Page 1

OKIP AGE 8c

Color LED Page Printer

T roubleshooting Manual

with Component Parts List

ODA/OEL/INT

1999. 2. 9 Rev.1

40985501TH Rev.1 1 / 157

Page 2

CONTENTS

1. OUTLINE ............................................................................................................ 3

2. TOOLS................................................................................................................ 3

3. CIRCUIT DESCRIPTION.................................................................................... 4

3.1 CU (controller unit : PCR)......................................................................... 4

3.1.1 Outline ...................................................................................................................... 4

3.1.2 CPU and Memory ..................................................................................................... 7

3.1.3 Reset Control............................................................................................................ 9

3.1.4 EEPROM Control ................................................................................................... 10

3.1.5 Centronics Parallel Interface................................................................................... 12

3.1.6 Operator Panel Control........................................................................................... 13

3.2 PU (Printer Unit : PX4) ........................................................................... 14

3.2.1 Outline ....................................................................................................................14

3.2.2 CPU, Memory and LSI............................................................................................ 16

3.2.3 Reset Control.......................................................................................................... 18

3.2.4 EEPROM Control ................................................................................................... 19

3.2.5 LED Head Control .................................................................................................. 21

3.2.6 Motor Control.......................................................................................................... 24

3.2.7 Fuser Temperature Control..................................................................................... 30

3.2.8 Fan Motor Control................................................................................................... 33

3.2.9 Sensor Supervision ................................................................................................ 34

3.2.10 Cover Open ............................................................................................................ 35

3.2.11 Power Supply Interface........................................................................................... 36

3.2.12 Option (2nd paper feeder) Interface ....................................................................... 37

3.2.13 Power Supply Board ............................................................................................... 38

3.3 PCR-PX4 I/F........................................................................................... 42

3.3.1 Outline ....................................................................................................................42

3.3.2 Video I/F ................................................................................................................. 43

3.3.3 Command Interface ................................................................................................ 45

4. TROUBLESHOOTING...................................................................................... 48

4.1 Troubleshooting Table............................................................................ 48

4.2 Troubleshooting Flowchart ..................................................................... 60

5. CIRCUIT DIAGRAM ......................................................................................... 66

6. COMPONENT PARTS LIST........................................................................... 104

40985501TH Rev.1 2 /

Page 3

1. OUTLINE

This manual has been written to provide guidance for troubleshooting of the OKIPAGE 8c Printer

(primarily for its printed circuit boards), on an assumption that the reader is knowledgeable of the

printer. Read the maintenance manual for this printer P/N 40029803TH if necessary.

Notes:

1. The power supply board containing a high voltage power supply is dangerous. From the

viewpoint of the safety standards, the local repairing of a defective board is not allowed. Also,

pay attention to the fact that a function can be rarely recovered by replacing a fuse when it is

burnt.

2. Replacement of CPU(NR4700) and LSIs (IMEM & IIF) on the PCR PCB is not recommended.

If these chips are founded to be defective, board replacement is suggested.

2. TOOLS

For troubleshooting the printer, the tools listed below may be needed in addition to general

maintenance tools.

Tool Remarks

Oscilloscope

Soldering iron

Extension Cord Used for drawing PCR PCB out for PX4

Frequency response 100 MHz or higher

A slender tip type, 15-20 Watt

PCB evaluation

40985501TH Rev.1 3 /

Page 4

3. CIRCUIT DESCRIPTION

3.1 CU (controller unit : PCR)

3.1.1 Outline

The PCR PCB controls the reception of data transferred through a host I/F and processes

command analysis, bit image development, raster buffer read. It also controls the operator panel.

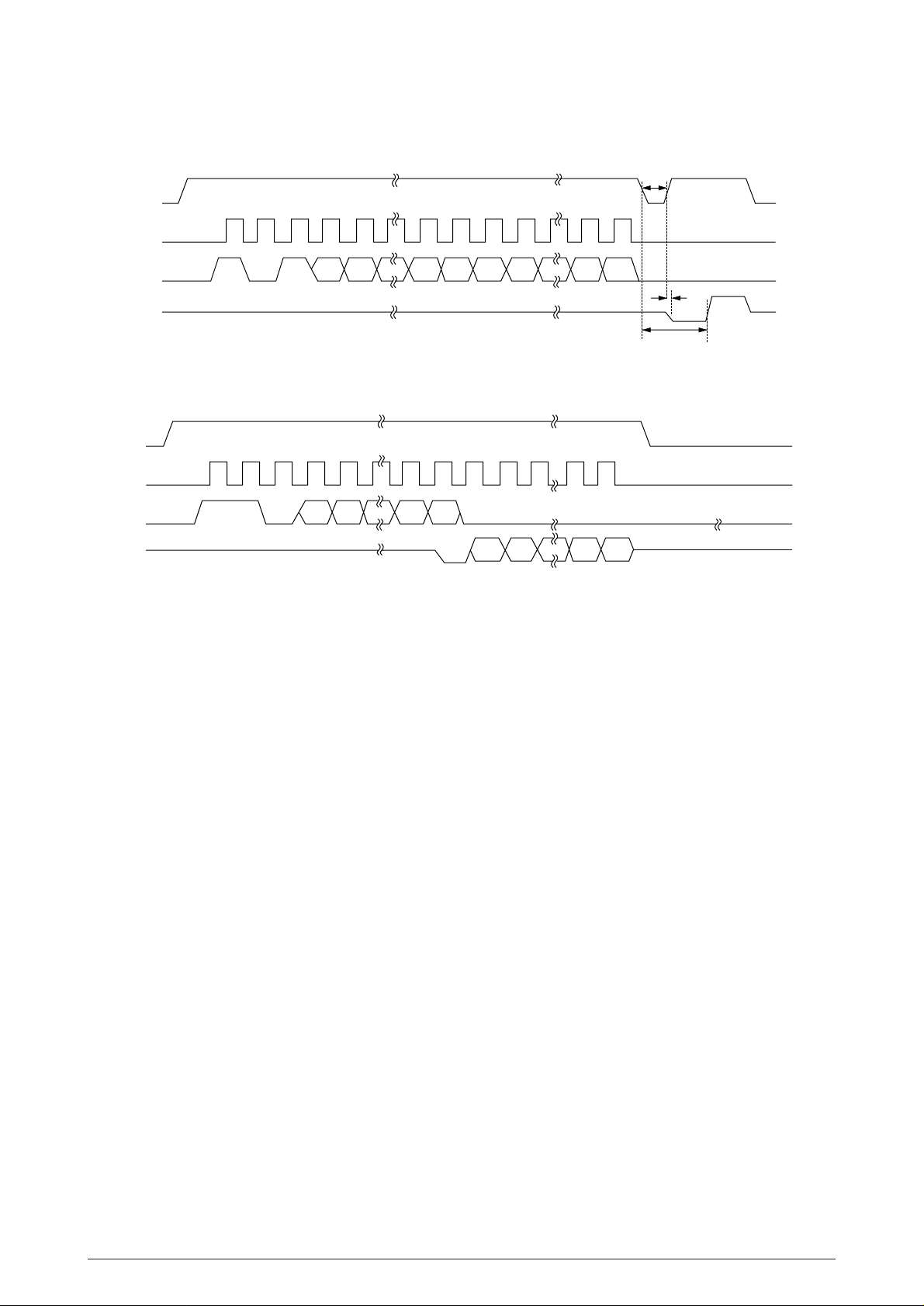

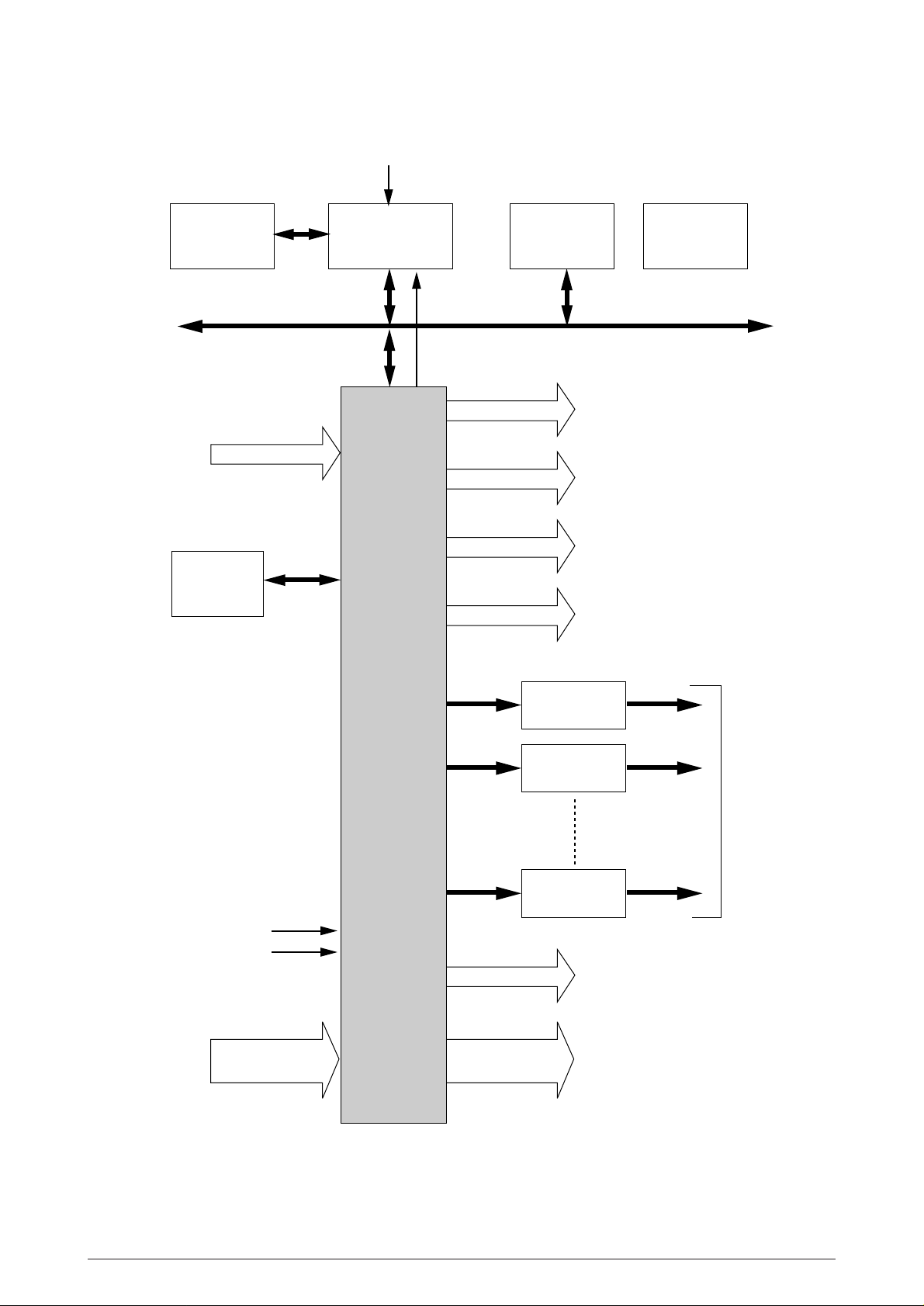

The block diagram of the entire OKIPAGE 8c including PCR PCB and details of PCR PCB are

shown in Figure. 3-1 and 3-2.

(1) Reception control

The OKIPAGE 8c has one centronics parallel I/F.

The centronics parallel I/F port can specify the following item when set by the control panel:

PARALLEL SPEED: HIGH/MEDIUM

BI-DIRECTION : ENABLE/DISABLE

I-PRIME : OFF/ON

An interface task stores all data received from the host into a receive buffer first.

(2) Command analysis processing

The OKIPAGE 8c has the following emulation mode.

Color Laser Jet : Hewlett Packard

PostScript Level 3 : Adobe

An edit task fetches data from the receive buffer, analizes commands, and reconstructs the

data in such a way that print data are aligned from up to down and from right to left; then it writes

the resultant data into a page buffer with such control data as print position coordinate, font

type, etc. added.

(3) Font Processing

When one page editing is finished, a developing task makes an engine start and fetches data

from the page buffer synchronizing with a printing operation; then it developes the fetched data

to a bit map as referring to data from a character generator, and writes the resultant data into

the raster buffer (of band buffer structure).

(4) Raster buffer read.

As controlling the engine operation, an engine task sends data from the raster buffer to the

LED head.

40985501TH Rev.1 4 /

Page 5

AC-IN AC switch

Crimp-style terminal

PXL board

PXL

Ejection sensor

LED head: Y M C K

Discharging lamp: Y M C K

Heat roller

thermistor

Backup roller

thermistor

Heater unit

SUMi card x 4

PD6 board

Y600 14P

YPOW 12P

M600 14P

MPOW 12P

C600 14P

CPOW 12P

K600 14P

KPOW 12P

HEAD1 13P HEAD2 14P HEADPOW 12P HEAD3 15P

FF form

sensor

Toner sensor x 4

ID sensor x 4

Low-voltage power supply

6P

6P'

JST3P

FAN 1

FAN 2

3P

Oil PAD MSW

FF

motor

Paper supply sensor board

FF Pos MSW

PXM board

40095001YU

REG.POS

sensor

Resist

motor

Y-IDU

motor

M-IDU

motor

C-IDU

motor

K-IDU

motor

Belt

motor

Heat

motor

PXF board

JODEN 8P

FSENS 8P

TONER

14P

PXFIF 30P

OPTION 7P

PENDTNR 6P

PX4 board

2nd tray

(option)

Form end

sensor

Waste toner

sensor

YIDREG

8P

MCKID

12P

HETBELT

8P

HEAD3

15P

HEAD2

14P

HEAD1

13P

HEADPOW

12P

FF 12P

PXFIF 30P

HVOLT 16P COVOPN 2P PSIZE 6P

High-voltage power supply

PXC board

Form size detector

Cover open

MSW

PCR

Operator

panel

PCO

board

CM

6P

PU 40P

72PX2

PS SIMM

72PX2

D-RAM SIMM

64P

OKI HSP

36P

Paralle

CUIF 40P

POWER 30P

THE.RM 6P

RSENS 7P

Interlock switch

UPDOWN

12P

40985501TH Rev.1 5 /

Figure 3-1 Block Diagram

Page 6

MPU Memory controller ROM, PS SIMM

SysAD

SysCmd

Control

64

9

5

SysAD

SysCmd

Control

A

D

Control

22

64

11

16244

16245

NMI

INTO

NR4700

LMQ-100

ExtReg

INT1

INT2

Reset

ColdReset

VCCOK

ModeIn

ModeClock

MasterClock

(Not installed)

External Agent

SysAD

SysCmd

Control

INT

REQ

ACK

AUX

CLK

RST

1

1

1

1

64

9

5

1

1

1

1

1

1

1

1

2

1

uPD94704

NMI

S1-001-F6

INT

CLK

RST

Interface controller

SysAD

SysCmd

Control

ExtReq

INT

ColdReset

VCCOK

ModeIn

ModeClk

uPU66044

GN-014-LMU

BusReq

BusAck

AUX

Reset

A

D

Control

WDATA

FSYNC

Control

PU I/F

OP I/F

EEPD

EEPCLK

EEPCS0

EEPCS1

PD

PCO

PCI

D

A

C

11

64

25

8

4

4

9

4

1

1

1

1

8

7

4

16

18

12

16244

D-RAM Max 80M

16245

16244

Engine

WDATA

ESYNC

Control

244

Operator

panel

244

EE-PROM #1

DI

CLK DO

CS

EE-PROM #2

DI

CLK DO

CS

74ACT1284 Bi-Centro

74ALS244

OKI HSP

Host I/F(Not installed)

PS -SIMM

OSC

Reset circuit

DIP SW

1

CLK

1

RSTIN

2

M

10

(TE6135 (6137), 16550, 53C80)

Figure 3-2 Block Diagram

40985501TH Rev.1 6 /

Page 7

3.1.2 CPU and Memory

(1) CPU (NR4700LMQ-100) (MIPS R4700)

CPU core : RISC CPU (MIPS R3000 compatible)

CPU clock : 100 MHz

Data bus clock : 50 MHz

Data bus width: Exterior 64 bits, Interior 64 bits

(2) ROM (HP Color LaserJet emulation)

ROM capacity : 8 Mbytes (16-Mbit mask or OTP ROM four pieces)

ROM type : 16 Mbits (1M x 16 bits)

Access time : 100 ns

(3) PostScript SIMM (Adobe PostScript emulation)

ROM capacity : 8 Mbytes [(16 Mbit ROM two pieces)x 2SIMMs]

ROM type : 16 Mbits (1M x 16 bits)

Access time : 100 ns

(4) Resident RAM

RAM capacity : 16 Mbytes (16 Mbit D-RAM eight pieces)

RAM type : 16 Mbits (1 M x 16 bits)

Access time : 60 ns

(5) Option RAM (SIMM: two slots)

RAM capacity : Max. 32 Mbytes (4 Mbytes, 8 Mbytes, 16 Mbytes, 32 Mbytes)

Access time : 60 ns, 70 ns, 80 ns

Note that only the product for ODA has been mounted with 16 Mbytes (8 Mbytes x 2) SIMM

as a resident.

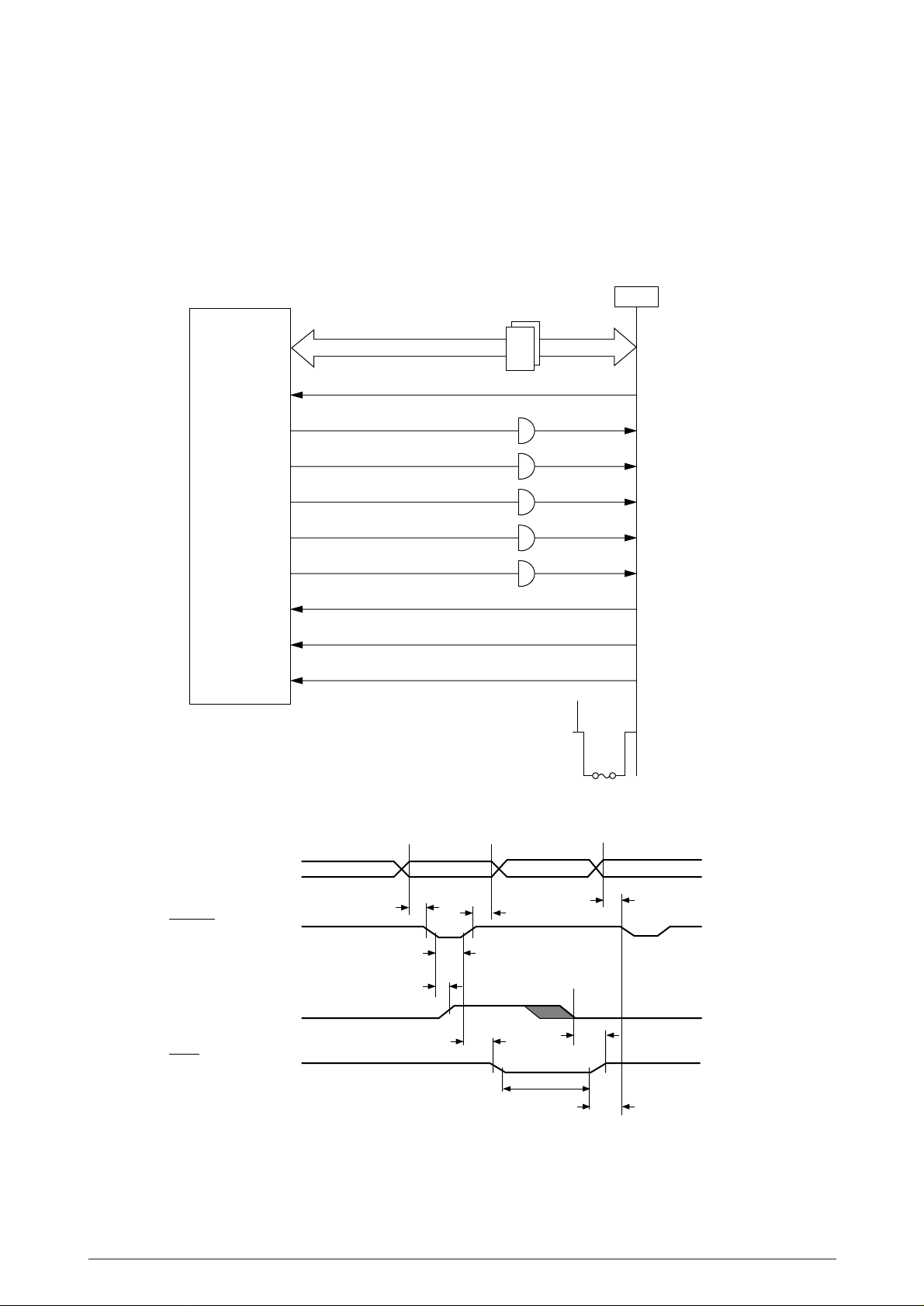

The block diagram of CPU and memory circuits is shown in Figure 3-3.

40985501TH Rev.1 7 /

Page 8

DRAM01~04

(RAS0, CAS7~0)

Resident RAM

(16M Bytes)

Option SIMM

(Resident SIMM:

Only ODA)

Mask ROM

(8M Bytes)

Flash ROM

(2M Bytes)

PS SIMM

(8M Bytes)

DRAM11~14

(RAS2, CAS7~0)

SIMM0 H, L

(RAS4, 5, CAS7~0)

CAS01~04

(CS0)

PSIMMH, L

(CS2)

IFL1~4

(CS3)

(NR4700 LMQ-100)

CPU

(Memory Control LSI)

IMEM

(I/F Control LSI)

IIF

Control signals

AD [63 : 0]

CMD [7 : 0]

11

64

64

11

16244

16244

16244

16244

16245 x 4

16245 x 4

16Mbit DRAM x 4

16MbitMask ROM x 4

16MbitMask ROM x 2 x 2

4Mbit Flash ROM x 4

16Mbit DRAM x 4

Figure 3-3 Block Diagram of CPU & Memory

40985501TH Rev.1 8 /

Page 9

3.1.3 Reset Control

When power is turned on, a RESET-N signal is generated by the reset control IC (7705) which

checks +5V power supply.

OKI HSP

IMEM

µ

PD94704)

(

21

RT1

1

2

CT1

+5V

R620

22

25V

µ

1.5

4.7K

12

+5V

16V

CP13

C583

µ

21

21

47

Power ON

25V

µ

0.1

7

2

3

8

4

SEN

IN

CT

V+

GND

IRST1

7705

WRST

0V

RST

VREF

6

5

1

+5V

R590

12

25V

C586

µ

12

0.1

(

µ

PD66044)

4.7K

C50

12

100p 50V

IIF

HWRESET-N

Power OFF

RESET-N

COLDRST-N

Flash ROMs

CPU

(NR4700)

+5V

HWRESET-N

COLDRST-N

RESET-N

+3V

40985501TH Rev.1 9 /

Page 10

3.1.4 EEPROM Control

The NM93C46LN is an electrical erasable/programmable ROM of 64-bit x 16-bit configuration and

the NM93C66N is an electrical erasable/programmable ROM of 256-bit x 16-bit configuration.

Data input to and output from the ROM are bidirectionally transferred in units of 16 bits through

a serial I/O port (EEPDAT-P) in serial transmission synchronized with a clock signal from the I/F

control LSI(IIF).

IIF

(

µ

PD66044)

EEPDAT-P

154

EEPCS0-P

150

EEPCS1-P

165

EEPCLK-P

151

NM93C46LN

3

DI DO

1

CS

2

NM93C66N

3

DI DO

1

CS

2

SK

SK

4

E2ROM1

(PCR-PCB)

4

PSIMMH

(PS SIMM)

The EEPROM operates in the following instruction modes

Instruction Start Bit

Operation

Code

NM93C46LN

Address

NM93C66N

: Option

Data

Read (READ)

Write Enabled (WEN)

Write (WRITE)

Write All Address (WRAL)

Write Disabled (WDS)

Erase

Chip Erasable (ERAL)

1

1

1

1

1

1

1

10

00

01

00

00

11

00

A5 to A0

11XXXX 11XXXXXX

A5 to A0 A7 to A0

01XXXX 01XXXXXX

00XXXX 00XXXXXX

A5 to A0 A7 to A0

10XXXX 10XXXXXX

A7 to A0

D15 to D0

D15 to D0

40985501TH Rev.1 10 /

Page 11

CS

SK

CS

SK

DI

DO

Write cycle timing (WRITE)

101

HIGH-Z

A5/A7

Read cycle timing (READ)

A4/A6

A1 A0 D15

D14

Min. 450 ns

STATUS

D1 D0

Max. 500 ns

BUSY READY

Max. 10 ms

DI

DO

HIGH-Z

11 0

A5/A7 A4/A6

A1 A0

A5/A7

A4/A6

D1 D00

40985501TH Rev.1 11 /

Page 12

3.1.5 Centronics Parallel Interface

The CPU sets a BUSY-P signal to ON at the same time when it reads the parallel data

(CENTDATA1-P to CENTDATA8-P) from the parallel port at the fall of STB-N signal. Furthermore,

it makes the store processing of received data into a receive buffer terminate within a certain fixed

time and outputs an ACK-N signal, setting the BUSY-P signal to OFF.

IIF

(

µ

PD66044)

87, 88, 91 to 96

97

85

86

83

81

79

80

82

84

PDATA [7 : 0]

STB-N

BSY-P

ACK-N

PE

SEL

FAULT

INIT-N

SELIN-N

AUTOFEED

IC16, 17

IC17

IC17

IC17

IC16

IC16

2 to 9

11

10

12

13

32

31

36

+5V 14

18

FU2

1A

CENT

DATA8-P

DATA1-P

STB-N

1

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFEED-N

+5V

to

PARALLEL DATA

(DATA BITs 1 to 8)

0.5 µs min.

0.5 µs min.

0.5 µs min.

nStrobe

0.5 µs min.

0.5 µs max.

Busy

0 min.

0 min.

nAck

0.5 µs to 10 µs

0 min.

40985501TH Rev.1 12 /

Page 13

3.1.6 Operator Panel Control

The operator panel consists of the following circuits.

PCR- PCO-

IIF

(µPD66044)

I/F Control LSI

OPCMD-P

146

OPSTS-P

147

OPSCLK-P

149

OPLOAD-N

150

IC19

3

4

6

1

CN1PANEL

4

3

1

6

Flexible

Cable

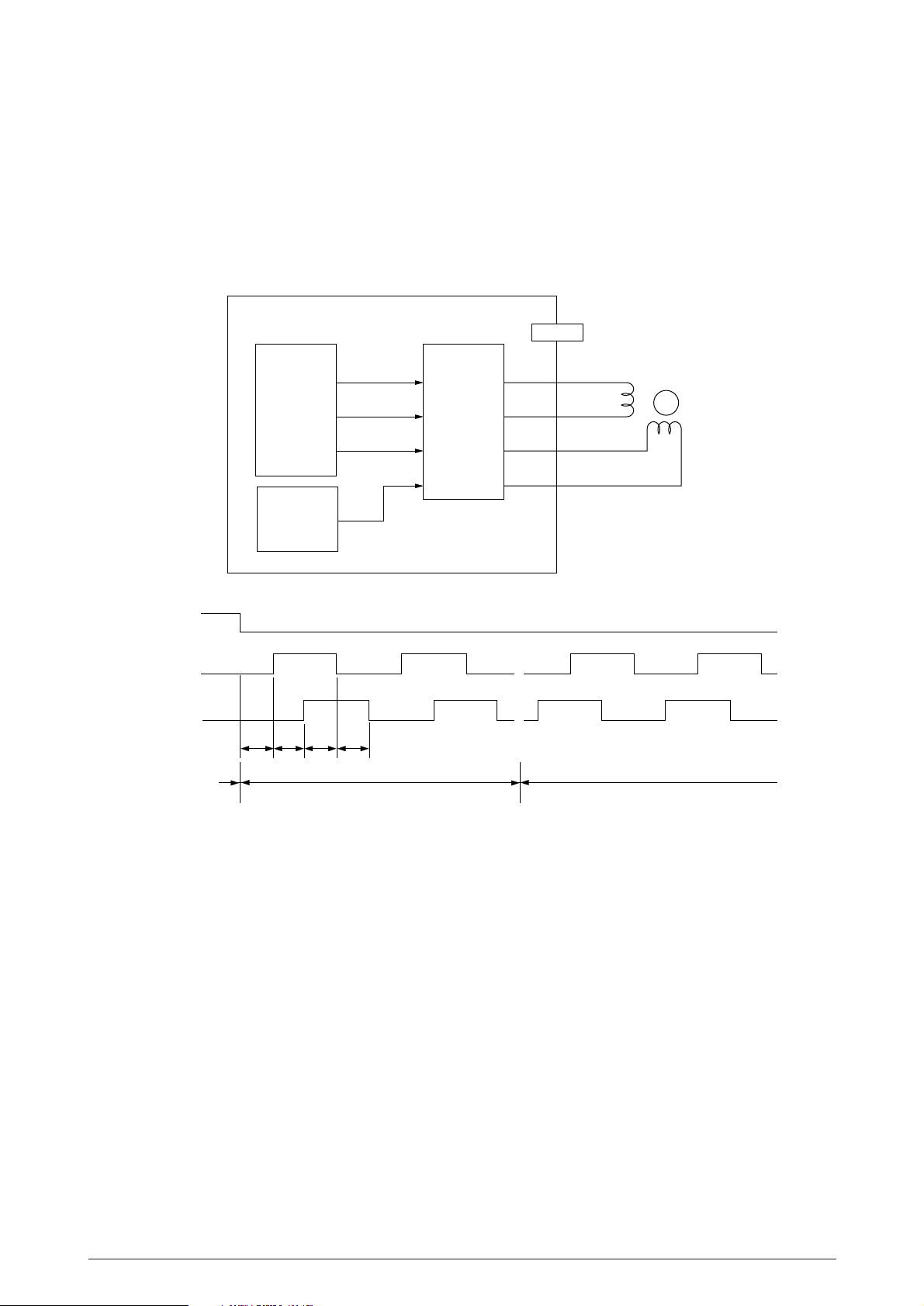

(1) BU6152S (LSI)

This LSI is connected to a clock synchronous serial port of the I/F Control LSI (IIF). It controls

switch data input, LED data output and LCD data input/output according to the commands

given by the I/F Control LSI. The I/F Control LSI sends the 2-byte (16-bit) command (OPCMDP) together with the shift clock signal (OPSCLK-N) to the Operator Panel Control LSI and then

makes a predetermined input/output control if the command decoded by the Operator Panel

Control LSI is found to be a normal command.

BU6152S

Operator Panel

Control LSI

DB4~DB7

RS

R/W

E

LED

44780

LCD

Control

Driver

Zebra Rubber

LCD

On receiving a command sent from the I/F Control LSI, the Operator Panel Control LSI,

synchronizing with the serial clock of the command, returns a 2-byte command response to

the I/F Control LSI.

OPCMD-P

OPSCLK-N

OPSTS-P

OPLOAD-N

bit 0 bit 15

Command

bit 0

bit 15

Command response

40985501TH Rev.1 13 /

Page 14

3.2 PU (Printer Unit : PX4)

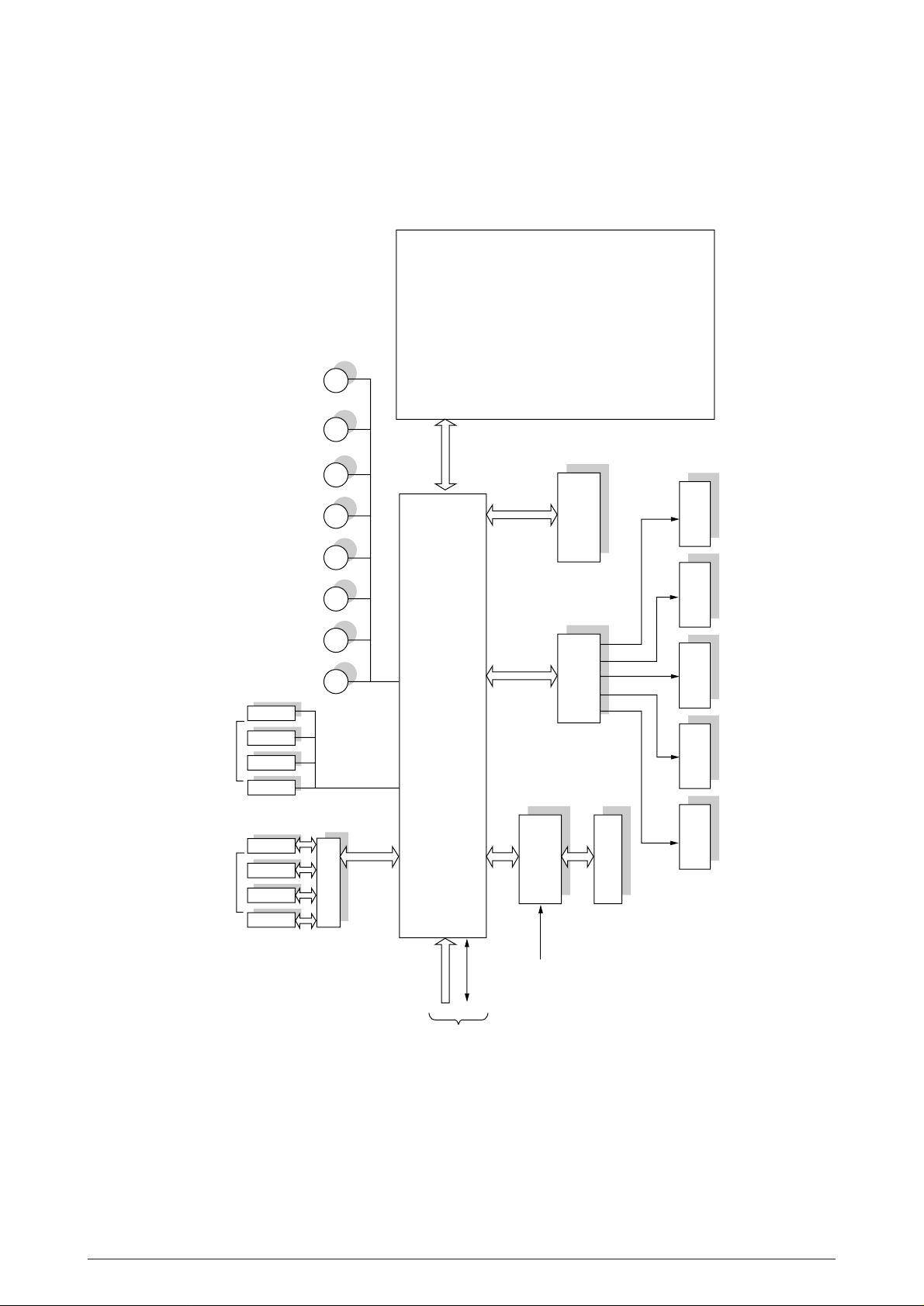

3.2.1 Outline

PU section executes controls such as LED head control, stepping motor control, high-voltage

control, video I/F control, command I/F control and fusing control, and performs color image

printing. The block diagram is shown in Fig3-4.

(1) The print data stored in the video memory is loaded to the LED head control and transferred

through each line to the LED head to light LEDs. This causes a static latent image to form on

the photoconductive drum I.

(2) Stepping motor control: executes ID up/down control for the supply, carriage and ejection of

print media

(3) High-voltage power supply control: executes ON/OFF control for various kinds of power supply

units through serial interface.

(4) Fusing control: executes the control of fusing temperature according to the type of media.

(5) Video I/F control: receives the print data from the controller section (CU) and stores it to the

video memory.

(6) Command I/F control: executes the receiving control of commands from the controller section

(CU) and sending control of status signals.

40985501TH Rev.1 14 /

Page 15

PD6-PCB

Low Voltage

Power Supply

High Voltage

Power Supply

Belt Unit

Y-ID Unit

M-ID Unit

C-ID Unit B-ID Unit

Second Tray

(option)

Fuser Unit

LED Head Eraser Lamp

M

M M M

M M

M M

Y-ID M-ID C-ID B-ID BELT HEATER REGIST FRONT

Stepping Motor

PX4-PCB

PXF-PCB

VIDEO I/F

COMMAND I/F

AC 120V/230V

<Sensors>

• Outlet sensor

• Inlet sensor1

• Inlet sensor2

• Write sensor

• Paper width sensor

• Humidity sensor

• Temperature sensor

• Paper end sensor

• Toner sensors (Y.M.C.K)

• ID Up/Down sensors (Y.M.C.K)

• Waste toner full sensor

• Waste box sensor

• Paper size sensor

• Oil roller sensor

• FF home sensor

• FF Paper end sensor

• Pinch roller up/down sensor

From CU

40985501TH Rev.1 15 /

Figure 3-4 Block Diagram

Page 16

3.2.2 CPU, Memory and LSI

(1) CPU (MSM65524)

CPU core : nX8 (Oki original)

CPU clock : 10 MHz

Data bus clock : 50 MHz

Data bus width: 8 bits

(2) ROM (27512)

ROM capacity : 64K bytes

ROM type : 512K bits, 8 bits

Access time : 150 ns

(3) Resident RAM (62256)

RAM capacity : 32K bytes (Static RAM)

Access time : 70 ns

(4) VIDEO RAM (658512)

RAM capacity : 512K bytes (Pseudo Static RAM)

Access time : 70 ns

The block diagram of CPU, memory and LSI circuits is shown in Figure 3-5.

40985501TH Rev.1 16 /

Page 17

Analogy input (Temperature, Humidity, etc)

CPU BUS

VIDEO I/F

EEPROM

NM93C66N

VIDEO MEM

HM658512

CPU

MSM65524

(include AD Converter)

ROM

27512

Y HEAD I/F (3.3V)

M HEAD I/F (3.3V)

C HEAD I/F (3.3V)

B HEAD I/F (3.3V)

RAM

62296

MT DRIVER

MTD2005F

MT DRIVER

MTD2005F

LSI

(MB87D113)

MT DRIVER

MTD2005F

RESET

CLOCK

High voltage Power Supply Serial I/F (2CH)

Input Port Output Port

Stepping Motor x 8

Figure 3-5 Block Diagram of CPU, Memory & LSI

40985501TH Rev.1 17 /

Page 18

3.2.3 Reset Control

When power is turned on, a RST-N signal is generated by the rising sequence of +5V power supply.

+5V

µ

21

C21

25V 0.1

0VL

PST592

VCC

GND

IC3

OUT

1

R61

0.1W 3.3K

2

13

IC12

QC

LS07

+5V

R63

0.1W 1K

21

Ω

22K

12

2

1

Q11

+5VD

3

Q12

2

D2

23

3

1

IC12

12

QC

+5V

0.1W 3.3K

R60

21

RST-N

+5V

RST-N

+5VD

LS07

Power OFF

Power ON

4V

Approx. 110ms Approx. 20ms

40985501TH Rev.1 18 /

Page 19

3.2.4 EEPROM Control

The NM93C66N is an electrical erasable/programmable ROM of 256-bit x 16-bit configuration.

Data input to and output from the ROM are bidirectionally transferred in units of 16 bits through

a serial I/O port (out DATA-P and IN DATA-P) in serial transmission synchronized with a clock

signal from the CPU(IC10).

IC10

(MSM65524)

OUT DATA-P

15

EEPRMCS0-P

13

INDATA-P

16

EEPRMCLK-P

14

NM93C66N

3

DI DO

1

CS

The EEPROM operates in the following instruction modes

Instruction Start Bit

Read (READ)

Write Enabled (WEN)

Write (WRITE)

Write All Address (WRAL)

Write Disabled (WDS)

Operation

Code

1

1

1

1

1

10

00

01

00

00

Address

NM93C66N

11XXXXXX

01XXXXXX

00XXXXXX

SK

2

A7 to A0

A7 to A0

4

IC2

(PX4-PCB)

Data

D15 to D0

D15 to D0

Erase

Chip Erasable (ERAL)

1

1

11

00

A7 to A0

10XXXXXX

40985501TH Rev.1 19 /

Page 20

CS

SK

CS

SK

DI

DO

Write cycle timing (WRITE)

101

HIGH-Z

A7

Read cycle timing (READ)

A6

A1 A0 D15

D14

Min. 450 ns

STATUS

D1 D0

Max. 500 ns

BUSY READY

Max. 10 ms

DI

DO

HIGH-Z

11 0

A7 A6

A1 A0

D1D14D15 D00

40985501TH Rev.1 20 /

Page 21

3.2.5 LED Head Control

LSI PIN

LSI

IC1

(MB87D113)

PX4-PCB

Y

M

C

K

Signal

HDDTY3

HDDTY2

HDDTY1

HDDTY0

STBY3

STBY2

STBY1

STBY0

HDCK0

HDLD0

HDDTM3

HDDTM2

HDDTM1

HDDTM0

STBM3

STBM2

STBM1

STBM0

HDCK1

HDLD1

HDDTC3

HDDTC2

HDDTC1

HDDTC0

STBC3

STBC2

STBC1

STBC0

HDCK2

HDLD2

HDDTK3

HDDTK2

HDDTK1

HDDTK0

STBK3

STBK2

STBK1

STBK0

HDCK3

HDLD3

Lsi Pin

IC1-136

IC1-135

IC1-134

IC1-133

IC1-144

IC1-143

IC1-142

IC1-141

IC1-137

IC1-140

IC1-149

IC1-148

IC1-147

IC1-146

IC1-157

IC1-155

IC1-154

IC1-153

IC1-151

IC1-152

IC1-161

IC1-160

IC1-159

IC1-158

IC1-169

IC1-168

IC1-167

IC1-166

IC1-164

IC1-165

IC1-173

IC1-172

IC1-171

IC1-170

IC1-181

IC1-180

IC1-179

IC1-178

IC1-176

IC1-177

CN2CN1 CN3 HEAD CN

PD6-PCB

CN1

HEAD1-4

HEAD1-3

HEAD1-2

HEAD1-1

HEAD1-10

HEAD1-9

HEAD1-8

HEAD1-7

HEAD1-5

HEAD1-6

HEAD2-1

HEAD1-13

HEAD1-12

HEAD1-11

HEAD2-7

HEAD2-6

HEAD2-5

HEAD2-4

HEAD2-2

HEAD2-3

HEAD2-11

HEAD2-10

HEAD2-9

HEAD2-8

HEAD3-3

HEAD3-2

HEAD3-1

HEAD2-14

HEAD2-12

HEAD2-13

HEAD3-9

HEAD3-8

HEAD3-7

HEAD3-6

HEAD3-15

HEAD3-14

HEAD3-13

HEAD3-12

HEAD3-10

HEAD3-11

CN2

HEAD1-4

HEAD1-3

HEAD1-2

HEAD1-1

HEAD1-10

HEAD1-9

HEAD1-8

HEAD1-7

HEAD1-5

HEAD1-6

HEAD2-1

HEAD1-13

HEAD1-12

HEAD1-11

HEAD2-7

HEAD2-6

HEAD2-5

HEAD2-4

HEAD2-2

HEAD2-3

HEAD2-11

HEAD2-10

HEAD2-9

HEAD2-8

HEAD3-3

HEAD3-2

HEAD3-1

HEAD2-14

HEAD2-12

HEAD2-13

HEAD3-9

HEAD3-8

HEAD3-7

HEAD3-6

HEAD3-15

HEAD3-14

HEAD3-13

HEAD3-12

HEAD3-10

HEAD3-11

Y HEAD

M HEAD

C HEAD

K HEAD

CN3

Y600-5

Y600-4

Y600-8

Y600-7

Y600-14

Y600-13

Y600-12

Y600-11

Y600-2

Y600-10

M600-5

M600-4

M600-8

M600-7

M600-14

M600-13

M600-12

M600-11

M600-2

M600-10

C600-5

C600-4

C600-8

C600-7

C600-14

C600-13

C600-12

C600-11

C600-2

C600-10

K600-5

K600-4

K600-8

K600-7

K600-14

K600-13

K600-12

K600-11

K600-2

K600-10

HEAD CN

Y-5

Y-4

Y-8

Y-7

Y-14

Y-13

Y-12

Y-11

Y-2

Y-10

M-5

M-4

M-8

M-7

M-14

M-13

M-12

M-11

M-2

M-10

C-5

C-4

C-8

C-7

C-14

C-13

C-12

C-11

C-2

C-10

K-5

K-4

K-8

K-7

K-14

K-13

K-12

K-11

K-2

K-10

40985501TH Rev.1 21 /

Page 22

PX4-PCB

LED Head

IC1

(MB87D113)

HDDTX0

HDDTX1

HDDTX2

HDDTX3

HDCLKX

HDLDX

STBX0

STBX1

STBX2

STBX3

5

4

8

7

2

10

14

13

12

11

Head Lsi

with EEPROM

Driver IC

Driver IC Driver IC

Driver IC

38

X=Y, M, C or B

Data is transferred to the head unit starting with the data at the left end of the paper in the

synchronous serial transfer mode using the HDCKX signal as the sync signal.

The total number of LEDs in the head unit is 4992. The data for the driver latches causes the

corresponding LEDs to light only during the time when the STBXn signal is output. There are four

STBXn signals (STBX0, STBX1, STBX2 and STBX3), each of which controls the corresponding

driver for 1248 LEDs (4992/4).

The four STBXn signals must be output within the time when the LEDs for one line continue to emit

light. After the data is moved to the latches by the STBXn signal, the transfer of the data of the next

line can be started.

40985501TH Rev.1 22 /

Page 23

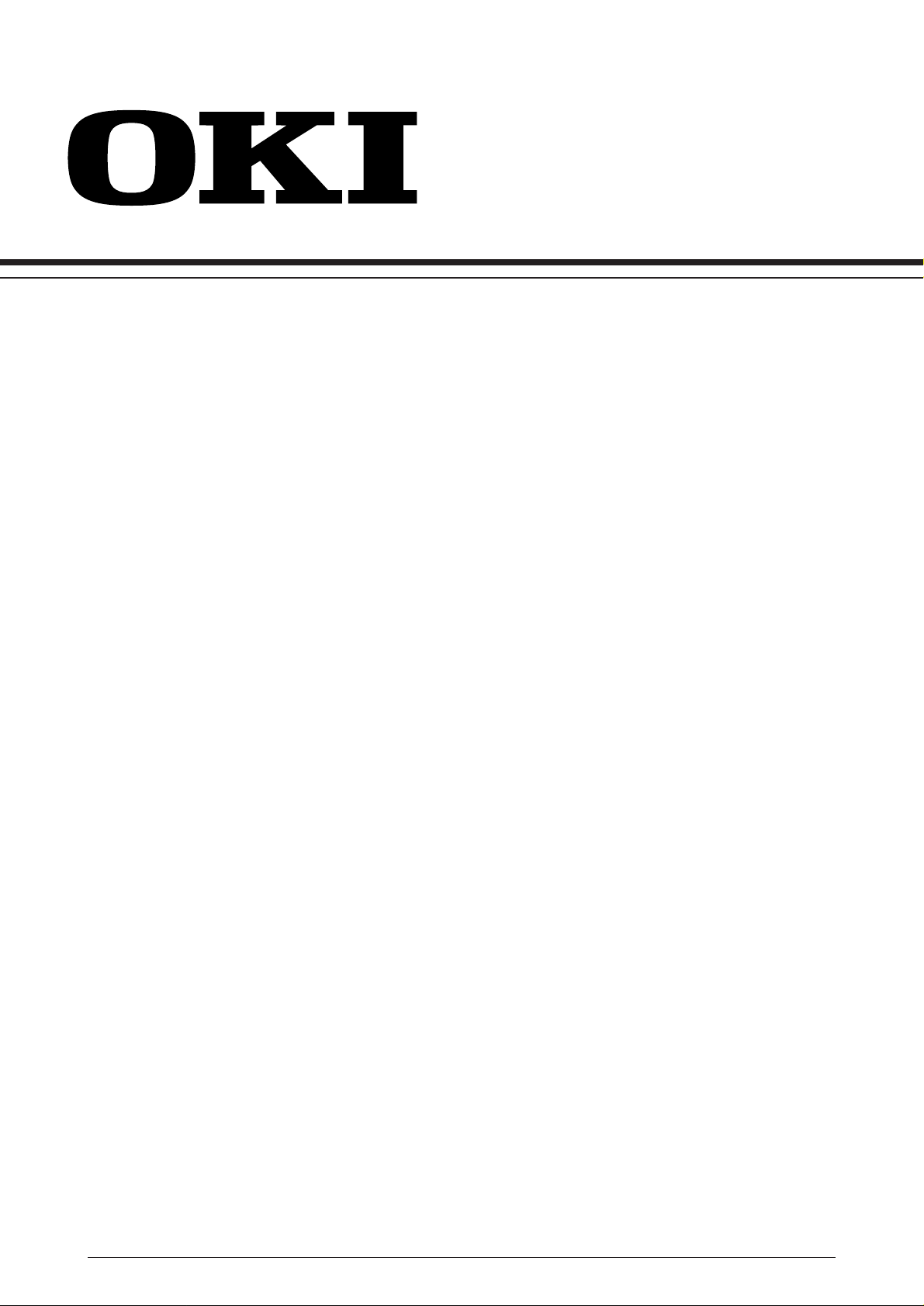

The timing chart for the outline of this operation is shown below.

HDCKX

HDDTX0

HDDTX1

HDDTX2

1

59

2 6 10 4986 4990

3

11 4987 4991

7

4985

4989

✰

The LED lights

when the head

data is HIGH.

HDDTX3

HDCKX

HDDTX0

HDDTX1

HDDTX2

HDDTX3

HDLDX

STBX0

STBX1

STBX2

STBX3

4 8 12 4988 4992

Each figure denotes the dot

position taking the left end bit

position as "1".

Print activation

timing for the

1st line

LEDs

1-1248

lit

LEDs

1249-2496

lit

LEDs

2497-3744

lit

Print activation timing

for the 2nd line

LEDs

3745-4992

lit

Print activation timing

for the final line

40985501TH Rev.1 23 /

Page 24

3.2.6 Motor Control

OKIPAGE 8c controls the paper flow by eight motors (Four ID Motors, Hopping Motor, Front feed

Motor, Belt Motor).

(1) ID motor

The four ID motors for rotate four color IDs are driven by the driver IC according to the control

signal from the IC1 (MB87D113).

The IC8 (62354) is a Digital to Analogy Converter controlled by CPU (IC10 : MSM65524) and

its output voltage controls several ID motor current.

40985501TH Rev.1 24 /

Page 25

IC1 (MB87D113)

189

188

111

YIDON

190

192

191

MIDON

193

195

194

CIDON

196

200

199

KIDON

201

YIDPHA

YIDPHB

IDMOTON-N

MIDPHA

MIDPHB

CIDPHA

CIDPHB

KIDPHA

KIDPHB

26

17

27

16

23

20

26

17

27

16

23

20

26

17

27

16

23

20

26

17

27

16

23

20

IC15

MTD2005F

IC16

MTD2005F

IC17

MTD2005F

IC18

MTD2005F

Y-ID REG

3

7

8

12

3

7

8

12

3

7

8

12

3

7

8

12

1

3

2

4

9

11

10

12

5

7

6

8

1

3

2

4

Y-ID motor

M

M-ID motor

M

C-ID motor

M

K-ID motor

M

IDREF

IDMOTON-N

XIDON

XIDPHA

XIDPHB

Rotation

IC8

(62354)

Power ON

6

IDREF

Initial process

Stop

T0 T1 T2

T3

T4 T5 T6

Reverse rotation

Forward rotation speed : T0 to T3= (Print operation)

Reverse rotation speed : T4 to T7= (ID up operation)

T7

40985501TH Rev.1 25 /

Page 26

(2) Regist motor

The Regist motor is driven by the driver IC14 according to the control signal from the LSI (IC1:

MB87D113). The Regist motor current is controlled by the DAC (IC8 : 62354).

REGON

REGPHA

REGPHB

PX4-PCB

IC1

(MB87D113)

IC8

(62354)

T0 T1 T2 T3

REGPHA

203

REGPHB

202

REGON

204

REGREF

11

26

17

27, 16

23, 20

IC14

(MTD2005F)

3

7

8

12

YIDREG

5

7

6

8

T4 T5 T6 T7

Regist

Motor

M

Rotation

Stop

Forward rotation

Reverse rotation

(Hopping operation) (Regist operation)

Hopping Operation speed: T0 to T3 =

Regist Operation speed: T4 to T7 =

µ

s

µ

s

40985501TH Rev.1 26 /

Page 27

(3) Front feed motor

The Front feed motor is driven by the driver IC13 according to the controll signal from the LSI

(IC1 : MB87D113).

The Regist motor current is controlled by the DAC (IC8 : 62354)

FFON

FFPHA

FFPHB

PX4-PCB

IC1

(MB87D113)

IC8

(62354)

T0 T1 T2 T3

211

208

212

12

FFPHA

FFPHB

FFON

FFREF

26

17

27, 16

23, 20

IC13

(MTD2005F)

FF

Front Feed

3

Motor

M

7

8

12

T4 T5 T6 T7

Rotation

Stop

Forward rotation

Reverse rotation

(Paper feed operation) (Pinch roller up/down operation)

Paper feed operation speed: T0 to T3 =

Pinch roller up/down operation speed: T4 to T7 =

µ

s

µ

s

40985501TH Rev.1 27 /

Page 28

(4) Belt motor

The Belt motor is driven by the driver IC19 according to the control signal from the LSI (IC1

: MB87D113).

The Belt motor current is controlled by the DAC (IC8 : 62354).

BELTON

BELTPHA

BELTPHB

PX4-PCB

IC1

(MB87D113)

IC8

(62354)

T0 T1 T2 T3

BELTPHA

21

BELTPHB

20

BELTON

22

BELTREF

9

26

17

27, 16

23, 20

IC19

(MTD2005F)

3

7

8

12

HETBELT

5

7

6

8

Belt Motor

M

Rotation

Forward rotation

(Belt feed operation)

Belt feed speed: T0 to T3 = µs

Reverse rotationStop

40985501TH Rev.1 28 /

Page 29

(5) Heat motor

The Heat motor is driven by the driver IC20 according to the control signal from the LSI (IC1

: MB87D113).

The Heat motor is controlled by the DAC (IC8 : 62354).

HETON

HETPHA

HETPHB

PX4-PCB

IC1

(MB87D113)

IC8

(62354)

T0 T1 T2 T3

HEATPHA

206

HEATPHB

205

HEATON

207

HEATREF

10

26

17

27, 16

23, 20

IC20

(MTD2005F)

3

7

8

12

HETBELT

1

3

2

4

Heat Motor

M

T4 T5 T6 T7

Rotation

Stop

Forward rotation

(Heating operation)

Heating speed: T0 to T3 = µs

Reverse rotation

40985501TH Rev.1 29 /

Page 30

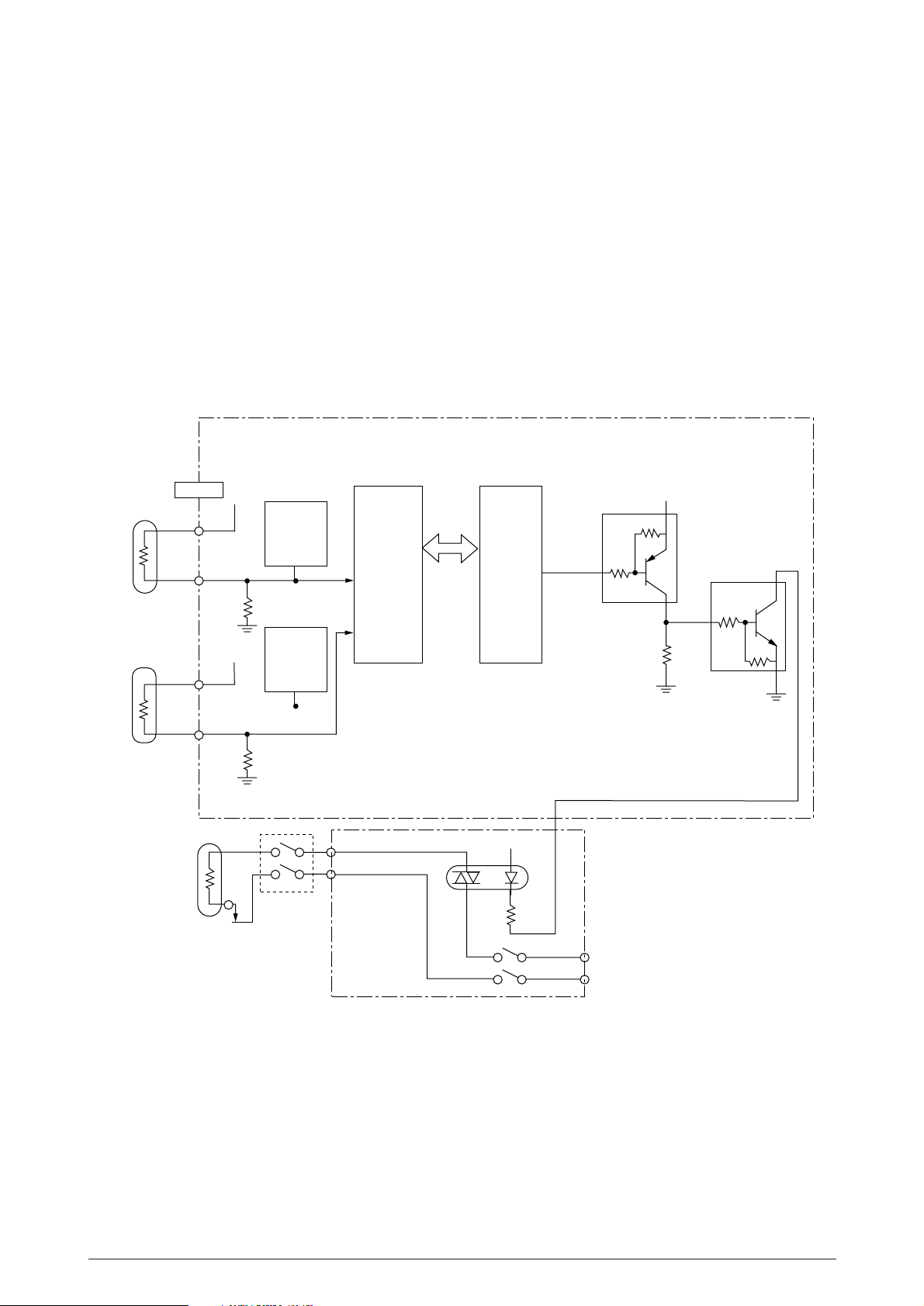

3.2.7 Fuser Temperature Control

For the temperature control by heater control, the variation in the resistance of the thermistor is A/

D converted in and the resultant digital value is read and transferred to the CPU. The CPU turns

on or off the HEATON-N signal according the value of the signal received from to keep the

temperature constant.

Immediately after the power is turned on, the thermistor is checked for shortcircuit and breakdown.

If the thermistor is shorted, the A/D converted value shows an extremely high temperature, so that

the shortcircuit can be detected. If the breakdown of the thermistor occurs, the A/D converted value

shows the normal temperature. In this case, the thermistor breakdown can be detected by the

sequence shown at the end of this section. If the heater is overheated, 5V supply is turned off by

detecting that the resistance of the thermistor exceeds the predetermined value.

PX4-PCB

Heat roller

Thermistor

: TH

Back-up roller

thermistor

: TB

Thermostat

Heater

THERM

+5V

+5V

Interlock SW

Thermistor

Thermistor

breakdown

detect

circuit

Thermistor

breakdown

detect

circuit

IC10

(MSM65524)

AD7

60

AD6

59

5V

Low Voltage Power Supply

Bus

IC1

(MB87D113)

+5V

HEATON-N

237

Q13

+5VD

Q10

AC120V/230V

Power SW

40985501TH Rev.1 30 /

Page 31

The temperature control is described below.

T : Heat roller temperature

Temperature

˚C

T

P

T = 150˚C

H

T= + 1/2

T

T

H

B

C Hopping C Hopping

H

T : Back-up roller temperature

B

T : Printing temperature

P

ON OFF OFFHEATON-N

Heater is controlled by CPU (IC10 : MSM65524) as followings.

Temperature

T<150˚C

150˚C<T<T

T <T

P

Relationship of the printing temperature (T ) and speed against media type as follows.

Media type

Light

Medium Light

Medium

Medium Heavy

Heavy

Special

Transparency

P

HEATON-N

ON

C Hopping

OFF

T

P

200˚C

200˚C

215˚C

215˚C

220˚C

225˚C

220˚C

P

Print Speed

8ppm

8ppm

8ppm

8ppm

8ppm

6ppm

6ppm

40985501TH Rev.1 31 /

Page 32

To detect the breakdown of the heater, the heater is turned on. If the corresponding temperature

rise is not detected, it is judged that heater breakdown occurs. To shorten the breakdown detecting

time, the following circuit is used. When the thermistor is checked for breakdown immediately after

the power is turned on, the THCHK-N signal is turned on to turn transistors Q1 and Q506 off. As

a result, the thermistor serial resistance is varied to increase the reading resolution.

5V

IC10

Heat roller

Thermistor

5V

Q1

(MSM65524)

Back-up roller

Thermistor

5V

IC1

(MB87D113)

230

Q506

40985501TH Rev.1 32 /

Page 33

3.2.8 Fan Motor Control

OKIPAGE 8c has two cooling fans.

The stop/rotation of the fan motor is controlled by a FANON0-P and FANON1-P signals. When

the fan motor rotates normally, a FANERR0-P and FANERR1-P signals generated in the hole

element built in the fan motor is input to the IC1 (MB87D113).

PX4-PCB

IC1

(MB87D113)

+32V

FAN1

FANON0-P

233

FANERR0-P

239

FANON1-P

232

FANERR1-P

238

FAN Motor1

1

+5V

M

2

3

+32V

POWER

FAN Motor2

19

+5V

M

20

Low Voltage Power Supply

n

FANON -P

FANALARM -N

n

1 sec max

0.7 sec max

FAN MOVE

Lockn=0, 1

Fan motor start:Power on

Fan motor stop: • The motor immediately stops when a fan error occurs.

• The motor stops in the cover open state (fan1 only).

40985501TH Rev.1 33 /

Page 34

3.2.9 Sensor Supervision

OKIPAGE8c unit is provided with 23 sensors.

The sensor signals are read directly from the input ports of CPU (IC10: MSM65524) and LSI (IC1:

MB87D113).

Front Feeder Unit

Pinch roller

up/down sensor

Front feeder

paper end sensor

Front feeder

Home position sensor

PD6-PCB

PENDF-N

EFPOS-N

PX4-PCB

2

3

22

IC10

(MSM65524)

IC1

(MB87D113)

6

10

9

8

7

57

58

10

217, 218

219,220

213, 214

215, 216

15

HEATR-N

HOP-N

PAPIN-N

PAPW1D-N

PSWR-N

HUM-P

TEMP-P

PEND-N

TNRY.M.C.K

IDPOSY.M.C.K

TNRFUL-N

PXF-PCB

4

4

PXM-PCB

Inlet

sensor1

Inlet

sensor2

Write

sensor

Paper width

sensor

Humidity

sensor

Temperature

sensor

Paper end

sensor

Toner

sensor(Y.M.C.K)

ID up/down

sensor(Y.M.C.K)

Wast toner

full sensor

OILPAD

Oil roller

sensor

27

16

TNRBOX-N

4, 5, 8, 9 4

PAPSIZE0~3

Toner box

sensor

PXC-PCB

1st Tray

Paper size sensor board

40985501TH Rev.1 34 /

Page 35

3.2.10 Cover Open

When the cover (upper cover, side cover, front cover) is opened, a cover open microswitch opened.

This makes a CPUCVOPN signal low, then off the +5VD, thereby the CPU detects the open state.

Furthermore, opening the cover stops applying a +32V power to the high voltage power supply unit

and stepping motor drivers, and stops applying a AC120V/230V power to the fuser unit, resulting

in stopping all high voltage outputs, motor driver outputs and heater output.

High Voltage

Power Supply

High Voltage

output

Low Voltage

Power Supply

AC120V/

230V

+32V

HTDV HTDV HTDV

stepping motor drivers

5VD+5V

11

IC10

(MSM65524)

PX4-PCB

MSW x 3

(Upper cover, side cover and Front cover)

Fuser Unit

Interlock SW

(Upper cover)

CPUCVOPN

+5VD

0V

Cover close Cover open

40985501TH Rev.1 35 /

Heater

Page 36

3.2.11 Power Supply Interface

The power supply interface is a 16 bit clock synchronous serial interface between the synchronous

serial I/O ports of CPU (IC1: MB87D113) and the power control LSI in the power supply board (High

voltage) under the control of the CPU (IC10: MSM65524).

When the control section transmits a command on POWDOUTn-P signal in synchronization with

the clock (POWSCLKn-N) to the power supply board, this power supply board transmits a

response on POWDINn-N signal in synchronization with the same clock to the control section.

The commands include the control data of the high-voltage power supply, etc.

The responses include high voltage output value, etc.

PX4-PCB

(MB87D113)

IC10

(MSM65524)

IC1

225

224

226

HVOLT

POWDOUT1-P

POWSCLK1-N

POWDIN1-P

High Voltage Power Supply Board

LSI

POWDOUTn-P

POWSCLKn-N

POWDINn-P

POWSQCR-N

223

228

227

229

LSB

b0 b1 b2 b3 b4 b5 b6 b7 b8 b9 b10 b11 b12 b13 b14 b15

POWSQCR-N

POWDOUT2-P

POWSCLK2-N

POWDIN2-P

Command

MSB

Response

b0 b1 b2 b3 b4 b5 b6 b7 b8 b9 b10 b11 b12 b13 b14 b15

LSI

n=1, 2

40985501TH Rev.1 36 /

Page 37

3.2.12 Option (2nd paper feeder) Interface

The option interface is a 8 bit clock synchronous serial interface between the synchronous serial

I/O ports of CPU (IC10: MSM65524) and 4 bit micro-controllers in the option control boards under

the control of the CPU (IC10: MSM65524).

First the control section transmits a command on OPTSD-P signal in synchronization with the clock

(OPTSCLK-N) to the option.

The option which receives the command will analyze it and assert OPTSDR-N signal after

becoming a ready state for returning a response. When the control section recognizes the

OPTSDR signal asserted, it will output a clock signal only at this time.

The option will output a response on the OPTSD-P signal line in synchronization with this clock

signal (OPTSCLK-N).

The commands include the control data, etc.

The responses include sensor information, etc.

OPTSD-P

OPTSCLK-N

OPTSDR-N

Jackln connector

PX4-PCB PXF-PCB

PXFIF

IC10

(MSM65524)

b0 b1 b2 b3 b4 b5 b6 b7 b0 b1 b2 b3 b4 b5 b6 b7

OPTSD-P

OPTSCLK-N

OPTSDR-N

COMMAND RESPONSE

PXFIF OPTION

A4

A4

B3

B3

B4

B4

(14P)

3

2

4

Jackln connector

(14P)

AOLO-PCB (2nd paper feeder)

Control

circuit

40985501TH Rev.1 37 /

Page 38

3.2.13 Power Supply Board

The power supply circuit consists of the low-voltage power supply circuit and the high-voltage

power supply circuit. The low-voltage power supply circuit adopts a switching power supply system

and provides DC voltages required for the control of the equipment. The high-voltage power supply

circuit receives low-voltage power from the low-voltage power supply circuit and provides various

high voltages required for the electrophotographic process according to the control signals from

the control section.

(1) Low-voltage power supply circuit

SW

F1 F52

ACIN

Noise

filter

circuit

Switching

circuit/

Resonation

Rectifying/

smoothing

circuit

+8V

–8V

ACON-N

POW ON

Heater

control

circuit

ACOUT

(CN1)

Switching /

resonance

control

circuit

Rectifying/

smoothing

circuit

Rectifying/

smoothing

circuit

over voltage/

over current

detector

circuit

F51

regulating

circuit

Voltage

detector

circuit

+32V

+3.3V

over voltage/

over current

detector

+5V

+12V

-12V

+32V

+5V

+ 5V

+ 32V

+ 3.3V

+ 12V

– 12V

40985501TH Rev.1 38 /

Page 39

(2) High-voltage power supply circuit

This high-voltage power supply circuit receives the high-voltage generation timing control

command that is transmitted in serial through the power supply interface from the control

section. It decodes this command by LSI (IC102, 201) and outputs high-frequency pulses

(PWM) to the corresponding high-voltage generating circuits through pins 11, 12, 13, 14, 15,

16, 17 and 18 of LSI (IC102, 201). It supplies +38V to each high-voltage generating circuit

as the source voltage. When the cover is open, the supply of +32V is interrupted to interrupt

all the high-voltage outputs. The relationship between the PWM output pins and the highvoltage outputs is shown in the following table.

Power Supply Board (High voltage)

Control section

G/A

+5V

+32V

+5V

+32V

LSI

(IC102)

LSI

(IC201)

11

12

13

14

15

16

17

18

11

13

15

+5V

DB2(-)

(common)

+5V

DB1(+)

+5V/+12V

Reference

generation

+5V

+5V

+5V

TR-Y

DB2(-)

(common)

DB2(-)

(common)

DB2(-)

(common)

DB2(-)

(common)

SB1(+)

SB2(-)

FIX

CH

+32V

TR-Y

DB-Y

DB-M

DB-C

DB-B

SB

FIX

CH

TR-Y

+12V

40985501TH Rev.1 39 /

+12V

Reset

circuit

Output inhibit

circuit

LSI Reset

16

17

18

Reference

generation

Reference

generation

Reference

generation

TR-M

TR-C

TR-B

TR-M

TR-C

TR-B

TR-M

TR-C

TR-B

Page 40

[IC102]

PWM

output pins

High-voltage

outputs

DB-Y DB-M DB-B SB

DB-C

11

11, 12

11, 13

11, 14

11, 15

16

17

18

—

-275V

+300V

—

-275V

+300V

—

-275V

+300V

-290V

+300V

+450V

-450V

Note 1) No output for 11 only. When DB2(-) is outputted, pulse is outputted simultaneously.

Note 2) -255V only for the first page printing

[IC201]

High-voltage

PWM

output pins

outputs

11

FIX CH TR-M TR-C

TR-Y

0.5~2.5KV

TR-B

13

15

16

17

18

1.35KV

0.5~4KV

0.5~4KV

0.5~4KV

0.5~4KV

40985501TH Rev.1 40 /

Page 41

Interface command

A.Output ON/OFF

b13

DB1

0

Higher 8 bits

b120b11

DB2-Y, M, C, B

BCMY

b10

b9

0

0

SB2

0

CH

0

b8

DB2

common

DB1/SB1

common

FIX

CHAN1

CHAN2

Lower 8 bits

22

30H

10H

30H

b14

b15

SB1

SB2

0

0

TR-Y, M, C, B

BCMY

Note 1) With the bit corresponding to each output, if it is 0, OFF and 1, ON.

Note 2) The output which has plural bit control is outputted by AND condition (where

both bits are 1(ON)). Also, the combination of bits such as reverses output

polarity is prohibited.

B. Output voltage settings

CHAN1

Lower 8 bits

34H

44H

54H

64H

Pertinent

output

DB-Y

DB-M

DB-C

DB-B

Higher 8 bits

DB2 Output voltage setting value

74H

84H

94H

CHAN2

24H

44H

64H

74H

84H

94H

C. Output current measurement

Read command

(Lower 8 bits)

CHAN2

17H

DB1

SB1

SB2

FIX

CH

TR-Y

TR-M

TR-C

TR-B

DB1 Output voltage setting value

SB1 Output voltage setting value

SB2 Output voltage setting value

FIX Output voltage setting value

CH Output voltage setting value

TR Output voltage setting value

Read data

(Higher 8 bits reply)

Measured current value of FIX output

Note 1)

40985501TH Rev.1 41 /

Page 42

3.3 PCR-PX4 I/F

3.3.1 Outline

PCR-PX4 I/F sends video data, which received, edited, extracted and produced, to PX4, the printer

engine control section, and allows inter-transmission of commands and status. Also, the power

for PCR is supplied through this I/F connector.

Video

Interface

CU PU

WDATA0~7

COL0, COL1

WCLK, LSYNC

FSYNCY, FSYNCM, FSYNCC, FSYNCK

8

LED head

write circuit

timing circuit

Command

Interface

Division

Video

interface

Command

Signal name

WDATA0~7

COL0

COL1

WCLK

LSYNC

FSYNCY

FSYNCM

FSYNCC

FSYNCK

PPRDY

PPRDY, PRDY, ERR, SCLK, SBSY

CPRDY, PRINT, CBSY

SC

Polarity

Neg.

Neg.

Neg.

Neg.

Neg.

Neg.

Neg.

Neg.

Neg.

Pos.

CU•CP

.

.

.

,

,

,

,

,

,

,

Print data (8 bit parallel)

Color designating signal

Color designating signal

Serial image signal clock

Synchronizing signal of line scan

Yellow page synchronizing signal

Magenta page synchronizing signal

Cyan page synchronizing signal

Black page synchronizing signal

Printer Power-on/ready

Transmit-receive

control

Functions

interface

40985501TH Rev.1 42 /

PPDY

ERR

SCLK

SBSY

CPRDY

PRINT

CBSY

SC

Neg.

Neg.

Neg.

Neg.

Pos.

Neg.

Neg.

Neg.

,

,

,

,

.

.

.

↔

Printer Ready

Changed status notifying signal

Clock for SC

PU occupies SC and SCLK

Controller Power-on/ready

Print start

CU occupies SC and SCLK

Status/command signal

Page 43

3.3.2 Video I/F

Video data is sent from PCR in synchronization with WCLK sent from PX 4

When PX4 is in ready status (PRDY = Low), PCR gives a printing start instruction to PX4 by PRINT

Low Plus or command to send an extracted video data. When receiving the printing start

instruction, PX4 becomes BUSY status (PRDY=High) and starts a paper hopping. After the paper

reached the specified position, PX4 sends each FSYNC of WCLK, LSYNC and YMCK.

FSYNC becomes enabled due to its tandem structure, synchronizing with the pass of a paper

through each ID.

If PX 4 becomes enabled to receive next page video data during printing the first page, it sets PRDY

to Low and returns to Ready status.

For 4-color video data, 4 colors are sent through 1 line in 8 bit width in synchronization with LSYNC.

4 patterns of status of COL1,_ indicate which YMCK the currently sent data is. The color data is

sent in accordance with each status by changing COL1,_ 4 times at one LSYNC. Even when

FSYNC is disabled, the sending mode of each color exists only for the specified WCLK, but the

sending of video data won’t be executed.

IMEM

µ

PD94704

WDATA7-N

~

WDATA0-N

COL1-N

COL0-N

WCLK-N

LSYNC-N

FSYNCY-N

FSYNCM-N

FSYNCC-N

FSYNCK-N

PX4-PCBPCR-PCB

+5V

IC13

88

16244

IC13

EM1

+5V

+5V

x 8

x 8

IC1

MB87D113PFV

(LSI)

WDATA7

~

WDATA0

COL1

COL0

WCLK

LSYNC

FSYNCY

FSYNCM

FSYNCC

FSYNCK

IIF

µ

PD66044

PRINT-N

PRDY-N

40985501TH Rev.1 43 /

IC20

IC20

IC10

M65524

(CPU)

PRDY

Page 44

PRINT

g

PRDY

FSYNCY

FSYNCM

FSYNCC

FSYNCK

LSYNC

COL1

COL2

WDATA0~7

WCLK

Print interval for one page

Drum one sycle or more, including heater warm up time (MAX. 60min.)

Under 4-color printin

LSYNC

COL0

COL1

WDATA0~7

WCLK

WCLK

LSYNC

WDATA0~7

Enlarged chart for 4-color printing

Y=00 M=01 C=10 K=11

YDATA MDATA CDATA KDATA YDATA MDATA CDATA KDATA

1 line 4-color data

40985501TH Rev.1 44 /

Page 45

3.3.3 Command Interface

(1) Command Interface Time Chart

Power on

Communication enabled status

PPRDY

*1

CPRDY

*1

CBSY

Command

SBSY

MSB LSB MSB LSB

SC

SCLK

*2

Status

*1 For timing to set PPRDY and CPRDY to on, which of them is earlier is not specified.

After powering on, they are set to on when the initial process is completed and they are

changed to the communication enabled status. Therefore, at the point when PPRDY and

CPRDY are set to on, the communications are to become the enabled status.

*2 SCLK should be 50% DUTY.

40985501TH Rev.1 45 /

Page 46

(2) Controlling Command Interface

a) Under regular operation

CU sets CBSY to ON and sends a command to PU. At this time, PU section sends clock

signals and CU recognizes the completion of command sending by receiving 8 clock

signals. And CU returns CBSY to OFF.

Next, PU sets SBSY to ON and sends a reply for the command it receives. At this time,

PU sends clock signals and returns SBSY to OFF in the same way. CU recognizes the

completion of the reply receiving by receiving 8 clock signals.

If the completion of sending or receiving cannot be recognized for a fixed time, a command

is retransmitted. Therefore, a timer is provided for monitoring the completion of

communication, and started when a command is sent and stopped when the receiving is

completed.

The value for timer should be determined from higher values than T max. value in the

following figure.

timer timer stop timer

CBSY

Sending completed

SBSY

Receiving completed

T max.

T max= 19ms

40985501TH Rev.1 46 /

Page 47

b) Under irregular operation-1 (when a command sending is not normally performed)

When CU sends a command to PU and a noise or hardware malfunction causes to skip

clock sending, CU cannot recognize the completion of sending, so CBSY is left ON.

Therefore, return CBSY to OFF once by the time-out of timer described in (1), and after

time compensation for T min., retry the sending and receiving sequence by retransmitting

the command.

When the communication cannot be succeeded by the first retry, execute the second retry.

When the second retry cannot succeed, some message is indicated to the operator and

the system is to be shut down.

Note: Since the PU section cannot recognize the skip of the clock, an irregular

command from CU is processed as it is, and when CBSY is set to OFF, a reply

for the command is returned. Thus, for CU section, a reply is returned even

though the sending cannot be completed, so it must receive and flush the

reply.

timer

CBSY

Sending completed

SBSY

Receiving completed

c) Under irregular operation -2 (When a reply receiving is not normally performed)

When PU returns a reply to CU and a noise or hardware malfunction causes to skip clock

sending, CU cannot recognize the completion of receiving. Therefore, retransmit the

command by the time-out described in (1) and retry the sending and receiving sequence.

When the communication cannot be succeeded by the first retry, execute the second retry.

When the second retry cannot succeed, some message is indicated to the operator and

the system is to be shut down.

timer timer

CBSY

time-out

retry

T min

time-out

retry

timer

Sending completed

SBSY

Receiving completed

40985501TH Rev.1 47 /

Page 48

4. TROUBLESHOOTING

4.1 Troubleshooting Table

Normal operation

When powered on, the page printer

turns on LEDs for about one sec-

ond to check whether the LEDs and

the LCD are normal.

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

Normal operation

To clear this message, press the

RESET switch.

To clear this message, press the

RESET switch.

Normal operation

Normal operation

When “CLEARABLE WARNINGS”

on the menu is set to “ON”, press

the RECOVER switch to clear the

message.

Normal operation

Displayed when the page printer is powered on.

Table 4.1 Status and alarm indication list

Undefined Undefined Undefined Undefined ON OFF

Displayed while the controller is initializing (after the

page printer is powered on).

The printer is in the on-line mode.

The printer is in the off-line mode.

Undefined Undefined Undefined Undefined OFF OFF

Undefined Undefined Undefined Undefined ON Undefined

Undefined Undefined Undefined Undefined OFF Undefined

Displayed while the page printer is printing.

Displayed while the page printer is receiving data

or performing the output processing.

Indicates that the data remains unprinted in the

buffer.

This message is displayed data remain unprinted

in the buffer (offline). This message prompts the

user to press the RESET switch, if cancel the data.

This message prompts the user need to press the

RESET switch before writing the new menu setting

in EEPROM.

This message is displayed when the printer cannot

reset automatically as there remain data and tem-

porary attributes (DLL, macro, user patter, or user

symbol set) .

Indicates that the data (to the end of processing) is

Undefined Undefined Undefined Undefined Undefined Undefined

Undefined Undefined Undefined Undefined Blink Undefined

Undefined Undefined Undefined Undefined Undefined Undefined

Undefined Undefined Undefined Undefined ON Undefined

Undefined Undefined Undefined Undefined OFF OFF

Undefined Undefined Undefined Undefined Blink OFF

being canceled.

Indicates that a printer language which is not avail-

able has been specified by the PJL command.

Undefined Undefined Undefined Undefined Undefined Undefined

Displays the number of a copies being printed out

when the number of copies being printed is two or

more.

Undefined Undefined Undefined Undefined Undefined Undefined

ttttt

ttttt

Message K C M Y READY ATTENTION Trouble or Status Remedy

INITIALIZING

ON-LINE . xxx

OFF-LINE . xxx

PRINTING

PROCESSING . xxx

DATA PRESENT. xxx

RESET TO FLUSH

Category LCD Status LED

Daily status

40985501TH Rev.1 48 /

RESET TO SAVE

FLUSHING JOB

PS NOT AVAILABLE

COPY nnn/mmm

Page 49

This massage is cleared when the

drum is properly positioned or

sensor lever which is exchanged

correspond to the LED color lights.

Normal operation

Normal operation

This message is cleared when the

toner cartridge is replaced.

Normal operation

This message is cleared when the

specified drum is replaced.

Indicates that Toner sensor is abnormal when page

counter is above thirty . (The LED of the color lights)

Indicates that the page printer enters the Power

Save mode (in which the heater is powered off).

Indicator that the toner of the specified color is

running out. However, when “LOW TONER” is set

to “OFF,” the ATTENTION indicator blinks.

Indicates that the life of a specified color drum has

come.

(The LED of the color lights.)

After the drum is replaced, its drum

counter must be reset. (See the us-

er’s manual.)

Normal operation

This message is cleared when the

Heat unit Assy is replaced. After the

Heat unit Assy is replaced, its

counter must be reset. (See the

user’s manual.)

Normal operation

This message is cleared when the

Indicates that the life of the Heat unit Assy has come.

Indicates that the life of the belt cassette Assy has

come.

belt cassette assembly is replaced.

After the belt cassette assembly is

replaced, its counter must be reset.

(See the user’s manual.)

Normal operation

Cleans the data left unprinted in the buffer and ini-

tializes the printer to the user default status. The

Normal operation

temporary DLL, macro, and user patterns are de-

leted.

Prints out a demo page.

This operation is started by a command when the

READY LED is on or by a switch when the READY

LED is blinking.

ON ON ON ON Undefined ON

Message K C M Y READY ATTENTION Trouble or Status Remedy

TNR SNS *******

Category LCD Status LED

Daily status

40985501TH Rev.1 49 /

ON ON ON ON Undefined ON or Blink

Undefined Undefined Undefined Undefined Undefined Undefined

POWER SAVING

TNR LOW *******

ON ON ON ON Undefined ON

CNG DRUM *******

Undefined Undefined Undefined Undefined Undefined ON

FUSER LIFE

Undefined Undefined Undefined Undefined Undefined ON

BELT LIFE

OFF OFF OFF OFF OFF OFF

RESET

Undefined Undefined Undefined Undefined Blink or ON Undefined

PRINT DEMO PAGE

Page 50

Normal operation

Prints out a menu setting.

This operation is started by a command when the

This massage is cleared when the oil

roller assy is replaced. After the oil roller

assy is replaced, its counter must be

reset. (See the user’s manual)

Normal operation

READY LED is on or by a switch when the READY

LED is blinking.

Indicates that the life of the Oil roller assy has come.

(Warning)

Indicates that the life of the Oil roller assy has come.

(Alarm)

Prints out all character sets (fonts) that the page

printer contains.

This operation is started by a command when the

This message temporarily disap-

pears when a cover of the page

printer is opened but will be dis-

READY LED is on or by a switch when the READY

LED is blinking.

Displayed when 50 pages are printed after “Toner

Low” was detected to prompt the user to replace

the toner cartridge.

played every 20 pages unless the

cartridge is replaced.

This error is reset when the box

toner Assy is replaced. Printing is

suppressed until it is replaced.

The front feeder becomes not avail-

able when the RECOVER switch is

pressed. The other tray is available.

This message is cleared when the

front feeder assembly is replaced.

This error is reset when the cover is

closed. If this error occurs fre-

quently, go to 6.5.2.

This error is recovered when the belt

Displayed when 100 pages are printed after “Box

toner Assy Full” was detected to prompt the user to

replace the box toner Assy.

Indicates that the front feeder has caused a home

position error.

Indicates that the printer covers is open.

Indicates that the belt cassette Assy has not been

cassette Assy is installed. Printing

is suppressed until the belt cassette

assembly is installed.

installed.

Undefined Undefined Undefined Undefined Blink or ON Undefined

Message K C M Y READY ATTENTION Trouble or Status Remedy

PRINT MENU

Category LCD Status LED

Daily status

40985501TH Rev.1 50 /

Undefined Undefined Undefined Undefined Undefined ON

Undefined Undefined Undefined Undefined OFF Blink

Undefined Undefined Undefined Undefined Blink or ON Undefined

OIL ROLLER LIFE

OIL ROLLER LIFE

PRINT FONTS

Blink Blink Blink Blink OFF Blink

*******

TONER EMPTY

Undefined Undefined Undefined Undefined OFF Blink

WASTE TONER FULL

Undefined Undefined Undefined Undefined OFF Blink

FRONT TRAY ERROR

PRESS

RECOVERKEY

Undefined Undefined Undefined Undefined OFF Blink

COVER OPEN

Undefined Undefined Undefined Undefined OFF Blink

BELT NOT

INSTALLED

Page 51

This error is recovered when the box

toner Assy is installed. Printing is

suppressed until the box toner

assembly is installed.

Nothing

Please install the Oil pad Assy.

This error is recovered when the

RECOVER switch is pressed.

Expand RAM or reduce data.

Indicates that the box toner Assy has not been

installed.

Indicates that the Box toner Assy is near full.

Indicates that the Oil pad Assy has not been

installed.

Indicates that data overflowed the memory space.

- Too much print data in one page

- Too much macro data

- Too much DLL data

This error is recovered when the

RECOVER switch is pressed.

Change the setting of Receive

Buffer Size in the User Maintenance

more bigger then send the data from

the host or expand RAM.

This message is cleared when pa-

per is set in the tray or the cassette

assembly is mounted.

- Data overflow after compression of frame data

Indicates that the receive buffer was overflowed.

Indicates that the tray is empty or the cassette as-

sembly has not been installed.

mm...m: paper size (Letter, Executive, Legal 14,

The second tray (optional) cannot

use A6-size paper. The A6-size

paper is available to the first tray or

to the front feeder.

Legal 13, A4, A5, A6, or B5 size)

tttttt: Tray type (Tray 1, Tray 2, or Front)

Displayed when the second tray (optional) contains

A6-size paper.

This message is cleared when the

first tray is remounted correctly.

Normal operation

This message is cleared when the

specified paper is loaded from

manual feeder.

Indicates that the first tray is pulled out also when

the second tray (optional) is used.

Requests the user to load the specified paper by

message from manual feeder.

mm...m: paper size (Letter, Executive, Legal 14,

Legal 13, A4, A5, A6, or B5 size)

Undefined Undefined Undefined Undefined OFF Blink

Message K C M Y READY ATTENTION Trouble or Status Remedy

WASTE TONER BOX

NOT INSTALLED

Category LCD Status LED

Daily status

40985501TH Rev.1 51 /

Undefined Undefined Undefined Undefined Undefined ON

Undefined Undefined Undefined Undefined OFF Blink

WASTE TNR NRFULL

OIL P AD NOT

Undefined Undefined Undefined Undefined OFF Blink

INSTALLED

ERROR MEMORY

OVERFLOW

Buffer

Overflow

Undefined Undefined Undefined Undefined OFF Blink

ERROR RECEIVE

BUFFER OVERFLOW

Undefined Undefined Undefined Undefined OFF Blink

PAPER OUT

mmmmmmmmm tttttt

Tray Paper

Out

Undefined Undefined Undefined Undefined OFF Blink

CANNOT USE A6

Undefined Undefined Undefined Undefined OFF Blink

Undefined Undefined Undefined Undefined ON OFF

PAPER ON TRAY 2

TRAY 1 INSTALL

mmmmmmm MANUAL

P APER REQUEST

Paper

Request

Page 52

Normal operation

This message is cleared when pa-

per is set in the specified tray.

Requests the user to load the specified paper in the

tray .

mm...m: paper size (Letter, Executive, Legal 14,

Check the size of paper in the tray

or whether two or more paper

sheets are fed at a time.

When the cover is opened and

closed, this error is reset and print-

ing resumes. If this error occurs fre-

quently, go to 6.5.2.

Check the size of paper in the tray

or whether two or more paper

sheets were fed at a time. When

the cover is opened and closed, this

error is reset and printing resumes.

Legal 13, A4, A5, A6, or B5 size)

tttttt: Tray type (Tray 1, Tray 2, or Front)

Indicates that paper of the illegal size was fed from

the specified tray.

tttttt: Tray type (Tray 1, Tray 2, or Front)

Indicates that a paper jam occurred on the paper

feeding from the specified tray.

tttttt: Tray type (Tray 1, Tray 2, or Front)

If this error occurs frequently, go to

6.5.2.

Check the size of paper in the tray

or whether two or more paper

sheets were fed at a time. When

the cover is opened and closed, this

error is reset and printing resumes.

If this error occurs frequently, go to

6.5.2.

Open the cover and remove a pa-

per jam from the inside of the page

printer. When the cover is opened

and closed, this error is reset and

printing resumes. If this error oc-

curs frequently, go to 6.5.2.

The page printer recovers automati-

cally when resetting is complete.

Indicates that a paper coming out of the tray jammed

on the paper traveling printer.

tttttt: Tray type (Tray 1, Tray 2, or Front)

Indicates that a paper jammed on the way to the

exit.

Indicates that the OKI HSP interface card is being

reset.

Undefined Undefined Undefined Undefined OFF Blink

Message K C M Y READY ATTENTION Trouble or Status Remedy

mmmmmmmmm tttttt

PAPER REQUEST

Category LCD Status LED

Paper

Request

40985501TH Rev.1 52 /

Undefined Undefined Undefined Undefined OFF Blink

ERROR P APER SIZE

CHECK tttttt

Paper Size

Error

Undefined Undefined Undefined Undefined OFF Blink

PAPER INPUT JAM

CHECK tttttt

Paper Jam

Error

Undefined Undefined Undefined Undefined OFF Blink

PAPER FEED JAM

CHECK tttttt

Undefined Undefined Undefined Undefined OFF Blink

PAPER EXIT JAM

REMOVE THE PA-

PER

Undefined Undefined Undefined Undefined OFF Blink

OKI HSP I/F CARD

RESETTING

Interface

Error

Page 53

Notifies that the power supply LSI

has been reset due to noise, etc.

(process error)

Open cover and remove the paper.

Close cover to recover and proceed.

The page printer recovers from the

error when the RECOVER switch is

pressed. If this error occurs fre-

quently, replace the OKI HSP inter-

face card or the main board (PCR

PCB).

printer is powered on.

mode starts or the page printer received a

Indicates that Process error occurred.

Indicates that a fatal OKI HSP interface error has

occurred.

xx=10: Interface timeout

xx=20: Initialization failed 10 seconds after the page

xx=21: It takes 3 seconds or more before the RUN

Sets the default values in EEPROM

and it’ll be recovered automatically.

Simplify the pages.

Run Mode command in the power-on mode.

xx=22: HSP-PC communication error

Indicates that the ID number of EEPROM is invalid.

Indicates that the interpreter detected one of the

errors given below . The data coming after this error

is recovered until the end of the command. When

the reception of the command is completed, this

message is reset automatically.

is full.

- Invalid PostScript command

- The page is complicated and the vertical memory

Undefined Undefined Undefined Undefined OFF Blink

Message K C M Y READY ATTENTION Trouble or Status Remedy

Jam 001

Error

Category LCD Status LED

Interface

Error

40985501TH Rev.1 53 /

Undefined Undefined Undefined Undefined OFF Blink

ERROR HOST I/F

OKI HSP xx

Undefined Undefined Undefined Undefined OFF Blink

Undefined Undefined Undefined Undefined Blink OFF

EEPROM

RESETTING

ERROR POSTSCRIPT

Controller

Error

Page 54

Remedy

Turn on the power of the page printer again.

If this error still occurs, replace the program

ROM on the main board (PCR PCB) or the

main board itself.

When replacing the main board (PCR PCB),

demount the EEPROM chip from the old main

board and remount it on the new main board.

Turn on the power of the page printer again.

If this error still occurs, replace the main board

(PCR PCB).

When replacing the main board (PCR PCB),

demount the EEPROM chip from the old main

Indicates that an error was found

in the program ROM by the pro-

gram ROM check.

Indicates that an error was found

in the resident RAM by the resi-

dent RAM check.

board and remount it on the new main board.

Turn on the power of the page printer again.

If this error still occurs, replace the program

ROM on the main board (PCR PCB) or the

main board itself.

When replacing the main board (PCR PCB),

demount the EEPROM chip from the old main

board and remount it on the new main board.

Turn on the power of the page printer again.

If this error still occurs, replace the optional

ROM on the main board (PCR PCB) or the

main board itself.

When replacing the main board (PCR PCB),

demount the EEPROM chip from the old main

board and remount it on the new main board.

Check the connection of the option RAM. Turn

Indicates that an error was found

in the EEPROM by the EEPROM

check.

Indicates that an error was found

in the optional ROM by the optional

ROM check.

Indicates that an error was found

on the power of the page printer again. If this

error still occurs, replace the main board (PCR

PCB) or the option RAM.

When replacing the main board (PCR PCB),

demount the EEPROM chip from the old main

board and remount it on the new main board.

Do not use this SIMM because it is

incompatible with the machine.

in the optional RAM by the optional

RAM check.

Indicates that an error in the allocation

to CAS and data bus, which is detected

from the results of 1byte write/ 8bytes

read check on the optional RAM.

10

(nn)

Code