Page 1

Matrix 3 Operating Instructions

Page 2

Thank you for buying this Numark product.

Please read these operating instructions so you will know how to operate this equipment properly.

After you have finished reading these instructions, keep them for future reference.

WARNING: TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR

MOISTURE.

CAUTION:

This product satisfies FCC regulations when shielded cables and connectors are used to connect the unit to other

equipment. To prevent electromagnetic interference with electric appliances such as radios and televisions, use

shielded cables and connectors for connections.

IMPORTANT NOTICE:

RECORD THE MODEL NUMBER AND SERIAL NUMBER OF THIS EQUIPMENT BELOW.

MODEL NO: Matrix-3

SERIAL NO:

SAFETY PRECAUTIONS

READ INSTRUCTIONS

All the safety and operating instructions should be read before the product is

operated.

RETAIN INSTRUCTIONS

The safety and operating instructions should be retained for future

reference.

HEED WARNINGS

All warnings on the product and in the operating instructions should be

adhered to.

FOLLOW INSTRUCTIONS

All operating and use instructions should be followed.

CLEANING

Unplug this product from the wall outlet before cleaning. The product should

be cleaned only with a polishing cloth or a soft dry cloth. Never clean with

furniture wax, benzene, insecticides or other volatile liquids since they may

corrode the cabinet.

ATTACHMENTS

Do not use attachments not recommended by the product manufacturer as

they may cause hazards.

WATER AND MOISTURE

Do not use this product near water - for example, near a bathtub, washbowl,

kitchen sink, or laundry tub; in a wet basement; or near a swimming pool;

and the like.

ACCESSORIES

Do not place this product on an unstable cart, stand, tripod, bracket, or

table. The product may fall, causing serious injury to a child or adult and

serious damage to the product. Use only with a cart, stand, tripod, bracket,

or table recommended by the manufacturer, or sold with the product. Any

mounting of the product should follow the manufacturer's instructions, and

should use a mounting accessory recommended by the manufacturer.

CART

A product and cart combination should be moved with care. Quick stops,

excessive force, and uneven surfaces may cause the product and cart

combination to overturn.

POWER SOURCES

This product should be operated only from the type of power source

indicated on the marking label. If you are not sure of the type of power

supply to your home, consult your product dealer or local power company.

LOCATION

The appliance should be installed in a stable location.

NONUSE PERIODS

The power cord of the appliance should be unplugged from the outlet when

left unused for a long period.

GROUNDING OR POLARIZATION

If this product is equipped with a polarized alternating current line plug (a

plug having one blade wider than the other), it will fit into the outlet only

one way. This is a safety feature. If you are unable to insert the plug fully

into the outlet, try reversing the plug. If the plug should still fail to fit,

contact your electrician to replace your obsolete outlet. Do not defeat the

safety purpose of the polarized plug. If this product is equipped with a threewire grounding type plug, a plug having a third (grounding) pin, it will only

fit into a grounding type power outlet. This is a safety feature. If you are

unable to insert the plug into the outlet, contact your electrician to replace

your obsolete outlet. Do not defeat the safety purpose of the grounding type

plug.

POWER-CORD PROTECTION

Power-supply cords should be routed so that they are not likely to be walked

on or pinched by items placed upon or against them, paying particular

attention to cords at plugs, convenience receptacles, and the point where

they exit from the product.

OUTDOORS ANTENNA GROUNDING

If an outside antenna or cable system is connected to the product, be sure

the antenna or cable system is grounded to provide some protection against

voltage surges and built-up static charges. Article 810 of the National

Electrical Code, ANSI/NFPA 70, provides information with regard to proper

grounding of the mast and supporting structure, grounding of the lead-in

wire to an antenna discharge unit, size of grounding conductors, location of

antenna-discharge unit, connection to grounding electrodes, and

requirements for the grounding electrode.

LIGHTNING

For added protection for this product during a lightning storm, or when it is

left unattended and unused for long periods, unplug it from the wall outlet

and disconnect the antenna or cable system. This will prevent damage to the

product due to lightning and power-line surges.

POWER LINES

An outside antenna system should not be located in the vicinity of overhead

power lines or other electric light or power circuits, or where it can fall into

such power lines or circuits. When installing an outside antenna system,

extreme care should be taken to keep from touching such power lines or

circuits, as contact with them might be fatal.

OVERLOADING

Do not overload wall outlets, extension cords, or integral convenience

receptacles as this can result in a risk of fire or electric shock.

OBJECT AND LIQUID ENTRY - Never push objects of any kind into this

product through openings as they may touch dangerous voltage points or

short-out parts that could result in a fire or electric shock. Never spill liquid

of any kind on the product.

SERVICING

Do not attempt to service this product yourself as opening or removing

covers may expose you to dangerous voltage or other hazards. Refer all

servicing to qualified service personnel.

DAMAGE REQUIRING SERVICE

Unplug this product from the wall outlet and refer servicing to qualified

service personnel under the following conditions:

When the power-supply cord or plug is damaged.

If liquid has been spilled, or objects have fallen into the product.

If the product has been exposed to rain or water.

If the product does not operate normally by following the operating

instructions. Adjust only those controls that are covered by the operating

instructions as an improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to

restore the product to its normal operation.

If the product has been dropped or damaged in any way.

When the product exhibits a distinct change in performance - this indicates a

need for service.

REPLACEMENT PARTS

When replacement parts are required, be sure the service technician has

used replacement parts specified by the manufacturer or have the same

characteristics as the original part. Unauthorized substitutions may result in

fire, electric shock, or other hazards.

SAFETY CHECK

Upon completion of any service or repairs to this product, ask the service

technician to perform safety checks to determine that the product is in

proper operating condition.

HEAT

The product should be situated away from heat sources such as radiators,

heat registers, stoves, or other products (including amplifiers) that produce

heat.

PAGE 1 SAFETY PRECAUTIONS

Page 3

CAUTION!

TO PREVENT THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR

BACK). NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

IMPORTANT

The lightning flash with arrowhead symbol, within an equilateral triangle, is

intended to alert the user to the presence of un-insulated "dangerous voltage"

within the product's enclosure that may be of sufficient magnitude to constitute

a risk of electric shock to persons.

NOTICE

The exclamation point within an equilateral triangle is intended to alert the user

to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

TABLE OF CONTENTS

Safety Precautions 1

Handling and Care 3

Setup Diagram 4

Controls

1. Microphone Controls 5

2. Mixing Controls for CH 1-CH 3 7

3. Meters and Lighting 9

4. Cueing Controls 9

5. Master Output Controls 11

6. Crossfader Controls 11

7. Special Crossfader Related Controls 13

8. Effects Processing Controls 13

9. Inputs and Outputs 15

10. Customizing and Servicing Your Mixer 17

Specifications 19

Limited Product Warranty 20

PAGE 2TABLE OF CONTENTS

Page 4

HANDLING AND CARE

Location

Install the mixer in a well-ventilated location where it will not be exposed to high temperatures or

humidity. Do not install the mixer in a location that is exposed to direct rays of the sun, or near stoves or

radiators. Excessive heat can adversely affect the cabinet and internal components. Installation of the unit

in a damp or dusty environment may also result in a malfunction or accident. (Avoid installation near

cookers etc., where the unit may be exposed to oily smoke, steam or heat.)

Cleaning the Unit

Use a polishing cloth to wipe off dust and dirt.

When the surfaces are very dirty, wipe with a soft cloth dipped in some neutral cleanser diluted five or six

times with water and wrung out well, then wipe again with a dry clothe.

Do not use furniture wax or cleaners.

Never use thinners, benzene, insecticide sprays or other chemicals on or near this unit, since these may

damage the surface and finishes.

Condensation

When this unit is brought into a warm room from previously cold surroundings or when the room

temperature rises sharply, condensation may form inside, and the unit may not be able to attain its full

performance. In cases like this, allow the unit to stand for about an hour or raise the room temperature

gradually.

PAGE 3 HANDLING AND CARE

Page 5

Page 6

CONTROLS

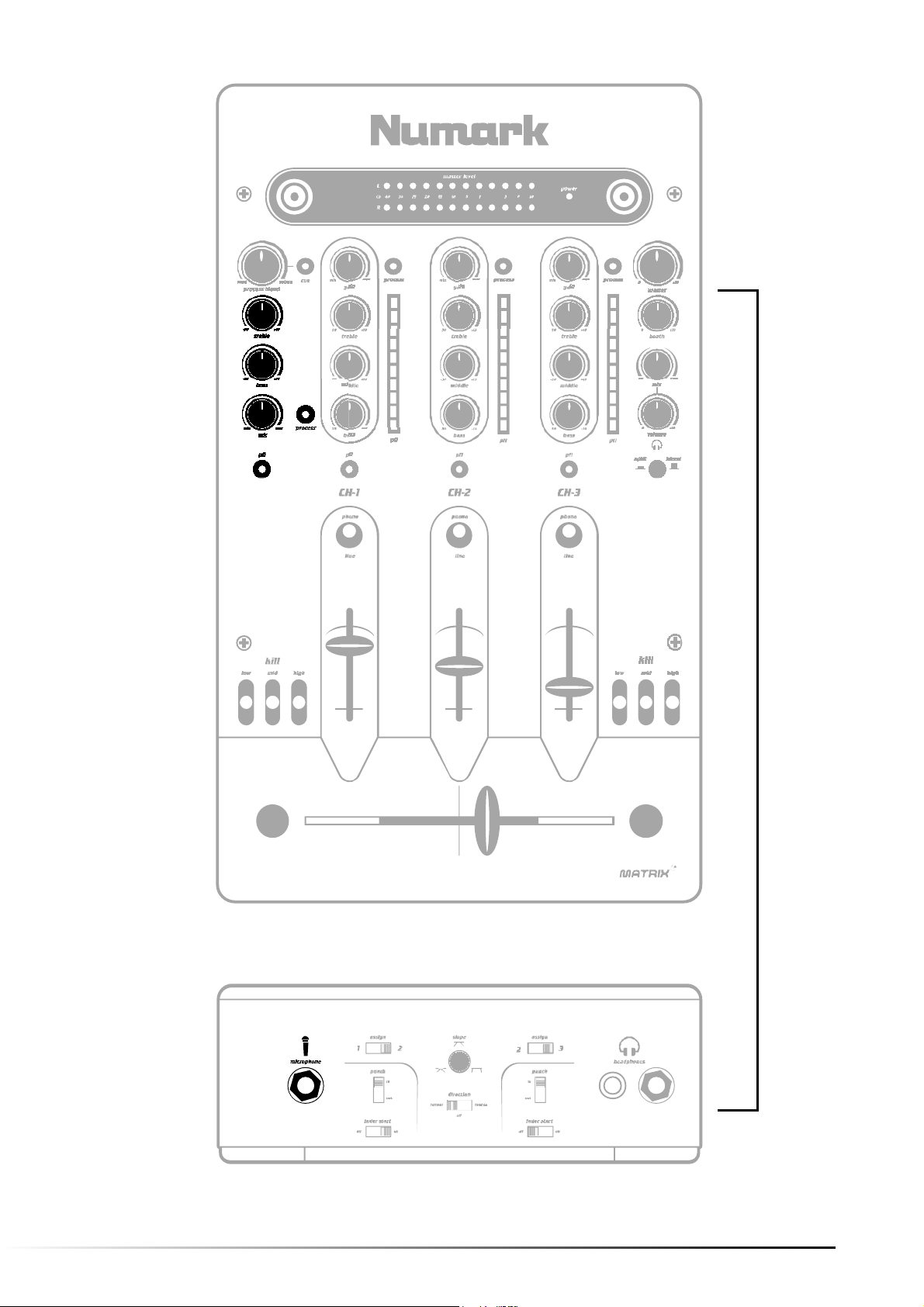

1. Microphone Controls

"Mic" (Microphone Trim)

This knob adjusts the volume of the main microphone. When turned all the way to the left, the volume is

at -8dB. When turned to the right, the volume is at 0dB. The Microphone Trim should be set at -8dB when

connecting and disconnecting a microphone from the Quarter-Inch "Microphone" Input on the front panel

of the mixer

"Treble" (Microphone High EQ)

This knob adjusts the high-tone input sound of the microphone (1kHz). The center position for this control

is flat (0dB.) Turning this knob to the right increases the high-tone input sound of the microphone (to

+10dB at 1kHz.) Turning this knob to the left decreases the high-tone input sound of the microphone (to

-30dB at 1kHz.)

"Bass" (Microphone Low EQ)

This knob adjusts the low-tone input sound of the microphone (70Hz). The center position for this control

is flat (0dB.) Turning this knob to the right increases the low-tone input sound of the microphone (to

+10dB at 70Hz.) Turning this knob to the left decreases the low-tone input sound of the microphone (to

-30dB at 70Hz.)

"Microphone" (Quarter Inch Microphone Input)

One microphone can be connected to this Quarter Inch output terminal. The Microphone Trim should

always be at its lowest setting while connecting and disconnecting a microphone to prevent damage to

the mixer and/or your audience.

"Process" (Microphone FX Processing)

See Section 8 "Effects Processing Controls."

"PFL" (Microphone Pre Fade Level Cueing)

See Section 4 "Cueing Controls."

PAGE 5 MICROPHONE CONTROLS

Page 7

SECTION 1

PAGE 6MICROPHONE CONTROLS

Page 8

CONTROLS

2. Primary Mixing Input Controls for CH-1 to CH-3

"Gain" (Input Level Trim)

This rotary control adjusts the input signal levels of the inputs. Turning the knob completely to the right

(clockwise) increases the level to +8dB. Turning the knob completely to the left (counter clockwise)

decreases the level to -8dB.

"Process" (Input FX Processing)

See Section 8 "Effects Processing Controls."

"Treble" (Input Level High EQ)

This rotary control adjusts the high-tone sound of the inputs. Turning the knob completely to the right

increases the level (to +10dB at 15kHz.) Turning the knob completely to the left decreases the level (to

-28dB at 15kHz.)

"Middle" (Input Level Midrange EQ)

This rotary control adjusts the mid-tone sound of the inputs. Turning the knob completely to the right

increases the level (to +12dB at 1kHz.) Turning the knob completely to the left decreases the level (to

-32dB at 1kHz.)

"Bass" (Input Level Low EQ)

This rotary control adjusts the low-tone sound of the inputs. Turning the knob completely to the right

increases the level (to +12dB at 40Hz.) Turning the knob completely to the left decreases the level (to

-32dB at 40Hz.)

"PFL" (Input Level Meter and Cue Button)

These meters display the peak levels of the inputs. You can use the "Gain" and EQ controls to match the

levels of input signals while Cueing.

For additional information on Cueing, see Section 4 "Cueing Controls."

"Phono/Line Switch" (Input Selector Switch)

These two-position toggles select what input source is engaged among the connected units (see Section 9

"Inputs and Outputs" for details on connecting sources.)

CH-1, CH-2 and CH-3 switch between a line level input (typically a CD player) and a Phono Level Input

(Turntable.)

These toggles can be rotated to suit your mixing preferences by removing the top Mixer Panel. See

Section 10 "Customizing and Servicing Your Mixer" for details.

Input Level Faders

These slide faders adjust the level for CH-1, CH-2 or CH-3 respectively.

PAGE 7 PRIMARY MIXING INPUT CONTROLS

Page 9

SECTION 2

PAGE 8PRIMARY MIXING INPUT CONTROLS

Page 10

CONTROLS

3. Meters and Lighting

"Master Level" (Master Level Meter)

This meter displays the stereo output levels of the master signal. The display ranges from -40dB to

+10dB.

Dual BNC Style Light Connectors

Two BNC style lights can be connected simultaneously to these 12V receptacles.

4. Cueing Controls

"Volume" (Headphone Level)

This rotary control adjusts the levels of the headphones connected to the front panel input. Turning the

knob completely to the right increases the level and turning the knob completely to the left decreases the

level.

"Split/Blend" (Master/Split Style Headphone Cueing Switch)

The split cueing mode is engaged by depressing the button into the low position. The split mode means

that any selected source (CH-1 to CH-3 and Mic) will be sent to the left channel of the headphones and

the master output is sent to the right. If the blend cueing mode is engaged (the button will be in the up

position) then the cued or master source (dependent on "Mix") will be heard in both the left and right

channels of the headphones.

"Mix" (Master/Cue Blend Control)

This control blends between the cued source(s) and the master output. At the center position an even mix

of both the master output and the cued source are monitored. Turning the knob completely to the right

selects only the master output and turning the knob completely to the left monitors only the cued

source(s.)

"Headphones" (Quarter Inch and Eighth Inch Headphone Output Terminals)

Two headphones can be connected simultaneously to these Quarter Inch and Eighth Inch output

terminals. The Volume should always be set at its lowest setting while connecting and disconnecting

headphones to prevent damage to headphones and/or your hearing.

"PFL" (CH-1, CH-2, CH-3 and Mic Cue Buttons)

CH-1, CH-2, CH-3 and the Microphone can be sent to the headphones one at a time or simultaneously for

cueing. When depressed, the PFL button illuminates yellow indicating that the source is being cued. Use

the "Mix" control to get a balance of the cued PFL source(s) and the master output in the headphones.

PAGE 9 METERS+ LIGHTING, CUEING CONTROLS

Page 11

SECTION 3

SECTION 4

METERS+ LIGHTING, CUEING CONTROLS PAGE 10

Page 12

CONTROLS

5. Master Output Controls

"Master" (Main Output Level Control)

This rotary control adjusts the main output levels for any equipment connected to the Master Output on

the rear panel (Section 9 "Inputs and Outputs"). Turning the knob completely to the right increases the

level to +10dB and turning the knob completely to the left mutes the signal.

"Booth" (Master/Split Style Headphone Cueing Switch)

This rotary control adjusts the auxiliary (AKA booth) output levels for any equipment connected to the

Booth Output on the rear panel (Section 9 "Inputs and Outputs"). Turning the knob completely to the

right increases the level to +10dB and turning the knob completely to the left decreases the level.

Blue Power LED

The blue power LED will illuminate when the mixer has been connected to a power source and switched to

the "on" position (See Section 9 "Inputs and Outputs.")

6. Crossfader Controls

Crossfader with Tracking Light System

This slide fader blends between the assigned inputs set by the "Assign" switches on the front Panel. Its

action can be fine-tuned using the "Slope" control or it can be reversed or deactivated by the "Direction"

switch. A red light glows on either the right, left or both sides for the Crossfader indicating only the

position of the Crossfader, not the amount of signal being sent to the master output.

"Slope" (Crossfader Curve Style Control)

The position of this knob determines where the startup level of the assigned channel (see "Assign"

switches) will lie on the Crossfader. When turned to the left, the Crossfader will gradually fade the

assigned channel in to the master output signal as it is engaged. When it is turned all the way to the

right, a very sharp fade of the assigned channel will occur immediately when the fader is engaged. The

center position is a mix of each of these actions.

"Assign" (1/2 switch and 2/3 switch)

The position of these switches determines which input channel is assigned to the Crossfader. The left

switch assigns either Channel 1 (left switch setting) or Channel 2 (right switch setting) to the left side of

the Crossfader. The right switch assigns either Channel 2 (left switch setting) or Channel 3 (right switch

setting) to the right side of the Crossfader.

"Direction" (Crossfader Reverse and Deactivation Control)

The position of this switch can reverse or deactivate the assigned channels of the Crossfader. In the left

switch setting, the channels are assigned according to the "assign" switches. In the right switch setting,

the channels are reversed from their settings of the "assign" switches. In the center position, the

Crossfader is deactivated.

PAGE 11 MASTER OUTPUT, CROSSFADER CONTROLS

Page 13

SECTION 5

SECTION 6

MASTER OUTPUT, CROSSFADER CONTROLS PAGE 12

Page 14

CONTROLS

7. Special Crossfader Related Features

"Kill" (Flash/Eliminate EQ Toggles)

These toggles eliminate the signal level for their respective frequency (low range, midrange and high.) In

the upward position, the switch will lock in position. In the downward position, the switch eliminates the

frequency until it is released. The left set of kill switches is used to control the sound of the input assigned

to the left side of the Crossfader. The right set of kill switches is used to control the sound of the input

assigned to the right side of the Crossfader.

Punch In/Out Transform Buttons

The punch buttons are used to instantly switch or eliminate the output of the mixer depending on the

Crossfader position. See "Punch" In/Out Switches for details on the settings and action of this control.

"Punch" (Punch In/Out switches)

The position of these switches determines whether the output sound will be eliminated or replaced with

the output assigned to the opposite channel. When the switch is in the upward position and the Punch

button is held then the output will be replaced with the signal assigned to the opposite to the mixer until

the button is released. This Punch "In" function will only swap the output signals when the Crossfader is

either completely to the left or completely to the right. When the position of the In/Out switch is in the

downward position then pressing the punch button will eliminate the output for that side until the button

is released. The Punch "Out" function works independently of the Crossfader position.

"Fader Start" (Fader Start On/Off switches)

When engaged the fader start can be used to instantly start a fader-start compatible device (See "Inputs

and Outputs" Section 9) by moving the Crossfader away from the endpoints. The behavior of this control

is largely dependent on the settings of your fader start compatible device.

NOTE: If the Fader Start function is on, then the Punch "In" Function may be deactivated depending on

the Fader Start mode that is selected on your compatible device. Consult your connected Fader Start

device manual for details on how this function interacts with the connected device.

8. Effects Processing Controls

"Process" (FX Processing Switch)

When engaged, this button illuminates red in color and routes the signal for that channel (CH1, CH2, CH3

or Microphone) to the Send Output on the Rear of the Mixer (See "Inputs and Outputs" Section 9.) When

processing a signal on more than one channel (CH1 and CH2 for example) then the signals will be blended

together because they are both being routed to the same destination via the Send Output. For optimum

performance, it is recommended that only one channel be processed at a time.

"Process Blend" (FX/Master Signal Blend)

This rotary control continuously blends the master output signal and the effect. Turning the knob

completely to the right maximizes only the return signal from the effects processor and turning the knob

completely to the left maximizes only the master output signal. In the center position a 50% blend of the

master and the return signal are sent to the master output. Use the "cue" button to preview the blend of

FX and the master signal in the headphones.

PAGE 13 SPECIAL CROSSFADER RELATED FEATURES, EFFECTS

Page 15

SECTION 8

SPECIAL CROSSFADER RELATED FEATURES, EFFECTS

SECTION 7

PAGE 14

Page 16

CONTROLS

9. Inputs and Outputs

CH-1, CH-2 and CH-3 Phono/Line Stereo Inputs

Each channel has a selectable phono level input (phonograph level/line level) and a line level input. The

line level input is used to connect CD players and other line level devices. When connecting a turntable to

the phono input, the switch must be set to "PHONO" instead of "AUX." When this switch is set to "AUX"

you can connect a line level device to the mixer (CD player, etc.) Please note that many turntables need

to be grounded to the mixer with a ground wire to prevent hum and excessive noise (see "GND.") It is

also recommended that the mixer be turned off before connecting and disconnecting any sources to the

inputs of the mixer.

"Effects" (Stereo Send Output/Stereo Return Input)

The RCA "Send" output will send a stereo Post Fader Level Signal (a signal that is effected by the

Equalizer) to the "Input" of an external effects processor (not included.) The RCA "Return" output is for

receiving a processed stereo signal from the connected external effects processor. These outputs are to be

used in conjunction with the "Process" and "Process Blend Controls" (See Section 8 "Effects Processing

Controls.")

"PFL Presend" (Stereo Pre Fade Level Output)

The RCA "PFL Presend" output will send a stereo Pre Fader Level Signal (a signal that is unaffected by the

Equalizer) to the "Input" of an external effects processor (not included.) The RCA "Return" output can

then be connected to receive a processed pre fader stereo signal from the connected external effects

processor. These outputs are also to be used in conjunction with the "Process" and "Process Blend

Controls" (See Section 8 "Effects Processing Controls.")

"Master" (Main Stereo Output)

This RCA output is for connecting an external monitoring device such as a PA system, powered monitors

or a home stereo. The level of the master stereo output signal increases as the "master" volume control is

increased.

"Booth" (Auxiliary Stereo Output)

This RCA output is for connecting a secondary external monitoring device such as a booth monitor or

second stereo output. The level of the booth output signal will increase as the "Booth" volume control is

increased.

"Rec" (Recording Level Stereo Output)

This RCA output is for connecting an external recording device such as a CD Recorder, MD Recorder or a

Tape Deck. The level of this signal is not affected by "master" volume or "booth" adjustments but is

affected by all other controls.

"GND" (Grounding Lug)

This screw connector should be used to secure any devices connected to the mixer that need to be

grounded. Most turntables that are connected to the mixer will need to have a ground wire that is

designed to connect to the mixer to eliminate hum and noise.

PAGE 15 INPUTS AND OUTPUTS

Page 17

"Balance Output" (Balanced Quarter Inch Stereo Output)

These Quarter Inch outputs are for sending a balanced level signal to a PA system or recording device.

The level of the balanced output signal will also increase with the "master" volume control. These outputs

are durable and offer a better output signal than the "master" or "booth" outputs.

"Player A/B" (Fader Start Eighth Inch Terminals)

These two eighth inch terminals allow Fader/Remote Start Compatible devices (CD Players, Turntables,

etc) to be connected to the unit using eighth inch fader start cables (not included.) Any connected device

can then be remotely started using the Crossfader (Section 7 "Special Crossfader Related Features.)

"Fader Start" must be switched to the on position for this feature to work properly.

AC In and Power Switch

This mixer will only work with the power supply assembly that comes with the unit. Make sure that the

arrow on the multi-pin power connection is facing upward before inserting the power cable into the mixer

(See illustration below.) The mixer should be switched on after all devices are already connected to

prevent damage to your equipment. A Blue Power LED indicates that the unit has been switched on (See

Section 3 "Meters and Lighting.")

INPUTS AND OUTPUTS

PAGE 16

Page 18

CONTROLS

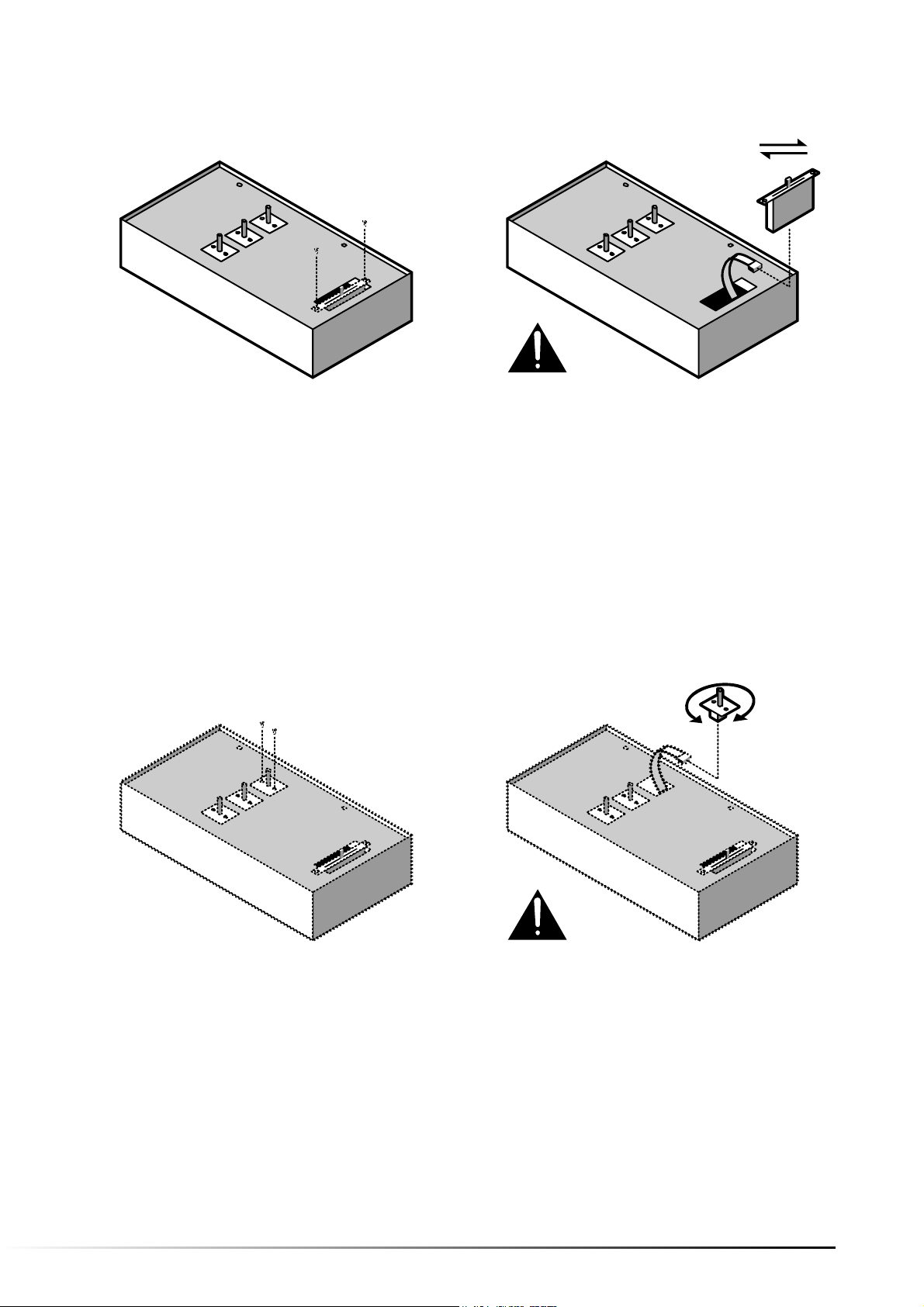

10. Customizing and Servicing Your Mixer

Replacing the Crossfader

This mixer features a replaceable Crossfader. The Crossfader can be

removed from the mixer by loosening the two screws at the endpoints of the fader (See illustrations at

right.) Follow the steps below for removing the top panel to have access to the Crossfader.

Customizing the Direction of the Input Selector Switches

This mixer features multi directional Input Switches that can be removed and rotated to one of eight

positions (See illustrations at right.) Each Input Selector Switch is secured to the mixer by two adjacent

screws. Be sure to make note of the current switch position and the new switch positions before rotating

the switches to prevent any uncertainty before re-securing the top panel. Follow the steps below for

removing the top panel to have access to the Input Selector Switches.

Removing the Top Panel

CAUTION!

BEFORE REPLACING ANY PARTS, IT IS EXTREMELY

IMPORTANT TO UNPLUG THE MIXER FROM ITS

POWER SOURCE.

1. Unplug the mixer and set it on a flat surface. 2. Remove the Four Fader Knobs.

3. Remove the four screws that secure the

top panel using a #2 Philips Screwdriver.

4. Carefully remove the top panel.

PAGE 17 CUSTOMIZING + SERVICING YOUR MIXER

Page 19

Replacing the Crossfader

1. After removing the top panel, remove the

two screws that secure the crossfader

using a #2 Philips Screwdriver.

Customizing the Direction of the Input Selector Switches

2. Carefully slide the crossfader out of the

mixer chassis, and unplug the harness

from the bottom of the part. Replace the

crossfader, refasten the two screws that

hold the crossfader in place.

3. Resecure the top panel, test the function,

and refasten the four screws that secure

the top panel.

1. After removing the top panel, remove the

two screws that secure the selector switch

you want to rotate using a #2 Philips

Screwdriver.

2. Carefully slide the switch out of the

mixer chassis, and unplug the harness

from the bottom of the part. Rotate and

replace the switch, refasten the two screws

that hold the switches in place.

3. Resecure the top panel, test the function,

and refasten the four screws that secure

the top panel.

PAGE 18CUSTOMIZING + SERVICING YOUR MIXER

Page 20

SPECIFICATIONS

Inputs:

Line: 10K ohm input impedance

80mV rms sensitivity for 1.22V output

Mic: 600 ohm input impedance unbalanced

0.85mV rms sensitivity for 1.22V output

57mV rms max input

Phono: 47Kohm input impedance

1.3mV rms sensitivity @ 1KHz for 1.22V output

Outputs:

Line: 9V rms max

Headphone: 0.5W into 47ohm

Distortion: less than 0.01%

Signal to Noise Ratio: (maximum output) JIS-A weighted

Line: Better than 92dB

Mic: Better than 82dB

Phono: Better than 85dB

Frequency response:

Line: 20Hz-20KHz +/-0.5dB

Mic: 20Hz-15KHz +/-0.5dB

Phono: +/-1dB except for controlled attenuation of -3dB

@ 20Hz to reduce rumble and feedback

Channel equalizer:

Bass: +12/-32dB @40Hz

Middle: +12/-32dB @1KHz

Treble: +10/-28dB @15KHz

Channel Kill:

Bass: Better than 80dB at 40Hz

Middle: Better than 80dB at 1KHz

Treble: Better than 80dB at 15KHz

Power consumption:

19.2 Watt typical

21.6 Watt with full headphone output

Dimensions:

220mm(W) by 370mm(D) by 90mm(H)

Weight: 4.8 kgs

PAGE 19 SPECIFICATIONS

Page 21

LIMITED PRODUCT WARRANTY

What is covered and for how long?

1. NUMARK INDUSTRIES LCC ("NUMARK") warrants to the original purchaser that NUMARK'S DJ mixers and amplifiers are free from

defects in material and workmanship under normal use and service for the period commencing upon the date of purchase from an

authorized NUMARK dealer and continuing for the following period of time after that date for (2) Years. The warranty is extended to (3)

Years with the completion of the warranty card provided that the warranty card is completed and returned within (30) days from the

date of purchase. All other NUMARK products are warranted for (1) Year including but not limited to CD players, CD Mix Stations,

turntables, preamplifiers, beatkeepers, equalizers, microphones, headphones, and all other accessories.

What is not covered? This Limited Warranty is conditioned upon proper use of the product by the purchaser.

2. This Limited Warranty does not cover: (a) defects or damage resulting from accident, misuse, abuse, neglect, unusual physical or

electrical stress, modification of any part of the product, or cosmetic damage; (b) equipment that has the serial number removed or

made illegible; (c) all plastic surfaces and other externally exposed parts that are scratched or damaged due to normal use; (d) defects

or damage from improper testing, operation, maintenance, installation, adjustment, or service of the mixers; (e) crossfaders.

3. What are NUMARK'S obligations? During the applicable warranty period, NUMARK will repair or replace, at NUMARK'S sole discretion,

without charge to the purchaser, any defective component part of the mixer. To obtain service under this Limited Warranty, purchaser

must first contact NUMARK and obtain a return authorization number ("RA#").

Purchaser must then return the mixer to NUMARK in an adequate container for shipping, accompanied by purchaser's sales receipt or

comparable proof of sale showing the date of purchase, the serial number of the product, and the seller's name and address. To obtain

an RA# and assistance on where to return the mixer, contact NUMARK customer service at 401-295 9000. Upon receipt, NUMARK will

repair or replace the defective products. NUMARK may, at NUMARK'S sole discretion, use rebuilt, reconditioned, or new parts or

components when repairing any product or replace a product with a rebuilt, reconditioned or new product. Repaired mixers will be

warranted for a period equal to the remainder of the original Limited Warranty on the original mixer or for (90) days, whichever is

longer. All replaced parts, components, boards and equipment become the property of NUMARK. If NUMARK determines that any mixer

is not covered by this Limited Warranty, purchaser must pay all parts, shipping, and labor charges for the repair or return of such mixer.

4. What are the limits on NUMARK'S liabilities?

THE WARRANTIES GIVEN IN THIS LIMITED WARRANTY, TOGETHER WITH ANY IMPLIED WARRANTIES COVERING NUMARK MIXERS,

INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED

TO THE DURATION OF THIS LIMITED WARRANTY. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, NUMARK SHALL NOT BE

LIABLE FOR ANY SPECIAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT OR SIMILAR DAMAGES, LOSS OF PROFITS, DAMAGES TO

PURCHASER'S PROPERTY, OR INJURY TO PURCHASER OR OTHERS ARISING OUT OF THE USE, MISUSE OR INABILITY TO USE ANY

NUMARK MIXER, BREACH OF WARRANTY, OR NEGLIGENCE, INCLUDING BUT NOT LIMITED TO NUMARK'S OWN NEGLIGENCE, EVEN IF

NUMARK OR ITS AGENT HAS BEEN ADVISED OF SUCH DAMAGES, OR FOR ANY CLAIM BROUGHT AGAINST PURCHASER BY ANY OTHER

PARTY. THIS LIMITED WARRANTY IS THE COMPLETE WARRANTY FOR NUMARK'S MIXERS, AND IS GIVEN IN LIEU OF ALL OTHER

EXPRESS WARRANTIES. THIS LIMITED WARRANTY SHALL NOT EXTEND TO ANYONE OTHER THAN THE ORIGINAL PURCHASER OF THIS

PRODUCT AND STATES PURCHASER'S EXCLUSIVE REMEDY. IF ANY PORTION OF THIS LIMITED WARRANTY IS ILLEGAL OR

UNENFORCEABLE BY REASON OF ANY LAW, SUCH PARTIAL ILLEGALITY OR UNENFORCEABILTY SHALL NOT AFFECT THE

ENFORCEABILITY OF THE REMAINDER OF THIS LIMITED WARRANTY WHICH PURCHASER ACKNOWLEDGES IS AND WILL ALWAYS BE

CONSTRUED TO BE LIMITED BY ITS TERMS OR AS LIMITED AS THE LAW PERMITS.

5. This Limited Warranty allocates risk of product failure between purchaser and NUMARK, and NUMARK'S product pricing reflects this

allocation of risk and the limitations of liability contained in this Limited Warranty. The agents, employees, distributors, and dealers of

NUMARK are not authorized to make modifications to this Limited Warranty, or ma ke additional warranties binding on NUMARK.

Accordingly, additional statements such as dealer advertising or presentation, whether oral or written, do not constitute warranties by

NUMARK and should not be relied upon.

6. How does state law apply to this warranty?

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES OR HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO PURCHASER.

7. This Limited Warranty gives you specific legal rights. You may also have other rights, which vary from one jurisdiction to another.

RETURN INFORMATION (US ONLY)

a) A Return Authorization number must be obtained from Numark through the address or phone numbers

below.

b) A copy of the original sales receipt must also be included for the equipment to be repaired under

warranty.

c) The faulty equipment must be packed in its original packaging.

d) One additional outer layer of packaging must be included to ensure product safety. Failure to do so

may inadequately protect the equipment in transit and, therefore, jeopardize the customer's warranty.

e) Numark will not accept COD shipments and no call tags will be issued for merchandise return.

f) Numark will not return repaired merchandise to customers by priority service, unless by written request

at the customer's cost. Requests must be submitted in writing with merchandise returned.

g) The defective Numark equipment should be sent, FREIGHT PREPAID with Return Authorization number

clearly printed on the outer packaging and original sales receipt enclosed to:

NUMARK INDUSTRIES

Attention: Service Department

11 Helmsman Avenue

North Kingstown, RI 02852 USA

Phone: 1 (401) 295-9000

Fax: 1 (401) 295-5200 Web: www.numark.com

PAGE 20LIMITED PRODUCT WARRANTY

Page 22

Copyright Numark Industries, LLC 2001Matrix 3 Manual /English

Loading...

Loading...