Ohlins 07235-01A5L.p65, 951-6001126 User Manual

V

Cannondale P/N 951-6001126

Safety signals

Important information concerning safety is

distinguished in this manual by the

following notations:

The Safety alert symbol means:

Caution! Your safety is involved.

WARNING!

Failure to follow warning instructions

could result in severe or fatal injury

to anyone working with, inspecting or

using the suspension, or to bystanders.

CAUTION!

Caution indicates that special precautions must be taken to avoid damage to the suspension.

NOTE!

This indicates information that is of

importance with regard to procedures.

© Öhlins Racing AB.

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Öhlins Racing AB is prohibited.

Printed in Sweden.

Introduction

All of Öhlins advanced suspension products are

adepted to the brand and model. This means that

length, travel springaction and damping characteristics, are tested individually just for the vehicle that you have decided to fit with Öhlins suspension.

Before installation

Öhlins Racing AB can not be held responsible for

any damage whatsoever to shock absorber or

vehicle, or injury to persons, if the instructions for

fitting and maintenance are not followed exactly.

Similarly, the warranty will become null and void

if the instructions are not adhered to.

Contents

Saftey signals ................................................ 2

Tuning the suspension ................................... 3

Design ........................................................... 3

Function ........................................................ 4

Compression damping ................................ 4

Rebound damping ....................................... 4

Settings ......................................................... 5

Preload adjustment ....................................... 6

Setting the damping ...................................... 7

Setting your vehicle: ...................................... 7

Start with rebound damping ........................ 8

Compression damping ................................ 8

Inspection and maintenance ......................... 9

WARNING!

1. Installing a shock absorber, that is not

approved by the vehicle manufacturer, may

affect the stability of your vehicle. Öhlins

Racing AB cannot be held responsible for

any personal injury or damage whatsoever

that may occur after fitting the shock

absorber. Contact an Öhlins dealer or other

qualified person for advice.

2. Please study and make certain that you

fully understand all the mounting instructions

and the owners manuals before handling this

shock absorber kit. If you have any questions

regarding proper installation procedures,

contact an Öhlins dealer or other qualified

person.

3. The vehicle service manual must be

referred to when installing the Öhlins shock

absorber

NOTE!

Öhlins products are subject to continual improvement and development. Consequently, although

these instructions include the most up-to-date

information available at the time of printing, there

may be minor differences between your suspension and this manual. Please consult your Öhlins

dealer if you have any questions with regard to

the contents of the manual.

2

Oil

Oil

Gas

Oil

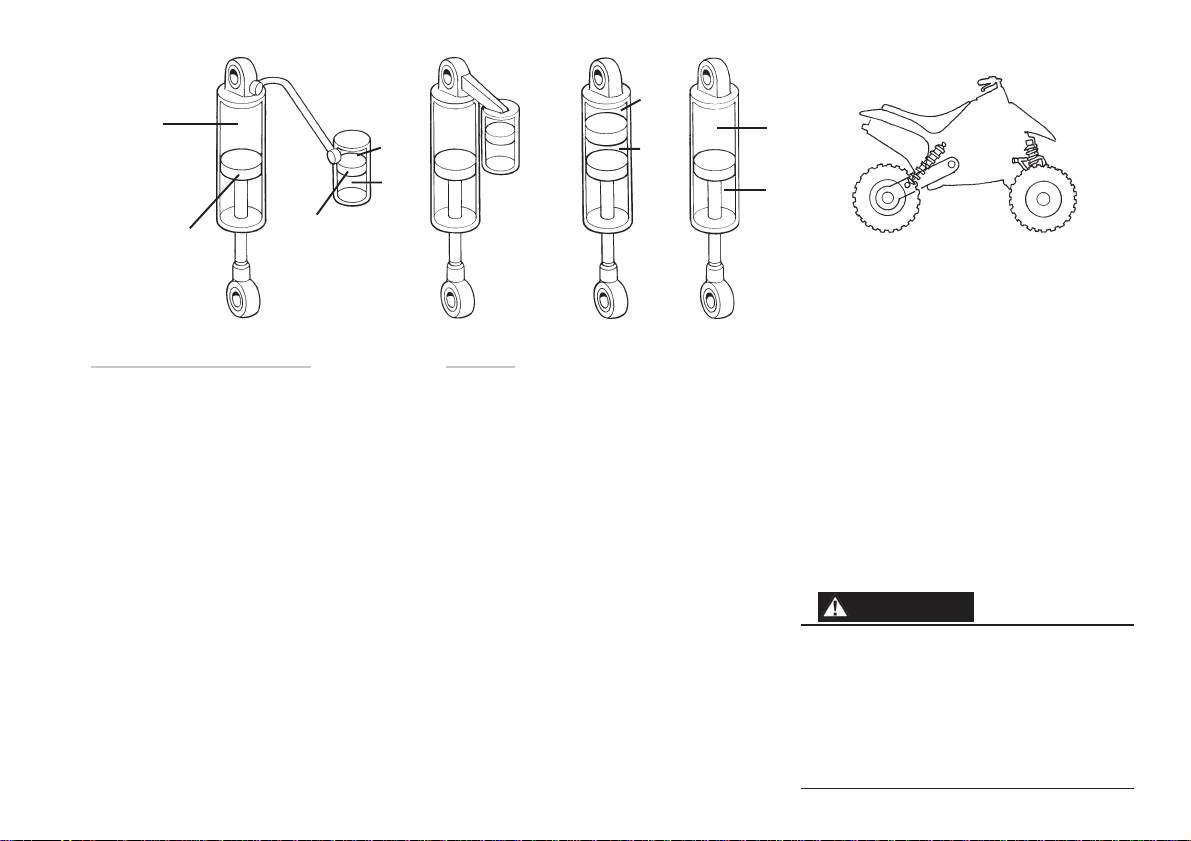

Shock absorber position

Gas and

oil

Gas

Shock absorber

piston

Separating

piston

Tuning the suspension

Road holding qualities

All vehicles are designed with a suspension geometry that includes wheel movements and angles. The changing of components can affect this

and it is therefore essential that both the rear and

the front ends match each other.

Changing to Öhlins suspension gives optimum

performance only when both the front and the

rear suspension interact properly. It is of greatest

importance that the front and rear loaded height

(ride height sag) are within the specified values

in the Mounting instructions.

4312

Design

Most of Öhlins suspensions are of the De Carbon

type. The fluid is put under gas pressure and the

gas and the fluid are kept apart by a separating

piston. The separating piston is often fitted in a

separate fluid reservoir, connected by hose (Fig.1)

or fixed direct on top of the shock absorber (Fig.2)

(piggyback).

There are also models where the separating

piston is fitted inside the main shock absorber (Fig.3)

(internal gas reservoir). Öhlins even manufacture a

small number of emulsion shock absorbers that do

not have a separating piston (Fig.4).

Pressurization of the fluid is made with nitrogen.

The pressurization prevents cavitation of the fluid

and the shock absorbing action is therefore more

even. The external fluid reservoirs also contribute

to better cooling of the fluid, giving longer service

life to both the fluid and components.

Öhlins shock absorbers have integrated

temperature compensation. As the temperature

increases and the fluid flows more easily the flow

Oil

1. External reservoir with hose connection

2. External piggyback reservoir

3. Internal gas reservoir

4. Emulsion shock absorber

is controlled accordingly. The shock absorbing

effect is therefore independent of the temperature.

Öhlins shock absorbers provide the possibility

for adjustment, making them adaptable to most

vehicles, drivers and ranges of use. All of the

shock absorbers, equipped with springs, have

adjustable preloading of the spring action. The

more advanced models permit individual adjustment of compression damping and rebound

damping.

WARNING!

All vehicles are designed with a suspension

geometry that includes wheel movements and

angles. The changing of components can affect

this and it is therefore essential that both the rear

and the front ends match each other. Changing to

Öhlins suspension gives optimum performance

only when both the front and the rear suspension

interact properly.

3

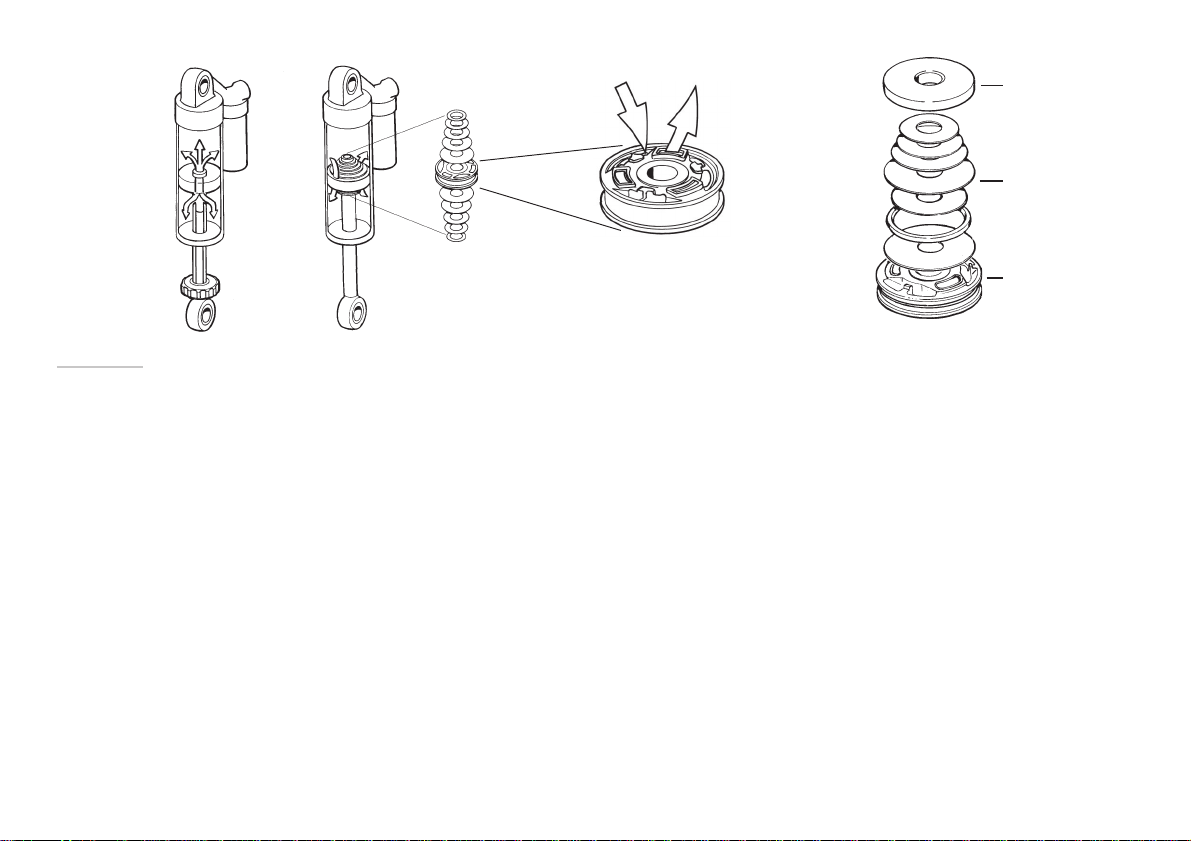

7. Shim stack

Compression flow Rebound flow

Stop washer

Shims stack

5. Flow through

needle valve 6. Flow through piston

Function

The function, in principle, is that fluid is forced

through needle valves at a low rate of flow (Fig.5)

and through a number of apertures in the piston

at a high rate of flow (Fig.6). The flow through these

apertures is regulated by shims (thin steel washers) that at high pressure are deflected to open for

the fluid (Fig.7). On some models the needle valves

can be set individually (illustration).

By altering the size of the shims-stack (ie,

number, thickness, diameter) (Fig.8) the

characteristics of the damping action can be varied

(this shall only be done by Öhlins authorized

service workshops).

4

Compression damping

When movement of the vehicle causes compression in the shock absorber, the fluid flows through

the needle valve (combined compression and return

valve) in the piston rod. If velocity of the piston is

high, ie, in the case of rapid compression, this will

not be sufficient and consequently the shims

underneath the piston will open to allow a greater

rate of flow.

The fluid that is displaced by the volume of the

piston rod is forced into the external fluid chamber

via a separate compression valve. Even this valve

is fitted with shims that open at high piston

velocity. The separating piston is displaced, thus

increasing the gas pressure.

Piston

8. Shim stack

Rebound damping

When the spring presses the shock absorber out

again, the fluid flows back through the needle

valve in the piston rod. The fluid flowing into the

chamber is forced by the pressure of the gas back

into the shock absorber via a separate non return

valve. If velocity of the piston is high, the shims

on top of the piston will also open to allow the

fluid to flow though.

Loading...

Loading...