TL/F/5283

DP8464B Disk Pulse Detector

June 1989

DP8464B Disk Pulse Detector

General Description

The DP8464B Disk Pulse Detector utilizes analog and digital

circuitry to detect amplitude peaks of the signal received

from the read/write amplifier fitted with the heads of disk

drives. The DP8464B produces a TTL compatible output

which, on the positive leading edge, indicates a signal peak.

Electrically, these peaks correspond to flux reversals on the

magnetic medium. The signal from the read/write amplifier

when reading a disk is therefore a series of pulses with

alternating polarity. The Disk Pulse Detector accurately replicates the time position of these peaks.

The DP8464B Disk Pulse Detector has three main sections:

the Amplifier, the time channel and the gate channel. The

Amplifier section consists of a wide bandwidth amplifier, a

full wave rectifier and Automatic Gain Control (AGC). The

time channel is made from the differentiator and its following bi-directional one shot, while the gate channel is made

from the differential comparator with hysteresis, the D flipflop and its following bi-directional one shot.

The Disk Pulse Detector is fabricated using an advanced

oxide isolated Schottky process, and has been designed to

function with data rates up to 15 Megabits/second. The

DP8464B is available in either a 300 mil wide 24-pin dual-inline package or a surface mount 28-pin plastic chip carrier

package. Normally, it will be fitted in the disk drive, and its

output may be directly connected to the DP8461 or the

DP8465 Data Separator.

Features

Y

Wide input signal amplitude rangeÐfrom 20 mVpp to

660 mVpp differential

Y

Data rates up to 15 Megabits/sec 2,7 code

Y

On-chip differential gain controlled amplifier, differentiator, comparator gating circuitry, and output pulse

generator

Y

Input capacitively coupled directly from the disk head

read/write amplifier

Y

Adjustable comparator hysteresis

Y

AGC and differentiator time constants set by external

components

Y

TTL compatible digital Inputs and Outputs

Y

Encoded Data Output may connect directly to the

DP8461 or DP8465 Data Separator

Y

Standard drive supply: 12Vg10%

Y

Available in 300 mil wide 24-pin dual-in-line package, a

surface mount 28-pin plastic chip carrier package, or a

40-pin TapePak

É

package

Block Diagram

Pin 5ÐNo connection

Pin 8ÐNo connection

TL/F/5283– 7

Note: All pin numbers in this data sheet refer to the 24-pin dual-in-line package.

TapePakÉis a registered trademark of National Semiconductor Corporation.

C

1995 National Semiconductor Corporation RRD-B30M105/Printed in U. S. A.

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Pins Limit

Supply Voltage 9 14V

TTL Input Voltage 11,13 5.5V

TTL Output Voltage 12,14,15 5.5V

Input Voltage 3,4 5.5V

Minimum Input Voltage 3,4

b

0.5V

Differential Input 6-7, 21-22, 3V or

b

3V

Voltage 2-23

ESD Susceptibility (see Note 5)

Storage Temperature

b

65§Ctoa150§C

Lead Temp. (Soldering, 10 seconds) 300

§

C

Maximum Power Dissipation at 25§C

Molded DIP Package

(derate 15.6 mW/

§

C above 25§C) 1950 mW

Plastic Chip Carrier Package

(derate 12.5 mW/

§

C above 25§C) 1560 mW

Operating Conditions

Symbol Parameter Min Typ Max Units

V

CC

Supply Voltage 10.8 12.0 13.2 V

T

A

Ambient Temperature 0 70§C

DC Electrical Characteristics Over Recommended Operating Temperature and Supply Range V

REF

e

0.5V,

Set Hysteresis

e

0.3V. Read/Writee0.3V unless otherwise noted. All Pin Numbers Refer to 24 Pin Dual-In-Line Package.

Symbol Pins Parameter Conditions Min Typ Max Units

AMPLIFIER

Z

IN

AI

6,7 Amp In Impedance T

A

e

25§C 0.75 1.0 1.25 kX

(Note 1)

A

VMIN

18,19 Min Voltage Gain AC Output 4 Vpp 6.0 V/V

Differential

A

VMAX

18,19 Max Voltage Gain AC Output 4 Vpp 200 V/V

Differential

V

C

AGC

16 Voltage on C

AGC

A

V

e

6.0 4.5 5.5 V

A

V

e

200 2.8 3.7 V

GATE CHANNEL

Z

IN

GCI

21,22 Gate Channel Input T

A

e

25§C 1.75 2.5 3.25 kX

Impedance (Note 1)

I

C

AGC

b

16 Pin 16 Current which V

PIN 16

e

3.9V

b

1.5

b

2.5

b

3.5 mA

Charges C

AGC

l

V

PIN 21

b

V

PIN 22

l

e

1.3 V

DC

I

C

AGC

a

16 Pin 16 Current which V

PIN 16

e

5V 1 5 mA

Discharges C

AGC

l

V

PIN 21

b

V

PIN 22

l

e

0.7 V

DC

I

V

REF

4V

REF

Input Bias

b

20

b

100 mA

Current

V

TH

AGC

22,21 AGC Threshold (Note 2) 0.88 1.0 1.12 V

4,16 V

PIN 16

e

4.2V

I

SH

3 Set Hysteresis Input

b

60

b

100 mA

Bias Current

V

TH

SH

22,21 Set Hysteresis (Note 3) 0.48 0.6 0.72 V

3,15 Threshold

TIME CHANNEL

Z

IN

TC

2,23 Time Channel Input T

A

e

25§C 3.5 5.0 6.5 kX

Impedance (Note 1)

I

C

d

24 Current into Pin 1 and 1.4 1.8 2.50 mA

24 that Discharges

C

d

2

DC Electrical Characteristics Over Recommended Operating Temperature and Supply Range V

REF

e

0.5V,

Set Hysteresis

e

0.3V. Read/Writee0.3V unless otherwise noted. All pin numbers refer to the 24 pin dual-in-line package.

(Continued)

Symbol Pins Parameter Conditions Min Typ Max Units

WRITE MODE

Z

IN

AI

6,7 Amp In Impedance V

PIN 11

e

2.0V 50 250 X

in Write Mode

I

C

AGC

b

16 Pin 16 Current V

PIN 11

e

2.0V 1 5 mA

in Write Mode V

PIN 16

e

3.9V

l

V

PIN 21

b

V

PIN 22

l

e

1.3 V

DC

DIGITAL PINS

V

IH

11,13 High Level Input 2 V

Voltage

V

IL

11,13 Low Level Input 0.8 V

Voltage

V

I

11,13 Input Clamp V

CC

e

Min

b

1.5 V

Voltage I

I

eb

18 mA

I

IH

11,13 High Level Input V

CC

e

Max 20 mA

Current V

I

e

2.7V

I

I

11,13 Input Current at V

CC

e

Max 1 mA

Maximum Input V

I

e

5.5V

Voltage

I

IL

11,13 Low Level Input V

CC

e

Max

b

200 mA

Current V

I

e

0.5V

V

OH

12,14, High Level Output V

CC

e

Min 2.7 V

15 Voltage I

OH

eb

40 mA

(Note 4)

V

OL

12,14, Low Level Output V

CC

e

Min 0.5 V

15 Voltage I

OL

e

800 mA

(Note 4)

I

OS

12,14, Output Short V

CC

e

Max

b

100 mA

15 Circuit Current V

O

e

OV

I

CC

9 Supply Current V

CC

e

Max 54 75 mA

AC Electrical Characteristics

Over Recommended Operating Temperature and Supply Range unless otherwise noted

Symbol Pins Parameter Conditions Typ Max Units

DP8464B-2 14 Pulse Pairing (See Pulse Pairing Set Up)

g

1.5

g

3ns

t

pp

DP8464B-3 14 Pulse Pairing (See Pulse Pairing Set Up)

g

2

g

5ns

t

pp

DP8464B-1 14 Pulse Pairing (See Pulse Pairing Set Up)

g

0.5

g

1ns

t

pp

at 25§CV

CC

e

12V only

Note 1: The temperature coefficient of the input impedance is typically 0.05% per degree C.

Note 2: The AGC Threshold is defined as the voltage across the Gate Channel Input (pins 21 and 22) when the voltage on C

AGC

(pin 16) is 4.2V.

Note 3: The Set Hysteresis Threshold is defined as the minimum differential AC signal across the Gate Channel Input (pins 21 and 22) which causes the voltage on

the Channel Alignment Output (pin 15) to change state.

Note 4: To prevent inductive coupling from the digital outputs to Amp In, the TTL outputs should not drive more than one ALS TTL load each.

Note 5: The following pins did not meet the 2000V ESD test with the human body model, 120 pF thru 1.5 kX: Pins 1, 2, 3, 10, 11, 12, 14, 21, 24.

3

Pulse Pairing Set Up

* Transformer (T1) is

Tektronix CT-2 current

probe or equivalent

TL/F/5283– 3

DP8464B

f

e

2.5 MHz

V

IN

e

40 mVppdifferential

V

REF

e

0.50V

C

D

e

50 pF

R

D

e

430X

Filter

R1e240X R2e680X

C1e15 pF C2e100 pF

L1

e

4.7 mH

This is a 3 pole Bessel with the corner frequency at 7.5

MHz.

TL/F/5283– 4

Pulse Pairing Measurement

Connect a scope probe to pin 14 (Encoded Data Out) and

trigger off its positive edge. Adjust the trigger holdoff so the

scope first triggers off the pulse associated with the positive

peak and then off the pulse associated with the negative

peak (as shown in the scope photo below). Pulse pairing is

displayed on the second pair of pulses on the display. If the

second pulses are separated by 4 ns, then the pulse pairing

for this part is

g

2 ns.

Circuit Operation

The output from the read/write amplifier is AC coupled to

the Amp Input of the DP8464B. The amplifier’s output voltage is fed back via an external filter to an internal fullwave

rectifier and compared against the external voltage on the

V

REF

pin. The AGC circuit adjusts the gain of the amplifier

to make the peak to peak differential voltage on the Gate

Channel Input four times the DC voltage on V

REF

. Typically

the signal on Amp Out will be set for 4 Vpp differential.

Since the filter usually hasa6dBloss, the signal on the

Gate Channel Input will be 2 Vpp differential. The user

should therefore set 0.5V on V

REF

which can be done with a

simple voltage divider from the

a

12V supply.

The peak detection is performed by feeding the output of

the Amplifier through an external filter to the differentiator.

The differentiator output changes state when the input pulse

changes direction, generally this will be at the peaks. However, if the signal exhibits shouldering (the tendency to return to the baseline), the differentiator will also respond to

noise near the baseline. To avoid this problem, the signal is

also fed to a gating channel which is used to define a level

either side of the baseline. This gating channel is comprised

4

Circuit Operation (Continued)

of a differential comparator with hysteresis and a D flip-flop.

The hysteresis for this comparator is externally set via the

Set Hysteresis pin. In order to have data out, the input amplitude must first cross the hysteresis level which will

change the logic level on the D input of the flip-flop. The

peak of the input signal will generate a pulse out of the

differentiator and bi-directional one shot. This pulse will

clock the new data at the D input through to the output. In

this way, when the differentiator is responding to noise at

the baseline, the output of the D flop is not changing since

the logic level into the D input has not changed. The comparator circuitry is therefore a gating channel which prevents any noise near the baseline from contaminating the

data. The amount of hysteresis is twice the DC voltage on

the Set Hysteresis pin. For instance, if the voltage on the

Set Hysteresis pin is 0.3V, the differential AC signal across

the Gate Channel Input must be larger than 0.6V before the

output of the comparator will change states. In this case,

the hysteresis is 30% of a 2V peak to peak differential signal at the gate channel input.

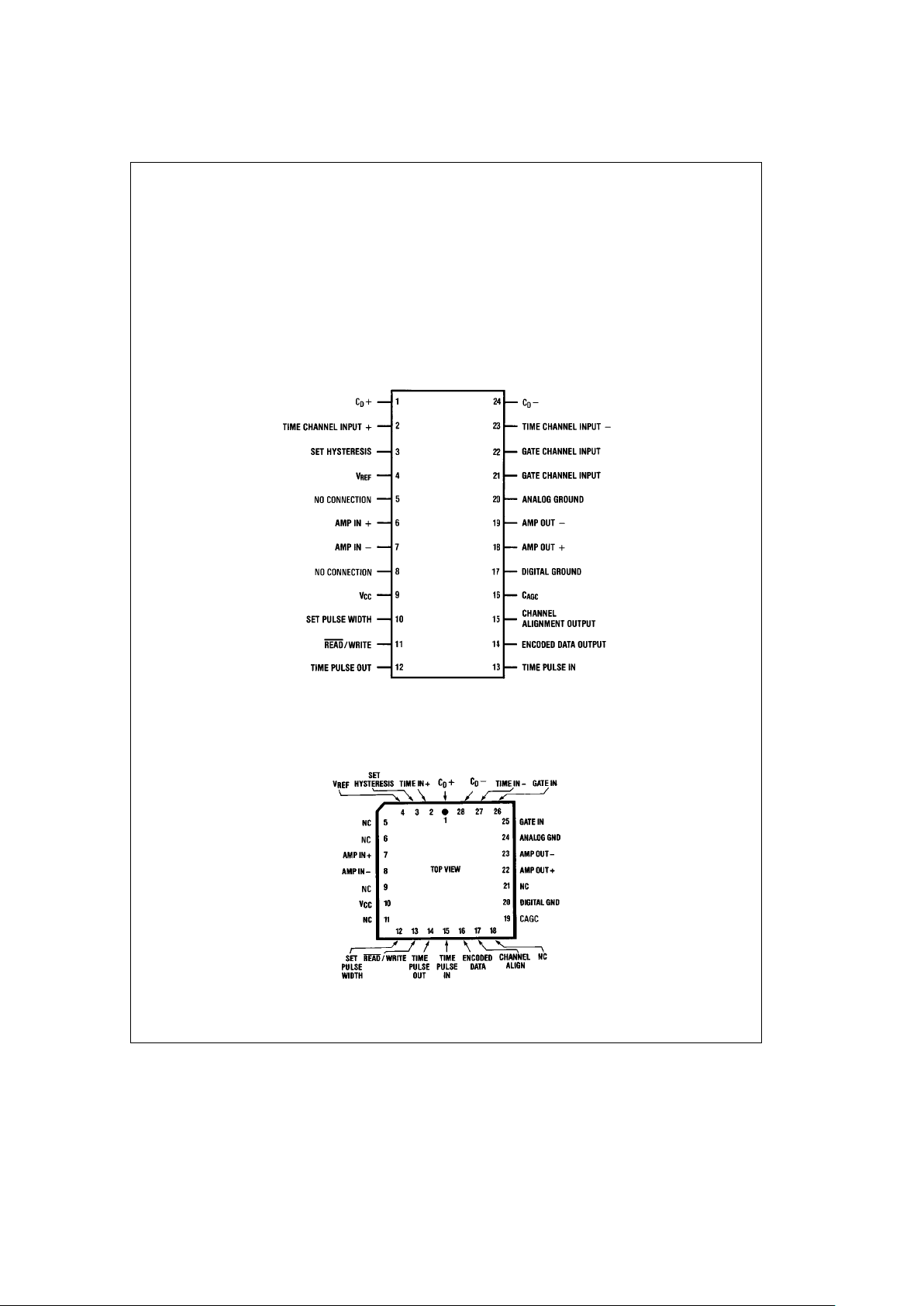

Connection Diagrams

Dual-In-Line (DIP) Package

TL/F/5283– 2

Top View

Order Number DP8464BN-3 or DP8464BN-2

See NS Package N24C

Plastic Chip Carrier (PCC) Package

TL/F/5283– 30

Order Number DP8464BV-3, DP8464BV-2 or DP8464BV-1

See NS Package V28A

5

Pin Definitions

(All pin numbers refer to the 24 pin dual-in-line package)

Pin

Ý

Name Function

Power Supply

9V

CC

The supply isa12Vg10%.

17 Digital Digital signals should be referenced

Ground to this pin.

20 Analog Analog signals should be referenced

Ground to this pin.

Analog Signals

6 Amp In

a

These are the differential inputs to

7 Amp In

b

the Amplifier. The output of the read/

write head amplifier should be capacitively coupled to these pins.

18 Amp Out

a

These are the differential outputs of

19 Amp Out

b

the Amplifier. These outputs should

be capacitively coupled to the gating

channel filter (if required) and to the

time channel filter.

22 Gate These are the differential inputs to

21 Channel the AGC block and the gating chan-

Inputs nel. These inputs must be capacitive-

ly coupled from the Amp Out.

2 Time These are the differential inputs to

Channel the differentiator in the time channel.

Input

a

In most applications, a filter between

23 Time the Amp Out (pins 18 and 19) and

Channel these inputs is required to band limit

Input

b

the noise and to correct for any

phase distortion introduced by the

read circuitry. In all cases this input

must be capacitively coupled to prevent disturbing the DC input level.

1C

d

a

The external differentiator network is

24 C

d

b

connected between these two pins.

3 Set The DC voltage on this pin sets the

Hysteresis amount of hysteresis on the differen-

tial comparator. Typically this voltage

can be established by a simple resistive divider from the positive supply.

4V

REF

The AGC circuit adjusts the gain of

the amplifier to make the differential

peak to peak voltage on the Gate

Channel Input equal to four times the

DC voltage on this pin. This voltage

can be established by a simple resistive divider from the positive supply.

5 No connection

8 No connection

16 C

AGC

The external capacitor for the AGC is

connected between this pin and Analog Ground.

Pin

Ý

Name Function

Digital Signals

10 Set Pulse An external capacitor to control the

Width pulse width of the Encoded Data Out

is connected between this pin and

Digital Ground.

11 Read

/Write If this pin is low, the Pulse Detector is

in the read mode and the chip is active. When this pin goes high, the

pulse detector is forced into a standby mode. This is a standard TTL input.

12 Time This is the TTL output from the bi-di-

Pulse rectional one shot following the difOut ferentiator. In most applications this

can be connected directly to the

Time Pulse In.

13 Time This is the TTL input to the clock of

Pulse the D flip-flop. Usually this is conIn nected directly to the Time Pulse Out

pin.

15 Channel This is the buffered output of the dif-

Alignment ferential comparator with hysteresis.

This is usually used in the initial system design and is not used in production.

14 Encoded This is the standard TTL output

Data Out whose leading edge, indicates the

time position of the peaks.

Application Information

GENERAL DESCRIPTION

All pin numbers refer to 24 pin dual-in-line package.

The DP8464B Disk Pulse Detector utilizes analog and digital

circuitry to detect amplitude peaks of the signal received

from the Read/Write Amplifier. The analog signal from a

disk is a series of pulses, the peaks of which correspond to

1’s or flux reversals on the magnetic medium. The pulse

detector must accurately determine the time position of

these peaks. The peaks are indicated by the positive leading edge of a TTL compatible output pulse. This task is complicated by variable pulse amplitudes depending on the media type, head position, head type and read/write amplifier

circuit gain. Additionally, as the bit density on the disk increases, the amplitude decreases and significant bit interaction occurs resulting in pulse distortion and shifting of the

peaks.

The graph in

Figure 1

shows how the pulse amplitude varies

with the number of flux reversals per inch (or recording density) for a given head disk system. The predominant disk

applications are associated with the first two regions on this

graph, Regions 1 and 2. Typical waveforms received by the

pulse detector for these regions are shown next to the

graph.

6

Application Information (Continued)

Region 1 is the high resolution area characterized by a large

spread between flux reversals and a definite return to baseline (no signal) between these peaks. Pulses of this type are

predominantly found in drives which use either thin film

heads or plated media, or in drives which utilize run length

limited codes (like the 2,7 code) which spread the distance

between flux reversals.

A Region 2 waveform will vary from a tendency to return to

the baseline (called shouldering) to almost sinusoidal at the

higher frequencies. These pulses come from drives which

use limited frequency codes (such as MFM). The pulses

may contain shouldering on the outer tracks of the disk and

be nearly sinusoidal on the inner tracks since the flux density increases towards the inner track.

Detecting pulse peaks of waveforms of such variable characteristics requires a means of separating both noise and

shouldering-caused errors from the true peaks. In the past,

mild shoulder-caused errors were blocked by self-gating circuits (such as the ‘‘de-snaker’’). These circuits fail when

shouldering is extensive, hence the need for the DP8464B

which includes a peak sensing circuit and an amplitude sensitive gating channel in parallel.

The main circuit blocks of the DP8464B are shown in

Figure

2

. The output from the read/write amplifier is fed directly to

the Amp Input of the DP8464B. This is the input of a Gain

Controlled Amplifier. The amplifier’s output voltage is fed

back via an external filter to an internal fullwave rectifier and

compared against the external voltage on the V

REF

pin. The

AGC circuit adjusts the gain of the amplifier to make the

peak-to-peak differential Gate Channel input voltage four

times the DC voltage on V

REF

.

The peak detection is performed by feeding the output of

the Gain Controlled Amplifier through an external filter to

the differentiator. The differentiator output changes state

when the input pulse changes direction, generally this will

be at the peaks. However, if the signal exhibits shouldering

(the tendency to return to the baseline) as seen in Region 1

and the upper part of Region 2, the differentiator will also

respond to noise near the baseline. To avoid this, the signal

is also fed to a gating channel which is used to define a

level either side of the baseline. This gating channel comprises a differential comparator with hysteresis and a D flipflop. The hysteresis for this comparator is externally set via

the Set Hysteresis pin. In order to have valid data out, the

input amplitude must first cross the hysteresis level. This will

change the logic level on the D input of the flip-flop. The

peak of the input signal will generate a pulse out of the

differentiator and bi-directional one shot. This pulse will

clock in the new data on the D input, which will appear at

the Q output. In this way, when the differentiator is responding to noise at the baseline, the output of the D flop is not

changing since the logic level into the D input has not yet

changed. The comparator circuitry is therefore a gating

channel to prevent any noise near the baseline from contaminating the data.

The amount of hysteresis is twice the DC voltage on the Set

Hysteresis pin. For instance, if the voltage on the Set Hysteresis pin is 0.3V, the differential Gate Channel Input must

be larger than 0.6V (

g

0.3V) before the output of the comparator will change states. The Time Pulse Out, Encoded

Data, and Channel Alignment Output are designed to drive 1

standard TTL gate.

TL/F/5283– 5

TL/F/5283– 6

FIGURE 1. Pulse Amplitude vs. Bit Density with Typical Waveforms

7

Block Diagram

Pin 5ÐNo connection

Pin 8ÐNo connection

TL/F/5283– 7

FIGURE 2. DP8464B Block Diagram, Region 1 Connection

8

Application Information (Continued)

GAIN CONTROLLED AMPLIFIER

The purpose of the Gain Controlled Amplifier is to increase

the differential input signal to a fixed amplitude while maintaining the exact shape of the input waveform. The Gain

Controlled Amplifier is designed to accept input signals from

20 mVpp to 660 mVpp differential and amplify that signal to

4 Vpp differential. The gain is therefore from 6 to 200 and is

controlled by the automatic gain control (AGC) loop. The

amplifier output is actually capable of delivering typically 5

Vpp differential output but the parts are only tested and

guaranteed to 4 Vpp.

The input to the Gain Controlled Amplifier is shown in

Figure

3

. The value of the input capacitors should be selected so

that the pole formed by the coupling capacitor and the 1k

bias resistor is a factor of 10 lower than the lowest signal

frequency. These input bias resistors have a

g

20% tolerance and a temperature coefficient of 0.05% per degree C.

When the pulse detector is in the write mode, these bias

resistors are automatically shunted by 425X resistors. This

allows the input circuit to recover quickly from the large tran-

sients encountered during a write to read transition. The

input impedance to the amplifier is therefore 1k during read

operations and 300X during write operations.

The output of the Gain Controlled Amplifier is shown in

Fig-

ure 4

. The outputs are biased at (12Vb(0.75 mAc2.4k)

b

0.75V) or 9.5V. Since each output will swingg1V (4 Vpp

differential), each output pin will swing from 8.5V to 10.5V. If

the total differential load placed on the output is 1k, (see

Figure 5

) then the circuit must supply 2V/1k or 2 mA. Since

the output is class A, external resistors to ground must be

used to provide the sink current. In this case, in order to sink

2 mA at the lowest voltage, then (8.5V/2 mA) or an external

4.3k resistor from each output to ground is required. Note

that the circuit has additional margin since the internal 2 mA

current sources were not included in the calculation. Typically the output impedance of the Gain Controlled Amplifier

is 17X, and the

b

3 dB bandwidth is greater than 20 MHz.

TL/F/5283– 8

FIGURE 3. Input to Gain Controlled Amplifier

9

Application Information (Continued)

TL/F/5283– 9

FIGURE 4. Output of Gain Controlled Amplifier

TL/F/5283– 10

FIGURE 5. Output Stage with 1k Differential Load

10

Application Information (Continued)

AUTOMATIC GAIN CONTROL (AGC)

The Automatic Gain Control holds the signal level at the

Gate Channel Input at a constant level by controlling the

gain of the Gain Controlled Amplifier. This is necessary because the amplitude of the input signal will vary with track

location, variations in the magnetic film, and differences in

the actual recording amplitude. The Gain Controlled Amplifier is designed for a maximum 4 Vpp differential output. To

prevent the Gain Controlled Amplifier from saturating, the

V

REF

level must be set so the maximum amplifier output

voltage is 4 Vpp. The AGC will force the differential peak-topeak signal on the Gate Channel Input to be four times the

voltage applied to the V

REF

pin. Normally some kind of filter

is connected between the Gain Controlled Amplifier’s output

and the Gate Channel Input. Typically this filter hasa6dB

insertion loss in its pass band. Since the AGC holds the

amplitude at the Gate Channel Input constant, this 6 dB loss

through the Gate Channel filter will cause the Gain Controlled Amplifier’s output to be 6 dB larger than the Gate

Channel Input.

The AGC loop starts out in the high gain mode. When the

input signal is larger than expected, the AGC loop will quickly reduce the amplifier gain so the peak-to-peak differential

voltage on the Gate Channel Input remains four times the

voltage on V

REF

. If the input amplitude suddenly drops, the

AGC loop will slowly increase the amplifier gain until the

differential peak-to-peak Gate Channel Input voltage again

reaches four times V

REF

. The AGC loop requires several

peaks to react to an increased input signal. In order to recover the exact peak timing during this transition, the V

OUT

level must be set somewhat lower than the maximum of

4 Vpp. For instance, if the V

REF

is 0.5V, and if the loss in the

gate channel filter is 6 dB, then the Amp Output is 4 Vpp. If

the Amp Input suddenly increases 30%, the amplifier may

saturate and the timing for a few peaks may be disturbed

until the AGC reduces the amplifier gain. If the peak detec-

tion is critical during this time, the system may fail. The proper operation, for this example, is to set the V

REF

at 0.35V so

the amplifier will not saturate if the input suddenly increases

30%.

A simplified circuit of the AGC block is shown in

Figure 6

.

When the full wave rectified signal from the Gate Channel

Input is greater than V

REF

, the voltage on the collector of

transistor T1 will increase and charge up the external capacitor C

AGC

through T2. The typical available charging cur-

rent is 2.5 mA. Conversely, if this input is less than V

REF

,

transistor T2 will be off, so the capacitor C

AGC

will be discharged by the base current going into the Darlington T3

and T4. This discharge current is approximately 1 mA. The

voltage across C

AGC

controls the gain of the Gain Controlled Amplifier. This voltage will vary from typically 3.4V at

the highest gain to 4.5V at the lowest gain.

When the AGC circuit has not received an input signal for a

long time, the base current of the Darlington will discharge

the external C

AGC

to 3.4V. The amplifier will now be at its

highest gain. When a large signal comes in, the external

C

AGC

will be charged up with the 2.4 mA from T2 thereby

reducing the gain of the amplifier. The formula, I

e

C

c

(dV/dt) can be used to calculate the time required for the

amplifier to go from a gain of 200 to a gain of 6. For instance, if C

AGC

e

0.01 mf, the charging current I is 2.4 mA,

and the dV required for the amplifier to go through its gain

range is 1.1V, then

dt

e

(0.01 mFc1.1V)/(2.4 mA) or 4.6 ms.

In reality, the gain does not change this quickly since the

C

AGC

would only be charging during a portion of the input

waveform.

By using the same argument, the time required to increase

the amplifier gain after the input has been suddenly reduced

can be calculated. This time, the discharging current is only

1 maso

dt

e

(0.01 mFc1.1V)/1 mA) or 11 ms.

TL/F/5283– 11

FIGURE 6. Simplified AGC Circuit

11

Application Information (Continued)

This time can be decreased by placing an external resistor

across the C

AGC

. For instance, if a 100k resistor is placed in

parallel with C

AGC

, then the discharge current is 40 mA. The

time required to increase the amplifier gain is now 40 times

faster or 275 ms. If this external resistor is made even smaller, say 10k, then the discharge time will go to 27.5 ms. Now

however, there is another problem introduced. The response time of the AGC is so fast that it distorts the signal

at the output of the Gain Controlled Amplifier. Distortion of

the signal at the Amplifier Output can affect the time position of the peaks of this signal. Be sure to check this distortion over the range of input levels you expect to encounter,

when choosing the external R and C values for the AGC.

If the value of the bleed resistor across the C

AGC

is decreased (in order to equalize the AGC attack and decay

times) the value of C

AGC

must be increased in order to

maintain an AGC response that does not distort the signal.

There is a second order effect on the amplitude that results

from this attack and decay time equalization. Referring to

Figure 2

, notice that the AGC is driven from a full wave

rectified version of the Gate Channel Input signal. When the

AGC is operated normally (ie. fast attack and slow decay)

the voltage that appears across C

AGC

is the peak detected

value of this full wave rectified waveform. However, if you

equalize the AGC attack and decay times the voltage

across C

AGC

is the RMS voltage (0.707 times the peak) of

the full wave rectified waveform. Thus, the voltage across

C

AGC

is less and the amplitude out of the Gain Controlled

Amplifier will consequently be 1.4 times larger.

It is possible to externally drive the C

AGC

pin to control the

gain of the amplifier. It must be noted that the gain of the

amplifier is not always exactly 200 when the voltage on

C

AGC

is 3.4V. The transfer curve between the gain of the

amplifier and the voltage on C

AGC

is only approximate. This

transfer curve will vary between parts and with temperature.

Care should be taken to prevent the voltage on the C

AGC

pin from going below ground or above 5.5V.

Figure 7

shows

a typical curve of the Gain Controlled Amplifier Gain vs. the

voltage across C

AGC

(Vpin 16.)

TL/F/5283– 12

FIGURE 7. Gain Controlled Amplifier Gain vs. Vpin 16

It is possible to change the time constant of the AGC circuit

by switching in different external components at the desired

times. For instance, as shown in

Figure 8

, an external open

collector TTL gate and resistor can be added in parallel with

C

AGC

to decrease the AGC response time. Similarly, an external capacitor could be switched in to increase the response time. Since in the absence of an external resistor

the discharge time of C

AGC

is much longer than the attack

time there may be some applications where it is desirable to

switch in a parallel resistor to quickly discharge C

AGC

then

switch it out to force a quick attack. Because of the quick

attack time, the AGC obtains the proper level quicker than it

would had C

AGC

simply been allowed to discharge to the

new level.

There are some applications where it is desirable to hold the

AGC level for a period of time. This can be done by raising

the READ

/WRITE pin. This will shut off the input circuitry,

and it will take time (about 2.5 ms) for the circuit to recover

when going back into the read mode.

Figure 9

shows a

method to hold the AGC level while remaining in the read

mode (which could be used in embedded servo applications). If the voltage on V

REF

is raised to 3V, then the amplifier output voltage cannot get large enough to turn on the

circuitry to charge up C

AGC

. For this to work properly, there

can not be a large discharge current path (resistor in parallel

with C

AGC

) across C

AGC

. The AGC block can be bypassed

altogether by connecting V

REF

to 3V. In this way, the user

can use his own AGC circuit to drive the C

AGC

pin directly.

TL/F/5283– 13

FIGURE 8. Circuit to Decrease AGC Response Time

TL/F/5283– 14

FIGURE 9. Circuit for AGC Hold

READ

/WRITE

In the normal read mode, the signal from the read/write

head amplifier is in the range of 20 mVpp to 660 mVpp.

However, when data is being written to the disk, the signal

coming into the analog input of the pulse detector will be on

the order of 600 mV. Such a large signal will disturb the

AGC level and would probably saturate the amplifier. In addition, if a different read/write amplifier is selected, there will

be a transient introduced because the offset of the preamplifiers are not matched. A READ

/WRITE input pin has

been provided to minimize these effects to the pulse detector. This is a standard TTL input.

When the READ

/WRITE pin is low, the pulse detector is in

the read mode. When the READ

/WRITE pin is taken high,

three things happen. First, the 1k resistors across the AMP

IN pins are shunted by 300X resistors, as described previously in the Gain Controlled Amplifier section. Next, the amplifier is squelched so there is no signal on the Amp Output.

12

Application Information (Continued)

Finally, the previous AGC level is held. This AGC hold function is accomplished by not allowing any current to charge

up the external C

AGC

. The voltage across this capacitor will

slowly reduce due to the bias current into the Darlington

(see

Figure 6

) or through any resistor placed in parallel with

C

AGC

. Therefore, as described in the Automatic Gain Control section, the gain of the amplifier will slowly increase. All

of these three events happen simultaneously.

When the READ

/WRITE input is returned low, the pulse

detector will go back to the read mode in a specific sequence. First of all, the input impedance at the Amp In is

returned to 1k. Then, after approximately 1 ms, the Gain

Controlled Amplifier is taken out of the squelch mode, and

finally approximately 1 ms after that, the AGC circuit is

turned back on. This return to the read mode is designed to

minimize analog transients in order to provide stable operation after 2.5 ms. It is very important that the analog input be

stable before the chip is returned to the read mode. It is

recommended that other than when writing, the Pulse Detector be in the read mode at all times in order to prevent

the 2.5 ms delay from slowing up the system. The READ

/

WRITE pin may be connected to the Write Gate output of a

controller (such as the DP8466 Disk Data Controller).

TIME CHANNEL FILTER

The peak detection is performed by feeding the output of

the Gain Controlled Amplifier through an external filter to

the differentiator. The differentiator output changes state

when the input pulse changes direction, generally this will

be at the peaks. The differentiator can also respond to

noise near the baseline, in which case the comparator gating channel will inhibit the output. The purpose of the external filter is to bandwidth limit the incoming signal for noise

considerations. Care must be used in the design of this filter

to ensure the delay is not a function of frequency. For this

reason, a high order Bessel filter with its constant group

delay characteristics can be used in this application. Often,

this filter must be specifically designed to correct errors introduced by the non-ideal phase characteristics of the input

read head. The typcial

b

3 dB point for this filter is around

1.5 times the highest recorded frequency. The design of this

filter is complex and will not be discussed here. However,

the following discussion does give a feel for some of the

considerations involved in the filter design. The reader is

referred to reference

Ý

3 listed at the end of the Applica-

tions Notes for further filter design information.

Figure 10

shows a typical Region 1 waveform where there is

no bit interaction. This waveform is primarily the sum of the

fundamental frequency and its 3rd harmonic (higher odd

harmonics are present when there is more shouldering).

If the filter is to preserve this wave shape (this would be the

case if no read/write head phase compensation were necessary) then the phase relationship between the fundamental frequency and its harmonics must not be altered.

Figure

11

shows the output when the 3rd harmonic has the proper

magnitude, but the phase relationship is not maintained.

The result is that the output waveform is not the same

shape as the input (in a severe case it may be almost unrecognizable) and the time position of the peaks has been altered.

One electrical parameter which describes how well a filter

will preserve a wave shape is called group delay. Group

delay is defined as the change in phase divided by the

change in frequency. If the group delay is constant over the

TL/F/5283– 15

FIGURE 10. Typical Region 1 Waveform

TL/F/5283– 16

FIGURE 11. Region 1 Waveform with

the Incorrect Phase Relationship

frequencies of interest, then the wave shape will be maintained. An MFM coded signal will contain three basic frequency components for the various digital patterns of data.

For instance, a 10 Megabit/sec MFM signal will consist of

analog frequencies of 2.5 MHz, 3.33 MHz and 5 MHz. On

the outer track the bit density is the lowest and the 5 and

3.33 MHz signals will look sinusoidal while the 2.5 MHz signal will have a tendency to return to the baseline. This returning to the baseline is called shouldering and is illustrated

in

Figure 10

. Since this shouldering is rich in 3rd harmonicÐ

the 2.5 MHz signal will have a strong 7.5 MHz component.

The 10 Megabit/sec MFM signal will therefore have

2.5 MHz, 3.33 MHz, 5 MHz, and 7.5 MHz components which

must be filtered with constant group delay in order to reproduce the original waveform. For example, if the phase shift

through the filter at 2.5 MHz is 33.3

§

, then at 3.33 MHz the

phase shift must be 44.3

§

, at 5 MHzÐ66.6§, and at

7.5 MHzÐ99.9

§

. The group delay

di

dt

for this case is

13.32

§

/MHz. This can be better interpreted as a time delay.

33.3

§

of a 2.5 MHz signal is equivalent to (33.3/360)

c

(1/2.5 MHz) or 37 ns. Similarly, 66.6§on a 5 MHz signal is

(66.6/360)

c

(1/5 MHz)e37 ns.

The third order Bessel Filter as shown in the 10 Mbit/sec.

pulse pairing measurement board on the data sheet is designed for a constant group delay and a

b

3 dB point of

7.5 MHz. At this frequency the delay through the filter is 35

ns. The Gain Controlled Amplifier of the DP8464B is designed for a group delay of a 7.8 ns

g

0.5 ns for frequencies

up to 7.5 MHz. The 7.8 ns delay in the Gain Controlled

Amplifier and the 37 ns delay in the Bessel Filter do not

introduce any timing error, only a delay of 44.3 ns from the

Amp Input to the output of the filter.

DIFFERENTIATOR

A simplified circuit of the first stage of the differentiator is

shown in

Figure 12

. The voltages at V3 and V4 are simply

two diodes down from V1 and V2. Therefore the voltage

13

Application Information (Continued)

TL/F/5283– 17

FIGURE 12. Simplified Differentiator First Stage

across the external differentiator network (Cdin series with

R

d

) is the differential input voltage V1bV2. When Rdis

zero, the current through C

d

is IeCc(dV/dt) or C

d

c

(dVIN/dt). The Q2 collector current is the sum of the 1.8 mA

current source plus the current through C

d

or

1.8 mA

a

C

d

c

(dVIN/dt).

Similarly, the Q3 collector current is

1.8 mAbC

d

c

(dVIN/dt).

Therefore, the differentiator output voltage, V5bV6, is

1.5k

c2c

C

d

c

(dV

IN

/dt).

The input is at a peak when V5

bV6e

0V.

The differentiator network (Cdand Rd) should be selected

so the maximum current into the differentiator network is not

greater than the minimum current of I1 and I2 over temperature. In the electrical specifications, the minimum current is

specified for 1.4 mA (I

Cd

Current into Pin 1 and 24 that

discharges C

d

). For example, the highest analog frequency

in a 10 Megabit/sec, MFM signal is 5 MHz. Since the AGC

loop has forced the input to the differentiator to 2 V

PP

(which includes the 6 dB loss of the filter), then the voltage

across the capacitor (assuming R

d

is 0) is:

V

IN

e

1csin(2

cqc

5E6ct)

and

dVIN/dte1c2

cqc

5E6ccos(2

cqc

5E6ct)

and the maximum slope is

(dV

IN

/dt)maxe1c2

cqc

5E6e314E5 V/sec.

For this example, Cdcan now be calculated. Since IeC

c

(dV/dt), then for Ie1.4 mA, dV/dte314E5, then the

maximum C

d

must equal 45 pF. From this example, a follow-

ing simple design equation for the value of C

d

can be de-

rived.

C

d

e

445/(V

IN

c

f

max

)

where

C

d

is the maximum external differentiator capacitor in pF

VINis the peak to peak differential Time Channel input

voltage

f

max

is the maximum analog frequency in MHz

Note that this is the maximum value for the capacitor when

the series resistor R

d

is zero. The value of the capacitor can

be increased if a series resistor is used, but the maximum

current through the differentiator network must not exceed

1.4 mA. If too large a value for C

d

is used, the delay through

the differentiator will become dependent on frequency. This

will not show up in a single frequency test such as a test for

pulse pairing.

For the MFM code, the maximum analog frequency is (/2 the

data rate. For the (/2(2,7) code, the maximum analog frequency is (/3 the data rate. The above sinusoidal analysis is

valid as long as the highest frequency on the outer track is

nearly sinusoidal. If, however, there is significant shouldering of this signal then the value of C

d

should be reduced

accordingly.

The following table summarizes the value of C

d

to use for a

2V

pp

differential signal to the time channel input.

Data Rate Code Maximum Frequency C

d

5 mbits/sec MFM 2.5 MHz 90 pF

5 mbits/sec 2,7 1.6 MHz 140 pF

10 mbits/sec MFM 5.0 MHz 45 pF

10 mbits/sec 2,7 3.3 MHz 67 pF

As noted above, the value of the capacitor can be increased

if a series resistor is used, but the maximum current through

the differentiator network must not exceed 1.4 mA. For example, the components used in the Pulse Pairing Setup

(see AC Electrical Specifications) are for a typical 10 Mbits/

sec MFM drive. The combination of the C

d

of 50 pF and the

R

d

of 430X gives a combined impedance of 768X at the

highest frequency of 5 MHz. This gives a maximum current

of 1.3 mAÐwell below the 1.4 mA limit.

A resistor is placed in series with C

d

in order to bandlimit the

differentiator response. This resistor also has an effect on

the phase linearity of the differentiator. An ideal differentiator produces an output that is 90 degree phase shifted from

the input regardless of the input frequency. The presence of

the series resistor produces an output phase shift that is

less than 90 degrees and changes with the input frequency.

This resistor can be used to correct for frequency related

phase problems encountered elsewhere in the read path.

14

Application Information (Continued)

To properly decode the information on the disk, the read

channel must determine if there is a peak (or a ‘‘1’’) during a

period of time called a detection window. The detection window for MFM and the (2,7) code is

1/(2

c

data bit rate).

This detection window must accommodate errors in many

parts of the system including filters, data separator, and

peak shift variations in the data pattern. The pulse pairing of

the DP8464B should be included in the error budget calculation.

Unequal delays through the bi-directional one shots will

contribute to pulse pairing. To minimize this effect, pin 2

should be connected to 22 and pin 23 should be connected

to 21. If connected this way, the delays tend to cancel. For

the PCC Package, Pin 26 to Pin 2, and Pin 25 to Pin 27.

DIFFERENTIAL COMPARATOR WITH HYSTERESIS

The actual peak detection is done in the time channel with

the differentiator. Unfortunately, the differentiator not only

responds to signal peaks but also responds to noise at the

baseline. In order to prevent this noise from generating false

data, the signal at the output of the Gain Controlled Amplifier is also passed through a gating channel which prevents

any output change before the input signal has crossed an

established level. This gating channel comprises a differential comparator with hysteresis and a D flip-flop. The hysteresis for this comparator is set externally via the Set Hysteresis pin. The amount of hysteresis is twice the voltage on the

Set Hysteresis pin. For instance, if the voltage on the Set

Hysteresis pin is 0.3V, the differential input signal must be

larger than 0.6V(

g

0.3V) before the output of the comparator will change states. The 0.6V hysteresis represents 30%

of a typical 2V differential input signal level to the

gating channel. The hysteresis level is usually set between

15% to 40% of the differential input signal.

The operation of the gating channel is shown in

Figure 13

.

At the top is a typical Region 1 waveform which exhibits

shouldering on the lowest frequency and is almost sinusoidal on the highest frequency. In this example, this waveform

is fed to both the timing and the gating channel. The hysteresis level (of about 25%) has been drawn on this waveform.

The second waveform is the output of the differentiator and

its bi-directional one shot. This is the waveform on the Time

Pulse Out pin. While there is a positive edge pulse at each

peak, there is also noise at the shoulders. In this example,

the Time Pulse Out is connected directly to the Time Pulse

In without any external delay. This output is therefore the

clock for the D flip-flop.

The third waveform in

Figure 13

is the output of the Comparator with Hysteresis which goes to the D input of the flipflop. The true peaks are the first positive edges of the Time

Pulse Out which occur after the output of the comparator

has changed states. The D flip-flop will ‘‘clock’’ in these

valid peaks to the output bi-directional one shot. Therefore,

the noise pulses (due to the differentiator responding to

noise at the baseline) just ‘‘clock’’ in the old data through

the flip-flop and the output does not change.

The Q output of the flip-flop drives the output bidirectional

one-shot which generates the positive edges corresponding

to the peaks. The width of the data pulses can be controlled

by an external capacitor from the Set Pulse Width pin to

ground. This pulse width can be adjusted from 20 ns to (/2

the period of the highest frequency. Typical values for this

capacitor are 20 pF for a 25 ns pulse width to 100 pF for a

100 ns pulse.

TL/F/5283– 19

FIGURE 13. Time and Gate Channel Operation for Region 1 Signals

15

Application Information (Continued)

PULSE DETECTOR OPERATION IN REGIONS 1 AND 2

Figure 14

shows the input waveform for the lowest frequency followed by the highest frequency for an MFM code. In

MFM the highest frequency is twice the lowest frequency.

The outer track has the least flux changes per inch (FCI)

and is illustrated in the waveforms at the top. There is so

much room between the pulses that the signal returns to the

baseline for the lowest frequency while there is shouldering

at the highest frequency. As you go towards the inner track,

the pulses become more crowded and bit interaction occurs. At the third curve down (N

c

1.7 FCI), there is shouldering at the lowest frequency while the highest frequency

is almost sinusoidal. At higher bit densities, the lowest frequency looks sinusoidal, while the highest frequency is decreasing in amplitude. In

Figure 14

, the first three waveforms are examples of Region 1 operation (very little

change in amplitude with frequency). The last two waveforms are examples of Region 2 operation.

In a disk system, the bit density changes about a factor of

1.7 between the inner and the outer track. For instance, if

the input waveform for the F-2F signal on the inner track of

a system looks similar to waveform

Ý

4in

Figure 14

(N

c

2.2 FCI), then the outer track will have a bit density that is

approximately N

c

2.2/1.7 or Nc1.3 FCI. This is shown in

the second waveform. Tracks half the way in will have a bit

density of the average between the inner and outer tracks,

in this case N

c

1.7 FCI which is illustrated in the third

waveform. Note that the analog waveforms change considerably with track location. Self-gating circuits (‘‘desnakers’’)

can be used in MFM systems which operate in these last

three curves (from N

c

1.7 FCI to Nc2.9 FCI). If the FCI

becomes much less, the shouldering on the lowest frequency will let in too much noise. If the FCI is increased, the peak

resolution gets very poor. Now we can compare these

waveforms to longer run length limited codes.

Figure 15

shows the analog waveform for the lowest frequency followed by the highest frequency for a 2,7 code. In

the 2,7 code, the frequency range is from F to 2.66

c

F.

Unlike the MFM code, there is no region where the self-gating ‘‘desnaker’’ will work on both the inner and outer tracks.

TL/F/5283– 20

FIGURE 14. MFM F-2F Pulse Waveforms

for Various Flux Changes per Inch

TL/F/5283– 21

FIGURE 15. F-2.66cF Pulse Waveforms

for Various Flux Changes per Inch

16

Application Information (Continued)

The simplest operation is for systems operating entirely in

Region 1, that is, no amplitude reduction between the highest and the lowest frequency at the inner track. The inner

track is specified because the pulse interaction is most severe on the inner track. For Region 1 operation, only the

Time Channel filter is required, so the Gate Channel Input is

connected to the Time Channel Input. Since no external

time delay is required to align the time and gate channels,

the Time Pulse Out is connected directly to the Time Pulse

In. The Region 1 connection is shown in

Figure 2

. The inter-

nal timing for this operation is shown in

Figure 13

.

If there is significant amplitude reduction at the highest frequency, the peak detection becomes more complex. If the

worst case waveform is like the fourth waveform on

Figure

14

, then the Region 1 connection might still work satisfactorily. However, if the input begins to approach the fifth waveform, this system configuration will completely fail. One

problem is that the AGC will respond to the frequency dependent amplitude modulation and distort the waveform.

Figure 16

illustrates this problem which is encountered in

systems operating in Region 2. If the input digital pattern

suddenly shifts from a high frequency to a low frequency,

the bit density may shift from the 70% level on the BPI

curve of

Figure 1

to a point at 90% on the BPI curve. As

shown, the AGC loop is correcting for this frequency-induced change in amplitude by quickly decreasing the amplifier gain. The situation gets worse if the input digital pattern

shifts back to a high frequency. The AGC loop now cannot

quickly increase the amplifier gain, so the output waveform

will very slowly increase. The AGC response to frequency

related amplitude change is not desirable since the AGC is

now distorting the input waveform. This can be prevented by

inserting a lead network between the Gain Controlled Amplifier’s output and the AGC input, as shown in

Figure 17

. This

will increase the amplitude of the higher frequency into the

AGC, thereby preventing the AGC from changing gain.

Another problem encountered in Region 2 operation is that

the amplitude of the highest frequency may be so low that it

may not trip the hysteresis level. If this happens, these

peaks would not be gated on to the output. This problem

can also be corrected by placing a separate filter to the

gating channel which will make the amplitude of the highest

frequency equal the amplitude of the lowest frequency. This

is illustrated in the following example.

Consider a disk system which uses the 2,7 code and has an

input at the inner track which looks like the fifth waveform in

Figure 15

. Since the flux density on the outer track is 1/1.7

times the flux density of the inner track, the outer track

waveform will look like the third waveform. One filter cannot

perfectly compensate both these extremes, so we design to

compensate a waveform between these two. The track

which is )/3 of the way in towards the inner track is a good

compromise. The filter in this example is a single zero

placed such that the lowest frequency followed by the highest frequency have the same amplitude on the track )/3 of

the way in.

Figure 18

shows the operation of the inner track

of this example. While the gating channel filter has made

the amplitudes of the two frequencies nearly the same, the

time relationship to the Time Channel Input has not been

preserved. The proper operation is to have the positive

edge of the signal at the Time Pulse In pin, which corresponds to a peak, be the first positive edge after the output

of the comparator has changed states. This can be accomplished either of two ways. One way is to insert an external

delay between the Time Pulse Out and the Time Pulse In as

shown in

Figure 18

. The required delay can be determined

by comparing the Time Pulse Out to the Channel Alignment

Output with both external filters in the circuit. Another way is

to design the Time Channel Filter with more group delay.

This will probably require additional poles.

Figure 19

shows the outer track operation of our example.

Notice how the system has taken care of the shoulder-induced-noise on the Time Pulse Out. The external delay has

shifted the Time Pulse In so the noise is not clocking in new

data to the flip-flop. It is important to select this delay such

that the positive edge corresponding to a signal peak is always the first positive edge after the output of the comparator has changed states.

While the gating filter has equalized the amplitudes between

the highest and the lowest frequency, the amplitude between the inner and the outer track has not been held constant. This can be seen by comparing the Gate Channel

Input between

Figure 18

and

Figure 19

. In order to avoid

saturating the Gain Controlled Amplifier, the voltage on the

V

REF

pin must be set so that the voltage out of the Gain

Controlled Amplifier is 4 Vpp or less for all tracks. The low

frequency signal on the inner track contains far more fundamental frequency than the low frequency signal on the outer

track. Consequently, the low frequency inner track signal

will experience more attenuation than the low frequency

outer track signal in passing through the gating channel filter which, for this example, has been optimized to pass

higher frequencies. The AGC tends to hold the input to the

gating channel constant for a fixed V

REF

level. Therefore

the largest output from the Gain Controlled Amplifier is for

the low frequency inner track signal. The voltage on V

REF

should be adjusted so that the differential output swing of

the Gain Controlled Amplifier is 4 Vpp maximum for this

signal. This means that the output voltage on the outer track

will be less than 4 Vpp.

TL/F/5283– 22

FIGURE 16. Improper AGC Response to Region 2 Signal

17

Application Information (Continued)

TL/F/5283– 23

FIGURE 17. Circuit Connection for Region 2 Operation

18

Application Information (Continued)

TL/F/5283– 24

FIGURE 18. Region 2 Inner Track Operation

TL/F/5283– 25

FIGURE 19. Region 2 Outer Track Operation

19

Application Information (Continued)

Another troublesome input pattern which should be investigated is a high frequency triplet surrounded by the lowest

frequency as shown in

Figure 20

. Since the center bit of the

triplet does not rise very much above the baseline, there is

the possibility it will not trip the hysteresis level. This pattern

should be checked to ensure the gating channel filter raises

this center bit enough for the proper operation of the gating

channel. The operation of the triplet in the previous example

is shown in

Figure 21

.

LAYOUT CONSIDERATIONS

Figure 22

is a top view of the component layout for the

DP8464B application board whose schematic is shown in

Figure 23

. Care must be exercised in the board layout in

order to isolate all digital signals from analog signals. The

layout shown in

Figure 22

is a good example of what is

required in this regard. In particular the Amp. In pins (pins 6

and 7) and the C

DIFF

pins (pins 1 and 24) must be isolated

from all digital signals. An analog ground plane will greatly

aid in this isolation as will separate digital and analog

grounds. The V

CC

(pin 9) should have a 0.1 mf bypass capacitor to analog ground located close to the DP8464B. The

component list is provided as an example. These components will need to be optimized for a specific read channel.

TL/F/5283– 26

FIGURE 20. (2,7) Triplet

TL/F/5283– 27

FIGURE 21. Region 2 Triplet Operation

20

Application Information (Continued)

TL/F/5283– 28

FIGURE 22. DP8464B Component LayoutÐTop View

21

Application Information (Continued)

TL/F/5283– 29

FIGURE 23. DP8464B Application Board Schematic

22

Application Information (Continued)

PARTS LIST FOR DP8464B BOARD

Component Note

Function

Value for Value for

Name

Ý

Value 5 Mbits/sec 10 Mbits/sec

R2 3 Adjustment for V

REF

(AGC amplitude) 1k pot

R3 3 Adjustment for Set Hyst. (threshold) 1k pot

R4 2 Adjustment for differentiator network Q 5k pot

R5 1 Low pass filter resistor 560X

R6 1 Low pass filter resistor 240X

R7 1 Low pass filter resistor 240X

R8 Amp Out emitter bias resistor 4.3k

R9 Amp Out emitter bias resistor 4.3k

R10 Pull down resistor for Read/Write Pin 5.1k

R11 Resistor in parallel with C

AGC

100k

R12 Encoded Data Out damping resistor 51X

R13 Read/Write damping resistor 51X

R14 Divider network for Set Hyst. and V

REF

2.4k

R17 6 Series resistor for Time Channel Input Not required on DP8464B

R18 6 Series resistor for Time Channel Input Not required on DP8464B

C1 V

REF

cap 0.1 mF

C2 Set Hyst. cap 0.1 mF

C3 2 Differentiator cap 100 pF 50 pF

C4 Time and Gate Channel In coupling cap 0.01 mF

C5 Time and Gate Channel In coupling cap 0.01 mF

C6 1 Low pass filter cap 200 pF 100 pF

C7 1 Low pass filter cap 30 pF 15 pF

C8 4 C

AGC

cap 0.01 mF

C10 V

CC

cap 1.0 mF

C11 V

CC

cap 0.1 mF

C13 5 Amp In coupling cap 2200 pF

C14 5 Amp In coupling cap 2200 pF

C16 Set Pulse Width cap 100 pF 50 pF

L1 2 Differentiator inductor 3.6 mH 1.6 mH

L2 1 Low pass filter inductor 10 mH 4.7 mH

L3 1 Low pass filter inductor 10 mH 4.7 mH

BREADBOARD OPERATION NOTES

1. The low pass filter is a 3 pole Bessel with the corner

frequency at 3.75 MHz for the 5Mbits/sec board (7.5

MHz for the 10 Mbits/sec board).

2. The differentiator is a simple RLC filter with the break

frequency at 8.5 MHz for the 5 Mbits/sec board (17 MHz

for the 10 Mbits/sec board). The resistor can be adjusted

to correct for phase distortion in the channel.

3. The V

REF

should be set at 0.5V. Since the low pass filter

hasa6dBloss, the signal on AMP OUT is 4 Vpp differential while the amplitude into the gate channel is 2 Vpp

differential. The Set Hyst. should be nominally set at

0.3V.

4. The AGC attack time (the response to an increased input

amplitude) is about 2 ms. To increase this time, increase

the value of C8 (the AGC capacitor). The AGC decay time

(the response to a decrease in amplitude) is about 10 ms.

To increase this time, increase the value of R11. Care

must be taken to not allow the response of the AGC loop

to become too fast, otherwise loop instability may occur.

5. The input pole is set at 72 kHz (1k input impedance and a

2200 pF input coupling capacitor).

6. Pulse pairing (described in the differentiator section of

this data sheet) can be caused by unequal delays through

the Bi-directional one shots. To minimize this effect, pin 2

should be connected to pin 22, and pin 23 should be

connected to pin 21. If connected this way, the delays

tend to cancel.

REFERENCES

1. I. H. Graham, ‘‘Data Detection Methods vs. Head Resolution in Digital Recording,’’ IEEE Transactions on Magnetics Vol. MAG-14, No. 4 (July 1978)

2. I. H. Graham, ‘‘Digital Magnetic Recording Circuits,’’ to be

published.

3. Anatol I., Zverev, Handbook of Filter Synthesis, John Wiley & Sons publisher, 1967.

23

Connection Diagrams (Continued)

TapePak

É

TL/F/5283– 31

Top View

Order Number DP8464BTP-3 or DP8464BTP-2

See NS Package Number TP40A

24

Physical Dimensions inches (millimeters)

Molded Dual-In-Line Package (N)

Order Number DP8464BN

NS Package Number N24C

25

DP8464B Disk Pulse Detector

Physical Dimensions inches (millimeters) (Continued)

Plastic Chip Carrier (V)

Order Number DP8464BV

NS Package Number V28A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

Fax: 1(800) 737-7018 English Tel: (

a

49) 0-180-532 78 32 Hong Kong

Fran3ais Tel: (

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

Italiano Tel: (

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...