NOVUS N480D User Manual

NOVUS AUTOMATION 1/6

Controller

N480D

UNIVERS

AL CONTROLLER – INSTRUCTIONS MANUAL – V5.0x

SAFETY SUMMARY

The symbols below are used on the equipment and throughout this

document to draw the user’s attention to important operational and

safety information.

CAUTION:

Read complete instructions prior

to installation and operation of

the unit.

CAUTION or WARNING:

Electrical Shock Hazard

All safety related instructions that appear in the manual must be observed

to ensure personal saf et y an d to p revent damage to eit he r t he instrument

or the system. If the inst rument is us ed in a manner n ot specified by the

manufacturer, the protection provided by the equipment may be impaired.

INSTALLATION

The controller must be installed on a panel with a square opening wi th

the specified di mensions. In order to fasten to the panel, remove the

clamps from the controller, introduce the controller in the panel’s

opening through the front and put the clamps back on the body of the

controller through the rear s ide of t he panel. Firmly press the clamps i n

order to fasten the controller to the panel.

The entire internal part of the controller can be removed from its

housing from the front of the panel, without needing to remove the

housing or clamps, or undo the con nections. To extract the controller

from its housing, hold it from the front and pull.

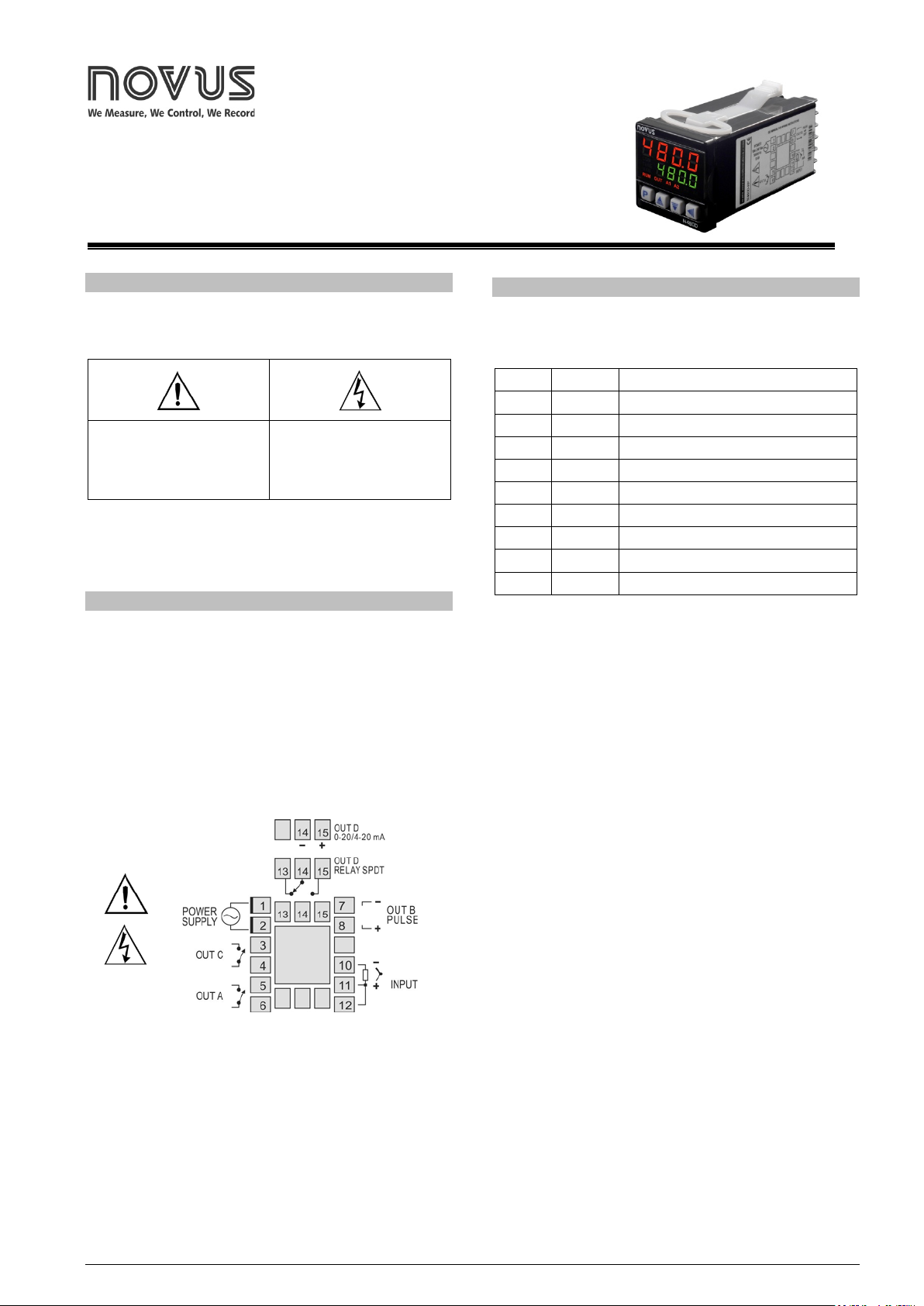

Fig. 1 shows the electrical terminals of the controller.

Fig. 1 - Elect rical connections of the cont roller

Thermocouples must be connected between pins 10 and 11. The

extension cable positive must be connected to terminal number 11.

Pt100 type sensors must be co nnected in 3 wires to termi nals 10, 11

and 12. For Pt100 in 2 wires, terminals 11 and 12 must be

interconnected. For adequate compensation of the cable length, the

conductors of this cable must have the same section (gauge).

RESOURCES

INPUT

Table 1 shows the types of temperature sensors accepted by the

controller and the respective code used to configure the controller.

TYPE CODE RANGE

J

Tc J

Range: -110 to 950 ºC (-166 to 1742 ºF)

K

Tc H

Range: -150 to 1370 ºC (-238 to 2498 ºF)

T

Tc T

Range: -160 to 400 ºC (-256 to 752 ºF)

N

Tc N

Range: -270 to 1300 ºC (-454 to 2372 ºF)

R

Tc R

Range: -50 to 1760 ºC (-58 to 3200 ºF)

S

Tc S

Range: -50 to 1760 ºC (-58 to 3200 ºF)

B

Tc B

Range: 400 to 1800 ºC (752 to 3272 ºF)

E

Tc e

Range: -90 to 730 ºC (-130 to 1346 ºF )

Pt100

Pt

Range: -199.9 to 850 ºC (-328 to 1562 ºF)

Table 1 - Types of sensors ac cepted by the controller

CONTROL OUTPUTS AND ALARM (OUTA, OUTB, OUTC AND

OUTD)

The controller can have 2, 3 or 4 outputs, which can be c onfigured as

control outputs or alarm outputs. These outputs are identified on t he

rear panel of the controller as OUTA, OUTB, OUTC and OUTD.

The output type (control or alarm) is defined in the controller’s

configuration. The output configurati on is individual and defined in the

ovt.A

,

ovt.B

,

ovt.(

, and

ovt.d

parameters respectively.

Output control is the output intended to control the process

temperature. It is possi ble to configure different out puts as the control

output, however, when the OUTD output i s configured as the Analog

Output Control, the other control outputs are disabled.

The output control is always off when the “

Erro

” message is shown

on the controller’s display, signaling a process failure, defect in the

sensor or connection error.

Alarm outputs are us ed for signaling and/or safety of the process. For

outputs defined as al arm output, it is also necessary to d efine the alar m

function (see the Alarm Function Description item of this manual).

USB INTERFACE

The USB interface is used f or CONFIGURING or MONITORING the

controller. The NConfig software must be used for the confi guration. It

makes it possible to create, view, save and open c onfigurations from

the equipment or files in your computer. The tool for saving and

opening configurations in files makes it possible to transfer

configurations between pieces of equipment and to make backup

copies. For specific models, the NConfig software also makes it

possible to update the firmware (internal software) of the controller

through the USB.

For MONITORING purposes you can use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication on a serial communi cations port. When connected to

the USB of a computer, the controller is recognized as a conventional

serial port (COM x). Use the NConfig software or co nsult the DEVICE

MANAGER in the Windows CONTROL PANEL to identify the COM port

that was assigned to the controller. Consult the mapping of the

MODBUS memory in the controller’s communications manual and the

N480D Controller

NOVUS AUTOMATION 2/6

documentation of your supervisory software to conduct the

MONITORING process.

Follow the procedure below to use the USB communication of the

equipment:

1. Download the NConfig softwa re from our website and ins tall it on

your computer. The USB drivers necessary for operating the

communication will be installed together with the software.

2. Connect the US B cable between the equipment and the com puter.

The controller does not have to be connected to a power suppl y.

The USB will provide enough power to operate the commu nication

(other equipment functions cannot operate).

3. Open the NConfig software, configure the communi cation and s tart

recognition of the device.

4. Consult the NConfig help desk fo r detailed instructions about how

to use it and solve problems.

The USB interface IS NO T SEPARAT E from the s ignal

input (PV) or the controller’s digital inputs and output s.

It is intended for temporary use during

CONFIGURATION and MONITORING periods. For the

safety of people and equipment, it must onl y be used

when the piece of equipment is completely

disconnected from the input/output signals. Using the

USB in any other type of connection is possible but

requires a careful analysis by the person responsible

for installing it. When MONITORING for long periods of

time and with connected inputs and outputs, we

recommend using the RS485 interface, which is

available or optional in most of our products.

CONFIGURATION AND OPERATION

Prior to first operation t he controlle r should be fully confi gured. The use r

must set basic parameters as temperature type (

TYPE

), the desired

control set point (

SP

), the alarms set points (

A1SP

and

A2SP

), etc.

The configuration ca n be performed directl y on the controll er or through

the USB interface. The NConfig software (free) is the configuration

management tool. Connected to the USB of a Windows comp uter, the

controller is recogni zed as a serial communi cations port (COM) runni ng

with a Modbus RTU protocol.

Through the USB interf ace, even if di sconnected f rom the power supply,

the configuration per fo rme d i n a piece of equipment can be c an be s ave d

in a file and repeated i n other piec es of equi pment that require t he same

configuration.

PARAMETERS FLOW CHART

The programming parameters are organized in 5 different levels

(parameter groups):

- Operation level

- Tuning level

- Program level

- Input level

- Calibration level

When Turned On, the controller displays the first screen of the

Operation Cycle. This screen shows on the red display (top), the

measured temperature value (PV ) and also the Set Point value of the

process (desired temperature for the process) on the green display

(bottom). During operation, the controller continues showing this

screen. In order to access other screens of this cycle, just press

.

All other Cycles are accessed when changes are required to the

controller’s configuration. In order to access these cycles just hold

down the

key for approximately three seconds. Af ter this ti me, the

controller displays the first paramete r of the next cycle (Tuning Cycle).

Holding the key down for three seconds, the nex t cycle (Input Cycle) is

also accessed.

Release the key in the des ired cycle. Press t he

key again to

access all other parameters of this c ycle. The key allows to return

parameters within the cycle.

The upper display shows the parameter and the lower dis play shows

the value of this parameter. T he and keys al low the operato r

to change the value of the shown parameter.

After accessing the last paramet er of the c ycle, the c ontroller returns to

the Operation cycle, indi cating the temperature proces s and SP. With

the keyboard inactive for more than 20 seconds, the controller also

returns to the Operation cycle.

The value of the changed parameter is s aved to permanent memory

and used by the controller when goi ng to the next parameter, or if no

key is pressed within 20 seconds.

PROTECTION OF CONFIGURATION

The controller allows to protect the configuration elaborated by the

user, avoiding unauthorized changes. The parameter Protection

(

PROt

), in the Calibration level, determines the protection strategy,

limiting the access to particular levels, as shown by the table below.

Protection

Level

Protected Cycles

1 Only the Calibration level is protected.

2 Input and Calibration level.

3 Program, Input and Calibration level.

4 Tuning, Program, Input and Calibration level.

5 All levels are protected.

Table 2 – Levels of Protection for the Configuration

Access Password

The protected levels, when acces sed, request the user to provide the

Access Password for granting permission to c hange the configur ation

of the parameters on these levels.

The prompt

PASS

precedes the parameters on the protected levels.

If no password is entered, the parameters of the protected levels can

only be visualized.

The Access Password is defined by the user in the parameter

Password Change (

PAS.(

), present in the Calibration level.

The new controllers leave the factory with the access password defined

as 1111.

Protection of the access password

The controller provides a security s ystem that helps prevent input of

numerous passwords trying to get the correct password. When 5 invalid

passwords in a row are identified, the controller stops accepting

passwords for 10 minutes.

Master Password

The Master Password is intended f or allowing the us er to define a new

password in the event of it being forgotten. The Master Password

doesn’t grant access to al l parameters, only to the Pas sword Change

parameter (

PAS(

). After defining the new password, the protected

parameters may be accessed (and modified) using this new password.

The master password is made up b y the last three digits of the serial

number of the controller added to the number 9000.

As an example, for the eq uipment with serial number 07154321, th e

master password is 9 3 2 1.

Loading...

Loading...