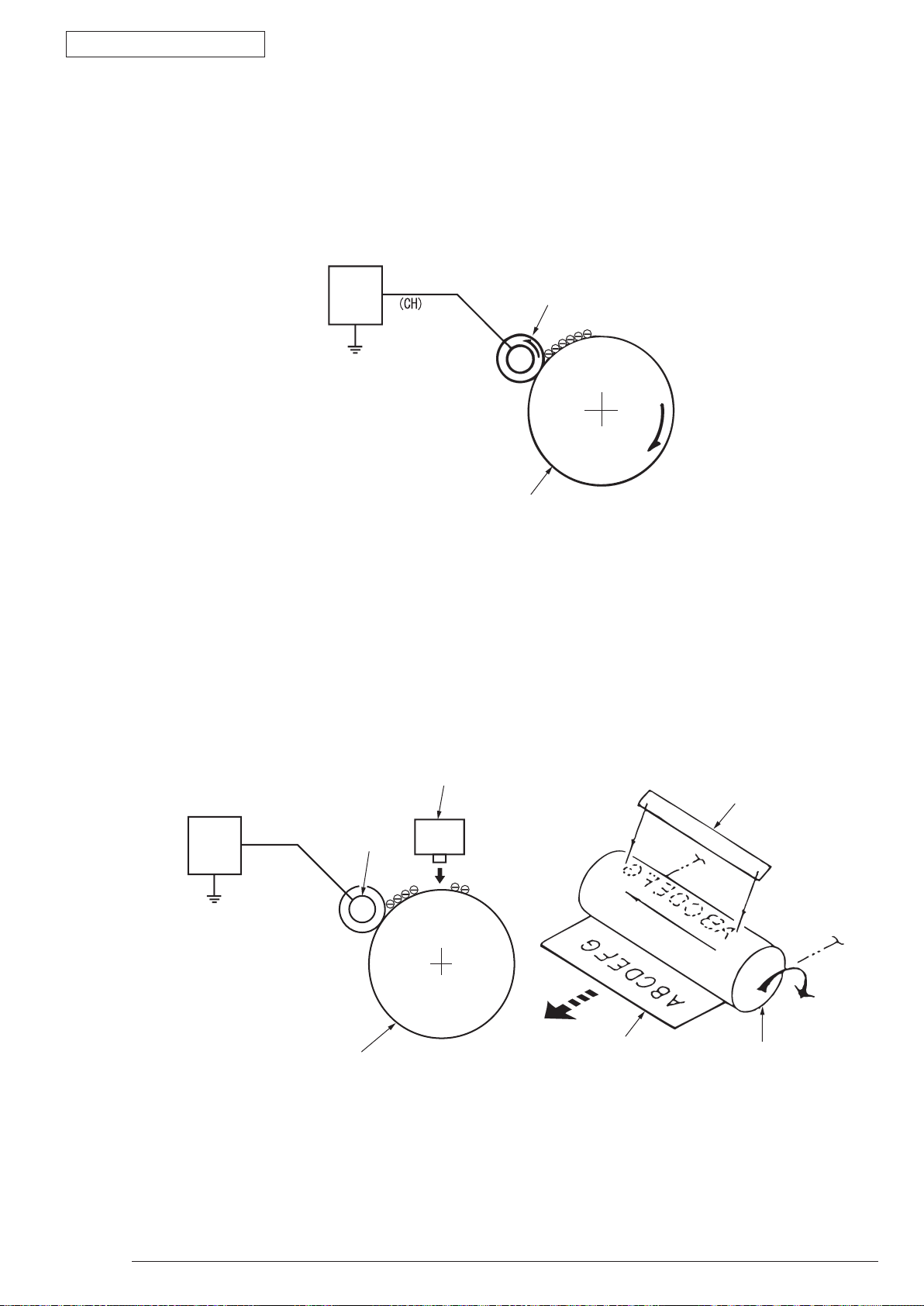

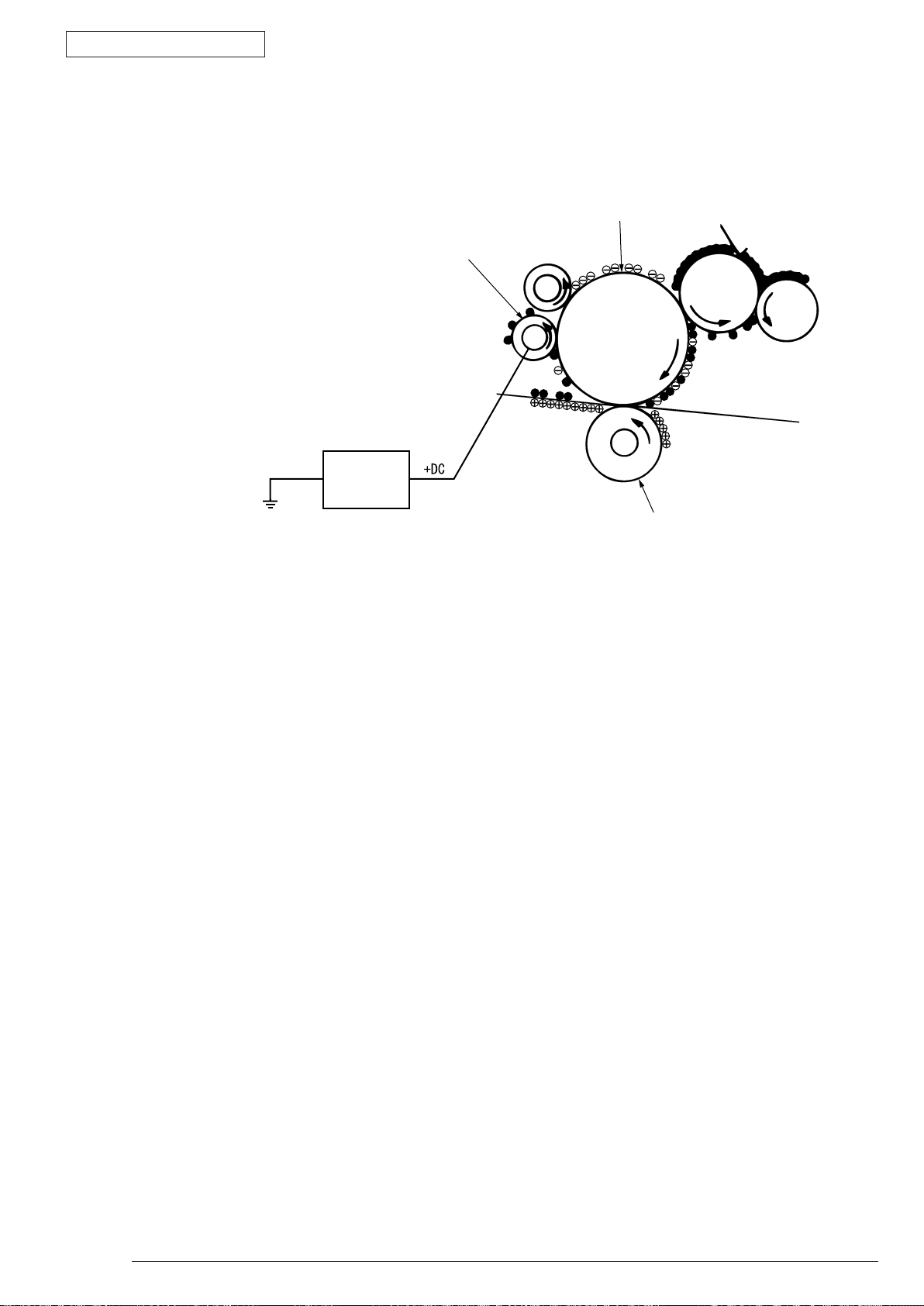

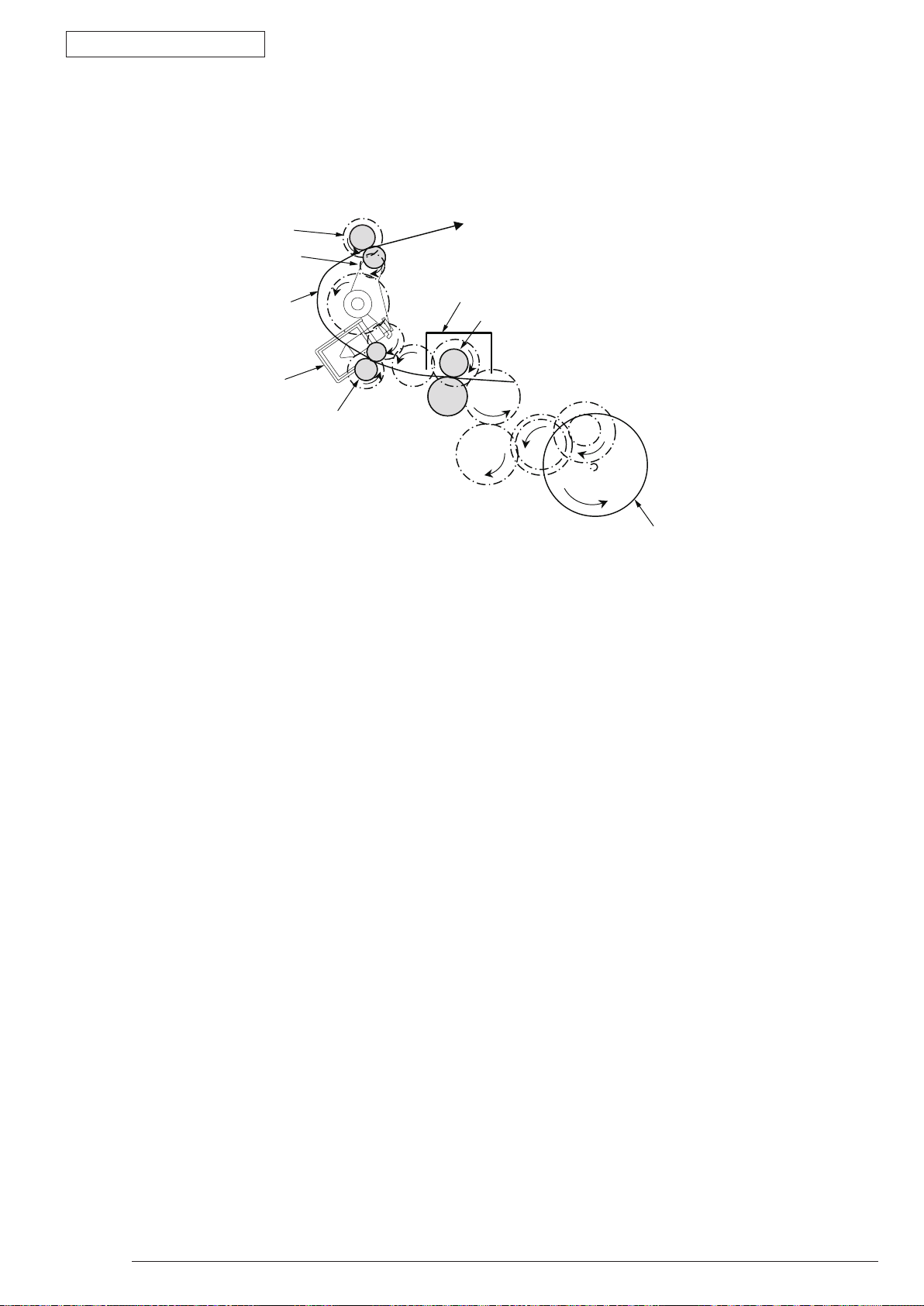

2.1 Electrophotographic process mechanism

(1) Electrophotographic process

The following describes the overview of electrophotographic process.

1. Charging

Equ

2. Exposure

The l

3. Development

Neg

ally charge the surface of image drum by applying negative voltage to the charged roller due to

negative charge.

ight from LED Head is exposed on the negative-charged surface of image drum. The surface

electrical potential of the exposed part of image drum surface becomes lower. Then forms electrostatic

latent image.

ative-charged toner is attracted to the electrostatic latent image due to electrostatic while touching

the image drum. Then forms viewable image.

2. Operational explanation

2. Operational explanation

4. Transfer

Ove

5. Drum cleaning

The remaining toner on the image drum that is not transferred is made to be equable by cleaning roller.

6. Fusing

The t

rlap paper on the surface of OPC drum, from the backside of paper transfer toner image to the

paper by applying electrical charge by transfer roller.

And is temporarily attracted to the cleaning roller due to electrostatic.

oner image that is transferred to paper is fused on paper by heat and pressure.

43984801TH Rev.1

17 /

Page 18

Oki Data CONFIDENTIAL

Image drum

Charged roller

Power

Charged roller

LED head

LED head

Image drum

Image drum

Paper

Power

1. Charging

Cha

rge the image drum surface by applying voltage to the charged roller that contacts the image drum

surface.

2. Operational explanation

2. Exposure

The light emitting from the LED Head will be exposed to the negative charged image drum. When the

surface electric potential of exposed part of the image drum goes to decrease, the electrostatic latent

image complying with image signal is formed.

Image drum is coated by basic layer (UL), charge generating layer (CGL), charge transferring layer (CTL)

on the basic material aluminum. The thickness of the organic light sensor (OPC) that is consisted by

CTL and CGL is approximate 20µm.

43984801TH Rev.1

18 /

Page 19

Oki Data CONFIDENTIAL

Image drum

Charged roller

Image developing plate

Toner supply roller

Image

developing

roller

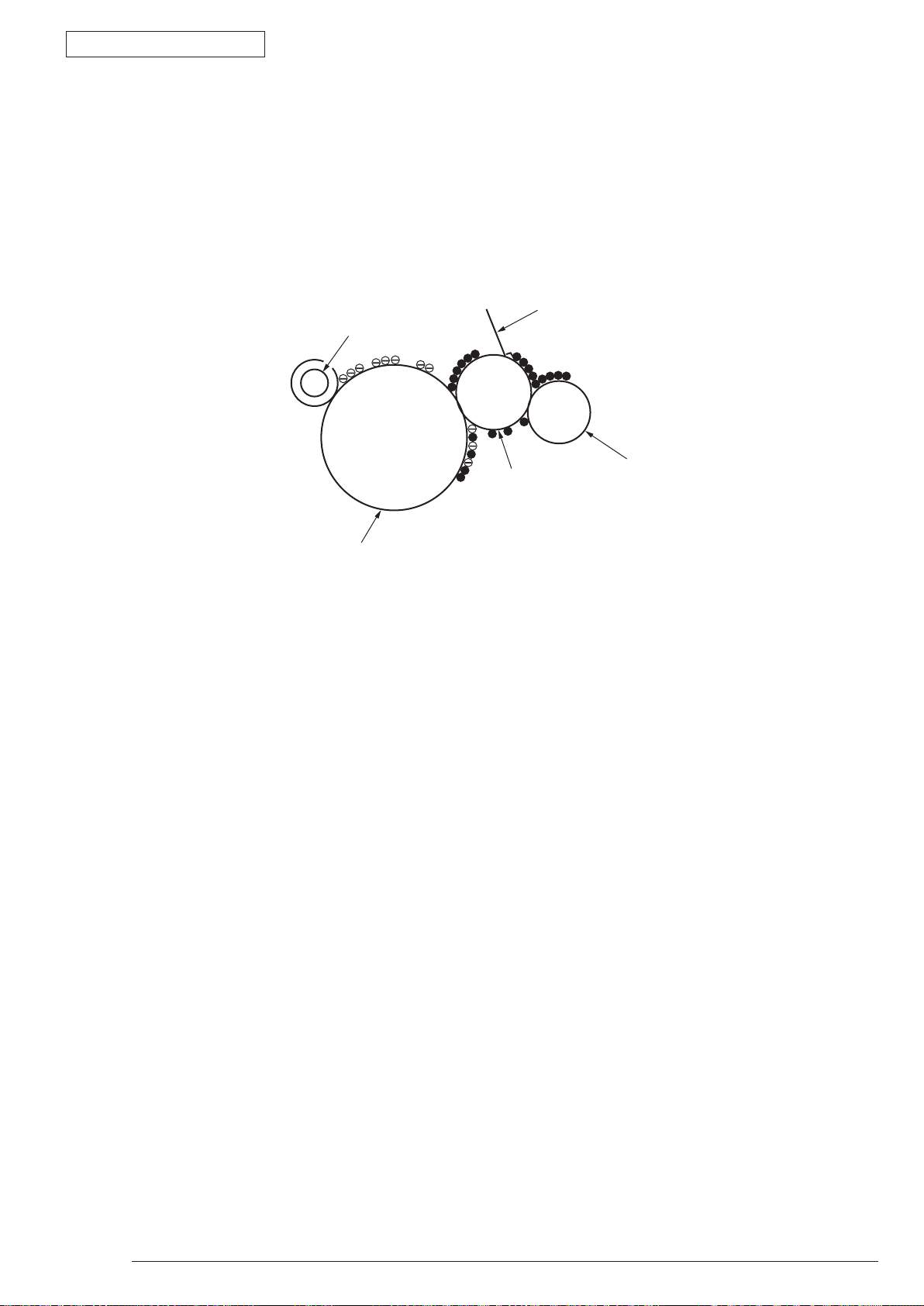

3. Image development

Toner is attracted to the electrostatic latent image on the image drum surface, then the electrostatic

latent image changes to toner image.

1 As the roller on the supply spot of toner rotates while scrubbing the image-developing roller,

2. Operational explanation

fiction electricity occurs between the image developing roller and toner; toner is attracted to

the image-developing roller.

2. The toner that has been attracted to the image-developing roller is dropped down to the

developing plate to make a thin toner film on the image developing roller side.

3 The toner is attracted by the exposed part (Low electrical potential part) of the image drum

when the image drum contact the image developing roller, so as to see the electrostatic latent

image.

43984801TH Rev.1

19 /

Page 20

Oki Data CONFIDENTIAL

Image drum

Basic material

Toner feeding roller

While the cover is closed it will be

connected and bias will be applied.

Image developing roller

2. Operational explanation

Note! The ne

and image developing roller as show below.

cessary bypass voltage in image processing is impressed on the toner feeding roller

43984801TH Rev.1

20 /

Page 21

Oki Data CONFIDENTIAL

Image drum

Transfer roller

Paper

Power

4. Transfer

Th

As high plus voltage is applied to transfer roller from the power supply, the plus charge on the transfer

e transfer roller, which is from conductive sponge material, is created to meet intimate attachment

of image drum roller surface and feeding paper. The feeding paper is set up on the surface of image

drum. Plus charge, which is the converse polarity with toner polarity, is applied from the backside of the

paper.

roller surface is induced and transferred to the paper while the paper contact the transfer roller. The

negative charged toner, which has been attracted to the image drum surface, is transferred to the

surface of feeding paper by the plus charge of the backside of the paper.

2. Operational explanation

43984801TH Rev.1

21 /

Page 22

Oki Data CONFIDENTIAL

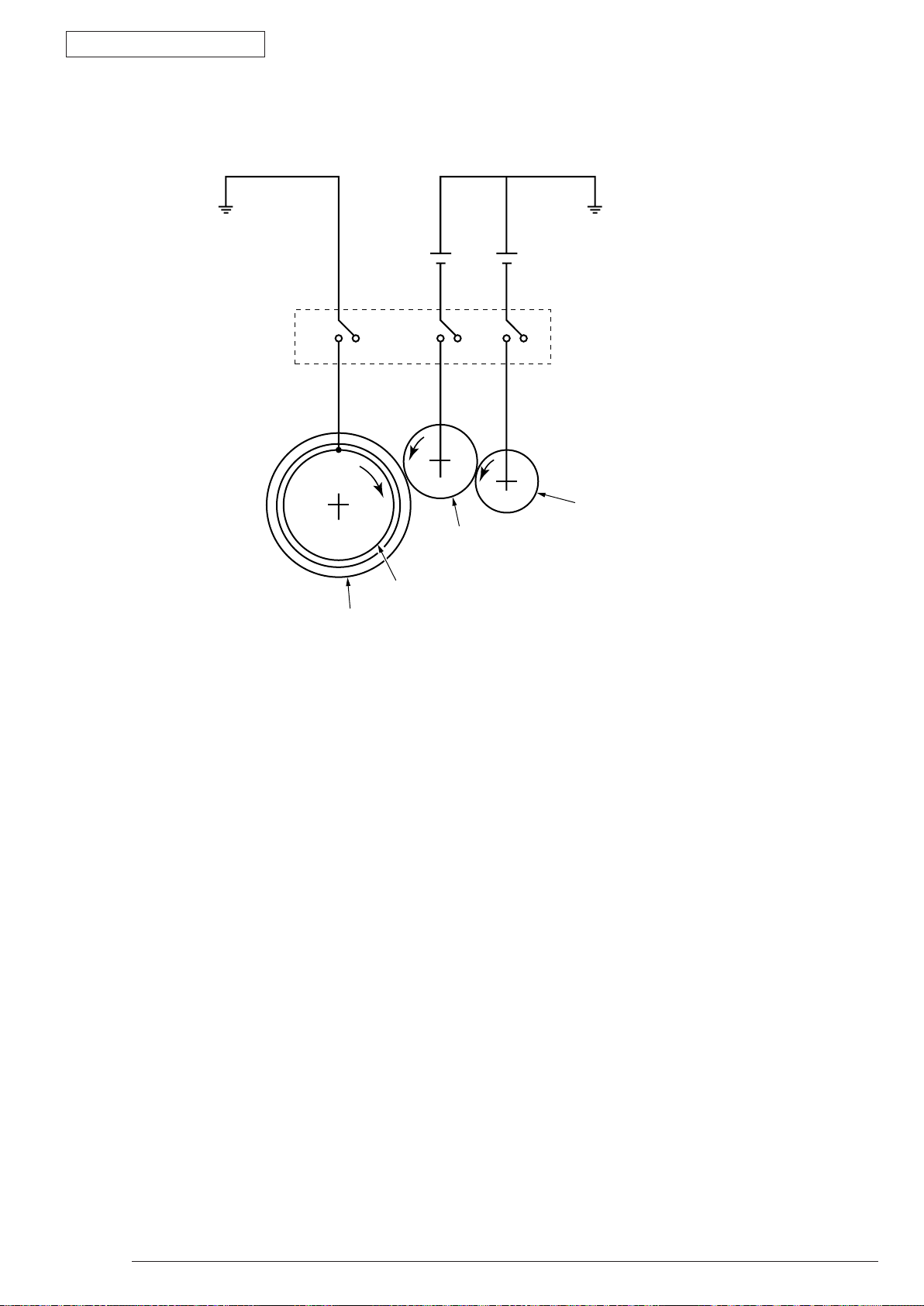

Power supply

Cleaning roller

Image drum

Transferring roller

5. Drum cleaning

1 Cleaning

After the completion of transferring, the remaining toner on the image drum is temporarily attracted

by the electrostatic and the image drum surface is cleaned.

2. Operational explanation

2 Roller cleaning

In the following case, there is a need of cleaning the charged roller, transfer roller, and cleaning roller.

•

Warming up as switching on the power supply

•

Warming up after open-close of the cover

•

In case of termination of printing operation

•

By periodically change the bias voltage that is implied to each roller during continuous printing,

transfer the attached toner from roller to image drum and then return it to developing device.

43984801TH Rev.1

22 /

Page 23

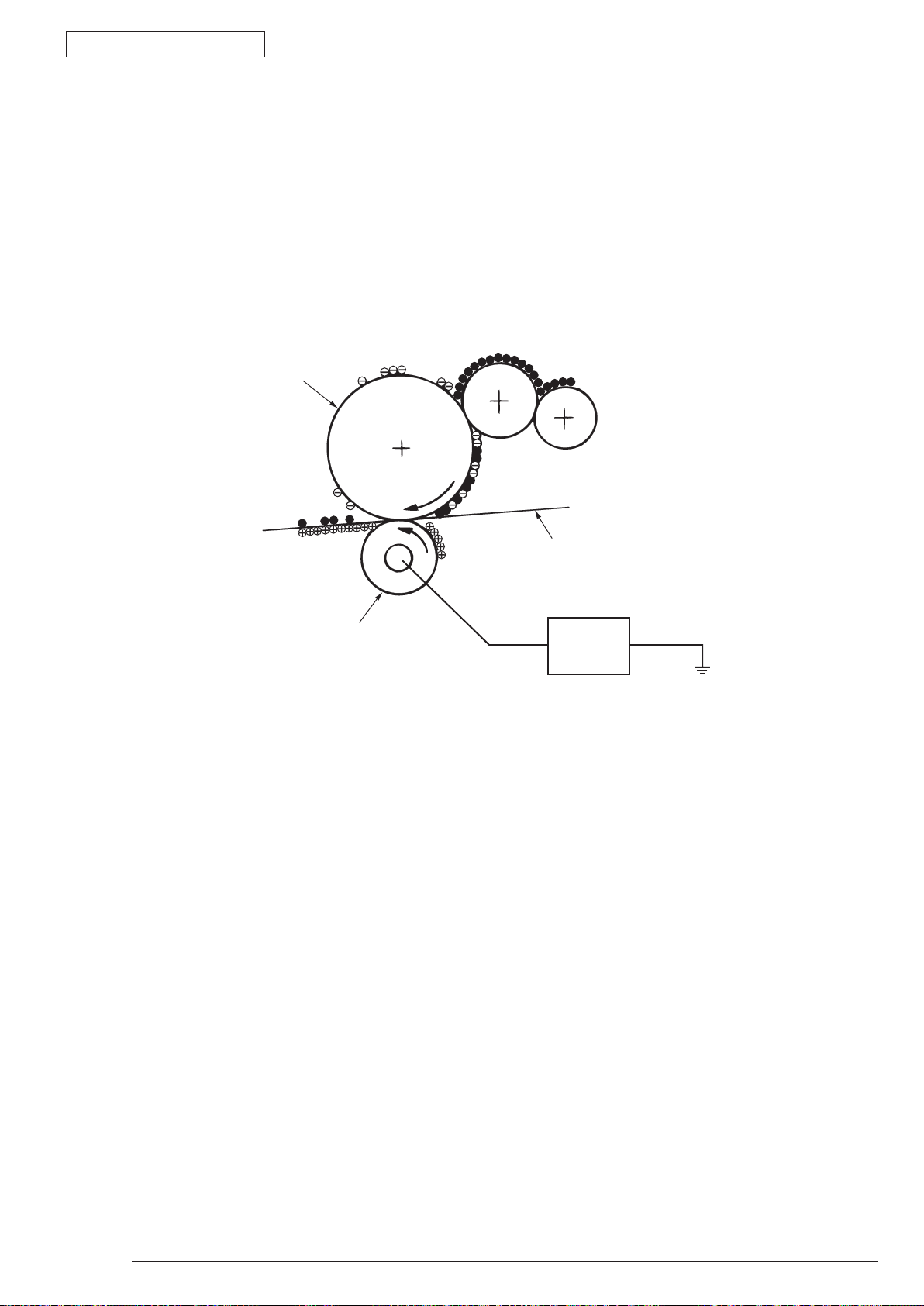

Oki Data CONFIDENTIAL

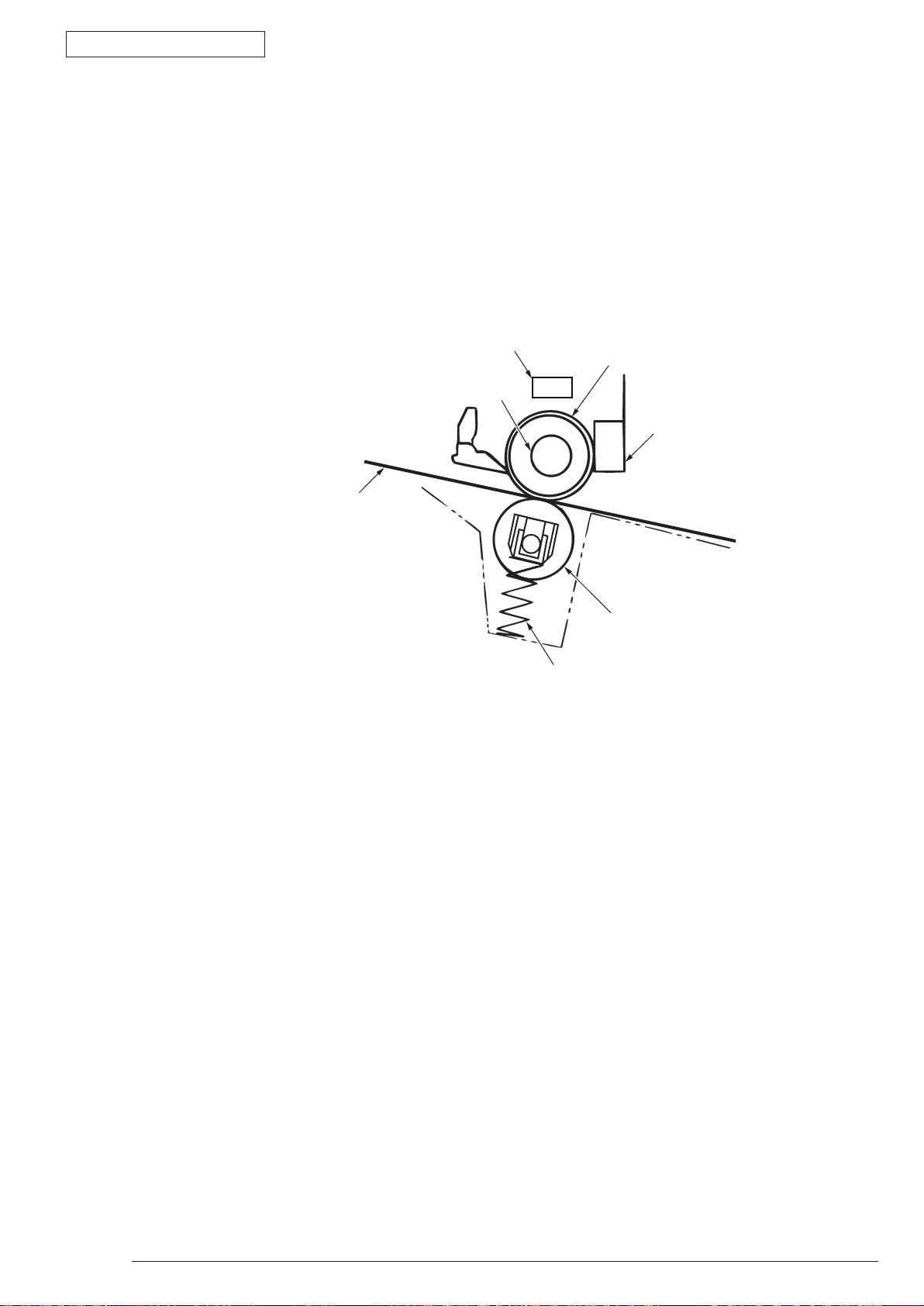

Separating clutch

Feeding paper

Heater

Heat roller

Thermistor

Backup roller

Pressuring spring

Thermostat

6. Fusing

Af

The thermistor that contacts the Heat roller adjusts the Heat roller temperature to the temperature

The back up roller is held by the pressure springs on each terminal due to the pressure applied.

ter the termination of transfer the unsettled toner image is settled to paper by heat and pressure

while passing between Heat roller and Back up roller. Heat roller is Teflon coated and is mounted by

heater that can generate heat (Halogen lamp).

specified by the menu complying with the paper width. For safety the thermostat shuts off the voltage

supply to the Heater by opening the thermostat in the case of abnormally temperature increasing.

2. Operational explanation

43984801TH Rev.1

23 /

Page 24

Oki Data CONFIDENTIAL

:

:

:

:

:

:

:

:

:

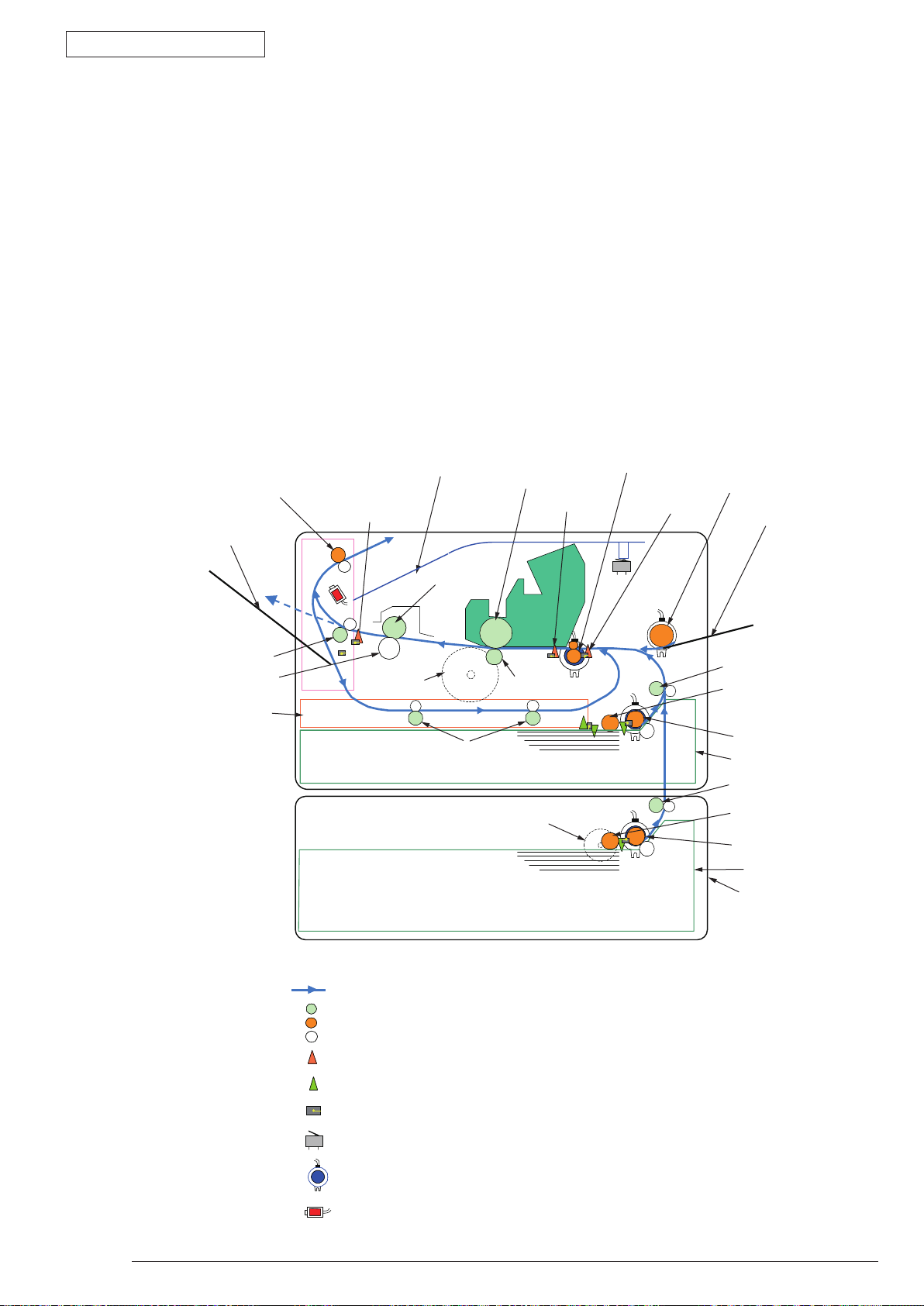

Face down stacker

Face up stacker

The 2nd ejecting roller

The 1st ejecting roller

Backup roller

Duplex unit

Ejecting

sensor lever

Resist roller

MPT feeding roller

Multipurpose tray

Conveying roller

Conveying roller

Transferring roller

Pulse motor

Paper conveying route

Driving roller (Continuous rotation)

Driving roller (Control rotation)

Driving roller

Paper level indicator lever

Indicating lever

Photo sensor

Micro switch

Magnetic clutch

Solenoid

DC motor

Heat roller

Conveying roller

Pick up roller

Pick up roller

Feeding roller

Feeding roller

Tray 1

Tray 2

2nd tray unit (option)

Entrance

sensor lever

Image drum

Writing out

sensor lever

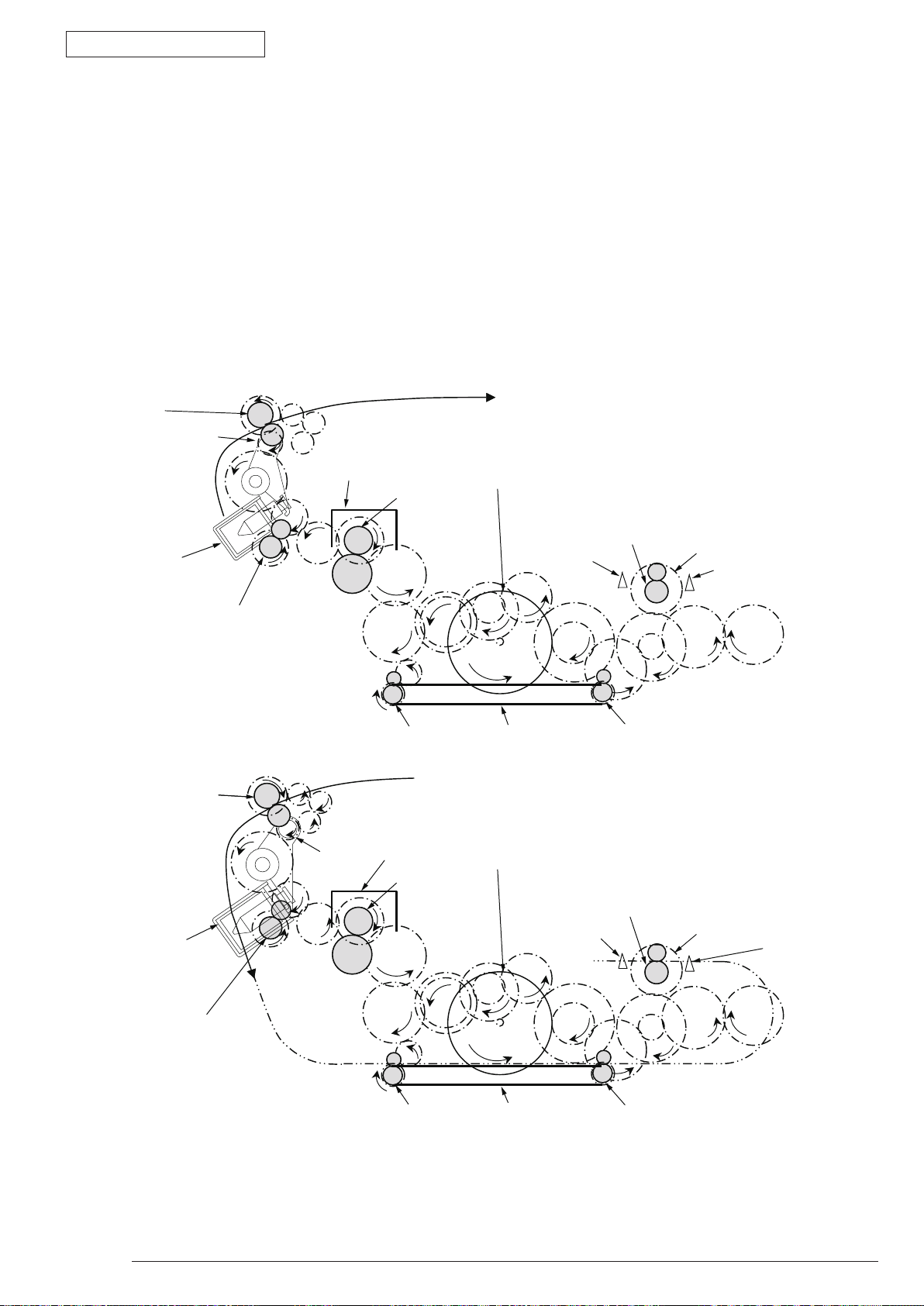

2.2 Printing process

The paper fed from Tray 1 and Tray 2 is conveyed by feeding roller, conveying roller, and resist roller.

When feeding paper is from MPT, it is conveyed by MPT, feeding roller, and resist roller. After that the

feeding paper that is conveyed by image drum and the nip part of transfer roller forms toner image

on the paper through electrophotographic process. And then, the toner on the paper is fused by the

heat and pressure as the fuser unit passing through. The paper that fused the toner image is ejected

from the face down stacker of the ejecting roller. In the case of face up ejecting, it needs to open

the backside cover and install face up stacker. (It is unavailable for duplex printing while it is face up

ejecting.)

The above is about the operations at simplex printing, yet the below explains the operations at duplex

printing. While duplex printing, the paper, which firstly passed through the fuser unit after the backside

printing, is conveyed to the inward of Duplex Unit, by the reverse operation of the second ejecting roller

that is a certain time after removing the first ejecting roller of the paper rear side. Paper, is conveyed by

conveying roller of Duplex Unit, and then merges to the same route with the feeding paper that is from

the tray. Onwards, it is the same with the simplex printing operation by the feeding paper from tray.

2. Operational explanation

43984801TH Rev.1

24 /

Page 25

Oki Data CONFIDENTIAL

Resist roller

Resist clutch

Entrance sensor lever

Conveying roller

Paper feeding roller

Pick up roller

DC motor

(Counterclockwise rotation)

Paper feeding clutch

Paper

Writing out sensor lever

Resist clutch

Writing out sensor lever

Resist roller

Entrance sensor lever

Paper feeding clutch

MPT paper feeding roller

Paper

DV motor

(Counterclockwise rotation)

(1) Paper feeding from Tray 1

1. As DC motor rotating (Counterclockwise rotation), if set the paper feeding clutch as ON, as the

paper feeding roller and pick up roller rotating, the paper that is inside the tray is conveyed.

2. The paper is conveyed by the conveying roller. After the entrance sensor level set to be ON, it

bumps into the stopping resist roller, a certain more amount of paper is conveyed. (This corrects

the paper skew.)

3. If set the resist clutch as ON, the paper is conveyed by resist roller.

2. Operational explanation

(2) Paper feeding from Multipurpose tray (MPT)(B420dn, B430d, B430dn)

1. As

DC motor rotating (Counterclockwise rotation), if set paper feeding clutch as ON the MPT paper

feeding roller starts to rotate, the paper in the tray is conveyed.

2. After setting th

more amount of paper is conveyed. (This corrects the skew of paper.)

3. If set the r

e entrance sensor lever as ON, the paper bumps into the stopping resist roller, a certain

esist clutch as ON, the paper is conveyed by resist roller.

43984801TH Rev.1

25 /

Page 26

Oki Data CONFIDENTIAL

Eject roller

Eject roller

Planet gear

Paper route

Solenoid

Fuser unit

Heat roller

DC motor

(Counterclockwise rotation)

(3) Fuser unit and paper ejecting

2. Operational explanation

1. The fuser u

2. Simultaneously th

nit and eject roller is

e eject roller rotates, and then the paper is ejected.

43984801TH Rev.1

26 /

Page 27

Oki Data CONFIDENTIAL

Fuser unit

Fuser unit

Heat roller

Heat roller

DC motor

(Counterclockwise rotation)

DC motor

(Counterclockwise rotation)

Resist roller

Resist roller

Resist clutch

Resist clutch

Resist Entrance

sensor lever

Resist Entrance

sensor lever

Duplex conveying roller

Writing out

sensor lever

Writing out

sensor lever

Duplex conveying roller

The 1st ejecting roller

The 1st ejecting roller

The 2nd ejecting

roller

The 2nd ejecting

roller

Planet gear

Planet gear

Solenoid

(OFF)

Solenoid

(ON)

[ Normal rotation ]

[ Inverse rotation ]

Belt

Duplex conveying rollerDuplex conveying roller

Belt

(4) Paper reversing and paper multi-feeding

2. Operational explanation

1. TRemoving th

planet gear starts to move, the second eject roller starts inverse rotating (Counterclockwise rotation).

2. By the i

3. Paper is c

4. After setting t

more amount of paper is conveyed. (This corrects the skew of paper.).

5. If set t

he Resist clutch as ON, paper is conveyed by Resist roller.

e first eject roller at the rear part of paper and set the solenoid as ON for a while, then the

nverse rotation of the second eject roller the paper is inversely rotated and conveyed to Duplex.

onveyed by Duplex conveying roller.

he entrance sensor lever as ON, paper bumps into the stopped resist roller, still a certain

43984801TH Rev.1

27 /

Page 28

Oki Data CONFIDENTIAL

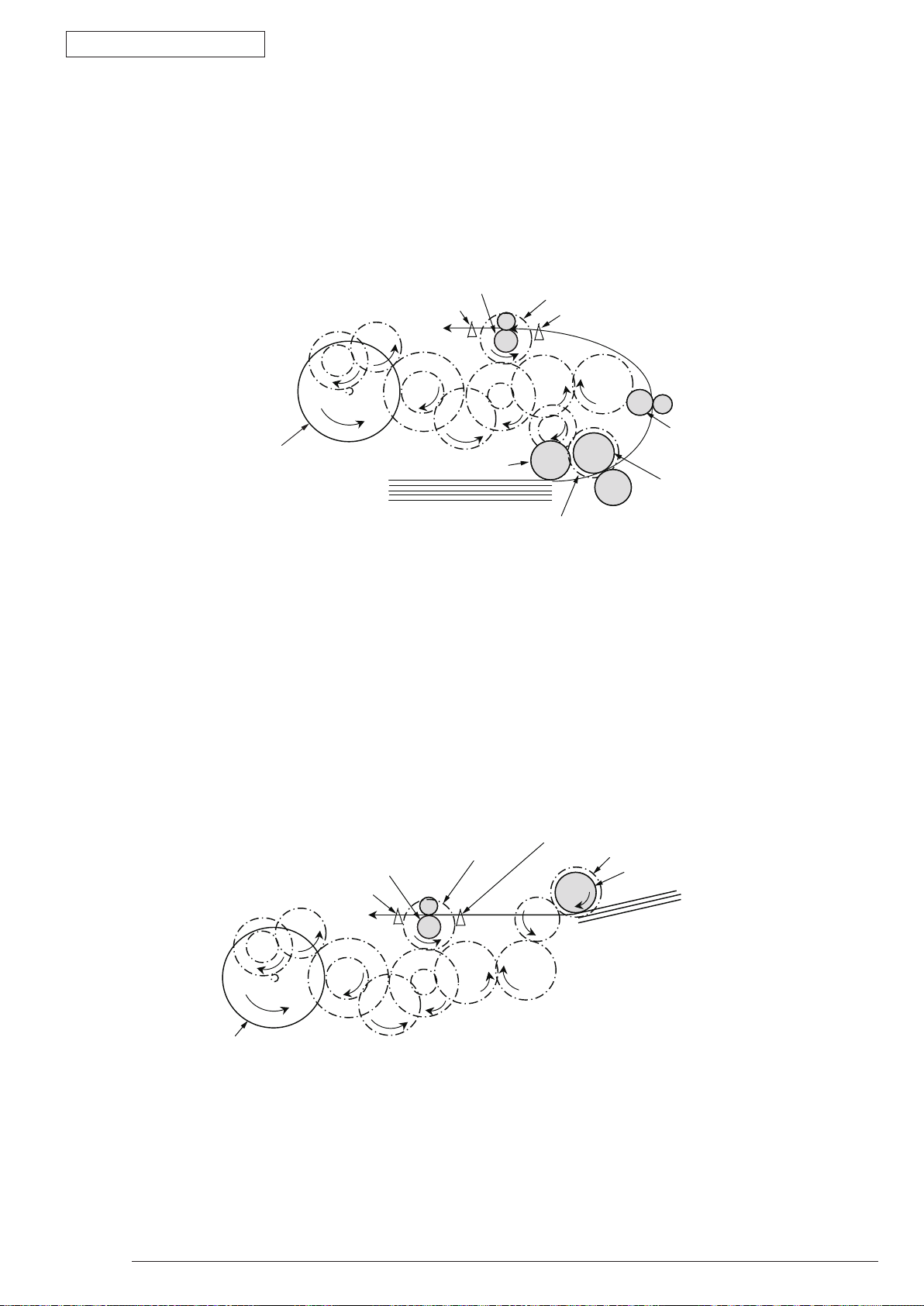

Magnet

Agitating bar Agitating gear

Crack part

Agitating bar

Agitating bar

Agitating gear

Sensor plate

Sensor plate

Toner sensor

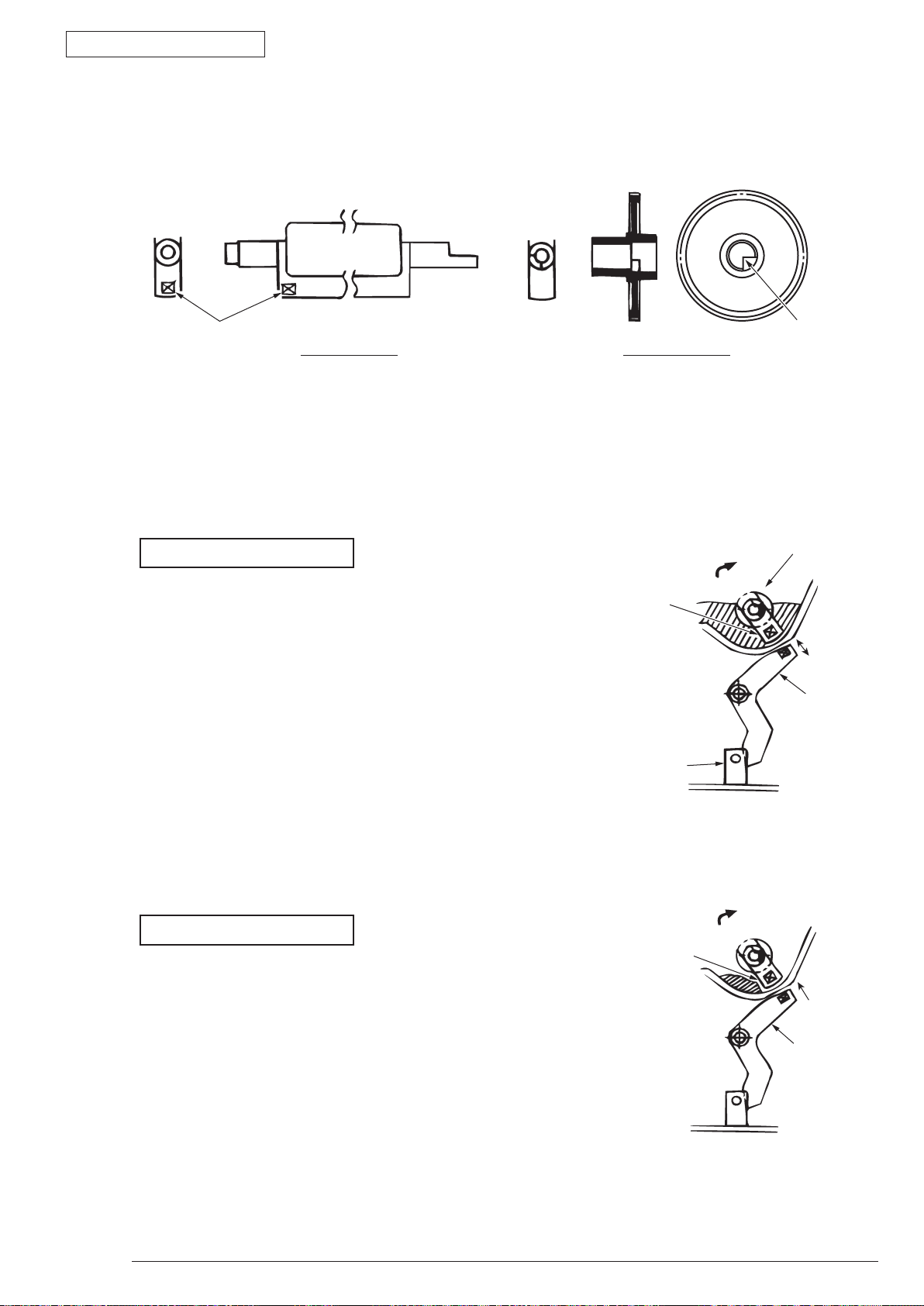

2.3 Toner entrance detection

• Equipment

Toner entrance detecting equipment consists the agitating gear that agitating the agitating bar at a

certain speed and magnet that is on the agitating bar.

•

Operation

Detecting the toner low by monitoring the congruous time intervals between the magnet that is set on

the sensor plate and the magnet attached on the agitating bar,

2. Operational explanation

Operation in toner full status

•

The crack part of agitating gear meshing with the

projection portion of agitating bar, the agitating bar

rotates in accordance with the rotating of gear.

•

Even after the magnet part of the agitating Bar reaches

the highest position, it still rotates at the same speed

by the pressure of the agitating gear due to the toner

resistance.

Operation in toner low status

•

When the magnet part of the agitating bar reaches the

highest position, because there is no resistance from

toner, the agitating bar drops earlier than the gear by

the gravity itself, and stops by that status.

For this reason, the time that the magnet of agitating

Bar magnetic attracts the magnet of sensor plate

becomes longer. The toner low status can be inspected

by monitoring this time.

43984801TH Rev.1

28 /

Page 29

Oki Data CONFIDENTIAL

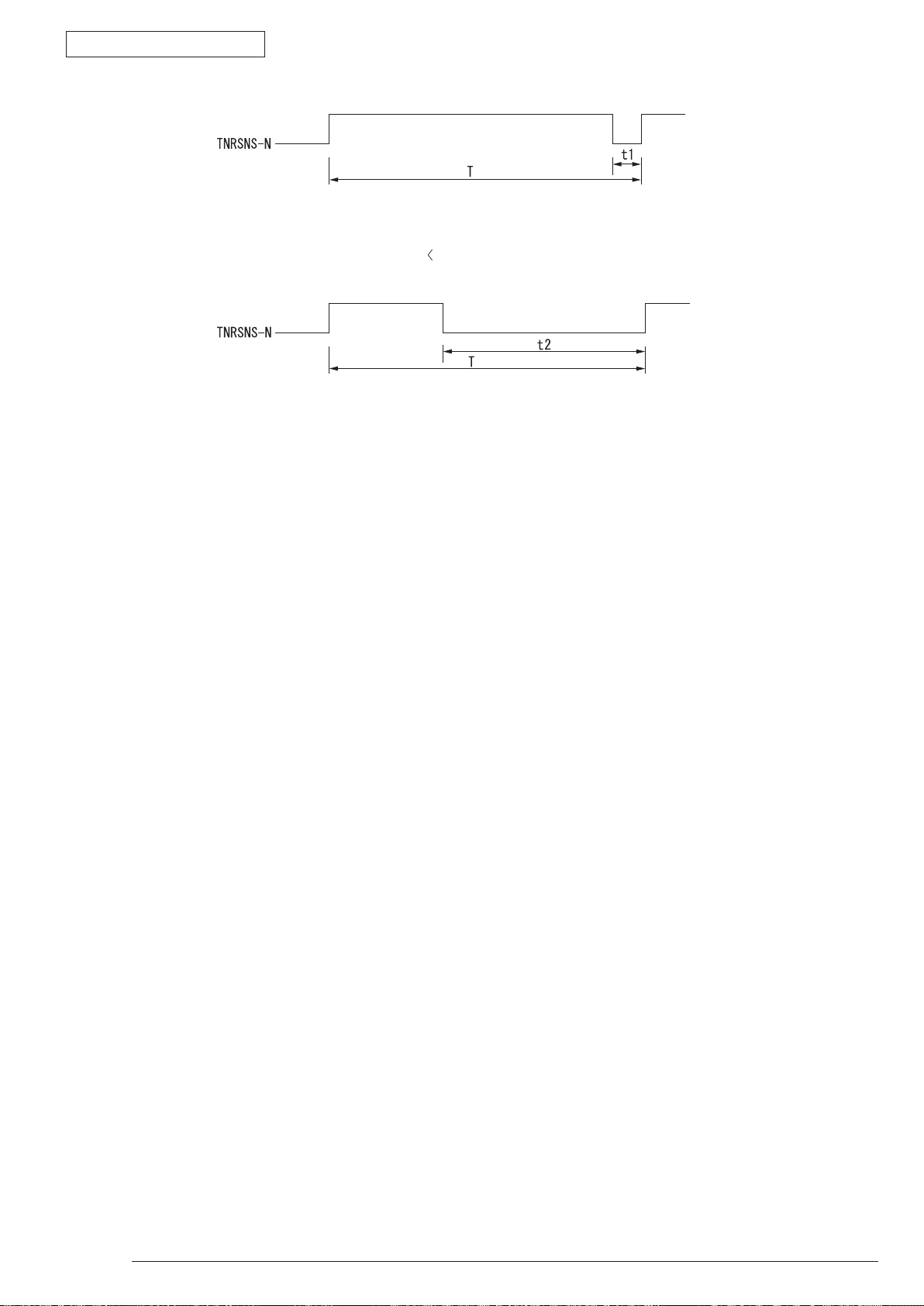

Toner full status

Toner low status t1 t2 t1,t2: Magnet attracting time

• Toner sensor alarm actuates if there is not any change on toner sensor.

• Toner sensor is not monitored while main (drum) motor is stopping.

2. Operational explanation

43984801TH Rev.1

29 /

Page 30

Oki Data CONFIDENTIAL

OFF

ON

Shutting

off

Reconnecting

Earth cable

Earth terminal

Warning

This section explains the replacement procedure of part, assembly, and unit in the working place.

Disassembling procedure relating to reassembling is conducted conversely.

3.1 Preparation for parts replacement

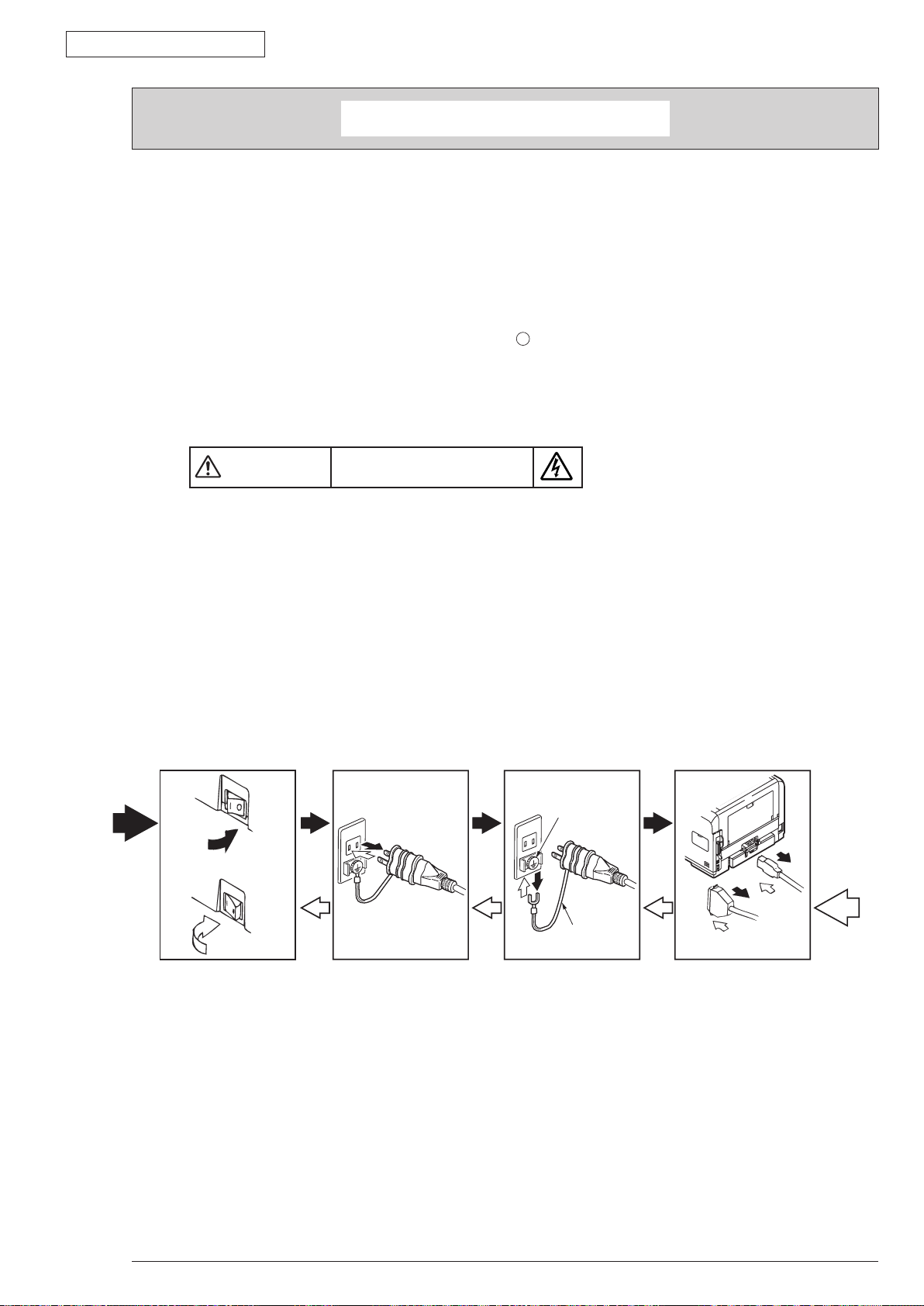

(1) Be sure to unplug the AC cord and interface cable before starting to replace parts.

(a) Unplugging the AC cord by the following procedures.

i) Shut off the power switch of the printer. (

ii) Unplug the AC insert plug of AC cord from the AC socket.

iii) Remove the earth wire from AC socket.

iv) Unplug the AC cord and interface cable from printer.

3. Parts replacement

)

」

「

Risk of Electric Shock

3. Parts replacement

There is a risk of electric shock during replacement of the low voltage power supply.

Use insulating gloves or avoid direct contact with any conducting part of the power supply, and caution should be

exercised during replacement.

The capacitor may take one minute to complete discharge after the AC cord is unplugged. Also, there is a possibility

that the capacitor doesn’t discharge because of a breakage of the PCB, etc., so remember the possibility of electric

shock to avoid electric shock.

(b) Reconnecting the printer by the following procedures.

i) Connect the AC cord and interface cable to the printer.

ii) Connect earth wire to the AC socket.

iii) Connect the AC insert plug to the AC socket.

iv) Turn on the power switch of the printer. (

「I」

)

(2) Do not disassemble the printer in the case of normal operation.

(3) Do not disengage the part that there is not any necessary to touch. Disassembly should be the

(4) B

(5) Be sure to temporarily install the small part such as screw, collar, and so on at its original position during

(6) D

(7) D

(8) Do not put the Print Circuit Board on the printer of on the floor directly.

43984801TH Rev.1

minimum.

e sure to use the specified maintenance tools.

disassembling because it is easy to be lost.

o not use the gloves that is easy to occur electrostatic while dealing with IC such as micro-sensor,

ROM, RAM, etc. and PCB.

o not put the print circuit board on the equipment or on the floor directly.

30 /

Page 31

Oki Data CONFIDENTIAL

[Maintenance tools]

The necessary tools for replacing the print circuit board, assembly, and unit is shown as graph 3-1.

No. Maintenance tools Quantity Application Remark

3. Parts replacement

Graph 3-1 Maintenance tools

1

2

3

4

5

6

7

Note! Use vacuum by the type that applying to toner. It may cause fire if use normal vacuum.

No.2-200 + Magnetic driver 1

No.3-100 Driver 1

No.5-200 Driver 1

Digital multi-meter 1

Pliers 1

Handy cleaner 1

E ring pliers 1

3~5mm

Screw

For E ring

removing

Refer to the

following Note!

43984801TH Rev.1

31 /

Page 32

Oki Data CONFIDENTIAL

A

A

A’

A’

Stacker-Cover-Assy

Cover-Side-R

Cover-Side-L

Plate-Base-PCB

Plate-Assy-Base

Motor-Fan

Duplex

Rear-Cover-Assy

Fuser-Assy

OPE Cover-Assy

Guide-Paper-Duplex

GuidePaper-R

Manual-Assy

Front-Guide-Assy

CU board

Toner cartridge

Low voltage

power board

High voltage

power board

Paper cassette

Image drum cartridge

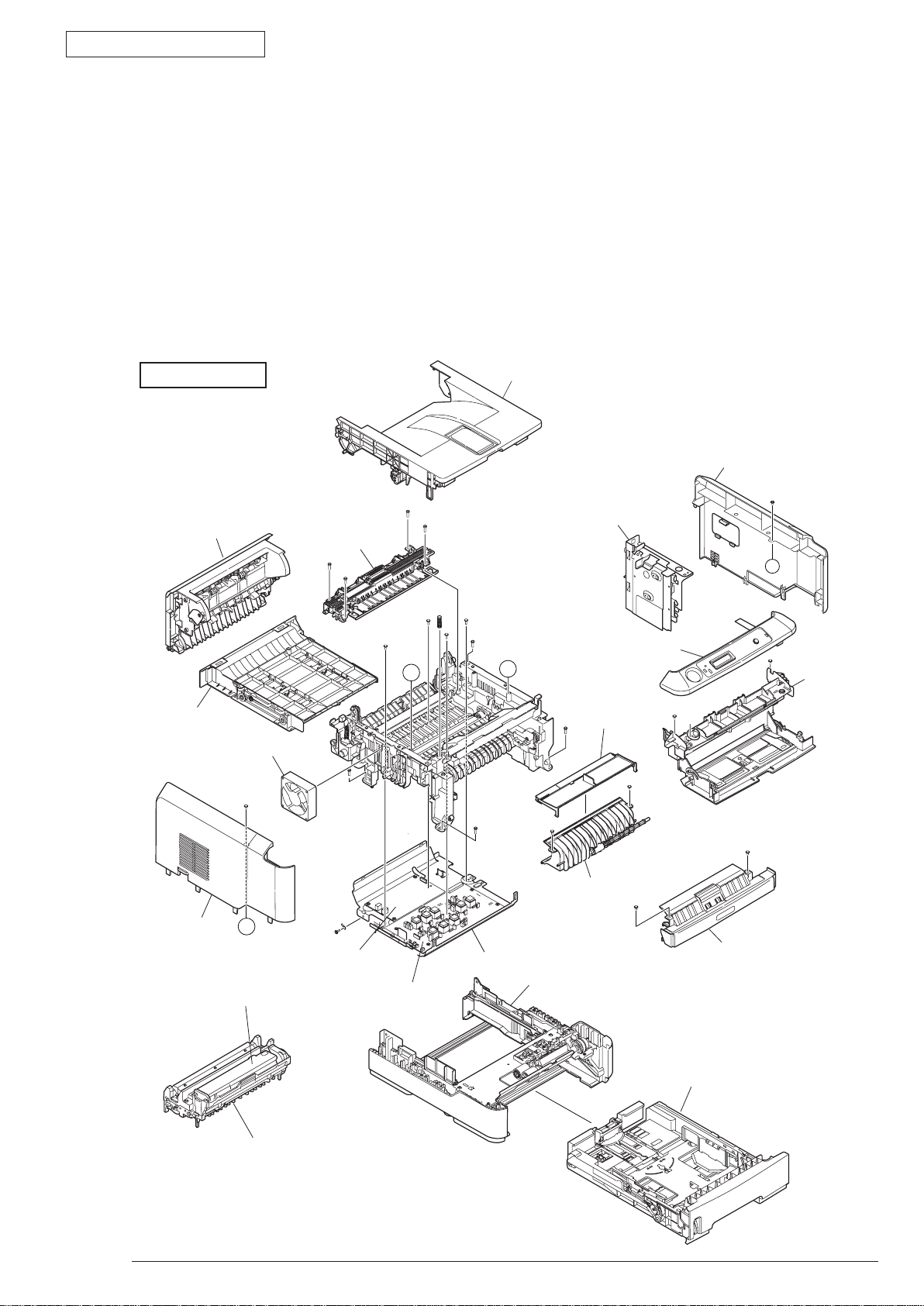

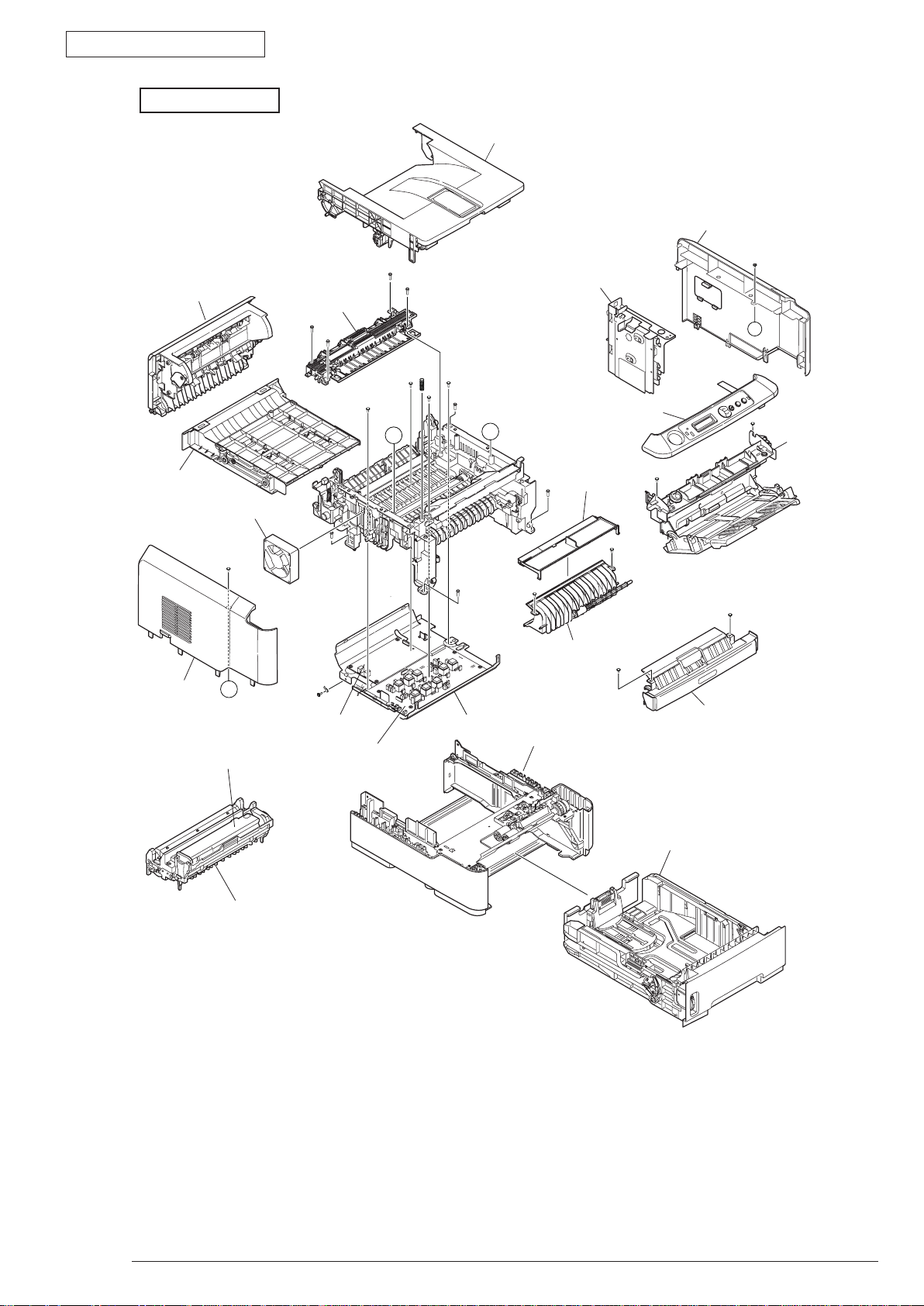

3.2 Parts layout

This section explains the main parts layout of the equipment.

B410d/B410dn

3. Parts replacement

43984801TH Rev.1

Figure 3-1

32 /

Page 33

Oki Data CONFIDENTIAL

A

A

A’

A’

Stacker-Cover-Assy

Cover-Side-R

Cover-Side-L

Plate-Assy-Base

Motor-Fan

Duplex

Rear-Cover-Assy

Fuser-Assy

OPE Cover-Assy

Guide-Paper-Duplex

GuidePaper-R

MPT-Assy

Front-Guide-Assy

CU board

Plate-Base-PCB

Toner cartridge

Low voltage

power board

High voltage

power board

Paper cassette

Image drum cartridge

B430d/B430dn

3. Parts replacement

43984801TH Rev.1

Figure 3-2

33 /

Page 34

Oki Data CONFIDENTIAL

B420dn

3. Parts replacement

Stacker-Cover-Assy

CU board

Rear-Cover-Assy

Duplex

Cover-Side-L

Motor-Fan

A’

Low voltage

power board

Fuser-Assy

Toner cartridge

A’

GuidePaper-R

Plate-Base-PCB

High voltage

power board

A

Plate-Assy-Base

Cover-Side-R

A

OPE Cover-Assy

MPT-Assy

Guide-Paper-Duplex

Front-Guide-Assy

Image drum cartridge

43984801TH Rev.1

Paper cassette

Figure 3-3

34 /

Page 35

Oki Data CONFIDENTIAL

Photo Interrupter

Roller-Pick-Up

Roller-Feed-Now

Guide-Cassette-L

Guide-Cassette-R

Plate-Base

Gear-Assy-Clutch

[Base unit]

B410d/B410dn/B430d/B430dn

3. Parts replacement

43984801TH Rev.1

Figure 3-4

35 /

Page 36

Oki Data CONFIDENTIAL

[Base unit]

3. Parts replacement

B420dn

Photo Interrupter

Gear-Assy-Clutch

Roller-Pick-Up

Roller-Feed-Now

Plate-Base

Guide-Cassette-L

(530sht)

Guide-Cassette-R

(530sht)

Figure 3-5

43984801TH Rev.1

36 /

Page 37

Oki Data CONFIDENTIAL

Cover Side-R

(3.3.3)

Cover Side-L

(3.3.6)

CU Board

(3.3.5)

Motor-DC-Main

(3.3.6)

Rear-Cover-Assy

(3.3.15)

OPE Cover Assy

(3.3.5)

Stacker-Cover-Assy

(3.3.13)

Ope Board

(3.3.8)

MPT-Assy

(In case of B410dn, it is Manual-Assy)

(3.3.9)

Front-Guide-Assy

(3.3.10)

Roller-Assy-Feed

(3.3.11)

Guide -Paper-Duplex

(3.3.12)

Fuser-Assy

(3.3.14)

Frame-Assy-Lower

(3.3.16)

Plate-Brecket-Motor

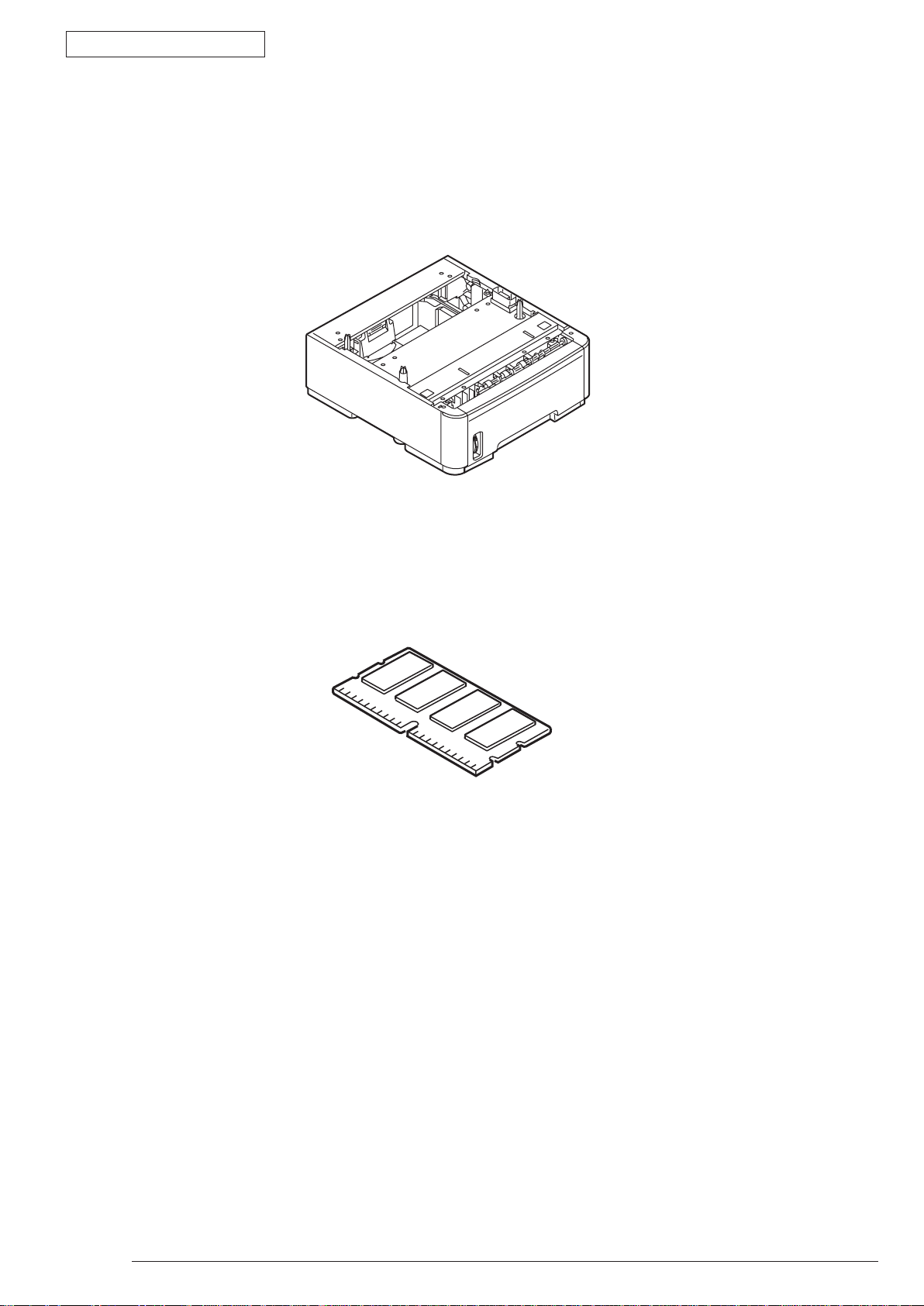

(3.3.18)

Roller-BackUP

(3.3.19)

Roller-Regist

(3.3.20)

Lever-In-Sensor

(3.3.21)

Lever-Eject-Sensor/Photo-Interrupter

(3.3.22)

Lever-End/Lever-Duplex/

Lever-Cassette/Gear-Assy-Clatch

(3.3.23)

PR Unit

LED Head

(3.3.1)

High/Low voltage Power Board

(3.3.17)

Paper Feeding Roller (Roller-Pick-Up,Roller-Feed-NOW,Roller-Assy-MPT)

(3.3.24)

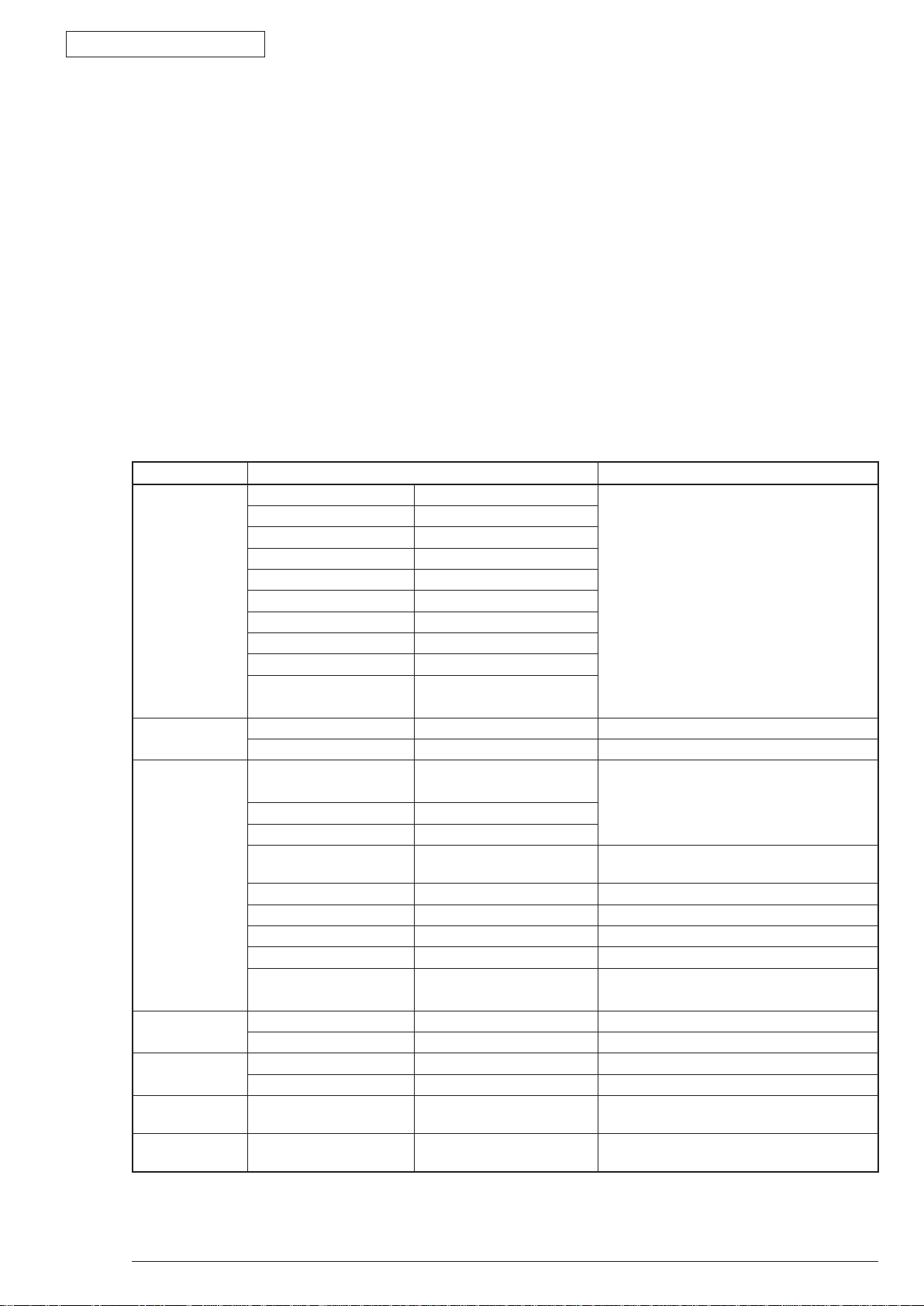

3.3 Parts replacement method

This section explains the replacement method of the parts and assemblies that are shown in the following

disassembling diagram.

About the parts replacement procedure, the parts that are shown by parts number using white number in the

are the RSPL parts.

The explaining diagram of parts replacement procedure is B430dn.

Replace part after performing the following operation.

(1) Unplug the AC power cord from the main unit inlet by the disconnected status of power switch.

(2) Unplug the interface cable from the main unit.

3. Parts replacement

43984801TH Rev.1

37 /

Page 38

Oki Data CONFIDENTIAL

Stacker-Cover-Assy

Cable

Hook B

Hook A

SLA

(Selfoc Lens Array)

3.3.1 LED Head

(1) Open the Stacker-Cover-Assy

(2) Remove the 2 screws (Black)

(3) Firstly open Hook A by narrow direction and then remove it. Secondly remove Hook B then remove LED

Assy

(4) Remove cable from the connector of LED Assy

(5) Installing is performed by the reverse procedure with removing.

Note! Beware of not to touch or press the SLA parts of LED Head directly.

. (At this moment, the 2 springs can be also removed jointly.)

3. Parts replacement

. Remove Holder-Head .

.

43984801TH Rev.1

38 /

Page 39

Oki Data CONFIDENTIAL

Stacker-Cover-Assy

Latch

③

❶

②

❷

❶

3.3.2 Roller-Transfer

(1) As the power switch shut off, unplug the AC power cord from the inlet of main unit.

(2) Open the Stack-Cover –Assy

(3) Remove latches in the 2 places of Gear-TR

any unnecessary pressure while removing the latch.)

lightly slide the Roller-transfer ❷ to the right side and remove the post on the top of gear from the

(4) S

contact of Frame-Assy-Lower. Remove the latches on the 2 places of Gearing-TR❶ of Gear.

(5) H

old the Bearing-TR ❶on the both side, and then lift up the Roller-Transfer ❷. (At this moment, Gear-

TR ③ is also removed.)

(6) I

nstalling is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

2. While installing, pay attention to the up-and-down direction of Bearing-TR

3. O

perating carefully, not to touch Roller-Transfer ❷ surface.

3. Parts replacement

and Bearing-TR ❶ on the conversing side. (Do not add

③

❶.

43984801TH Rev.1

39 /

Page 40

Oki Data CONFIDENTIAL

Rear-Cover-Assy

Stacker-Cover-Assy

①

②

③

3.3.3 Cover-Side-R

(1) As the power switch shut off, unplug the AC power cord from the inlet of main unit.

(2) Unplug the interface cable from the main unit.

(3) Open the Rear-Cover-Assy.

(4) Open the Stacker-Cover-Assy.

(5) Take out the image drum cartridge.

(6) Remove the Cover-Access

(7) R

emove the screw (Black) ②. Remove the Cover-Side-R ③.

(8) I

nstalling is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

①

3. Parts replacement

.

43984801TH Rev.1

40 /

Page 41

Oki Data CONFIDENTIAL

②

Stacker-Cover-Assy

Rear-Cover-Assy

①

3.3.4 Cover-Side-L

(1) As the power switch shut off, unplug the AC power cord from the inlet of main unit.

(2) Unplug the interface cable from the main unit.

(3) Open the Rear-Cover-Assy.

(4) Open the Stacker-Cover-Assy.

(5) Take out the image drum cartridge.

(6) Remove the 2 screws (Black)

(7) Installing is performed by the inverse procedure with removing.

Note! Attach the Label Motor-Fan on the outside that is obviously to be seen.

3. Parts replacement

. Remove Cover-Side-L .

43984801TH Rev.1

41 /

Page 42

Oki Data CONFIDENTIAL

②

①

⑥

④

⑤

③

⑦

⑨

⑦

DC motor

③

⑤

❽

3.3.5 CU Board

(1) Remove the Cover-Side-R. (Refer to 3.3.3)

(2) Remove the 4 pieces of screws (Silver) ①. Remove the Plate-Cover-Shield-CU ②.

3. Parts replacement

(3) Remove the 2 pieces of big screws (Silver) ③. Remove the Film-Core-Holder ④. In the meantime

remove the cable connector (with core) ⑤ together.

(4) Remove the 2 pieces of small screws (Silver) ⑥, 2 pieces of big screws (Silver) ⑦, and cable

connector from the CU board ❽. Remove the Spring-FG-Solenoid ⑨ and CU board ❽.

(5) I

nstalling is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

eware of not to tuck down the cable while installing the Plate-Cover-Shield-CU ②.

2. B

43984801TH Rev.1

42 /

Page 43

Oki Data CONFIDENTIAL

❹

③

⑤

②

①

Cable

3.3.6 Motor-DC-Main

(1) Remove the Cover-Side-R. (Refer to 3.3.3)

(2) Remove the Plate-Cover-Shield-CU. (Refer to 3.3.5(2))

(3) Remove the connector

ut the TY-RAP that is bundling the cable of Motor-DC-Main and the cable of Resist clutch.

(4) C

(5) Remove the 3 pieces of screws (Silver)

emove the Motor-DC-Main ❹. Unplug the cable from the Piece-Guide ⑤.

(6) R

(7) I

nstalling procedure is performed by the opposite order with removing. Bundle the cable of Motor-DC-

Main and the cable of Resistor clutch by TY-RAP.

(Note on removing / installing)

1. Beware of not to touch the DC motor inattentively (Do not rotate motor).

of Motor-DC-Main from CU board.

①

and the 1 piece of screw (Black) ③.

②

3. Parts replacement

43984801TH Rev.1

43 /

Page 44

Oki Data CONFIDENTIAL

①

②

③

CU board

Stacker-Cover-Assy

Rear-Cover-Assy

Cover-Assy-MPT

❹

Claw A

Claw B

Claw B

3.3.7 OPE Cover-Assy

(1) Open the Rear-Cover-Assy.

(2) Open the Stacker-Cover-Assy.

(3) Remove the Cover-Side-R and Cover –Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove the Plate-Cover-Shield-CU. (Refer to 3.3.5(2))

(5) Remove the screw (Silver)

emove the FFC cable ③ from the CU board.

(6) R

(7) O

pen the Cover-Assy-MPT.

(8) Pull Claw A by the arrow direction. Remove the clamp by pushing Claw B as the arrow direction.

Remove the OPE Cover-Assy ❹.

nstalling is performed by the reverse procedure with removing.

(9) I

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

. Remove the Film-Core-Holder ②.

①

3. Parts replacement

43984801TH Rev.1

44 /

Page 45

Oki Data CONFIDENTIAL

Claw

Claw

Cover-OPE

④

③

①

②

3.3.8 Ope-Board

(1) Remove OPE Cover-Assy. (Refer to 3.3.7)

(2) Remove Ope-Board ① from Cover-OPE by pulling the claw as the arrow direction.

(3) U

nplug FFC cable ② from Ope-Board ①.

(4) R

emove Button-KEY ③ and Lens-LCD ④ from Ope-Board ①.

(5) I

nstalling is performed by the reverse procedure with removing.

3. Parts replacement

43984801TH Rev.1

45 /

Page 46

Oki Data CONFIDENTIAL

A

A

B

B

Driver

Pay attention not to let Separating- Pad- Assy pop out to

your front side while installing MPT-Assy.

C

Frame-Assy-Lower

❹

❹ʼ

②

②

②

②

③

①

③

3.3.9 MPT-Assy (In case of B410dn, it is Manual-Assy)

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Cover-Side-R and Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove OPE Cover-Assy. (Refer to 3.3.7)

(5) Remove the clamp of claw by pushing by arrow A direction, and then remove Cover-Lever-Lock

emove the 2 screws (Black)

(6) R

(7) Open the Frame-Assy-Lower by arrow B direction, and then remove Lever-Lock-Top ③.

(8) H

olding up MPT-Assy

(9) Installing is performed by the inverse procedure with removing.

Note! While removing the Lever-Lock-Top , it is easy to remove it by inserting the driver between

the Frame-Assy-Lower and Lever-Lock-Top and press the driver by Arrow C direction.

(Note on removing / installing)

.

(Manual-Assy ) and remove it.

3. Parts replacement

.

①

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

43984801TH Rev.1

46 /

Page 47

Oki Data CONFIDENTIAL

③

②

②

①

3.3.10 Front-Guide-Assy

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Cover-Side-R and Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove OPE Cover-Assy. (Refer to 3.3.7)

(5) Remove MPT-Assy. (Refer to 3.3.9)

(6) Remove the clamp of claw by pushing by arrow direction, and then remove Cover-Paper-R

(7) R

emove the 2 screws (Black) ②. Remove Front-Guide-Assy ③.

(8) I

nstalling is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

3. Parts replacement

.

①

43984801TH Rev.1

47 /

Page 48

Oki Data CONFIDENTIAL

❶

3.3.11 Roller-Assy-Feed

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Cover-Side-R and Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove OPE Cover-Assy. (Refer to 3.3.7)

(5) Remove MPT-Assy. (Refer to 3.3.9)

(6) Remove Guide-Assy-Front. (Refer to 3.3.10)

(7) Remove Roller-Assy-Feed

nstalling is performed by the inverse procedure with removing.

(8) I

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

by arrow direction.

❶

3. Parts replacement

43984801TH Rev.1

48 /

Page 49

Oki Data CONFIDENTIAL

①

②

①

3.3.12 Guide-Paper-Duplex

(1) Open the Rear-Cover-Assy.

(2) Open the Stacker-Cover-Assy.

(3) Remove Cover-Side-R and Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove OPE Cover-Assy. (Refer to 3.3.7)

(5) Remove MPT-Assy. (Refer to 3.3.9)

(6) Remove Front-Guide-Assy. (Refer to 3.3.10)

(7) Remove Roller-Assy-Feed. (Refer to 3.3.11)

(8) Remove Duplex-Assy.

(9) Remove the 2 screws (Black)

) Installing is performed by the reverse procedure with removing.

(10

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

. Remove Guide-Paper-Duplex ②.

①

3. Parts replacement

43984801TH Rev.1

49 /

Page 50

Oki Data CONFIDENTIAL

①

②

LED cable

CU board

Frame-Assy-Lower

3.3.13 Stacker-Cover-Assy

(1) Open the Rear-Cover-Assy.

(2) Open the Stacker-Cover-Assy.

(3) Remove Cover-Side-R and Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove Plate-Cover-Shield-CU. (Refer to 3.3.5(2))

(5) Remove film-Core-Holder. (Refer to 3.3.7(5))

(6) Remove LED cable from CU board.

(7) Remove the screw (Silver)

pen the Stacker-Cover-Assy ② by the arrow direction and remove Stacker-Cover-Assy ② from the

(8) O

supporting point of Frame-Assy-Lower.

(9) I

nstalling is performed by the reverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

①

3. Parts replacement

.

43984801TH Rev.1

50 /

Page 51

Oki Data CONFIDENTIAL

3.3.14 Fuser-Assy

Note! Replace the Fuser-Assy by Assy unit.

It is forbidden for disassembling the Fuser-Assy, also, reusing the disassembled Fuser-Assy.

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Cover-Side-R and Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove Stacker-Cover-Assy. (Refer to 3.3.13)

(5) Unplug connector (Motor-Fan)

remove Piece-Guide ③.

(6) R

emove Motor-Fan ④. Remove Piece-Guide ⑤.

(7) U

nplug the connector ⑥ of Fuser-Assy, which is at the back side of Piece-Guide ⑤.

(8) R

emove the 4 screws (Silver) ⑦. Remove the Fuser-Assy ❽ by bowing down the lock at the left side.

(9) I

nstalling is performed by the inverse procedure with removing.

Note! Fuser-Assy ❽ may be really hot, beware of handling.

3. Parts replacement

and connector (Semester) ② from high voltage power board, and

①

(Note on removing / installing)

1. I

nstall the screw (Silver) ⑦ in its original groove. (Do not make new screw tap.)

o not add excessive pressure while tightening the screw (Silver) ⑦.

2. D

3. B

eware of not to touch the DC motor inattentively (Do not rotate the motor).

4. I

nstall the Motor-Fan ④ by combining the arrow indicating Fan flowing direction and the arrow

direction that is incused on the Fan-Lower.

5. B

eware of not to deform the thermistor while replacing the Fuser-Assy.

6. W

hile removing or installing FAN, do not press impeller of the FAN as shown by the following photo.

In case of the impeller unfastened by mistake, do not reuse it and install a new FAN.

Impera

43984801TH Rev.1

51 /

Page 52

Oki Data CONFIDENTIAL

①

③

④

⑤

②

⑥

⑦

❽

Connector for Thermistor

Connector for FAN

Arrow

High voltage

power board

3. Parts replacement

Thermistor

43984801TH Rev.1

52 /

Page 53

Oki Data CONFIDENTIAL

❹

①

❺

②

③

②

Supprting point

Plunger

3.3.15 Rear-Cover-Assy

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Cover-Side-R. Remove Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove Cover-Face Up-A

of Rear-Cover-Assy.

(5) R

emove the 2 screws (Black) ②. Remove Plate-Solenoid ③.

(6) R

emove Solenoid ❹ from Rear-Cover-Assy ❺.

Bec

(7) Remove Rear-Cover-Assy by bowing down the supporting point part of Rear-Cover-Assy to the inner

(8) I

ause the plunger is not fixed, beware of not to drop or lose it.

side.

nstalling is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

bout the installing of Rear-Cover-Assy ❺, remove Cover-Face Up-A ①, make the supporting

2. A

point part to a bowed situation and then perform installing.

3. Parts replacement

from the supporting point with opening the right side supporting point part

①

43984801TH Rev.1

53 /

Page 54

Oki Data CONFIDENTIAL

Plate-Braket-Motor

A

②

②

③

①

④

Supporting point

3.3.16 Frame-Assy-Lower

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Cover-Side-R. Remove Cover-Side-L. (Refer to 3.3.3/3.3.4)

(4) Remove CU Board. (Refer to 3.3.5)

(5) Remove Motor-DC-Main. (Refer to 3.3.6)

(6) Remove Piece-Guide

(7) Remove the 3 screw (Silver)

(8) Pass the connector of Low Voltage Power Board through the Portion A of Plate-Bracket-Motor from

above to the downward.

(9)

Remove OPE Cover-Assy. (Refer 3.3.7)

(10) Remove MPT-Assy. (Refer to 3.3.9)

(11) Remove Front-Guide-Assy. (Refer to 3.3.10)

(12) Remove Roller-Assy-Feed. (Refer to 3.3.11)

(13) Remove Guide-Paper-Duplex. (Refer to 3.3.12)

(14) Remove Stacker-Cover-Assy. (Refer to 3.3.13)

(15) Remove Fuser-Assy. (Refer to 3.3.14)

(16) Remove Rear-Cover-Assy. (Refer to 3.3.15)

) Remove all the cable from Hook A of Holder-SNS, extend them and put on the right front side of the

(17

printer.

(18) Remove connector B from high voltage power board.

(19) Remove the 4 long screws (Silver)

(20) Remove Hook C and Hook D of Plate-Base-PCB using minus driver.

(21) Remove Frame-Assy-Lower

(22) Installing is performed by the inverse procedure with removing.

3. Parts replacement

.

and screw (Black) . Remove Plate-Shield-CU .

, the 4 screws (Black) , the short screw (Silver) .

.

(Note on removing / installing)

1

eware of not to touch the DC motor inattentively (Do not rotate motor).

. B

bout the installing of Rear-Cover-Assy

2. A

point part to a bowed situation and then perform installing.

3. While installing Frame-Assy-Lower

Frame-Assy-Lower and Plate-Base-PCB.

, remove Cover-Face Up-A , make the supporting

, beware of not to tuck Cable Ⓕ and Cable Ⓖ between

43984801TH Rev.1

54 /

Page 55

Oki Data CONFIDENTIAL

Hook Ⓐ

Hook Ⓓ

Cable Ⓔ

Cable Ⓕ

Connector Ⓑ

②

❹

②

③

②

①

②

Attention to

wire interwining

Attention to

wire interwining

High voltage

power board

Plate-Base-PCB

Hook Ⓒ

Cable G

3. Parts replacement

Hook C

Hook D

43984801TH Rev.1

55 /

Page 56

Oki Data CONFIDENTIAL

Short plug connector

100/120V Printer : Installation

230V Printer : De-installation rejection

Guide-Cassette-L

Plate-Base-PCB

PCB-Assy

Earth wire

①

❼

⑥

④

②

③

❺

⑥

Warning

3.3.17 High voltage / Low voltage power board

There is a risk of electric shock during replacement of the low voltage power supply.

Use insulating gloves or avoid direct contact with any conducting part of the power supply, and caution should be

exercised during replacement.

The capacitor may take one minute to complete discharge after the AC cord is unplugged. Also, there is a possibility

that the capacitor doesn’t discharge because of a breakage of the PCB, etc., so remember the possibility of electric

shock to avoid electric shock.

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Frame-Assy-Lower. (Refer to 3.3.16)

(4) Remove the big screw (Silver)

(5) R

emove the AC socket ② and power switch ③. Remove Guide-Cassette-L.

(6) R

emove the 3 small screws (Silver) ④. Remove Low voltage power board ❺.

(7) R

emove the 4 small screws (Silver) ⑥. Remove High voltage power board ❼.

(8) I

nstalling is performed by the inverse procedure with removing.

Risk of Electric Shock

. Remove the earth wire.

①

3. Parts replacement

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

2. Do not apply excessive pressure to the power switch ③.

3. W

hile installing High voltage / Low voltage power board to the Plate-Base-PCB, do not deform the

Plate-Base-PCB.

Pay attention not

to scratch the FFC.

Pay atte ntio n to the

bending direction as

the text printed side up.

43984801TH Rev.1

56 /

Page 57

Oki Data CONFIDENTIAL

Frame-Assy-Lower

Gear-Idle-Drum-Z27-82

Gear-Idle-Drum-Z24-48

①

②

3.3.18 Plate-Bracket-Motor

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Motor-DC-Main. (Refer to 3.3.6)

(4) Remove Frame-Assy-Lower. (Refer to 3.3.16)

(5) Assemble Frame-Assy-Lower as the diagram.

(6) Remove the 4 screws (Black)

(7) I

nstalling is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

hile installing beware of not to tuck Cable between Frame-Assy-Lower and Plate-Bracket-Motor.

2. W

3. B

eware of not to drop the gear or scratch the surface of gear.

4. B

ecause Gear-Idle-Drum-Z24-48 and Gear-Idle-Drum-Z27-82 are high precision gear, beware of

handling them with particular care.

. Remove Plate-Bracket-Motor ②.

①

3. Parts replacement

43984801TH Rev.1

57 /

Page 58

Oki Data CONFIDENTIAL

View A

View A

①

②

③

④

❺

⑦

❽

❽

❾

❿

❿

❻

❻

⑦

❾

Contact

3.3.19 Roller-Back up

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Frame-Assy-Lower. (Refer to 3.3.16)

(4) Remove Plate-Bracket-Motor. (Refer to 3.3.18)

(5) Remove the screw (Black)

emove Lever-Reset-R ④.

(6) R

(7) L

ift up Roller-Back up ❺ and remove it. (At this moment, 2 of Holder-BU ❻, Spring-Bias (Back up) ⑦,

Bearing-Ball ❽, and Washer-C ❾ are also removed.)

(8) R

emove color ❿ that are attached on both tops of the shaft of Roller-Back up ❺.

(Note on removing / installing)

1

eware of not to touch the DC motor inattentively (Do not rotate motor).

. B

hile installing Washer-C ❾, confirm it existing between contact and Holder-BU ❻. (Refer to View A)

2. W

. Remove the screw (Color) ② and Lever-Reset-L ③.

①

3. Parts replacement

43984801TH Rev.1

58 /

Page 59

Oki Data CONFIDENTIAL

⑤

❻

⑦

⑦

①

❷

③

❹

⑪

⑬

⑨

❿

⑧

⑫

3.3.20 Roller-Resist

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Frame-Assy-Lower. (Refer to 3.3.16)

(4) Remove Plate-Bracket-Motor. (Refer to 3.3.18)

(5) Remove the E ring

emove the lock of Gear-Resist ⑤. Remove Gear-Resist ⑤, Bearing-Resist-Assy

(6) R

(7) L

ift up the left side of Roller-Resist-Assy ⑦ and remove it at the arrow direction.

(8) R

emove the lock of Gear-Pressure ⑧. Remove Gear-Pressure⑧ from Roller-Pressure

(9) R

emove Plate-Contact-PA ⑪ and Holder-Resist from Roller-Resist

Rem

(10

(Note on removing / installing)

1. B

ove Holder-Resist

) Installing is performed by the inverse procedure with removing.

eware of not to touch the DC motor inattentively (Do not rotate motor).

3. Parts replacement

. Remove the Gear-Assy-Clutch ❷, Spacer-Clutch ③ and Bearing-R ❹.

①

❻.

⑨.

❿ .

⑬ .

43984801TH Rev.1

59 /

Page 60

Oki Data CONFIDENTIAL

❶

❶

❸

❷

❶

(Paper)

(Entrance)

Clamp

3.3.21 Lever-In-Sensor

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Frame-Assy-Lower. (Refer to 3.3.16)

(4) Remove the 2 Lever-In-Sensor (Entrance and Paper). Press the Clamp of

as up direction and then remove them. While remove Lever-In-Sensor ❶, beware of not to loss or break

Spring-Sensor-In

(5) I

nstalling is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

Spring-Write-Sensor

❷ ,

❸ .

3. Parts replacement

, press Lever-In-Sensor ①

❶

43984801TH Rev.1

60 /

Page 61

Oki Data CONFIDENTIAL

❷

❶

③

③

❶

Frame-Assy-Lower

Frame-Assy-Lower

Clamp

3.2.22 Lever-Eject-Sensor/Photo-Interrupter

(1) Open Rear-Cover-Assy.

(2) Open Stacker-Cover-Assy.

(3) Remove Frame-Assy-Lower. (Refer to 3.3.16)

(4) Press the clamp of Lever-Eject-Sensor

remove it. While remove Lever-Eject-Sensor ❶, beware of not to loss or break Spring-SNS❷.

(5) P

ress the claw of Frame-Assy-Lower as the arrow direction. Remove Photo-Interrupter ③ by down

direction.

(6

) Installing is performed by the inverse procedure with removing.

(Note on removing / installing)

eware of not to touch the DC motor inattentively (Do not rotate motor).

1. B

3. Parts replacement

Exit)❶ . Press Lever-Eject-Sensor ❶ as down direction and

(