Page 1

OKIPAGE8

p

LED Page Printer

Troubleshooting Manual

with Component Parts List

(ODA/OEL/INT)

All specifications are subject to change without notice.

Page 2

CONTENTS

1. OUTLINE..................................................................................................... 1

2. TOOLS........................................................................................................ 1

3. CIRCUIT DESCRIPTION............................................................................ 2

3.1 Outline ..................................................................................................................... 2

3.2 CPU and Memory .................................................................................................... 4

3.3 Reset Control........................................................................................................... 6

3.4 EEPROM Control..................................................................................................... 7

3.5 Centronics Parallel Interface.................................................................................... 8

3.6 Front Operator Panel ............................................................................................... 9

3.7 LED Head Control ................................................................................................. 10

3.8 Motor and clutch control ........................................................................................ 12

3.9 Fuser Temperature Control.................................................................................... 14

3.10 Sensor Control....................................................................................................... 17

3.11 Cover Open ........................................................................................................... 18

3.12 Power Supply Part ................................................................................................. 19

4. TROUBLESHOOTING.............................................................................. 21

4.1 Troubleshooting T able ............................................................................................ 21

4.2 Troubleshooting Flowchart..................................................................................... 23

5. CIRCUIT DIAGRAM.................................................................................. 27

6. COMPONENT PARTS LIST

Page 3

1. OUTLINE

This manual has been written to provide guidance for troubleshooting of the OKIPAGE8p Printer

(primarily for its printed circuit boards), on an assumption that the reader is knowledgeable of the

printer. Read the maintenance manual for this printer if necessary.

Note:

1. High voltage power supply board and power supply unit containing a high voltage power

supply is dangerous. From the viewpoint of the safety standards, the local repairing of a

defective board is not allowed. Thus, the objects to be locally repaired as a result of

troubleshooting are switches.

2. TOOLS

For troubleshooting the printer, the tools listed below may be needed in addition to general

maintenance tools.

Oscilloscope Frequency response 100 MHz or higher

Soldering iron A slender tip type, 15-20 watts

Tool Remarks

- 1 -

Page 4

3. CIRCUIT DESCRIPTION

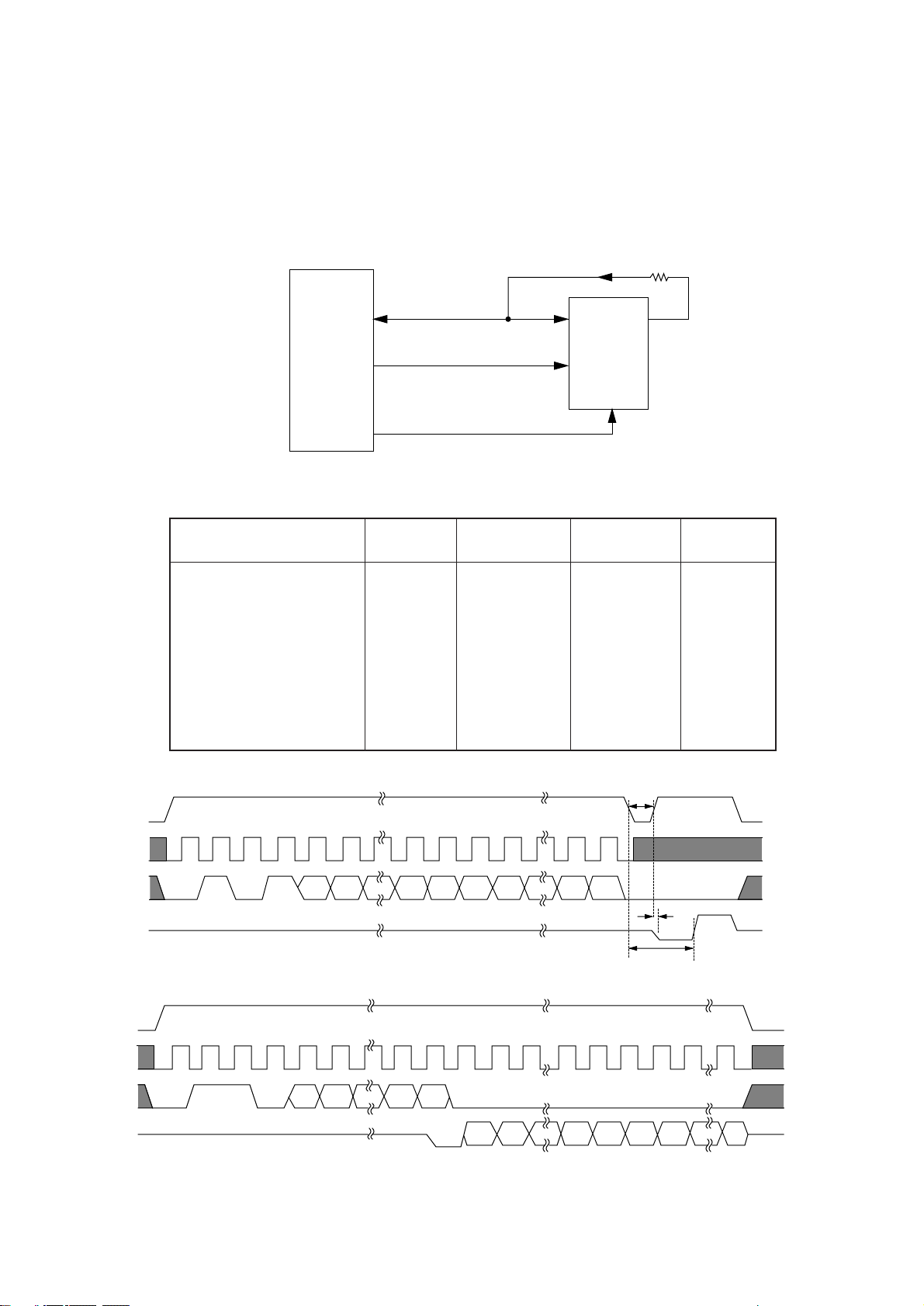

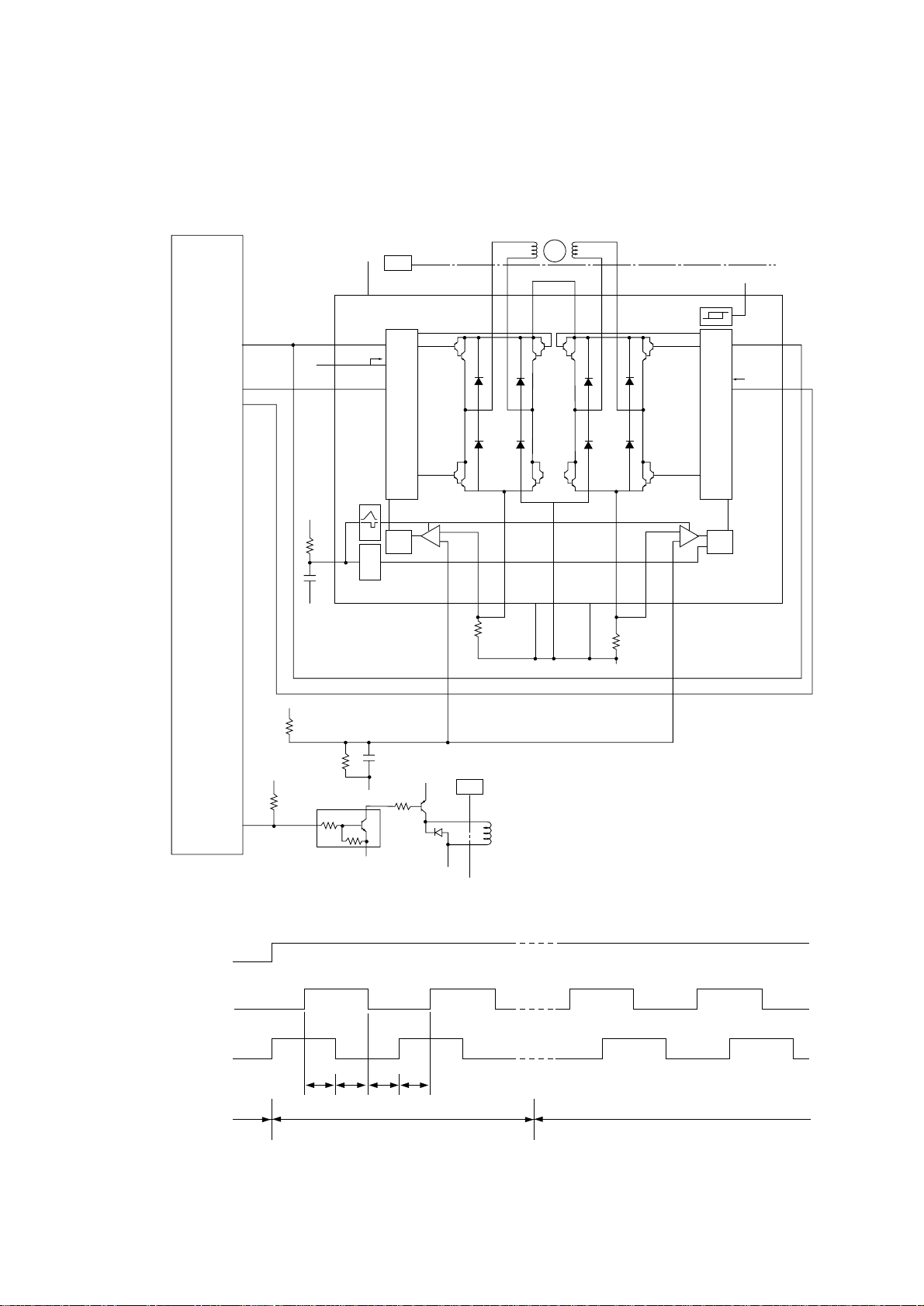

3.1 Outline

The circuit of OKIPAGE8p consists of a main control board, a main high voltage power supply

board, a sub-high voltage power supply board and a power supply unit. The block diagram is

shown in Fig. 3-1. The main control board controls the reception and transmission of data with

a host I/f and processes command analysis, bit image development, raster buffer read. It also

controls the engine and high voltage outputs.

(1) Reception control

The main control board has one parallel I/F port which is compliant to the IEEE 1284

specification.

The parallel I/F port can specify the following item when set by the control panel:

I-PRIME: Enabled/ Disabled

(2) Command analysis processing

The OKIPAGE8p printers support PCL5e (Hewlett Packard LJ6P compatible).

An edit task fetches data from the receive buffer, analizes commands, and reconstructs the

data in such a way that print data are aligned from up to down and from right to left; then it

writes the resultant data into a page buffer with such control data as print position coordinate,

font type, etc. added.

(3) Font Processing

When one page editing is finished, a developing task makes an engine start and fetches data

from the page buffer synchronizing with a printing operation; then it developes the fetched

data to a bit map as referring to data from a character generator, and writes the resultant data

into the raster buffer (of band buffer structure).

(4) Raster buffer read

As controlling the engine operation, an engine task sends data from the raster buffer to the

LED head.

(5) High voltage control (main, sub)

The high voltage control circuit in the CPU.

The high voltage power supply board generates high voltage outputs, and have sensors, LED for

display.

The power supply unit generates +26VDC output, +5DC output.

- 2 -

Page 5

PLUNGER LED HEAD

Motor

M

- 3 -

HEAD2HEAD1PJ

Figure 3-1 OKIPAGE8p Block Diagram

Parallel

I/F

CENT

LS07

+5V+26V

POWER

MOTOR Main PCB NMA-

0V5V

0VP0V

Motor Driver

MTD2005F

CPU

(NKK3 or 5)

Data Bus

Address Bus

OSC

7MHz

RST

EEPROM

Serial I/F

(x16)

LC26023A

1kb

OSC

10MHz

LSI

HIVOL

DRAM 2MB

M-ROM

4M x 16

Mask ROM 8MB

HC244

HIVOL2

Red

Amber

Amber

DRAM

1M x 16

0V

OPTION

O

P

T

I

O

N

PCB N4A-

DRAM

1M x 16

DRAM 4MB

Power Supply Unit

AC

(120V/ 230V)

Heater

(Halogen lamp)

High Voltage Power Unit

P2H

High Voltage Power Unit

P6L

ID Unit

Page 6

3.2 CPU and Memory

(1) CPU (NKK3 or NKK5)

CPU core RISC CPU (MIPS R3000)

CPU clock 7.067 MHz, Internal CPU CLK 28.268 MHz

Data bus width External 16 bits, Internal 32 bits

(2) Program ROM

ROM capacity 8M-bytes (Mask ROM)

ROM type 64Mbits (4M x 16 bits)

Access time 100 nsec

(3) Resident RAM

RAM capacity 2M bytes (1Mx 16 bits)

RAM type 16M bits (1M x 16 bits)

Access time 60 ns

(4) Option Board

RAM capacity 4M bytes (16M bits D-RAM two pieces)

RAM type 16M bits D-RAM two pieces

Access time 60 n

The block diagram of CPU and memory circuit is shown in Fig. 3-2.

- 4 -

Page 7

CPU

CS0

RAS0

RAS1

RAS2

A00 to A25

D00 to D15

CS0

Mask ROM

(4M x 16 bits)

<Program>

RD

CAS0

CAS1

RAS0

RD/WR

CAS0, 1

RAS1, 2CAS0, 1 WR

RAS1, 2 WR

CAS0,1

DRAM

(1M x 16 bits)

Main

control

board

Option

board

DRAM

4M Byte

Figure 3-2 Block Diagram of CPU & Memory in OKIPAGE8p

- 5 -

Page 8

3.3 Reset Control

When power is turned on, RST-N signal is generated by RST.

+5V+5V

+5V

Power ON

RST

1

3

2

Power OFF

172

CPU

RSTN

CL RST-N

- 6 -

Page 9

3.4 EEPROM Control

The BR93LC46A on the main control board is an electrical erasable/programmable ROM of 64bit x 16-bit configuration. Data input to and output from the ROM are bidirectionally transferred

in units of 16 bits through I/O port (EEPRMDT-P) in serial transmission synchronized with a clock

signal from the CPU.

The EEPROM operates in the following instruction modes.

Instruction Start bit Operation Address Data

Read (READ) 1 10 A5 to A0

Write Enabled (WEN) 1 00 11XXXX

Write (WRITE) 1 01 A5 to A0 D15 to D0

CPU

154

150

151

SSTXD-P

EEPRMCSO-P

EEPRMCLK-P

code

3

DI DO

EEPROM

1

CS

IC4

4

SK

2

CS

SK

DI

CS

SK

DI

DO

Write All Address (WRAL) 1 00 01XXXX D15 to D0

Write Disabled (WDS) 1 00 00XXXX

Erase 1 11 A5 to A0

Chip Erasable (ERAL) 1 00 10XXXX

Write cycle timing (WRITE)

1 2 4 9 10 25

10 1

HIGH-Z

A5 A4 A1 A0 D15

D14

D1 D0

Min. 450 ns

STATUS

Max. 500 ns

BUSY READY

Max. 10 ms

Read cycle timing (READ)

12

110

4

A5 A4 A1 A0

910

25 26

DO

HIGH-Z

D15 D14 D1 D00 D15 D14

- 7 -

Page 10

3.5 Centronics Parallel Interface

The CPU sets a BUSY-P signal to ON at the same time when it reads the parallel data (PDATA1P to PDATA 8-P) from the parallel port at the fall of PSTB-N signal. Furthermore, it makes the store

processing of received data into a receive buffer terminate within a certain fixed time and outputs

an ACK-N signal, setting the BUSY-P signal to OFF.

87, 88, 91 to 96

97

85

86

CPU

83

81

79

80

82

84

PDATA1-P to PDATA8-P

PSTB-N

Q4

PBUSY-P

PACK-N

PRE-P

PSEL-P

PERROR-P

PINIT-N

PSELIN-N

PALITOFD-N

2 to 9

1

11

10

12

13

32

31

36

14

CENT

DATA8-P

to

DATA1-P

STB-N

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFEED-N

PARALLEL DATA

(DATA BITs 1 to 8)

DATA STOROBE

BUSY

ACKNOWLEDGE

0.5 µs min.

0.5 µs min.

0.5 µs max.

0 min.

0.5 µs to 10 µs

+5V+5V or High Level

18

0.5 µs min.

0.5 µs min.

0 min.

0 min.

0 min.

- 8 -

Page 11

3.6 Front Operator Panel

Front operator panel have three LED lamps and a switch on the main control board which is

connected to by the CPU.

The light from the LED lamp can be seen on the Lens Cover through the LED Lens.

5V

CPU

110

5V

Ready (Amber)

114

Manual Feed (Amber)

113

Error (Red)

161

- 9 -

0V

Page 12

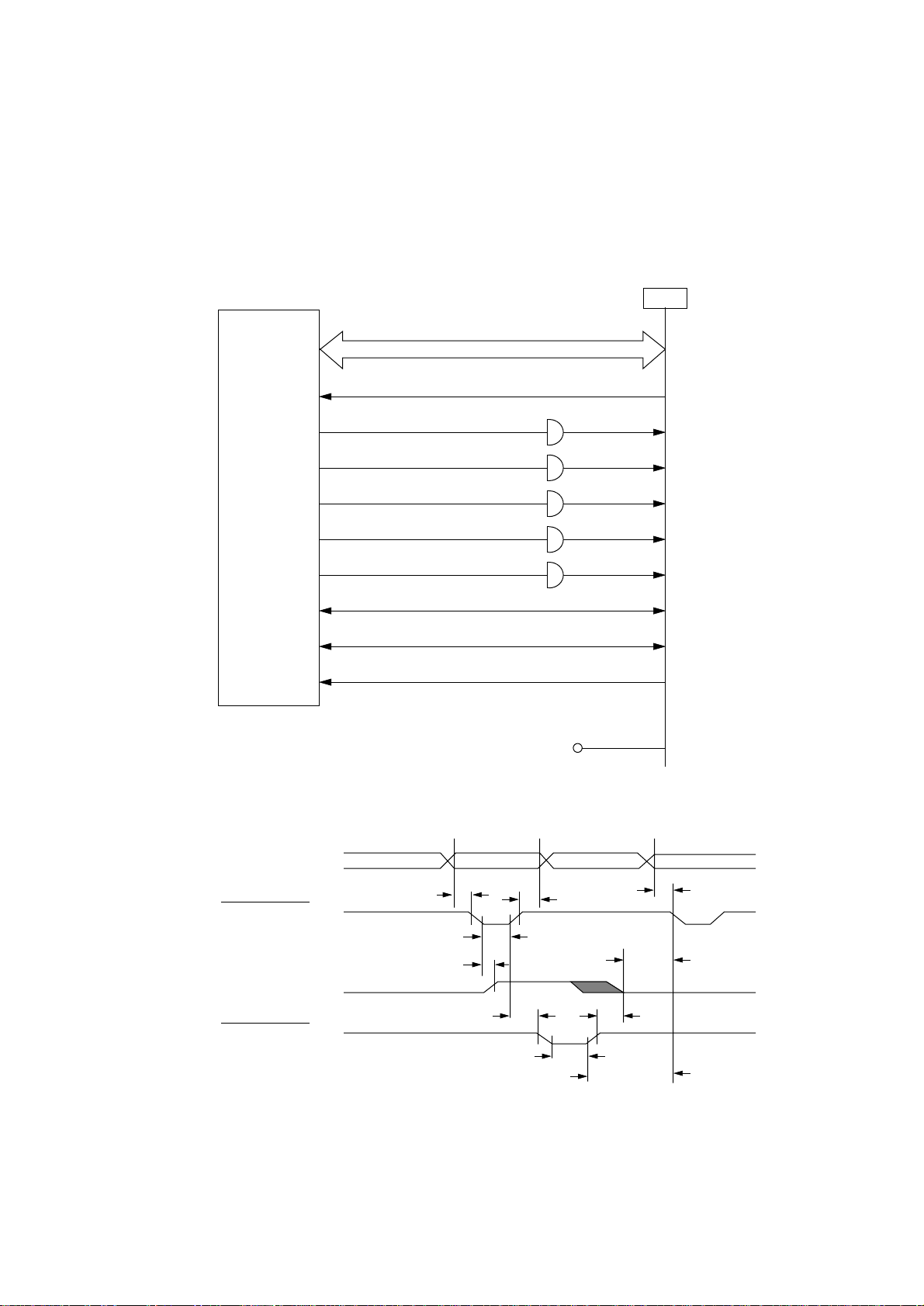

3.7 LED Head Control

An LED correcting head, which is capable of correcting the illumination of the LED for each dot,

is being used in this printer. LED illumination correction function of 16 steps is carried out by using

an EEPROM which is installed in the LSI that maintains the LED illumination correction values,

and an LED correction drivers (MSM6731BWAF or MSM6732BWAF) together as a pair.

The LED correcting head consists of the correction control LSI (MSM6730WAF), LED drivers

(MSM6731BWAF or MSM6732BWAF), and an LED array.

From

CPU

STRB1-N

STRB2-N

STRB3-N

STRB4-N

LOADI

CLOCKI

DATAI0

DATAI1

DATAI2

DATAI3

MSM6730

WAF

EEPROM

Correction

Values

LED Driver

MSM6732BWAF

LED Array

LED LED LED LED LED LED LED

LED Driver

MSM6731BWAF

Printing and correction data combined signal line

Correction data signal line

LED Driver

MSM6731BWAF

LED Driver

MSM6732BWAF

- 10 -

Page 13

CLOCKI

LOADI

DATAI3~0

STRB1I-N

STRB2I-N

STRB3I-N

STRB4I-N

Normal Mode Printing Timing Chart

First line printing data sent Second line printing data sent

First line printing

The printing operation is carried out in the following sequence. First, the printing data DATAI3

through DATAI0 are stored, sequentially shifted, in the shift registers of the LED drivers, by the

printing data synchronous clock, CLOCKI. Then the printing data stored in shift registers are

latched by the high level pulse of LOADI. The latched printing data turns the LEDs on by STRB1IN through STRB4I-N and actuates printing.

- 11 -

Page 14

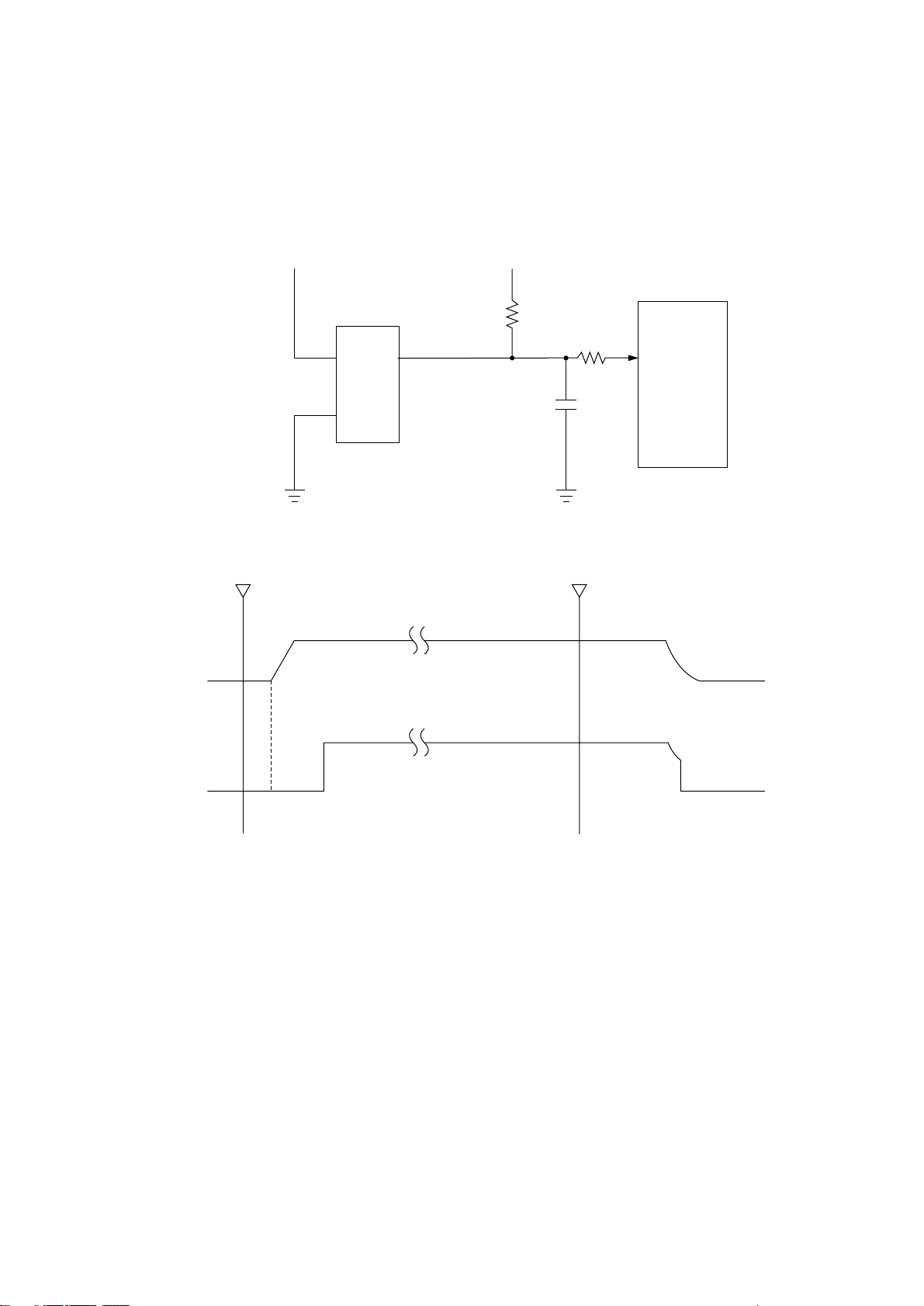

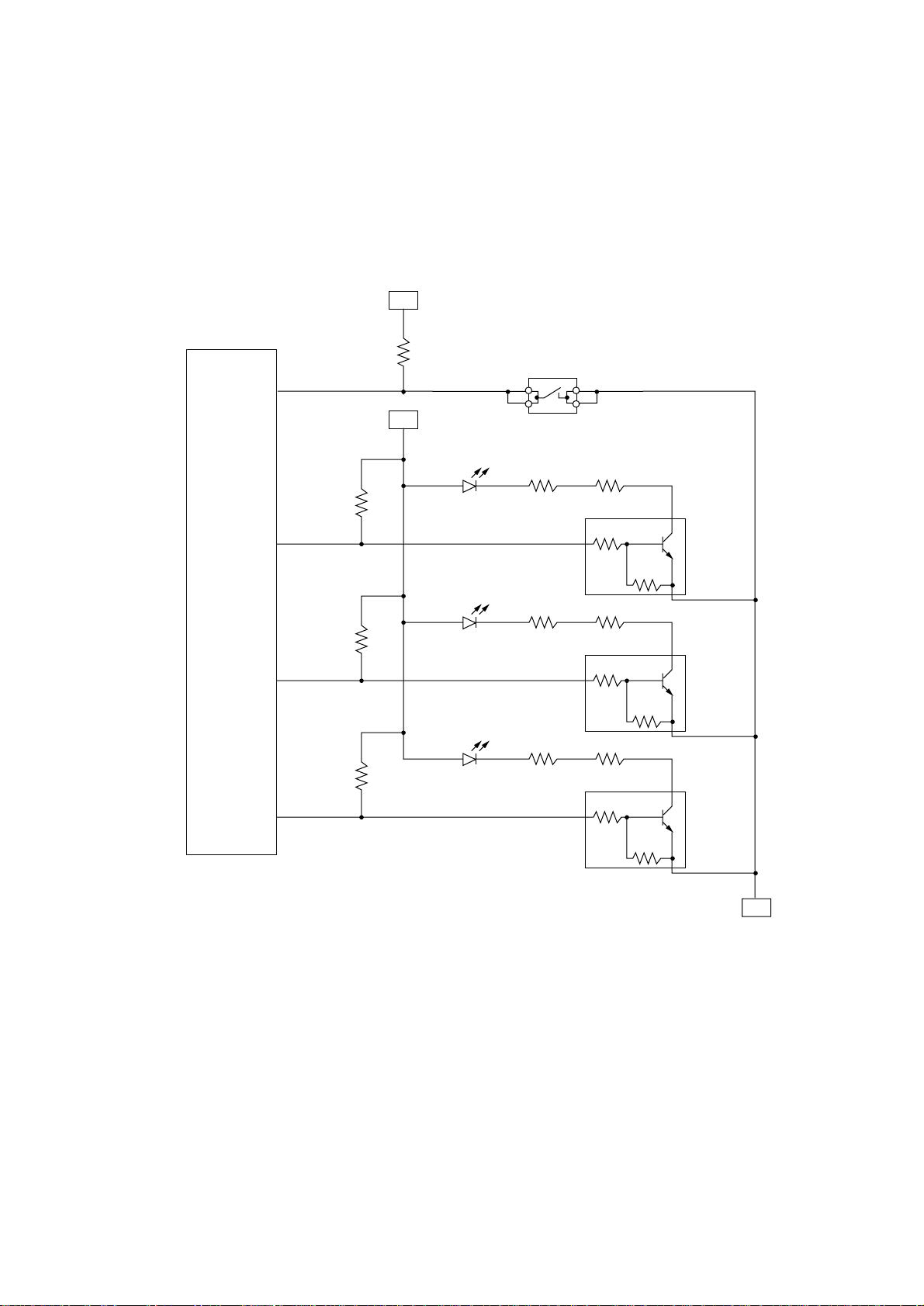

3.8 Motor and clutch control

The electromagnetic clutch is driven by a control signal from the CPU and the drive circuit shown

below.

The main motor is driven by the control signals from the CPU and the driver IC.

CPU

DMON1N

DMPH1P

DMPH2P

127

132

131

MTDV

+5V

+5V

ENA A

27

To Out3, 4Logic

18

DECAY

26

PHASE A PHASE B

Motor

19

Out1

SW1 SW3

GATE CIRCUIT

M

Main Motor

+26V OPEN

37 1 1412 24

Out2 Out3

8

Out4Vmm A Vmm B

ALARM

120°C 140°C

ENA B

SW1 SW3

GATE CIRCUIT

Signal of

DECACY

16

17

+5V +26V

RMONN

128

(1) Main motor

+5V

+5V

0V

25

BRUNK

0V

0V

SW4SW2

Current

Q

-

R

+

S

Sensor

OSC

Vref A Vref B

Vs A Vs BRs A Rs BLG A PG LG B

23 22 28 15 10 21 20TAB5

PJ

Electromagnetic clutch

0VP

0V

SW4SW2

Current

Sensor

RQ

+

S

DMON-P

DMPH1-P

DMPH2-P

Rotation

T0 T1 T2 T3

Forward rotation

Reverse rotationStop

Operation at normal speed: T0 to T3 = 0.781 ms

- 12 -

Page 15

(2) Motor drive control

Time T0 to T3 determines the motor speed, while the phase different direction between

phase signals DMPH1-P and DMPH2-P determines the rotation direction. DMON-N signal

control a motor coil current. According to the polarity of the phase signal, the coil current flow

as follows:

1) +26V → SW1 → motor coil → SW4 → resistor → earth

2) +26V → SW3 → motor coil → SW2 → resistor → earth

The drop voltage across the resistor is input to comparator, where it is compared with a

reference voltage. If an overcurrent flows, a limiter operates to maintain it within a certain

fixed current.

(3) Electromagnetic clutch control

Mechanical operation mode is switched by the combination of the clutch status and the

direction of motor rotation.

clutch status

off

off

on

on

rotation direction

Forward

Reverse

Forward

Reverse

operation mode

cleaning

Hopping from manual

feed slot

illegal operation

Hopping from tray

- 13 -

Page 16

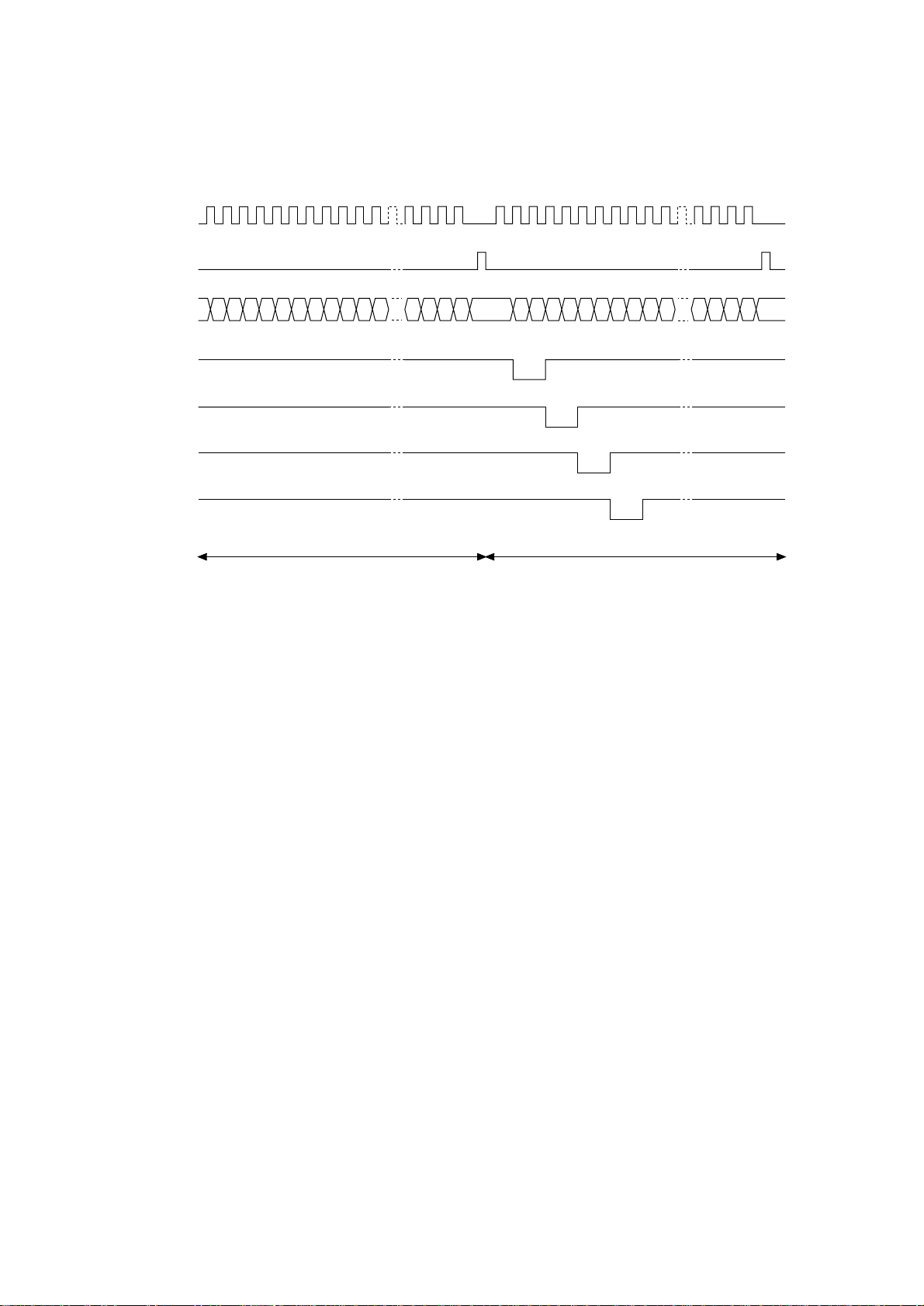

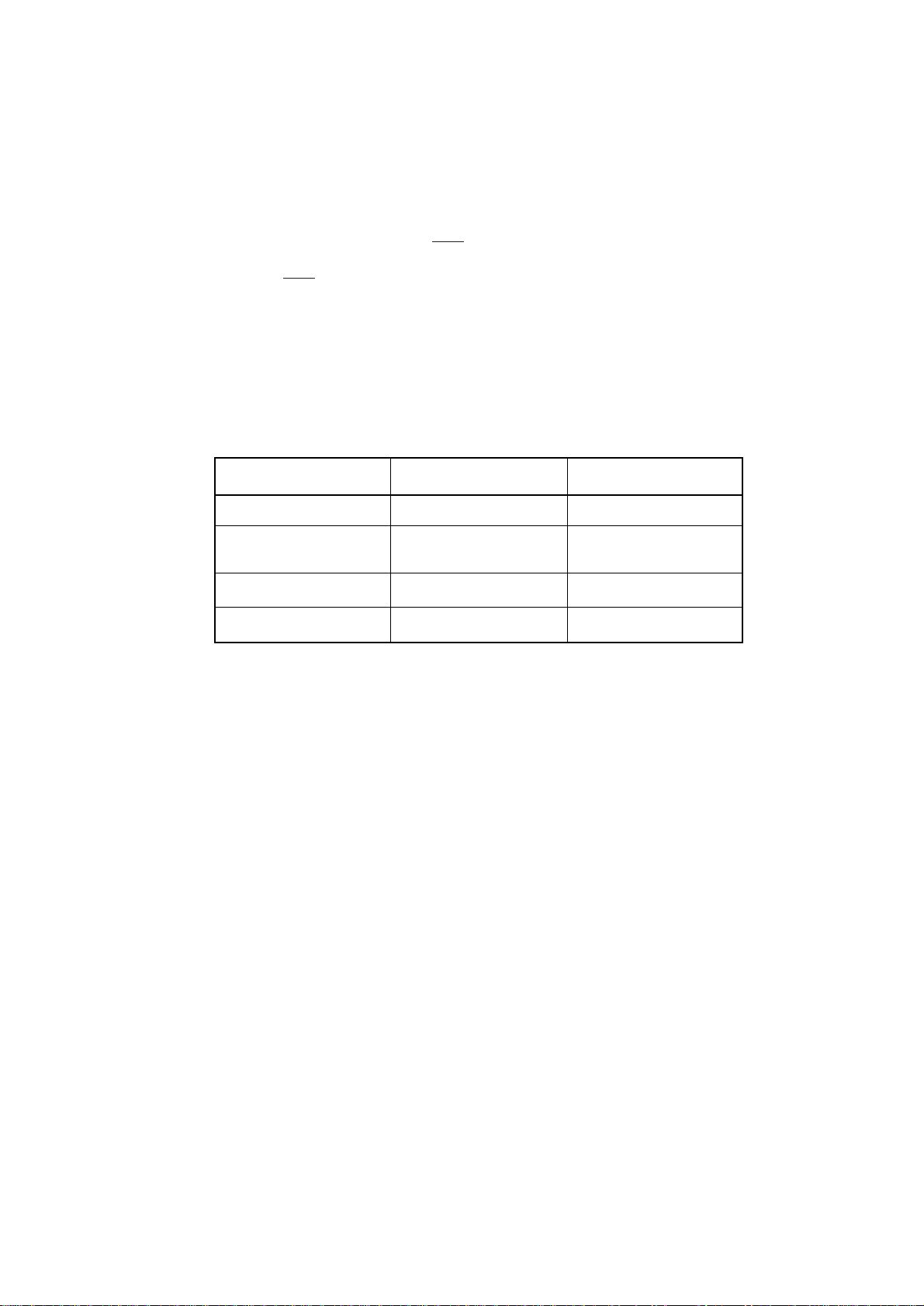

3.9 Fuser Temperature Control

For the temperature control by heater control, the variation in the resistance of the thermistor is

A/D converted in LSI and the resultant digital value is read and transferred to the CPU. The CPU

turns on or off the HTON-N signal according to the value of the signal received from LSI to keep

the temperature at a constant level.

Immediately after the power is turned on, the thermistor is checked for shortcircuit and

breakdown. If the thermistor is shorted, the A/D converted value shows an abnormally high

temperature, so that the shortcircuit can be detected. If the breakdown of the thermistor occurs,

the A/D converted value shows the normal temperature. In this case, the thermistor breakdown

can be detected by the sequence shown at the end of this section. If the heater is overheated,

5V supply is turned off when the resistance of the thermistor is detected to be exceeding the

predetermined value.

Main Control BoardHigh Voltage Power Supply Board

CN2

Thermistor

Heater

TH1

TH2

5V

Power Supply Unit

CN1

1

2 PC1

5V

36

8

ACIN

LSI CPU

Abnormally

High

Temperature

Detection

Circuit

HTON

116

Shutdown

5V

Circuit

Q3

0C

5V

13

Q3

0C

14

- 14 -

Page 17

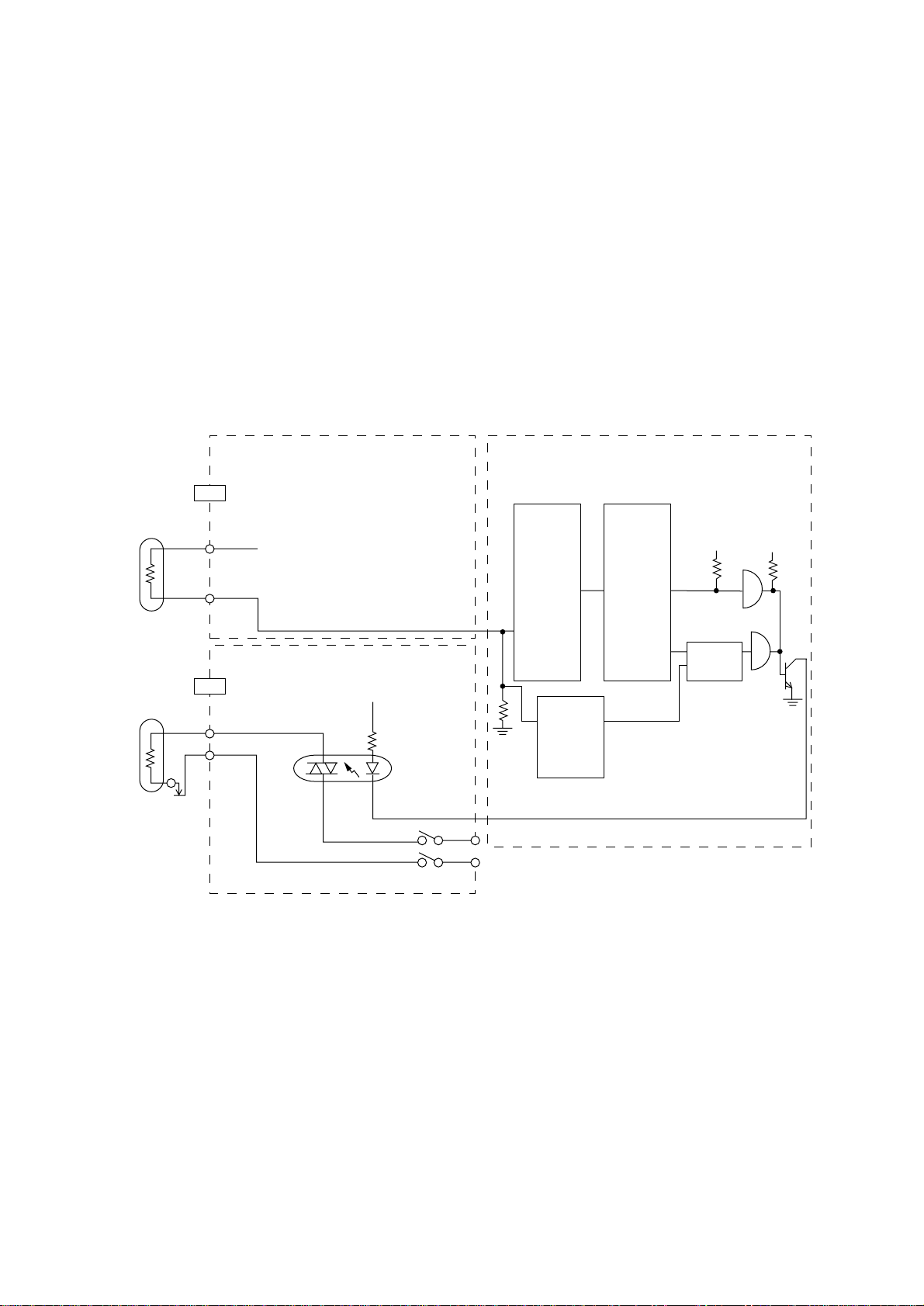

Flowchart of Thermistor Circuit Check

START

HEATER OFF

Short check timer(t16)set

No

Time-out ?

Short error TEMP ?

Thermistor error check

timer (t2) set

Thermistor disconnection

check timer (t35) set

Heater On

Temperature > Tn

Thermistor

error check timer (t2)

within time

No

No

Yes

Yes

Yes

Thermistor short error

End

Yes

To constant

temperature control

No

Fuser error

Thermistor

disconnection check timer

(t35) within time

Yes

t2 =

90 sec

t16 =

520 msec

t35 =

10 sec

No

A/D value changed?

Yes

Thermistor

disconnection error

End

- 15 -

No

Thermistor gain change

(THERMCMP-N"0" "Z")

No

A/D value more than

End

20H?

Yes

Fuser error

End

Page 18

Temperature

Controlled

Temperature

T

HEATER ON

OFF

Time

Temperature table

THERMCMP-N

O

Z

T

145˚C:

150˚C:

155˚C:

160˚C:

165˚C:

Heater control mode

Normal operation

Fuser Error Check

Paper Thickness

light

medium light

medium

medium heavy

heavy

- 16 -

Page 19

3.10 Sensor Control

The CPU supervises the state of each sensor every 40 ms.

Main Control Board High Voltage Power Supply Board

HIVOL CN1

+5V

CPU

Sensor

signal

124

120

122

123

OFF

+5V

+5V

+5V

+5V

TNRSNS-N

PSIN-N

PSOUT-N

WRSNS-N

TransparentShield

PS1

PS2

PS3

PS4

ON

- 17 -

Page 20

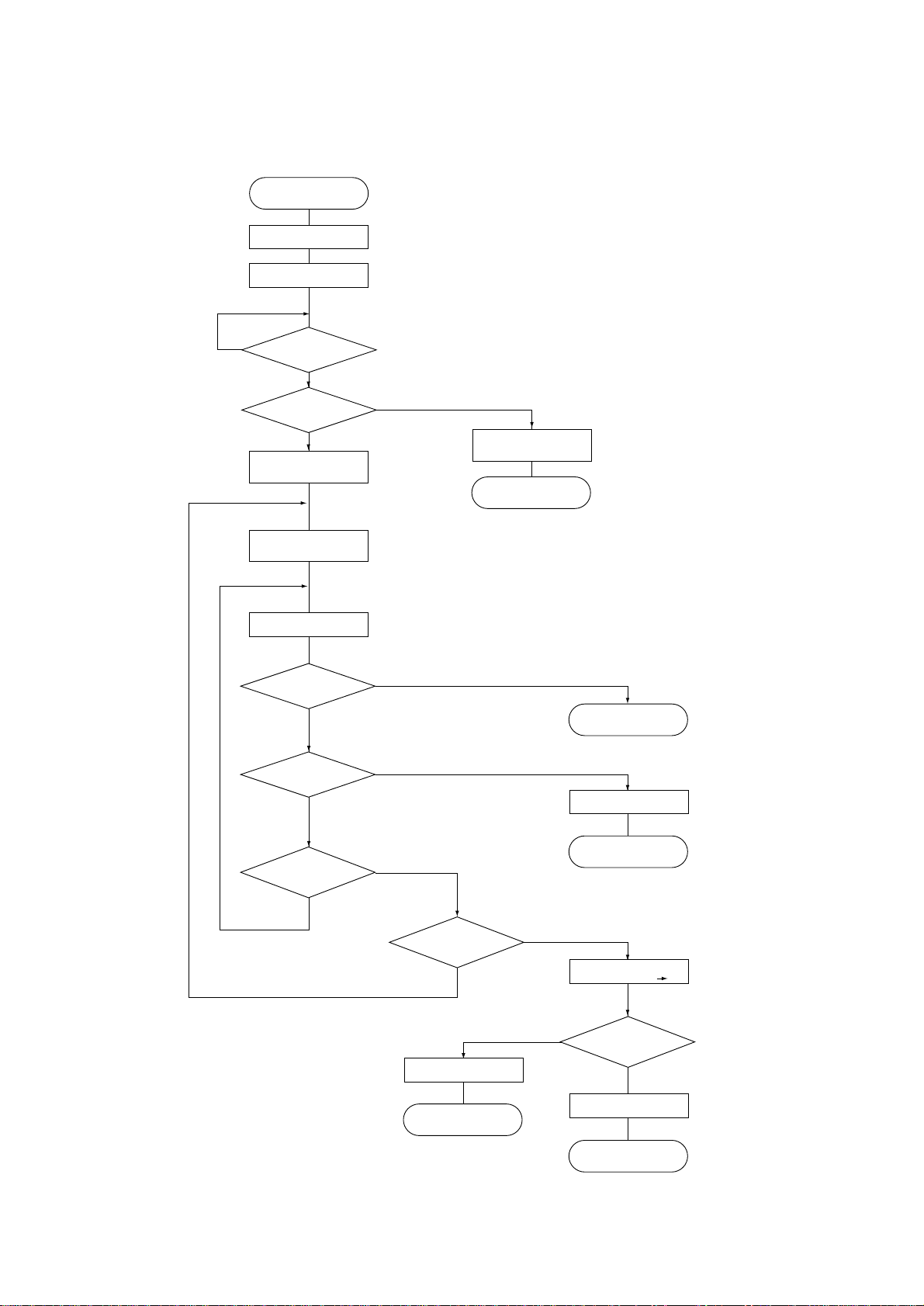

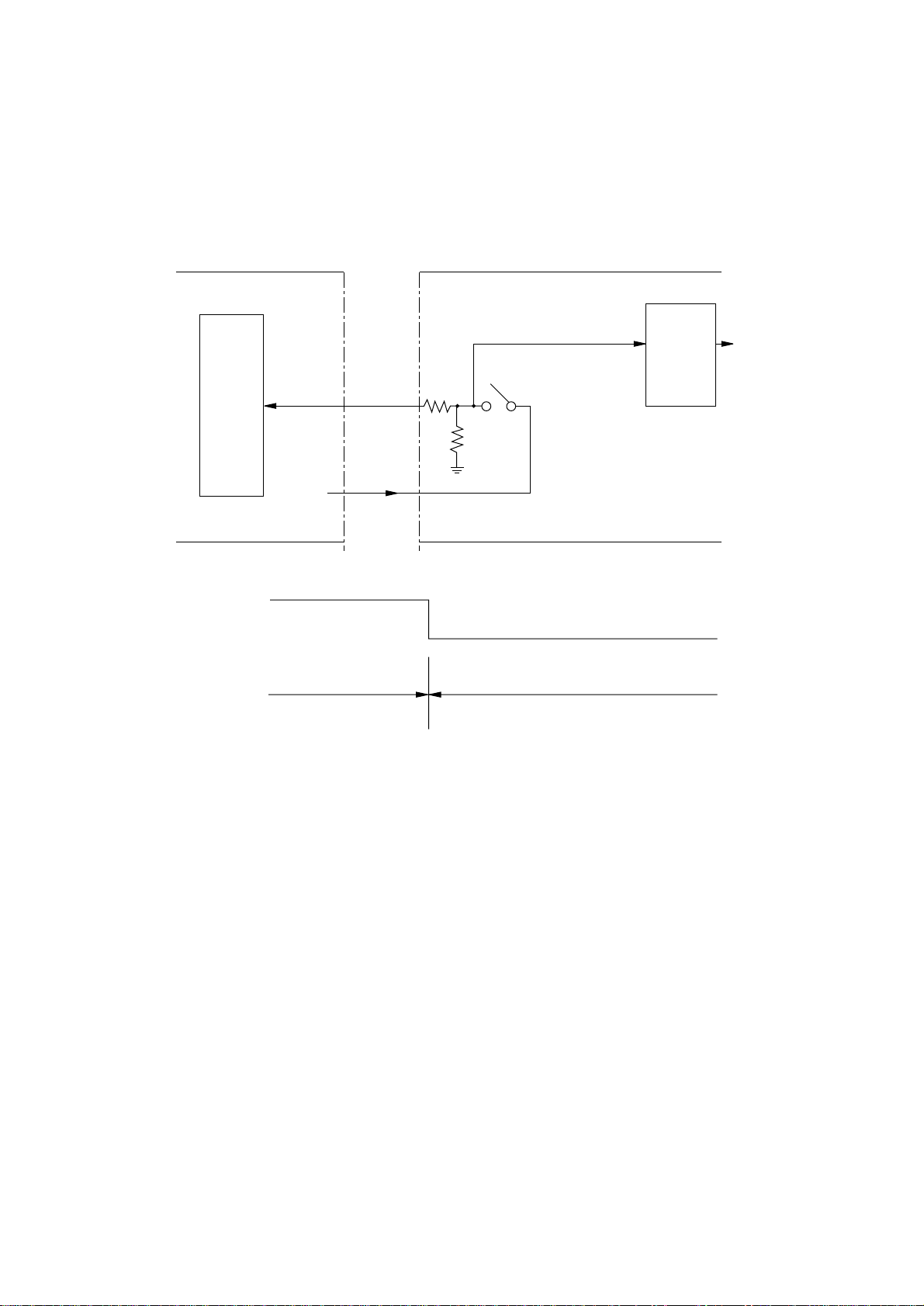

3.11 Cover Open

When the cover is opened, a cover open microswitch is opened. This makes a CVOPN-N signal

low, thereby the CPU detects that cover is open. Furthermore, opening the cover stops applying

a +5V power to the high voltage power supply part, resulting in stopping all high voltage outputs.

HIVOL CN1

Main Control Board

CVOPN-N

CPU

+5V

0V

125

Cover close Cover open

CVOPN-N

Cover

Open

Microswitch

+5V

High Voltage Power Supply Board

High

Voltage

Power

Supply

+5V

Part

High

voltage

output

- 18 -

Page 21

3.12 Power Supply Part

(1) Power supply unit

An AC power from an inlet is input to Switching Reg. part .AC power is converted to a +26

VDC output and +5 VDC output.

ACIN

F1 F2L

FG

N

Filter

Circuit

Power supply unit

+26V

+5V

0V

HEATER

Switching Reg. Part

CONTROLER

HEATON-N

to AC output

Fuse Ratings

AC Input

Fuse

F1

F2

230 V

250 V 6.3 A

250 V 2 A

120 V

125 V 8 A

250 V 2.5 A

(2) High voltage power supply board

The +5 VDC power supplied to the high voltage power supply part via the cover open

microswitch as source voltage. The high voltage power supply part supplies necessary

voltage for electro-photography print to output terminals CH, DB, SB, TR, and CB according

to a control signal from the LSI. The table on the next page shows the relationship between

control signals and high voltage outputs.

HIVOL

MainControl Board High Voltage Power Supply Board

TR1PWM

11

TR2PWM

12

CHPWM

13

DB1ENB-P

24

LSI

23

14

15

16

3

DB2ENB-P

DBPWM

CVOPN-N

+5V

CB2PWM

CB1PWM

CN1

P2H

High Voltage

Power Supply

Part

P6L

CH

DB

SB

TR

Cover Open

Microswitch

CB

- 19 -

Page 22

Control Signals and High Voltage Outputs

Control signal name Level Function

TR1PWM

TR2PWM

CHPWM

DB1ENB-P

DB2ENB-P

DBPWM-P

CB1PWM

H/L

(PWM)

L

H/L(PWM)

L

H/L(PWM)

L

H

L

H

L

H/L(PWM)

L

H/L(PWM)

L

Makes the part put out a power to TR.

+3 to 5 µA

+0.5 to 4 KV

Makes the part put out a -750V power to TR.

Makes the part put out a -1300 KV power to CH.

Makes the part put out the following power:

0V power to SB

+265V power to DB

Makes the part put out the following power:

-550V power to SB

-265V power to DB

Makes the part put out the power to SB, DB, CB.

Makes the part put out a

+400V to CB

CB2PWM

H/L(PWM)

L

Makes the part put out a -1350V to CB

- 20 -

Page 23

4. TROUBLESHOOTING

4.1 Troubleshooting Table

(A) High Voltage Power Supply Board

Note:

A malfunction of the power supply is not repaired by an agency. The abnormality to be

treated here is that of sensors only.

Failure

A paper input jams occur

frequently.

A paper feed jams occur

frequently.

A paper-exit jams occur

frequently.

A paper size errors occur

frequently.

Paper can not be fed from the

manual feed slot .

The message "COVER OPEN"

remains displayed on the PC

display.

Error(RED)

Flash2

Flash2

Flash2

Flash2

off

LED

Manual Feed

(amber)

off

off

off

off

Undefined

Ready

(amber)

off

off

off

off

off

PC Display Message

PAPER

INPUT JAM

PAPER

FEED JAM

PAPER

EXIT JAM

PAPER

SIZE ERROR

COVER OPEN

Flowchart

No.

A - 1

A - 2

A - 3

A - 4

A - 5

A - 6

The message "TONERLOW"

remains displayed on the PC

display.

The message "TONERSNS"

remains displayed on the PC

display.

Flash2 : Blinking

Flash3 : Fast Blinking

Flash2

off

Undefined

Undefined

- 21 -

Undefined

Undefined A - 8

TONER LOW

TONER SENSOR

A - 7

PROBLEM

Page 24

(B) Main Control Board

LED

Failure

Initialization error

and not restored

Program ROM

error

Resident RAM

error

EEPROM error B - 4

Fuser error Flash3 B - 5

Thermister Open

error

Error(RED)

Flash3

Flash3

Flash3

Flash3

Manual Feed

(amber)

Flash3

Flash3

Flash3

Flash3

Flash3

Ready

(amber)

Flash3

Flash3

Flash3

Flash3

Flash3

PC Display Message

ERROR 10

ERROR 30

ERROR 40

ERROR 71

ERROR 72

Flowchart

No.

B - 1

B - 2

B - 3

B - 5

Thermister Short

error

Watchdog timer

timeout occurs

frequently.

Data sent through the

Parallel I/F cannot be

received.

Flash2 : Blinking

Flash3 : Fast Blinking

Flash3

Flash2 B - 6

Flash3

Flash2

Flash3

Flash3

Flash2

Flash3

ERROR 73

ERROR 90

CONNECTION PROBLEM

B - 5

B- 7Flash3

- 22 -

Page 25

4.2 Troubleshooting Flowchart

A-1 Paper input jams occur frequently.

• Is PS4 (Write Sensor ) operating normally?

• No Replace PS4.

▼

• Yes Is Pin1 of PJ connector in main control board operating normally?

• No Replace TR501 or TR502 in main control board.

▼

• Yes Failure of CPU in main control board.

A-2 A paper feed jams occur frequently.

• Is PS4 (Write Sensor ) operating normally?

• No Replace PS4.

▼

• Yes Is PS3 (Outlet Sensor ) operating normally?

• No Replace PS3.

▼

• Yes Failure of CPU in main control board.

A-3 A paper exit jams occur frequently.

• Is PS3 (Outlet Sensor) operating normally?

• No Replace PS3.

▼

• Yes Failure of CPU in main control board.

A-4 A paper size errors occur frequently.

• Is PS4 (Write Sensor ) operating normally?

• No Replace PS4.

▼

• Yes Failure of CPU in main control board.

A-5 Paper can not be fed from manual feed slot.

• Is PS2 (Manual Feed Sensor) operating normally?

• No Replace PS2.

▼

• Yes Failure of CPU in main control board.

- 23 -

Page 26

A-6 The message “COVER OPEN” remains displayed on the PC display.

• Is CVSW (Cover Open Switch) operating normally?

• No Replace CVSW.

▼

• Yes Failure of CPU in main control board.

A-7 The message “TONERLOW” remains displayed on the PC display.

• Is PS1 (Toner Sensor) operating normally?

• No Replace PS1.

▼

• Yes Failure of CPU in main control board.

A-8 The message “TONERSNS” remains displayed on the PC display.

• Is PS1 (Toner Sensor) operating normally?

• No Replace PS1.

▼

• Yes Failure of CPU in main control board.

- 24 -

Page 27

B-1 Initialization error and not restored

• Replace ROM.

▼

• OK?

▼

• No Is the 7.065-MHz clock signal being put out to pin 3 of OCS1?

• No Replace OSC1 (CST 7.065M).

▼

• Yes Failure of CPU

B-2 Program ROM error

• Replace ROM.

B-3 Resident RAM error

• Are negative pulses being put out to Pin 14 , 30, 31 (DRAS0-N , DCSA1-N, DCAS0 N) of DRAM?

• No Failure of CPU

▼

• Yes Are the signals at pins, 2 TO 5 , 7 TO 10 , 33 TO 36, 38 TO 41

(D00-P to D15-P) of DRAM being changed?

• No Failure of CPU

▼

• Yes Replace DRAM.

B-4 EEPROM error

• Replace EEPROM.

▼

• OK?

▼

• No Failure of CPU

B-5 Fuser error/ Thermistor Open error/ Thermistor Short error

• Is the heater on?

▼

• No Is the voltage at Pin 116 (HTON-P) of CPU 5V?

• Yes Replace Q3 or TR2

▼

• No Failure of CPU

B-6 Watchdog timer timeout occurs frequently.

• Replace ROM.

▼

• OK?

▼

• No Failure of CPU

- 25 -

Page 28

B-7 Data sent through the Parallel I/F cannot be received.

• Is the signal at Pin 11 (BUSY-P) of CENT connector being at low level?

• No Is the signal at Pin 13 (BUSY-P) of Q4 (74LS07) changed as shown

below, at data reception?

ON-LINE OFF-LINE

BUSY-P Low High

• No Failure of CPU

▼

• Yes Replace Q4 (74LS07).

▼

• Yes Is the level of the signal at Pin 1 (STB-N) of CENT connector changed at data

reception?

• No Make sure of the connection of I/F cable or the operation of the h ost

computer.

▼

• Yes Are the signals at Pin 1 (PACK-N), Pin 5 (PERROR-N) of Q4 (74LS07) being

respectively at low level and high level in on-line mode?

• No Replace Q4 (74LS07).

▼

• OK?

• No

▼

• Yes Failure of CPU

- 26 -

Page 29

5. CIRCUIT DIAGRAM

Figure 5-1 ~ 5-11 Main Control PCB (NMA-) Circuit Diagram (Rev. 5)

Figure 5-12 High voltage Power Supply PCB (P2H-) Circuit Diagram (Rev.2)

Figure 5-13 High voltage Power Supply PCB (P6L-) Circuit Diagram (Rev.2)

Figure 5-14 Option memory PCB (N4A-) Circuit Diagram (Rev.2)

- 27 -

Page 30

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

2028K/ 3AR3

(1/3)

CPU

OSC2

OSC1

VDD18

VDD17

VDD16

VDD15

VDD14

VDD13

VDD12

VDD11

VDD10

VDD9

VDD8

VDD7

VDD6

VDD5

VDD4

VDD3

VDD2

VDD1

VSS19

VSS18

VSS17

VSS16

VSS15

VSS14

VSS13

VSS12

VSS11

VSS10

VSS9

VSS8

VSS7

VSS6

VSS5

VSS4

VSS3

VSS2

VSS1

CLKOTP

A25P

A24P

A23P

A22P

A21P

A20P

A19P

A18P

A17P

A16P

A15P

A14P

A13P

A12P

A11P

A10P

A09P

A08P

A07P

A06P

A05P

A04P

A03P

A02P

A01P

A00P

AITV2P

D31P

D30P

D29P

D28P

D27P

D26P

D25P

D24P

D23P

D22P

D21P

D20P

D19P

D18P

D17P

D16P

D15P

D14P

D13P

D12P

D11P

D10P

D09P

D08P

D07P

D06P

D05P

D04P

D03P

D02P

D01P

D00P

Figure 5-1 Main Control PCB (NMA-1/11) Circuit Diagram Rev.5

- 28 -

Page 31

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

2028K/ 3AR3

(2/3)

CPU

BENDNP

CS0WP

TSTENP

FRCMN

CLRSTN

WMRSTN

DRDYN

BREQN

SCRRQP

INT2N

INT1N

CDCNN

PDT8P

PDT7P

PDT6P

PDT5P

PDT4P

PDT3P

PDT2P

PDT1P

CSTBN

INITN

AUTOFN

SELINN

RXD0N

DSRP

CTSP

CDP

RDN

RD2N

RTXN

WRN

MXSN

DTN

CS5N

CS4N

CS3N

CS2N

CS1N

CS0N

DRAS5N

DRAS4N

DRAS3N

DRAS2N

DRAS1N

DRAS0N

DCAS3N

DCAS2N

DCAS1N

DCAS0N

IOS1N

IOS0N

BGNTP

SCRAKN

RECN

ACKN

BUSYP

SLCTP

PEP

ERRORN

TXD0P

DTRN

RTSN

SSDN

2028K/ 3AR3

(3/3)

CPU

VD1P

V D0P

VCLKP

FSYNCN

LSYNCN

LGATEN

HDLDP

STB4N

STB3N

STB2N

STB1N

TXD1P

SCLKN

SLD1N

EECLKP

EECSP

RCLKN

DMPH2P

DMPH1P

DMON2N

DMON1N

RMPH2P

RMPH1P

RMONN

FANONP

THCK2N

THCK1N

HTONN

DBON1P

DBON0P

CHONP

TRON2P

TRON1P

RXD1P

EVSDPN

FNALMN

TEMP2N

TEMP1N

CVOPNN

TNSNSN

PAPERN

PSIN2N

PSIN1N

WRSNSN

PSOUT

Figure 5-2 Main Control PCB (NMA-2/11) Circuit Diagram Rev.5

- 29 -

Page 32

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

DRAM

5118160J

A11/NC

A10/NCA9A8A7A6A5A4A3A2A1A0

RASN

UCASN

LCASN

WEN

OEN

NC1

NC2

NC3

VCC1

VCC2

VCC3

GND1

GND2

GND3

I/O16

I/O15

I/O14

I/O13

I/O12

I/O11

I/O10

I/O9

I/O8

I/O7

I/O6

I/O5

I/O4

I/O3

I/O2

I/O1

ROM

23C6411SOP

A21

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10A9A8A7A6A5A4A3A2A1A0CEOE

BYTE

VCC

VSS1

VSS2

D15ZA-1

D14

D13

D12

D11

D10

D9D8D7D6D5D4D3D2D1

D0

Figure 5-3 Main Control PCB (NMA-3/11) Circuit Diagram Rev.5

- 30 -

Page 33

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

MTDV

MTD2005F

PHAA

NENA

PHAB

NENBCRREFA

VSA

REFB

VSB

DCAY

VCC

LGA

LGB

VMM1

VMM2

GND1

GND2

OUT1

OUT2

OUT3

OUT4

NALM

RSA

RSB

NC1

NC2

NC3

NC4

NC5

NC6

Figure 5-4 Main Control PCB (NMA-4/11) Circuit Diagram Rev.5

- 31 -

Page 34

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-5 Main Control PCB (NMA-5/11) Circuit Diagram Rev.5

- 32 -

Page 35

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-6 Main Control PCB (NMA-6/11) Circuit Diagram Rev.5

- 33 -

Page 36

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

LSI

Q1

74HC244

VCC=D5V, GROUND=0V

1A1

1A2

1A3

1A41C2A1

2A2

2A3

2A4

2C

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

LC26023A

CLK0

CLK1

SQCR

SCLK

DINP

DOUTP

RESETN

ANSW9

ANSW8

ANSW7

ANSW6

ANSW5

ANSW4

ANSW3

ANSW2

ANSW1

ANSW0

INPORT6

INPORT5

INPORT4

INPORT3

INPORT2

INPORT1

INPORT0

VRH

VRM

VRL

AVDD

VDD

AVSS

VSS

I_O0

I_O1

PWMOUT7

PWMOUT6

PWMPUT5

PWMOUT4

PWMOUT3

PWMOUT2

PWMOUT1

PWMOUT0

TEST

Figure 5-7 Main Control PCB (NMA-7/11) Circuit Diagram Rev.5

- 34 -

Page 37

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-8 Main Control PCB (NMA-8/11) Circuit Diagram Rev.5

- 35 -

Page 38

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-9 Main Control PCB (NMA-9/11) Circuit Diagram Rev.5

- 36 -

Page 39

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-10 Main Control PCB (NMA-10/11) Circuit Diagram Rev.5

- 37 -

Page 40

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-11 Main Control PCB (NMA-11/11) Circuit Diagram Rev.5

- 38 -

Page 41

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-12 High voltage Supply PCB (P2H-1/1) Circuit Diagram Rev.2

- 39 -

Page 42

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

Figure 5-13 High voltage Supply PCB (P6L-1/1) Circuit Diagram Rev.2

- 40 -

Page 43

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 67 89 XY

DRAM

5118160J

A11/NC

A10/NCA9A8A7A6A5A4A3A2A1A0

RASN

UCASN

LCASN

WEN

OEN

NC1

NC2

NC3

VCC1

VCC2

VCC3

GND1

GND2

GND3

I/O16

I/O15

I/O14

I/O13

I/O12

I/O11

I/O10

I/O9

I/O8

I/O7

I/O6

I/O5

I/O4

I/O3

I/O2

I/O1

DRAM2

5118160J

A11/NC

A10/NCA9A8A7A6A5A4A3A2A1A0

RASN

UCASN

LCASN

WEN

OEN

NC1

NC2

NC3

VCC1

VCC2

VCC3

GND1

GND2

GND3

I/O16

I/O15

I/O14

I/O13

I/O12

I/O11

I/O10

I/O9

I/O8

I/O7

I/O6

I/O5

I/O4

I/O3

I/O2

I/O1

Figure 5-12 Option memory PCB (N4A-1/1) Circuit Diagram Rev.2

- 41 -

Page 44

COMPONENT PARTS LIST

- 1 -

Page 45

Drawing List

Main Control Board (NMA PCB, Rev. 5) 40433801YA

High Voltage Power Supply Board (P2H PCB, Rev.2) 40607401YA

High Voltage Power Supply Board (P6L PCB, Rev.2) 40605601YA

Option Board (N4A PCB, Rev.2) 40559001YA

- 2 -

Page 46

108

107

SW1

C28

C27

C1

LED3

LED2LED1

3- 110

HIVOL2

1

2

C17

C18

DRAM

1

2

16

OPTION

C19

23

22

TR4

R98

R59

R97

R60

C20

LSI

R54

R53

OSC2

C9

15

14

30

2917

R92

R61

R55

R62

R63

R64

R65

C16

HIVOL

R66

R67

1

1

2

D3

R68

R56

R57

Q1

R1

R2

F1

R94

TR2

R49

R47

OSC1

RST

MTDV

R50

R45

R44

R93

R15

R69

RM5

R51

R52

RM1 RM2 RM3 RM4

R48

C12

D2D1TR1

R46

C4

PJ

POWER

C6 C7

ROM

RM6 RM7 RM8

CPU

18

RM9

Q2

TR3

EEPROM

R42

C14

R41

R40

R39

R38

R37

R36

C22

C24

Q3

1124

MOTOR

C21

R87

R86

1

R85

R3

R84

R83

R82

R81

R80

R79

R78

R77

R76

R75

R74

R73

R72

R71

R70

R95

R43

R93

C1

R9

R10

R11

19

CENT

18

36

S1

Q4

1

2

HEAD2

11

12

14

13

R12

R13

R14

HEAD1

2

1

R593

R591

R592

R590

R582

R581

R583

R563

R564

C533

R559

C502

C522

C556

R510

C560

C505

C554

C532 C549

C547

R589

R558

R557

R556

R555

R502 C501

R501

C540

R554

R618

R580

R536

R527

C539

R553

R607

R579

R606

R526

R605

C538

C514

R604

C531

C519

R615

R603

C577

R614

R602

R613

R601

C549

C529

R612

R600

C514

R611

R599

C527

R610

C553

C511

R609

R598

R512

R608

R597

C551

C503

R543

C526

R523

R511

C504

R620

R522

C552

C525

C517

R521

R587

R520

R616

C546

R586

R519

R595

R596

D501

C545

R518

TR506

C537

R574

TR502

C544

R585

C536

R584

R573

C543

R503

NMA Printed Circuit Board REV.5

(40433801YA-1/2)

TR501

C548

R571

C535

C509

R570

C534

R569

R568

R567

R566

R532

R531

C542

TR505

TR504

C541

C516

C550

TR503

R562

R552

R530

R515

R561

R550

R529

R565

R551

R538

- 3 -

Page 47

NMA Printed Circuit Board Rev. 5

(40433801YA-2/2-1/7)

REF.

NO.

1

2

3

4

5

6

7

8

9

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D1,D3,D501

D2

R554

R97,R547,R548

R98,R556

R44,R55

R558

R54

SS100MA80VACP

D-Signal -C

RD 3.3M-B2

D-Zener -C

CR/RK73H/ERJ/MCRF102

RES-MET RN -C

CR/RK73H/ERJ/MCRF103

RES-MET RN -C

CR/RK73H/ERJ/MCRF104

RES-MET RN -C

CR/RK73H/ERJ/MCRF105

RES-MET RN -C

CR/RK73H/ERJ/MCRF122

RES-MET RN -C

CR/RK73H/ERJ/MCRF151

RES-MET RN -C

611A0000N0001

613A0233M0062B

3235003F0102

3235003F0103

3235003F0104

3235003F0105

3235003F0122

3235003F0151

3

1

1

3

2

2

1

1

R579

10

R557

11

R42

12

R511

13

R43

14

R580

15

R593

16

R15,R64,R66,R69,R74,

17

R87,R502,R503,R559,

R478,R595,R596,R599,R611

CR/RK73H/ERJ/MCRF181

RES-MET RN -C

CR/RK73H/ERJ/MCRF204

RES-MET RN -C

CR/RK73H/ERJ/MCRF243

RES-MET RN -C

CR/RK73H/ERJ/MCRF302

RES-MET RN -C

CR/RK73H/ERJ/MCRF362

RES-MET RN -C

CR/RK73H/ERJ/MCRF471

RES-MET RN -C

CR/RK73K/ERJ/MCRJ101

RES-MET RN -C

CR/RK73K/ERJ/MCRJ102

RES-MET RN -C

3235003F0181

3235003F0204

3235003F0243

3235003F0302

3235003F0362

3235003F0471

3235003J0101

3235003J0102

1

1

1

1

1

1

1

14

- 4 -

Page 48

NMA Printed Circuit Board Rev. 5

(40433801YA-2/2-2/7)

REF.

NO.

18

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R61~R63,R65,R67,R68,

R549, R560

19

R38

20

R36

21

R608~R610

22

R57

23

R501,R597

24

R41,R48~R50

25

R563,R564,R581~R583,

R 590~R592

26

R585

CR/RK73K/ERJ/MCRJ103

RES-MET RN -C

CR/RK73K/ERJ/MCRJ121

RES-MET RN -C

CR/RK73K/ERJ/MCRJ122

RES-MET RN -C

CR/RK73K/ERJ/MCRJ151

RES-MET RN -C

CR/RK73K/ERJ/MCRJ152

RES-MET RN -C

CR/RK73K/ERJ/MCRJ153

RES-MET RN -C

CR/RK73K/ERJ/MCRJ181

RES-MET RN -C

CR/RK73K/ERJ/MCRJ220

RES-MET RN -C

CR/RK73K/ERJ/MCRJ221

RES-MET RN -C

3235003J0103

3235003J0121

3235003J0122

3235003J0151

3235003J0152

3235003J0153

3235003J0181

3235003J0220

3235003J0221

8

1

1

3

1

2

4

8

1

27

R598

28

R605,R606

29

R573,R574,R584,R586,R587

30

R518~R522,R566~R571

31

R70~R73,R75~R86,R95,R523

32

R543

33

R56,R512,R515,R526,R536,

R538,R551,R553,R565,R577

34

R53

CR/RK73K/ERJ/MCRJ223

RES-MET RN -C

CR/RK73K/ERJ/MCRJ272

RES-MET RN -C

CR/RK73K/ERJ/MCRJ301

RES-MET RN -C

CR/RK73K/ERJ/MCRJ331

RES-MET RN -C

CR/RK73H/ERJ/MCRJ332

RES-MET RN -C

CR/RK73K/ERJ/MCRJ470

RES-MET RN -C

CR/RK73K/ERJ/MCRJ270

RES-MET RN -C

CR/RK73K/ERJ/MCRJ472

RES-MET RN -C

CR/RK73K/ERJ/MCRJ473

RES-MET RN -C

3235003J0223

3235003J0272

3235003J0301

3235003J0331

3235003J0332

3235003J0470

/ 3235003J0270

3235003J0472

3235003J0473

1

2

5

11

18

1

10

1

IF CPU(REF.No79)

Part No. is

851A0940N0041,

then R543 Part No.

is 3235003J0470.

If CPU Part No.is

8510440N001,

then R543 Part No.

is 3235003J0270.

- 5 -

Page 49

NMA Printed Circuit Board Rev. 5

(40433801YA-2/2-3/7)

REF.

NO.

35

36

37

38

39

40

41

42

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R37,R46,R47

R602

R59,R60,R545,R555,R620

R9,R39,R40,R603,R614,R615

R604

R51,R52

R607

R10~R14,R45,R92,R93,R96,

R510,R527,R531,R532,R600,

R601,R612,R613,R616,R618

CR/RK73K/ERJ/MCRJ510

RES-MET RN -C

CR/RK73K/ERJ/MCRJ511

RES-MET RN -C

CR/RK73K/ERJ/MCRJ512

RES-MET RN -C

CR/RK73K/ERJ/MCRJ560

RES-MET RN -C

CR/RK73K/ERJ/MCRJ562

RES-MET RN -C

CR/RK73K/ERJ/MCRJ680

RES-MET RN -C

CR/RK73K/ERJ/MCRJ681

RES-MET RN -C

CR/RK73Z/ERJ/MCRJ-0V

RES-Zero ohm -C

3235003J0510

3235003J0511

3235003J0512

3235003J0560

3235003J0562

3235003J0680

3235003J0681

3255003P0001

3

1

5

6

1

2

1

19

43

R58

44

R529,R530,R550,R552,R561,

R562

45

R3

46

47

RM1~RM9

48

49

R94

50

R1R2

51

RM73B2A271J

RES-MET RN -C

RM73B2A750J

RES-MET RN -C

ERJ-12YJ750

RES-MET RN -C

MNR14ABJ680

RES-Block -C

RD1/2Y2.4KΩJ

RES-Carbon flm -

MSF1/2B1ΩJ

RES-MET OX -

323A5003J0271

323A5003J0750

323A5019J0750

334A5012J0680

321A1431J0242

324A1001J0109

1

6

1

9

1

2

- 6 -

Page 50

NMA Printed Circuit Board Rev. 5

(40433801YA-2/2-4/7)

REF.

NO.

52

53

54

55

56

57

58

59

60

61

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C9

C517,C525,C534,C535

C511,C514,C521,C531,C533,

C551,C552

C553

C536,C537,C544~C546

C543

C547

C540

C12,C14,C16~C19,C20,C501~

C504,C509,C522,C526,C529,

C538,C541,C532,C548~C550

C21,C22,C24,C27,C28,C505,C516,

C519,C527,C532,C539,C554,

C556

GRM/UMK/MCH/330CH

CAP-Ceramic -C

GRM/UMK/MCH/680CH

CAP-Ceramic -C

GRM/UMK/MCH/102B

CAP-Ceramic -C

GRM/UMK/MCH/222B

CAP-Ceramic -C

GRM/TMK/MCH/223B 25V

CAP-Ceramic -C

GRM/TMK/MCH/473B 25V

CAP-Ceramic -C

GRM/UMK/MCH/561B 50V

CAP-Ceramic -C

GRM/UMK/MCH/103Z 50V

CAP-Ceramic -C

GRM/UMK/MCH/104Z 25V

CAP-Ceramic -C

CK2012F1C105Z 16V

CAP-Ceramic -C 1µF

3033003C0330

3033003C0680

3036003K0102

3036003K0222

3036003K0223

3036003K0473

3036003K0561

3036003Z0103

3036003Z0104

303A6008Z1105

1

4

7

1

5

1

1

1

21

13

62

63

64

65

66

67

68

S1

C1

C7

C4,C6

C5

DD104B102K50V 50V

CAP-Ceramic -

UMA/50MS5-1M 50V

CAP-Alum(CE) -P 1µF

16MS5-47M 16V

CAP-Alum(CE) - 47µF

KME50VB-47 50V

CAP-Alum(CE) - 47µF

UVS1A332MHA 10V

CAP-Alum(CE) -

- 7 -

302A4011K3102

3041103H1109

304A1046C1470

304A1115H1470

304A1137A1332

1

1

1

2

1

Page 51

NMA Printed Circuit Board Rev. 5

(40433801YA-2/2-5/7)

REF.

NO.

69

70

71

72

73

74

75

76

77

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

Q4

LSI

Q1

Q2

Q3

MTDV

RST

DRAM

74LS07FP

Digital IC-BIP-S

LC26023A-NA5

Digital IC-MOS-

74HC244FP

Digital IC-MOS-S

TL431CLP/NJM431L-T3

Analog-BIPLIN -P

NJM2901M/UPC339G2

Analog-BIPLIN -S

MTD2005F

Analog-BIPLIN -S

PST592D-2

Analog-BIPLIN -

5118160JP-60

Memory-MOSDRAM -S

700A0503N0007

7024633M2003

702A1703N0244

7200903M9001

720A0503N0007

720A1816N0001

720A4037M0015

8020003N4613

1

1

1

1

1

1

1

1

78

EEPROM

79

CPU

80

ROM

81

82

TR4

83

TR1,TR502

84

TR506

85

TR2,TR501,TR503~TR505

93C46LDP-NW

Memory-MOSEEPR -

MHM2029-002K

CPU-MOS -F

MHM2029-004K-29

CPU-MOS -F

KM23C64000G-KF-0001

Memory-MOSMROM -S

2SA1331/2SA1037K

TR-PNP/H FREQ -C

2SA1338

TR-PNP/H FREQ -C

2SC3361/2SC2412KVL

TR-NPN/H-FREQ -C

DTC123YK

TR-NPN/H-FREQ -C

8160303M0000

851A0940N0041

/ 8510440N0001

8176601N0001

600A1003N0002

600A1032N0010

602A1003N0002

602A1035N0019

1

1

1

1

2

1

5

OR Design

(See REF. No.32)

- 8 -

Page 52

NMA Printed Circuit Board Rev. 5

(40433801YA-2/2-6/7)

REF.

NO.

86

87

88

89

90

91

92

93

94

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

TR3

SW1

CENT

HEAD2

HEAD1

OPTION

PJ

MOTOR

2SD1623S

TR-NPN/L-FREQ -C

SOA-113HS

Switch-Push -

57RE-40360-830B-D29

Connector-SQR -

SLD12S-2

Connector-PCB -

SLD14S-S

Connector-PCB -

TX25-40P-LT-H1

Connector-PCB -

00-8263-0211-00-000

Connector-PCB -

00-8263-0411-00-000

Connector-PCB -

603A1132N0001S

205A1162P1001

2201001P0360

2243001P0120

2243001P0140

2244120P0400

224A3358P0020

224A3358P0040

1

1

1

1

1

1

1

1

95

96

97

98

99

100

101

102

103

POWER

HIVOL2

HIVOL

OSC1

OSC2

F1

B8B-XH-A

Connector-PCB -

00-5062-301-006-000

Connector-PCB -

00-5062-301-023-000

Connector-PCB -

CST7.06MTW040-TF01

OSC-Ceramic -P

CST10.0MTW

OSC-Ceramic -

241-001

FUSE -

224A3530P0080

224A5114P0060

224A5114P0230

3811000B0001

381A1045B0014

540A2208S1102

1

1

1

1

1

1

- 9 -

Page 53

NMA Printed Circuit Board Rev. 5

(40433801YA-2/2-7/7)

REF.

NO.

104

105

106

107

108

109

110

111

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

LED3

LED1,LED2

SEL3213C/GL3HD47

PHOTO-LED -

SEL3913KYZ/GL3HY47BC

PHOTO-LED -

SMCD23/TWVF23-210

CONN PAR- -

SMCD6/TWVF6-55

CONN PAR- -

Cap-LED

650A0103M0001

650A0203M0001

2381003P0003

2381003P0005

40666901

1

2

1

1

3

- 10 -

Page 54

D84

D58

D56

D61

D60

D52

D67

D69

D68

D71

D76

EXT

D59

D55

C240

R124

LED

C237

C110

D63

TR

D62

Q15

D72

D87

R48

D65

D66

D74

D82

D85

D57

D51

R233

R47

R116

R121

C105

C103

C104

C241

C106

C108

C107

C118

C251

C310

R238

C311

C113

C300

Q16

C101

C102

J23

J7

J1

J2

HR

J42

J9

J11

J12

J10

J25

J22

J36

J16

J8

J24

R102

R103

R122

R123

J20

J18

J4

J3

J40

J26

J27

J36

J29

J32

J34

J33

J30

J17

J19

L10

J21

C119

C112

CN2

21

CVSW

C117

C114

J13

J15

J14

R236

R229

R100

R234

R115

R237

R104

R105

R113

DB

SB

CH

R114

C301

C302

C111

C115

C116

CN1

T4

T3

T2

1

2

23

C236

R118

R228

Q11

Q21

Q22

PS2

PS1

PS4

IN

TNR

WR

PS3

Q23

Q17

Q10

Q13

Q12

P2H Printed Circuit Board REV.2

(40607401YA-1/2)

- 11 -

Page 55

P2H Printed Circuit Board Rev. 2

(40607401YA-2/2-1/4)

REF.

NO.

1

2

3

4

5

6

7

8

9

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D60, D61, D68, D69

D63,D67, D72, D74

D51, D55-D59, D62,

D71, D84

D52

D65,D66

D76

D82

D87

D85

1S953/ 1S2075K/ 1S2473

D-Signal -

OR-DHM/ ESJA/ SHV-06

EU02A/ RL105F-F

D-Rectifying -Q

1ZB300-Y/ Z

D-Zener -

1ZB3900

D-Zener -

RD22E-B2

D-Zener -

RD27E-B1

D-Zener -

RD200E-B

D-Zener -

1ZB270-Y/ Z (TPA2)

D-Zener -Q

611A0003L0001

40681301

6100003M0001

613A2003M0001

613A2258M0350

613A1231L0262B

613A1231L0282A

613A1231L0522

6132003M0001

4

4

9

1

2

1

1

1

1

10

11

R234

12

R47, R48

13

R102, R116, R121

14

R103, R123

15

R118

16

R122, R124, R229

17

R105

18

R104

RD1/4Y33ΩJ

RES-Carbon flm -

RD1/4Y130ΩJ

RES-Carbon flm -

RD1/4Y330ΩJ

RES-Carbon flm -

RD1/4Y1KΩJ

RES-Carbon flm -

RD1/4Y4.7KΩJ

RES-Carbon flm -

RD1/4Y5.1KΩJ

RES-Carbon flm -

RD1/4Y24KΩJ

RES-Carbon flm -

RD1/4Y75KΩJ

RES-Carbon flm -

321A1421J0330

321A1421J0131

321A1421J0331

321A1421J0102

321A1421J0472

321A1421J0512

321A1421J0243

321A1421J0753

1

2

3

2

1

3

1

1

- 12 -

Page 56

P2H Printed Circuit Board Rev. 2

(40607401YA-2/2-2/4)

REF.

NO.

19

R235

20

R228, R233

21

R100

22

R115

23

R114, R236

24

R237

25

R238

26

27

C105, C107, C119,

C240, C241

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

MRH30MK/ HV-22-30MK

RES-MET solid -

RD1/4Y1MΩJ

RES-Carbon flm -

RD1/4Y3MΩJ

RES-Carbon flm -

RNL1/4C3F576KΩ

RES-MET RN -

MRH100MK/ HV-38-100MK

RES MET solid -

RD1/4Y5.1ΩJ

RES-Carbon flm -

RD16UJ1.5KΩ

RES-Carbon flm -

HNY5P/ DE07-1KV-471K

CAP-Ceramic -P

3263103K0306

321A1421J0105

321A1421J0305

323A1222F5763

3263103K0107

321A1421J0519

3213420J0152

3024003K7471

1

2

1

1

2

1

1

5

28

C113, C114, C117

29

C112

30

C101, C102, C106

31

C103, C104,C108,C110,

C111, C115,C237,C251,

C300, C301, C311

32

C116

33

C118

34

C302, C310

35

C236

DE07/ HCYB3F471

CAP Ceramic -Z

DE1010B471K6K 6KV

CAP-Ceramic -

HLY5P/ DD05-500V-471K

CAP-Ceramic -P

MLRD/ FK16Y5V1H104Z

CAP-Ceramic -N

MLRD/ FK16Y5V1H473Z

CAP-Ceramic -N

MY2A/ CQMF-100V-103J

CAP-Plast flm -P

CQMF/ MY2A472J-T 100V

CAP-Plast flm -P

UVX/ SME-63V-10µF 63V

CAP-Alum (CE) -P

3024203K2471

302A4028K4471

3024003K6471

3034003Z3104

3034003Z3473

3064003J2103

3064003J2472

3041003J1100

3

1

3

11

1

1

2

1

- 13 -

Page 57

P2H Printed Circuit Board Rev. 2

(40607401YA-2/2-3/4)

REF.

NO.

36

37

38

39

40

41

42

43

44

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

Q11, Q13

Q12

Q21-Q23

Q15-Q17

Q10

L10

T2-T4

BCR1AM-12/ MAC97-008

THY-Bi/ Dir -

CR04AM-12

THY-Gate -

2SC1815-Y

TR-NPN/ H-FREQ -

2SC2235-Y

TR-NPN/ H-FREQ -

2SC2752

TR-NPN/ H-FREQ -

C-14576/ SA-8506183

Coil-Choke -

HIGH VOLTAGE TRANSFORMER

622A0003M0001

620A0022M0008

602A1025M0006Y

602A1125M0039Y

602A1223M0039

3502003P0102

YB4049-7078P003

2

1

3

3

1

1

3

45

46

47

48

49

50

51

52

53

PS1-PS4

CVSW

LED

CN1

CN2

RPI-574/ #9568

PHOTO-Coupler -

SM05S/ SS5GL13

Switch-Micro -

SEL3910D/ 204AD

PHOTO-LED -

23FE-BT-VK-N

Connector-PCB -

53254-0210

CONNECTOR-PCB -

652A0103M0002

2071003P0001

6500003M0001

224A4134P0230

224A4407P0020

4

1

1

1

1

- 14 -

Page 58

P2H Printed Circuit Board Rev. 2

(40607401YA-2/2-4/4)

REF.

NO.

54

55

J1, J2, J40

56

J3, J4, J7-J12

57

J13-J21, J23-J27, J29J36

58

J22

59

60

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

SHORT WIRE

SHORT WIRE

SHORT WIRE

SHORT WIRE

TA-0.6

TA-0.6

TA-0.6

TA-0.6

3

8

22

1

- 15 -

Page 59

R4

CN1

14

C4

1

2

Q2

5

6

D8

S1

T2

R6

C6

56

D9

C5

Q1

R5

C1

D1

1

4

D4

FG

56

CN2

T1

R3

D7 D6 D5

C2

C3

1

R2

D3

P6L Printed Circuit Board REV.2

(40605601YA-1/2)

- 16 -

Page 60

P6L Printed Circuit Board Rev. 2

(40605601YA-2/2-1/2)

REF.

NO.

1

2

3

4

5

6

7

8

9

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D1,D8

D2,D3,D9

D4

D5~D7

R1,R4~R6

R2

R3

EU02A/RL105F-F

D-Rectifying -Q

DHM3FJ60/ESJA58-06

D-Rectifying -

ERZV05D391

SEMICO-Vari -

ERZ/JVR-05N471

SEMICO-Vari -

RD16U/VTJ5.1KΩ

RES-Carbon flm -

RD1/4Y1MΩJ

RES-Carbon flm -

MRH100MK/HV-38-100MK

RES-MET solid -

6100003M0001

610A0003M0002

6320229M0003

6320003M0001

3213420J0512

321A1421J0105

3263103K0107

2

3

1

3

4

1

1

10

11

12

13

14

15

16

17

18

C1,C4

C2,C3,C5

C6

S1

Q1,Q2

T1,T2

MY2A/CQMF-100V-103J

CAP-Plast flm -P

DE07/HCYB3F471

CAP-Ceramic -Z

UVX/SME-63V-10µF 63V

CAP-Alum(CE) -P

SHORT WIRE

2SC2235-Y

TR-NPN/H-FREQ -

HIGH VOLTAGE TRANSFORMER

3064003J2103

3024203K2471

3041003J1100

TA-0.6

602A1125M0039Y

YB4049-7078P0003

2

3

1

1

2

2

- 17 -

Page 61

P6L Printed Circuit Board Rev. 2

(40605601YA-2/2-2/2)

REF.

NO.

19

20

21

23

24

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

CN1

CN2

06FE-ST-VK-N

Connector-PCB -

RT-01T-1.0B

Connector-PCB -

2244101P0060

2247000P0001

1

1

- 18 -

Page 62

DRAM2

DRAM1

C1 C2

CN1 1

R501

R502

R503

R504

R505

R506

R507

R508

R516

R515

R514

R513

R512

R511

R510

R509

N4A Printed Circuit Board REV.2

(40559001YA-1/2)

- 19 -

Page 63

N4A Printed Circuit Board Rev. 2

(40559001YA-2/2)

REF.

NO.

1

2

3

4

5

6

7

8

9

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R501~R516

C1,C2

DRAM1,DRAM2

CN1

CR/RK73K/ERJ/MCRJ151

RES-MET RN -C

CK2012F1C105Z 16V

CAP-Ceramic -C 16µF

5118160JP-60

Memory-MOSDRAM-S

TX24-40R-LT-H1

Connector-PCB -

3235003J0151

303A6008Z1105

8020003N4613

2244110P0400

16

2

2

1

10

- 20 -

Page 64

Oki Data Corporation

4-11-22, Shibaura, Minato-ku,

Tokyo 108-8551, Japan

Tel: (03) 5445-6162 Fax: (03) 5445-6189

Loading...

Loading...