NOVUS N1500FT User Manual

N15

FLOW RATE INDICATOR

InLL

InKL

k.1nst

k.tot

Un1t 1

k.1nst

k.tot

Un1t1

k.1nSt

k.tot

k.1nst

k.tot

Un1t1

1N.TYPE

InLL

InKL

k.tot

Un1t1

InLL

InKL

InLL

InKL

k.tot

00FT Indicator

– INSTRUCTIONS MANUAL – V1.2x

SAFETY ALERTS

The symbols below are used on th e equipment and throughout this

document to draw the user’s att ention to important operational and

safety information.

CAUTION:

Read this manual carefully prior to

installation and operation of the

unit.

All safety related instructions that appear in the manual must be

observed to ensure pe rsonal safety and to prevent damag e to either

the instrument or the sys tem. If the device is used in a manner not

specified in this manual, its safety features may be impaired.

CAUTION OR DAN GER:

Electric shock hazard

INTRODUCTION

This flow rate indicator provides indication, totalization,

retransmission, alarm and RS4 85 communication features (optional

RTU Modbus slave). It reads most flow signals available in the

market, such as pulse, magneti c pickup and 4-20 mA. The pulse

input allows connecting sensors with outputs such as reed-switch,

NPN, PNP and tension. Both for pul se input and 4-20 mA in put, unit

is selectable and a scal e factor is s et to turn the input signal i nto the

unit of choice. It provi des an isolated pulse output for totalized flow

retransmission and a 4-20 mA output for immediate flow

retransmission. Alarms are set off through 2 to 4 relays, depending

on the equipment model.

AC models provide a 24 Vdc / 50 mA output.

INPUTS

The flow rate indicator allows for two basic input types:

• Instantaneous flo w input through a 4-20 mA signal. In t his case,

flow totalization is obtained by integrating instantaneous flow rate.

• Totalized flow input through a pulse signal. In this case,

instantaneous flow rate is obtained by deriving totalized flow rate.

Pulse signals may c o me fr om sensors/transmit te rs wi t h NPN , P NP, dry

contact (reed switch) and tension signal output, or even magnetic

pickup outputs.

When the input is set to 4-20 mA, you should establish on screens

and

which flow values are equivalent to 4-20 mA.

When the 4-20 mA input is not used as flow input, it may be used

alternatively as auxiliary input. This way it i s possibl e to measure the

pressure of a pipeline, for instance.

The pulse flow input may be scaled, both for instantaneous and

totalized flow rates (independentl y), through ‘ K’ multipl ication factors:

and

.

Both flow time base and uni t must be defined on scr een

To do so, there are six char acters, the first fi ve of which are us ed to

set the unit and the las t one (to the right) is used to set the ti me b as e

on which the flow rate is measured. Available time bases are ‘s’

(seconds), ‘m’ (minutes), ‘h’ (hours) and ‘d’ (days).

.

With pulse flow input, totalizati on wi ll cont inue ev en if the input rate is

below the minimum rate required. Instantaneous flow rate i ndication

will be zero whenever there is a time lapse of 10 secon ds without

input variation. In this cas e, whenever the re is a total ization i ncrease

(more input pulses), the ins tantaneous flow value will be s hown for

the nest 10 seconds.

“K” FACTORS

The instantaneous K factor (

allow the user to view the instantaneous and totalized flow in different

units.

The instantaneous K factor will be available only i n case the s elected

flow input type is different from 4-20 mA. When the input type is 4-20

mA, the configured ra nge limits already provide the parameters for

the indication.

Instantaneous flow is directly related to the time base set in

parameter

In case user erroneously configures parameters

with value “0” (zero), this will be assigned value “0.00001”.

Example 1:

Chosen meter gives us an information of (pulses per volume) 50

pulses per liter. User wants to v iew the i nstantan eous flo w in li ters (l)

and the totalized flow in cubic meters (m³).

In order to do that, parameter

so indicating the instantaneous flow in liters. Parameter

be set a value of “50000”, so indicating the totalized flow in m³.

Instantaneous flow will be vi ewed ba sed on the selected time base in

which means 1 liter/second, and the selected time base is m

(minute), the instantaneous flow indication will be 60 (liters/minute).

Example 2:

Chosen sensor gives us an inf ormation in 4-20 mA that corresponds

to a flow between 0 and 100 liters per minute. Us er wants to v iew the

totalized flow in cubic meters (m³).

On this case, parameter

and parameters

“100”. This way, we pass to the equipment the infor mation that 4 mA

relates to 0 liters per minute and 20 mA relates to 100 liters per

minute. In case sensor output is 12 mA, flow will be displayed as 50

liters/minute.

Parameter

This way, the totalized flow will be converted and displayed in m³

(cubic meters).

When the instantaneous flow type is selected as 4-20 mA, the time

base selected in

having just unit display purposes. The indication conversion from

“liters per minute” to “liters per hour” should be adj usted directly on

input limits

In case user wanted instantaneous flow indicated in cubic meters per

hour (m³/h) with the same meter, the values “0” and “6” should h ave

been selected in input limits

value means 100 l/min conve rted to m³/h.

be changed to “1” because input is already in m³.

.

. In case the example meter output is 50 pulses per second,

should have a value of 0.001 (1 liter = 0.001 m³).

and

) and the total K factor (

should be set a value of “50”,

and

have no influence over the indicated val ues,

sholud be selected as 4-20 mA

should b e configured as “0” and

.

and

, where the second

parameter should

and

should

)

NOVUS AUTOMATION 1/9

N1500FT Flow Indicator

InLL

InKL

1n LL

1n xl

RTLL

RTKL

off

I.error

FEEDER

ADVANCED

Alarm Event

Alarm

Output

Alarm Event

Alarm

Output

T2

Alarm Event

Alarm

Output

T1

Alarm Event

Alarm

Output

T1

T2

T1

CUSTOMIZED LINEARIZATION

When the flow rate is read through a 4-20 mA input, it is possibl e to

apply a customized linearizati on composed of 30 input points and 30

output points. Whenever the re adi ng fal ls between two i nput poi nts, it

will be normalized to the range defined by the res pecti v e points i n the

output range.

The input range considered as an input to the li nearization table is

and

the range defined by the user in the

parameters (it is

not the current in mA). In case us er wants to enter the v alues directly

in mA to convert to the desired viewing uni t, parameter

be set as 4 (mA) and parameter

as 20 (mA), using as many

must

decimal places as needed to the desired precisi on. It will be possible

then to enter values between 4-20 (mA) as input points for the

customized linearization.

The search for framing the valu e read is done while the lis t of input

points is incrementally decl ared. The search is terminated i f the next

point in the list is l ower than the current one. If the input value is

lower than the first val ue in the list of input points, li nearization will

return the first output value. Similarly, if the input value is greater

than the highest value in the list of input points, linearization will

return the highest value in the output list.

IMPORTANT: At least t wo pairs of input-output points are required

for adequate customized linearization.

RETRANSMISSION

Flow rate retransmission c an be done vi a 4-20 mA output a nd pulse output.

The 4-20 mA output may be used regardless of the type of flow i nput.

and

To use it, just set the retransmission range to

associating the flow rates to 4-20 mA.

In the case of retransmission via pulse output, one must choose between volumetric pulse output and frequency pulse output. The former may be used regardless of th e type of i nput, while the l atter i s available only for pulse inputs.

In the volumetric mode, a pulse of configurable length is generated

every time the totalizer accumulates a preset volume. For example,

for a period of 1 second and volume of 10 liters, a 1-second pulse will

be generated for every 10 liters totalized. The counting to the output

pulse will be reset every time the user resets the totalizer or

whenever a feeding process is finished.

Note: In case the feeding process is running and the totalizer is reset

by the user, the process will remain running normally, but the output

pulse will not be synchronized with this process anymore, which can

lead to a missing pulse informed at the end of the feeding process.

As it is always reset at the end of the process, output pulse counter

will synchronize again for a new feeding process.

In the frequency mode, the pulse output will divide the input frequency by a programmable constant whose val ue is equal to or higher than 2.

IMPORTANT: Maximum output frequency has hardware limitation. See Specifications. Check the “Specifications”.

ALARMS

The indicator’s basic versi on has 2 alarm outputs , with the option of

up to 4 alarms. Whenever an alarm is on, a corresponding light

signal will be displayed on the front panel.

• Minimum Value – Lo

It sets off when the reading is below the value determined by the

alarm Setpoint.

• Maximum Value – Ki

It sets off when the reading is abov e the value determined by the

alarm Setpoint.

• Feeder Function –

It activates the output relay when it is s tarted by pressing or

via the auxiliary digital input (according to setup) and deactivates

when the reading reaches the value determined by the alarm setpoint

or when the key or digital input is pressed/closed again,

putting the process on hol d. In case of pressing the key or

digital input more than 3 seconds, process is reset and stays waiti ng

to be started.

Further details in the “Feeder” section.

ALARM TIMER

The indicator allows setting up an Alarm Timer , where users can set

the alarm to go off with a delay, to go off in only one pulse or to go off

in sequential pulses.

Figures in Table 1 show these functions. There, times T1 and T2

may vary from 0 to 32000 seconds and are defined while

programming the indicator. For regular (no timers) operation of

alarms, simply set T1 and T2 to 0 (zero).

He alarm light signals will be displayed whenever there is alarm

condition, regardless of the c urrent status of the outpu t relay, which

,

may be temporarily out of power because of the timer function.

FUNCTION

Regular

Operation

Delay 0 1 to 32000

Pulse 1 to 32000 0

Oscillator 1 to 32000 1 to 32000

T1 T2 ACTION

0 0

Table 1 - Alarm timer functions

ALARM HYSTERESIS

Hysteresis defines the difference between the value measured when

the alarm is triggered and the value at which it is deactivated.

INITIAL ALARM BLOCK

The initial block opti on pr ev e nts the al ar m fro m goin g off i n c ase the re

is alarm condition at the time the indicator is being energized. The

alarm may be trigger ed only after a non-alarm condit ion is follow ed by

an alarm condition. This function is not valid for alarms programmed as

Open Sensor.

SPECIAL FUNCTIONS

ALARM FUNCTIONS

The alarms can be programmed to operate with four different

functions, described below. They may also be turned

.

Alarms use only the instantaneous flow rate reading. Totalization

readings cannot be used as input for alarms. T he auxiliary 4-20 mA

input (when it is not being used f or flow rate measurement) may b e

MAXIMUM AND MINIMUM

The flow indicator continuously rec ords the minimum and maximum

values of instantaneous f low rate. These values can be viewed on

the first screen of the main cycle by pushing and ,

respectively. The key can be set to zero maximum and

minimum values.

used only as input for the open sensor alarm.

• Open Sensor –

The open sensor alarm operates whenever the input sensor is badly

connected or broken. Valid only for 4-20 mA inputs.

NOVUS AUTOMATION 2/9

N1500FT Flow Indicator

Bat.rst

AUXILIARY DIGITAL INPUT AND KEY

Similarly to a digital input, the key can be set to zero the

totalizer, freeze the main screen, zero minimum and maximum

readings or control the feeder function.

FEEDER

The feeder function is used t o control the volume of fluids based on

its flow rate. It is typicall y used for storage applic ations, where the re

is a start signal that triggers a relay and the flow rate begins to be

measured. When reaching a gi ven setpoint, this relay is deactivated

to stop flow.

Its use depends on correct configuration of the related alarm.

During the feeder process, it is not possible to change the alarm

setpoint. Process should be reset first to allow it.

Functions of key and/or digital input, when assigned to the

feeder function:

• When the key or digital input is activated, the feeder

process is started, activating all relays related to the feeder alarm;

• In case the key or digital input i s act ivated onc e agai n, the

process i s frozen and all relays related to the feeder alarm are

deactivated;

• To restart the feeder process, key or digital input must be

activated for 3 seconds, until the process is restarted, ze roing all

existing feeder indication. This can be done with the process

stopped or running;

• At the end of the feeder process, when alarm setpont is reached,

process values are frozen and all rel ated relays are deactivated.

To restart a new process , just activate the key or digital

input for all counters to be reset and process will start running;

• In case of a power shorta ge, if the feeder batch reset parameter

(

powers up again the proces s will restore from where it s topped.

This means that, if it was in the middle of a f eeder process, all

relays assigned to the feeder alarm will be activated. If the

process was stopped, all counte rs will keep their values an d the

process will remain stopped until it is activated either by the

) is configured as no, whenever the equipment

key or the digital input.

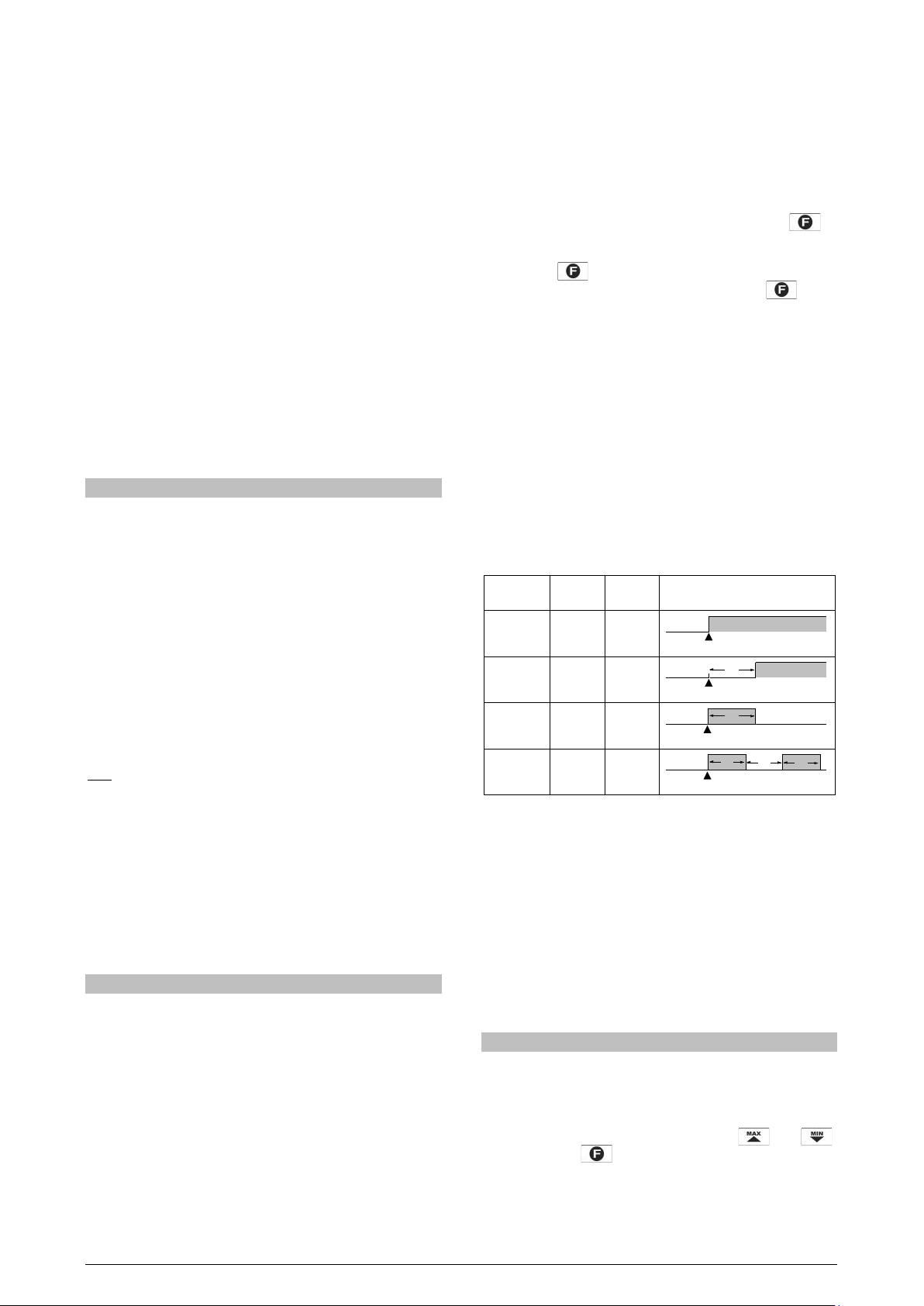

ELECTRICAL CONNECTIONS

All the inside can be removed without the need to undo the el ectrical

connections. Disposition of si gnal s in the rear panel of t he indi cat or is

shown in Fig. 1.

Fig. 1 – Rear panel connect ions

POWER SUPPLY CONNECTION

Fig. 2 – Power supply terninals

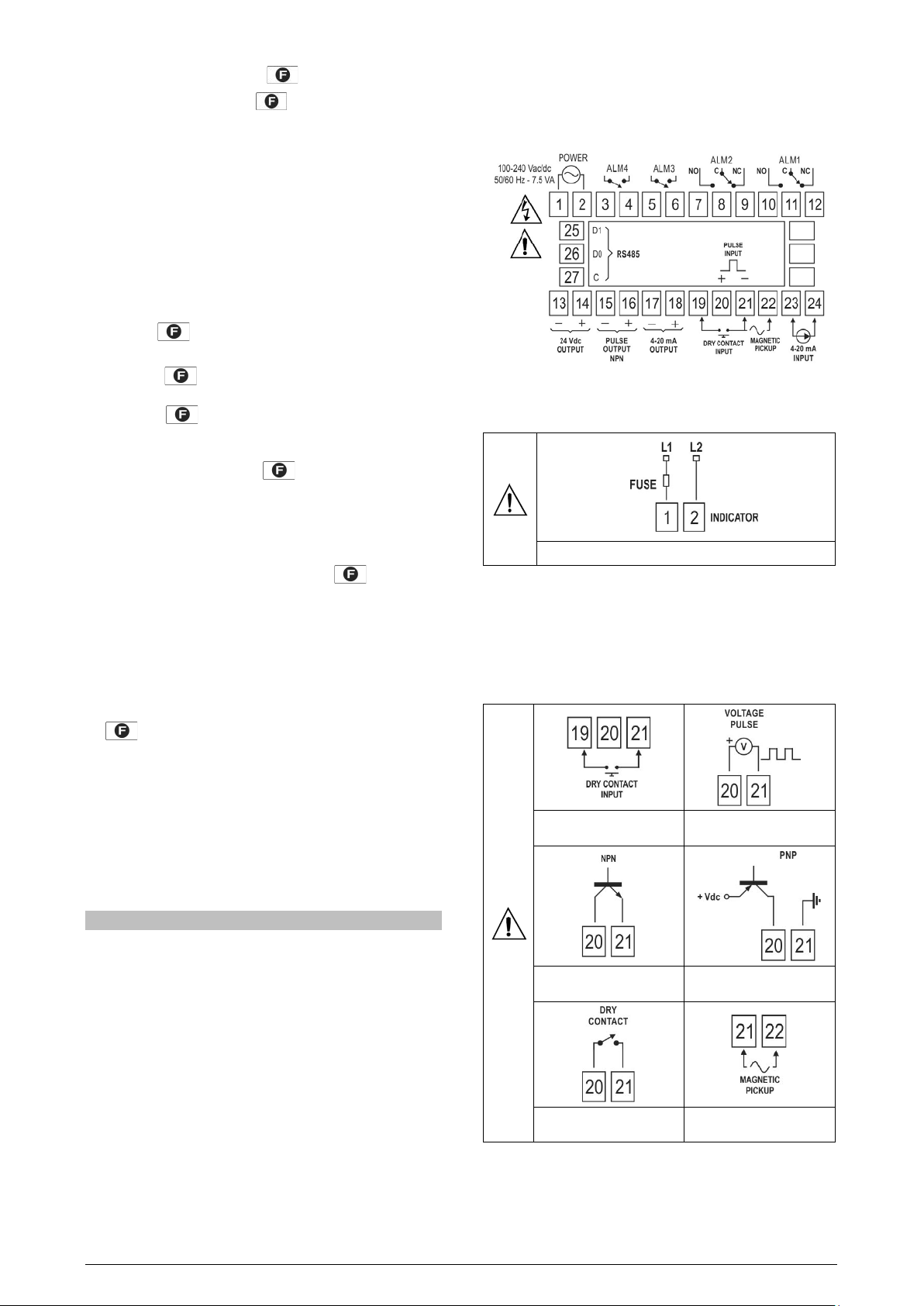

CONNECTIONS FOR INPUT AND OUTPUT SIGNALS

It is important that these connections are well made, with signal or sensor wires securely attached to rear panel terminals. Check the “Specifications” section for the range of the input signals.

The images below show connections for different input types:

MANUAL OPERATION MODE

In the hardware cycle, outputs can be set manually. This can be

extremely useful for tests and simulations. After exiting the cycle,

outputs go back to their regular status.

24 VDC AUXILIARY POWER SUPPLY

DC power supply models provide a 24 Vdc output for field transmitters.

INSTALLATION

The indicator must be installed on a panel. T o do so, remov e the two

plastic clamps, introduce the devi ce in the panel cutout and put the

clamps back from the rear side of the indicator.

INSTALLATION RECOMMENDATIONS

• Input signal conducers should be disposed in the system

separately from output conducers and power conducers,

preferably in grounded electrodes.

• Instruments should be powered through a dedicated network.

• For control and monitoring applicati ons it is vital to consider what

might happen if any part of the system fai ls. The alarm internal

relay does not ensure total protection.

• It is recommended to use RC FILTERS (47 Ω and 100 nF, series)

in contactor coils, solenoid coils, etc.

Fig. 3 – Auxiliary digital input

connection

Fig. 5 - Flow pulse input –

NPN signals

Fig. 7 - Flow pulse input – Dry

contact signals

Fig. 4 - Flow pulse input –

Voltage signals

Fig. 6 - Flow pulse input –

PNP signals

Fig. 8 – Coil Signal connection

(magnetic pickup)

NOVUS AUTOMATION 3/9

Loading...

Loading...